Page 1

Voltage dips, also called sags, are brief reductions in AC

mains voltage, typically between half a cycle to a few seconds.

The best-known sources of voltage dips and interruptions are

listed below:

The starting of a large load such as a motor or resistive

heater.

Loose or defective wiring such as insufficiently tightened

box screws on mains conductors leading to the increase of

your system impedance, thus, making itself vulnerable to

the effect of current increase.

Faults or short circuits draw excessive currents until the

protective devices such as a fuse or circuit breaker operates.

Faults on distant circuit typically which can be automatically

switched and removed by reclosers. This type of event is

sometimes a series of voltage dips caused by continuous

operation of reclosers.

Loads that have continuously varying power levels cause

voltage variations rather than an abrupt change.

In any case, these voltage changes can degrade the

performance of electronic equipment in many different

ways: digital circuit upset, data-loss or distortion and so

on. Therefore, immunity testing for these types of events

should be performed to ensure your product's safe and

reliable operation.

In fact, in the scheme of international compliance, the

IEC 61000-4-11 compliance voltage dip test is a must

for all products having a rated input current not

exceeding 16A per phase.

Clearly from the above, voltage dips, interruptions, and

variations are everywhere and unavoidable.

Voltage dips and short interruptions are not always abrupt

because of the reaction time of rotating machines and

protection elements- the rotating machines will operate as

generators sending power into the network. Some equipment,

typically containing a power-fail detection circuit, is more

vulnerable to gradual variations than to abrupt change.

The NoiseKen VDS-2002 Voltage Dip and Up Simulator,

uncompromising on and fully compliant with all the test

generator requirements in the standard including fast

rise and fall times, peak inrush current drive capability,

overshoot/undershoot and others, fulfills accurate

testing needs.

