Ateq AX6000 User Manual

USER MANUAL

ATEQ AX6000

Version 03.03

Reference: UM-30300D-U

REVISIONS OF THE ATEQ AX6000 USER MANUAL

Due to continuing improvements, the information contained in this user manual, the features and design of

this device are subject to be changed without prior notice.

Edition/Revision Reference

First edition UM-30300B-U 40/2009

Second edition UM-30300C-U 37/2011

Third edition UM-30300D-U 07/2013

Date

Week/Year

Chapters up dating

Indices B to be the same as the

French version.

General update following device

evolution. Program upgrade to the 2.0

version. Add 3A current ranges option.

Characteristics measurement update.

Sequences process update. Device

firmware version 3.0.

0940/CE-30300A-U

DECLARATION OF CONFORMITY 00

We the undersigned, ATEQ, manufacturers of the ATEQ AX6000 REF : 303.00 declare that it

complies with the requirements of :

- LOW VOLTAGE Directive 73/23/CEE partially modified by Directive 93/68/CEE.

• standard EN 61 010-1 « Safety requirements for electrical equipment for measurement,

control and laboratory use »,

- EMC Directive 89/336/CEE partially modified by EMC Directive 92/31/CEE regarding :

• standard EN 61 326-1 « Electrical equipment for measurement, control and laboratory –

EMC requirements »,

9 standard EN 61 000-4-2 « Electrostatic discharge immunity tests »,

9 standard EN 61 000-4-3 « Radiated, radio-frequency, electromagnetic fields immunity

tests »,

9 standard EN 61000-4-6 « Immunity to conducted disturbances, induced by radio-

frequency fields »,

• standard EN 55 011 « Industrial, scientific and medica radio-frequency equipment - limits

et methods of measurements ».

9 standard EN 55 022 « Information technology equipment - limits and methods of

measurements »,

This enables ATEQ to guarantee that this instrument may be used in complete safety under the

following environmental conditions :

• indoor use,

• altitude up to 3000 metres,

• ambient operating temperature from 0°C to 50°C,

• 95 % maximum relative humidity without condensation,

• degree of pollution 2 as in CEI 664 (only non-conductive pollution, however a temporary

conductivity caused by condensation may occasionally be expected).

Chairman and Managing Director.

Mr. Jacques MOUCHET

Tél. : +33 (0) 1 30 80 10 20 - Fax : +33 (0) 1 30 54 11 00

15, rue des Dames - 78340 LES CLAYES SOUS BOIS – France

www.ateq.com

Recommendations for electrical

testing intruments

Precautions on the test environment

Let the test area dry and clean, free from explosive gas.

Precautions on the operators

ATEQ recommends that the operators using the instruments should have a suitable

qualification and training with respect to the work bench requirements.

General precautions

Read the users manual before using the instrument,

all electrical connections coming to the instrument must be equipped with a safety

system (fuse, circuit breaker…) adapted to the needs and adhering to the norms,

to avoid electromagnetic interference, the cable connections to the instrument

should be less than two meters in length,

the electrical main supply must absolutely have proper connection to the earth,

disconnect the electrical connections to the equipment for maintenance,

do not open the instrument under power voltage,

avoid water spillage in the direction of the instrument,

ATEQ is at your disposal for any further information concerning the use of the

instrument under maximum safety conditions.

!

We would like to bring to your attention that ATEQ will not be held

responsible for any accident connected to the improper use of the

instrument, to the work bench or to the lack of compliance with safety

rules.

ATEQ Company is free from any responsibility for any adjustment of

its instrument which would not have been done by its own

technicians.

RelAX6000-U/0940

ATEQ, THE ASSURANCE OF A COMPETENT AFTER SALES

SERVICE

THE ATEQ AFTER SALES SERVICE IS :

• a team of qualified technicians,

• a permanent telephone assistance,

• agencies close to you for faster reaction,

• a stock of spare parts available immediately,

• a car fleet for rapid intervention,

• a commitment to quality ...

THE OVERHAUL

ATEQ carries out the overhaul of your instruments at interesting prices.

The overhaul corresponds to the maintenance of the instrument (checking, cleaning, replacing of used

parts) as part of preventive maintenance.

