Atlantic Aurea M, Aurea M 5, Aurea M 10, AEYC-1039U-AT2, AEYC-1639U-AT Installation Manual

...Page 1

Heat pumps & boilers

INSTALLATION

Aurea M

Air/water heat pump single service Monobloc system

EN

Outdoor unit

AEYC-0639U-AT

AEYC-1039U-AT1

AEYC-1039U-AT2

AEYC-1639U-AT

Hydraulic unit

023227

U0618930_1883_EN_5

22/02/2019

For professionals

To be kept by the user for future reference

Page 2

■ Installation and maintenance rules

■ Hydraulic connections

The appliance must be installed and maintained by

an approved professional in accordance with the

prevailing regulations and code of practice.

■ Handling

The outdoor unit must not be in a horizontal position

during transport.

Transport in a horizontal position may damage the

appliance by moving the refrigerant and damaging

the compressor's suspensions.

Damage caused by transportation in a horizontal

position is not covered by the warranty.

If necessary, the outdoor unit may be tilted during

manual handling (to go through a door or use a

staircase). This operation must be conducted very

carefully and the appliance must be immediately

restored to the upright position.

The connection must comply with good engineering

practices according to the regulations in force.

Reminder: Make the assembly seals according to

good engineering practices in force for plumbing

work:

- Use suitable seals or gaskets (bre seals, O rings).

- Use Teon or hemp tape.

- Use sealant (synthetic as required).

Use glycol water if the min starting temperature set

is lower than 10°C.

Use glycol water if the outdoor hydraulic links are

subject to a frost risk.

For the outdoor hydraulic links, use an insulator

which is suitable for outdoor use and is UV-resistant

(usage temperature -20 to +70 °C).

If glycol water is used, carry out an annual check of

the quality of the glycol. Use monopropylene glycol

only. The recommended concentration is 30%

minimum. Never use monoethylene glycol.

• In certain installations, the presence of dierent

metals can cause corrosion problems; in this

case, the formation of metal particles and

sludge in the hydraulic circuit is seen.

• Use a corrosion inhibitor in the proportions

recommended by its manufacturer.

• It is also necessary to ensure that the treated

water does not become aggressive.

Page 3

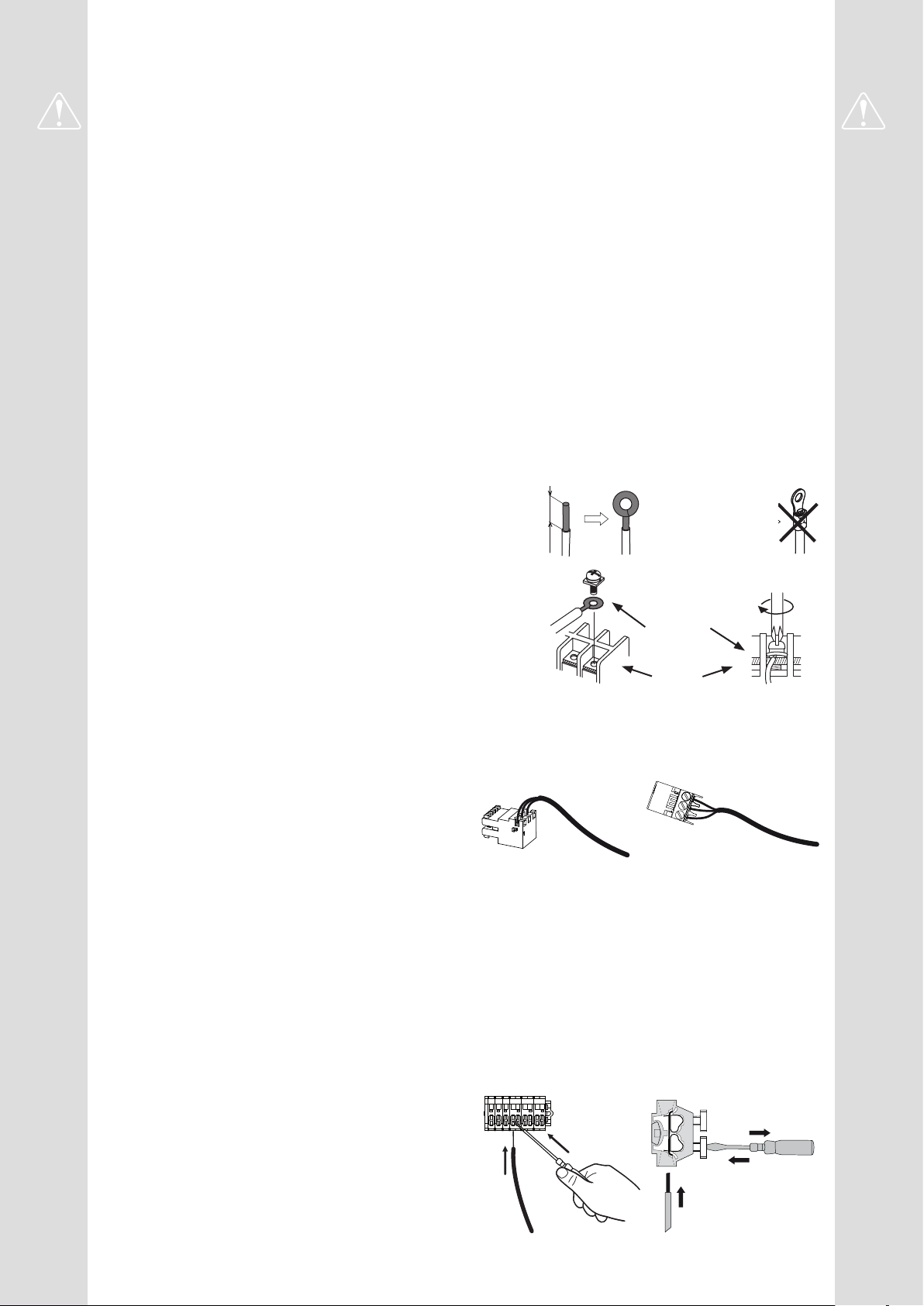

■ Electrical connections

2

1

3

• Always check that the electric power supply is

switched o before works.

• Characteristics of the electrical power supply

The electrical installation must be conducted in

accordance with the regulations in eect:

For installations with no neutral, a galvanic insulation

transformer earthed to the secondary must be used.

The electrical connections will only be made when

all of the other assembly operations (attachment,

assembly, etc.) have been carried out.

Warning!

The contract taken out with the energy supplier

must be sucient to cover the power of the heat

pump as well as the sum of the power requirements

of all of the appliances likely to be operated at the

same time. If the power supply is insucient, check

with your energy supplier the value of the power

supply dened in your contract.

Never use a socket for the power supply.

The heat pump must be directly powered (without

external switch) by dedicated lines that are protected

from the electrical housing by bipolar circuit breakers

dedicated to the heat pump, curve D for the outdoor

unit, curve C for the electrical DHW back-ups

(see “Specications”, page 7).

The electrical installation must be equipped with a

dierential protection of 30 mA.

This appliance is designed to operate under a

nominal voltage of 230 V +/- 10%, 50 Hz.

• General remarks on electrical connections

It is essential to maintain the phase-neutral polarity

when making the electrical connections.

Rigid wire is always preferable for xed installations,

especially in buildings.

Clamp the cables with stung glands to avoid any

accidental disconnection of the conductive wires.

Connection to earth and earth bonding continuity

are essential.

• Connecting to screw terminals

Use of ring terminals or tips is prohibited.

- Always choose a wire that complies with current

standards.

- Strip the end of the wire over a length of around

25 mm.

- With round nosed pliers, make a loop with a

diameter that corresponds to the terminal's

tightening screws.

- Tighten the terminal screw on the loop very rmly.

Insucient tightening can cause overheating,

leading to breakdown or even a re.

Rigid wires

25 mm

Loop

Lug on

exible wires

prohibited

Special screw and

washer

Terminal

block

• Connecting to regulation boards

- Remove the corresponding connector and make

the connection.

Precabled wiring connector and/or screw connector

• Connecting to spring terminals

- Strip the end of the wire over a length of around

10 mm.

- Push the spring with a screwdriver so that the wire

enters the cage.

- Slide the wire into the opening provided for this

purpose.

- Remove the screwdriver and then check that the

wire is jammed in the cage by pulling on it.

Page 4

Contents

Presentation of the equipment 6

Packing list ..............................6

Unpacking and reservations .................6

Optional equipment ........................6

Scope ..................................6

Specications ............................7

Operating principle .......................12

Location 14

Installing the outdoor unit ..................14 the hydraulic unit .........................16

Hydraulic connection 18

Rinsing the installation ....................18

Hydraulic connection of the outdoor unit .......18

Hydraulically connecting the heating circuit ....18

Heating installation volume .................19

Filling and draining the installation ...........19

Electrical connection 20

Cable section and protection rating ...........21 Electrical connections on the outdoor unit side ..22

Electrical connections on the hydraulic unit side ..24

Start-up 28

Conguration of the ambient sensor ..........28

Conguration of the room control unit .........28

Heating circulation pump speed settings .......29

Minimum ow settings of the installation .......29

Cleaning the lter valve ....................29

Regulation interface 30

The user interface, the central ambient unit (option)

and the ambient sensor (option) .............30

Description of the display ..................32

Weather-dependent control .................32

Regulation menu 34

List of function lines .......................35

- 4 -

Aurea M / Installation / 1883 - EN

Page 5

Fault diagnostic 50

Faults displayed on the hydraulic unit .........50

Faults displayed on the outdoor unit ..........51

Information display .......................54

Maintenance 55

Hydraulic checks .........................55 Checking the electrical circuit ...............55

Maintenance 55

Draining the hydraulic unit ..................55 Directional valve .........................55

Appendices 56

Overall hydraulic layout ....................56 Electrical cabling diagrams .................60

Start procedure 64

Commissioning check-list ..................64

Conguration le .........................66

Start-up data sheet .......................67

ErP performance gures 67

Instructions for the user 67

Aurea M / Installation / 1883 - EN

- 5 -

Page 6

Presentation of the equipment

Packing list

►

- 1 package: Outdoor unit.

- 1 package: Hydraulic unit and outdoor temperature

sensor.

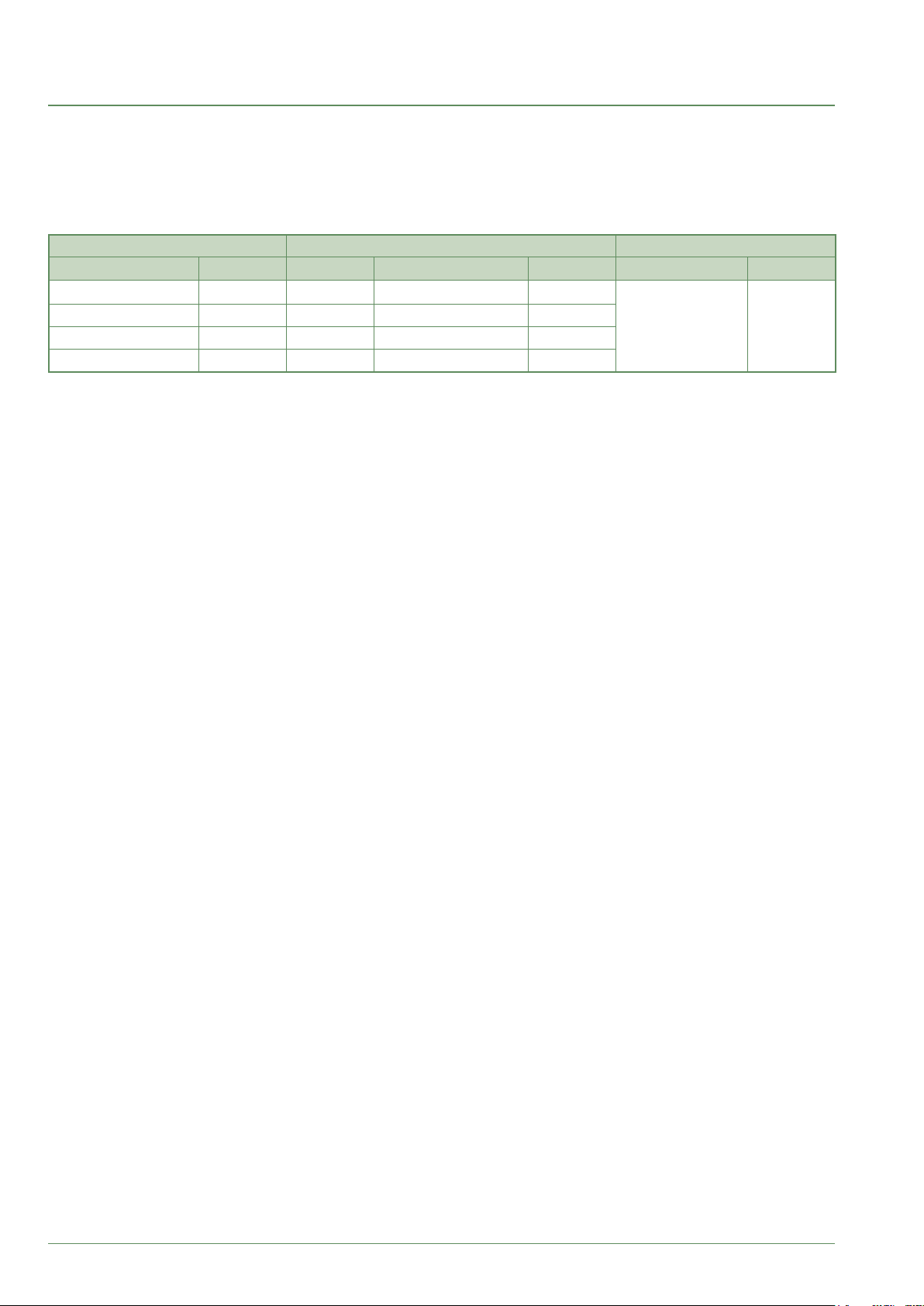

Heat pump Outdoor unit Hydraulic unit

Model Reference Model Reference Code Reference Code

Aurea M 5 526900 Aurea 5 AEYC-0639U-AT 700125

Aurea M 8 526901 Aurea 8 AEYC-1039U-AT2 700126

Aurea M 10 526902 Aurea 10 AEYC-1039U-AT1 700127

Aurea M 16 526903 Aurea 16 AEYC-1639U-AT 700129

Aurea M 023227

Unpacking and reservations

►

In the presence of the carrier, carefully inspect the

general appearance of the appliances and check that

the outdoor unit has not been placed in a horizontal

position.

In the event of disagreement, write to the carrier within

48 hours mentioning all reserves and send a copy of

this letter to the After Sales Department.

Optional equipment

►

- Dual circuit kit (ref. 074046)

for connecting 2 heating circuits.

- Electrical back-up kit (ref. 073985)

- DHW kit Internal (ref. 074047)

for connecting a DHW tank

(with built-in electrical back-ups).

[Not compatible with Boiler connection kit]

- DHW kit External (ref. 073991)

for connecting a DHW tank

(with built-in electrical back-ups).

