Page 1

Form Measurement

Portable Surface Roughness Tester

SURFTEST SJ-310 Series

Bulletin No. 2078

Page 2

The Surftest SJ-310 is a compact, portable, easy-to-use

surface roughness measurement instrument equipped

with extensive measurement and analysis features.

Easy to use Enhanced power for making measurements on site

Large color graphic LCD

The color touch-screen provides excellent

readability and an intuitive display that is easy

to negotiate. The LCD also includes a backlight

for improved visibility in dark environments.

The integrated printer allows you to print

measurement results on the spot.

Highly functional

Internal memory

Up to 10 measurement conditions and one measured

profile can be stored in the internal memory.

Optional memory card

The optional memory card can be used as an

extended memory to store large quantities of

measured profiles and conditions and adds the

convenience of automatically saving data from

he 10 most recent measurements (Trace 10).

t

Password protection

Access to each feature can be password-protected,

which prevents unintended operations and allows

protection of your settings.

Multilingual support

The display interface supports 16 languages, which

can be freely switched.

Stylus alarm (patent pending in Japan, U.S.A., EU)

An alarm warns you when the cumulative

measurement distance exceeds a preset limit.

Despite its reduced charging time — approximately 1/4 that required for conventional

models, the Surftest SJ-310 is capable of making approximately 2.5 times the number

of measurements when fully charged. The detector supports a variety of measurement

orientations and can make measurements up against a wall surface or while facing upward.

When combined with optional accessories such as a height gauge adapter, the detector can

make measurements in various orientations and settings.

Extensive analysis and display features

Complies with many industry standards

The Surftest SJ-310 complies with the following

standards: JIS (JIS-B0601-2001, JIS-B0601-1994, JIS

B0601-1982), VDA, ISO-1997, and ANSI.

Displays assessed profiles and graphical data

In addition to calculation results, the Surftest SJ-310

can display sectional calculation results and assessed

profiles, load curves, and amplitude distribution curves.

2

Page 3

S

ur

f

test SJ-3

1

0

User friendly, high-functionality display unit with integrated high-speed printer

The large 5.7-inch color graphic touch-screen LCD provides excellent readability. Furthermore, selecting icons from the touch panel display*

provides intuitive and easy operation. The integrated high-speed printer also allows the user to perform the entire process from making

measurements to printing the results with the push of a single button (START button).

Printer

BAC and ADC curves can be printed in addition

t

o calculation results (including pass/fail results)

and assessed profiles. The printer offers an

easy-to-understand layout and can also print

horizontally to match the content displayed on the

LCD. Furthermore, printing speed is approximately

50% faster than conventional models.

Built-in battery

With drastically enhanced power compared

to conventional models, the Surftest SJ-310

can make 1,500 continuous measurements

on a full charge achieved in 4 hours.

Highly functional detectors and drive units

*1 Text display can also be selected.

5.7-inch color graphic LCD

with touch screen

Measurement Result

Measured profile

Sheet buttons

Frequently used functions, such as the measurement start button,

are provided as rugged sheet buttons with excellent durability.

←→

One-touch

switching

BAC curve

ADC curve

1

Detector supplied

as standard

One of two types may be selected:

Measuring force : 0.75mN

•

Stylus form: Tip radius 2µm

Measuring force : 4mN

•

Stylus form: Tip radius 5µm

Links to a wide variety of external instruments

You can save parameter recalculations and measurement results in text format on a memory card and import into commercial spreadsheet software

on a PC. You can also connect to a PC using the USB connector and use a dedicated software application to

perform everything from measurement control and condition modification to issuing inspection result reports.

T

ip angle 60°

T

ip angle 90°

Side of display unit

A wide range of optional detectors

is available, including detectors for

small holes, extra small holes, gear

tooth surfaces, and deep grooves.

Memory card

RS-232C I/F

(Option)

USB I/F

Drive units

Standard drive unit

•

•

Popular standard drive unit

Transverse tracing drive unit

•

• Best suited for measurement

of narrow, shrouded workpiece

features such as crankshaft

bearings, EDM parts, etc.

(Patent Registered in Japan)

USB Input Tool

Direct *

2

Input Tool

for USB *

Retractable drive unit

•

•

The detector is in the retracted

position at rest so it is immune

from damage when inserted into

a feature whose shape cannot be

easily seen, such as a blind hole, etc.