Preventive maintenance is the best way to guarantee reliability and efficiency. It allows the

maintenance of a group of instruments in good operational order and prevent eventual break-downs.

MAINTENANCE KITS

The ATEQ After Sales Service proposes, two kits destined for the preventive maintenance of the

pneumatic circuits of instruments.

CALIBRATION

This may be carried out on site or in our offices.

ATEQ is attached to the COFRAC and delivers a certificate following a calibration.

TRAINING COURSES

In the framework of partnership with our customers, ATEQ offers two types of training in order to

optimise the usage and knowledge of our instruments. They are aimed at different levels of technician:

• method / control training,

• maintenance / upkeep training.

A TARGETED TECHNICAL DOCUMENTATION

A number of technical documents are at your disposal to allow you to intervene rapidly in the event

minor breakdowns:

• problem sheets describing and offering solutions to the main pneumatic and electronic

problems,

• several maintenance manuals.

A QUALITY GUARANTEE

The instruments are guaranteed for parts and labour in our offices:

• 2 years for leak detection equipment,

• 1 year for electrical tests to norms instruments,

• 1 year for the accessories.

Our After Sales Service is capable of rapidly answering all your needs and queries.

We strongly recommend to send the instrument

back to ATEQ once a year for re-calibration

SAV-Uc/0650

PREFACE

Dear Customer,

You have just purchased an ATEQ instrument, we thank you for the trust you have

placed on our brand. This instrument has been designed to ensure a long and

unparalleled life expectancy, and we are convinced that it will give you complete

satisfaction during many long years of operation.

In order to maximise the life expectancy and reliability of your ATEQ instrument, we

recommend that you install this instrument on a secured workbench and advise you to

consult this manual in order to familiarise yourself with the functions and capabilities of

the instrument.

Our ATEQ After Sales Service centre can give you recommendations based on your

specific operation requirements.

ATEQ

0650/PREFd-U

Table of contents

TABLE OF CONTENTS

Preamble MEASUREMENT PRINCIPLE

1. DEFINITION .........................................................................................................................................3

2. PRINCIPE.............................................................................................................................................3

3. GENERAL DIAGRAM..........................................................................................................................4

4. AUTOMATIC ZERO.............................................................................................................................5

5. BATTERY / INSTRUMENT AUTONOMY............................................................................................5

6. MEASUREMENT CHARACTERISTIC ................................................................................................6

6.1. Measurement ranges selection ....................................................................................................6

Chapter 1 INSTRUMENT INSTALLATION

1. APPEARANCE ....................................................................................................................................7

2. INSTRUMENT INSTALLATION ..........................................................................................................8

2.1. Battery block / Supply ..................................................................................................................8

2.2. Electrics connectors .....................................................................................................................9

Chapter 2 USER INTERFACES

1. PRESENTATION ...............................................................................................................................11

2. KEYBOARD PRESENTATION..........................................................................................................12

2.1. On / Off key ................................................................................................................................12

2.2. Navigation keys..........................................................................................................................12

2.3. Start cycle key ............................................................................................................................12

3. LCD DISPLAY ...................................................................................................................................13

4. FUNCTIONS OF THE INDICATOR LIGHTS.....................................................................................13

5. BATTERY LEVEL..............................................................................................................................13

6. CARRYING CASE .............................................................................................................................14

6.1. Open the carrying case ..............................................................................................................15

6.2. Close the carrying case..............................................................................................................16

Chapitre 3 STARTING UP AND ADJUSTMENTS

1. TURN ON THE DEVICE ....................................................................................................................17

2. LOCK / UNLOCK...............................................................................................................................18

2.1. Lock operation............................................................................................................................18

2.2. Unlock operation ........................................................................................................................19

2.3. Password erase..........................................................................................................................19

3. MODE FUNCTION .............................................................................................................................20

3.1. Program number choice.............................................................................................................20

4. TEST PROGRAM CREATION...........................................................................................................21

5. PARAMETERS ADJUST...................................................................................................................22

5.1. Parameters to adjust ..................................................................................................................22

6. MEASUREMENT TRIGGERING .......................................................................................................25