- Boiler connection kit (code 073989)

for connecting a boiler to the heat pump.

- Ambient sensor T55 (ref. 073951),

Radio ambient sensor T58 (ref. 075313)

to correct the ambient temperature.

- Central ambient unit T75 (ref. 073954),

Central radio ambient unit T78 (ref. 074061)

to correct the ambient temperature and programme

the heat pump.

- Heating cable (ref. 809644)

Scope

►

This heat pump provides:

- Heating in winter,

- the addition of electrical back-ups, for extra heating

on the coldest days,

or

- Installation with boiler connection* as a supplementary

heating for the coldest days,

- Control of two heating circuits*,

- Production of domestic hot water* (provided that

combined with a DHW tank),

- Cooling in summer* (for underoor heating-cooling

system or fan-convectors).

*: These options require the use of additional kits

(see § “Optional equipment”, page 6).

- 6 -

Aurea M / Installation / 1883 - EN

Page 7

Specications

►

Model name Aurea 5 8 10 16

Nominal heating performances (outdoor temperature/ initial temperature)

Heat output

+7°C/+35°C - Under-oor heating kW 5.00 8.00 10.00 16.00

-7°C / +35°C - Under-oor heating kW 3.55 7.10 8.00 12.50

+7°C / +55°C - Radiator kW 3.88 7.50 8.90 12.80

-7°C / +55°C - Radiator kW 2.91 4.80 5.80 8.40

Power absorbed

+7°C / +35°C - Under-oor heating kW 1.19 1.78 2.30 4.08

-7°C / +35°C - Under-oor heating kW 1.38 2.93 3.32 5.68

+7°C / +55°C - Radiator kW 1.56 2.67 3.25 5.10

-7°C / +55°C - Radiator kW 1.78 2.95 3.35 5.53

Coecient of performance (COP) (+7°C/+ 35°C) 4.20 4.50 4.35 3.92

Nominal cooling performances (outdoor temperature/ initial temperature)

Cool output

+35°C / +18°C - Cooling oor system kW 3.15 6.00 7.50 14.30

+35°C / +7°C - Fan convector kW 2.40 4.50 5.60 10.70

Power absorbed

+35°C / +18°C - Cooling oor system kW 0.75 1.75 2.35 4.15

+35°C / +7°C - Fan convector kW 0.76 1.79 2.40 4.23

Cooling Eciency (EER) (+35°C / + 18°C) 4.20 4.43 3.19 3.45

Electrical characteristics

Electrical voltage (50 Hz): V 230

Maximum current of the appliance A 10.9 15.2 17.5 25.3

Nominal current A 5.6 8.0 10.2 17.8

Heating maximum electrical back-up current (option) A 13.05 / 26.1

Heating electrical back-up power (option) kW 6 kW

Outdoor unit maximum power absorbed W 2500 3500 4025 5820

Rates as per EN14825 0.008 0.005 0.004 0.002

Hydraulic circuit

Maximum operating pressure MPa (bar) 0.3 (3)

Minimum/maximum ow rate of the hydraulic circuit at

4°C<Δt<8°C (nominal conditions)

l/h 300 / 1200 600 / 2100 600 / 2100 900 / 3000

Miscellaneous

Weight of the outdoor unit kg 49 72 72 117

Noise level at 5 m 1 (Outdoor unit) dB (A) 47

(4)

47

(4)

47

(4)

47

(4)

Sound power level as per EN 12102-1 Annex A 2 (Outdoor unit) dB (A) 60 62 65 66

Pipe diameters Flow/Return (Outdoor unit) Inches 3/4 1 1 1 1/4

Weight of hydraulic unit (empty/full of water) kg 40 / 62

Hydraulic module water capacity l 22

Noise level at 1 m 1 (Hydraulic unit) dB (A) 39

(4)

Sound power level as per EN 12102-1 Annex A 2 (Hydraulic unit) dB (A) 46

Heating system operating limits

Min /max outdoor temperature °C -20 / +43

Initial max. heating water temperature °C Under-oor heating °C 45

(4)

Max. water temperature for start of heating LT radiator °C 55

Initial min. water temperature °C 8

(4)

Refrigerant circuit

Factory charge of refrigerating uid R410A 3 g 1050 1720 1720 2990

Maximum operating pressure MPa (bar) 4.1 (41)

1

Sound pressure level at (x) m from the appliance, 1.5m from the ground, free eld, directivity 2.

2

The acoustic power is a measurement made in the laboratory of the power of the noise emitted but contrary to the noise level, it does not correspond to the measurement of what is felt.

3

Refrigerant R410A in compliance with standard NF EN 378.1.

4

Temporary values.

Page 8

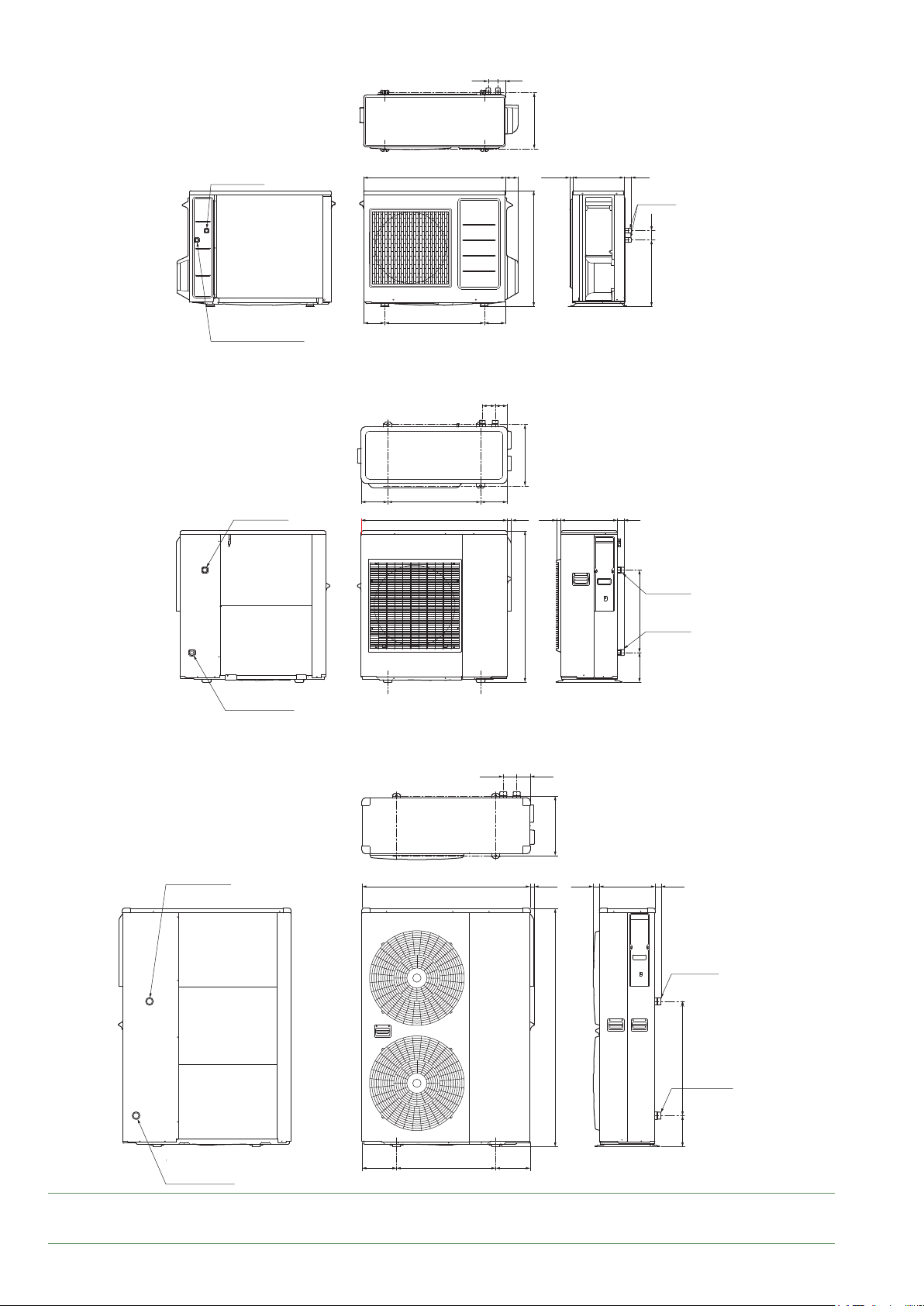

■ Outdoor unit Aurea 5

Circulating water

Circulating water

return port

return port

Circulating water

Circulating water

outgoing port

outgoing port

■ Outdoor unit Aurea 8 & Aurea 10

825

580

57

122.5122.5

75 70

43

327

73

675

357

30015.3 42

R3/4(20A)

54

388

■ Outdoor unit Aurea 16

Circulating water

Circulating water

outgoing port

outgoing port

Circulating water

Circulating water

outgoing port

outgoing port

Circulating water

Circulating water

return port

return port

155540155

850 24

80 80

25 330 38

882

357

241000 3637 330

R1(25A)

480173

R1(25A)

Circulating water

Circulating water

return port

return port

g. 6 - Outdoor unit dimensions (in mm)

- 8 -

R1 1/4(32A)

1418

680185

R1 1/4(32A)

205590205

Aurea M / Installation / 1883 - EN

Page 9

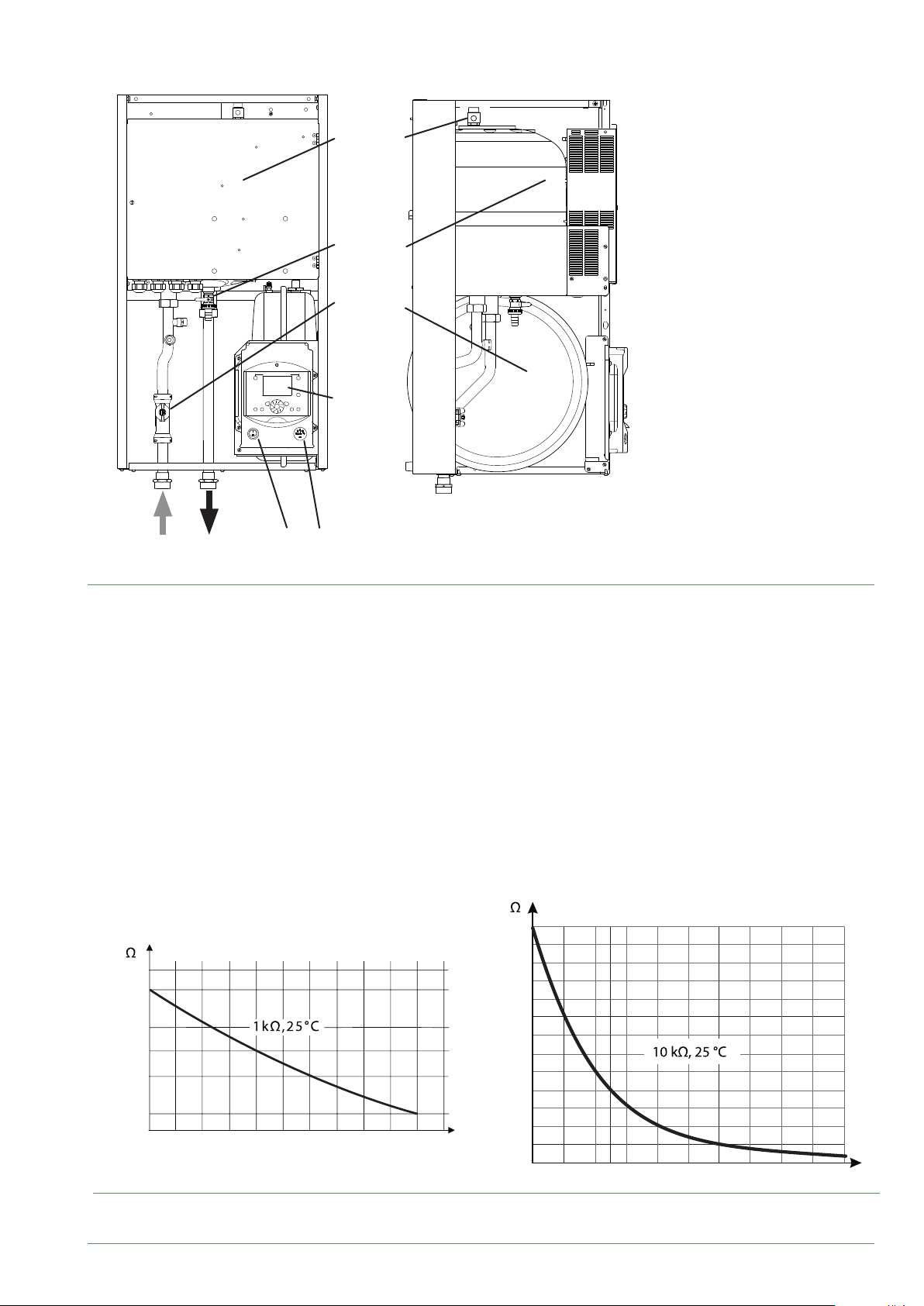

■ Hydraulic unit Aurea M

1*

3**

2*

4

803

845

450

97

g. 7 - Hydraulic unit dimensions in mm

98

84

457

479

2 3

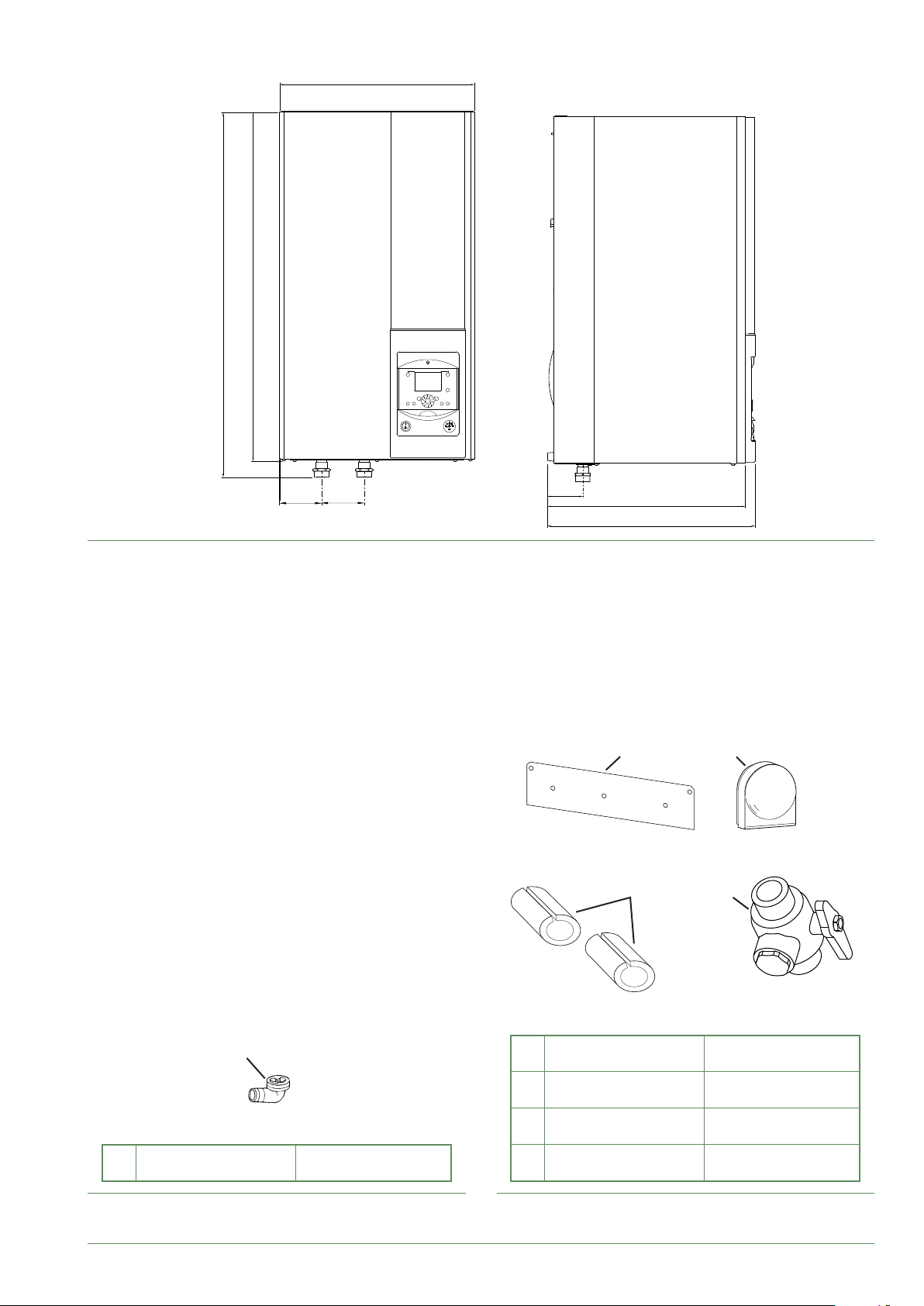

4 5

1

1 Elbow

g. 8 - Accessories supplied with the outdoor unit g. 9 - Accessories provided with the hydraulic module.