Page 2

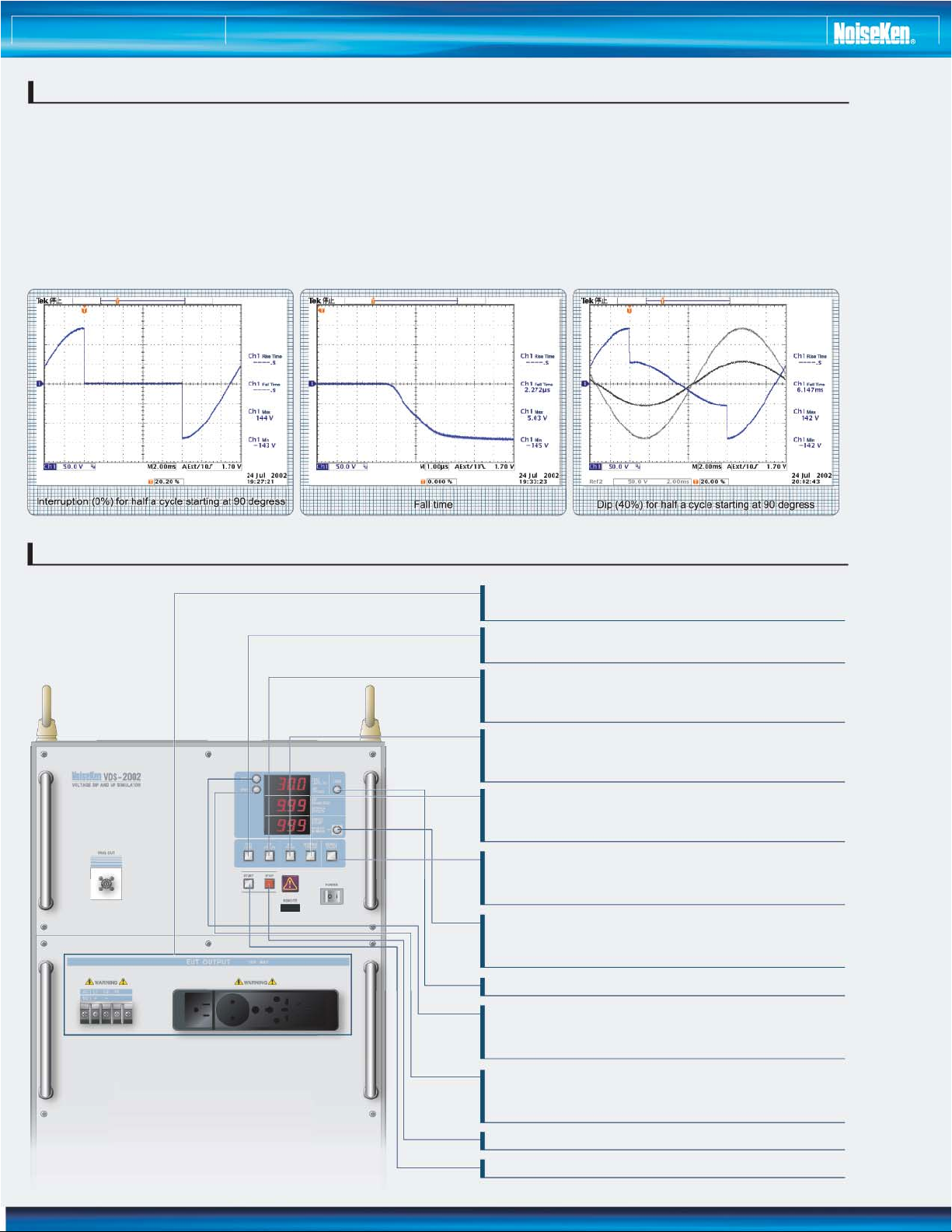

VDS-2002 Voltage Dip and Up Simulator

FEATURES

Fully compliant with all the test generator requirements of IEC standard

One unit solution for dip, swell, interruption, and variation tests up to 16A 290V single phase AC

Interruption test up to 16A 125V DC*

Two motor-driven transformers approach enables switching between any voltages*

Preset IEC test levels 0%/40%/70% additional 120%

Two modes for 0% (interruption) test: open & short*

Optional Windows Application Software available to more extensively control the unit

Accurate waveforms

* Optional software required

CONTROL PANEL

EUT OUTPUT:

receptacles (Multi-type) +Terminal Blocks for AC/DC.

TEST LEVEL:

selects a test level among 0, 40, 70 and 120%.

DIP CYCLES:

selects the duration of a dip among 0.5, 1, 5, 10, 25 and

50 cycles.

DIP PHASE:

selects the phase angle at which a dip starts among 0,

45, 90, 135, 180, 225, 270 and 315 degrees.

INTERVAL CYCLES:

selects the time interval between each dip among 1, 3,

5, 10, 30, 50, 100, 300, 500 cycles and 10s.

REPEAT COUNT:

selects the number of dips among 1, 3, 5, 10, 30, 50,

100 and infinite.

MEMORY NUMBER:

used to save or call up the selected test setting among

preset 5 settings

LINE: turns on and off power to the EUT

SW1:

for output verification, the unit outputs the normal

voltage adjusted by the slide transformer 1.

SW2:

for output verification, the unit outputs the dip/swell

voltages adjusted by the slider transformer 2.

START: starts the test.

STOP: stops the test.

Page 3

VDS-2002 Voltage Dip and Up Simulator

ELECTRICAL SCHEMATIC

OPERATING PRINCIPLE

As shown in the above schematic, the VDS employs two

independent motor-driven slide transformers and two IGBT

switches. Under complete control by the unit control circuitry, it

generates voltages dips, interruptions and variations with much

wider parameter settings than those originally required in the IEC

61000-4-11 standard.

Since the unit employs two slide transformers, it can generate

two variable voltage levels, which are independently preset,

corresponding to dip (or variation) and normal voltage (voltage in

interval cycles). The two IGBT switches enable to fulfill the fast

rise and fall time requirements called for in the relevant standard.

AC/DC selection terminals are provided to insert the two

transformers for an AC test and to bypass them for the DC test.

DC interruption test, therefore, can be done by utilizing the same

IGBT switches.

To offer short and open mode selection in AC interruption test,

two magnet relays, MG22 and MG21, work to realize low

impedance and high impedance as seen from the load side.

