Page 1

Document No. 00BNO9132-# / 23.02.2015

VARMAX TWIN

GAS CONDENSING BOILER

550 to 900 kW

with modulating burner for

natural gas

ENFR DE ES IT NL

Instructions

for installation,

use and main-

tenance

MANUFACTURER:

R

P

O

E

D

V

I

U

T

C

E

L

L

O

C

C

T

PONT DE VAUX

(FRANCE) SITE

1 route de Fleurville - BP 55

FR - 01190 PONT-DE-VAUX

Page 2

Page 3

VARMAX TWIN - Installation, Use and Maintenance

SOMMAIRE

1. AVERTISSEMENTS ET RECOMMANDATIONS ....................................................................4

1.1. Limite de fourniture de la VARMAX TWIN .....................................................................................................4

1.2. Transport et stockage ....................................................................................................................................4

1.3. Symboles utilisés dans ce document ............................................................................................................4

1.4. Qualifi cation du personnel pour l'installation, le réglage, l'utilisation et l'entretien ........................................5

1.5. Consignes de sécurité ................................................................................................................................... 5

1.6. Caractéristiques de l'eau ...............................................................................................................................5

2. HOMOLOGATIONS ................................................................................................................6

2.1. Conformités aux Directives Européennes .....................................................................................................6

2.2. Conditions réglementaires d’installation pour la France ...............................................................................6

2.3. Conditions réglementaires d'installation pour la Belgique .............................................................................6

2.4. Conditions réglementaires d'installation autres pays ....................................................................................7

2.5. Compatibilité environnementale ....................................................................................................................7

2.6. Catégorie gaz ................................................................................................................................................7

2.7. Pressions d'alimentation gaz ......................................................................................................................... 7

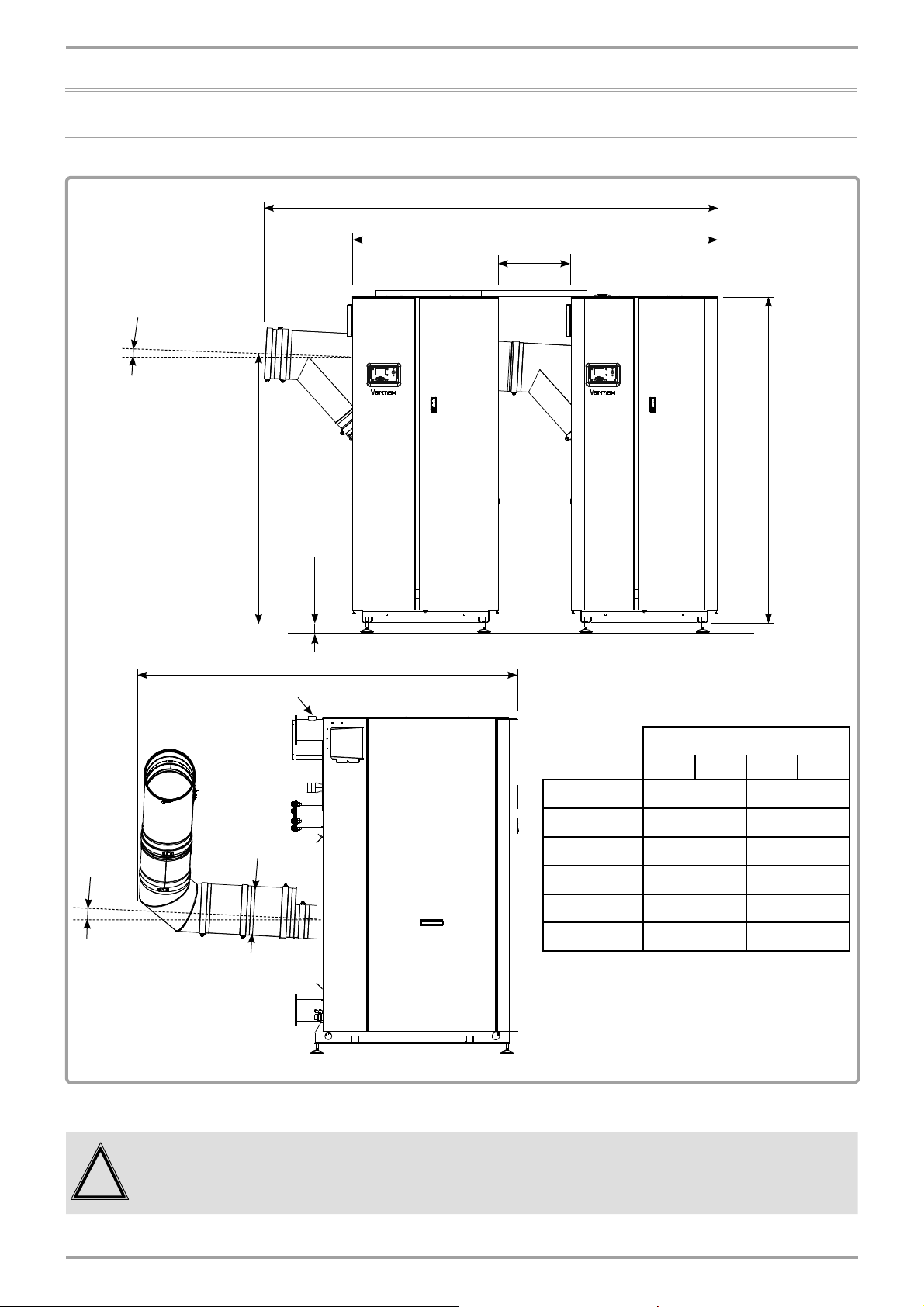

3. SPÉCIFICATIONS TECHNIQUES ..........................................................................................8

3.1. Dimensions ...................................................................................................................................................8

3.2. Passage de porte ..........................................................................................................................................9

3.3. Combustion à 15°C et 1013 mbar .................................................................................................................9

3.4. Conditions d'utilisation .................................................................................................................................10

3.5. Raccordement électrique ............................................................................................................................10

4. INSTALLATION .....................................................................................................................11

4.1. Mise en place des fi ltres à air et des nappes fi ltrantes ............................................................................... 1 1

4.2. Mise en place de la chaudière .................................................................................................................... 11

4.3. Mise en place des goulottes de passage câble bus LPB ............................................................................13

4.4. Ouverture / fermeture des portes d'habillage .............................................................................................. 14

4.5. Démontage des panneaux de commande (IHM) ........................................................................................14

4.6. Démontage / remontage des portes d'habillage..........................................................................................14

4.7. Démontage / remontage des panneaux latéraux ........................................................................................14

4.8. Démontage / remontage des panneaux supérieurs ....................................................................................14

4.9. Marchepied .................................................................................................................................................14

4.10.Changement de gaz (de G20 à G25) .........................................................................................................14

4.11.Raccordement fumées ...............................................................................................................................15

4.12.Raccordement hydraulique ........................................................................................................................19

4.13.Raccordement gaz .....................................................................................................................................22

4.14.Raccordement électrique ...........................................................................................................................22

5. MISE EN SERVICE ...............................................................................................................24

6. CONTRÔLES APRÈS LA MISE EN SERVICE.....................................................................24

7. OPÉRATIONS D'ENTRETIEN ..............................................................................................24

8. SCHÉMAS HYDRAULIQUES ET PARAMÉTRAGES ..........................................................25

9. LISTE DES PIÈCES DÉTACHÉES .......................................................................................55

Edition: 02 / 2015 Page 3 / 56

Page 4

VARMAX TWIN - Installation, Use and Maintenance

1. WARNINGS AND RECOMMENDATIONS

PLEASE READ THIS MANUAL CAREFULLY BEFORE INSTALLING,

MAINTAINING AND USING THE BOILER. IT CONTAINS IMPORTANT

SAFETY INFORMATION.

1.1. VARMAX TWIN supply limits

The VARMAX TWIN boiler you have received is composed of:

• 2 VARMAX type generators with the same power to be connected to each

other

• 1 450 mm common exhaust fl ue between the generators

• 4 T efl on plates (to help position the generators)

• 2 LPB bus cable trays with holding screws

• 1 LPB bus cable

• 2 OCI 345 communication modules with holding screws

• 1 QAZ 36 fl ow sensor

INFORMATION:

The hydraulic connection elements to be added according to the

diagram are not supplied (refer to chapters 4.12 and 8).

This manual describes the specifi c features of the assembly. Everything

which relates to one of the 2 generators (internal accessibility, settings,

maintenance, spare parts, etc.) is described in the particular generator's

manual. The following data must therefore be used:

- For the VARMAX TWIN 550, see the information for the VARMAX 275,

- For the VARMAX TWIN 640, see the information for the VARMAX 320,

- For the VARMAX TWIN 780, see the information for the VARMAX 390,

- For the VARMAX TWIN 900, see the information for the VARMAX 450.

1.2. Transport and storage

The generators:

- must be arranged horizontally in a place where the temperature is between

0 °C and +50 °C and whose relative humidity is between 5% and 95%.

- must not be stacked,

- must be protected from humidity.

1.3. Symbols used in this document

INFORMATION: This symbol draws attention to comments.

Failure to comply with these instructions may

IMPORTANT:

!

Page 4 / 56 00BNO9132-#

cause damage to the installation or to other

objects.

Page 5

VARMAX TWIN - Installation, Use and Maintenance

WARNING:

!

WARNING:

Failure to comply with these instructions may

cause injury and serious material damage.

Failure to comply with these instructions may

cause electrocution.

1.4. Qualifi cation of personnel for installation, adjustment, use and mainte-

nance

The operations to install, adjust and maintain the boiler must be carried out

by qualifi ed and approved professionals in accordance with current local

and national regulations. These operations may required intervention under

voltage, with the casing doors (located on the front of the generators) open.

The basic usage operations must be carried out with the casing doors closed.

1.5. Safety instructions

• Always remove the power supply to the boiler and shut off the overall gas

supply to it before carrying out any work on it.

!

!

WARNING:

WARNING:

WARNING:

• Check that there are no gas leaks on the installation after any intervention

on the boiler (maintenance or repair).

If you smell gas:

• Do not use any naked fl ames, smoke or activate any contacts or

electric switches.

• Switch off the gas supply.

• Ventilate the premises.

• Look for the leak and correct it.

If any smoke is released:

• Switch off the generators.

• Ventilate the premises.

• Look for the leak and correct it.

This boiler's earth continuity is provided by link cables (green/yellow)

and specifi c holding screws. During any disassembly operations,

make sure that the cables in question are reconnected; you MUST

also reuse the original holding screws.

1.6. Water characteristics

Refer to the V ARMAX generator's installation, use and maintenance manual.

Edition: 02 / 2015 Page 5 / 56

Page 6

VARMAX TWIN - Installation, Use and Maintenance

2. APPROVALS

2.1. Compliance with European Directives

- Low voltage (2006/95/CE)

This appliance is not intended for use by persons (including children)

whose physical, sensory or mental abilities are reduced, or persons

without experience or knowledge, unless they have been able to

benefi t, through someone responsible for their safety , from supervision

or prior instruction concerning the use of the appliance.

Children must be supervised to ensure they do not play with the

appliance.

- Electromagnetic compatibility (2004/108/CEE)

- Effi ciency (92/42/CEE)

- Gas appliances (2009/142/CE)

2.2. Regulatory installation conditions

The appliance must be installed and maintained by a qualifi ed professional,

in accordance with the regulations and current regulatory practices in the

country where the boiler is installed.

2.3. Environmental compatibility

This appliance contains electrical and electronic elements which must not be

thrown away with household waste.

Local legislation must be complied with.

2.4. Gas category

This boiler has been adjusted in the factory to work with group H (type G20)

natural gas with a supply pressure of 20 mbar.

INFORMATION: Any work on a sealed component will lead to loss of the guarantee.

Category

CZ, DK, EE, FI, GB, GR, HU, IE, LT,

LV, NO, RO, SE, SI, SK, TR

Page 6 / 56 00BNO9132-#

I

2H

Page 7

2.5. Gas supply pressures

VARMAX TWIN - Installation, Use and Maintenance

INFORMATION:

The pressures provided below must be taken at the input to the gas

valve (20 mbar).

