Page 1

Form Measurement

Portable Surface Roughness Tester

SURFTEST SJ-410 Series

Bulletin No. 2080

Portable surface roughness tester evolution

Rich choice of options provide easier, smoother and more accurate

measurements

Page 2

Portable surface roughness tester evolves!

The large touch-screen, color-graphic LCD ensures both intuitive control and advanced operability

Applicable standardsEnhanced power for making measurements on site

Color-graphic LCD

The color-graphic LCD with excellent visibility

displays calculated results and assessed

profiles even clearer. This is really useful for

checking results without printing them out.

Backlight provided

A backlight improves usability in dim testing

environments.

Touch screen for easier operations

The screen display can be switched between icon display and text display.

Successfully combining operability with utility and usability.

Icon display

Text display

Easy to use and highly functional

This portable surface roughness tester is equipped with analysis

functionality rivaling that of benchtop surface roughness testers.

Complies with many industry standards

The Surftest SJ-410 complies with the

following standards: JIS (JIS-B0601-2001,

JIS-B0601-1994, JIS B0601-1982), VDA, ISO1997, and ANSI.

Data compensation

Simple contour analysis function

Multilingual support

The display interface supports 16 languages.

High accuracy measuring

A wide range, high-resolution detector

Measuring range/ resolution

800µm

/0.01µm

80µm /0.001µm

8µm /0.0001µm

High straightness

drive unit

Straightness/ traverse length

0.3µm/25mm (SJ-411)

0.5µm/50mm (SJ-412)

2

SJ-412

SJ-411

Page 3

Interfaces Data storage

S

ur

f

test SJ-

4

1

0

A variety of interfaces supplied as standard

The external device interfaces that come as standard include USB, RS232C, SPC output and footswitch I/F.

Memory card (optional) is supported

The measurement conditions and data can be stored in a memory card

(optional) and recalled as required. This enables batch analysis and

printout of data after on-site measurement.

•

Measurement condition

Internal memory: 10 sets

Memory card: 500 sets

•Measurement result

Memory card: 1000 sets

Password protection

Access to functions can be restricted by a password

A pre-registered password can limit use of measurement conditions

and other settings to the tester’s administrator.

→

Key-sheet buttons

A sturdy key-sheet-button panel with superior durability in any environment is provided. For repeat measurement of the same work,

simply pressing the start switch can complete measurement,

analysis and printout.

Printer

High-speed printer prints out measurement results on site

A high-quality, high-speed thermal printer prints out measurement results.

It can also print a BAC curve or an ADC curve as well as calculated

results and assessed profiles. These results and profiles are printed out

in landscape format, just as they appear on the color-graphic LCD.

Carrying case

The unit is easily transported in a dedicated carrying case

which includes holders for the accessories as well as the

tester itself. (Standard accessory.)