Page 4

VDS-2002 Voltage Dip and Up Simulator

SPECIFICATIONS

Parameters

Compliant standard

Number of lines

Test mode

Input voltage range

Output voltage range

Output VA

Output current

capability

Peak inrush current

drive capability

Load regulation

Overshoot/undershoot

Rise time/fall time

Normal voltage setting

Dip/Swell level

Repetition of events

Interval cycle

Dip cycle

Dip phase

(Starting phase angle of

events)

Voltage variation test

Memory

Equipment input

Interruption

AC/DC

Dip and swell

Var iat io n

AC

DC

AC100~120V

AC220~240V

100% of input voltage

0~16A rms

70% of input voltage

0~23A rms

100% of input voltage

0~40A rms

Setting by percent

Setting by voltage

Accuracy

Setting by percent

Setting by voltage

Accuracy

No. of events

Setting by cycle

Setting by time

Setting by cycle

Setting by time

Setting by phase angle

Setting by time

Setting by time

Test level

100% of input voltage

70% of input voltage

40% of input voltage

Specifications Remarks

IEC 61000-4-11

Single phase

Synchronous Short circuit

Asynchronous

Synchronous/Asyn

chronous

Synchronous

Asynchronous

Asynchronous

AC90~264V, 50/60 Hz

DC0~125V

AC0V~120% of input voltage

DC0V~input voltage

4.224kVA

16A rms

23A rms

40A rms

16A

쏜250A

쏜500A

쏝5%

쏝7%

쏝10%

쏝5%

PC

Local

PC

PC

Local

PC

PC

Local

Synchronous

Setting for short

duration

Setting for long

duration

Setting for short

duration

Setting for long

duration

Changing time

Changed time

Interval

AC100~115V/200~240V앧10%, 50/60Hz, 120VA

optical RS-232External interface

15~35쎶COperating temperature

25~75%R.H. (No dewing)Operating humidity

(W)430҂(H)745҂(D)600mm(projection excluded)Dimensions

Approx.150 kgs.Weight

1~5애S

~120%

100%

10V~290V

(interruption)

(interruption) setting

Short/Open selectable for 0V

(interruption)

앧5V

1~1000 or continuous

1, 3, 5, 10, 30, 50, 100 or continuous

PC

Local

Synchronous

Asynchronous

Asynchronous

Synchronous

Synchronous

Asynchronous

Asynchronous

Synchronous

Asynchronous

PC/local

PC

PC

PC/local

PC

PC/Local

Only 2s-1s-2s standard defined test

available in local mode

0.5~5000.5 cycles

1,3,5,10,30,50,100,300,500 cycles, 10s

1~100s

PC

10ms~100s (50Hz)

8.3ms~100s (60Hz)

1s~10h

0.01~5000 cycles

PC

0.5, 1, 5, 10, 25, 50 cycles

Local

0.1 ms~100s

PC

0.1 ms~100s

1s~10h

0~359쎶

PC

Local

0, 45, 90, 135, 180, 225, 270, 315

0~19.9 ms for 50Hz

PC

0~16.6 ms for 60Hz

PC

0.1s~10 s

at least 0.1s required for 10% change

of input

0~10s

0~100s

0~120%

PC

Local

5 tests

PC

10 steps

Open circuit

0~120%Short/Open selectable for 0%

0/40/70/120%Short circuit for 0%

0~290V (0~120%

AC290V max

Continuous

Continuous

쏝5S

쏝5S

Continuous

at 100% output,

쏝10ms

100 ohm loaded

100 ohm loaded

10V minimum

5V step

0V~16A output앧5V

4 steps

)

5V step

1 event step

8 steps

0.5 cycle step

10 steps

1s step

0.1 ms step

1s step

0.01 cycle step

6 steps

0.1ms step

0.1ms step

1s step

1쎶 step

8 steps

(45 degrees step)

0.1ms step

0.1s step

0.1s step

0.1s step

Test sequence stored

up to 10 steps when

controlled by PC

Page 5

VDS-2002 Voltage Dip and Up Simulator

쏝

IEC 61000-4-11 Standard/Voltage Dips, Short Interruptions and Variations

Test levels

Test Level

%U

T

0

Voltage dip and

short interruptions

%U

T

100

Duration

(in perriod)

