Page 1

AN EXTRA MEASURE OF ACCURACY

All W&T Portable Pneumatic

Calibrators are subjected to rigorous and extensive testing. Each

has to perform at bet

ter than the

rated accurac

y to be accepted.

It’s accurate enough to double

as a shop standard.

Calibration traceable to NBS

Calibration is with primary standards

which are directly traceable to the German National

Bureau of Standards (PTB).

DESIGN AND CONSTRUCTION

The Series 65-120 Portable Pneumatic Calibrator is a

pressure-vacuum test stand wholly contained in a

carrying case. The front panel accommodates the

precision pressure gauge, all pressure connections,

two air-regulator controls, and a selector valve. With

the selector valve, three different test pressures can

be applied individually to the gauge. A fourth selector

setting vents the gauge to atmosphere.

The precision pressure gauge has a Ni-Span C, capsule-type pressure element which gives excellent

temperature stability and speed of response. An

almost frictionless mechanical linkage amplifies

capsule movement and transmits it to the pointer.

Although highly sensitive and accurate, the mechanism is built to withstand the handling normally associated with on-site calibration of pneumatic instrumentation.

A filter on the air supply keeps oil and moisture out.

Two regulators apply known pressures to the devices

under test. The connection block has

1

/8-inch femalepipe-threaded connections. Small gauges can be

threaded directly into the block; or as with larger

instruments, connected by flexible tubing.

The standard scale contains two sets of calibrations:

–100 to 0 to 850 inches of water and –3.6 to 0 to

30.6 psi.

Other ranges and units of calibration (from min.

0–4,5 psi

to max. 0–100 psi) are available.

The Series 65-120 Pneumatic Calibrator provides high-degree accuracy

for on-site testing and calibration service. This versatile portable test

stand combines precision measurement and durable construction in a

compact unit that is capable of simulating, applying, holding, regulating

and measuring both pressures and vacuum. The dial, all pressure connections, and the controls are panel-mounted for easy access.

Technical Information

FEATURES:

• Accuracy 0.066% FS

• Scale length 45 inches

(1140 mm)

• Clear readout

• Versatile capabilities

• Calibration traceable to NBS

• Easy to use

• DKD calibration on request

• Dual scale calibration for

standard range

PUBLICATION

TI 650.504DE

1

Portable Pneumatic

Calibrator

Series 65-120

Wallace & Tiernan GmbH

Postfach 1563, D-89305 Günzburg, GERMANY

Street address: Auf der Weide 10,

D-89312 Günzburg, GERMANY

Tel.: (49) 8221-9040, Fax: (49) 8221-904203

a U.S. Filter Company

DIN EN ISO 9001 certificated

DKD-Calibrations

(German Calibration Service)