Aurea M / Installation / 1883 - EN

for condensate

evacuation

2 Support

3 Outdoor sensor

4 Insulating sleeves

5 Filter valve

to secure the hydraulic

unit.

to detect the outdoor

temperature

to insulate the

hydraulic connectors

to be installed on the

hydraulic circuit return

- 9 -

Page 10

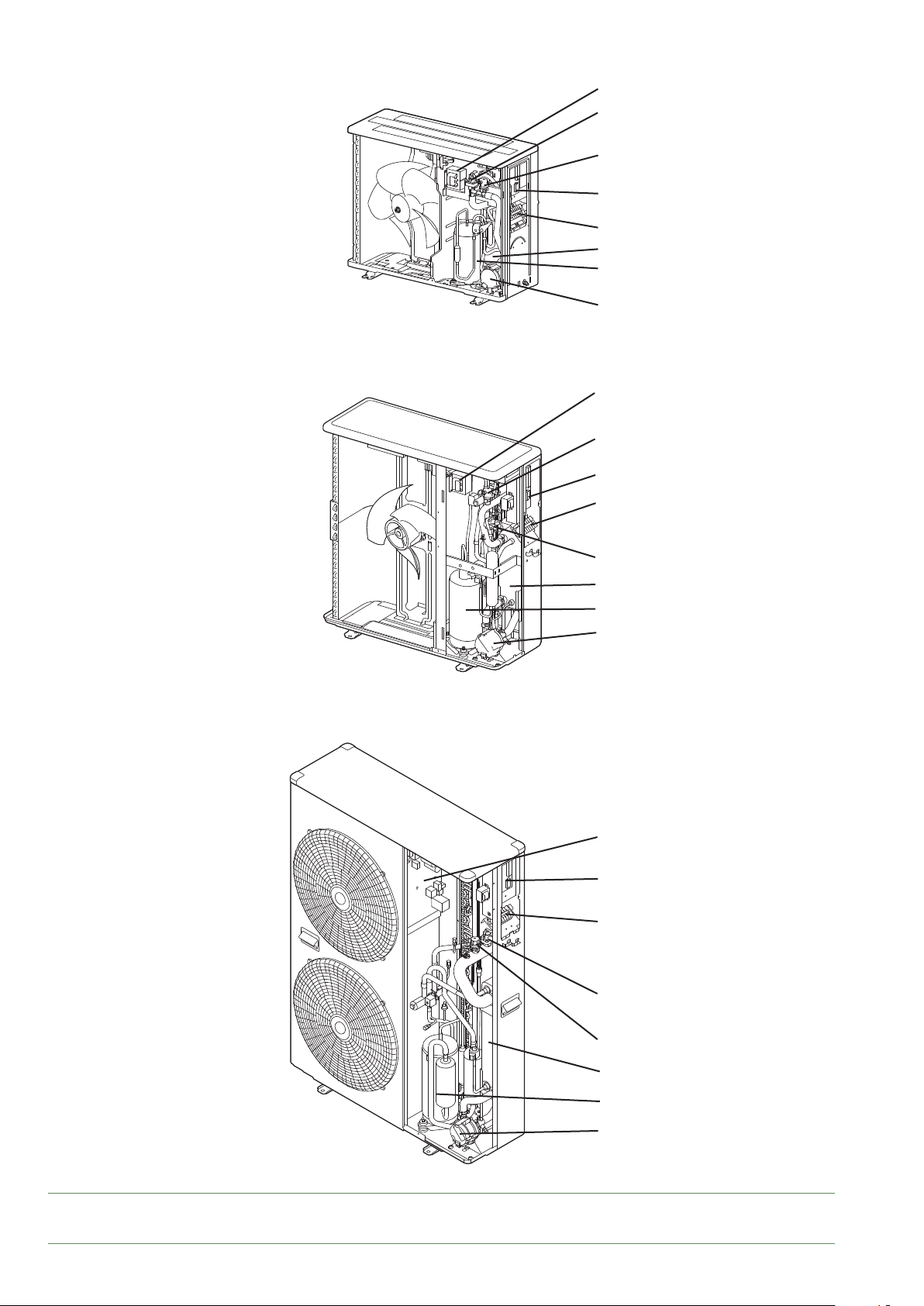

■ Outdoor unit Aurea 5

■ Outdoor unit Aurea 8 & Aurea 10

1

4

5

2

3

8

6

7

1

5

2

3

■ Outdoor unit Aurea 16

4

8

6

7

1

2

3

4

g. 10 - Components (outdoor units)

- 10 -

5

8

6

7

Aurea M / Installation / 1883 - EN

1 - Main board.

2 - Board.

3 - Terminal block.

4 - Safety valve.

5 - Bleed valve.

6 - Compressor.

7 - Circulation pump.

8 - Plate heat exchanger.

Page 11

°C

0102030405060708090 100

■ Hydraulic unit Aurea M

1

4

9

8

7

6

1 - Electric box.

2 - Regulator / User interface.

3 - On/O switch

2

4 - Bleed tap.

5 - Manometer

6 - Expansion vessel.

7 - Buer

(Electrical back-up optional).

8 - Manual drainer.

9 - Flow-meter.

3 5A B

A - Outdoor unit intake

B - Outgoing heating ow.

g. 11 - Hydraulic unit components

Outdoor sensor QAC34.

43907

10000

2490

1000

338

-50

-25025 50 75

32500

30000

27500

25000

22500

20000

17500

15000

12500

10000

7500

5000

2500

Return sensor.

Outlet sensor.

°C

0

g. 12 - Ohmic value of the sensors (hydraulic unit)

Aurea M / Installation / 1883 - EN

- 11 -

Page 12

Operating principle

►

The hydraulic unit has a regulator that controls the

indoor temperature based on the measurement of the

outdoor temperature, known as weather-dependent

control. The room thermostat (optional) corrects the

weather-dependent setpoint.

The hydraulic unit may be equipped with an electrical

back-up system*, which is designed to provide additional

heat during the coldest periods.

■ Regulation functions

- The initial temperature of the heating circuit is

controlled by the weather-dependent setpoint.

- The power of the heat pump is modulated according to

ow heating temperature via the "inverter" compressor.

- Control of the electrical back-up*.

- The daily timer programme enables you to dene

the periods for comfortable or reduced ambient

temperature.

- Switching between summer/winter operation is

automatic.

- Room thermostat*: The room thermostat corrects the

weather-dependent setpoint.

- Domestic hot water* Heating time program, control of

the operation of the DHW circulation pump.

- Managing the cooling.

■ Fan coil units with integrated regulation

Do not use a room thermostat in the zone concerned.

■ Protection functions

- Legionella cycle for domestic hot water.

- Frost protection: Frost protection cuts in if the lowtemperature point of the heating circuit falls below 5 °C.

■ Domestic hot water (DHW) operating principle*

Two domestic hot water (DHW) temperatures may

be set: comfort temperature (line 1610 at 55 °C)

and reduced temperature (line 1612 at 40 °C).

The DHW programme (line 560, 561 and 562) is set by

default to a comfort temperature from 0:00 to 5:00 and

from 14:30 to 17:00 and a reduced temperature for the

rest of the day, which optimises electricity consumption

while ensuring comfortable levels of hot water and

heating.

Setting for reduced temperature can be useful to prevent

the DHW from switching on too often and for too long

during the day.

The production of domestic hot water (DHW) is triggered

when the temperature in the tank falls 7 °C below the

temperature setpoint.

The heat pump produces domestic hot water (DHW),

which is then heated further, if required, by the electrical

back-up system inside the tank.

To ensure a DHW setting over 45 °C, the electrical

back-up heating must be left on.

Depending on how the parameter (1620) is set, nominal

temperature can be reached 24h/day or only at night or

depending on the heat pump program.

If the contract concluded with the energy provider

includes a subscription to day/night tari, the electrical

back-up is subordinate to the supplier's power tari and

the comfort temperature may only be reached at night.

If no particular contract is concluded, the comfort

temperature can be reached at any time, including

during the day

DHW production takes priority over heating;

nevertheless the production of DHW is controlled by

cycles that control the times assigned to the heating

and the production of DHW in the event of simultaneous

demand.

A switching function of "reduced" to "comfort" is available

on the front panel of the user interface (see item g. 27,

page 30).

Legionella cycles can be programmed.

*: These options require the use of additional kits (see § “Optional equipment”, page 6).

