Page 1

TORKEL 840/860 Battery Load Units

Programma

TORKEL 840/860 Battery Load Units

■

Batteries can be tested “in service”

■

Unit adjusts to include load currents in

the test parameters

■

User adjustable alarm and shutdown

points to avoid excessive discharge

■

Easily expandable for larger battery

banks using TXL extra load units

■

View test parameters/results “real time”

as testing progresses using TORKEL WIN

software

Programma

DESCRIPTION

TORKEL®840 - UTILITY is used for battery systems

ranging from 12 to 250 V – often encountered in

switchgear and similar equipment. Discharging can take

place at up to 110 A, and if higher current is needed, two

or more TORKEL 840 units, or extra load units (TXL), can

be linked together. Tests can be conducted at constant

current, constant power, constant resistance or in

accordance with a pre-selected load profile.

TORKEL 860 - MULTI is designed primarily for people

who travel from place to place to maintain battery systems

having dif

capacity plus a broad voltage range and outstanding

portability – a unique combination.

The TORKEL 860 is used for systems ranging from 12 to

480 V, and discharging can proceed at up to 110 A. If

higher curr

or extra load units (TXL), can be linked together.

Discharging can take place at constant current, constant

output, constant resistance or in accordance with a preselected load pr

ferent voltages. It featur

ent is desired, two or more TORKEL 860 units,

ofile.