NEW ACCURACY

AND

EXTENTED RANGES

WITH SERIES 1500

HIGH PERFORMANCE

GAUGE LINE

Page 2

Features

2

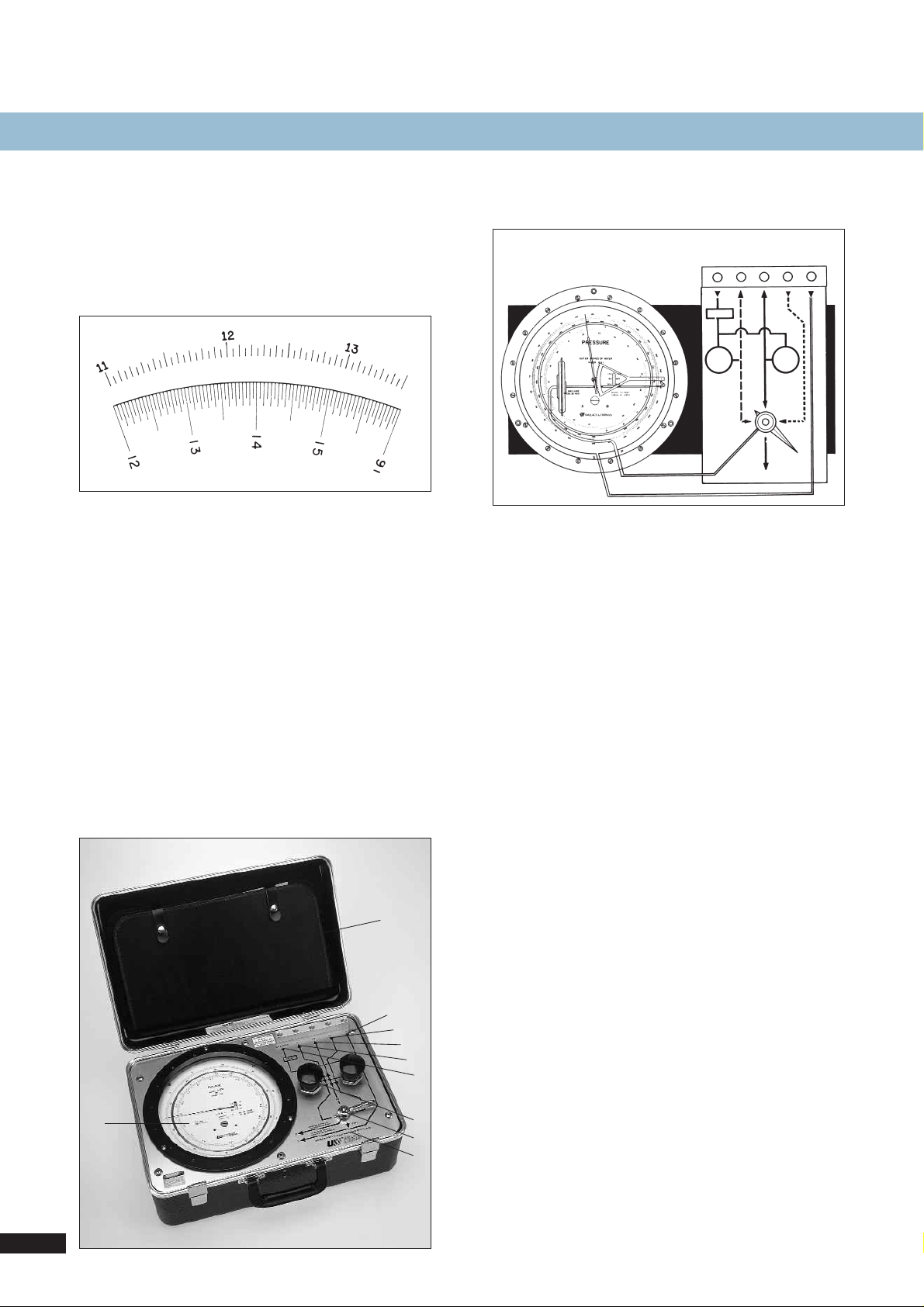

Clear, Accurate Readout

Sharply defined graduations, a 45-inch (1140 mm) scale length

over two pointer revolutions, and a knife-edge pointer facilitate

precise readouts. All scale calibrations are individually plotted

and hand marked to produce a dial custom fitted to the pressure element and mechanism of that gauge.

Connections for different Pressure readouts

For gauge pressure:

test pressure is applied to the capsule through the appropriate

P connection; the case is open to atmosphere through S.

For differential pressure:

high test pressure is applied to the capsule through the appropriate P connection. Low test pressure is applied to the case

through S.

For absolute pressure:

test pressure is applied to the capsule through the appropriate

P connection and the case is continuously subjected to full

vacuum through S.

For vacuum:

the capsule is open to atmosphere through connection P; the

case is connected to test vacuum at S.

For positive and negative pressures:

test pressure is applied to the capsule through the appropriate

P connection and the case is open to atmosphere through S.

Engineered for perfomance

The gauge housing is heavy cast aluminum with a tempered

glass dial cover. A built-in pressure-relief valve has a dumping

capacity which protects the case against overpressures to 10

times the maximum pressure rating. A separate pressure-relief

valve protects the capsule mechanism. The gauge is mounted

inside the carrying case on rubber-padded shock mounts. The

carrying case is constructed of strong but lightweight molded

ABS that flexes to absorb shock from impact.

Compact, built for on-site service

The W&T Portable Pneumatic Calibrator weights only 20 lb

(9 kg) and is only slightly larger than a attache case. The easy

portability, simple set-up, and the versatile capabilities of this

unit extends its usefulness for service in the field. Its portability

saves the time and expense of shop calibration.

W&T (top) and competitive scales of the same range.

Diff

Input

Input

to be

Read

Regulated

Output 2

Regulated

Output 1

Air

supply

Filter

Reg. Reg

.

P1P2P3S

P

1

P

2

P

3

Vent

1

2

3

4

5

6

7

8

9

10

1 Compartment for accessories

2 Differential Input

3 Input to be read

4 Regulated output no. 2

5 Regulated output no. 1

6 Air supply connection

7 Regulators

8 Selector Valve

9 Schematic flow diagram

10 Shock-mounted gauge

Page 3

The W&T Portable Calibrator eliminates the need for

special arrangements or external controls. The carrying case has a compartment for adapters, tubing, and

other accessories; the case cover is easily removed.

Complete information on the use of the calibrator is

given in an instruction book. A schematic flow diagram on the panel shows the calibrator’s connections

at a glance.

USES OF THE W&T PORTABLE

CALIBRATOR

Simplest use of the calibrator is to carry it to an onstream gauge, indicator, or recorder. Calibration of

such instruments can be quickly checked by making

simple connections without taking the instrument out

of service. Also, the calibrator can simulate the set

and process-variable signals to a pneumatic control

device and check its output. These three pressures

can be read out and checked in any order and in

rapid sequence. By evacuating the calibrator, absolute pressure measurements can be made.

PUBLICATION

TI 650.504DE

Calibrator Uses

3

Calibration of a pressure transmitter

Using a common supply pressure for both the calibrator and the transmitter, transmitter input is

regulated to the desired value and held. Transmitter output is accurately indicated by the calibrator.