- 12 -

Aurea M / Installation / 1883 - EN

Page 13

Page 14

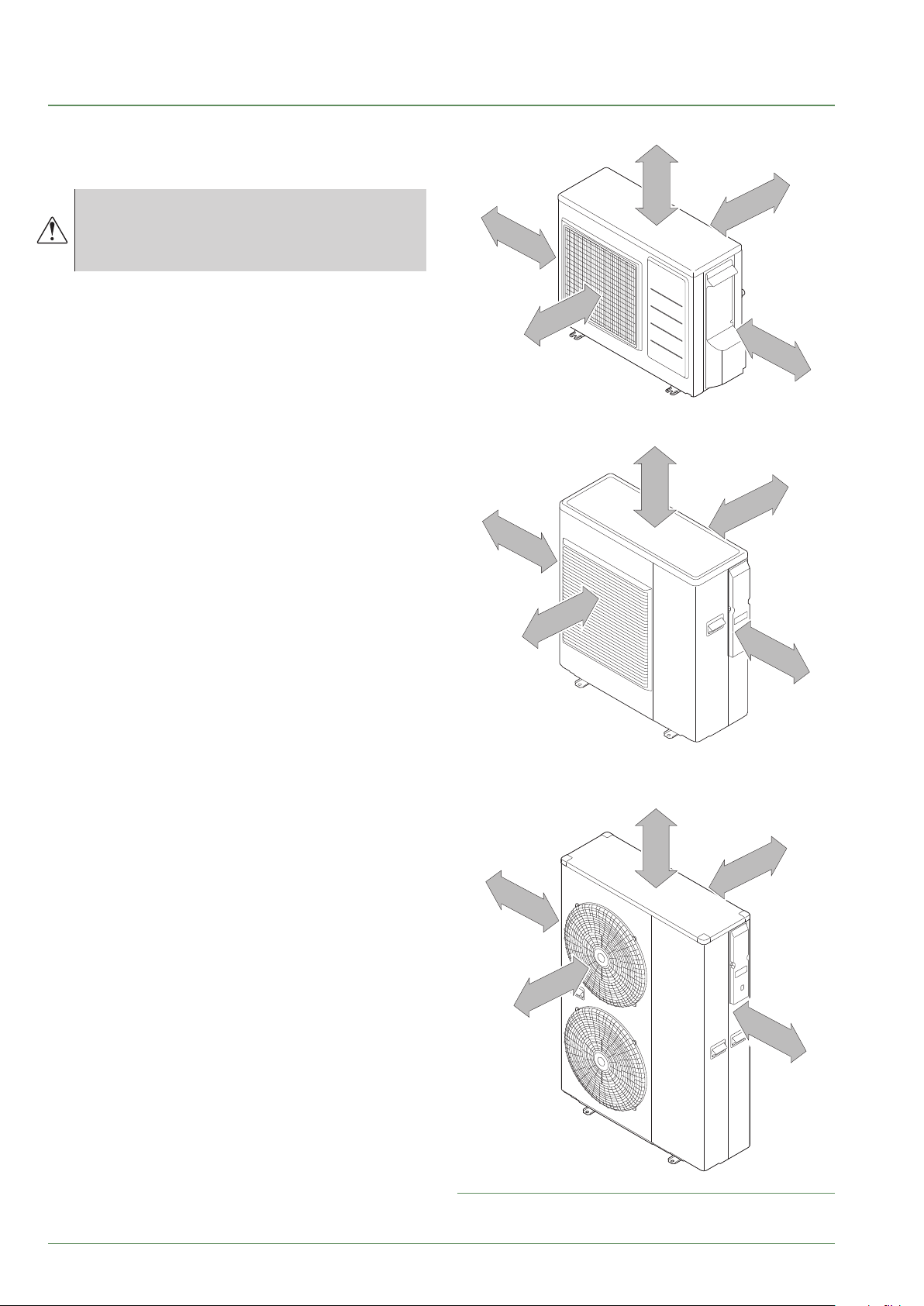

Location

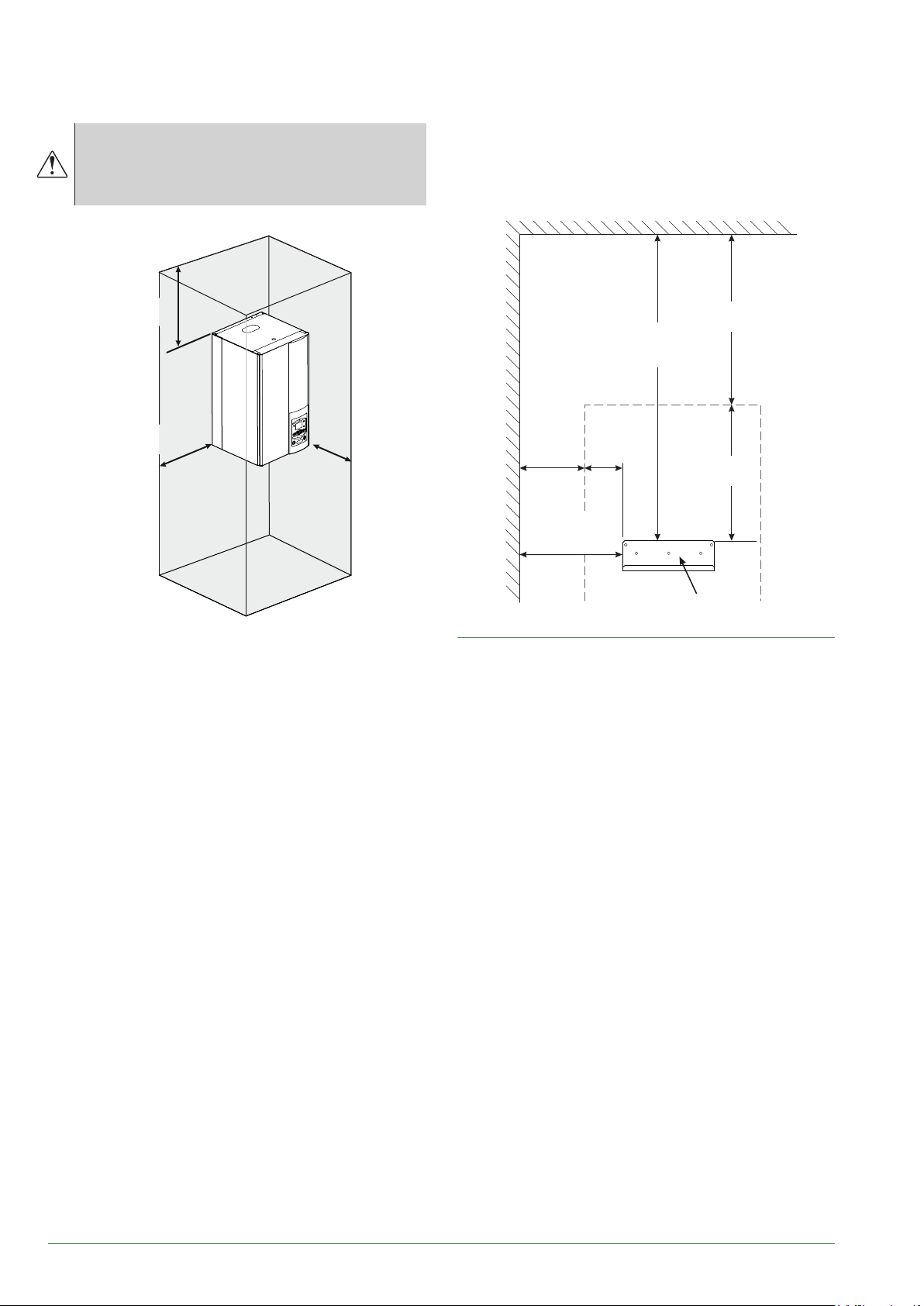

Installing the outdoor unit

►

Installation precautions

▼

The outdoor unit must only be installed

outdoors. If a shelter is required, it must have

broad openings on all 4 walls and comply with

the installation clearances.

• Choose the installation site after talks with the

customer.

• Prefer a sunny location, sheltered from strong and

cold dominant winds.

• The unit must be easily accessible for future installation

and maintenance work.

• Ensure that the connectors can be easily connected to

the hydraulic unit.

• The outdoor unit can be exposed to bad weather,

however avoid installing it in places where it will

become dirty or have excessive water dripping onto it

(for example under a leaky drainpipe).

• When operating water may escape from the outdoor

unit. Do not install the appliance on a terrace; install

it in a well-drained location (bed of gravel or sand).

If installed in a region where the temperature may

drop below 0 °C for a long period of time, check

that the ice does not cause any danger. A drainage

pipe can also be connected to the outdoor unit

(see g. 14, page 15).

• Nothing should obstruct the air from circulating through

the evaporator and out of the fan.

• Keep the outdoor unit away from sources of heat or

inammable products.

• Ensure that the appliance does not disturb neighbours or

users (noise level, draughts caused, low temperature of

the air blown causing a risk of freezing plants in its path).

• The surface on which the outdoor unit is mounted must:

- Be permeable (earth, gravel bed...),

- Support the weight comfortably,

- Permit it to be solidly attached,

- Not transmit any vibration to housing.

Anti-vibration pads are available as an optional extra.

• The wall bracket cannot be used in conditions likely to

transmit vibrations, where installation on the ground is

preferred.

■ Outdoor unit Aurea 5

>300 mm

> 100 mm

> 600 mm

■ Outdoor unit Aurea 8 & Aurea 10

>300 mm

> 100 mm

> 600 mm

■ Outdoor unit Aurea 16

>300 mm

> 100 mm

> 600 mm

>100 mm

> 600 mm

>100 mm

> 600 mm

>100 mm

> 600 mm

- 14 -

g. 13 - Minimum installation clearances

around the outdoor unit

Aurea M / Installation / 1883 - EN

Page 15

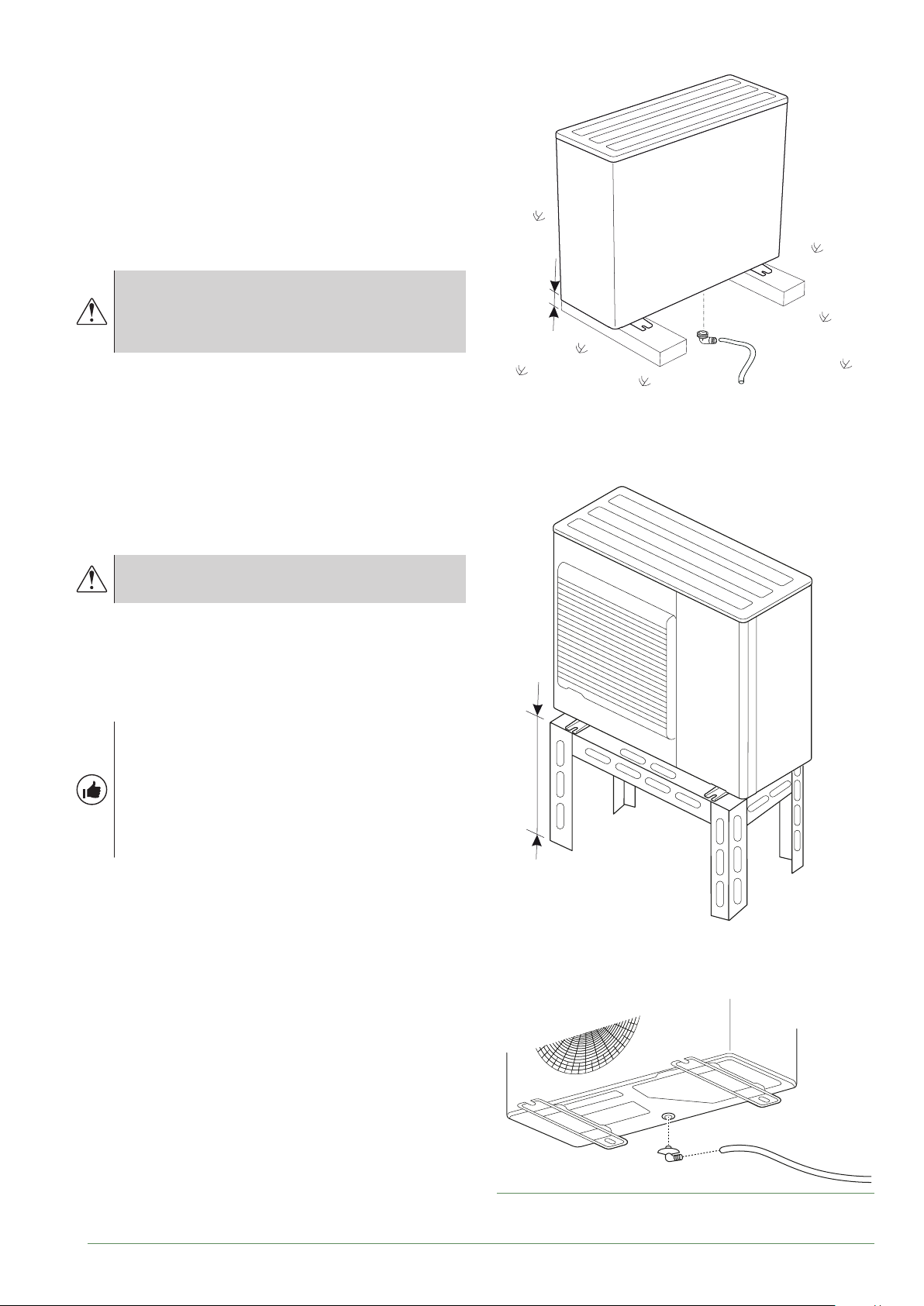

Positioning the outdoor unit

▼

The outdoor unit must be raised by at least 50 mm

from the ground. In snowy regions, this height must be

increased but must not exceed 1.5 m.

Fasten the outdoor unit using screws and elastic

tightening or toothed lock washers to prevent them from

coming loose.

In regions with heavy snowfall, if the outdoor

unit's entrance and exit are blocked by snow

it may be dicult to heat up and may probably

cause a breakdown.

Build a canopy or position the unit on a high stand (local

conguration).

- Put the appliance on a solid support to minimise

impact and vibration.

- Do not set the unit directly on the ground as this may

generate disruptions.

Connecting the condensate evacuation

▼

pipe

The outdoor unit may generate a large volume

of water (called consensates).

If the use of a drain hose is imperative:

- Use the elbow provided (C) and connect a hose of

16 mm diameter to discharge the condensates.

- Provide for the gravitational discharge of the

condensates (waste water, rainwater, gravel bed).

H

C

* In regions subject to frequent snow,

(H) must be greater than the average snow layer.

If the appliance is installed in a region where

the temperature may fall below 0 °C for long

periods, t the drain hose with a trace heater

to prevent it from icing over. The trace heater

must not only heat the drain hose but also the

bottom of the appliance's condensate drain

pan.

H

C

Aurea M / Installation / 1883 - EN

g. 14 - Positioning the outdoor unit,

Discharging condensates

- 15 -

Page 16

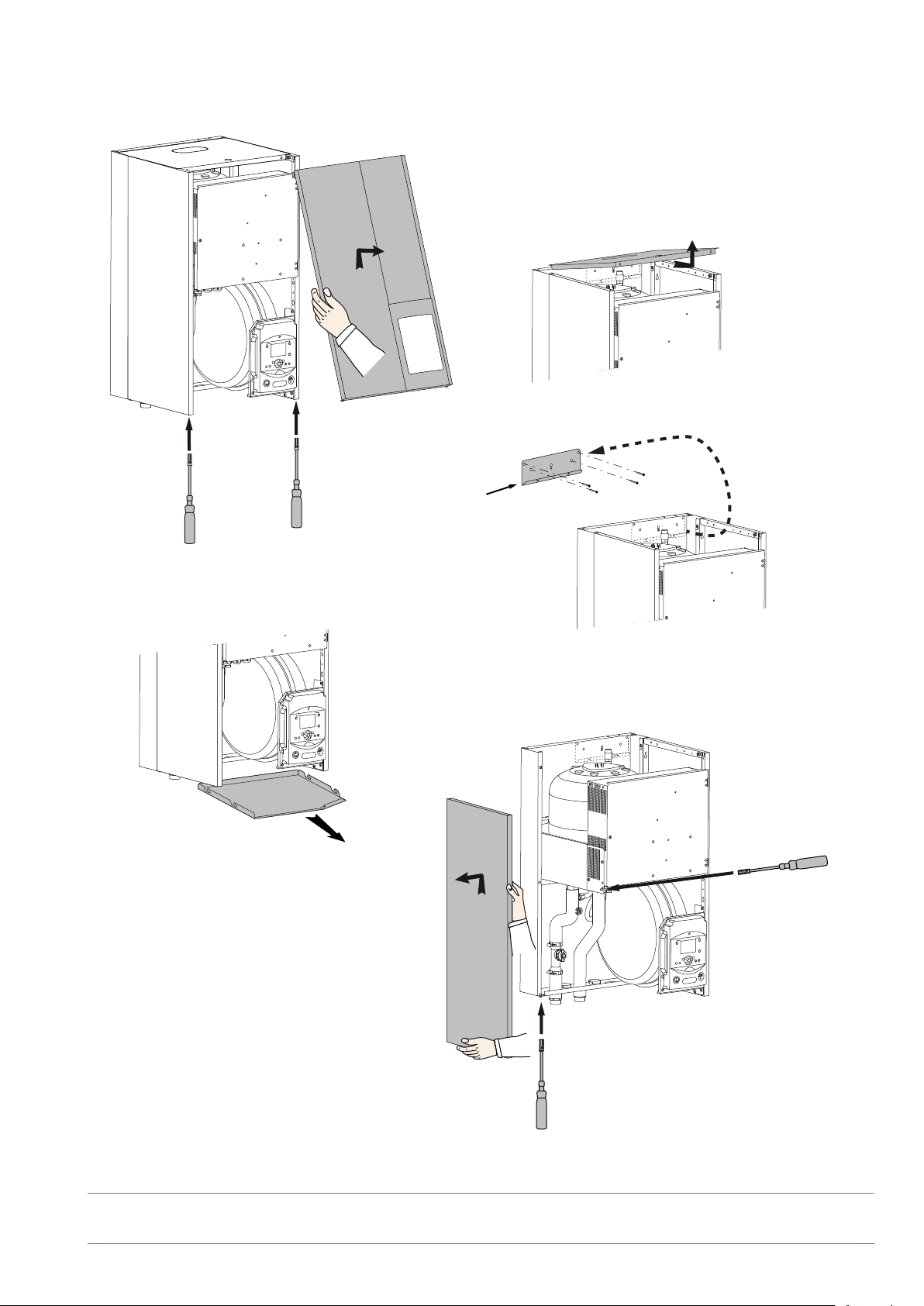

the hydraulic unit

►

Installation precautions

▼

The choice of the position for installation is

particularly important insofar as any later

movement is a delicate operation requiring the

intervention of a qualied person.

350 mm

mini

300 mm

mini

1000 mm

Positioning the hydraulic unit

▼

- Secure the support (4 screws and plugs) to a at,

sturdy wall (not a light-weight partition) ensuring that

it is correctly levelled.

- Hook the appliance onto its support.

350 mm

mini

538 mm

mini

300 mm

mini

118 mm

188 mm

418 mm

mini

• Choose the site of the heat pump and the hydraulic

unit after discussion with the customer.

• The room where the appliance operates must comply

with the regulations in force.

• To ease maintenance operations and provide access

to the various parts, sucient space should be left

around the hydraulic unit.

• Be careful to keep the heat pump away from

inammable gas during installation, in particular when

it requires brazing. The appliances are not reproof

and should therefore not be installed in a potentially

explosive atmosphere.