3

Page 4

Enhanced measuring functions

Traverse direction

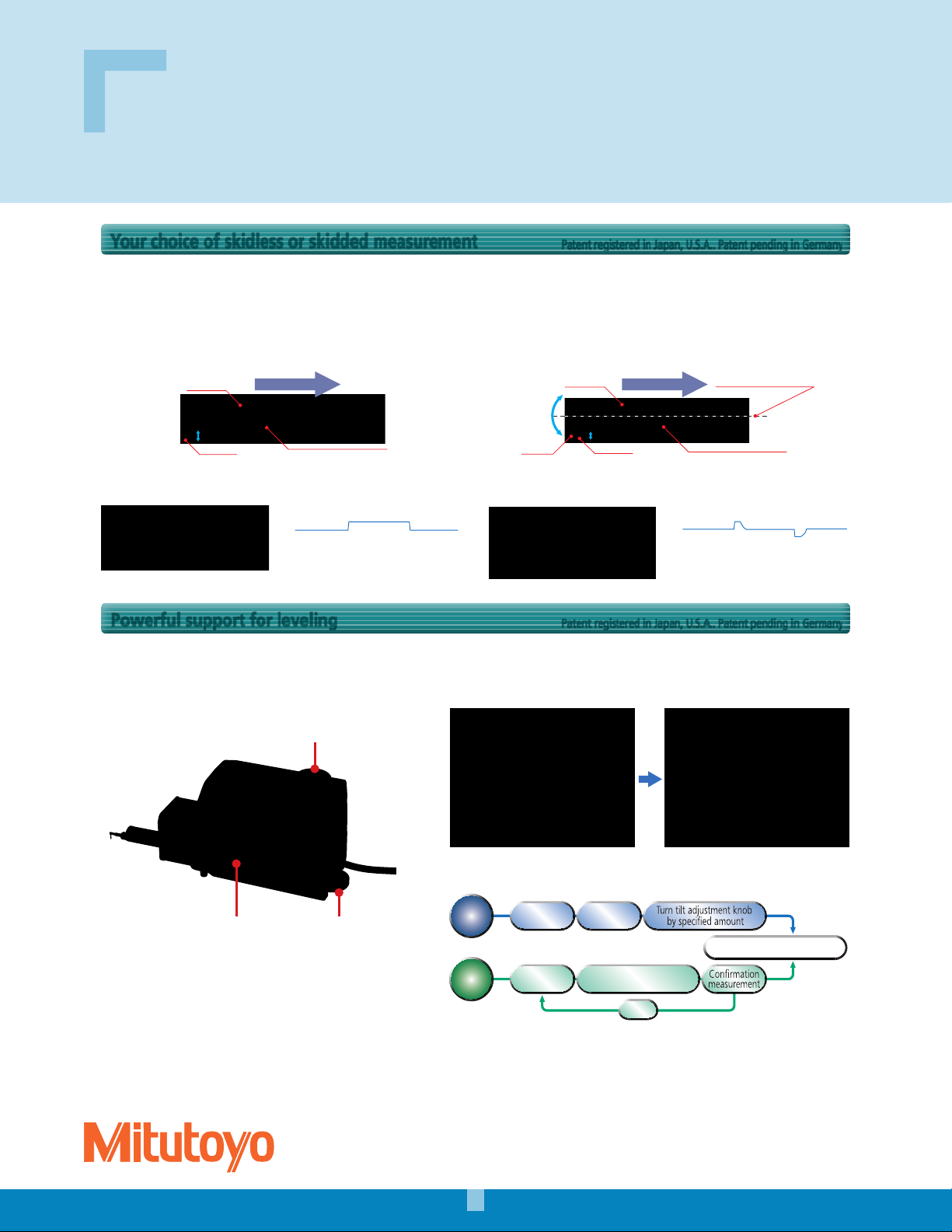

Your choice of skidless or skidded measurement

Skidless measurement

•

Skidless measurement is where surface features are measured relative

to the drive unit reference surface. This measures waviness and finely

stepped features accurately, in addition to surface roughnness, but

range is limited to the stylus travel available. The SJ-410 series supports

a variety of surface feature measurements simply by replacing the

stylus.

Detector

Stylus

Traverse direction

Fulcrum point of Stylus

Measuring example of stepped

features: Skidless

Powerful support for leveling

Skidded measurement

•

In skidded measurements, surface features are measured with reference

to a skid following close behind the stylus. This cannot measure

waviness and stepped features exactly but the range of movement

within which measurement can be made is greater because the skid

tracks the workpiece surface contour.

Measuring example of stepped

features: Skidded

Patent registered in Japan, U.S.A.. Patent pending in Germany

Fulcrum point of Skid

Fulcrum point of Stylus

Skid

Detector

Traverse direction

Stylus

Measured profileMeasured profile

Patent registered in Japan, U.S.A.. Patent pending in Germany

The height/tilt adjustment unit comes as standard for leveling the drive unit prior to making skidless measurements and, supported by guidance from

the unique D.A.T. function, makes it easy to achieve highly accurate alignment.

Height/tilt adjustment unit (Standard accessory)

•

Height adjustment knob

Preliminary measurement Amount of tilt adjustment

With

With

DAT

Tilt adjustment knobHeight/tilt adjustment unit

DAT

Preliminary

measurement

DAT screen

(adjustmentamount)

Final measurement

Without

Without

DAT

DAT

When the SJ-410 Series detector is mounted on the manual column stand*1 for measurement, it can be combined with any of the optional products for easier

leveling: leveling table*

*1: For details about optional products, see P6-7.

1

, 3-axis alignment table*1 or tilt adjustment unit*1.