U-WAVE-T *

2

U-WAVE-R *

PC

2

2

Rear of display unit

SPC I/F

3

DP-1VR *

2

*2: Refer to P11 for more details

Page 4

Measurement assistance and analysis features

offering the ultimate in ease of use

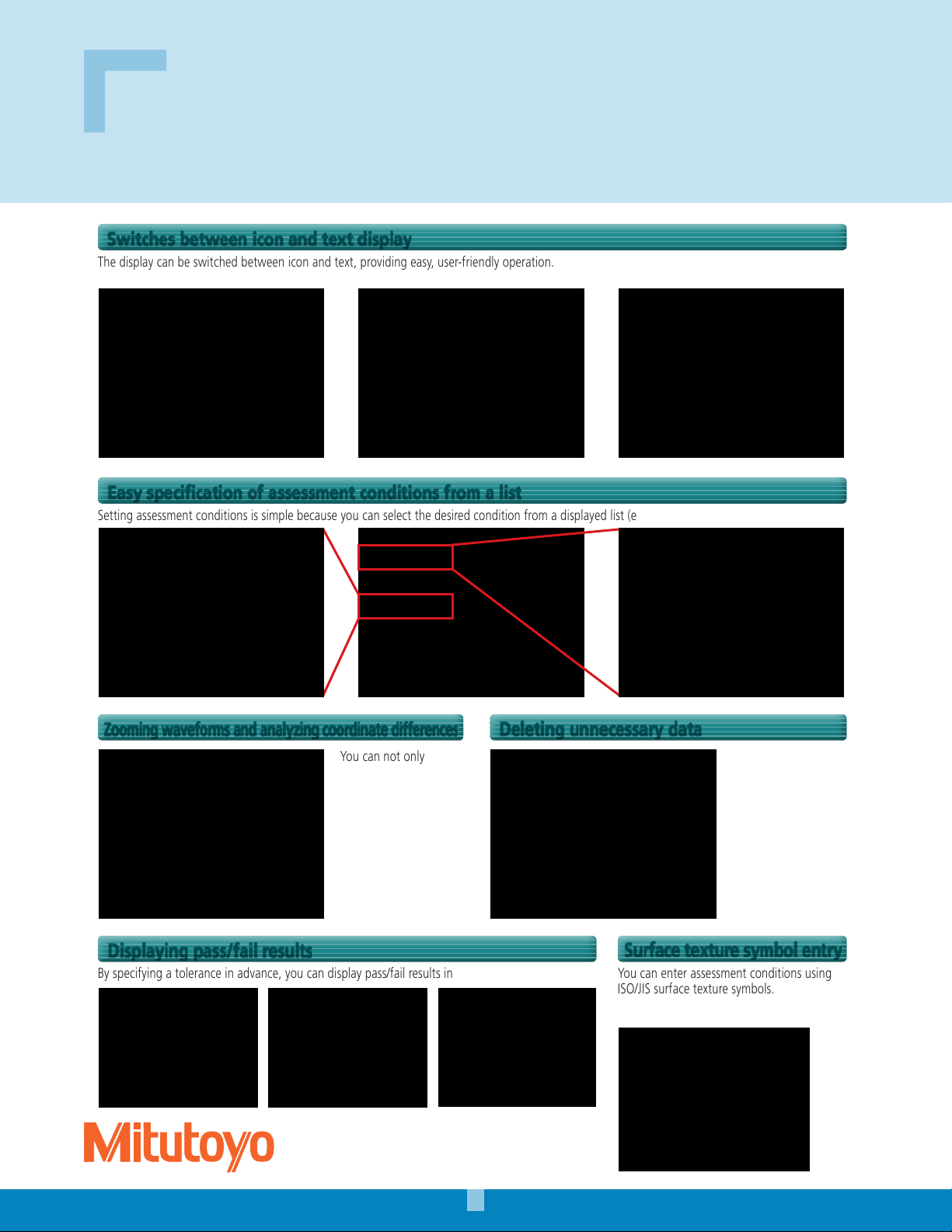

Switches between icon and text display

The display can be switched between icon and text, providing easy, user-friendly operation.

Additionally, the guidance feature provides detailed explanations of touch-screen buttons.

Icon Text

Easy specification of assessment conditions from a list

Setting assessment conditions is simple because you can select the desired condition from a displayed list (e.g., standard, parameter).

Zooming waveforms and analyzing coordinate differences

You can not only

magnify or shrink

waveforms, but also

calculate the coordinate

difference between

two points using a ruler

operation.