Natural gas H G20

20 mbar

Nominal pressure (mbar) 20

Minimum pressure (mbar) 17

Maximum pressure (mbar) 25

Edition: 02 / 2015 Page 7 / 56

Page 8

VARMAX TWIN - Installation, Use and Maintenance

3. TECHNICAL SPECIFICATIONS

3.1. Dimensions

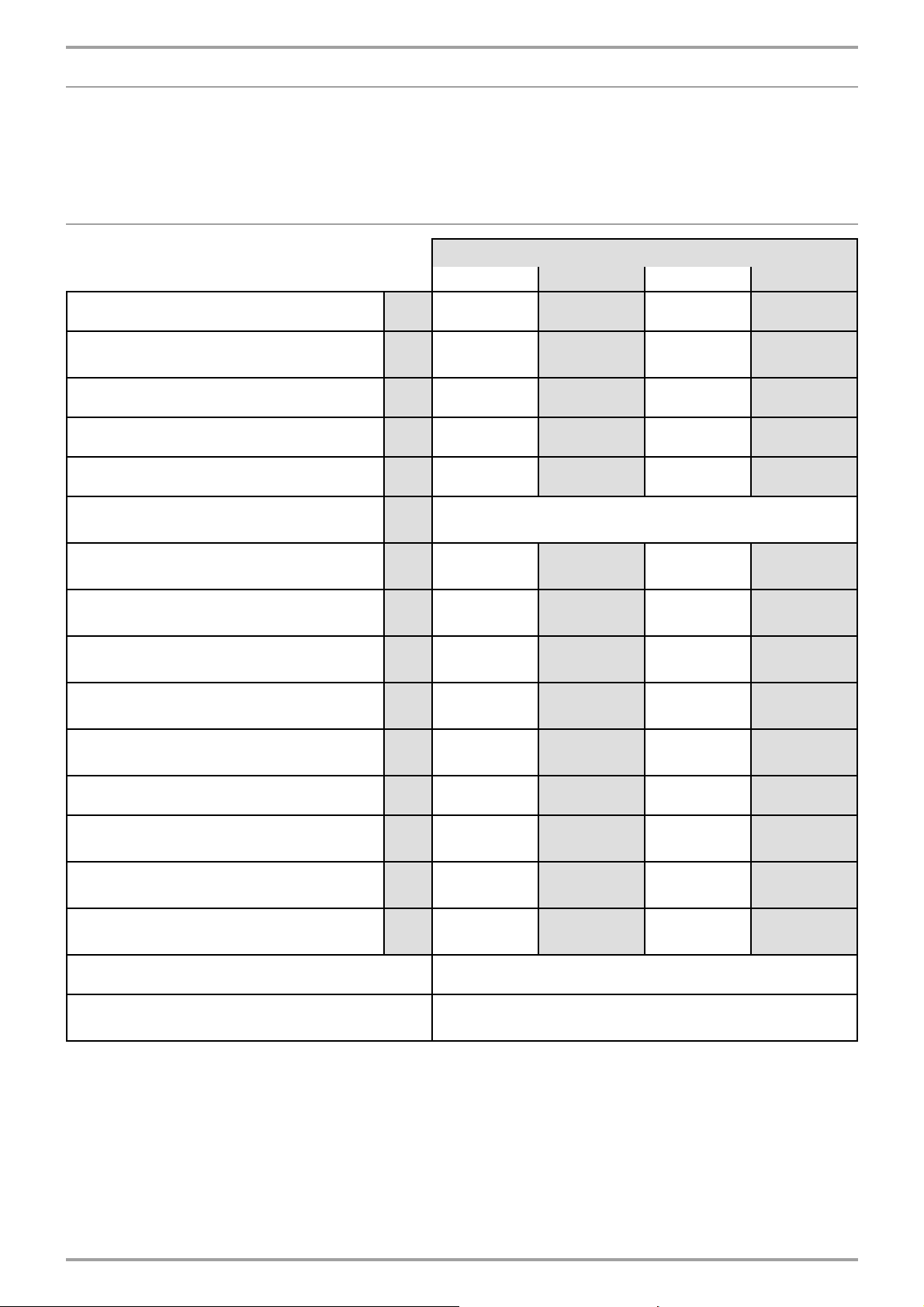

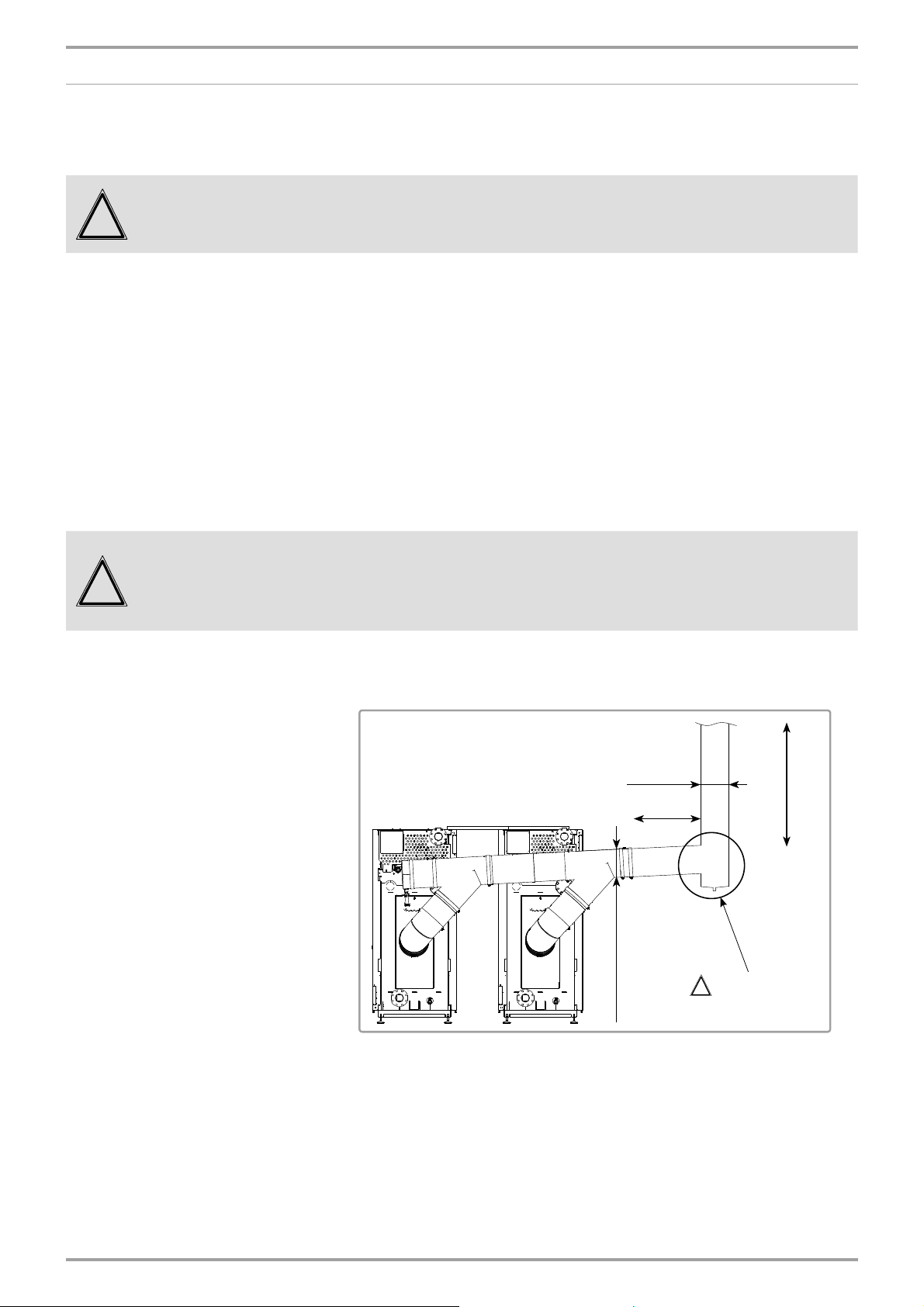

3°

D

A

±

10

450

B

3°

E

sleeve for safety valve on

each generator (F 1"1/4)

F

ø

45 min

60 max

C

MODELS

550 640 780 900

A (mm) 2059 2259

B (mm) 1877 2023

C (mm) 2032 2114

D (mm) 2519 2749

E (mm) 1500 1590

Ø F (mm) 250 300

The diameter indicated is the interior

diameter.

fi gure 1 - Dimensional characteristics

The dimension of 450 mm between the 2 generators must be respected

IMPORTANT:

!

Page 8 / 56 00BNO9132-#

to assemble the exhaust fl ue (it is not a minimum or maximum

dimension).

Page 9

VARMAX TWIN - Installation, Use and Maintenance

3.2. Doorway

Refer to the V ARMAX generator's installation, use and maintenance manual.

3.3. Combustion at 15°C and 1013 mbar

MODELS

550 640 780 900

Nominal power Pn (80/60°C) kW 536 624 762 878

Nominal power when condensing Pn

(50/30°C)

kW 580 676 830 956

Rated heat input Qn kW 550 640 780 900

Min heat input Qmin kW 66 66 87 87

Gas fl ow rate at Pn (15 °C) * m

CO

value range %

2

Exhaust mass fl ow rate at Qn / Qmin

(80/60°C) *

Exhaust mass fl ow rate at Qn / Qmin

(50/30°C) *

Exhaust temperature at Qn / Qmin

(80/60°C) *

Exhaust temperature at Qn / Qmin

(50/30°C) *

Firebox pressure at nominal Qcal

(B23)

3

/h 58.2 67.72 82.6 95.2

g/s

g/s

240.1 and 31257.7 and

225.9 and 26239.5 and

°C 61 and 54.7

°C

35.4 and

30.7

at Qmin: 8.3 % < CO

at Qmax: 8.8 % < CO

30.9

26.6

60.8 and

55.1

37.1 and 31 36 and 29.3 36 and 30.4

< 8.7 %

2

< 9.2 %

2

352 and 43 398 and 44

327 and 41 378 and 42

60.3 and

54.5

62.1 and

55.6

Pa 132 162 152 203

Exhaust outlet interior diameter mm 250 250 300 300

Maximum allowable nozzle pressure

(B23P) at Qn / Qmin (80/60°C)*

Maximum allowable nozzle pressure

(B23P) at Qn / Qmin (50/30°C)*

Combustion air fl ow rate at Qn *

(15°C)

Pa 127 and 3 151 and 3 177 and 3 200 and 3

Pa 104 and 3 123 and 3 149 and 3 178 and 3

3

m

/h 704.8 820.2 999.6 1153.4

NOx class 5

Smoke removal and air inlet type

classifi cations

B23, B23P

* values corresponding to a G20 setting.

Edition: 02 / 2015 Page 9 / 56

Page 10

VARMAX TWIN - Installation, Use and Maintenance

3.4. Operating conditions

MODELS

550 640 780 900

Max fl ow temperature setting °C 85

Max fl ow temperature °C 88

Maximum safe temperature °C 110

Max service pressure

Min cold pressure

hPa

(bar)

hPa

(bar)

Hydraulic pressure loss at ∆T 20 per generator

2 or 3 tapping version 820 1185 770 970

4 tapping version

Main exchanger

Condenser

Nominal water fl ow rate (P/20) VARMAX TWIN m

Nominal water fl ow rate (P/20) per generator m

Maximum water fl ow rate (P/10) per generator m

daPa

790

50

3

/h 23 26.8 32.8 37.8

3

/h 11.5 13.4 16.4 18.9

3

/h 23.0 26.8 32.8 37.8

Total water content (2 generators) L 478 478 574 574

Total weight without water (2 generators) kg 1050 1050 1240 1240

Installation premises temperature (min / max) °C 5 and 45

Installation premises relative humidity between 5% and 95%

Protection level IP20

Maximum installation altitude m 2000

1060

65

6000

(6)

1000

(1)

660

190

840

230

3.5. Electrical connection

MODELS

550 640 780 900

Electrical supply V 230 V AC (+10% -15%), 50Hz

Electrical power consumed at Qn (excluding

accessory) VARMAX TWIN

Electrical power consumed in standby mode

VARMAX TWIN

Maximum length of sensor cables m

Power terminal output per generator

W 476 704 960 1320

W10

DHW sensor: 10

Outdoor sensor: 40 in 0.5 mm² (120 in 1.5 mm²)

Ambient thermostat: 200 in 1.5 mm²

Room thermostat: 200 in 1.5 mm²

V 230V AC (+10%, -15%)

A 5 mA at 1A

Page 10 / 56 00BNO9132-#

Page 11

VARMAX TWIN - Installation, Use and Maintenance

4. INSTALLATION

4.6. Positioning the air fi lters and the fi ltering layers

!

IMPORTANT: The air fi lters provided with the generators MUST be installed.

The air fi lters must be installed before the gas lines are connected.

Refer to the VARMAX generator's installation, usage and maintenance

manual, paragraph "4-1 Positioning the air fi lter and the layer").

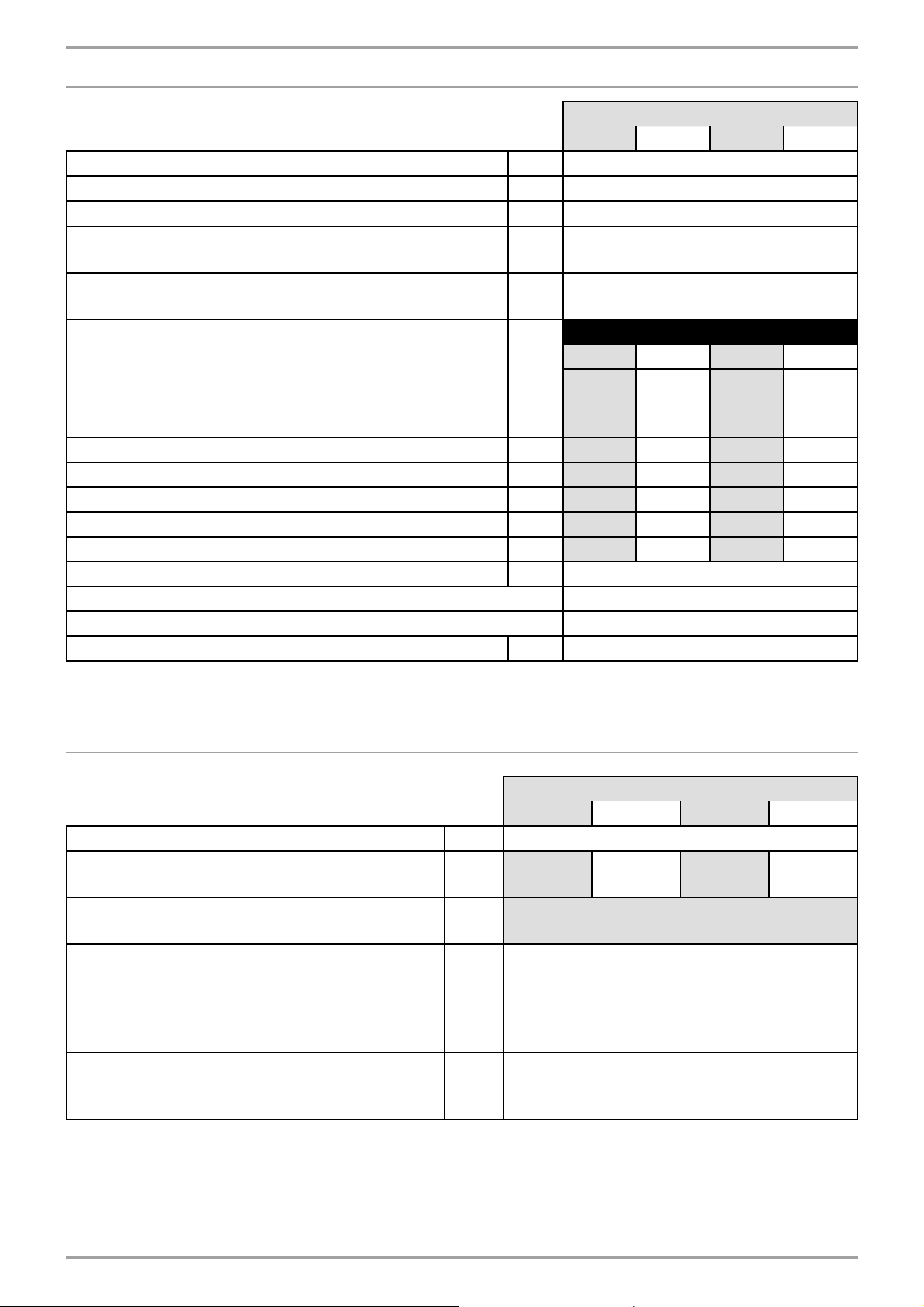

4.7. Installing the boiler

The VARMAX TWIN boilers must not be installed on an fl ammable surface

(wooden fl oor , plastic fl oor covering, etc.).