Preliminary

measurement

Intuitive adjustment

using the tilt adjustment knob

Repeat

OK

NG

4

Page 5

More measuring functions than expected from a compact tester

Example: surface roughness measuring

Example: surface roughness measuring

The run-up distance can

Usually, a spherical or cylindrical surface (R-surface) cannot be evaluated, but, by removing

the radius with a filter, R-surface data is processed as if taken from a flat surface.

R-Surface

R-Surface

compensation

compensation

Recalculating

Previously measured data can be recalculated for use in other

evaluations by changing the current standard, assessed profile and

roughness parameters.

GO/NG judgement function

An “OK/NG” judgment symbol is displayed when limits are set for

the roughness parameter. In case of “NG,” the calculated result

is highlighted. The calculated result can also be printed out.

The “OK” symbol means the measurement

is within the limits set; “NG” means it is not,

in which case an arrow points to either the

upper or lower limit in the printout.

Narrow space measuring function

Surface roughness measurement requires a run-up distance before

starting the measurement (or retrieving data). When the SJ-410

Series measures, its run-up distance is normally set to 0.5mm. This

distance, however, can be shortened to 0.15mm using the narrow

part measurement function (starting from the origin point of the drive

unit). The function extends the possibility of measurement of narrow

locations such as grooves in piston ring / O-ring mounts.

Narrow space measuring Typical applications

•

be shortened to 0.15mm

by measuring from the

origin point.

Run up for narrow parts

: 0.15mm

Normal run up: 0.5mm

of piston-ring groove

0.5

1.8

0.1

0.5

2.5

3.5

Evaluation length

λ

1 sampling length

Overruns surface

using 0.5mm run-up

c=2.5mm

Patent pending in Japan

of mounting groove for O-ring

ø1.2

Workpiece

Stylus

1.3

2.5

Run-up of 0.5mm is not

enough for performing

the measurement

Evaluation length

λ

c=0.8mm

1 sampling length

Assessing a single measurement result under

two different evaluation conditions

A single measurement enables simultaneous analysis under two

different evaluation conditions. A single measurement allows calculation

of parameters and analysis of assessed profiles without the need for

recalculation after saving data, contributing to higher work efficiency.

Arbitrary sampling length setting

This function allows a sampling length to be arbitrarily set in 0.01mm

increments (SJ-411: 0.1mm to 25mm, SJ-412: 0.1mm to 50mm).

It also allows the SJ-410 series to make both narrow and wide range

measurements.

Simple contour analysis function

Point group data collected for surface roughness evaluation is used

to perform simplified contour analysis (step, step height, area and

coordinate variation). It assesses minute forms that cannot be assessed

by a contour measurer.

Step

Step volume

Real sampling

This function samples stylus displacement for a specified time

without engaging detector traverse, which enables use as a

simplified vibration meter or displacement gage incorporated in

another system.

Dimensions

Coordinate difference

5

Page 6

Optional Accessories

Simple column stand

Can be adjusted to match the height of the item to be measured.

No.178-039

Vertical adjustment range: 250mm

Dimensions: 400×250×578mm

Mass: 20kg

Dimensions

Unit: mm

578

8.5

7

11

15

60

40

400

12

250

T-groove dimensions

120

Options for simple column stand

Three new optional products are available to be attached to the manual column stand (No.178-039). You can choose the unit that suits your application.

Or, you can also use the three products in any combination. Using the optional units makes SJ-411/412 more convenient and easier to use to ensure

accurate measurements.

Auto-set unit (178-010)*

•

This unit enables the vertical (Z axis) direction to be positioned

automatically (auto-set function).

A single button operation completes a series of operations from

measurement, saving and auto-return (saving and auto-return can be

switched on and off by operating the drive unit).

10mm

X-axis adjustment unit (178-020)*

•

This unit helps fine-tune the horizontal (X axis) direction.

Complete set of optional

units for the manual

column stand

Tilting adjustment unit (178-030)*

•

This unit is used for aligning the workpiece surface with the detector

reference plane. It supports the DAT function to make the leveling of

workpiece surfaces easier.

Preliminary measurement

1.5°

±

Tilt adjustment

Auto-set unit

Tilting adjustment unit

12.5mm 12.5mm

X-axis adjustment unit

* Cannot be used when the tester’s main

unit is an older model (SJ-401/402).