You can quickly check

the irregularity status

without waiting for a

printout.

Displaying pass/fail results

By specifying a tolerance in advance, you can display pass/fail results in color.

OK +NG - NG

Deleting unnecessary data

With the Surftest

SJ-310, you can

delete portions of

measurement data.

This feature allows

you to make new

calculations by deleting

data that should not be

included in parameter

calculation, such as

data on a scratch.

Surface texture symbol entry

You can enter assessment conditions using

ISO/JIS surface texture symbols.

(Patent registered in Japan, U.S.A., Germany, UK, France)

(Patent pending in China)

4

Page 5

Measurement results can be displayed in several ways

Measurement results can be presented in the form of a 1-parameter, profile, 4-parameter or trace display.

1-parameter display: one parameter

measurement result

Profile display: one parameter measurement

result and the measured profile

4-parameter display: four parameter

measurement results

Trace display: the ten latest measurement

results using the same parameter

Recalculation function

After completing measurement, you can modify the assessment conditions (standard, profile, and parameter) and easily recalculate the results using

the new condition.* *

Not possible with all measurement conditions.

Dual assessment of a single measurement Stylus alarm function

Using the result of a single measurement, you can make calculations or

analyze assessment profiles under two different assessment conditions

(standard, profile, filter, etc.) without using the recalculation feature.

Displayed settings can be easily changed by pressing the left and right

arrow keys under the sliding cover. For example, these keys can be used

to switch the cut-off value(λc) and the number of sampling lengths (N)

on the measurement screen. (Patent pending in Japan.)

Positive stylus contact indication

Stylus contact with the workpiece is indicated by color coding

in the display. This is helpful when visibility of the surface to be

measured is restricted (e.g. when measuring within a shrouded

feature or groove).

No contact Contac t

Extensive statistical processing features

You can make a maximum of 300 statistical measurements using up to three

parameters to obtain averages, standard deviations, maximums, minimums,

passing rates, and histograms (upper and lower limits can be displayed).

This feature is ideal for day-to-day data management.

5

Page 6

Specifications

Specifications

Type of detector Standard drive unit type Retractable drive unit type Transverse tracing drive unit

Model No.

Order No. inch/mm 178-571-01A 178-571-02A 178-573-01A 178-573-02A 178-575-01A 178-575-02A

Measuring

range

Measuring speed In the measurement: 0.25mm/s (.01inch/s), 0.5mm/s (.02inch/s), 0.75mm/s (.03inch/s), In the return: 1mm/s (.04inch/s)

Measuring force / Stylus tip 0.75mN type: 0.75mN / 2µmR 60°, 4mN type: 4mN / 5µmR 90°

Skid force 400mN or less

Standard JIS’82 / JIS’94 / JIS’01 / ISO’97 / ANSI / VDA

Measured profiles Primary, Roughness, DF, R-Motif, W-Motif

Parameters

Graph analysis BAC and ADC curves

Filter Gaussian, 2CR75, PC75

Cut-off length

Sampling length 0.08, 0.25, 0.8, 2.5, 8 mm (.003, .01, .03, .1, .3 inch)

Number of sampling lengths

LCD dimensions 117.8 × 88.2 mm

Display languages

Measurement result display

Printing function

External I/O USB I/F, Digimatic output, RS -232C I /F, External SW I /F

Functions

Power-saving Auto-sleep function (30-600sec) *

Power supply

Size (W×D×H)

Mass About 1.8kg (Display unit + Drive unit + Standard detector)

Standard accessories

X axis 16.0 mm (.63inch) 5.6 mm (.22inch)

Detector

Customization Desired parameters can be selected for calculation and display

GO/ NG judgement *

Storage of measurement condition

Storage

Calibration Auto-calibration with the entry of numerical value / Average calibration with multiple measurement (MA X.12 times) is available

Range 360 µm (-200 µm ~ +160 µm) [14400 µinch (-7900 µinch to +6300 µinch)]

Range/

resolution

c 0.08, 0.25, 0.8, 2.5, 8 mm (.003, .01, .03, .1, .3 inch)

λ

5

s *

λ

6

Display unit 275 × 109 × 198 mm

Drive unit 115 × 23 × 26.7 mm

SJ -310

(0.75mN type)

Ra, Rc, Ry, Rz, Rq, Rt, Rmax*

Rmr

(c)