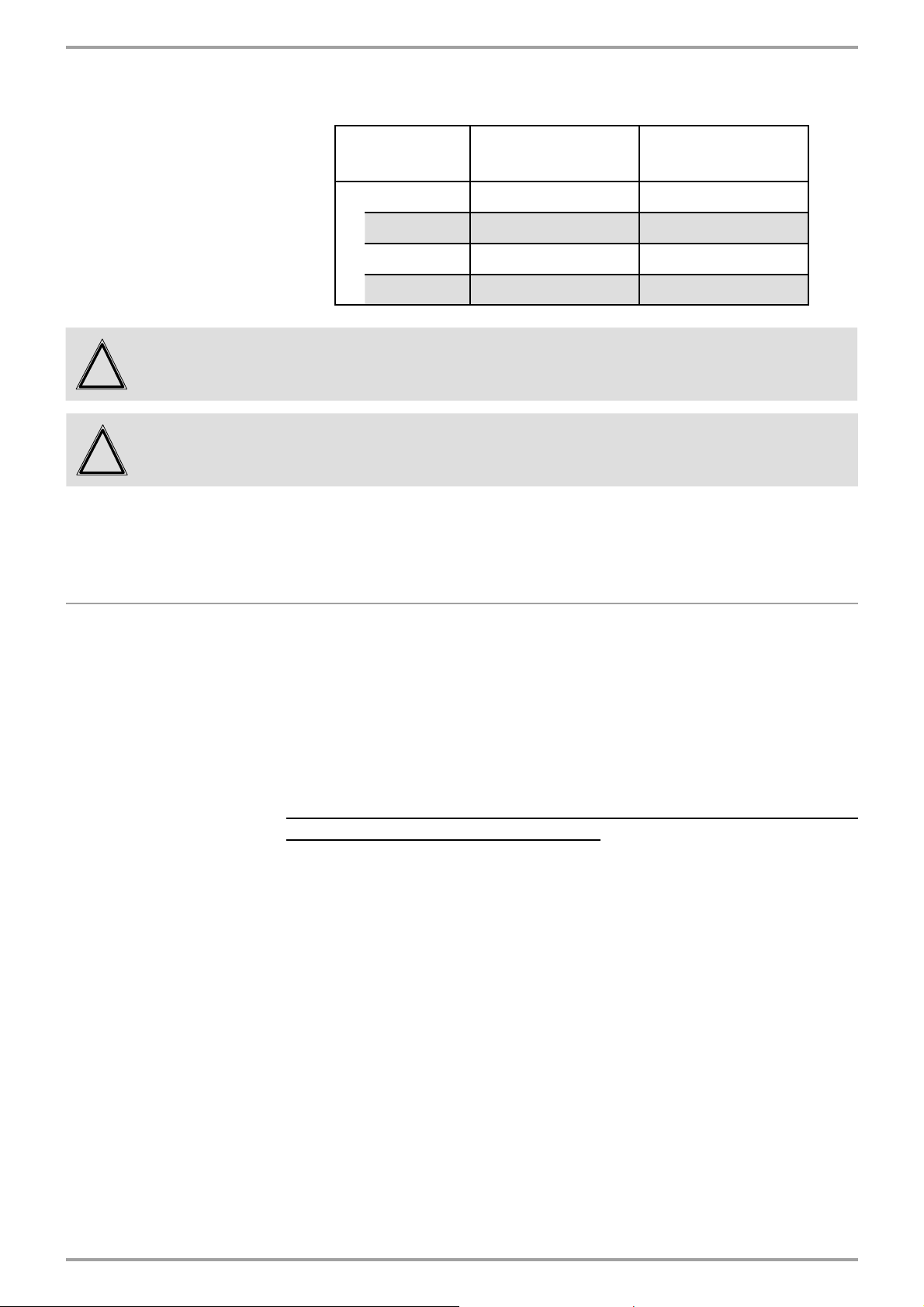

Recommended distances relative to walls and ceiling:

Suffi cient clearances must be provided to permit easy maintenance

operations on the boilers.

The minimum values (in mm) are indicated in fi gure 2 and in the table below.

A* B* C H

550 450 600 263

640 450 600 263

780 450 700 427

MODELS

900 450 700 427

A

±10

C

450

H

B

fi gure 2 - Peripheral clearance

The greyed out zone above the boiler must remain free of any obstacles

to enable the burner to be inspected and cleaned.

These values cannot be substituted for the specifi c regulatory

requirements.

Edition: 02 / 2015 Page 11 / 56

Page 12

VARMAX TWIN - Installation, Use and Maintenance

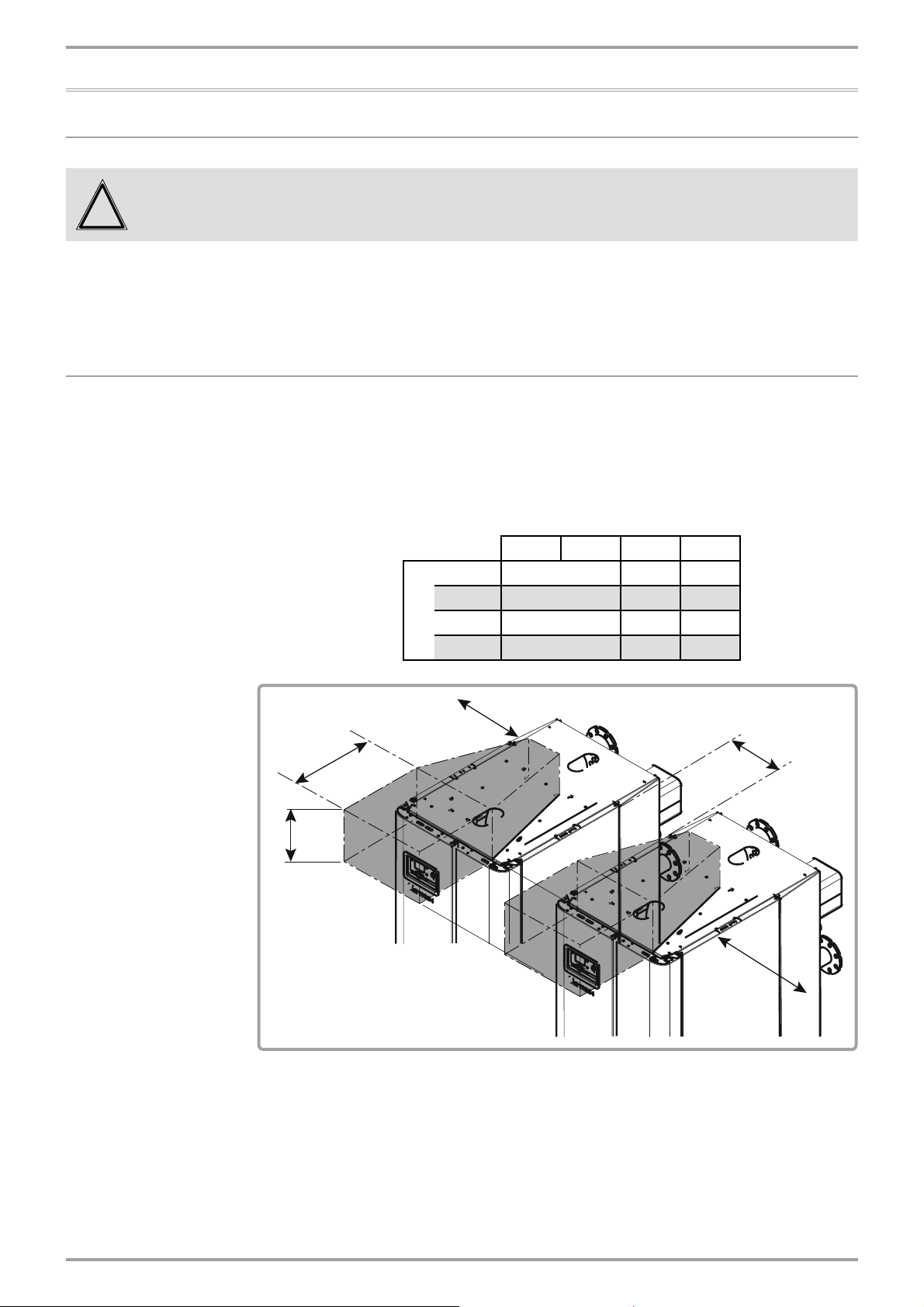

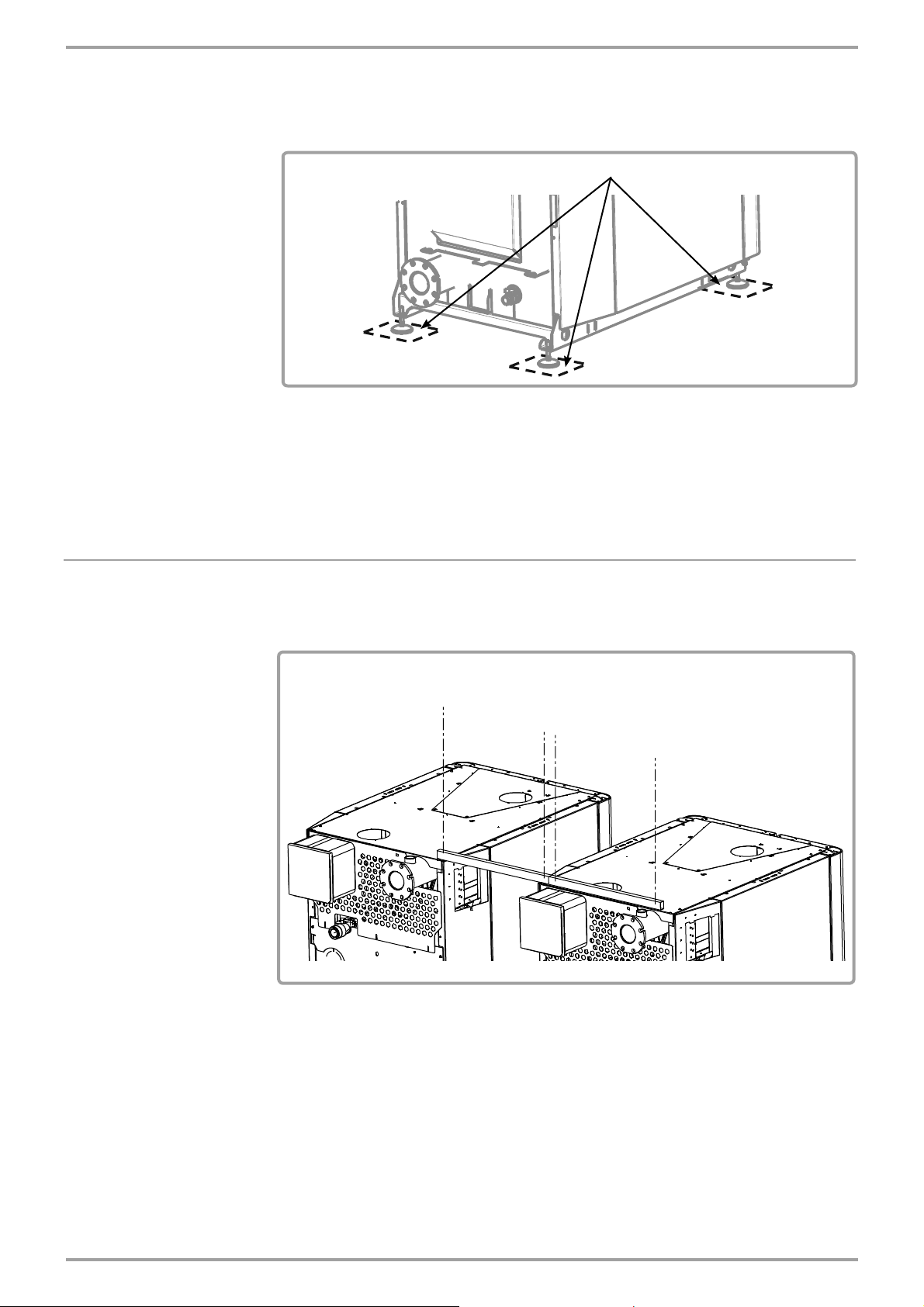

• The 2 VARMAX generators must be positioned horizontally using a

spirit level to enable effective gas release for the exchanger body

(use the base as the reference surface).

!

IMPORTANT:

• The space between the 2 VARMAX generators must be 450

• A 2 cm free space must also be left above the side panels to allow

for their disassembly and reassembly.

• The 2 generators must be in the same alignment and on the same

horizontal level.

450

±10

±10

mm.

OK

OK

OK

fi gure 3 - Generator positioning

To adjust the fl ush level, screw or unscrew the 4 adjustable feet, using a 17

mm wrench.