6

Page 7

3-axis Adjustment Table: 178-047

7

43

13

Patent registered in Japan, U.S.A.. Patent pending in Germany

This table helps make the alignment adjustments required when measuring cylindrical surfaces. The corrections for the pitch angle and the swivel angle

are determined from a preliminary measurement and the Digimatic micrometers are adjusted accordingly. A flat-surfaced workpiece can also be leveled

with this table.

Aligned

Traverse direction

End point

Axial line

Start point

Recorded profiles

Not aligned

Traverse direction

End point

Axial line

Start point

DAT Function for the optional leveling table

Patent registered in Japan, U.S.A.. Patent pending in Germany

The levelling table can be used to align the surface to be tested with the detector reference plane. The operator is guided through the procedure by

screen prompts.

No.178-048

Inclination adjustment angle: ±1.5°

Table dimensions: 130×100mm

Maximum load: 15kg

Digimatic micrometer

head

Leveling table (DAT)

(Option)

DAT screen guides the

user when leveling

Amount of micrometer

head adjustment required

XY leveling tables Precision vise

The tester includes X- and Y-axes micrometer

•Movement is in X- and Y-axes only.

heads. Thi s makes axis alignment much

easier because the tilt adjustment center is

the same as the rotation center of the table.

(Code No.178-042-1/178-043-1)

178-042-1 178-049

Order No.

Table dimensions 130×100mm

Maximum load 15kg

Inclination adjustment angle ±1.5° —

Swiveling angle ±3° —

X/Y-axis travel range ±12.5mm ±12.5mm ±12.5mm

Resolution 0.001mm 0.01mm 0.001mm

Dimensions (WxDxH) 262×233×83mm 220×189×83mm 262×233×55mm

Mass 6.3kg 6kg 5kg

178-042-1(mm)

178-052-1(inch)

*with digital heads

178-043-1(mm)

178-053-1(inch)

*with analog heads

178-049(mm)

178-058(inch/mm)

*with digital heads

•T-groove dimensions

Unit: mm

•Fits on the stand.

Application

Order No. 178-019

Clamping method Sliding jaws

Jaw opening 36mm

Jaw width 44mm

Jaw depth 16mm

Height 38mm

Cylinder attachment Reference step specimen

This block can be positioned on top of

cylindrical objects to perform measurements.

No.12AAB358

Diameter: ø15~60mm

Configuration:

•Cylindrical measurement block

•Auxiliary block

•Clamp

*Drive unit not included.

Used to calibrate detector sensitivity.

No.178-611

Step nominal values: 2µm/10µm

7

Page 8

Optional Accessories: Detectors / Styli

Detectors Unit: mm Extension rods

10

11.5

14

φ

3.6

1.3

7

φ

4

3.1

Skidless nosepiece

(

12AAB355

60

)

Order No. Measuring force

178-396-2 0.75mN ISO-1997 and JIS-2001 compliant detectors

178-397-2 4mN

Detectors that comply with previous standards,

for general use, etc.

Styli Unit: mm

Standard stylus

Color

coding*

7.6

3

0.9 37.7

5.2

Detail-A

For small hole

0.6

0.4

Detail-A

(

S=5/1

φ

°

90

)

1.6

0.6

0.6

1.6

3.4

A

For extra-small hole

0.4

1.2

φ

0.3

1.2

A

Detail-A

(

90

S=5/1

°

)

For ultra-small hole

0.4

0.8

φ

0.3

°

Detail-A

(S=

90

)

5/1

0.8

A

For deep hole (double-length and triple-length) *

0.9

Color

3

coding*

5.2

7.6

Detail-A

2X stylus

12AAC740 (2μm) *

12AAB413 (5μm)

12AAB425 (10μm)

( ): Tip radius

*1: Tip angle 60°

*2: For downward-facing measurement only.

94.7

87.7

A

φ

1.2

°

90

44.7

A

2.4

φ

1.2

φ

°

90

44.4

37.7

15

8.9

0.6

φ

2.4

φ

2.4

1.2

Color

coding*

2.4

φ

Color

coding*

3

3

φ

44.2

37.7

2.5

44.2

37.7

8.9

0.6

φ

2.4

φ

1

2.4

φ

2.5

Color

3

coding*

Color

coding*

Detail-A

*3 :

*4 : Use d fo r cal ib ratio n, a stan dard st ep ga ug e (No .17 8-611, o pti on) is als o req uired

14

14

φ

8

φ

Detector

• 12AAG202 Extension rod 50mm

• 12AAG203

xtension rod 100mm

E

* No more than one extension rod can be connected.