es excellent discharging

■

Easily save results to a PC for analysis,

report generation and storage

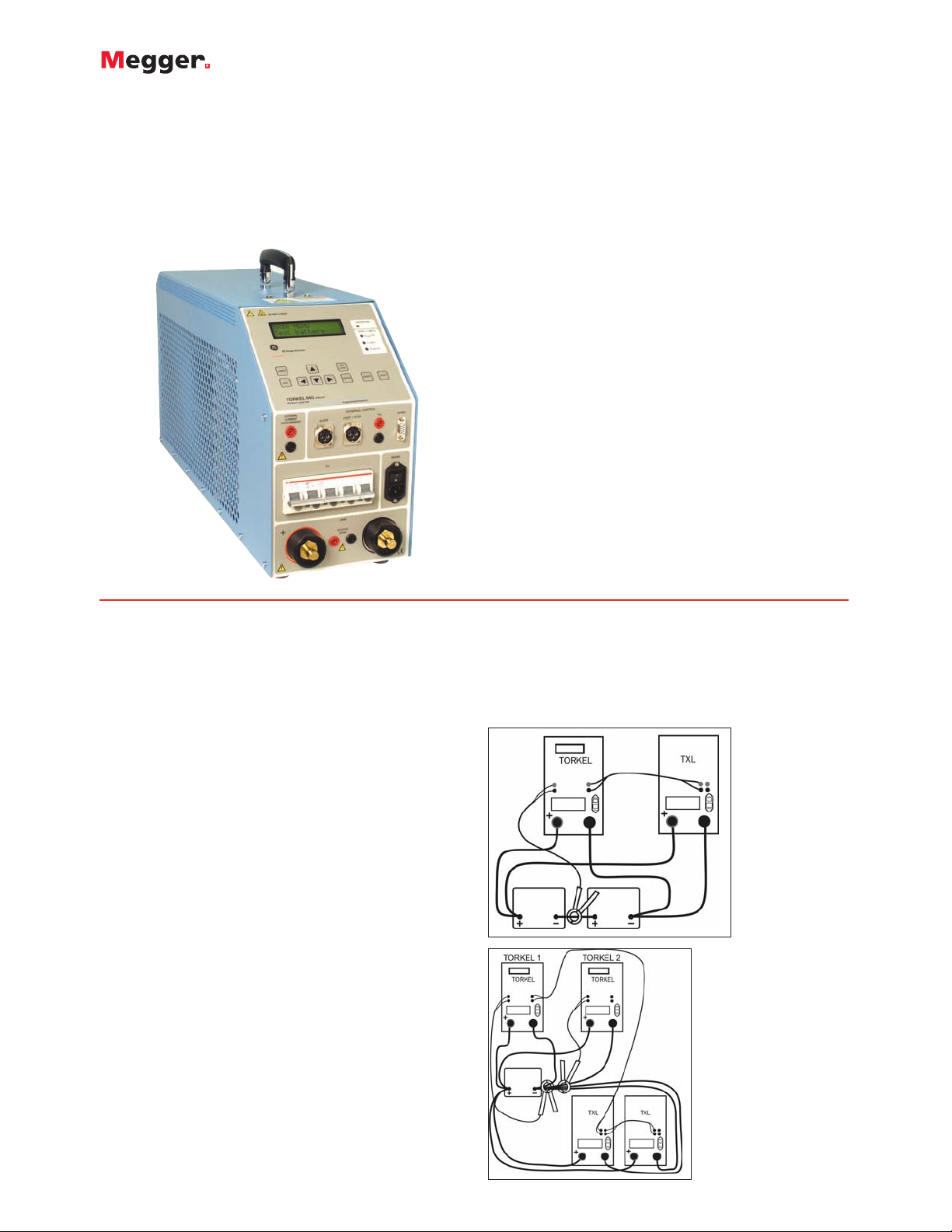

Application examples with TORKEL/TXL systems

TORKEL and TXL can be combined into systems to match

different battery capacities. Below are two examples. Other

combinations can be found in the section called

TORKEL/TXL System examples.

TORKEL and the

extra load TXL unit

APPLICATION

Batteries in power plants and transformer substations must

provide the equipment they serve with standby power in

the event of a power failure. Unfortunately, however, the

capacity of such batteries can dr

number of reasons before their calculated life expectancy

is reached. This is why it is so important to check batteries

at regular intervals, and the only reliable way of measuring

battery capacity is to conduct a dischar

op significantly for a

ge test.

Example of multiple TORKEL

and TXL arrangement

Page 2

FEATURES AND BENEFITS

■

atteries can be tested “in service”. TORKEL will adjust

B

to include the load current in the test parameters.

■

ser adjustable alarm and shutdown points to avoid

U

excessive discharge.

■

No loss of test data in the event of a power loss during

testing.

■

Easily expandable for larger battery banks using TXL

extra load units.

■

Can be used “stand alone” or with a PC running

TORKEL WIN Software.

SPECIFICATIONS

pecifications are valid at nominal input voltage and an ambient

S

temperature of +25° C, (77° F). Specifications are subject to

change without notice.

Environment

Application field

The instrument is intended for use in high-voltage substations and

industrial environments.

Temperature

Operating 0° C to +40° C (32° F to +104° F)

Storage & transport -40° C to +70° C (-40° F to +158° F)

Humidity 5% – 95% RH, non-condensing

CE-marking

Safety standards IEC 61010-1:2001 Incl. national dev. for US

and CAEN 61010-1:2001

EMC standards EN 61326: 1997+A1:1998+A2:2001

General

Power supply voltage 100 – 240 V AC, 50/60 Hz

Power

consumption (max) 150 W

Protection Thermal cut-outs, automatic overload

protection

Dimensions

Instrument 210 x 353 x 700 mm (8.3” x 13.9” x 27.6”)

ransport case 265 x 460 x 750 mm (10.4” x 18.1” x 29.5”)

T

eight

W

Display LCD

Available languages English, French, German, Spanish, Swedish

21.5 kg (47.4 lbs)38 kg (83.8 lbs) with

accessories and transport case.