6.1. Auto-test .....................................................................................................................................25

7. TEST STOP........................................................................................................................................25

7.1. Measurement fail detection ........................................................................................................25

8. SEQUENCES CONFIGURATION (WINATEQ300/AX).....................................................................26

8.1. Window details ...........................................................................................................................26

8.2. Available commands detail ........................................................................................................27

8.3. Sequence management .............................................................................................................27

9. SEQUENCE MODE RUNNING..........................................................................................................29

9.1. "Sequence" mode setting...........................................................................................................29

9.2. Sequence selection....................................................................................................................30

9.3. Operator name input ..................................................................................................................30

9.4. Carrying out the measurement of a sequence...........................................................................30

9.5. Change a step attribute..............................................................................................................31

9.6. Sequence validation and completion .........................................................................................31

9.7. Display age the sequences filters ..............................................................................................32

UM-30300D-U User manual AX 6000 Page 1 / 54

Table of contents

Chapter 4 FUNCTIONS OF THE INSTRUMENT

1. MENU STRUCTURE..........................................................................................................................33

1.1. Main menu..................................................................................................................................33

1.2. Special cycles menu ..................................................................................................................34

2. SYSTEM SETTINGS..........................................................................................................................35

2.1. Language ...................................................................................................................................35

2.2. Date and hour.............................................................................................................................36

2.3. Lighting the screen.....................................................................................................................37

2.4. Auto Off ......................................................................................................................................38

2.5. Buzzer ........................................................................................................................................38

2.6. Automatic start ...........................................................................................................................39

2.7. Programs deletion ......................................................................................................................39

3. DATA MANAGEMENT ......................................................................................................................40

3.1. Results storage ..........................................................................................................................40

3. SPECIALS CYCLES MENU ..............................................................................................................41

3.1. Special cycles available .............................................................................................................41

3.2. Run specials cycles....................................................................................................................41

Chapter 5 ACCESSORIES

1. ACCESSORIES .................................................................................................................................43

1.1. Power supply..............................................................................................................................43

1.2. Battery ........................................................................................................................................43

1.3. USB Cable..................................................................................................................................44

1.4. Soft carrying case ......................................................................................................................44

1.5. Transport case ...........................................................................................................................44

Chapter 6 ERROR MESSAGES

ERROR MESSAGES .................................................................................................... 45

Chapter 7 OPERATIONAL PROBLEMS

1. PROBABLES FAILURES..................................................................................................................47

Appendices ATEQ AX6000

1. TECHNICALS CHARACTERISTICS.................................................................................................49

2. DIMENSION DRAWING ....................................................................................................................49

3. SAFETY INFORMATION...................................................................................................................50

4. RECYCLING ......................................................................................................................................52

Index 53

UM-30300D-U User manual AX 6000 Page 2 / 54

Preamble

Preamble

MEASUREMENT PRINCIPLE

1. DEFINITION

The AX 6000 instrument is a milliohmmeter designed to test metallization encountered

in aviation. This quality test controls the mechanical assembly of each part who

constituting a plane.

For this, he characterized the control of the junction between two or more parts using

the principle of measuring electrical continuity.

Each branch is then represented by an ohmic resistance which must be as low as

possible.