12AAE882 (1μm) *

12AAE924 (1μm)

12AAC731 (2μm) *

12AAB403 (5μm)

12AAB415 (10μm)

12AAE883 (250μm) *

( ): Tip radius

12AAC732 (2μm) *

12AAB404 (5μm)

12AAB416 (10μm)

( ): Tip radius

12AAC733 (2μm) *

12AAB405 (5μm)

12AAB417 (10μm)

( ): Tip radius

12AAC734 (2μm) *

12AAB406 (5μm)

12AAB418 (10μm)

( ): Tip radius

1

1

4

1

Double-length for deep hole *

0.9

3

1.8

2.4

0.6

φ

For small hole / Double-length for deep hole *

0.6

0.6

φ

0.6

30

Detail-A

1.6

1

For small hole *2 *

φ

4

1.2

A

3.4

41

Ball φ1.6

1

For ultra-small hole *

Ball φ0.5

0.3

φ

Detail-A

1.2

φ

4

8.5

3.1

A

2

12AAE898 (2μm) *

12AAE914 (5μm)

( ): Tip radius

2

12AAE892 (2μm) *

12AAE908 (5μm)

( ): Tip radius

12AAE884 (φ1.6mm)

( ): Tip radius

87.7

87.7

87.7

94.7

94.4

2.4

93.8

2.4

φ

2.4

φ

12AAJ662 (φ0.5mm)

2.4

φ

( ): Tip radius

37.7

43.8

2

0.9

3

7.6

5.2

137.7

A

φ

1.2

°

90

3X stylus

12AAC741 (2μm) *

12AAB414 (5μm)

144.7

For small slotted hole *

0.6

2.4

φ

1

1.6

φ

0.6

0.4

Detail-A

2

94.4

0.6

87.7

45

0.3

φ

A

1.2

φ

2.4

φ

12AAE938 (2μm) *

12AAE940 (5μm)

( ): Tip radius

12AAB426 (10μm)

( ): Tip radius

Tip radius 1μm 2μm 5μm 10μm 250μm

Color coding White Black No color Yellow No notch or color

1

1

1

8

Page 9

φ

1.2

Styli Unit: mm

For deep groove (10mm)

0.9

13

14.2

3

°

90

Detail-A

Color

coding*

For deep groove *2 (20mm)

23

24.2

3

φ1.2

°

90

Detail-A

Color

coding*

For deep groove *2 (30mm)

φ

2.4

33

31.8

5.2

3

Detail-A

Color

coding*

90

For gear tooth

Color

3

coding*

Detail-A

6.4

7.6

A

φ

60

1.2

°

44.7

37.7

A

2.4

φ

φ

1.2

44.7

37.7

12AAC735 (2μm) *

12AAB409 (5μm)

12AAB421 (10μm)

( ): Tip radius

12AAC736 (2μm) *

12AAB408 (5μm)

12AAB420 (10μm)

φ2.4

A

( ): Tip radius

12AAC737 (2μm) *

37.7

2.4

45.2

φ

A

φ

1.2

°

43.8

37.7

60

°

2.4

φ

12AAB407 (5μm)

12AAB419 (10μm)

( ): Tip radius

12AAB339 (2μm) *

12AAB410 (5μm)

12AAB422 (10μm)

( ): Tip radius

For deep groove *2 (20mm)

1

95.2

87.7

φ

5.2

23

21.8

For deep groove *

1

(40mm) 12AAE895 (2μm) *

For deep groove (30mm) / Double-length for deep hole *

1

36.5

35

For gear tooth / Double-length for deep hole *

1

36.5

35

2.4

φ

1.2

2

45.2

37.7

2.4

φ

43.8

42.6

φ

5.2

2.4

93.8

87.7

3

φ

5.2

φ

1.2

93.8

87.7

60

°

3

6.77

φ

12AAE893 (2μm) *

12AAE909 (5μm)

( ): Tip radius

12AAE911 (5μm)

( ): Tip radius

2

12AAE894 (2μm) *

12AAE910 (5μm)

