Page 1

Surface, Form and Contour Measurement

Bulletin No. 1795

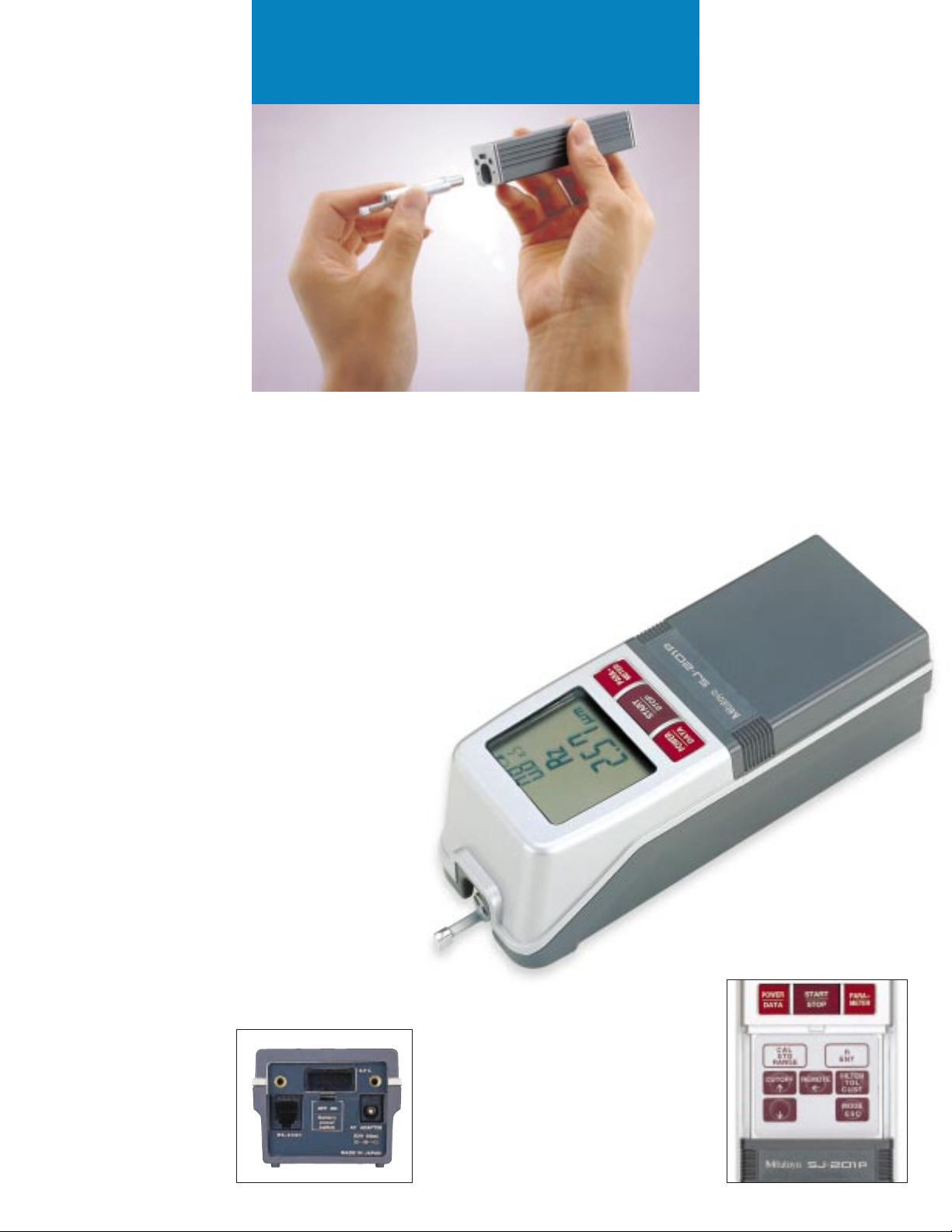

Surftest SJ-201P

Portable Surface Roughness Tester

Smart tool

in the workshop

Page 2

• Large characters are displayed on the large

easy-to-view LCD.

• Portable for easy measurement anywhere necessary.

• The detector/drive unit can be detached from the

display unit for effortless measurement of awkwardly

oriented workpieces.

• Wide 350µm (-200µm to +150µm) measurement range.