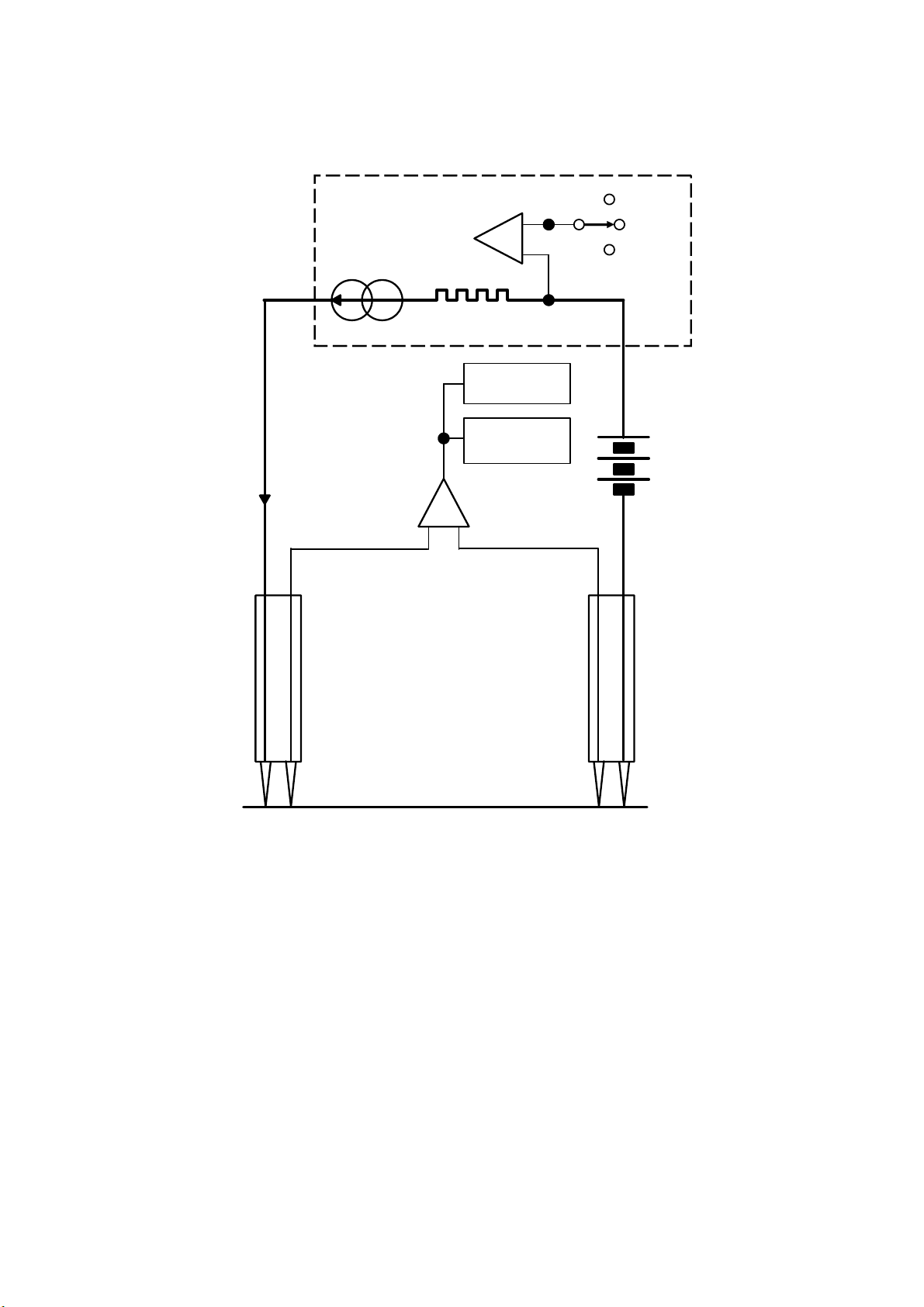

2. PRINCIPE

The measurement principle is to circulate a calibrated continued current 0.1A, 1A or

10A between any two points A and B materializing the resistance to measure RX. Then

it proceed to read the potential between these two points, the measured voltage at

terminals of the resistance is proportional to the current passing through, according to

the ohm's law:

U = RI

To realize these measurements the instrument uses:

9 A constant current generator supplied with a 12 V Lithium Polymer battery.

9 Two probes with doubles contacts for the "4 wires" measurement:

• A contact (point) to establish the current in the resistance to measure.

• Another contact (point) to measure the potential difference through an

instrumentation amplifier.

9 A voltmeter allows reading the voltage kept at the amplifier output.

Note: the three measurement currents are: 10 A for the metallic and aluminium parts,

1 A and 0.1 A for the composites materials parts.

UM-30300D-U User manual AX 6000 Page 3 / 54

3. GENERAL DIAGRAM

y

Preamble

I measure

Current

generator

Shunt

Voltmeter

Automatic

Instrumentation

amplifier

10 A

1 A

0.1 A

zero

Batter

Probe

RX

A B

Probe

UM-30300D-U User manual AX 6000 Page 4 / 54

Preamble

4. AUTOMATIC ZERO

During its measurement cycle, the instrument carried out automatically an auto-zero

measurement to eliminate undesirables' thermo-electrics effects in the measurement

circuit and carried out the measurement zero of the instrument compensating the

offset errors in the measurement amplifier.