( ): Tip radius

2

12AAE896 (2μm) *

12AAE912 (5μm) *

( ): Tip radius

1

1

1

1

1

1.588

44.7

45.2

37.7

4

2.4

φ

2.4

φ

2.4

φ

For rolling circle waviness surface *

44.7

Ball

37.7

φ

0.9

5.2

7.6

φ

1.2

For knife-edge *4

Color

3

coding*

Detail-A

For eccentric arm *

10

2.4

φ

Color

3

coding*

0.9

A

7.6

2

1.4

7.6

37.7

φ

1.2

°

90

A

φ

1.2

°

90

Detail-A

*1: Tip angle 60°

*2: For downward-facing measurement only.

❈Customized special interchageable styli are available on request,

Please contact any Mitutoyo office for more information.

12AAB338 (φ1.588)

( ): Tip radius

12AAC738 (2μm) *

12AAB411 (5μm)

12AAB423 (10μm)

( ): Tip radius

12AAC739 (2μm) *

12AAB412 (5μm)

12AAB424 (10μm)

( ): Tip radius

*3 :

*4 : Use d fo r cal ib ratio n, a stan dard st ep ga ug e (No .17 8-611, o pti on) is als o req uired

φ

1.2

For rolling circle waviness / Double-length for deep hole *2 *

0.9

φ

1.2

5.2

6.4

7.6

For corner hole / Double-length for deep hole *

1

2.4

φ

94.7

87.7

93.8

87.7

35

45

°

For hole bottom

1

5.8

φ

5

0.5

7.4

6.2

0.8

1.6

φ

37.7

φ

5

1

44.3

2.4

φ

2.4

φ

Tip radius 2μm 5μm 10μm

Color coding Black No color Yellow

9

12AAE886 (250μm)

( ): Tip radius

2

12AAE897 (2μm) *

12AAE913 (5μm) *

( ): Tip radius

12AAE899 (2μm) *

12AAE915 (5μm)

( ): Tip radius

4

1

2

1

Page 10

Optional Accessories: For External Output

Contour / Roughness analysis software

FORMTRACEPAK

More advanced analysis can be performed by loading SJ-410 series

measurement dat a to soft ware program FORMTRACEPA K via a

memory card (option) for processing back at base.

SJ-410

FORMTRACEPAK

Digimatic mini processor DP-1VR

By connecting this printer to the Surftest SJ-410's digimatic output,

you can print calculation results, per form a variety of statistical

analyses, draw a histogram or D chart, and also perform complicated

operations for X-R control charts.

No.264-504 -5A

Simplified communication program for

SURFTEST SJ series

The Surftest SJ-410 series has a USB interface, enabling data to be

transferred to a spreadsheet or other software.

We also provide a program that lets you create inspection record

tables using a Microsoft Excel* macro.

This program can be downloaded free of charge from the Mitutoyo website.

http://w ww.mitutoyo.co.jp

Required environment*

• OS: Windows XP-SP3

ndows Vista

Wi

Windows 7

*Windows OS and Microsoft Excel are products of Microsoft Corporation.

The optional USB cable is also required.

• USB cable for SJ-410 series

• Spreadsheet software: Microsoft Excel 2002

Mi

Mi

Mi

No.12AAD510

crosoft Excel 2003

crosoft Excel 2007

crosoft Excel 2010

Calculation results input unit INPUT TOOL

This unit allows you to load Surftest SJ-410 calculation results (SPC

output) into commercial spreadsheet software on a PC via a USB

connector. You can essentially use a one-touch operation to enter

the calculation result s (values) into the cells in the spreadsheet

software.

SJ-410→DP-1VR Connecting cable

1m: No.936937

2m: No.965014

Measurement Data Wireless Communication System

U-WAVE

This unit allows you to remotely load Surftest SJ-410 calculation

results (SPC output) into commercial spreadsheet software on a PC.

You can essentially use a one-touch operation to enter the

calculation results (values) into the cells in the spreadsheet

software.

U-WAVE-R

(Connects to the PC)

No.02AZD810D

U-WAVE-T

(Connects to the SJ-410)

No.02AZD880D

* Requires the optional Surftest SJ- 410

connection cable.

No.02AZD790D

*

USB-ITN-D

No.06ADV380D

USB keyboard signal conversion type*

IT-012U

No.264-012-10

* Requires the optional Surftest SJ- 410

connection cable.