• Roughness parameters compatible with ISO, DIN,

ANSI, and JIS.

• 19 analysis parameters are provided, including the

basic Ra, Rq, Rz, and Ry parameters.

• Customize function allows hiding of unnecessary

parameters.

• GO/NG judgment on a desired parameter.

• Auto-calibration for simple gain-adjustment.

• Auto-sleep function saves energy.

• 10 Measurement data is retained in memory

even after the power is turned off.

• Data output is available for SPC operation.

• RS-232C interface enables data transfer

to computer or other devices using an

external device.

• 2-way power system (AC adapter/rechargeable

built-in battery).

Setting Modification Keys:

The top cover of the display unit slides to

allow access to the setting modification

keys underneath.

REMOTE Key for Data Output:

To use the RS232C cable, it is possible to

connect the printer to print the measured

profile. It is also possible to connect PC

by changing the cable.

SPC Data Output

and Communication:

The SJ-201P is provided with

functions to output SPC

data and communicate with

external devices via the

RS-232C interface.

SURFTEST

SJ-201P

Portable Surface

Roughness Tester

• A dedicated carrying case is included for safe transport.

• A precision roughness specimen is supplied.

• A hard copy of the measurement data is available

with the optional printer (64AAA779).

SURFTEST

SJ-201P

Page 3

Specifications

Code No. 64AAA779

Printing Method Line Thermal Dot Printing

Interface Serial (RS-232C)

Input Buffer 2KB

Printing Width 1.89"

Dot Density 8 dots/mm

Printing Speed Approx.11 lines/sec at maximum

Power Supply 120 VAC

Weight Approx. 1.61 lbs.

Dimension 4.17" (W) x 7.24" (D) x 4.33" (H)

SJ Printer (Optional)

The compact SJ printer (64AAA779) prints out

measurement data at high speed and high quality.

Printer Cable (64AAA299).

Applications

• If the detector/

drive unit is

attached to the

display unit:

• If the detector/drive unit is detached from the display unit:

Dimensions

Various optional accessories widen the application range of measurements.

Page 4

Measurement with the

detector facing upward.

Measurement

in the vertical

direction.

The bottom of the detector

has V-grooves for stable

measurement

of cylindrical

workpieces.

Measurement

in the horizontal

direction.

Support foot set (pair) 12AAA216

Detector Retracting

Function:

If moving the SJ-201P or if

it will not be used for a long

period of time, the detector

retracting function prevents

damage to the detector

caused by the tip being

accidentally hit.

Height Gage Adapter – 12AAA222

Detectors

• Adjustable

height:

1.1" (28mm)

Select a detector appropriate for the material and shape of the workpiece to be measured.

Page 5

Ra, Rq, Ry, Rz,

S, Sm, Pc, R3z, mr, Rt, Rp, Rk,

Rpk, Rvk, Mr1, Mr2, A1, A2, Vo

Calibration

Mode:

Pressing the [CAL/STD/RANGE]

key in the measurement mode,

the calibration mode is entered

allowing the detector to be

calibrated to the precision

roughness specimen with

simple key operation.

Parameter Ra value

being displayed

Measurement:

Pressing the [START/STOP]

key in the measurement mode

starts the detector measurement

traversing.

Measurement traversing indicator

“- - - -” on the LCD turns out

into the parameter value display

if measurement is complete.

Measurement traversing length

can be set according to a

national/international standard

or to an arbitrary length.

Measuring

Parameter

Reduction:

Parameter calculations and

resultant display can be limited

only to those actually required.

Reducing the parameters

simplifies the key operation

and parameter calculations.

Ra, Rq, Ry, and Rz

Plus ElevenMore

Parameters:

Seven more analysis/display

parameters can be set up in

addition to the factory default

parameters Ra, Rq, Ry, and Rz.

After measurement, press the

[PARAMETER] key repeatedly

until the desired one is

displayed on the LCD.

GO/NG judgment

19 Surface Roughness

Parameters...