Then, at each measurement, the instrument memorizes the spurious external voltage

of the thermocouple present in the R

terminal before the passage of the current in

X

order to subtract it from its new value obtained during the passage of the current.

5. BATTERY / INSTRUMENT AUTONOMY

The 12VDC 4400 mA/h battery with Lithium Polymer (Li-Po) technology is integrated in

a bloc. This technology allows for the best space / electrical capacity. The battery pack

is removable from the device without tools.

The battery capacity guaranteed to carry out 1000 measurements. Following the

battery state, number of charges and its age, it's possible that the number of

measurement will decrease significantly, in this case, change the battery with a new

one and recycle the old one (see the recycling conditions in the appendices).

The battery charge is carried out with the power supply which connected with a jack

connector. The battery is fitted with a light (LED) which indicates to the user the charge

state. The complete charge time is less than 3 hours. The charge can be carried out the

battery out of the instrument.

Use only the power supply fitted with the instrument. See the instructions and security

precautions concerning the instrument use in the appendices.

UM-30300D-U User manual AX 6000 Page 5 / 54

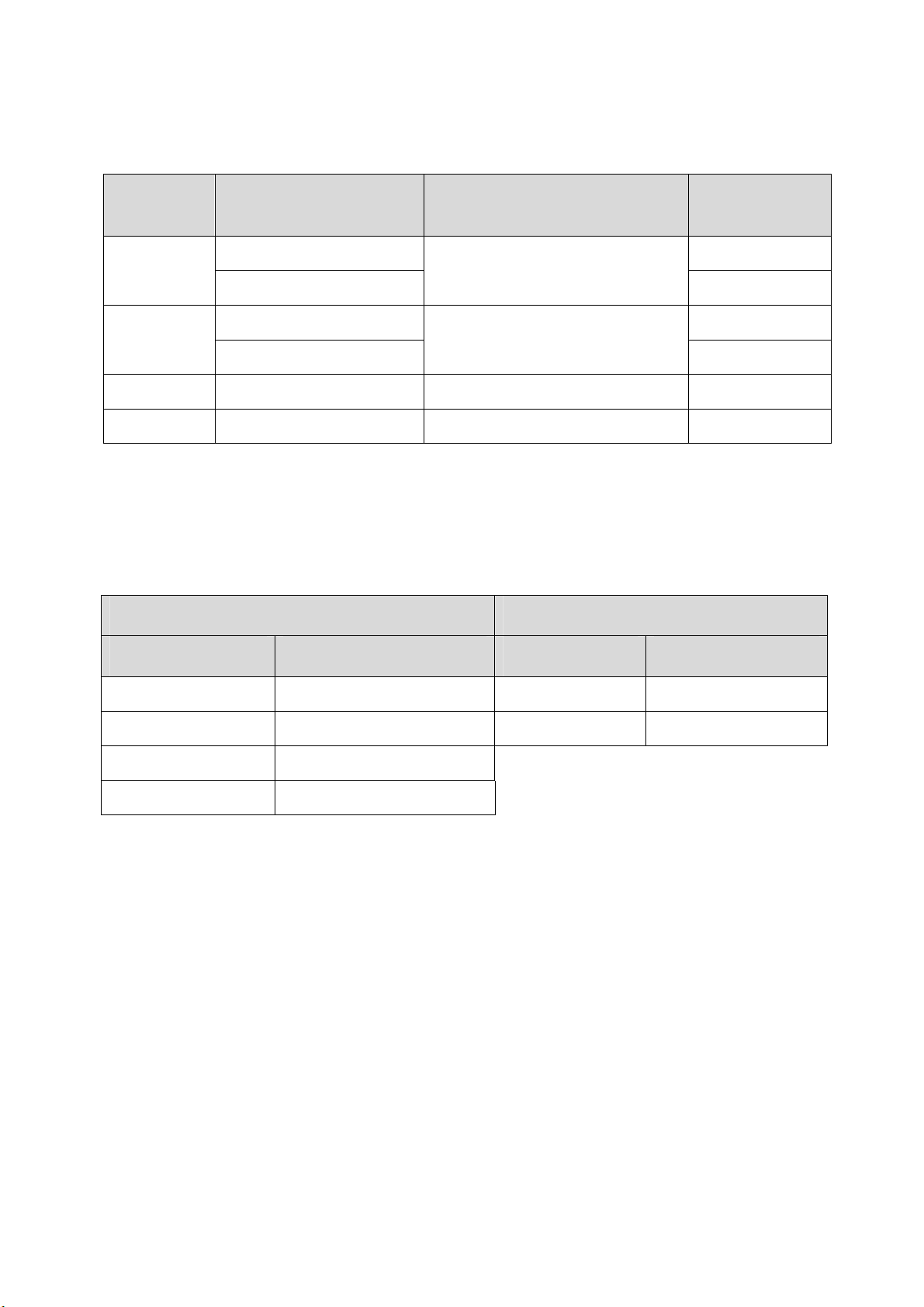

6. MEASUREMENT CHARACTERISTIC

Preamble

Range

Measurement

Current