(S)

g. 15 - Mounting bracket

- 16 -

Aurea M / Installation / 1883 - EN

Page 17

A

3

(S)

4

5

1

2

A

1

g. 16 - Remove the panel

Aurea M / Installation / 1883 - EN

7

6

B

B

6

- 17 -

Page 18

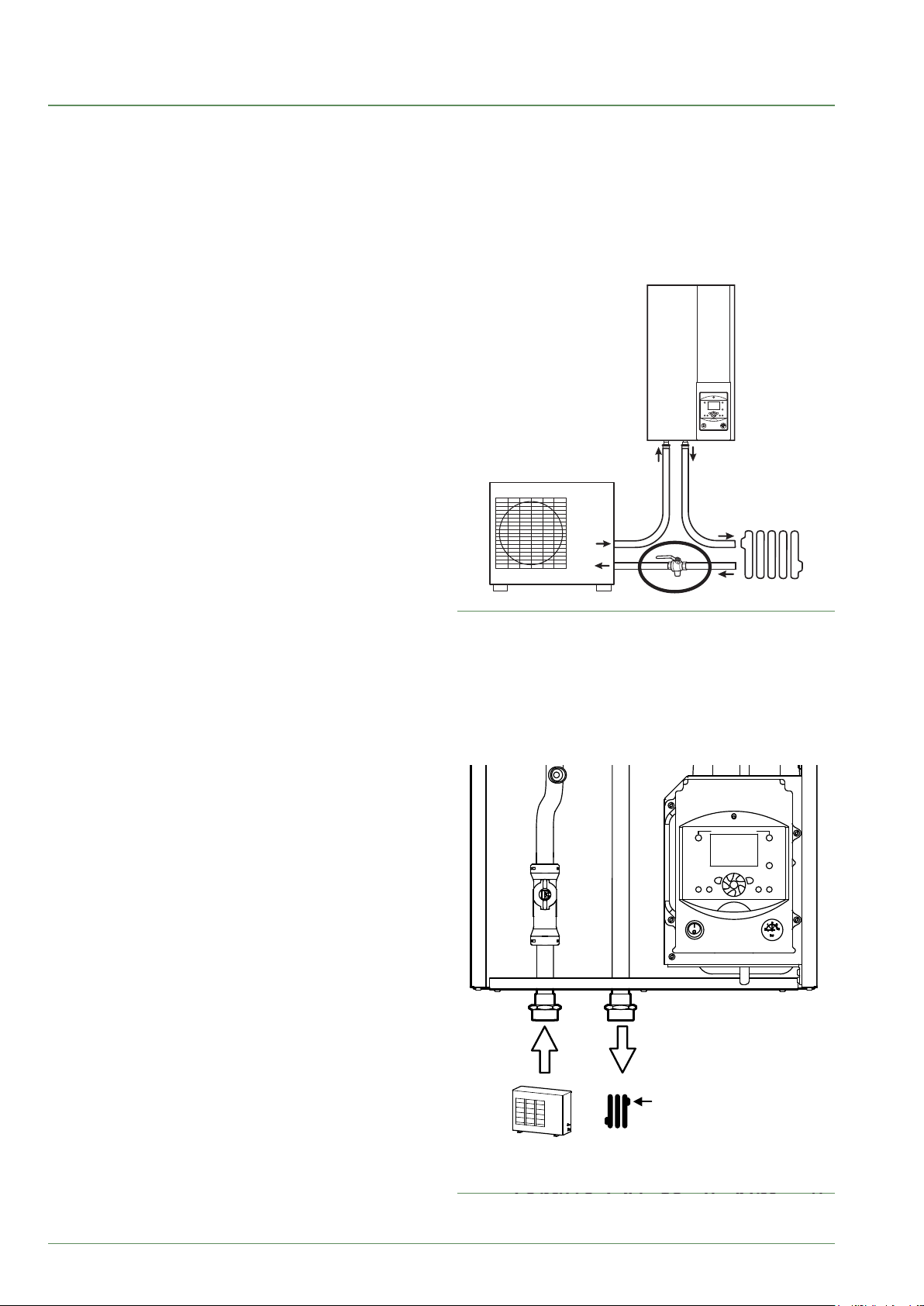

Hydraulic connection

Rinsing the installation

►

Before connecting the hydraulic unit to the installation,

rinse the heating system correctly to eliminate the

particles that could compromise the correct operation

of the appliance.

Do not use solvents or aromatic hydrocarbons (petrol,

paran, etc.).

For older installations, t a decanting pot of adequate

capacity on the boiler return circuit and at the lowest

point equipped with a drain, in order to collect and

evacuate the impurities.

Add an alkaline product to the water and a dispersant.

Rinse the installation several times before nal lling.

Hydraulic connection of the

►

outdoor unit

Connect the pipe of the outdoor unit to the hydraulic unit

respecting the direction of ow.

Install the valve lter on the heating return circuit in the

manner suggested.

Use union connectors to facilitate removal.

Hydraulically connecting the

►

heating circuit

Connect the pipe of the central heating to the hydraulic

unit respecting the direction of ow.

The diameter of the pipe between the hydraulic unit and

the heating manifold must be at least equal to 1 inch

(26x34 mm).

Use union connectors to facilitate removal.

Prioritise connector hoses to avoid transmitting noise

and vibrations to the building.

Calculate the diameter of the pipes according to the

ow rates and the lengths of the hydraulic systems.

Tightening torque: 15 to 35 Nm.

Connect the drains from the drain valve and the safety

valve to the main sewer system.

Check that the expansion system is operating correctly.

Control the vessel pressure (precharge 1 bar) and the

safety valve setting.

The installation ow rate must be at least equal to

the min. value noted in the table “Specications”,

page 7. Installing a regulation mechanism (other

than those present in our congurations) which reduces

or stops the ow through the hydraulic unit is prohibited.

g. 17 - Installing the lter valve

- 18 -

Tightening torque: 15 to 35 Nm

Couple : 15 à 35 Nm

g. 18 - Hydraulic connections

Aurea M / Installation / 1883 - EN

Page 19

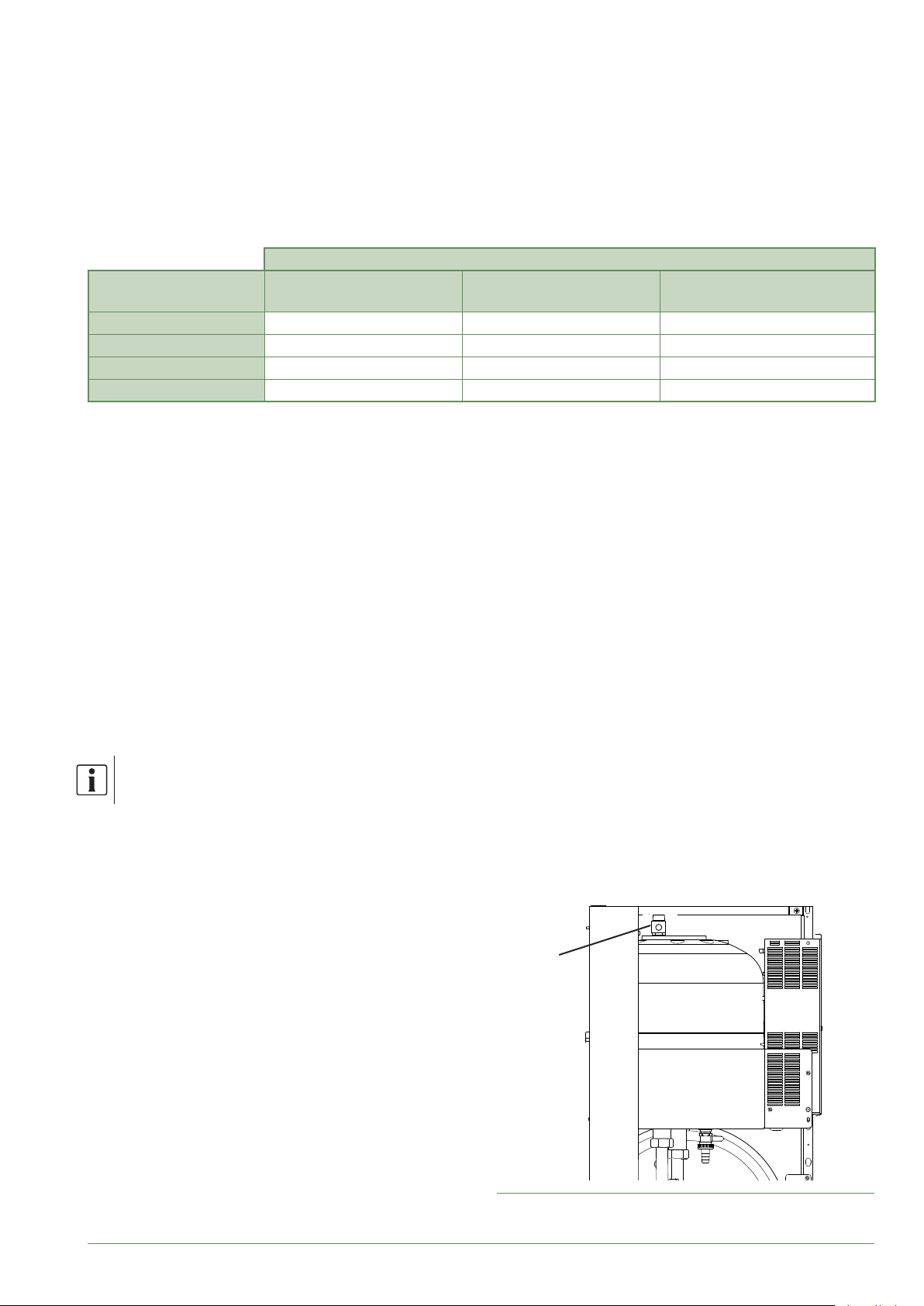

Heating installation volume

►

The installation's min. water volume must be respected.

Install a buer tank on the heating circuit return if the

volume is lower than this value. In the case of an

installation equipped with thermostat valves, you must

ensure that this min. water volume can circulate.

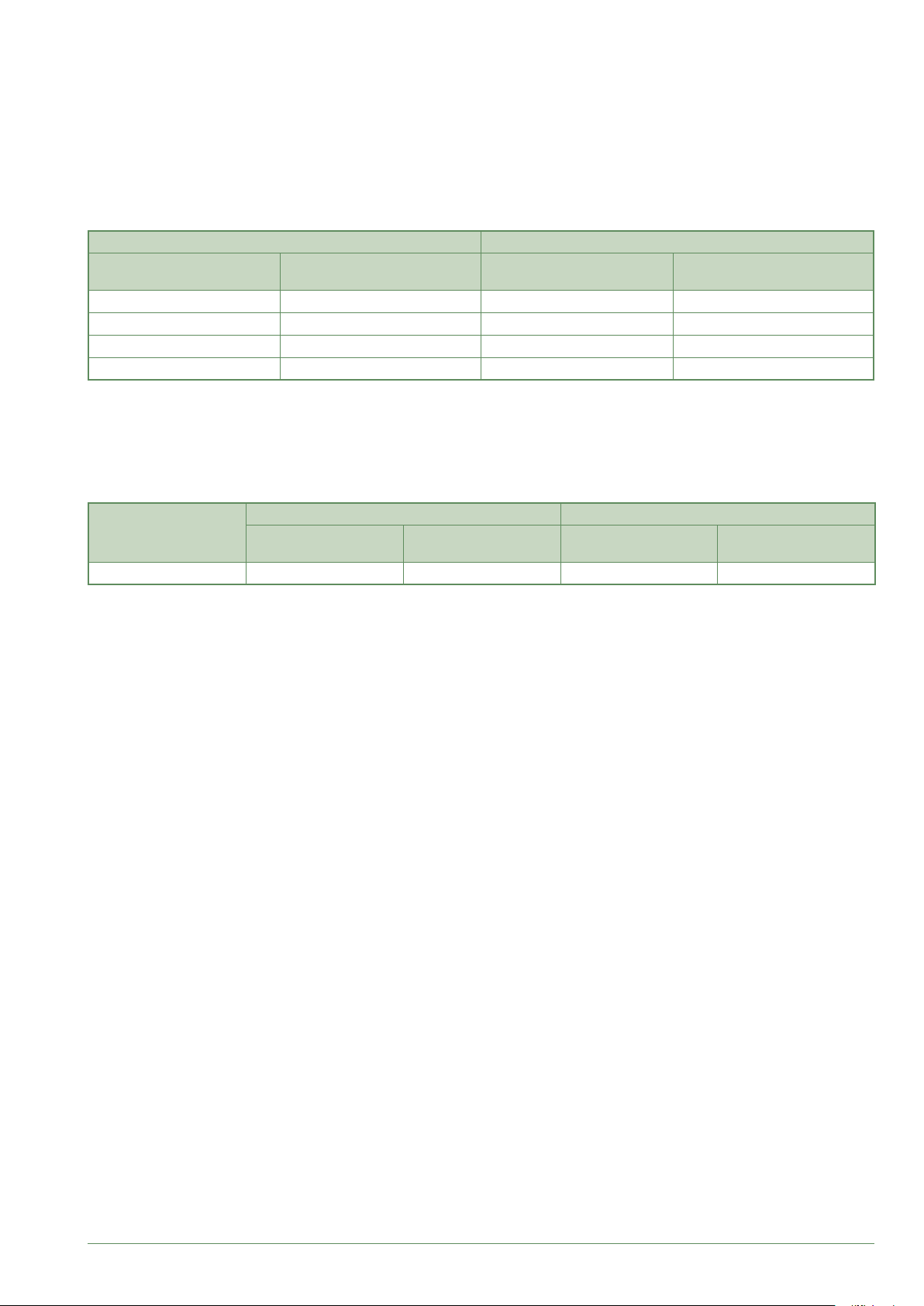

Theoretical volume in litres PER CIRCUIT (excl. HP)

Equipment

Aurea M 5 23 12 2

Aurea M 8 23 12 2

Aurea M 10 36 33 15

Aurea M 16 49 44 22

Filling and draining the installation

►

- Check the attachment of the pipes, that the connectors

are tight and that the hydraulic unit is stable.

- Check the water ow direction and that all of the valves

are open.

- Fill the installation.

Do not operate the circulating pump while lling. Open all

the drain valves in the installation and the bleeder valve

(P) for the hydraulic unit to remove the air contained in

the conduits.

- Close the drains and add water until the pressure of

the hydraulic circuit reaches 1 bar.

- Check that the hydraulic circuit is drained correctly.

- Check that there are no leaks.

After the “ Start-up”, page 28 stage, once the

machine has started, purge the hydraulic unit again.

Obligation

Fan convector

Recommendation

Radiators

Recommendation

Floor heating-cooling system

Precise lling pressure is determined by the

manometric head of the installation.

P

g. 19 - hydraulic unit manual bleeder valve

Aurea M / Installation / 1883 - EN

- 19 -

Page 20

Electrical connection

Ensure that the general electrical power supply has been cut o

before starting any repair work.

The electrical installation must be conducted in accordance with

the prevailing regulations.