Page 12 / 56 00BNO9132-#

Page 13

VARMAX TWIN - Installation, Use and Maintenance

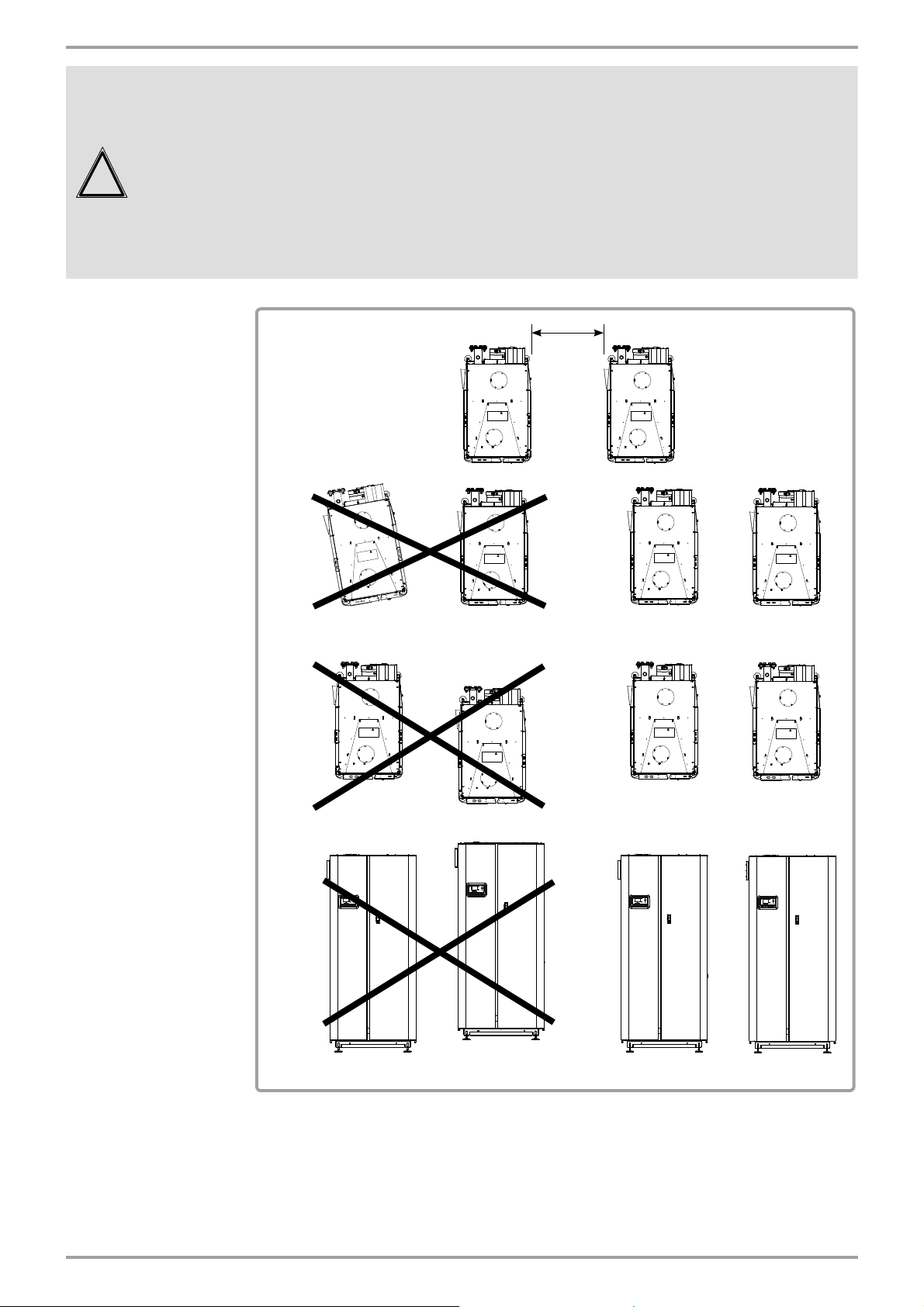

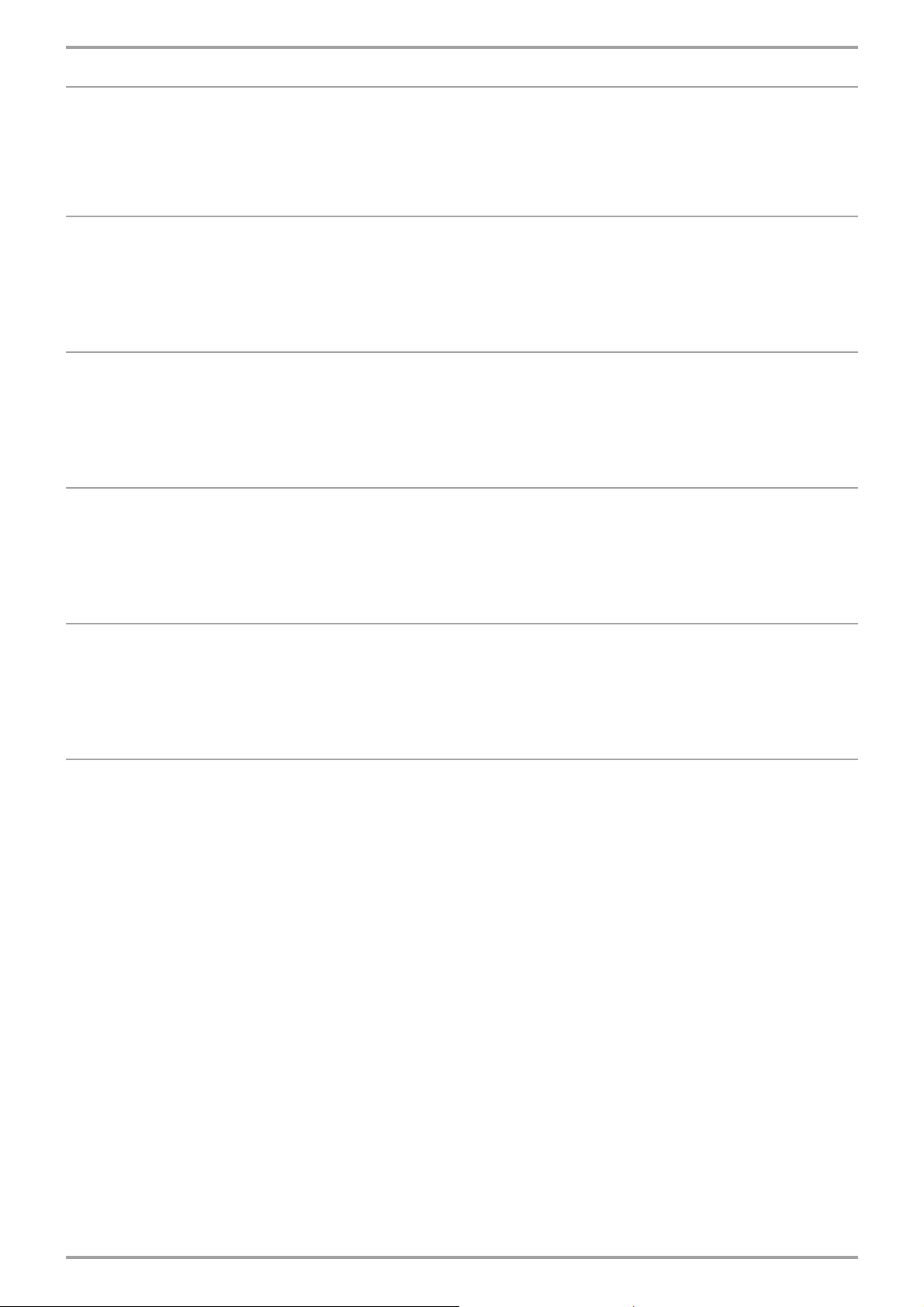

4 Tefl on plates are provided to facilitate the introduction of the 2 generators

in relation to each other:

• Put one plate under each of the 4 feet of the generator to be moved,

Tefl on plates (x4)

fi gure 4 - Tefl on plate positioning

• Position the generator,

• Remove the Tefl on plates.

4.8. Installing the LPB bus cable trays

Position the 2 trays for the LPB bus cable on the rear of the 2 generators and

secure them using the 4 self-tapping screws provided.

4 self-tapping screws provided

}

fi gure 5 - cable trays

The roof of each generator must be drilled (Ø 4 bit); to do so, use the trays

as scale.

Edition: 02 / 2015 Page 13 / 56

Page 14

VARMAX TWIN - Installation, Use and Maintenance

4.9. Opening / closing the casing doors

Refer to the V ARMAX generator's installation, use and maintenance manual.

4.10. Removing the control panels (MMI)

Refer to the V ARMAX generator's installation, use and maintenance manual.

4.11. Installing / removing the casing doors

Refer to the V ARMAX generator's installation, use and maintenance manual.

4.12. Installing / removing the side panels

Refer to the V ARMAX generator's installation, use and maintenance manual.

4.13. Installing / removing the upper panels

Refer to the V ARMAX generator's installation, use and maintenance manual.

4.14. Step

Refer to the V ARMAX generator's installation, use and maintenance manual.

Page 14 / 56 00BNO9132-#

Page 15

4.15. Exhaust connection

There is a specifi c connection for the exhausts to the VARMAX TWIN

!

IMPORTANT:

INFORMATION:

boilers. Do not refer to the VARMAX generator's installation, use and

maintenance manual.

The size of the chimney pipes must be determined taking account of

combustion gas pressure on boiler output equal to 0 Pa (see table § 3.3).

You must comply with the regulatory texts and rules of the art that apply in

the country where the boiler will be installed, i.e.:

One exhaust temperature sensor per generator guarantees the

protection of the combustion product evacuation ducts.

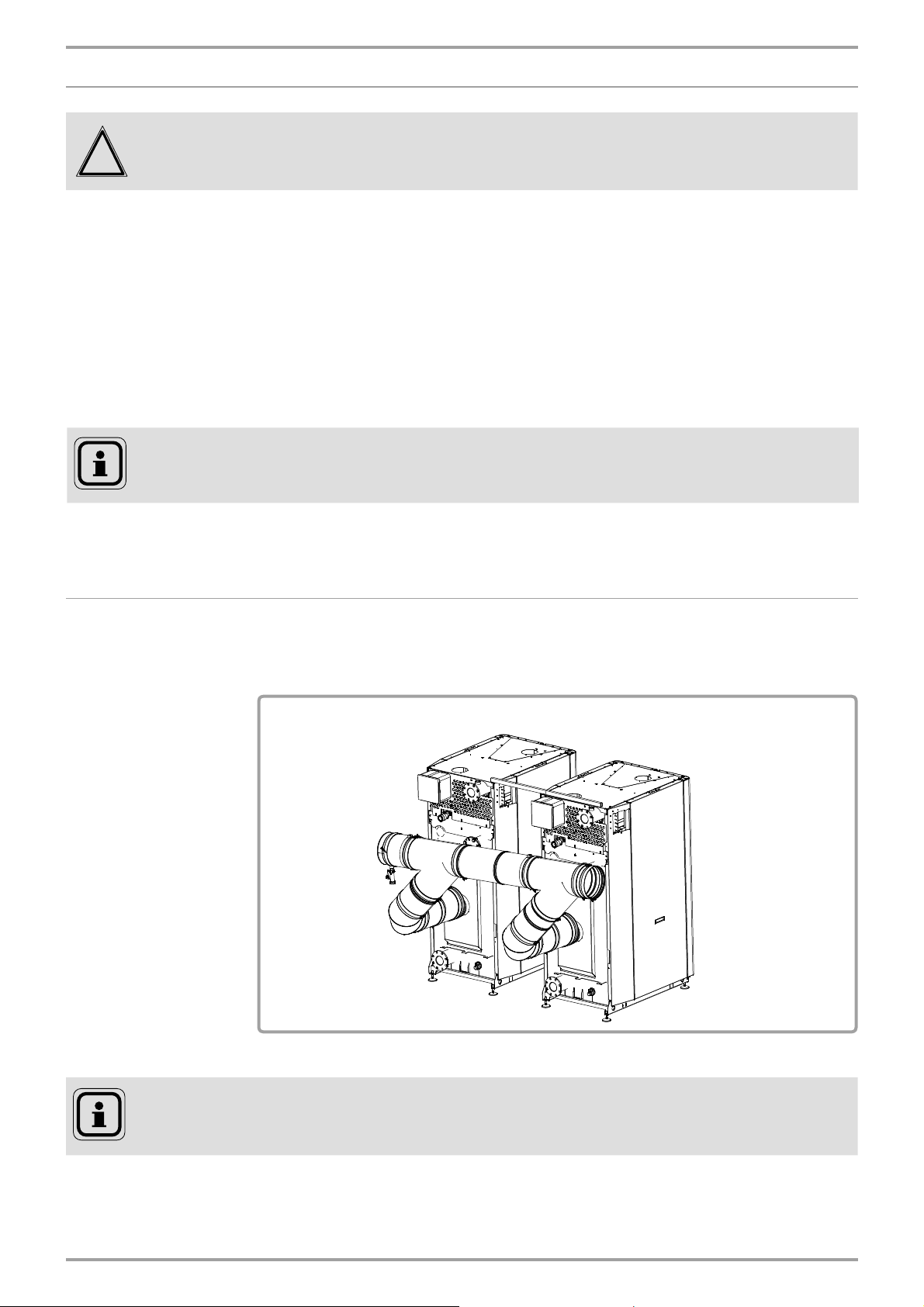

The VARMAX TWIN boilers are approved to be connected to:

The duct lengths provided below are in linear metres (ml). The total length

of all the ducts is rounded to a straight-line length (the curves have a

straight-line equivalent).

VARMAX TWIN - Installation, Use and Maintenance

• a B23 chimney (all models)

• a B23P chimney (all models)

4.15.1. Installing the exhaust fl ue

The fl ue provided may be installed either to the right or the left of the VARMAX

TWIN boiler.

Example with exhaust outlet to the left:

fi gure 6 - Flue orientation

When assembling the fl ue, we recommend fi tting the assembly on

INFORMATION:

Edition: 02 / 2015 Page 15 / 56

the ground then installing it on the 2 generators. At least 3 people are

required to handle and secure the assembly.

Page 16

VARMAX TWIN - Installation, Use and Maintenance

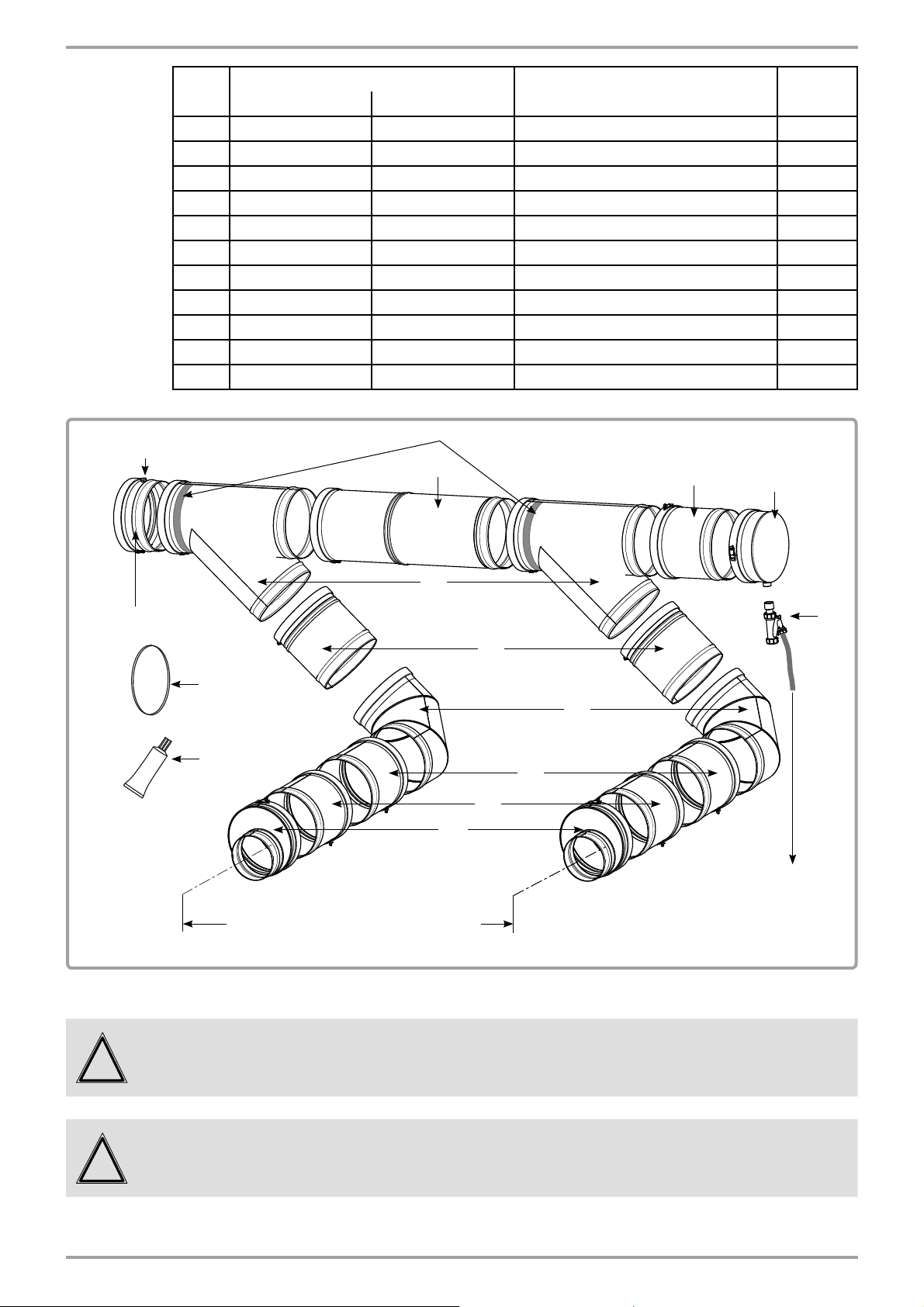

Measurement

(upwards)

ITEM

1

2

3

4

5

6

7

8

9

10

11

MODELS

DESCRIPTIONS QTY

550 - 640 kW 780 - 900 kW

AC-250-180 AC-300-200 Offset increase

ED 250-250 CD ED 250-300 CD Straight element length 250

EC 90-250 CD EC 90-300 CD 90° curved element

ER 26/40 250 CD ER 26/40 300 CD Adjustable element length 260-400

T 135-250 CD T 135-300 CD T 135°

EPMF 250 EPMF 300 Measurement element

ER 55/90 250 ER 55/90 300 Adjustable element length 550-900

CEPL 250 CD CEPL 300 CD Side drain buffer

SIPHON 1" SIPHON 1" Siphon

JOINT-CD-250 JOINT-CD-300 Seal

-- -- Tube of grease for seals

support collars

7

2

2

4

2

2

2

1

1

1

1

19

1

8

5

6

4

10

3

11

Indicative values

550 - 640 kW models: 1250 mm

780 - 900 kW models: 1350 mm

1

1

fi gure 7 - Flue assembly

2

2

to condensation

neutraliser

9

The 2 collars delivered with the smoke works kit may be used to

IMPORTANT:

!

support the assembly either on the ceiling or on the ground (their

position is "greyed out" on each T at 135° - fi gure 7).