, Rδc, Rk, Rpk, Rvk, Mr1, Mr2, A1, A2, Vo, λa, λq, L0, Rpm, tp*4, Htp*4, R, Rx, AR, W, AW, Wx, Wte, Possible Customize

Trad it ional Chinese, Si mplified Chines e, C zech, Polish, H un garian Turkish, Swedish, D utch

Measurement conditions / Calculation results / GO / NG judgement result / Calculation results for each sampling length /

Internal memory: Measurement condition (10 sets)

Memory card (option): 500 measurement conditions, 10000 measuring data, 10000 text data, 500 statistic data,

12A

12AAA217 Nosepiece for plane surface

12AAA218 Nosepiece for cylinder

12AAA216 Supporting leg

12

12BAG834 Stylus pen

12

270732 Printer paper (5 pieces)

12

Roughness reference specimen

Strap for stylus pen, Operation manual, Quick reference manual, Warranty

*1: Only for VDA/ANSI/JIS’82 standards.

*2: Only for JIS’97 standard.

*3: Only for JIS’01 standard.

*4: Only for ANSI standard.

*5: λs may not be switchable depending on a standard selected.

*6: Standard deviation only can be selected in ANSI.16% rule cannot be selected in VDA.

*7: Auto-sleep function is invalid when AC adapter is used.

*8: For connecting the calculation display unit and drive unit.

SJ -310

(4mN type)

1

, Rp, Rv, R3z, Rsk, Rku, Rc, RPc, Rsm, Rz1max*2, S, HSC, RzJIS*3, Rppi, R∆a, R∆q, Rlr, Rmr,

×1, ×2, ×3, ×4, ×5, ×6, ×7, ×8, ×9, ×10,

Arbitrary (0.3 ~ 16.0mm: 0.01mm Interval)

Japanese, En gl ish, German, French , It alian, Spanis h, P ortuguese, Korean,

1-parameter display: one parameter measurement result

4-parameter display: four parameter measurement results

Profile display: one parameter measurement result and the measured profile

Trace display: The ten latest measurement results using the same parameter

Measurement curve / BAC / ADC / Environmental setting information

Max rule / 16% rule / Average rule / Standard deviation (1σ, 2σ, 3σ)

1 backup of machine setting, the last ten traces (Trace 10)

Two-way power supply: battery (rechargeable Ni-MH battery) and AC adapter

*Charging time: about 4 hours (may vary due to ambient temperature)

*Endurance: about 1500 measurements (differs slightly due to use conditions / environment)

AM475

Connecting cable

BAK700

BAL402

Calibration stage

Protection sheet

Carrying case

BAL400

(Ra3µm), AC adapter, Philips screwdriver,

SJ -310

(0.75mN type)

360 µm / 0.02 µm (14400 µinch / .8 µinch)

100 µm / 0.006 µm (4000 µinch / .2 µinch)

25 µm / 0.002 µm (1000 µinch / .08 µinch)

2.5, 8 µm (100, 320 µinch)

Save the condition at power OFF

8

*

SJ -310

(4mN type)

7

SJ -310

(0.75mN type)

×1, ×2, ×3, ×4, ×5, ×6, ×7, ×8, ×9, ×10,

Arbitrary (0.3 ~ 5.6mm: 0.01mm Interval)

12AA

12AAE643 Point-contact adapter

AAE644

12

BAK700

12

12BAG834 Stylus pen

BAL402

12

270732 Printer paper (5 pieces)

12B

Roughness reference specimen (Ra1µm), AC

adapter, Philips screwdriver, Strap for stylus pen,

Operation manual, Quick reference manual, Warranty

M475

V

Protection sheet

Carrying case

AL400

Connecting cable

-type adapter

Calibration stage

SJ -310

(4mN type)

8

*

6

Page 7

標準

退避形

R

横駆動

S

Dimensions: Display Unit and Drive Unit

Drive unit, Display unit

Drive unit type Drive unit external view

23.026.026.0 23.0 26.0 23.0

Standard drive unit

25.2

115.026.7

Retractable drive unit

1

23.2

2.0

26.7

115.0

Unit: mm

Transverse tracing drive unit

●Display unit external view

Cable length: 1m

198

3.0

6.6

275

45.5

115.047

109

15°

7

Page 8

Dimensions: Detectors

Detectors

Standard detectors

3.5

Order

No.