Programma

TORKEL 840/860 Battery Load Units

easurement section

M

Current measurement

Display range 0.0 – 2999 A

Accuracy ±(0.5% of reading +0.2 A)

Resolution 0.1 A

Internal current measurement

Range 0 – 270 A

Input for clamp-on ammeter

Range 0 – 1 V

mV/A-ratio Software settable, 0.3 to 19.9 mV/A

Input impedance >1 MΩ

Voltage measurement

Display range 0.0 – 60 V

Accuracy ±(0.5% of reading +0.1 V)

Resolution 0.1 V

Display range 0.0 – 500 V

Accuracy ±(0.5% of reading +1 V)

Resolution 0.1 V

Time measurement

Accuracy ±0.1% of reading ±1 digit

Load section

Max. battery voltage 288 V DC (TORKEL 840)

480 V DC (TORKEL 860)

Max. current 110 A

Max. power 15 kW

Load patterns Constant current, constant power, constant

resistance, current or power profile

Current setting 0-110.0 A (2999.9 A)

Power setting 0-15.00 kW (299.99 kW)

Resistance setting 0.1-2999.8Ω

Battery voltage range, 4 ranges, selected automatically at

TORKEL 840 start of test

Battery voltage range, 5 ranges, selected automatically at

TORKEL 860 start of test

Stabilization ±(0.5% of reading +0.5 A)

(For internal

current measurement)

Battery Highest Resistor

voltage permissible element

Range 1

10 – 27.6 V

Range 2 10 – 55.2 V 110 A 0.275 Ω

Range 3 10 – 144 V 110 A 0.55 Ω

Range 4 10 – 288 V 55 A 3.3 Ω

2

Range 5

10 – 480 V 55 A (max 3.3 Ω

power 15 kW)

1) Maximum value for a system with mor

TORKEL 860

2)

1

1

current (Nominal values)

110 A 0.165 Ω

e than one load unit

Page 3

Programma

ORKEL 840/860 Battery Load Units

T

nputs, maximum values

I

External current 1 V DC, 300 V DC to ground. Current

measurement shunt should be connected to the negative

side of the battery

Start/Stop Momentary closure starts a test. Momentary

closure stops a test.

Delay until start 200 – 300 ms

Stop delay 100 – 200 ms

Battery 480 V DC, 500 V DC to ground

Voltage sense 480 V DC, 500 V DC to ground

Serial < 15 V

Alarm 250 V DC 0.28 A 28 V DC 8 A

250 V AC 8 A

Outputs, maximum values

Start/Stop 5 V, 6 mA

TXL Relay contact

Serial < 15 V

Alarm Relay contact

Discharging capacity examples

12 V battery (6 cells)

3

Final voltage Constant current Constant power

1.80 V/cell (10.8 V) 0 – 50.0 A 0 – 0.54 kW

1.75 V/cell (10.5 V) 0 – 49.0 A 0 – 0.51 kW

1.67 V/cell (10.0 V) 0 – 46.0 A 0 – 0.46 kW

24 V battery (12 cells)

3

1.80 V/cell (21.6 V) 0 – 110 A 0 – 2.37 kW

1.75 V/cell (21.0 V) 0 – 110 A 0 – 2.31 kW

1.60 V/cell (19.2 V) 0 – 100 A 0 – 1.92 kW

48 V battery (24 cells)

3

1.80 V/cell (43.2 V) 0 – 110 A 0 – 4.75 kW

1.75 V/cell (42.0 V) 0 – 110 A 0 – 4.62 kW

1.60 V/cell (38.4 V) 0 – 110 A 0 – 4.22 kW

110 V battery (54 cells)

3

1.80 V/cell (97.2 V) 0 – 110 A 0 – 10.7 kW

1.75 V/cell (94.5 V) 0 – 110 A 0 – 10.4 kW

1.60 V/cell (86.4 V) 0 – 110 A 0 – 9.5 kW

120 V battery (60 cells)

3

1.80 V/cell (108 V) 0 – 110 A 0 – 11.9 kW

1.75 V/cell (105 V) 0 – 110 A 0 – 11.5 kW

1.60 V/cell (96 V) 0 – 110 A 0 – 10.5 kW

220 V battery (108 cells)

3

1.80 V/cell (194 V) 0 – 55 A 0 – 10.7 kW

1.75 V/cell (189 V) 0 – 55 A 0 – 10.4 kW

1.60 V/cell (173 V)

240 V battery (120 cells)

0 – 51.0 A

3

0 – 8.82 kW

1.80 V/cell (216 V) 0 – 55 A 0 – 11.9 kW

1.75 V/cell (210 V) 0 – 55 A 0 – 11.5 kW

1.60 V/cell (192 V)

0 – 55 A

0 – 10.5 kW

UPS battery (180 cells)3(TORKEL 860)