Calibration of a gauge, indicator or recorder

Test pressure is applied to the instrument and to

the calibrator simultaneously. Instrument and calibrator readings are compared for an accuracy

check.

Calibration of a differential pressure transmitter

The transmitter’s supply and high-input pressures

are regulated to the desired values and held.

Transmitter output is indicated accurately by the

calibrator.

Calibration of a typical stacked diaphragm

pneumatic controller

Controller supply pressure is regulated to the desired value and held. Controller set and measured

inputs and output A are regulated to the desired

value and held. The calibrator then reads out controller output accurately. P3equals P2for any value

of P2if the controller is in calibration.

Calibration of a ratio relay

The ratio relay’s input and reference pressures are

regulated to the desired values and held. Relay

output is indicated accurately by the calibrator.

Pressure

Transmitter

3-15 psi output

Air supply

P1P

3

Input

Regulator

Supply

Regulator

500-psi gauge

supply

(May also be connected to P2)

Air supply

P

1

Low pressure input (atmosphere for test)

Differential

pressure

transmitter

supply

Air supply

High pressure input

3-15 psi output

P1P2P

3

Supply

Set

Input

Output A

Output B

Measured

Input

Air supply P1P2P

3

Output

Reference pressure if required

Air supply P

1P2P3

Ratio replay

Supply

Input

Page 4

Technical Data

PUBLICATION

TI 650.504DE

Ordering Numbers

The standard scale contains two sets of calibrations (dual scale) in the pressure units inches of water and psi. Dial

markings in the negative range are in red colour and in the positive range in black colour.

Range and Calibration Ordering No. Graduation

Outer scale: –100 to 0 to 850 65-120 000 1.0 inch water

inches of water (20 C)

Inner scale: –3.6 to 0 to 30.6 psi 0.05 psi

Other available ranges

Range and Calibration Ordering No. Graduation

0 to 4.5 psi (0 to 300 mbar) 65-120 005 0.005 psi (0.5 mbar)

0 to 10 psi (0 to 700 mbar) 65-120 010 0.01 psi (1 mbar)

0 to 15.5 psi (0 to 1 bar) 65-120 015 0.02 psi (0.001 bar)

0 to 20 psi (0 to 1.4 bar) 65-120 020 0.02 psi (0.002 bar)

0 to 30 psi (0 to 2 bar) 65-120 030 0.05 psi (0.002 bar)

0 to 45 psi (0 to 3 bar) 65-120 045 0.05 psi (0.005 bar)

0 to 60 psi (0 to 4 bar) 65-120 060 0.1 psi (0.005 bar)

0 to 100 psi (0 to 7 bar) 65-120 100 0.1 psi (0.01 bar)

Other units of calibration are available at no extra cost. Two sets of calibrations (dual scales) are available at extra

cost.

4

Accuracy

0.066% of full scale

Repeatability

0.03% of full scale

Sensitivity

0.01% of full scale

Hysteresis

0.1% of full scale

Readability

0.02% of full scale

Temperature effect

Maximum is 0.1% of full scale per 10 C change

from 23 C

Scale length

45 inches (1140 mm) through 2 pointer revolutions

Dial diameter

8

1

/2inches (215 mm)

Capsule system volume

6.9 cc with pointer at zero; 8.6 cc, at full scale

Case volume

3070 cc

Case pressure

35 psi (2,5 bar) maximum

Overpressure protection

A pressure relief valve protects the mechanism

(capsule); pressure up to 90 psi will not damage the

mechanism nor affect accuracy. A built-in relief valve

and a flow restrictor protect the case from pressures

up to 10 times the case rating of 35 psig. This valve

is an emergency-protective device only.

Wallace & Tiernan GmbH

Postfach 1563, D-89305 Günzburg, GERMANY

Street address: Auf der Weide 10,

D-89312 Günzburg, GERMANY

Tel.: (49) 8221-9040, Fax: (49) 8221-904203

a U.S. Filter Company

Due to continual product development and improvement, certain specifications

may change without prior announcement.

12/98

Maximum case leak rate

Will not exceed 1.03 x 10–7std cc/sec or 0.018 psi/hr

Materials exposed to measured gas

Capsule system: Ni-Span C; soft solder; brass;

303 stainless steel; silver solder.

Case system: Ni-Span C; brass; phosphor bronze,

beryllium copper, magnesium, aluminum, nylon,

303 stainless steel; Elgiloy; soft solder, silver solder,

Hypalon.

Inlet manifold to pressure gauge; aluminum; brass;

polyethylene; copper; steel; glass wool; carbon;

Buna N.

Gauge case

Anodized aluminum with tempered-glass dial cover

Carrying case

ABS plastic 17

1

/2in. x 12 in. x 71/2in.

(445 x 305 x 190 mm)

Accessories

6 adapters for 1/8” pipe thread to 1/4” plastic tubing,

20 ft of 1/4” OD plastic tubing, instruction book,

sheet with summary of important instructions

Shipping weight

approx. 26 lb (12 kg); approx. 20 lb (9 kg) net

Note: Calibrator for use with non-corrosive gases.

It should not be used with liquids

Loading...

Loading...