Compatible with

ISO / DIN / ANSI / JIS

Page 6

SJ-201P Specifications

Order No. 178-923A

Type inch (mm)

Drive Unit

Drive speed

Measuring: .01"/s (0.25mm/s), .02"/s ( 0.5mm/s), Returning: .03"/s (0.8mm/s)

Evaluation length*

1

.49" (12.5mm)

Mass

.42 lbs. (190g)

Detector provided 178-390

Detecting method

Differential inductance

Measuring range

13780µin (350µm) (-7880µin/-200µm to +5900µin/+150µm)

Material of stylus

Diamond

Radius of skid curvature

1.57" (40mm)

Mass

.04 lbs. (18g)

Stylus tip radius

200µin (5µm)

Measuring force

4mN

Display Unit

Assessed profile

Primary profile (P), Roughness profile (R), DIN4776 profile

Roughness parameter

Ra, Ry, Rz, Rq, S, Sm, Pc, R3z, mr, Rt, Rp, Rk, Rpk, Rvk,

Mr1, Mr2, A1, A2, Vo (can be customized)

Roughness standard

JIS, DIN, ISO, ANSI

Sampling length (L)

.01", .03", .1" (0.25mm, 0.8mm, 2.5mm)

Number of sampling spans

x1, x3, x5, xL*

1

Digital filter

2CR-75% (without phase compensation), PC-75%, PC50% (Gaussian)

Cut-off lc

.01", .03", .1" (0.25mm, 0.8mm, 2.5mm)

Length ls

100µin, 320µin (2.5µm, 8µm)

Resolution/range

Auto/depending on the measurement range

16.4µin/14000µin (0.4µm/350µm)

4.1µin/4000µin (0.1µm/100µm)

2.0µin/2000µin (0.05µm/50µm)

.5µin/400µin (0.01µm/10µm)

Displaying range

Ra, Rq

.4µin - 4000µin (0.01µm - 100µm)

Rz, Ry, Rp, Rt,

.8µin - 13780µin

R3z,Rk, Rpk, Rvk

(0.02µm - 350µm)

Pc

6.35 - 12700/inch (2.5 - 5000/cm)

mr

1 - 100%

Sm, S

80µin - .16" (2 - 4000µm)

Mr1, Mr2

0 - 100%

A1, A2

0 - 15000

Vo

0.000 - 10.00(mm3/cm2)

GO/NO-GO judgment

Upper and lower limit values can be specified.

Power supply

Via AC adapter/built-in rechargeable battery

Rechargeable battery

Charging time: 12 hours (for 500 measurements)

Auto-sleep (turning off)

After 30 seconds without operation

Data output

Via RS-232C interface unit, SPC output, PC output, Printer output

Mass

.64 lbs. (290g)

*1 Evaluation length can be specified arbitrarily in the range from .01" (0.3mm) to .49" (12.5mm).

Standard Accessories

12BAA303 Connecting cable (1m)

178-602

Roughness specimen (inch/mm)*

*Either of them supplied.

353134 Calibration stand

538612 Phillips screwdriver

12BAA304 Carrying case

99MBB079A

User's manual (for SJ-201P)

99MBB081A

One-sheet manual

526688 AC adapter

Optional Accessories

178-391 Detector for soft materials

(Stylus tip radius: 10µm)

178-392 Small hole detector (ø4.5mm)

178-393 Small hole detector (ø2.8mm)

178-394 Deep groove detector

178-395 Detector for low pressure type

(Stylus tip radius: 2µm, Measuring force:

0.75mN)

936937 SPC cable (1m)

965014 SPC cable (2m)

12AAA208 RS-232C connecting cable

12AAA216 Support foot set (pair)

12AAA217 Nosepiece for flat surface

12AAA218 Nosepiece for cylindrical sur-

face

12AAA219 Vertical positioning adapter

12AAA220 Magnetic stand adapter

(3/8" DIA. stem)

12AAA221 Magnetic stand adapter

(Ø8mm stem)

12AAA222 Height gage adapter (mm)

12AAA233 Height gage adapter (inch)

12AAA210 Extension rod (50mm)

178-033 Setting attachment:V type

178-034 Setting attachment: Slider type

178-035 Setting attachment: Inside

diameter type

178-241-2A Display unit for SJ-301

Roughness specimen

© 2004 Mitutoyo America Corporation, Aurora IL We reserve the right to change specifications and prices without notice. 1004-08 • Printed in USA • October 2004

Loading...

Loading...