0.5

1

Test Level

%U

T

40%U

T

Time for

decreasing

voltage

2s앧20%

Time at

reduced

voltage

앧20%

1s

Time for

increasing

voltage

앧20%

2s

5

40

60

10

0%U

2s

T

앧20%

1s

앧20%

2s

앧20%

25

70

30

The voltages in this standard use the rated voltage for the equipment (U

50

x

xxx

) as a basis for voltage test level specifications. If the

T

equipment has a specified input voltage range, then testing should be performed at the lower and upper limits of the voltage range

specified. However, in practice it is only necessary to perform the tests at the lowest specified input voltage, since all the tests

concern a reduction or interruption of supply voltages. "X" is an open duration. One or more of the above test levels and durations

may be chosen.

IEC61000-4-11 is a basic EMC standard defining test generator, methods and others and does not specify particular test levels and

durations, but it is the Generic Immunity standards, as well as the Product family standards, that specify the test revel and pass/fail

performance criteria applied to a particular class of equipment.

For an open set of duration, the IEC standard says other values may be taken in a justified case and shall be specified in product

specifications. For possible future requirements, VDS-2002 has provisions of a variable slew rate from 1s to 10s (0~100% output)

Characteristics of the test generator

Peak inrush current drive capability (not required for voltage variation tests)

500A for 220V-240V mains

250A for 100V-120V mains

The test generator has to simulate the very low output impedance characteristics of the real world mains. In other words, the

generator must be able to provide inrush currents of a similar level to the actual power mains.

Most electronic products such as those using switching power supplies exhibit high start up currents needed to charge capacitive

input circuitry in their input section. Conventional AC amplifiers cannot meet this requirement, and worse yet, they perform as

external soft-start circuits for the EUT. For verifications, the generator shall be switched from 0% to 100% of full output, when driving

a load consisting of an uncharged capacitor whose value is 1700

애F in series with a suitable rectifier. A bleeder resistor in a range of

100 ohm to 10k ohm shall be connected in parallel with the capacitor. Several time constants must be allowed between tests. The

standard specifies the current monitor's characteristics used to measure peak inrush current capability.

Overshoot/Undershoot (loaded with 100 ohms) :

Voltage rise/fall time (for abrupt change, generator loaded with 100 ohms): 1 to 5

쏝

5%

애s. Conventional AC amplifiers cannot meet

this requirement

Phase shifting: 0 to 360쎶

Execution of test

3 dips/interruptions/variations with interval of 10s minimum

Abrupt change in supply voltage shall occur at zero crossing of the voltage.Additional angles (45, 90, 135, 180, 225, 270, 315

쎶)are

specified for use by product committees or individual product specifications.

The IEC standard requires the monitoring of EUT line voltage within a accuracy of 2%.ALM-21 is suitable for this purpose with its

logging capability. This power Line Monitor also can monitor the VDS output voltages.

ALM-21 accuracy:

앧(0.5% rdg쎵0.8V)

Page 6

VDS-2002 Voltage Dip and Up Simulator

OPTIONAL ACCESSORIES

Control Software

Model 14-00029A

Wider parameter settings than locally allowed

Setting to IEC 61000-4-11 are preprogrammed

Intuitive setting for all test parameters

GUI (graphical user interface)

Sequential operation up to 10 steps

Test report generation

RS232C Optlink set

Model 07-00017A

Main Window

IEC Test

AC Dip Test

AC Variation Test

DC Interruption Test

AC Line Monitor

Model ALM-21

The IEC 61000-4-11 requires monitoring of the main voltage for testing (voltage to AC EUT INPUT) within an accuracy

of 2%. A compact, portable AC Line Monitor ALM-21, originally intended for site surveys, is suitable for this purpose with

its data logging capability. It also can monitor the output from the VDS-2002.

Designs and specifications are subject to change without notice.

NOISE LABORATORY CO., LTD.

1-4-4, Chiyoda, Sagamihara City,

Kanagawa Pref., 229-0037 Japan

쎵81

(0)

42-712-2051 Fax: 쎵81(0)42-712-2050

0208-05K

Tel:

http://www.noiseken.com/

E-mail: sales@noiseken.com

Loading...

Loading...