Accuracy Resolution

1A 1 µΩ

6 mΩ

10A

+/- (0.1 % MV + 6 µΩ)

1 µΩ

0.1A 100 µΩ

60 mΩ

1A – 10A

+/- (0.1 % MV + 60 µΩ)

10 µΩ

600 mΩ 0.1A – 1A – 10A +/- (0.1 % MV + 0.6 mΩ) 100 µΩ

6 Ω 0.1A – 1A +/- (0.1 % MV + 6 mΩ) 1 mΩ

MV = Measured Value.

6.1. MEASUREMENT RANGES SELECTION

The measurements ranges can de selected automatically (auto-ranging) or manually

by the user, it's the following ones:

Manual mode Automatic mode

Range Current Range Current

6 mΩ (2 mΩ) 1A – 10A (3A) 1µΩ – 600mΩ 10A

60 mΩ (20 mΩ) 0.1A – 1A – 10A (3A) 10µΩ – 6Ω 1A / 0.1A

600 mΩ (200 mΩ) 0.1A – 1A – 10 A (3A)

6 Ω 0.1A – 1A

UM-30300D-U User manual AX 6000 Page 6 / 54

1. APPEARANCE

Chapter 1 – Instrument installation

Chapter 1

INSTRUMENT INSTALLATION

The ATEQ AX6000 case is made with two anodized aluminum parts assuring durability

and lightness. The case is surrounded by two rubbers to protects the device from falls

and avoid marking the shocked part.

UM-30300D-U User manual AX 6000 Page 7 / 54

2. INSTRUMENT INSTALLATION

2.1. BATTERY BLOCK / SUPPLY

Chapter 1 – Instrument installation

The ATEQ AX6000 is running with a 12 V DC

battery.

The battery has a LED light for charge state:

9 Red: The battery is charging.

9 Green: battery full.

To remove the battery from the device,

proceed as follows:

1) Press the burst above to unlock.

2) Turn the battery outwards.

To reinstall the battery, do the same

operation in the reversal way.