The electrical diagram of the hydraulic unit is detailed in g. 34, page 62.

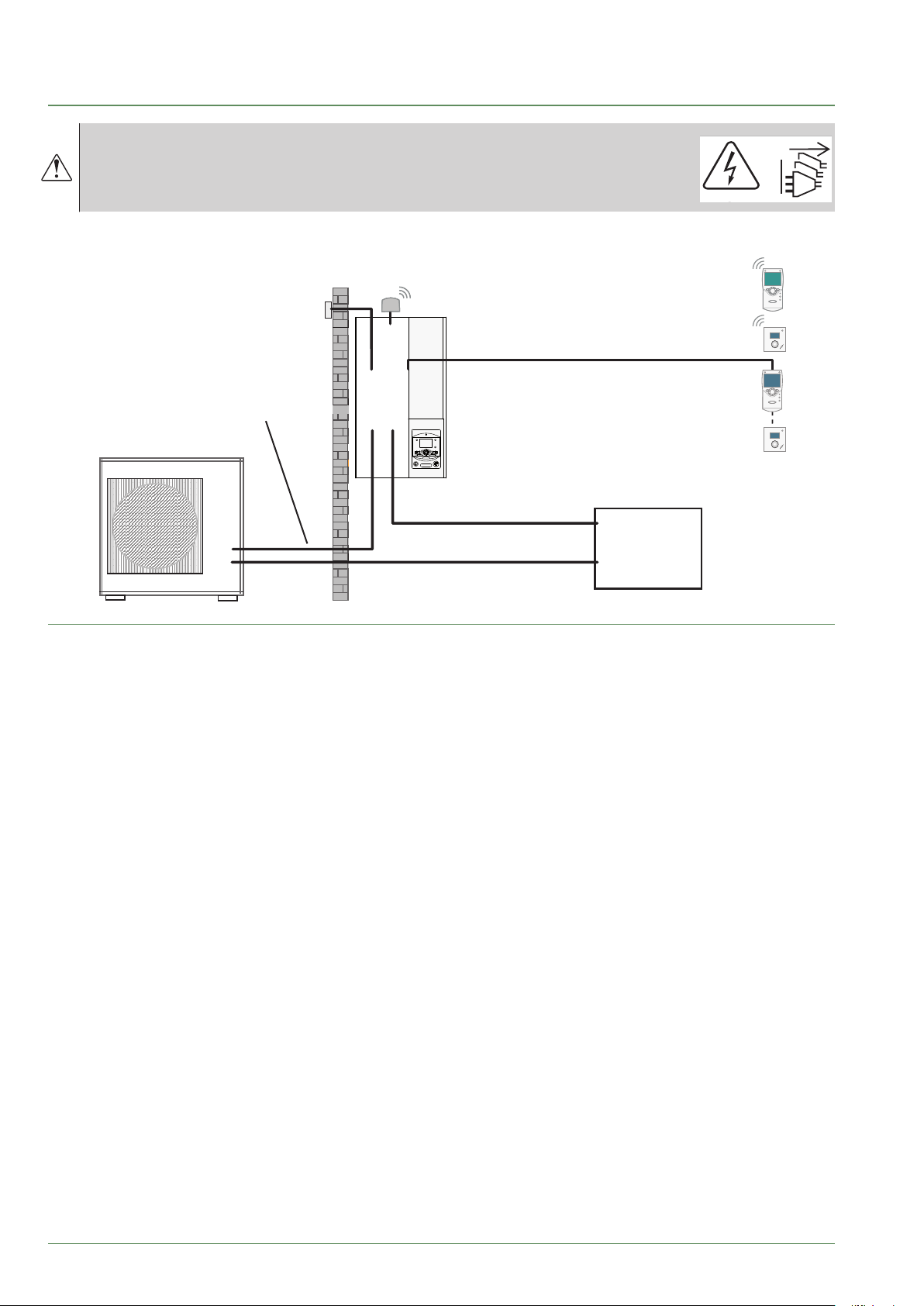

Outdoor sensor

cable 2 x 0.75 mm²

the heat pump and the hydraulic unit

Phase, Neutral, Earth, Communication bus

Interconnection between

4 x 1.5mm² cable

OK

ESC

2

3

1

4

0

bar

Electrical back-up power supply

(see table below)

General electrical power supply

(see table below)

Radio central ambient unit (option)

Radio room thermostat UA55

(optional)

Central ambient unit (option)

cable 3 x 0.5 mm²

Room thermostat (optional)

cable 2 x 0.5 mm²

Electrical

panel

or

or

or

g. 20 - Overall layout of the electrical connections for a single installation

- 20 -

Aurea M / Installation / 1883 - EN

Page 21

Cable section and protection rating

►

The cross sections of the cables are provided for information only and do not dispense the electrician from checking

that these cross sections correspond to the requirements and satisfy the standards in force.

■ Power supply to outdoor unit

Heat pump (HP) 230 V - 50 Hz electric power supply

Model Max. power absorbed

Aurea M 5 2500 W 3 x 1.5 mm² 16 A

Aurea M 8 3500 W 3 x 2.5 mm² 20 A

Aurea M 10 4025 W 3 x 2.5 mm² 20 A

Aurea M 16 5820 W 3 x 4 mm² 32 A

Connector cable

(phase, neutral, earth)

Curve C

circuit breaker size

■ Interconnection between the heat pump and the hydraulic unit

The hydraulic unit is powered by the heat pump, via a cable 4 x 1.5 mm² (phase, neutral, earth, communication bus).

■ Power supply for electrical back-up (optional)

The hydraulic unit contains two stages of electrical back-ups installed in a heat exchange tank.

Electrical back-ups Power supply to the electrical back-ups

Model

Aurea M 2x3 kW 26.1 A 3 x 6 mm² 32 A

Power Nominal current

(phase, neutral, earth)

Cable

Curve C

circuit breaker size

Aurea M / Installation / 1883 - EN

- 21 -

Page 22

Electrical connections on the outdoor unit side

►

Access to the connection terminals

▼

■ Outdoor unit Aurea 5

- Remove the cover.

Cable clamp

Unscrew the

cover

(1 screw)

Cables

■ Outdoor unit Aurea 8 & Aurea 10

& Outdoor unit Aurea 16

- Remove the cover.

Cable clamp

Unscrew the

cover

(3 screw)

Cables

Cable clampCable clamp

- 22 -

Unscrew the

cover

(3 screw)

Cables

Use cable clamps to prevent the conductors

from being disconnected accidentally.

Obstruct the space at the cable inlet in the

outdoor unit with the insulating plate.

Aurea M / Installation / 1883 - EN

Page 23

Heating cable (optional)

▼

- Locate the heating part (see g. 21).

- Place the thermostat at the bottom of the tank.

- Run the bottom of the tank with the heating part of the

cable (make sure that the drain hole is covered by the

heating part).

- Fix the heating part on the bottom of the tank with the

aluminum tape supplied.

- Route the cable to the terminal block away from the

propeller blades (use the attachment points with clamps).

Thermostat

Thermostat

Repère

mark

Avoid metal edges that could damage the

insulation.

- Connect the heating cable to the terminal block

(terminals L and N).

Heating part

Partie chauffante

1 m

1 m

Cold part

Partie froide

Supply

Alimentation

1.5 m

1.5 m

Aurea M / Installation / 1883 - EN

L N

L N

POWER

Main electricity

supply

Heating cable

g. 21 - Heating cable mounting

1

Interconnection

between outdoor unit

and hydraulic unit

2 3

- 23 -

Page 24

Electrical connections on the hydraulic unit side

L

N

►

Access to the connection terminals

▼

- Remove the front panel (2 screws) (g. 16, page 17).

- Open the power control box.

- Make the connections according to the diagram

g. 22, page 24.

Do not t the sensor wires and the power supply wires

in parallel in order to avoid interferences due to the

voltage surges in the power supply.

Ensure that all of the electrical cables are housed in the

spaces provided.

Interconnection between the heat pump

▼

and the hydraulic unit

Comply with the correspondence between the markings

on the hydraulic unit's terminals and those on the heat

pump when connecting the interconnection cables.

An incorrect connection can cause the destruction of

one of the units.

1 2 3

5

4

to outdoor element

contact *

6

green/yellow

brown

blue

red

Outdoor unitHydraulic unit

L N

POWER

Single phase 230 V

electric power supply

1

Interconnection between

the heat pump

and the hydraulic unit

2 3

g. 22 - Connection to the terminal blocks

- 24 -

Aurea M / Installation / 1883 - EN

Page 25

Electrical backup (optional)

▼

- Connect the electrical supplies of electrical back-up to

the electrical panel ( see g. 22, page 24).

- Select the electrical back-up power

Electrical back-up power

Shunt A + shunt B

Adjust :

- 5891 = Electric

immersion heater 1

ow K25

shunt B

shunt A

Second heating circuit (optional)

▼

- 5892 = Electric

immersion heater 2

ow K26

Shunt A only

Adjust :

- 5891 = Electric

immersion heater 1

ow K25

- 5892 = None

= 6 Kw

= 3 Kw

- Please refer to the instructions supplied with the

second circuit kit.

- Set the parameter 5715 - Heating circuit 2 to On.

Domestic hot water tank (optional)

▼

If the installation is equipped with a DHW tank (with

electrical back-up):

- Please refer to the instructions supplied with the DHW kit.

- Please refer to the instructions supplied with the DHW tank.

Contract with the power supplier.

▼

It is possible to control the HP's operation with

specic peak/o-peak and day / night contracts.

In particular, domestic hot water (DHW) at Nominal

temperature will be produced during the o-peak hours

when electricity is cheaper.

- Connect the "Power Provider" contact to input EX2.

- Set the parameter 1620 to "O peak tari".

- 230V on input EX2 = "Peak hours" information

activated.

Load shedding or peak shaving

▼

The purpose of load shedding is to reduce the electrical

consumption when it is too high compared to the

contract with the energy supplier.

- Connect the power limiting device to input EX1,

the back-ups for the heat pump and the DHW stop in

the event of over-consumption by the dwelling.

- 230 V on input EX1 = power limitation in progress

Faults outside the heat pump

▼

All information devices (thermostat, pressure switch,

etc.) may indicate an external problem and stop the

heat pump.

- Connect the external device to input EX3.

- 230 V on input EX3 = heat pump shutdown (the system

displays error 369).

For under-oor heating, insert the under-oor heating

thermal safety into the under-oor heating circulator

link.

Aurea M / Installation / 1883 - EN

- 25 -

Page 26

Outdoor sensor

▼

The Outdoor sensor is required for the correct operation

of the heat pump.

Consult the assembly instructions on the packaging of

the sensor.

Place the sensor on the coldest part, generally the

northern or north-eastern side.

In any case, it must not be exposed to the morning sun.

It must be installed so that it is easily accessible but at

least 2.5 m from the ground.

Avoid sources of heat such as chimneys, the tops of

doors or windows, nearby extraction ducts, underneath

balconies and porches, that would insulate the sensor

from the variations in the temperature of the air outdoors.

Connect the outdoor sensor to the X84 connector

(M and B9 terminals on the hydraulic unit regulation board).

Ambient sensor and/or central ambient

▼

unit (option)

The ambient sensor (the central ambient unit) is

optional.

Consult the assembly instructions on the packaging of

the sensor.

The sensor must be installed in the living room area on

a very uncluttered wall. It must be installed so as to be

easily accessible.

Avoid sources of direct heat (chimney, television, cooker,

sunlight) and areas exposed to draughts (ventilation,

doors).

Draughts due to the building usually cause cold air

to enter via the electrical ducts. Seal the electrical

ducts if there is a cold draught at the back of the room

thermostat.

Installing an ambient sensor

• Ambient sensor T55

Connect the sensor to the X86 connector of the

RVS regulation board using the connector provided

(terminals 1, 2).

• Radio room thermostat T58

Connect the wireless room thermostat to the connector X60.

Installing a central ambient unit

• T75 central ambient unit

Connect the sensor to the X86 connector of the

RVS regulation board using the connector provided

(terminals 1, 2 and 3).

• T78 radio room control unit

Connect the radio central ambient unit to the connector X60.

Fan convector zone

If the installation is equipped with fan-coils / dynamic

radiators, do not use a room thermostat.

- 26 -

Aurea M / Installation / 1883 - EN

Page 27

Hydraulic unit regulator

Cable grommet

Electricity supply terminal strip

g. 23 - Hydraulic module's electrical cabinet

Shedding or EJP

Délestage ou EJP

(Peak Day Clear)

(Effacement Jour de Pointe)

Tarifds, day/night, peak/o-peak

Tarifs, jour/nuit, HP/HC

External fault

Défaut externe

Contact d'organe

External component

externe*

contact *

(défauts, délesteur,

(faults, shedder energy meter)

compteur d'énergie)

EX1

EX2

EX3

X11

X86

1 5

Interface board

X84

M B9

L

7

6

ou

** Sonde

** T55

d'ambiance

room

T55

thermostat

* If the command does not supply a potential free contact, the contact must be relayed to obtain equivalent wiring.

In all cases, refer to the instructions for the external parts (load shedder, energy meters…) for the wiring.

** Option

Terminal 3 of the central ambient unit does not need to be connected (central ambient unit lighting).

765

12 1 3 2

ou

** Centrale

** T75

ambiance

room

T75

control unit

765

13 2

** Centrale

** T78

ambiance

radio room

radio T78

control unit

Oudoor

Sonde

Sensor

extérieure

ou

**Sonde

** T58

d'ambiance

radio room

radio T58

thermostat

g. 24 - Connections to the Hydraulic module regulator (accessories and options)

Aurea M / Installation / 1883 - EN

- 27 -

Page 28

Start-up

- Engage the main isolator switch of the installation.

When rst put into service (or in winter), to preheat

the compressor, engage the main isolator switch

of the installation (heat pump power supply) for

several hours before the tests.

- Switch on the Start/Stop button of the heat pump.

To guarantee the correct operation of inputs EX1,

EX2, EX3: Check that the phase-neutral polarity

of the electrical power supply is respected.

When the power is switched on and every time that the

ON/OFF button is switched o and then switched on

again, the heat pump will take approximately 4 minutes

to start up, even if the setting is requesting heating.

The display can show error 370 when

the appliance (re)starts. Do not worry,

the communication will be reestablished between

the heat pump and the hydraulic module after a

few minutes.

During the initialisation phase of the regulator, all of

the symbols are displayed, then the "Data, update",

then"Heat pump status" is displayed.

- Make all of the specic settings for the regulation

(conguration of the installation in particular):

- Press OK.

Conguration of the ambient

►

sensor

To congure the ambient sensor and associate it to the

adequate heating zone:

Hold down the presence button for over 3s.

The ambient sensor displays RU and a gure ashes.

- Press the presence button, the ambient

sensor displays P1 and a gure ashes.

1: Automatic storing; a correction of the value with

the knob is adopted without any specic validation

(timeout) or by pressing the operation button.

2: Save with conrmation; a correction of the value with

the knob is only adopted after pressing the operation

button.

- Press the presence button again, the ambient sensor

displays P2 and a gure ashes.