1m: No.936937

2m: No.965014

Optional accessories, consumables, and

others for SJ-410

•

Printer paper (5 rolls)

•

Durable printer paper (5 rolls)

•

Touch-screen protector sheet (10 sheets)

•

Memory card (2GB) *

•

Connecting cable (for RS-232C)

* micro SD card (with a conversion adapter to SD card)

No.270732

No.12AAA876

No.12AAN040

No.12AAL069

No.12AAA882

10

Page 11

Specifications

Model No.

Measuring

range

Detector

Drive unit: X-axis

Height-tilt

adjustment unit

Standards JIS1982 / JIS1994 / JIS2001 / ISO1997 / ANSI / VDA

Parameters

Measured profiles Primary, Roughness, DF, Filtered waviness curve, R-Motif, W-Motif

Graph analysis BAC and ADC curves

Data compensation Parabola/ Hyperbola/ Ellipse/ Circle/ Conic/ Tilting, Compensation off

Filter 2CR, PC75, Gaussian filter

Cut-off length

Sample length 0.08, 0.25 , 0.8, 2.5 , 8.0, 25.0mm

Number of sampling lengths ×1, ×2, ×3, ×4, ×5, ×6, ×7, ×8, ×9 , ×10, ×11, ×12, ×13, ×14, ×15, ×16, ×17, ×18, ×19, ×20

Arbitrary length 0.1~25mm 0.1~50mm

Functions

Power supply

Size

(W×D×H)

Mass

Standard accessories

*1: Only for VDA/ANSI/JIS'82 standards.

*2: Only for JIS'97 standard.

*3: Only for JIS'01 standard.

*4: Only for ANSI standard.

*5: λs may not be switchable depending on standard selected.

*6: Standard deviation only can be selected in ANSI.16% rule cannot be selected in VDA.

*7: Either No.178-396-2 or No.178-397-2 is supplied as a standard accessory depending on the Order No. of the main unit for SJ-410 Series.

*8: The standard stylus (No.12AAC731 or No.12AAB403), which is compatible with the detector supplied, is a standard accessory.

inch/mm

X axis 25mm (1inch) 50mm (2inch)

Z1 axis (detector unit)

Measuring principle Differential inductance

Resolution

Stylus tip 60°/2µm (80µinch) 90°/5µm (200µinch) 60°/2µm (80µinch) 90°/ 5µm (200µinch)

Measuring force 0.75mN 4mN 0.75mN 4mN

Radius of skid curvature R40 mm (R1.57")

Measuring method Skidded measurement / skidless measurement

Measuring speed 0.05, 0.1, 0.2, 0.5, 1.0mm/s (0.002, 0.004, 0.02, 0.04 inch/s)

Drive speed 0.5, 1, 2, 5mm/s (0.02, 0.04, 0.08, 0.2 inch/s)

Straightness 0.3µm / 25mm (12µinch/ 1inch) 0.5µm / 50mm (20µinch/ 2inch)

Height adjustment 10mm (0.39inch)

Tilt adjustment ±1.5°

c 0.08, 0.25 , 0.8, 2.5 , 8.0mm

λ

5

s *

λ

Customization Desired parameters can be selected for calculation and display

Simple contour analysis function

DAT function Helps to adjust leveling during skidless measurement

Real sampling function Samples stylus displacement for a specified time without engaging detector traverse.

Statistical processing

GO/ NG judgement*

Storage functions 10 measuring conditions can be stored in internal memory

Printing function

Display languages

Storage

External I/O USB I/F, Digimatic output, RS-232C I/ F, Ex ternal SW I/ F

Battery

Power consumption 50W

Display unit 275×198×109mm (10.83×4.29×7.80inch)

Height adjustment unit 130.9×63×99mm (5.16×2.48×3.90 inch)

Drive unit 128×35.8×46.6mm (5.04×1.41×1.83 inch) 154.5×35.8×46.6mm (6.08×1.41×1.83inch)