During fi nal connection to the generator exhaust outlet nozzles, make

IMPORTANT:

!

Page 16 / 56 00BNO9132-#

sure that there are not too many mechanical demands on the 2 offset

increases (item 1) as this may create seal losses for the exhaust.

Page 17

4.15.2. Connection to a B23 chimney

B23 type connection:

Air from the installation premises, gas evacuation through the roof via a

natural draft pipe.

Check that the boiler installation premises have high and low

!

IMPORTANT:

ventilation, that it conforms to current regulations and that it is not

obstructed.

The size of the chimney pipes must be determined taking account of

combustion gas pressure on boiler output equal to

The exhaust extraction ducts must be made in a material resistant to the

condensate that can form when the boiler is operating. These materials

must also be able to withstand exhaust temperatures up to 120°C. Horizontal

pipes must be avoided to limit condensation build-up.

Check that the combustion gas is evacuated via a sealed connection.

VARMAX TWIN boilers are high performance boilers with very low exhaust

temperatures; consequently to retain a favourable draft the ducts must run

upwards from the boiler outlet.

VARMAX TWIN - Installation, Use and Maintenance

0 Pa (see table § 3.3).

Check:

!

WARNING:

1. That the fl ue is not under pressure, with both generators operating.

2. If one of the generators is operating at minimum power, that the

other generator does not discharge into it.

Dimensioning recommendations based on a POUJOULAT type

(Condensor type) supply:

ø duct

(1 m)

ø connection

hose PROHIBITED

!

for the elbow joint

H

fi gure 8 - Sizing recommendations

Edition: 02 / 2015 Page 17 / 56

Page 18

VARMAX TWIN - Installation, Use and Maintenance

Exhaust duct height in linear metres (ml)

ø

connection

ø

550 15 to 50 3 to 50 -- --

640 16 to 50 3 to 50 -- --

(in 50/30°C operating regime)

250 mm 300 mm

duct

300 mm 350 mm 350 mm 400 mm

MODELS

!

!

4.15.3. Connection to a B23P chimney

WARNING:

WARNING:

The values below are provided for information purposes. They must

be checked by calculation.

The VARMAX TWIN fl ue must not be made to support the exhaust

duct's weight.

B23P type connection:

Air from the installation premises, gas evacuation through the roof via a

pressurised duct.

780 -- -- 15 to 50 5 to 50

900 -- -- 33 to 50 6 to 50

Check that the boiler installation premises have high and low

!

!

!

IMPORTANT:

WARNING:

WARNING:

ventilation, that it conforms to current regulations and that it is not

obstructed.

For B23P type connection, it is VITAL to use ducts with CONDENSOR

(Poujoulat) type CSTB notice (pressurised ducts).

The combustion product extraction duct must be dimensioned by

using the parameters set out in the table in chapter 3.3.

Depending on the actual confi guration of the duct, a calculation is

required to check that the pressures at the boiler outlet do not exceed

the maximum allowable values (200 Pa).

Values corresponding to the 50/30°C regime are to be used for this

calculation.

Dimensioning recommendations based on a POUJOULAT (Condensor

type) supply: See the fi gure on the previous page.

Page 18 / 56 00BNO9132-#

Page 19

VARMAX TWIN - Installation, Use and Maintenance

Exhaust duct height in linear metres (ml)

(in 50/30°C operating regime)

ø

connection

ø

duct

550 1 to 100 --

640 1 to 100 --

250 mm 300 mm

250 mm 300 mm

!

!

WARNING:

WARNING:

The values below are provided for information purposes. They must

be checked by calculation.

The VARMAX TWIN fl ue must not be made to support the exhaust

duct's weight.

4.16. Hydraulic connection

A water circulation pump integrated into each generator and a smart

regulation logic enable optimum operation up to Pinst/30 (Pinst =

Instant output power expressed as Th/h - 1Th/h = 1.163 kW).

Below this rate of Pinst/30, the generators will continue to operate, but

will gradually reduce their power (shutdown below Pinst/46).

In the main exchanger, as in the condenser on each generator, you must

ensure that the rates recommended in paragraph 3.4 are not exceeded

(i.e. Output power in nominal Th/h generator / 10).

MODELS

780 -- 1 to 100

900 -- 1 to 100

Therefore, a differential pressure valve must be integrated into

the circuit according to the diagam.

Sizing the pipes connecting the boiler to the installation must be done

carefully, to minimise the pressure losses and so avoid oversized circulating

pumps.

In some cases the diameter of the connection pipes will be greater than the

diameter of the boiler tappings. The diameter increase can then be made

advantageously after the union connectors, the stop valves, and/or the

hydraulic balancing valves.

Tichelmann assembly encourages a natural balance of the fl ow rate between

the 2 generators.

The VARMAX TWIN boilers are equipped with the following elements:

• A drainage valve on each generator's main exchanger,

• A drainage valve on each generator's condenser.

Edition: 02 / 2015 Page 19 / 56

Page 20

VARMAX TWIN - Installation, Use and Maintenance

In accordance with the diagram, it is imperative to fi t the boiler and its

installation with the following components:

• powered isolating valve (with an end of run contact*) on the fl ow tapping

on each generator's main exchanger,

• balancing / isolating valve on each generator's return tapping,

• anti-return fl ap,

• fi lters,

• mud cup,

• expansion vessel,

• effective drain mechanism,

• safety valve set at 6 bars, on each generator, sized according to each

generator's heat output (see location fi gure 1 page 8).

• disconnector on the boiler's fi lling circuit in relation to the supply network.

(*) The end of run contact only allows the generator to start up when full

opening is reached.

The VARMAX TWIN are delivered either in 2/3 tapping connection

version or in 4 tapping connection version. A 2/3 tapping version cannot

be converted into a 4 tapping version and vice versa.

4.16.1. Hydraulic connection using 2 tappings

câble «bus LPB»

LPB bus cable

(supplied)

(fourni)

B3000

OCI345

OCI345

(supplied)

(fourni)

B3000

OCI345

OCI345

(supplied)

(fourni)

QAZ36

QAZ36

(supplied)

(fournie)

Main exchanger

output

Cold return

(hot return fl ange blocked)

fi gure 9 - Hydraulic connection using 2 tappings

Page 20 / 56 00BNO9132-#

Page 21

4.16.2. Hydraulic connection using 3 tappings

VARMAX TWIN - Installation, Use and Maintenance

QAZ36

QAZ36

(supplied)

(fournie)

Main exchanger output

câble «bus LPB»

LPB bus cable

(fourni)

(supplied)

B3000

OCI345

OCI345

(supplied)

(fourni)

B3000

OCI345

OCI345

(supplied)

(fourni)

fi gure 10 - Hydraulic connection using 3 tappings

4.16.3. Hydraulic connection using 4 tappings

Hot return (high temperature circuit)

Cold return (heated

fl oors and low temperature radiators)

B3000

OCI345

OCI345

(supplied)

(fourni)

câble «bus LPB»

LPB bus cable

(fourni)

(supplied)

QAZ36

QAZ36

(supplied)

(fournie)

B3000

OCI345

OCI345

(supplied)

(fourni)

fi gure 11 - Hydraulic connection using 4 tappings

Main exchanger output

Main exchanger return

Condenser output

Condenser return

Edition: 02 / 2015 Page 21 / 56

Page 22

VARMAX TWIN - Installation, Use and Maintenance

4.17. Gas connection

!

IMPORTANT:

• The gas must be connected on the 2 VARMAX generators

• The use of Propane is prohibited on the VARMAX TWIN boilers.

Refer to the V ARMAX generator's installation, use and maintenance manual.

4.18. Electrical connection

WARNING:

!

!

WARNING:

IMPORTANT:

Ensure that the general electrical power supply has been cut off

before starting any repair work.

You must respect the live (L) - neutral (N) polarity during electrical

connection.

The VARMAX generators must be connected to the earth and the

national standards concerning low voltage electric installations in the

country must be respected.

Provide a two pole circuit breaker upstream of EACH VARMAX

GENERATOR (distance between contacts: 3.5 mm minimum).

Fitting the electrical installation with a 30 mA differential protective

device is strongly advised.

Please refer to the installation and usage manual for the NAVISTEM B3000

boiler controller for information about the electrical connections to the control

panel (electricity supply characteristics, cable section and connection to

terminal blocks).

Refer to the VARMAX generator's installation, usage and maintenance

manual for all information about accessing the generators' control panel and

the cable runs.

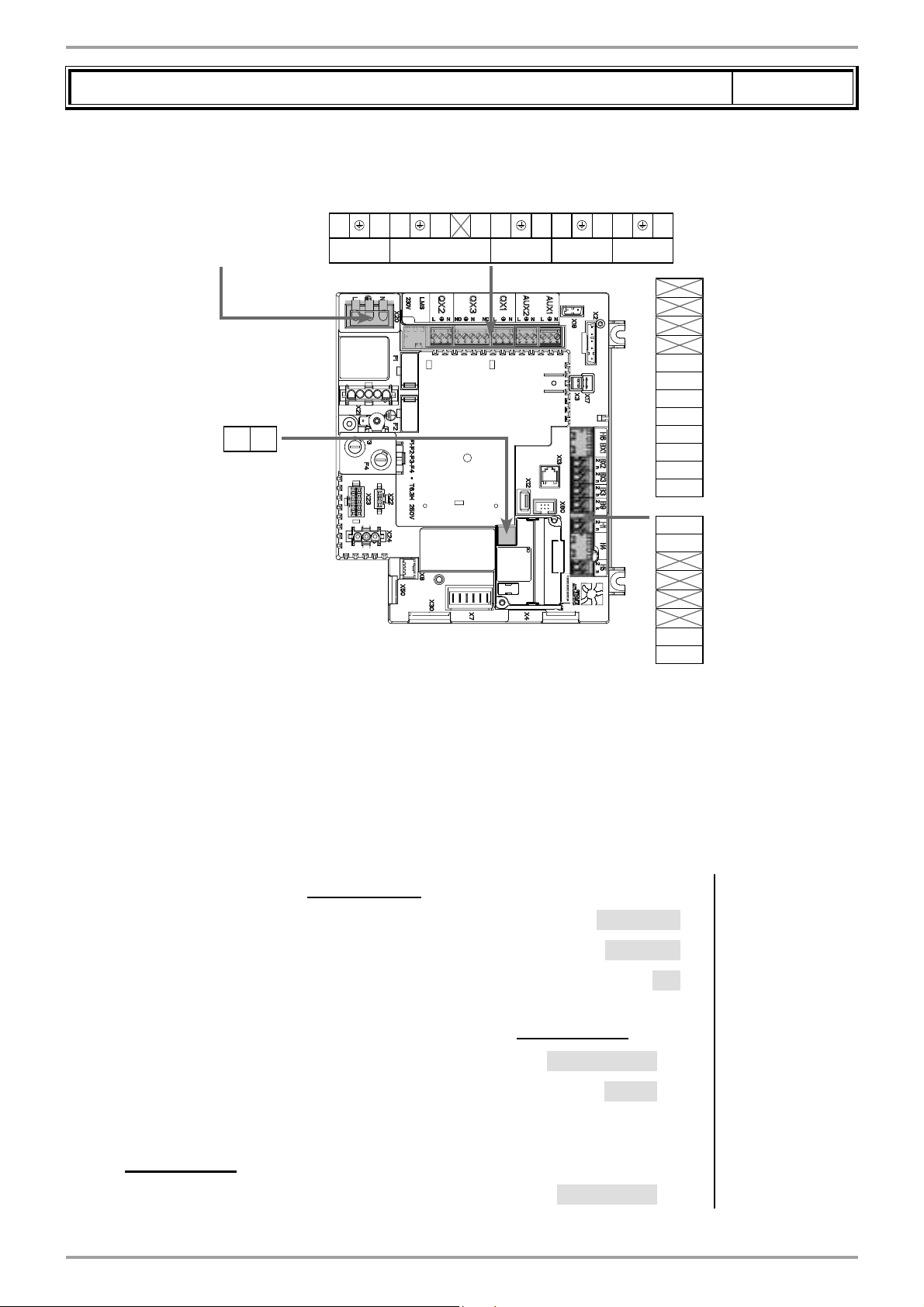

4.18.1. Connecting the OCI345 communication modules

4.18.1.1. Installing the communication modules

The modules are installed on the NAVISTEM B3000 boiler controllers,

located in the control panel for the 2 VARMAX generators.

Page 22 / 56 00BNO9132-#

Page 23

VARMAX TWIN - Installation, Use and Maintenance

On each VARMAX generator:

- Access the control panel and remove its protective cover.

- Secure the module to the boiler controller with the 2 screws supplied.

- Connect the communication layer from the OCI345 module to the boiler

controller's X11 connector (see previous fi gure).

!

IMPORTANT: Proceed carefully during connection.

4.18.1.2. Electrical connection

Holding

OCI345

screw

X11

fi gure 12 - OCI345 attachment

- Connect the VARMAX generators via the LPB bus (the LPB bus connects

to the OCI345 communication module's DB and MB terminal blocks).