1.70 V/cell (306 V)

0 – 38 A

0 – 15 kW

1.60 V/cell (288 V) 0 – 38 A 0 – 15 kW

UPS battery (204 cells)3(TORKEL 860)

1.80 V/cell (367 V)

0 – 34 A

0 – 15 kW

1.60 V/cell (326 V) 0 – 34 A 0 – 15 kW

3) 2.15 V per cell when test starts

nvironment

E

Application field The instrument is intended for use in high-

voltage substations and industrial

environments.

Temperature

Operating 0° C to +40° C (32° F to +104° F)

Storage & transport -40° C to +70° C (-40° F to +158° F)

Humidity 5% – 95% RH, non-condensing

CE-marking

Safety standards IEC 61010-1:2001 Incl. national dev. for US

and CAEN 61010-1:2001

MC standards EN 61326: 1997+A1:1998+A2:2001

E

General

Power supply voltage 100 – 240 V AC, 50/60 Hz

Power consumption 75 W (max)

Protection Thermal cut-outs, automatic overload

protection

Dimensions

Instrument 210 x 353 x 600 mm (8.3” x 13.9” x 23.6”)

Transport case 265 x 460 x 750 mm (10.4” x 18.1” x 29.5”)

eight 13 kg (28.7 lbs)21.4 kg (47.2 lbs) with

W

transport case

Cable sets

for TXL830/850 2 x 3 m (9.8 ft), 70 mm2, 270 A, with cable

lug. Max. 100 V. 5 kg (11 lbs)

for TXL870 2 x 3 m (9.8 ft), 25 mm2, 110 A, with cable

clamp/lug. Max. 480 V. 3 kg (6.6 lbs)

Load section

TXL830 TXL850 TXL870

Max. voltage (DC) 28 V 56 V 140 V/ 280 V

Max. current 300 A 300 A 112 A at 140 V

56 A at 280 V

Max. power 8.3 kW 16.4 kW 15.8 kW

Internal resistance, 3-position selector

Position 1 TXL830 TXL850 TXL870

Current 0.275 Ω 0.55 Ω 4.95 Ω

100 A at 27.6 V at 55.2 V –

(12 x 2.3 V) (24 x 2.3 V)

78.5 A at 21.6 V at 43.2 V –

(12 x 1.8 V) (24 x 1.8 V)

50.1 A – – at 248.4 V

(108 x 2.3 V)

39.2 A – – at 194.4 V

(108 x 1.8 V)

Position 2 TXL830 TXL850 TXL870

Curr

ent 0.138 Ω 0.275 Ω 2.48 Ω

200 A at 27.6 V at 55.2 V –

(24 x 2.3 V)

156 A

at 21.6 V

43.2 V–

–

(24 x 1.8 V)

Position 3 TXL830 TXL850 TXL870

Curr

300 A

ent

Ω

0.092

at 27.6 V

Ω

0.184

at 55.2 V

1.24 Ω

–

(24 x 2.3 V)

235 A at 21.6 V 43.2 A –

(24 x 1.8 V)

100 A – – at 124.2 V

(54 x 2.3 V)

78.4 A – – at 97.2 V

(54 x 1.8 V)

Page 4

ORKEL/TXL Systems – Examples

T

TORKEL 820 + TXL830, 12 V battery (6 cells)

1

Max. constant current Number of Number of

(A) TORKEL-units TXL-units

234 1 1

571 1 4

918 2 6

TORKEL 820 + TXL830, 24 V battery (12 cells)

1

495 1 1

1170 1 4

1890 2 6

TORKEL 820 + TXL850, 48 V battery (24 cells)