UM-30300D-U User manual AX 6000 Page 8 / 54

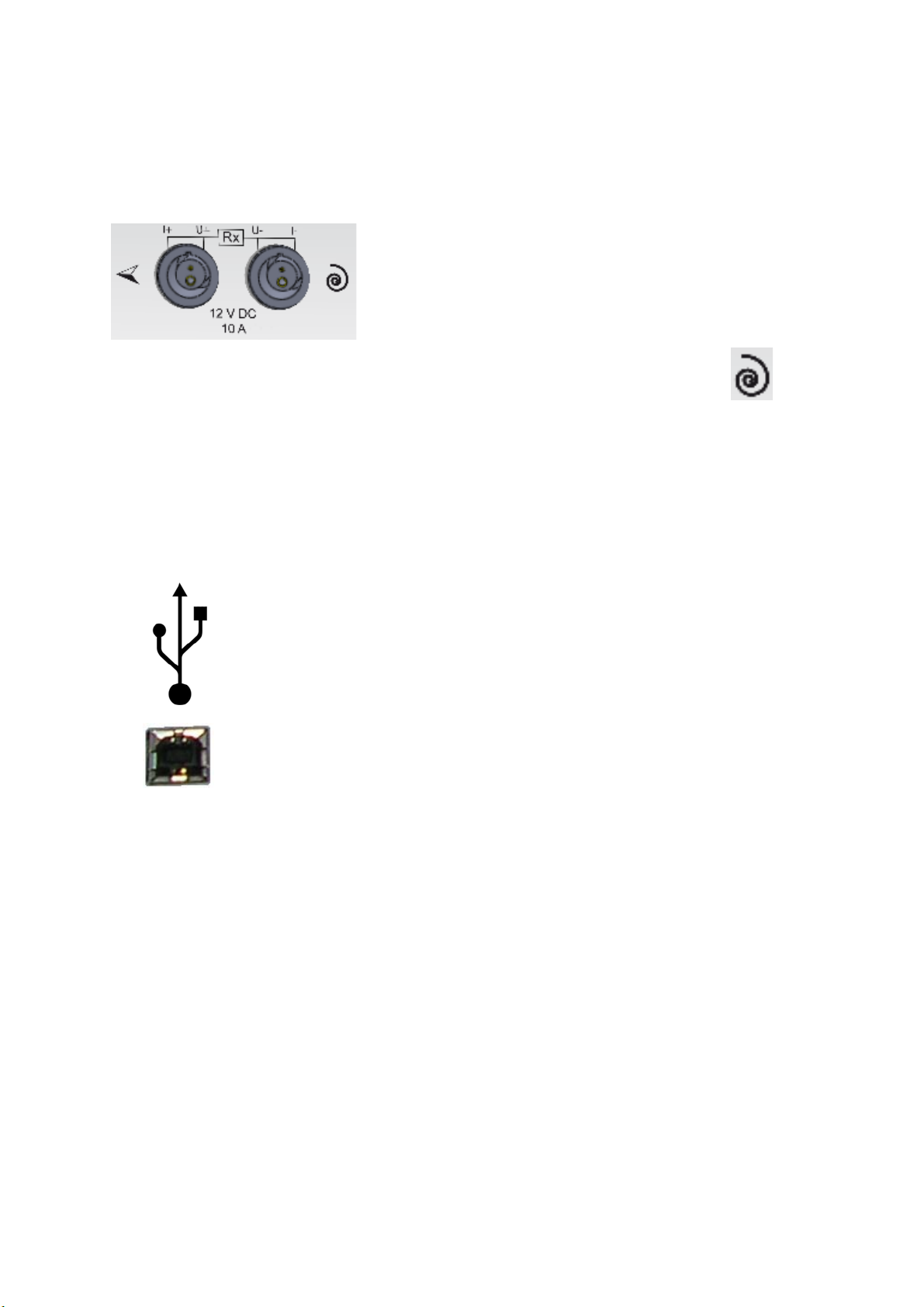

Chapter 1 – Instrument installation

2.2. ELECTRICS CONNECTORS

2.2.1. Test accessories connectors

The test accessories, probes, Kelvin probes pliers, etc.

are connected on these two plugs. There are two

connectors on the front face and two on the rear face

that the user will choose following the use.

If a spool of wire is used, it must connect this spool to the plug identified by

.

Note: if a winding is used and if it's partially or not unwound, it's possible that the device

has some measurements problems and displays the "Continuity U fault" message. In

this case, it's strongly advisable to configure the instrument in the "Inductive" mode. See

the chapter 3, paragraph 5.1.6 "Measurements modes".

2.2.2. USB Connector (front and rear faces)

Allows the connection to a PC. Allows the supervision with the

Winateq300 software:

9 Configuring (save / restore the parameters in a PC).

9 Duplicate an instrument.

9 Up dating the device.

9 Results recovery for archiving and statistic analysis with

spreadsheet software's.

See the Winateq300 software manual.

UM-30300D-U User manual AX 6000 Page 9 / 54

Loading...

Loading...