LPB bus

VARMAX 1 generator

OCI345

fi gure 13 - LPB bus connection

VARMAX 2 generator

OCI345

The "LPB bus" cable must be run from generator 1's control panel to

!

Edition: 02 / 2015 Page 23 / 56

WARNING:

generator 2's control panel via the 2 generators' "low current" trays

and via the "LPB bus cable run" trays (see § 4.3). Hold the cable using

the cable clamps.

Page 24

VARMAX TWIN - Installation, Use and Maintenance

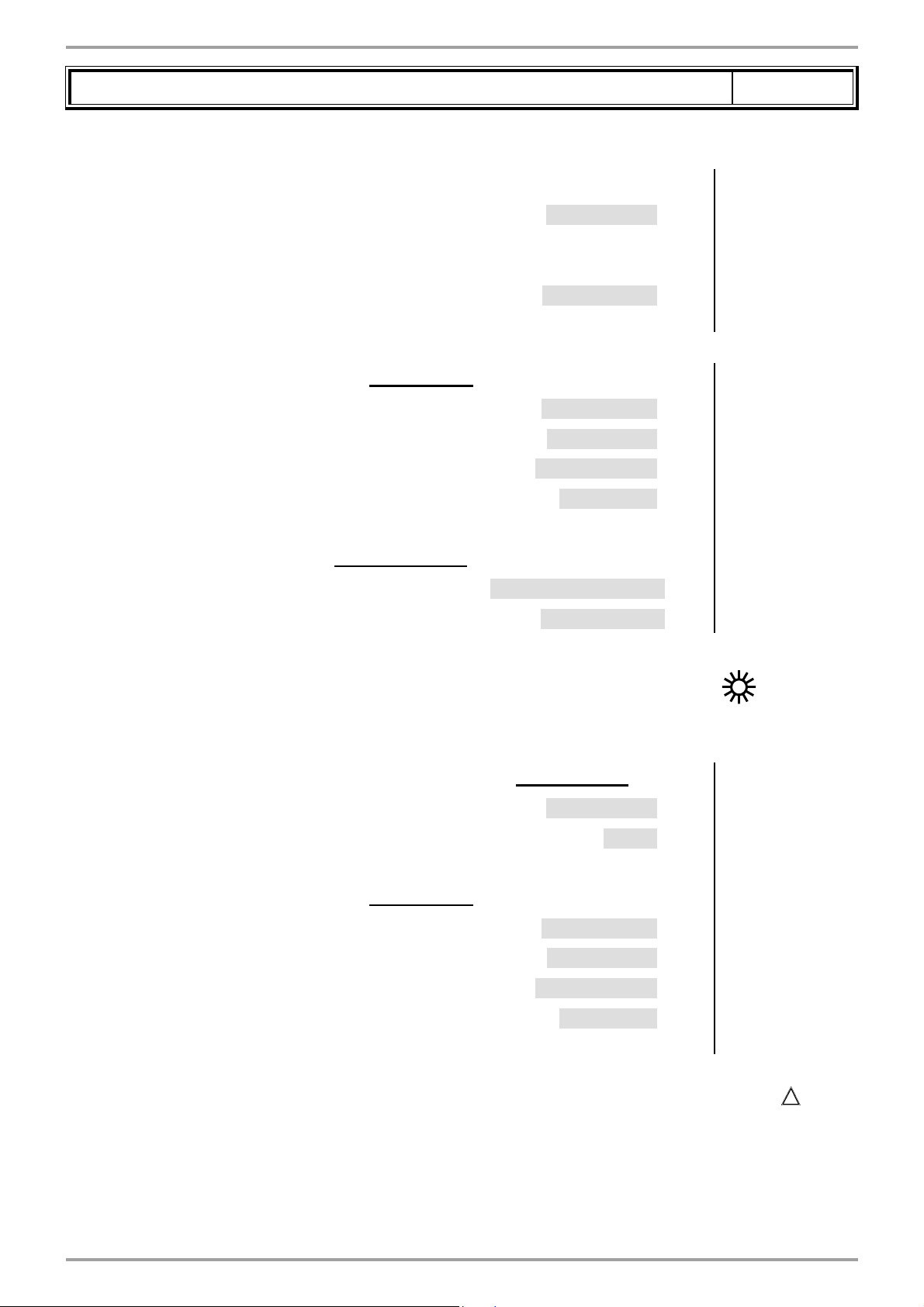

4.18.2. Connecting the QAZ36 fl ow sensor

4.18.2.1. Installing the sensor

The sensor must be placed in a pocket as close as possible to the 2

generators' common hydraulic output.

4.18.2.2. Electrical connection

- Connect the QAZ36 fl ow sensor to terminal block BX2 on generator 1's

NAVISTEM B3000 boiler controller (see chapter 8).

!

4.18.3. Connection to the boiler controller's terminal blocks

WARNING:

The sensor cable must be run to generator 1's control panel via the

"low current" tray. Hold the cable using the cable clamps.

OCI345

fi gure 14 - Flow sensor connection

BX2 terminal

Refer to the NAVISTEM B3000 boiler controller's manual.

5. START-UP (COMMISSIONING)

Refer to the V ARMAX generator's installation, use and maintenance manual.

6. CHECKS AFTER COMMISSIONING

Refer to the V ARMAX generator's installation, use and maintenance manual.

7. MAINTENANCE OPERATIONS

Refer to the V ARMAX generator's installation, use and maintenance manual.

Page 24 / 56 00BNO9132-#

Page 25

VARMAX TWIN - Installation, Use and Maintenance

8. HYDRAULIC DIAGRAMS AND CONFIGURATIONS

Management of secon-

V ARMAX TWIN

dary systems by

external regulation

Management of

secondary systems

by A TLANTIC

Not

communicating

Communicating via

signal 0...10V

(temperature)

Communicating via

LPB bus

direct circuit

regulated network +

consumer circuit constant

T° and throughput

+

1 regulated network with

accumulated DHW

+

No communication with the

secondary system

VX201

Secondary networks regula-

ted by communicating

external regulation

VX211

Secondary networks regula-

ted by communicating

external regulation

VX211

1 direct network

VX200

1 network regulated by 3-chan-

nel valve and 1 circuit with

constant temperature and

VX220

throughput

1 network regulated by V3V

with accumulated DHW

VX210

3 or 4 regulated

networks

...

3 or 4 regulated networks with

semi-instantaneous DHW

3 or 4 networks regulated by

3-channel valve, without DHW

VX202

3 or 4 networks regulated by

3-channel valve, with semi-

instantaneous DHW

...

+

VX212

Symbol Function Symbol Function

Isolation valve open Balancing valve

2-channel powered valve 3-channel powered valve

Filter Anti-return fl ap

Safety unit Pump

Mud cup Bleed valve

External sensor Temperature sensor

Edition: 02 / 2015 Page 25 / 56

Page 26

VARMAX TWIN - Installation, Use and Maintenance

x

B3000

B3000

REGULATEUR NON COMMUNICANT

1 direct network, no communication with the secondary

A. MAIN AND VARIANT HYDRAULIC DIAGRAMS

B9

Diagram

VX200

VX201

page 1 / 6

Q2

x

B10

B9

B3000

B3000

Q1.1

fi gure 15 - VX200 diagram

Q1.2

NON-COMMUNICATING

REGULATOR

B10

Q1.2

Q1.1

fi gure 16 - VX201 diagram (variant)

Page 26 / 56 00BNO9132-#

Page 27

VARMAX TWIN - Installation, Use and Maintenance

Diagrams: VX200 / VX201

B. REGULATION ACCESSORIES REQUIRED

Quantity

Communication kit 2 OCI 345 supplied

Communication cable 1 LPB BUS supplied

Output sensor kit 1 QAZ 36 supplied

Output sensor kit 1 QAC 34 059260

C. CUSTOMER'S ELECTRICAL CONNECTION

Generator No. 1:

INFORMATION:

If the isolation valve is not equipped with an automatic reset valve, connect

the Q1.1 isolating valve's closure contact to Y2.

Appliance

reference

page 2 / 6

Order No.

230 VAC 50 Hz

power supply

LPB bus

DB MB

VX200 diagram:

Direct circuit

circulator Q2

L NY1 NY2L NL NL N

QX2 QX3 QX1 AUX2 AUX1

}

Isolating valve

Q1.1

}

}

Alarm

relay

}

BX2

Gnd

BX3

Gnd

B3

Gnd

B9

Gnd

H1

Gnd

TWIN B10 output

}

sensor

External sensor B9

}

H5

Gnd

Generator No. 2:

INFORMATION:

Edition: 02 / 2015 Page 27 / 56

If the isolation valve is not equipped with an automatic reset valve, connect

the Q1.2 isolating valve's closure contact to Y2.

Isolating valve end

}

of run

Page 28

VARMAX TWIN - Installation, Use and Maintenance

230 VAC 50 Hz

power supply

LPB bus

DB MB

Diagrams: VX200 / VX201

Isolating

valve Q1.2

Alarm

}

L NY1 NY2L NL NL N

QX2 QX3 QX1 AUX2 AUX1

}

page 3 / 6

relay

}

BX2

Gnd

BX3

Gnd

B3

Gnd

B9

Gnd

H1

Gnd

D. SPECIFIC START-UP PROCEDURE

Make the accessories' electrical connections.

Start up the generator on its own.

Make the following settings:

On generator No. 1

• Set the date and time: Time and date menu

Set the time

Set the date

Set the year

• Confi gure the isolating valve and its end of run: Confi guration menu

Valve command

Relay output QX3 (5892) K37 exhaust fl ap

H5

Gnd

Line No. Value

Hour / minute (1) HH.MM

Day / month (2) DD.MM

Year (3) YYYY

Isolating valve end

}

of run

End of run

• Confi guration menu

Start up heating circuit 1

Page 28 / 56 00BNO9132-#

Heating circuit 1 (5710) Start

Input H5 (5977) Exhaust fl ap info

return

Page 29

VARMAX TWIN - Installation, Use and Maintenance

Diagrams: VX200 / VX201

VX200 diagram only:

Confi gure pump Q2

All diagrams:

Confi gure TWIN B10 output sensor

• Confi gure as generator No. 1: LPB network menu

Appliance number

Segment number

Adjust the bus supply

Adjust the clock rate

page 4 / 6

Line No. Value

Relay output QX2 (5891) Pump CC1 Q2

BX2 sensor input (5931) Common fl ow sensor

B10

Appliance address (6600) 1

Segment address (6601) 0

Bus supply function (6604) Automatic

Clock operation (6640) Master

• Adjust the heating circuit Heating circuit 1 menu

Adjust the comfort setting

Adjust the curve slope

Comfort setting temperature (710) - - -

Heating curve slope (720) - - -

• Switch the heating regime to permanent comfort

On generator No. 2

• Confi gure the isolating valve and its end of run: Confi guration menu

Valve command

End of run

Relay output QX3 (5892) K37 exhaust fl ap

Input H5 (5977) Exhaust fl ap info return

• Confi gure as generator No. 2: LPB network menu

Appliance number

Segment number

Adjust the bus supply

Appliance address (6600) 2

Segment address (6601) 0

Bus supply function (6604) Automatic

Adjust the clock rate

Clock operation (6640) Slave without

adjustment

• Make sure that the communication cable is fully connected between the 2 generators (

respect

!

the polarity).

• Switch off and back on again generator 2. If the communication has been correctly established,

the clock is updated correctly.

Edition: 02 / 2015 Page 29 / 56

Page 30

VARMAX TWIN - Installation, Use and Maintenance

Diagrams: VX200 / VX201

E. ELECTRICAL AND HYDRAULIC VALIDATION

On generator No. 1

• Flow diagnostic menu

Validate the presence of all the generators

• Inputs/outputs test menu

Check the outputs

Alarm relay

Pump Q2 (VX200 diagram)

Isolating valve Q1.1

page 5 / 6

Line No. Value

Gener 1 status (8100) Released / not

released

Gener 2 status (8101) Released / not

released

...............................

Relay test (7700) Relay output QX1

Relay test (7700) Relay output QX2

Relay test (7700) Relay output QX3

Reset the outputs

Check the sensor values

External sensor B9

TWIN B10 output sensor

• Confi guration menu

Check the hydraulic diagram

On generator No. 2

• Inputs/outputs test menu

Check the outputs

Relay test (7700) No test

External T° B9 (7730) in °C

BX2 sensor T° (7821) in °C

Generator 1 inspection No. (6212) 14

Generator 2 inspection No. (6213) 0

DHW information (6215) 0

Information about heating circuits 3, 2 and 1 (6217) 1

Alarm relay

Isolating valve Q1.2

Reset the outputs

• Confi guration menu

Check the hydraulic diagram

Information about heating circuits 3, 2 and 1 (6217) 0

Page 30 / 56 00BNO9132-#

Generator 1 inspection No. (6212) 14

Generator 2 inspection No. (6213) 0

Relay test (7700) Relay output QX1

Relay test (7700) Relay output QX3

Relay test (7700) No test

DHW information (6215) 0

Page 31

VARMAX TWIN - Installation, Use and Maintenance

Diagrams: VX200 / VX201

F. CONFIGURATION OPTIMISATION

On generator No. 1

Heating circuit optimisation:

• Heating circuit 1 menu

Adjust the reduced setting

• Heating circuit 1 timer programme menu

Preselection

Adjust the timer programming

• Heating circuit 1 holiday menu

Preselection

page 6 / 6

Line No. Value

Reduced setting temperature (712) - - -

Preselection (500) - - -

On / off phases (501...506) - - -

Preselection (641) - - -

Adjust the timer programming

• Switch the heating regime to automatic

On / off phases (642--643) - - -

Auto

VARMAX TWIN optimisation:

The Varmax Twin may be optimised as necessary using the parameters in the Flow menu. Refer to

the NAVISTEM B3000 boiler's controller manual for more details.

Maintenance optimisation

A maintenance message may be generated that does not set the generator to fault. This maintenance

message may be displayed after the following 3 counters have expired:

• Time since last maintenance (or commissioning): set parameter 7044 to 12 months

(Maintenance / Special regime menu)

• Burner's operating hours (parameter 7040 - menu Maintenance / Special regime menu)

• Number of starts (parameter 7042 - menu Maintenance / Special regime menu)

These last 2 parameters are dependent on the boiler's hydraulic installation. We recommend

using at least parameter 7044 for annual maintenance.

Edition: 02 / 2015 Page 31 / 56

Page 32

VARMAX TWIN - Installation, Use and Maintenance

Secondary networks regulated by external regulator

communicating over LPB bus or 0...10V temperature

A. HYDRAULIC DIAGRAM

COMMUNICATING REGULATOR

REGULATEUR COMMUNICANT

0/10 V SIGNAL TO NAVISTEM B3000

SIGNAL 0/10 V VERS LMS

or LPB BUS TO OCI345

ou bus LPB sur OCI 345

B10

x

Diagram

VX211

page 1 / 6

Q1.1 Q1.2

B3000 B3000

fi gure 17 - VX211 diagram

B. REGULATION ACCESSORIES REQUIRED

Quantity

Communication kit 2 OCI 345 supplied

Communication cable 1 LPB BUS supplied

Output sensor kit 1 QAZ 36 supplied

Appliance

reference

Order No.