0: OFF; all of the operating elements are available.

1: ON; the following operating elements are locked:

- Switching the operation mode of the heating

circuit.

- Adjusting the comfort value.

- Changing the operating level.

The ambient sensor displays OFF for 3s when a locked

button is pressed.

- Hold the button for 3s and select the access level

"Putting into service" using the knob .

- Conrm with the OK button.

- Parameter the heat pump's setting (consult the “List of

function lines”, page 35).

On commissioning (or the case of error 10), the electrical

back-up heaters are liable to start up even if the outdoor

temperature at the time is above the back-up trigger

temperature.

The regulating system uses an average initial outdoor

temperature of 0 °C and requires some time to update

this temperature.

To counter this situation, with the outdoor sensor correctly

connected, reset the parameter 8703 (commissioning

level, consumer diagnosis menu).

Conguration of the room control

►

unit

When putting into service, after a reset of around

3 minutes, the user language needs to be set:

- Press OK.

- Select the "User interface" menu.

- Select the language.

Select the language (English, Deutsch, Français,

Italiano, Nederlands, Español,

- 28 -

Aurea M / Installation / 1883 - EN

Page 29

Heating circulation pump speed settings

AEYC-0639U

AEYC-1039U

AEYC-1639U

Fermeture

►

Main water pump in the heat pump has 3 levels of speed. Factory default value is Level 3.

Select dip switch of DIP SW. on PCB(Terminal) to change the setting.

■ Outdoor unit Aurea 5, 8 & 10 ■ Outdoor unit Aurea 16

PCB (Display)

PCB(Display)

SW5 position

ON

1 2

OFF

1 2

ON

OFF

1 2

ON

OFF

■ Outdoor unit Aurea 5

(m)

12

11

10

9

8

7

6

5

4

3

2

1

0 5 10 15

Level 3

Vitesse 3

Level 2

Vitesse 2

Vitesse 1

Level 1

Level 3

Level 3

(Maximum)

Level 2

Level 2

(Medium)

Level 1

Level 1

(Minimum)

20(L/min)

PCB(Display)

Level 3 Level 2 Level 1

Level 3

(Maximum)

■ Outdoor unit Aurea 16

(m)

14

12

10

8

6

4

2

0

10 20 30 40

MODE SW

ON

1 2 3 4

OFF

Turn ON the dip switch 3

1 - Turn ON the SW3

2 - Press SW-Pump

PUMP SW

Level 2

(Medium)

3 - Turn OFF the SW3

Vitesse 2

Level 2

Level 1

Vitesse 1

1 2 3 4

ON

OFF

Level 1

(Minimum)

Level 3

Vitesse 3

50(L/min)

The quantity should not be less than 5L/min.

■ Outdoor unit Aurea 8 & Aurea 10

(m)

8

7

6

5

4

3

2

1

0 105 20

Vitesse 1

Level 1

15 25 30 35

Vitesse 2

Level 2

Level 3

Vitesse 3

The quantity should not be less than 10L/min.

Aurea M / Installation / 1883 - EN

40(L/min)

The quantity should not be less than 15L/min.

Minimum ow settings of the

►

installation

Adjust parameter 2899 (page 43) according

to the heat pump installed.

Cleaning the lter valve

►

Immediately after commissioning, clean the lter of the

lter valve (remove waste generated by the installation:

seals, oakum, lings, etc.).

- Close the valve.

- Unscrew the cap.

- Remove the clip

using pliers.

- Clean the lter.

Closure

- 29 -

Plug

Bouchon

Clips

Clips

Filtre

Filter

Page 30

Regulation interface

The user interface, the central ambient unit (option)

►

and the ambient sensor (option)

1

2

3

4

g. 27 - User interface

5

6

7

8

9

1

Auto

2

3

0 4 8 12 16 20 24

ESC

4

g. 25 - Central ambient unit T75/T78

5

Auto

5

7

OK

11

2

°C

10

11

8

6

g. 26 - Radio room thermostat T55/T58

- 30 -

Aurea M / Installation / 1883 - EN

Page 31

Ref. Functions - Denition of the functions

Arrêt

Auto

1 Selecting the DHW operation

On

Marche

- Start: Production of DHW in function of the timer programme.

- Stop: Production of the DHW stopped with antifreeze function of the

domestic water active.

- Manual start button: Press the DHW button for 3 s (switches from

O

"reduced" to "comfort" until the DHW timer programme is switched again).

2 Digital display - Check the operation, read the current temperature of the heating

operation, or a possible fault.

- View the settings.

3 "ESC" output - Exit the menu.

4 Navigation and setting - Setting the comfort temperature value.

- Menu selection

- Setting the parameters.

5 Selecting the heating operation

-

Service heating according to the heating programme

(automatic summer/winter switching).

- Permanent comfort temperature.

- Permanent reduced temperature.

- "Stand-by" operation with antifreeze protection (provided that the

electrical power supply of the heat pump is not interrupted).

6 Displaying information - Miscellaneous information (see “Information display”, page 54).

- Reading the error codes (see “ Fault diagnostic”, page 50).

- Information on maintenance, special operation.

7 Validation "OK" - Enter the selected menu.

- Validate the parameter settings.

- Validate the comfort temperature value setting.

8 Selection of the refresh mode

- Service cooling according to the heating programme

(automatic summer/winter switching).

9 Reset

(Press and relief)

- Reset the parameters and cancel the error messages.

Do not use during normal operation

10 Setting button - Setting the comfort temperature value.

11 Presence button - Comfort / reduced switching.

Aurea M / Installation / 1883 - EN

- 31 -

Page 32

Description of the display

►

Xxxxxxxxxxxxxxxxxxxxxxxxxxx

Xxxxxxxxxxxxxxxxxxxxxxxxxxx

Xxxxxxxxxxxxxxxxxxxxxxxxxxx

Icons Denitions

- Heating mode active with reference

to the heating circuit.

- Heating in comfort mode.

- Heating in reduced mode.

- Heating in "standby" mode

(antifreeze).

- Refresh mode active.

Weather-dependent control

►

The operation of the heat pump is controlled by the

weather-dependent setpoint.

The set temperature for the water in the heating circuit

is adjusted according to the outdoor temperature.

If there are thermostatic valves tted to the installation,

they must be opened fully or set higher than the normal

value of the ambient temperature.

Setting

▼

During installation, the weather-dependent setpoint

must be congured according to the heat emitters and

the residence's insulation.

The weather-dependent setpoint curves (g. 29, page 33)

refer to an ambient setpoint of 20 °C.

The water logic slope (parameter 720) determines

the impact of variations in outdoor temperature on the

variations in heating start temperature.

The steeper the slope, the more a slight reduction in

the outdoor temperature causes a signicant increase

in the initial water temperature in the heating circuit.

The shift in water logic (parameter 721) modies the

start temperature of all the curves, without modifying

the slope (g. 30, page 33) .

The corrective actions if discomfort is experienced are

listed in the table (g. 31, page 33).

INFO

PROG

ECO

temperature ambiante

- Holiday function activated.

- Process in progress.

- Compressor operation.

- Burner operation.

- Default message.

- Maintenance, special operation

- Information level activated.

- Programming activated.

- ECO function activated (Heating

stopped temporarily)

- Time /

Parameter number /

Setpoint value.

- 32 -

temperature ambiante

temperature ambiante

- Ambient temperature /

Setpoint value.

- Setpoint information /

Parameter information.

g. 28 - Closing the display

Aurea M / Installation / 1883 - EN

Page 33

° C

empérature départ chau

Application PAC seule

Heat pump application only

100

90

ffage °C

80

70

60

50

Heating start temperature °C

40

30

T

20

10

Température extérieure °C

Outdoor temperature °C

g. 29 - Slope of the heating curve (line 720)

70

60

Heating start

30

+4,5

50

temperature °C

40

30

20

-4,5

Displacement

Pente de la

2.753

2.5

2.25

2

1.75

1.5

1.25

1

0.75

0.5

0.25

-100

-20

Heating curve

courbe de chauffe

slope

Radiateur classique

Traditional radiator

Radiateur BT

Low temperature radiator

(basse température)

Dynamic radiator

Radiateur dynamique

Underoor heating

Plancher chauffant

° C

Weather-dependent

setpoint slope

0.5

10

10

0

-55

Outdoor temperature °C

0

-20-15-10

g. 30 - Slope of the heating curve (line 721)

Feelings...

... in warm weather ... in cold weather

OK

Cold

Cold

Cold Cold

OK

OK

Hot

Hot

Hot

&

&

&

&

&

&

&

&

&

OK

Hot

OK

Hot

Cold

Hot

OK

Cold

Corrective actions

on the weather-dependent setpoint:

Slope (line 720) Shift (line 721)

No correction

No correction

No correction

No correction

No correction

No correction

g. 31 - Corrective actions in case of discomfort

Aurea M / Installation / 1883 - EN

- 33 -

Page 34

OK

Regulation menu

General

▼

Only the parameters accessible at the levels:

U - end user.

I - Commissioning

S - Specialist.

are described in this document.

The access levels are specied in the second column of

the table by means of the letters U, I and S.

The OEM parameters are not described and require a

manufacturer access code.

Setting parameters

▼

- Selecting the desired level.

- Scroll the list of menus.

- Selecting the desired menu.

- Scroll the function lines.

- Selecting the desired line.

- Adjusting the parameter.

- Validate the setting by pressing OK.

- To return to the menu, press ESC.

If no setting is made for 8 minutes, the screen

automatically returns to the basic display.

OK

Press and release

Press for 3

seconds

End user

OK OK

Time of day and date Hours / minutes 1 Time 1...24 h

User interface Day/Month 2 Minutes 0...60 min

Heating circuit 1 timer

programme

...

End user Start-up Specialist OEM

Time of day and date

User interface

Heating circuit 1 timer

programme

...

Year 3

Hours / minutes 1

Day/Month 2

Year 3

End date of summer time 4 01.01...31.12

End date of summer time 5

- 34 -

Recommended settings for the parameters depending on the installation's emitters

▼

Heating curve

slope

Curve

displacement

Min.

outgoing value

Max.

initial setpoint

DHW charging

time limitation

VLT Radiators /

Heating-cooling oor

720 (CC1)

1020 (CC2)

721 (CC1)

1021 (CC2)

740 (CC1)

1040 (CC2)

741 (CC1)

1041 (CC2)

5030 Factory (90 min) Factory (90 min) 40 min

0.25 to 0.5 0.5 to 1.25 0.4 to 1.1 1.25 to 3

0 0 4 * 0

Factory (17 °C) Factory (17 °C) 30 or 35 °C

50 °C Factory (55 °C) 65 °C 65 °C

Low temperature

radiators

Dynamic radiators or

fan-coil heaters

Aurea M / Installation / 1883 - EN

Classic

temperature

radiators

Factory

(17 °C)

Factory

(90 min)

Page 35

List of function lines

►

Line Function Setting range or display

Setting

increment

Basic

setting

Time of day and date

1 U Hours / minutes 00:00... 23:59 1 --:--

2 U Day/Month 01:01... 31.12 1 --.--

3 U Year 1900... 2099 1 ----

5 S Start summer time (Day / Month) 01:01... 31.12 1 25.03

6 S End summer time (Day / Month) 01:01... 31.12 1 25.10

The time change appears at 03h00 on the rst Sunday after the date set.

User interface

20 U Language English, Français, Italiano, Nederlands... English

22 S Info Temporary, Permanent Temporary

26 S Operation locking Stop, Start Stop

27 S Programming locking Stop, Start Stop

44 I Operation heating circuit 1

(heating circuit 2 command)

Common with heating circuit 1,

Independent

Common with

heating circuit 1

This function permits the choice to be made if the ambient sensor (in option) has an action on the two zones or on a single zone.

46 I Operation HCP

(domestic hot water pump command, output QX2)

Common with heating circuit 1,

Independent

Common with

heating circuit 1

If "Independent" see timer program 3 / HCP

70 S Version of display unit software

Time program heating, Circuit 1

500 U Pre-selection (day / week) Mon-Sun, Mon-Fri, Sat-Sun, Monday, ... ,

Mon-Sun

Saturday, Sunday

501 U 1

st

In service phase (start) 00:00... --:-- 10 min 06:00

502 U 1st Out of service phase (end) 00:00... --:-- 10 min 22:00

503 U 2

nd

In service phase (start) 00:00... --:-- 10 min --:--

504 U 2nd Out of service phase (end) 00:00... --:-- 10 min --:--

505 U 3

nd

In service phase (start) 00:00... --:-- 10 min --:--

506 U 3rd Out of service phase (end) 00:00... --:-- 10 min --:--

516 U Standard values No, Yes No

Yes + OK: The default values memorised in the regulator replace and cancel the customised heating programs.

Your personal settings are therefore lost.

Time program heating, Circuit 2

Only with the 2nd circuit kit option.

520 U Pre-selection (Day / Week) Mon-Sun, Mon-Fri, Sat-Sun, Monday, ... ,

Mon-Sun

Saturday, Sunday

521 U 1

st

In service phase (start) 00:00... --:-- 10 min 6:00

522 U 1st Out of service phase (end) 00:00... --:-- 10 min 22:00

523 U 2

nd

In service phase (start) 00:00... --:-- 10 min --:--

524 U 2nd Out of service phase (end) 00:00... --:-- 10 min --:--

525 U 3

nd

In service phase (start) 00:00... --:-- 10 min --:--

526 U 3rd Out of service phase (end) 00:00... --:-- 10 min --:--

536 U Standard values No, Yes No

Yes + OK: The default values memorised in the regulator replace and cancel the customised heating programs.

Your personal settings are therefore lost.

Aurea M / Installation / 1883 - EN

- 35 -

Page 36

Line Function Setting range or display

Time program cooling, Circuit 1 (Only available when parameter 5711 is set to “2-pipe system”)

Setting

increment

Basic

setting

470 U Pre-selection (day / week) Mon-Sun, Mon-Fri, Sat-Sun,

Mon-Sun

Monday, ... , Saturday, Sunday

471 U 1

st

In service phase (start) 00:00... --:-- 10 min 06:00

472 U 1st Out of service phase (end) 00:00... --:-- 10 min 22:00

473 U 2

nd

In service phase (start) 00:00... --:-- 10 min --:--

474 U 2nd Out of service phase (end) 00:00... --:-- 10 min --:--

475 U 3

nd

In service phase (start) 00:00... --:-- 10 min --:--

476 U 3rd Out of service phase (end) 00:00... --:-- 10 min --:--

479 U Standard values No, Yes No

Yes + OK: The default values memorised in the regulator replace and cancel the customised heating programs.

Your personal settings are therefore lost.

Time program cooling, Circuit 2 (Only available when parameter 5716 is set to “2-pipe system”)

Only with the 2nd circuit kit option.