Display unit 1.7kg

Height adjustment unit 0.4kg

Drive unit 0.6kg 0.64kg

6

178-581-01A 178-581-02A 178-583-01A 178-583-02A

Ra, Rq, Rz, Ry, Rp, Rv, Rt, R3z, Rsk, Rku, Rc, RPc, RSm, Rmax*

Rσc, Rk, Rpk, Rvk, Mr1, Mr2, A1, A2, Vo, λa, λq, Lo, Rpm, tp*

Static measurement (max. 3 parameters) is possible. Static processing for MAX, MIN, AVERAGE,

Measurement conditions / Calculation results / GO / NG judgement result / Calculation results for each sampling length /

Internal memory: Measurement condition (10 sets)

Memory card (option): 500 measurement condition, 10000 measuring data, 10000 text data, 500 statistic data,

*Endurance: about 1500 measurements (differs slightly due to use conditions / environment)

7

Detector*

, Stylus*8, Roughness specimen

270732

Printing paper

12BAL402

Touch-scr

SJ-411 SJ-412

800µm, 80µm, 8µm

*Up to 2,400µm with an optional stylus

0.01µm (800µm range) / 0.001µm (80µm range) / 0.0001µm (8µm range)

0.4µinch (32000µinch) / 0.04µinch (3200µinch) / 0.004µinch (320µinch)

1

, Rz1max*2, S, HSC, RzJIS*3, Rppi, RΔa, RΔq, Rlr, Rmr, Rmr(c),

4

, Htp*4, R, Rx, AR, W, AW, Wx, Wte, Possible Customize

2.5, 8.0, 25mm (100, 320, 1000µinch)

Step, Step volume, Dimensions, Coordinate difference

standard deviation, histogram and pass rate is possible

Max rule / 16% rule / Average rule / Standard deviation (1σ, 2σ, 3σ)

Measurement curve / BAC / ADC / Environmental setting information

Japanese, English, German, French, Italian, Spanish, Portuguese, Korean,

Traditional Chinese, Simplified Chinese, Czech, Polish, Hungarian Turkish, Swedish, Dutch

1 backup of machine setting, the last ten traces (Trace 10)

Two-way power supply: battery (rechargeable Ni-MH battery) and AC adapter

*Charging time: about 4 hours (may vary due to ambient temperature)

een protection sheet

12BAG834

12AAN041

Touch pen

Carrying case

AC adapter, Philips scr

Strap for stylus pen, Operation manual,

Quick reference manual, Warranty

ewdriver,

11

Page 12

Connecting cable (1.5m)

Unit: mm

ø14

35.8

Vertical travel

length

10

°

45.8

1.5

±

25.4

Tiltin g range

(

)

50.8

(0.9)

(60)

33.5

54

*The dimensions in parentheses indicate those for

219.3

(

Example of mounting on simple column stand. (Code No. 178-039)*

245.8

130.9

)

63

90

SJ-412

109275

99

198

15

°

Unit: mm

*For details see page 6.

)

25(50

578

250

40

175(201.5

400

Note : All information regarding our products, and in part icular the illustrations, drawings, dimensional and performance data

containe d in this printed matter as well as other technic al data are to be regarded as ap proximate average values. We therefore

reserve the right to make chang es to the corresponding designs. The s tated standards , similar te chnical regulatio ns, desc riptions

and illustrations of the produc ts were valid at the time of printing. In addition, the latest applicable version of our General Trading

Conditions will apply. Only quotat ions submi tted by ourselves may be regarded as definitive.

Mitutoyo produ cts are subject to US E xport Administrati on Regulations (EAR). Re-ex port or relocation of our products may require

prior app roval by an appropriate governing authorit y.

Trademark s and Registrations

Designations used by companies to distinguish their product s are often claimed as trademark s. In all instances whe re Mitutoyo

America Corporation is aware of a claim, the product names appear in initial capital or all capital letters. The appropriate companies

should be contacted for more complete trademark and registration information.

60

)

12

40

120

250

*The dimensions in parentheses indicate those for

8.5

15

T-groove dimensions

Measuring range

7

11

SJ-412

One Number to Serve You Better

1-888-MITUTOYO (1-888-648-8869)

Aurora, Illinois

(Corporate Headquarters)

Westford, Massachusetts

Huntersville, North Carolina

Mason, Ohio

Plymouth, Michigan

City of Industry, California

Birmingham, Alabama

© 2012 Mitutoyo America Corporation, Aurora IL

2.5M 0612-06 Printed in USA, June 2012

Precision is our Profession

Loading...

Loading...