Page 32 / 56 00BNO9132-#

Page 33

VARMAX TWIN - Installation, Use and Maintenance

Diagram: VX211

C. CUSTOMER'S ELECTRICAL CONNECTION

Generator No. 1:

INFORMATION:

230 VAC 50 Hz

power supply

If the isolation valve is not equipped with an automatic reset valve, connect

the Q1.1 isolating valve's closure contact to Y2.

Isolating

valve Q1.1

L NY1 NY2L NL NL N

QX2 QX3 QX1 AUX2 AUX1

Alarm relay

}

}

page 2 / 6

LPB bus

}

DB MB

Generator No. 2:

BX2

Gnd

BX3

Gnd

B3

Gnd

B9

Gnd

H1

Gnd

H5

Gnd

TWIN B10 output

}

sensor

0 to 10V temperature

}

analogue input

Isolating valve end

}

of run

INFORMATION:

Edition: 02 / 2015 Page 33 / 56

If the isolation valve is not equipped with an automatic reset valve, connect

the Q1.2 isolating valve's closure contact to Y2.

Page 34

VARMAX TWIN - Installation, Use and Maintenance

230 VAC 50 Hz

power supply

LPB bus

DB MB

}

Diagram: VX211

Isolating

valve Q1.2

L NY1 NY2L NL NL N

QX2 QX3 QX1 AUX2 AUX1

Alarm relay

}

}

page 3 / 6

BX2

Gnd

BX3

Gnd

B3

Gnd

B9

Gnd

H1

Gnd

D. SPECIFIC START-UP PROCEDURE

Make the accessories' electrical connections.

Start up the generator on its own.

Make the following settings:

On generator No. 1

• Time and date menu

Set the time

Set the date

Set the year

• Confi gure the isolating valve and its end of run: Confi guration menu

Valve command

Relay output QX3 (5892) K37 exhaust fl ap

H5

Gnd

Line No. Value

Hour / minute (1) HH.MM

Day / month (2) DD.MM

Year (3) YYYY

Isolating valve end

}

of run

End of run

• Confi guration menu

Confi gure the TWIN B10 output sensor

Page 34 / 56 00BNO9132-#

BX2 sensor input (5931) Common fl ow sensor

Input H5 (5977) Exhaust fl ap info return

B10

Page 35

VARMAX TWIN - Installation, Use and Maintenance

Diagram: VX211

Line No. Value

For a request via 0...10V input

Confi gure the H1 input

For a request via LPB

Check that the secondary regulatory is defi ned on an LPB segment other

than 0 (reserved for the generators)

In all cases (LPB network menu)

H1 input function (5950) 10V consumption

H1 voltage 1 value (5953) 0.0

H1 function value (5954) 0

H1 voltage 2 value (5955) 10.0

H1 function 2 value (5956) 1000 (for

page 4 / 6

circ. request

equivalence 10 V =

100 °C)

Confi gure as generator No. 1

Appliance address (6600) 1

Segment address (6601) 0

Bus supply function (6604) Automatic

Clock operation (6640) Master

On generator No. 2

• Confi gure the isolating valve and its end of run: Confi guration menu

Valve command

End of run

Relay output QX3 (5892) K37 exhaust fl ap

Input H5 (5977) Exhaust fl ap info return

• LPB network menu

Confi gure as generator No. 2

Appliance address (6600) 2

Segment address (6601) 0

Bus supply function (6604) Automatic

Clock operation (6640) Slave without

adjustment

• Make sure that the communication cable is fully connected between the 2 generators (

respect

!

the polarity).

• Switch off and back on again generator 2. If the communication has been correctly established,

the clock is updated correctly.

Edition: 02 / 2015 Page 35 / 56

Page 36

VARMAX TWIN - Installation, Use and Maintenance

Diagram: VX211

E. ELECTRICAL AND HYDRAULIC VALIDATION

On generator No. 1

• Flow diagnostic menu

Validate the presence of all the generators

For a request via 0...10V input

• Inputs/outputs test menu

Voltage in H1

page 5 / 6

Line No. Value

Gener 1 status (8100) Released / not

released

Gener 2 status (8101) Released / not

released

...............................

H1 voltage signal (7840) To be validated with

the voltage sent by

the boiler room's

PLC

For a request via LPB

If the boiler room's regulator is confi gured

as slave clock, it must retrieve the date

and time.

• Inputs/outputs test menu

Check the outputs

Alarm relay

Isolating valve Q1.1

Reset the outputs

Check the sensor values

External sensor B9

B1 fl ow sensor

• Confi guration menu

Relay test (7700) Relay output QX1

Relay test (7700) Relay output QX3

Relay test (7700) No test

External T° B9 (7730) in °C

BX2 sensor T° (7821) in °C

Check the hydraulic diagram

Information about heating circuits 3, 2 and 1 (6217) 0

Page 36 / 56 00BNO9132-#

Generator 1 inspection No. (6212) 14

Generator 2 inspection No. (6213) 0

DHW information (6215) 0

Page 37

VARMAX TWIN - Installation, Use and Maintenance

On generator No. 2

• Inputs/outputs test menu

Check the outputs

Alarm relay

Isolating valve Q1.2

Reset the outputs

• Confi guration menu

Check the hydraulic diagram

Diagram: VX211

Information about heating circuits 3, 2 and 1 (6217) 0

page 6 / 6

Line No. Value

Relay test (7700) Relay output QX1

Relay test (7700) Relay output QX3

Relay test (7700) No test

Generator 1 inspection No. (6212) 14

Generator 2 inspection No. (6213) 0

DHW information (6215) 0

F. CONFIGURATION OPTIMISATION

VARMAX TWIN optimisation:

The Varmax Twin may be optimised as necessary using the parameters in the Flow menu. Refer to

the NAVISTEM B3000 boiler's controller manual for more details.

Maintenance optimisation

A maintenance message may be generated that does not set the generator to fault. This maintenance

message may be displayed after the following 3 counters have expired:

• Time since last maintenance (or commissioning): set parameter 7044 to 12 months

(Maintenance / Special regime menu)

• Burner's operating hours (parameter 7040 - menu Maintenance / Special regime menu)

• Number of starts (parameter 7042 - menu Maintenance / Special regime menu)

These last 2 parameters are dependent on the boiler's hydraulic installation. We recommend

using at least parameter 7044 for annual maintenance.

Edition: 02 / 2015 Page 37 / 56

Page 38

VARMAX TWIN - Installation, Use and Maintenance

1 network regulated by three-channel valve, DHW

production, or 1 direct circuit with constant temperature and

fl ow rate

A. HYDRAULIC DIAGRAM

B9

B10

x

B3000

Q1.1

B3000

Q1.2

Diagram

B1

Q2

Y1/Y2

Q3

B3

VX210

VX220

page 1 / 8

x

B3000

B9

Q1.1

fi gure 18 - VX210 diagram

B3000

Q1.2

DIRECT CIRCUIT WITH

CIRCUIT DIRECT AVEC

CONSTANT TEMPERATURE

TEMPERATURE ET DEBIT

AND THROUGHPUT

CONSTANT

B1

x

Q2

Q15

Y1/Y2

x

B10

fi gure 19 - VX220 diagram

Page 38 / 56 00BNO9132-#

Page 39

VARMAX TWIN - Installation, Use and Maintenance

Diagrams: VX210 / VX220

B. REGULATION ACCESSORIES REQUIRED

Quantity

Extension module kit (delivered with a

network sensor QAD 36)

Communication kit 2 OCI 345 supplied

Communication cable 1 LPB BUS supplied

Output sensor kit 1 QAZ 36 supplied

DHW sensor kit (diagram VX210) 1 QAZ 36 059261

Output sensor kit 1 QAC 34 059260

C. CUSTOMER'S ELECTRICAL CONNECTION

1 AVS 75 059751

Appliance

reference

page 2 / 8

Order No.

Generator No. 1:

INFORMATION:

VX210 diagram:

VX220 diagram:

230 VAC 50 Hz

power supply

DHW pump Q3

Direct circulator Q15

LPB bus

}

DB MB

If the isolation valve is not equipped with an automatic reset valve, connect

the Q1.1 isolating valve's closure contact to Y2.

Isolating valve

Q1.1

}

L NY1 NY2L NL NL N

QX2 QX3 QX1 AUX2 AUX1

}

Alarm

relay

}

BX2

Gnd

BX3

Gnd

B3

Gnd

B9

Gnd

TWIN B10 output

}

sensor

VX210 diagram:

}

DHW sensor B3

External sensor B9

}

H1

Gnd

H5

Gnd

Edition: 02 / 2015 Page 39 / 56

VX220 diagram:

Shunt to be put in

place

Isolating valve end

}

of run

Page 40

VARMAX TWIN - Installation, Use and Maintenance

Diagrams: VX210 / VX220

Heating circuit No. 1 mixer

valve Y1/Y2

Heating circuit No. 1

circulator Q2

Generator No. 2:

INFORMATION:

page 3 / 8

Module 1

BX21

Gnd

BX22

Gnd

H2

Gnd

}

Regulated circuit output sensor

}

B1

QX21

}

No.

QX22

}

No.

QX23

If the isolation valve is not equipped with an automatic reset valve, connect

the Q1.2 isolating valve's closure contact to Y2.

AVS75

230 VAC 50 Hz

power supply

LPB bus

DB MB

}

Isolating valve

Q1.2

L NY1 NY2L NL NL N

QX2 QX3 QX1 AUX2 AUX1

}

Alarm

relay

}

BX2

Gnd

BX3

Gnd

B3

Gnd

B9

Gnd

H1

Gnd

H5

Gnd

Page 40 / 56 00BNO9132-#

Isolating valve end

}

of run

Page 41

VARMAX TWIN - Installation, Use and Maintenance

Diagrams: VX210 / VX220

D. SPECIFIC START-UP PROCEDURE

Make the accessories' electrical connections.

!

Start up the generator on its own.

Make the following settings:

On generator No. 1

• Time and date menu

IMPORTANT: Confi gure the switches on the AVS75 extension module.

Set the time

Set the date

Set the year

page 4 / 8

Line No. Value

Hour / minute (1) HH.MM

Day / month (2) DD.MM

Year (3) YYYY

• Confi gure the isolating valve and its end of run: Confi guration menu

Valve command

End of run

• Confi guration menu

Confi gure the DHW pump (VX210

diagram)

Confi gure the Q15 pump (VX220

diagram)

Confi gure the TWIN B10 output sensor

Confi gure the H1 input (VX220 diagram)

Confi gure the extension module

• Confi gure as generator No. 1: LPB network menu

Extension module 1 function 1 (6020) Heating circuit 1

Relay output QX3 (5892) K37 exhaust fl ap

Input H5 (5977) Exhaust fl ap info

Relay output QX2 (5891) DHW pump/valve Q3

Relay output QX2 (5891) Consumption circuit

BX2 sensor input (5931) Common fl ow sensor

H1 input function (5977) Consumption circuit 1

return

pump 1 Q15

B10

request

Appliance number

Segment number

Adjust the bus supply

Adjust the clock rate

Edition: 02 / 2015 Page 41 / 56

Appliance address (6600) 1

Segment address (6601) 0

Bus supply function (6604) Automatic

Clock operation (6640) Master

Page 42

VARMAX TWIN - Installation, Use and Maintenance

Diagrams: VX210 / VX220

• Heating circuit 1 menu

Adjust the comfort setting

Adjust the curve slope

• Switch the heating regime to permanent comfort

VX210 diagram only:

• Domestic hot water menu

Adjust the comfort setting

• Activate the DHW mode

page 5 / 8

Line No. Value

Comfort setting temperature (710) - - -

Heating curve slope (720) - - -

Comfort setting (1610) - - -

VX220 diagram only:

• Consumption circuit 1 menu

Set the output setting to be taken into

Cons request output T° (1859) - - -

account if the consumption circuit is

requested

On generator No. 2

• Confi gure the isolating valve and its end of run: Confi guration menu

Valve command

End of run

Relay output QX3 (5892) K37 exhaust fl ap

Input H5 (5977) Exhaust fl ap info return

• Confi gure as generator No. 2: LPB network menu

Appliance number

Segment number

Adjust the bus supply

Appliance address (6600) 2

Segment address (6601) 0

Bus supply function (6604) Automatic

Adjust the clock rate

Clock operation (6640) Slave without

adjustment

• Make sure that the communication cable is fully connected between the 2 generators (

respect

!

the polarity).

• Switch off and back on again generator 2. If the communication has been correctly established,

Page 42 / 56 00BNO9132-#

Page 43

VARMAX TWIN - Installation, Use and Maintenance

Diagrams: VX210 / VX220

the clock is updated correctly.

E. ELECTRICAL AND HYDRAULIC VALIDATION

On generator No. 1

• Flow diagnostic menu

Validate the presence of all the generators

• Inputs/outputs test menu

Check the outputs

page 6 / 8

Line No. Value

Gener 1 status (8100) Released / not

released

Gener 2 status (8101) Released / not

released

...............................