480 U Pre-selection (Day / Week) Mon-Sun, Mon-Fri, Sat-Sun,

Mon-Sun

Monday, ... , Saturday, Sunday

481 U 1

st

In service phase (start) 00:00... --:-- 10 min 6:00

482 U 1st Out of service phase (end) 00:00... --:-- 10 min 22:00

483 U 2

nd

In service phase (start) 00:00... --:-- 10 min --:--

484 U 2nd Out of service phase (end) 00:00... --:-- 10 min --:--

485 U 3

nd

In service phase (start) 00:00... --:-- 10 min --:--

486 U 3rd Out of service phase (end) 00:00... --:-- 10 min --:--

489 U Standard values No, Yes No

Yes + OK: The default values memorised in the regulator replace and cancel the customised heating programs.

Your personal settings are therefore lost.

Time program 4/DHW

If the installation is equipped with the DHW kit (only appears with the DHW kit option).

560 U Pre-selection (day / week) Mon-Sun, Mon-Fri, Sat-Sun,

Mon-Sun

Monday, ... , Saturday, Sundary

561 U 1

st

In service phase (start) 00:00... --:-- 10 min 00:00

562 U 1st Out of service phase (end) 00:00... --:-- 10 min 05:00

563 U 2

nd

In service phase (start) 00:00... --:-- 10 min 14:30

564 U 2nd Out of service phase (end) 00:00... --:-- 10 min 17:00

565 U 3

nd

In service phase (start) 00:00... --:-- 10 min --:--

566 U 3rd Out of service phase (end) 00:00... --:-- 10 min --:--

576 U Standard values No, Yes No

Yes + OK: The default values memorised in the regulator replace and cancel the customised heating programs.

Your personal settings are therefore lost.

- 36 -

Aurea M / Installation / 1883 - EN

Page 37

Line Function Setting range or display

Holiday programs, Circuit 1 (the heating mode must be on "AUTO")

641 U Preselection Period 1 to 8 Period 1

642 U Date of start of holidays (day/month) 01:01... 31.12 1 --.--

643 U Date of end of holidays (Day/Month) 01:01... 31.12 1 --.--

Setting

increment

Basic

setting

648 U Heating rate during the holidays Antifreeze protection, Reduced Antifreeze

Holiday programs, Circuit 2 (the heating mode should be on “AUTO”).

If the installation consists of 2 heating circuits (Only with the 2nd circuit kit option).

651 U Preselection Period 1 to 8 Period 1

652 U Date of start of holidays (day/month) 01.01... 31.12 1

653 U Date of end of holidays (Day/Month) 01.01... 31.12 1

658 U Heating rate during the holidays Antifreeze protection, Reduced Frost protection

Heating, Circuit 1

710 U Ambient comfort temperature value Reduced temperature…

712 U Reduced ambient temperature value Antifreeze temperature...

714 U Ambient "antifreeze" temperature value 4 °C… Reduced temperature 0.5 °C 8 °C

716 S Maximum comfort value Comfort temperature... 35 °C 1 °C 28 °C

720 I Heating curve slope

(see g. 29, page 33)

721 I Translation of the heating curve

(see g. 30, page 33)

Comfort value

Comfort temperature

0.1... 4 00:02 0.5

-4.5... 4.5 °C 0.5 °C 0 °C

0.5 °C 20 °C

0.5 °C 19 °C

protection

730 I Summer/winter heating limit 8... 30 °C 0.5 °C 18 °C

When the mean of the external temperatures over the last 24 hours reaches 18 °C the regulator stops the heating (economy).

In summer operation, the display shows "Eco". This function is only active in automatic operation.

740 I Min. start value 8 °C... Max. start value 1 °C 17 °C

(with dynamic radiator, set from 30 to 35 °C)

741 I Max. start value Min. start value 70 °C 1 °C 55 °C

Under-oor heating = 50 °C / Radiators = 65 °C.

Important remark: The maximum limit is not a safety function as that required for under-oor heating.

750 S Room temperature inuence 1 %... 100 % 1 % 50 %

If the installation is equipped with an ambient sensor:

This function enables you to choose the ambient temperature's inuence on the setting.

If no value is entered, the regulation is via the water logic.

If the parameter is set to 100%, the regulation is only made using the ambient temperature.

760 S Room temp limitation 0.5... 4 °C 0.5 °C 0.5 °C

As soon as the room temperature = [Setpoint line 710 (ex.20 °C) + Room temperature limitation setpoint line 760

(ex.0.5 °C)] > 20.5 °C => The heat pump is stopped. It restarts when the room temperature falls below the setpoint

(in the example, Room temperature < 20.0 °C).

780 S Quick setback O, Up to reduced setpoint,

790 S Maximum optimisation on trigger

(Anticipated start to reach the comfort value)

Up to protection setpoint

0... 360 min 10 min 180 min

O

791 S Maximum optimisation on disconnection

(Anticipated stop to switch from the comfort value

to the reduced value)

Aurea M / Installation / 1883 - EN

0... 360 min 10 min 30 min

- 37 -

Page 38

Line Function Setting range or display

800 S Start increasing the reduced operation -30... 10 °C 1 °C --

801 S End of increase in reduced operation -30... 10 °C 1 °C -5 °C

830 S Raising of mixing valve 0... 50 °C 1 °C 0 °C

834 S Servomotor travel time 30... 873 s 1 s 240 s

850 I Control of oor drying (g. 1) O

0: O: Advanced stoppage of the programme running, programme not active

1: Heating functional.

2: Heating ready for occupation.

3: Functional heating + heating ready.

4: Heating ready + functional heating.

5: Manual: Manual mode enables you to program your own concrete slab drying time.

The function ends automatically after 25 days.

Setting

increment

setting

Respect the standards

55

50

45

40

35

30

25

Heating start temperature°C

20

0 1 5 10 18 1

X

Heating ready for occupation

1

Heating functional + Heating ready for occupation

5 7

Functional

heating

Day

25

and values of the building

constructor!

Correct operation of this

function is only possible with a

correct installation (hydraulic,

electricity and settings)!

The function may be interrupted

earlier by setting to "Stop".

Basic

g. 1 - Diagram of the oor drying programmes

851 I Manual oor drying value (if line 850 = manual) 0... 95 °C 1 °C 25 °C

This function allows the customised oor drying temperature to be set. This temperature remains xed.

The oor drying programme stops automatically after 25 days of operation.

856 I Current drying day 0... 32 0

857 I Drying days completed 0... 32 0

900 S Switching of operation None, Protection mode,

Reduced, Comfort, Automatic

Operating mode at the end of oor drying.

Cooling, Circuit 1 (Only available when parameter 5711 is set to "2-pipe system")

901 U Operating mode Protection, Automatic, Reduced,

Comfort

902 U Ambient comfort temperature value 17... 40 °C 0.5 °C 24 °C

903 U Reduced ambient temperature value 17... 40 °C 0.5 °C 26 °C

Reduced

Protection

- 38 -

Aurea M / Installation / 1883 - EN

Page 39

Line Function Setting range or display

Setting

increment

setting

908 I Flow temp setp at OT° 25°C 6... 35 °C 0.5 °C 20 °C

Starting cooling temperature setting for an outdoor temperature of 25 °C.

909 I Flow temp setp at OT° 35°C 6... 35 °C 0.5 °C 16 °C

Starting cooling temperature setting for an outdoor temperature of 35 °C.

Flow temperature setpoint

°C

20

908

18

16

909

25 35

30

Outdoor temperature

°C

g. 2 - Slope of the Cooling curve

912 I Cooling limit at T° ex mixed (8704) --, 8... 35 °C 0.5 °C 24 °C

Basic

If the mixed outside temperature is below this value, the cooling mode is disabled.

913 S Lock time at end of heating/cooling --, 8... 100 1 h 24 h

The time delay for operating in cooling mode after having operated in heating mode and vice versa.

918 S Summer comp start at OT° 20... 50 °C 1 °C 26 °C

The comfort setting (902) is increased in line with the outdoor temperature rising above this reading.

919 S Summer comp end at OT° 20... 50 °C 1 °C 40 °C

Above this reading, the comfort setting (902) is no longer aected by an increase in the outdoor temperature.

920 S Summer comp setp increase --, 1... 10 °C 1 °C 4 °C

Maximum increase in the comfort setting (902).

Nominal ambient temperature setpoint

°C

In summer, the comfort setting for cooling (Line 902)

92 0

902

91 9918

Outdoor temperature

is oset upwards in line with the increase in outdoor

temperature.

The saves on cooling power and prevents too great a

dierential between the ambient indoor and outdoor

temperatures.

°C

Remark: Summer compensation explains the dierence

between the value set on Line 902 (or on the setting

knob) and the reading on line 8740.

g. 3 - Compensation for the comfort setting

Aurea M / Installation / 1883 - EN

- 39 -

Page 40

Line Function Setting range or display

Setting

increment

setting

923 S Flow temp setp min OT° 25°C 6... 35 °C 0.5 °C 18 °C

The lowest starting temperature for cooling for an outdoor temperature of 25 °C.

924 S Flow temp setp min OT° 35°C 6... 35 °C 0.5 °C 18 °C

The lowest starting temperature for cooling for an outdoor temperature of 35 °C.

Flow temperature setpoint

°C

908

923

924

20

18

Flow temperature setpoint

(WITH minimum limit)

Basic

909

16

Flow temperature setpoint

(WITHOUT minimum limit)

25 35

30

°C

Outdoor temperature

g. 4 - Limitations on the starting temperature setting

928 S Room temperature inuence --, 1... 100 % 1 % 80 %

If the installation is equipped with an ambient sensor:

This function enables you to choose the ambient temperature's inuence on the setting.

If no value is entered, the regulation is via the water logic.

If the parameter is set to 100%, the regulation is only made using the ambient temperature.

932 S Room temp limitation 0... 4 °C 0.5 °C 0.5 °C

938 S Mixing valve decrease 0... 20 °C 1 °C 0 °C

941 S Servomotor travel time 30... 650 s 1 s 240 s

963 S With prim contr/system pump No, Yes Yes*

*Basic setting: 1 circuit = No; 2 circuits = Yes.

Heating, Circuit 2

Only with the 2nd circuit kit option (If the installation consists of 2 heating circuits).

1010 U Comfort setpoint Reduced setpoint…

Comfort setpoint maximum

0.5 °C 20 °C

1012 U Reduced setpoint Frost protection setpoint…

Comfort setpoint

0.5 °C 19 °C

1014 U Frost protection setpoint 4 °C… Reduced setpoint 0.5 °C 8 °C

1016 S Comfort setpoint maximum Comfort temp... 35 °C 1 °C 28 °C

1020 I Heating curve slope

(see g. 29, page 33)

1021 I Translation of the heating curve

(see g. 30, page 33)

0.1... 4 0.02 0.5

-4.5... 4.5 °C 0.5 °C 0 °C

1030 I Summer / Winter heating limits 8... 30 °C 0.5 °C 18 °C

When the average of the outdoor temperatures over the past 24 hours reaches 18 °C, the regulator switches o the heating

(as an economy measure). During summer mode, the display shows "Eco". This function is only active in automatic mode.

1040 I Flow temp setpoint min 8... 70 °C 1 °C 17 °C

(with dynamic radiator, adjust from 30 to 35 °C)

1041 I Flow temp setpoint max 8... 70 °C 1 °C 60 °C

Under-oor heating = 50 °C / Radiators = 65 °C.

Important remark: The maximum limit is not a safety function as that required for under-oor heating.

- 40 -

Aurea M / Installation / 1883 - EN

Page 41

Line Function Setting range or display

1050 S Room inuence 1 %... 100 % 1 % 50 %

If the installation is tted with a room thermostat:

This function enables you to choose the ambient temperature's inuence on the setting.

If no value is entered, the setting is made based on the temperature control.

If the parameter is set at 100%, the setting is only based on the ambient temperature.

1060 S Room temperature limitation 0.5... 4 °C 0.5 °C 0.5 °C

As soon as the room temperature = [Setpoint line 1010 (ex. 20 °C) + Room temperature limitation setpoint line 1060

(ex. 0.5 °C)] > 20.5 °C => The heat pump is stopped. It restarts when the room temperature falls below the setpoint

(in the example, Room temperature < 20.0 °C).

Setting

increment

Basic

setting

1080 S Quick setback O, Up to reduced setpoint,

1090 S Optimum start control max 0... 360 min 10 min 180 min

1091 S Optimum stop control max 0... 360 min 10 min 30 min

1100 S Reduced setpoint increase start -30... 10 °C 1 °C --

1101 S Reduced setpoint increase end -30... 10 °C 1 °C -5 °C

1130 S Mixer valve increase 0... 50 °C 1 °C 0 °C

1134 S Actuator running time 30... 650 s 1 s 240 s

1150 I Control of oor drying (g. 1, page 38) O

0: O: Advanced stoppage of the programme running, programme not active

1: Heating functional.

2: Heating ready for occupation.

3: Functional heating + heating ready.

4: Heating ready + functional heating.

5: Manual: Manual mode enables you to program your own concrete slab drying time.

The function ends automatically after 25 days.

1151 I Floor curing setpoint manually

(if line 1150 = manual)

This function enables you to set the custom concrete slab drying temperature. This temperature remains xed.

The concrete slab-drying program stops automatically after running for 25 days.

1156 I Floor curing day current 0... 32

Up to protection setpoint

0... 95 °C 1 °C 25 °C

O

1157 I Floor curing day completed 0... 32 0

1200 S Operating mode changeover None, Protection mode,

Reduced, Comfort, Automatic

Operating mode at end of concrete slab drying period.

Cooling, Circuit 2 (Only available when parameter 5716 is set to “2-pipe system”)

If the installation is tted with the cooling kit (Only with the cooling kit option).

1201 U Operating mode Protection, Automatic, Reduced,

Comfort

1202 U Comfort cooling setpoint 17... 40 °C 0.5 °C 24 °C

1203 U Reduced setpoint 5... 40 °C 1 °C 26 °C

1208 I Flow temp setp at OT° 25°C 6... 35 °C 0.5 °C 20 °C

Starting cooling temperature setting for an outdoor temperature of 25 °C.

1209 I Flow temp setp at OT° 35°C 6... 35 °C 0.5 °C 16 °C

Starting cooling temperature setting for an outdoor temperature of 35 °C.

1212 I Cooling limit at T° ex mixed (8704) --, 8... 35 °C 0.5 °C 24 °C

If the mixed outside temperature is below this value, the cooling mode is disabled.

1213 S Lock time at end of heating --, 8... 100 1 h 24 h

The time delay for operating in cooling mode after having operated in heating mode and vice versa.

Reduced

Protection

Aurea M / Installation / 1883 - EN

- 41 -

Page 42

Line Function Setting range or display

1218 S Summer comp start at OT° 20... 50 °C 1 °C 26 °C

The comfort setting (1202) is increased in line with the outdoor temperature rising above this reading.

1219 S Summer comp end at OT° 20... 50 °C 1 °C 40 °C

Above this reading, the comfort setting (1202) is no longer aected by an increase in the outdoor temperature.

1220 S Summer comp setp increase --, 1... 10 °C 1 °C 4 °C

Maximum increase in the comfort setting (1202).

1223 S Flow temp setp min OT° 25°C 6... 35 °C 0.5 °C 18 °C

The lowest starting temperature for cooling for an outdoor temperature of 25 °C.