1

499 1 1

1189 1 4

1918 2 6

TORKEL 840/860 + TXL830, 24 V battery (12 cells)

1

263 1 1

670

22

1005 3 3

TORKEL 840/860 + TXL850, 48 V battery (24 cells)

264

11

1

909 2 3

TORKEL 840/860 + TXL870, 110 V battery (54 cells)

188 1 1

532 2 4

845 28

TORKEL 840/860 + TXL870, 120 V battery (60 cells)

194 1 1

557 2 4

895 2 8

TORKEL 840/860 + TXL870, 220 V battery (108 cells)

94 1 1

266 2 4

423 2 8

1) Discharge from 2.15 V to 1.8 V per cell

2) Discharge from 2.15 to 1.75 V per cell

Programma

ORKEL 840/860 Battery Load Units

T

BATTERY TESTING ACCESSORIES

TORKEL Win

PC software

•Shows the complete voltage curve

• Last recorded time, voltage, current and discharged

capacity

• Scroll-window for all recorded values

Remote control of TORKEL

•

• Report functions

1

2

1

TORKEL Win showing total voltage curve

TXL units

• Extra loads

• These resistive extra loads do not perform any

regulating functions.

• They are designed for use together with TORKEL Battery

Load Units.

• Their purpose is to provide higher load currents for use

in constant current or constant power tests. Together,

TORKEL and the TXL Extra Loads form a system that

can discharge batteries with currents of up to several kA.

TXL Extra Loads are connected directly to the battery,

and TORKEL measures the total current using a clampon ammeter.

• TXL Extra Loads are shut down automatically when

TORKEL is stopped.

Cable Set GA-00550

TXL870

Page 5

Programma

TORKEL 840/860 Battery Load Units

ORDERING INFORMATION

Item (Qty) Cat. No.

egister

BS-49094

BS-59095

ed trademark

TORKEL840 complete with cable set GA-00550 and transport case GD-00054

TORKEL860 complete with cable set GA-00550 and transport case GD-00054 BS-49096

TXL850 is intended for 48 V systems. Complete with cable set GA-00554 and transport case GD-00054.

A DC clamp-on ammeter must be used to enable TORKEL 850 to measure the total current.

TXL870 is intended primarily for 125 and 240 V battery systems.

Complete with cable set GA-00550 and transport case GD-00054.

A DC clamp-on ammeter must be used to enable TORKEL 870 to measure the total current. BS-59097

Cable sets

Cable set for TXL830 and TXL850 2 x 3 m, 70 mm2, with cable lug. Max 100 V 270 A. W

eight: 5.0 kg (11 lbs) GA-00554

Extension cable set, 110 A 2 x 3 m, 25 mm2. Max 480 V. Weight: 3.0 kg (6.6 lbs) GA-00552

Sensing lead set for measuring voltage at battery terminals. 2 x 5 m (16.4 ft) GA-00210

DC clamp-on ammeter, 200 A to measure current in circuit outside TORKEL XA-12992

DC clamp-on ammeter, 1000 A to measure current in circuit outside TORKEL XA-12990

Optional accessories

TORKEL Win BS-8208X

See battery testing Accessories

UK

Archcliffe Road, Dover

CT17 9EN England

T +44 (0) 1 304 502101

F +44 (0) 1 304 207342

UKsales@megger.com

UNITED STATES

4271 Bronze Way

Dallas, TX 75237-1019 USA

T 1 800 723 2861 (USA only)

T +1 214 333 3201

F +1 214 331 7399

USsales@megger.com

OTHER TECHNICAL SALES OFFICES

Täby SWEDEN, Norristown USA,

Sydney AUSTRALIA, Toronto CANADA,

Trappes FRANCE, Kingdom of BAHRAIN,

Mumbai INDIA, Johannesburg SOUTH

AFRICA, and Chonburi THAILAND

Registered to ISO 9001:2000 and

ISO 14001:2004

Cert. no. GBG0005937

TORKEL840_DS_en_V01

www.megger.com

Megger is a r

Loading...

Loading...