178-296 0.75mN 2 µmR/60˚

178-390 4 mN 5 µmR/90˚

178-387 0.75mN 2 µmR/60˚

178-386 4 mN 5 µmR/90˚

178-391 4 mN 10 µmR /90˚

*Tip radius / Tip angle

Small hole detectors

ф

Order

No.

178-383 0.75mN 2 µmR/60˚

178-392 4 mN 5 µmR /90˚

*Tip radius / Tip angle

Extra small hole detectors

ф

Measuring

3.8

3.5

Measuring

2.4

1.5

force

1.5

force

Unit: mm

Gear-tooth surface detectors

°

force

60.1

Stylus

1.8

0.4

9

ф

Stylus form*

61

Stylus

Stylus

9

ф

2.4

59.5

Remarks

Dedicated to the

standard /retractable

drive unit

Dedicated to the

transverse tracing

drive unit

Dedicated to the

standard /retractable

drive unit

2.4

ф

Order

178-388 0.75mN 2 µmR /60˚

178-398 4 mN 5 µmR /60˚

*Tip radius / Tip angle

16.4

6

4.8

form*

No.

R40

0.6

1.4

12.6

60

0.9

Measuring

Deep groove detectors

16.2

12.8

4.8

Stylus

form*

60.7

Stylus

9

ф

Remarks

Minimum

measurable hole

diameter:

60.3

Stylus

ø4.5mm

Order

2

No.

3.5

Measuring

9

force

16.4

13.6

1.5

178-385 0.75mN 2 µmR/60˚

178-394 4 mN 5 µmR/90˚

*Tip radius / Tip angle

4.8

Stylus

form*

61

Stylus

10

Remarks

Not available for the

transverse tracing

drive unit

9

ф

1.6

0.8

Order

No.

Measuring

force

Stylus

form*

178-384 0.75mN 2 µmR /60˚

178-393 4 mN 5 µmR /90˚

*Tip radius / Tip angle

9

ф

0.4

1.8

Remarks

Minimum

measurable hole

diameter: ø2.8mm

8

Page 9

Dimensions: Display Unit and Drive Unit

Vertical positioning

Magnetic stand

Drive unit, Display unit

Nosepiece for flat surfaces

No.12AAA217

• SJ-310/310R standard accessories

• Not available for the transverse

tracing drive unit.

V-type adapter

No.12AAE644

• SJ-310S standard accessories

• Dedicated to the transverse tracing

drive unit.

Extension rod (50 mm)

• Not available for the transverse

tracing drive unit.

Support feet set

No.12AAA216

• SJ-310 standard

accessory

• Not attachable to

the detector side

of the transverse

tracing drive unit.

Nosepiece for flat surface

No.12AAA217

7.7mm

72mm

Extension rod 50 mm

No.12AAA210

Support feet set

No.12AAA216

Detector side

Nosepiece for cylindrical surfaces

No.12AAA218

• SJ-310/310R standard accessories

• Not available for the transverse

tracing drive unit.

• ø30mm or smaller workpiece.

Nosepiece for

cylindrical surface

No.12AAA218

Point-contact adapter

No.12AAE643

• SJ-310S standard accessories

• Dedicated to the transverse

tracing drive unit.

Extension cable (1 m)

No.12BAA303

• For connecting calculation display unit and drive unit.

Vertical positioning adapter

No.12AAA219

• Not available for the

transverse tracing drive unit

adapter

No.12AAA219

Magnetic stand adapter

No.12AAA221(ø8mm)

No.12AAA220(ø9.5mm)

Setting attachments

adapter

Height gage adapter

No.12AAA222(9x9mm)

No.12AAA233(1/4inx1/2in)

Height gage adapter

(Note: Not available for the transverse tracing drive unit)

Enhances measurement efficiency by facilitating the measurement setup of multiple workpieces of the same type and of the hard-to-access

sections of a workpiece.

V-type for measuring axially

No.178-033

The V-width is adjustable

to the cylindrical workpiece

diameter, facilitating axial

measurement of a wide

range workpiece sizes.

• Adjustable range:

ø 5 ~ 150 mm

Slider type Inside diameter type

No.178-034

This attachment is ideal for measuring

a flat area of a workpiece that has

an indentation or step that makes it

difficult to attach the drive unit. You

can further improve the ease of use

by using this attachment with the

magnetic installation base (option:

No. 12AAA910).

No.178-035

Greatly facilitates measurement

of internal wall surfaces of, for

example, a cylinder block.