Alarm relay

DHW pump Q3 (VX210 diagram)

Constant circuit pump Q15 (VX220 diagram)

Heating circuit 3-channel valve opening

Heating circuit 3-channel valve closure

Heating circuit pump

Reset the outputs

Check the sensor values

External sensor B9

DHW sensor B3

B1 fl ow sensor

• Confi guration menu

Relay test (7700) Relay output QX1

Relay test (7700) Relay output QX2

Relay test (7700) Relay output QX2

Relay test (7700) Relay output QX21

module 1

Relay test (7700) Relay output QX22

module 1

Relay test (7700) Relay output QX23

module 1

Relay test (7700) No test

External T° B9 (7730) in °C

DHW temperature B3/B38 (7750) in °C

Temperature sensor BX21 module 1 (7830) in °C

Check the hydraulic diagram

Information about heating circuits 3, 2 and 1 (6217) 3

Edition: 02 / 2015 Page 43 / 56

Generator 1 inspection No. (6212) 14

Generator 2 inspection No. (6213) 0

DHW information (6215) 4

0

(

VX210 diagram)

(

VX220 diagram)

Page 44

VARMAX TWIN - Installation, Use and Maintenance

Diagrams: VX210 / VX220

On generator No. 2

• Inputs/outputs test menu

Check the outputs

Alarm relay

Isolating valve Q1.2

Reset the outputs

• Confi guration menu

Check the hydraulic diagram

page 7 / 8

Line No. Value

Relay test (7700) Relay output QX1

Relay test (7700) Relay output QX3

Relay test (7700) No test

Generator 1 inspection No. (6212) 14

Generator 2 inspection No. (6213) 0

DHW information (6215) 0

Information about heating circuits 3, 2 and 1 (6217) 0

F. CONFIGURATION OPTIMISATION

Heating circuit optimisation:

• Heating circuit 1 menu

Adjust the reduced setting

• Heating circuit 1 timer programme menu

Preselection

Adjust the timer programming

• Heating circuit 1 holiday menu

Preselection

Adjust the timer programming

• Switch the heating regime to automatic

DHW optimisation:

Reduced setting temperature (712) - - -

Preselection (500) - - -

On / off phases (501...506) - - -

Preselection (641) - - -

On / off phases (642--643) - - -

Auto

• Domestic hot water menu

Adjust the comfort setting

Page 44 / 56 00BNO9132-#

Reduced setting (1612) - - -

Page 45

VARMAX TWIN - Installation, Use and Maintenance

Diagrams: VX210 / VX220

Adjust the DHW release mode DHW release (1620) Timer program 4/

DHW

Line No. Value

• Timer programme 4/DHW menu

Preselection

Adjust the timer programming

• DHW tank menu

Adjust the over value

VX210 diagram only:

• Domestic hot water menu

Confi gure an Anti-Legionnaires' Disease

function

On / off phases (561...566) - - -

Output setting temperature over value (5020) - - -

Anti-Legionnaires' Disease function

Preselection (560) - - -

- - -

(1640)

page 8 / 8

Periodic Anti-Legionnaires' Disease

function (1641)

Day week Anti-Legionnaires' Disease function (1642) - - -

Anti-Legionnaires' Disease setting temperature (1645) - - -

Anti-Legionnaires' Disease function duration (1646) - - -

- - -

VARMAX TWIN optimisation:

The Varmax Twin may be optimised as necessary using the parameters in the Flow menu. Refer to

the NAVISTEM B3000 boiler's controller manual for more details.

Maintenance optimisation

A maintenance message may be generated that does not set the generator to fault. This maintenance

message may be displayed after the following 3 counters have expired:

• Time since last maintenance (or commissioning): set parameter 7044 to 12 months

(Maintenance / Special regime menu)

• Burner's operating hours (parameter 7040 - menu Maintenance / Special regime menu)

• Number of starts (parameter 7042 - menu Maintenance / Special regime menu)

These last 2 parameters are dependent on the boiler's hydraulic installation. We recommend

using at least parameter 7044 for annual maintenance.

Edition: 02 / 2015 Page 45 / 56

Page 46

VARMAX TWIN - Installation, Use and Maintenance

x

x

x

x

x

B3000

B3000

Entrée

eau froide

bouclage

ECS

ECS

3 or 4 networks regulated by three-channel valve, with or

without DHW production

A. MAIN AND VARIANT HYDRAULIC DIAGRAMS

Diagram

VX202

VX212

page 1 / 9

B9

B3000

Q1.1

B3000

B1

Q2

Y1/Y2

x

B10

Q1.2

fi gure 20 - VX202 diagram

B12

x

x

Q6 Q20

Y5/

Y6

B14 B1.2

x

Y11/

Y12

x

Q2.2

Y1.2/

Y2.2

B9

Q1.1

Y1/Y2

B10

Q1.2

fi gure 21 - VX212 diagram (variant)

B1

Q2

B12

Q6

Y5/

Y6

B14 B1.2

Q20

Y11/

Y12

Q2.2

Y1.2/

Y2.2

B3

Page 46 / 56 00BNO9132-#

Page 47

VARMAX TWIN - Installation, Use and Maintenance

Diagrams: VX202 / VX212

page 2 / 9

B. REGULATION ACCESSORIES REQUIRED

Quantity

Extension module kit (delivered with a

network sensor QAD 36)

Communication kit 2 OCI 345 supplied

Communication cable 1 LPB BUS supplied

Output sensor kit 1 QAZ 36 supplied

Output sensor kit 1 QAC 34 059260

DHW sensor kit (VX212 diagram) 1 QAZ 36 059261

3 (4) AVS 75 059751

Appliance

reference

Order No.

C. CUSTOMER'S ELECTRICAL CONNECTION

Generator No. 1:

INFORMATION:

230 VAC 50 Hz

power supply

LPB bus

}

DB MB

If the isolation valve is not equipped with an automatic reset valve, connect

the Q1.1 isolating valve's closure contact to Y2.

Isolating valve

Q1.1

L NY1 NY2L NL NL N

QX2 QX3 QX1 AUX2 AUX1

}

Alarm

relay

}

BX2

Gnd

BX3

Gnd

B3

Gnd

B9

Gnd

TWIN B10 output

}

sensor

VX212 diagram:

}

DHW sensor B3

External sensor B9

}

H1

Gnd

H5

Gnd

Edition: 02 / 2015 Page 47 / 56

VX212 diagram

only:

Isolating valve end

}

of run

Page 48

VARMAX TWIN - Installation, Use and Maintenance

Heating circuit No. 1 mixer

valve Y1/Y2

Heating circuit No. 1

circulator Q2

Heating circuit No. 2 mixer

valve Y5/Y6

Heating circuit No. 2

circulator Q6

Diagrams: VX202 / VX212

QX21

}

No.

QX22

}

No.

QX23

QX21

}

No.

QX22

No.

}

QX23

AVS75

AVS75

BX21

Gnd

BX22

Gnd

H2

Gnd

BX21

Gnd

BX22

Gnd

H2

Gnd

page 3 / 9

Module 1

}

Regulated circuit output sensor

}

B1

Module 2

}

Regulated circuit output sensor

}

B12

Heating circuit No. 3 mixer

valve Y11/Y12

Heating circuit No. 3

circulator Q20

Generator No. 2:

INFORMATION:

Module 3

BX21

Gnd

BX22

Gnd

H2

Gnd

}

Regulated circuit output sensor

}

B14

QX21

}

No.

QX22

}

No.

QX23

If the isolation valve is not equipped with an automatic reset valve, connect

the Q1.2 isolating valve's closure contact to Y2.

AVS75

Page 48 / 56 00BNO9132-#

Page 49

VARMAX TWIN - Installation, Use and Maintenance

230 VAC 50 Hz

power supply

LPB bus

DB MB

Diagrams: VX202 / VX212

Isolating

valve Q1.2

}

L NY1 NY2L NL NL N

QX2 QX3 QX1 AUX2 AUX1

}

page 4 / 9

Alarm

relay

}

BX2

Gnd

BX3

Gnd

B3

Gnd

B9

Gnd

H1

Gnd

QX21

}

Heating circuit No. 4 mixer

valve Y1.2/Y2.2

Heating circuit No. 4

circulator Q2.2

D. SPECIFIC START-UP PROCEDURE

Make the accessories' electrical connections.

No.

QX22

No.

}

QX23

(for the heating circuit in dotted lines

on the hydraulic diagrams)

AVS75

BX21

Gnd

BX22

Gnd

H2

Gnd

H5

Gnd

Module 1

}

Regulated circuit output sensor

}

B1.2

Isolating valve end

}

of run

IMPORTANT: Confi gure the switches on the AVS75 extension modules.

!

Start up the generator on its own.

Carry out the adjustments below.

Edition: 02 / 2015 Page 49 / 56

Page 50

VARMAX TWIN - Installation, Use and Maintenance

Diagrams: VX202 / VX212

On generator No. 1

Line No. Value

• Time and date menu

Set the time

Set the date

Set the year

• Confi gure the isolating valve and its end of run: Confi guration menu

Valve command

End of run

• Confi guration menu

Start up heating circuit 1

Start up heating circuit 2

Start up heating circuit 3

Relay output QX3 (5892) K37 exhaust fl ap

Hour / minute (1) HH.MM

Day / month (2) DD.MM

Year (3) YYYY

Input H5 (5977) Exhaust fl ap info return

Heating circuit 2 (5710) Start

Heating circuit 2 (5715) Start

Heating circuit 3 (5721) Start

page 5 / 9

VX212 diagram only:

Defi ne a low heel H1 input function (5950) Consumption circuit 1

request .

Position a shunt on H1 OR reverse the

contact direction

For the DHW to be effective, an

activator must be defi ned, even if it is

not connected

Confi gure pump Q1

Confi gure TWIN B10 output sensor

Confi gure the extension modules

• Confi gure as generator No. 1: LPB network menu

Extension module 1 function 1 (6020) Heating circuit 1

Extension module 2 function 1 (6021) Heating circuit 2

Extension module 3 function 1 (6022) Heating circuit 3

Contact type (5951) Normally-closed

contact (NC)

Relay output QX2 (5891) DHW pump/valve Q3

Relay output QX3 (5892) Boiler pump Q1

BX2 sensor input (5931) Common fl ow sensor

B10

Appliance number

Segment number

Adjust the bus supply

Adjust the clock rate

Page 50 / 56 00BNO9132-#

Appliance address (6600) 1

Segment address (6601) 0

Bus supply function (6604) Automatic

Clock operation (6640) Master

Page 51

VARMAX TWIN - Installation, Use and Maintenance

Diagrams: VX202 / VX212

• Heating circuit 1 / 2 / 3 menu

Adjust the comfort setting

Adjust the curve slope

• Switch the heating regime to permanent comfort

VX212 diagram only:

• Consumption circuit 1 menu

Set the output setting to be taken into

account if the consumption circuit is

requested

Comfort setting temperature (710/1010/1310) - - -

page 6 / 9

Line No. Value

Heating curve slope (720/1020/1320) - - -

Cons request output setting (1859) 60 °C (depends on

the Rubis setting)

• Domestic hot water menu

Adjust the comfort setting

Adjust the DHW release mode

• Activate the DHW mode

On generator No. 2

• Confi gure the isolating valve and its end of run: Confi guration menu

Valve command

End of run

• Confi guration menu

If 4th heating circuit present: Start up

heating circuit 1

Confi gure the extension module

Extension module 1 function 1 (6020) Heating circuit 1

Comfort setting (1610) 55 °C

DHW release (1620) 24/24

Relay output QX3 (5892)

Input H5 (5977)

Heating circuit 1 (5710) Start

K37 exhaust fl ap

Exhaust fl ap info

return

• Confi gure as generator No. 2: LPB network menu

Appliance number

Segment number

Adjust the bus supply

Adjust the clock rate

Edition: 02 / 2015 Page 51 / 56

Appliance address (6600) 2

Segment address (6601) 0

Bus supply function (6604) Automatic

Clock operation (6640) Slave without

adjustment

Page 52

VARMAX TWIN - Installation, Use and Maintenance

Diagrams: VX202 / VX212

Line No. Value

If 4th heating circuit present:

• Adjust the heating circuit Heating circuit 1 menu

Adjust the comfort setting

Adjust the curve slope

• Switch the heating regime to permanent comfort

• Make sure that the communication cable is fully connected between the 2 generators (!respect

the polarity).

• Switch off and back on again generator 2. If the communication has been correctly established,

the clock is updated correctly.

Comfort setting temperature (710) - - -

Heating curve slope (720) - - -

page 7 / 9

E. ELECTRICAL AND HYDRAULIC VALIDATION

On generator No. 1

• Flow diagnostic menu

Validate the presence of all the generators

• Inputs/outputs test menu

Check the outputs

Alarm relay

Isolating valve Q1.1

All the extension module relays

Line No. Value

Gener 1 status (8100) Released / not

released

Gener 2 status (8101) Released / not

released

...............................

Relay test (7700) Relay output QX1

Relay test (7700) Relay output QX3

Relay test (7700) Relay output QX2...

module ...

Reset the outputs

Check the sensor values

External sensor B9

DHW sensor B3 (VX212 diagram)

TWIN B10 output sensor

B1 fl ow sensor

Page 52 / 56 00BNO9132-#

Temperature sensor BX21 module 1 (7830) in °C

DHW temperature B3/B38 (7750) in °C

Relay test (7700) No test

External T° B9 (7730) in °C

BX2 sensor T° (7821) in °C

Page 53

VARMAX TWIN - Installation, Use and Maintenance

Diagrams: VX202 / VX212

Line No. Value

B12 fl ow sensor Temperature sensor BX21 module 2 (7832) in °C

B14 fl ow sensor

VX212 diagram only:

Check the status of contact H1

• Confi guration menu

Check the hydraulic diagram

Information about heating circuits 3, 2 and 1 (6217) 30303

Temperature sensor BX21 module 3 (7834) in °C

Status of contact H1 (7841) Closed if the shunt

Generator 1 inspection No. (6212) 14

Generator 2 inspection No. (6213) 0

DHW information (6215) 0

page 8 / 9

is in place

(VX202 diagram)

4

(VX212 diagram)

On generator No. 2

• Inputs/outputs test menu

Check the outputs

Alarm relay

Isolating valve Q1.2

Reset the outputs

Check the sensor values (if 4th heating circuit present)

B1.2 fl ow sensor

• Confi guration menu

Check the hydraulic diagram

Information about heating circuits 3, 2 and 1 (6217) 3 (if 4th heating

Temperature sensor BX21 module 1 (7830) in °C

Relay test (7700) Relay output QX1

Relay test (7700) Relay output QX3

Relay test (7700) No test

Generator 1 inspection No. (6212) 14

Generator 2 inspection No. (6213) 0

DHW information (6215) 0

circuit present)

F. CONFIGURATION OPTIMISATION

On generators 1 and 2

Heating circuit optimisation

• Heating circuit 1 / 2 / 3 menu

Adjust the reduced setting

Edition: 02 / 2015 Page 53 / 56

Reduced setting temperature (712/1012/1312) - - -

Page 54

VARMAX TWIN - Installation, Use and Maintenance

Diagrams: VX202 / VX212

• Heating circuit 1 / 2 / 3 timer programme menu

Preselection

Adjust the timer programming

• Heating circuit 1 / 2 / 3 holiday menu

Preselection

Adjust the timer programming

• Switch the heating regime to automatic

Line No. Value

Preselection (500/520/540) - - -

On / off phases (501...506)

(521...526)

(541...546)

Preselection (641/651/661) - - -

On / off phases (642--643)

(652-653)

(662-663)

- - -

- - -

Auto

page 9 / 9

DHW optimisation:

• DHW tank menu

Adjust the over value

Output setting temperature over value (5020) 16 °C

VARMAX TWIN optimisation:

The Varmax Twin may be optimised as necessary using the parameters in the Flow menu. Refer to

the NAVISTEM B3000 boiler's controller manual for more details.

Maintenance optimisation

A maintenance message may be generated that does not set the generator to fault. This maintenance

message may be displayed after the following 3 counters have expired:

• Time since last maintenance (or commissioning): set parameter 7044 to 12 months

(Maintenance / Special regime menu)

• Burner's operating hours (parameter 7040 - menu Maintenance / Special regime menu)