• Applicable diameter:

ø 75 ~ ø 95 mm

• Accessible depth:

30 ~ 135 mm

9

Page 10

Optional Accessories: For External Output

Simplified communication program for SURFTEST SJ series

The Surftest SJ-310 series has a USB interface, enabling data to be transferred to a spreadsheet or other software.

We also provide a program that lets you create inspection record tables using a Microsoft Excel* macro.

Required environment*:

•

• OS

:

W

indows XP-SP3

Windows Vista

W

indows 7

*Windows OS and Microsoft Excel are products of

Microsoft Corporation.

Required environment*:

•

USB cable for SJ-310 series

No. 12AAD510

Spreadsheet software:

M

icrosoft Excel 2002

Microsoft Excel 2003

M

icrosoft Excel 2007

icrosoft Excel 2010

M

This program can be downloaded free of charge from

the Mitutoyo website.

http://www.mitutoyo.co.jp

Contour / Roughness analysis software FORMTRACEPAK

More advanced analysis can be performed by loading SJ-310 series measurement data to software program FORMTRACEPAK

via a memory card (option) for processing back at base.

10

Page 11

Optional Accessories: For External Equipment

Digimatic mini processor DP-1VR

By connecting this printer to the Surftest SJ-310's digimatic

output, you can print calculation results, perform a variety

of statistical analyses, draw a histogram or D chart, and also

perform complicated operations for X-R control charts.

No.264-504-5A

SJ-310→DP-1VR Connecting cable

1m: No.936937

2m: No.965014

Footswitch

A footswitch is used to trigger measurement. This tool is

very useful in cases where you need to measure the same

workpiece multiple times using jigs and other fixtures.

Calculation results input unit INPUT TOOL

This unit allows you to load Surftest SJ-310 calculation

results (SPC output) into commercial spreadsheet software

on a PC via a USB connector. You can essentially use a onetouch operation to enter the calculation results (values) into

the cells in the spreadsheet software.

USB Input Tool Direct

USB-ITN-D

No.06ADV380D

USB keyboard signal conversion type*

IT-012U

No.264-012-10

* Requires the optional Surftest SJ-310

connection cable.

1m: No.936937

2m: No.965014

Measurement Data Wireless Communication System U-WAVE

This unit allow s you to remotely load Surftest SJ-310

calculation results (SPC output) into commercial spreadsheet

software on a PC.

You can essentially use a one-touch operation to enter the

calculation results (values) into the cells in the spreadsheet

software.

No.12AAJ088

Optional accessories and consumables for SJ-310

•

Printer paper (5 rolls)

•

Durable printer paper (5 rolls)

•

Touch-screen protector sheet (10 sheets)

•

Memory card (2GB) *

•

Connecting cable (for RS-232C)

* micro SD card (with a conver sion adapter to SD card)

No.270732

No.12AAA876

No.12AAN040

No.12AAL069

No.12AAA882

11

U-WAVE-R

(Connects to the PC)

No.02AZD810D

U-WAVE-T

(Connects to the SJ-310)

No.02AZD880D

* Requires the optional Surftest SJ-310

connection cable.

No.02AZD790D

*

Page 12

Note : All information regarding our products, and in part icular the illustrations, drawings, dimensional and performance data

containe d in this printed matter as well as other technic al data are to be regarded as ap proximate average values. We therefore

reserve the right to make chang es to the corresponding designs. The s tated standards , similar te chnical regulatio ns, desc riptions

and illustrations of the produc ts were valid at the time of printing. In addition, the latest applicable version of our General Trading

Conditions will apply. Only quotat ions submi tted by ourselves may be regarded as definitive.

Mitutoyo produ cts are subject to US Export Admin istration Regulations (EAR) . Re-export or relocation of our products may require

prior app roval by an appropriate governing authorit y.

Trademark s and Registrations

Designations used by companies to distinguish their product s are often claimed as trademark s. In all instances whe re Mitutoyo

America Corporation is aware of a claim, the product names appear in initial capital or all capital letters. The appropriate companies

should be contacted for more complete trademark and registration information.

One Number to Serve You Better

1-888-MITUTOYO (1-888-648-8869)

Aurora, Illinois

(Corporate Headquarters)

Westford, Massachusetts

Huntersville, North Carolina

Mason, Ohio

Plymouth, Michigan

City of Industry, California

Birmingham, Alabama

© 2012 Mitutoyo America Corporation, Aurora IL

2.5M 0612-04 Printed in USA, June 2012

Precision is our Profession

Loading...

Loading...