Page 1

Agilent N3300 Series

DC Electronic Loads

Data Sheet

Increase your manufacturing test throughput with

fast electronic loads

• Increase test system throughput

• Lower cost of ownership

• Decrease system development time

• Increase system reliability

• Increase system flexibility

• Stable operation down to zero volts

• DC connection terminal for ATE applications

Page 2

Increase Test Throughput

Today’s high volume manufacturing

requires optimization of test system

throughput, to maximize production

volume without increasing floorspace.

The N3300 Series electronic loads

can help you in a number of ways to

achieve this goal.

Reduced command processing time:

Commands are processed more

than 10 times faster than previous

electronic loads.

Automatically execute stored

command sequences: “Lists” of

downloaded command sequences can

execute independent of the computer,

greatly reducing the electronic load

command processing time and computer interaction time during product

testing.

Programmable delay allows for

either simultaneous or sequential

load changes: This is the most

multiple output DC power supplies,

simulating real-life loading patterns,

with a minimum of programming

commands.

Buffer measurement data: Voltage,

current, and power measurements

can be buffered for later readback

to the computer, reducing computer

interaction.

Control measurement speed vs.

accuracy: Decrease the number of

measurement samples to achieve

greater measurement speed, or

increase the number of samples to

achieve higher measurement accuracy. You can optimize your measurements for each test.

Control rising and falling slew rates

separately: Reduce rate of loading

change when necessary for DUT

stability or to simulate real life conditions, but otherwise change load

values at maximum rate.

Increase System

Flexibility…for Both

Present and Future

Requirements

Most power supply and battery

charger test systems designed today

need to test a variety of products

and/or assemblies. In the future,

additional products or assemblies

may be needed. A flexible family

of electronic loads makes present

system design and future growth

much easier.

Test low voltage power supplies:

The N3300 Series electronic loads

operate with full stability down to

zero volts. Many other electronic

loads available today have been found

to become unstable in the operating

region below one volt. When designing power supply test platforms, the

trend towards lower voltage requirements should be taken into account.

Refer to the specification and

supplemental characteristic tables

for details of lower voltage operating

characteristics.

Choose DC load connection method:

Automatic test systems need

consistency and reliability. Option

UJ1 8 mm screw connectors provide

a simple screw onto which your

wires, terminated with insulated ring

terminals, may be securely mounted.

This optional connector is specifically

designed for test systems. Wires may

exit the plastic cover in any direction,

and multiple wires may be placed on

each screw terminal for easy parallel

load connections. Up to AWG 4 wire

may be used.

Applications which require repeated

connections/disconnections are better suited to the standard connector.

The standard connector accepts an

unterminated wire, and may be handtightened. This connector is specifically designed for bench applications

and short-term automated tests.

Standard DC connectors

Option UJ1 8 mm screw connectors

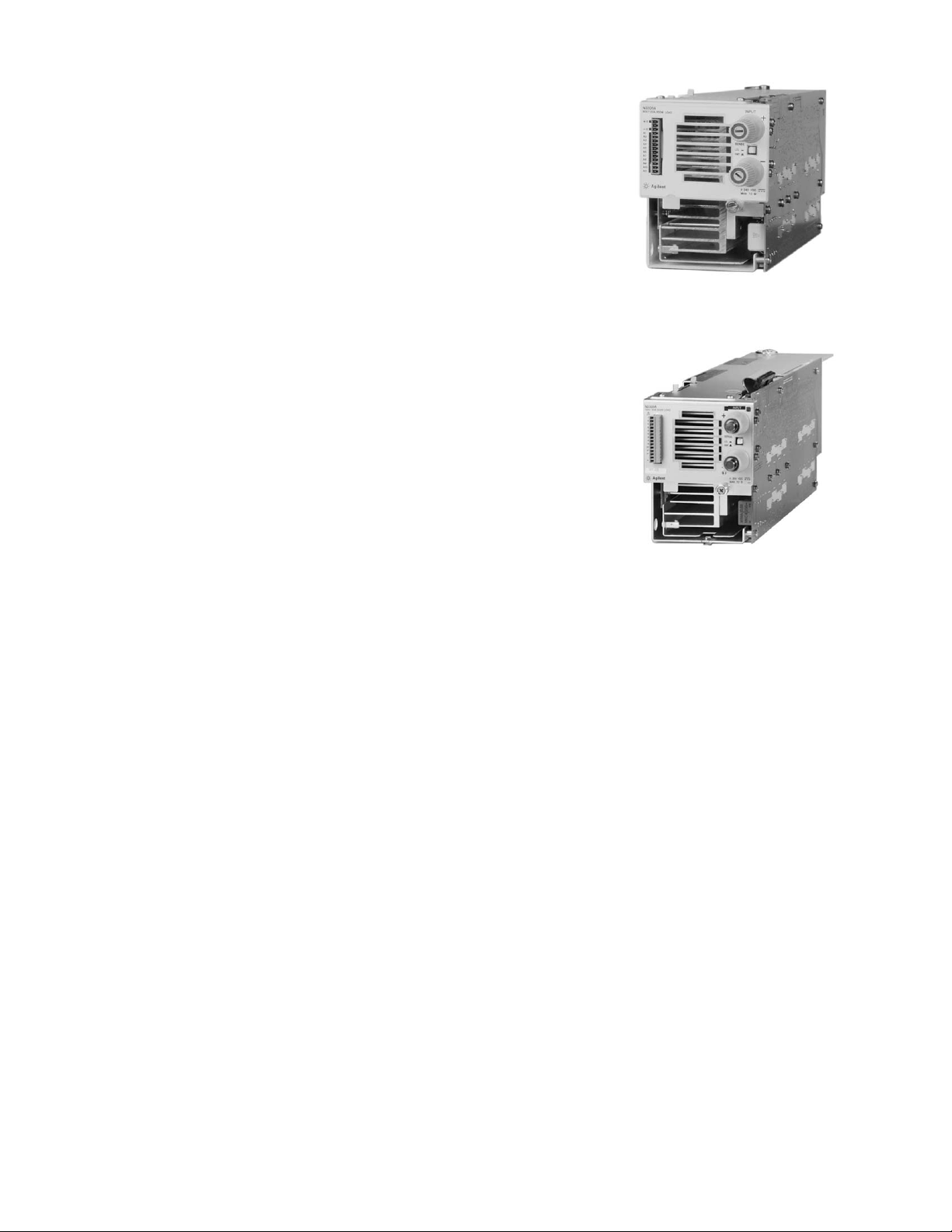

Design a system to test a variety

of products: This series consists of

2 mainframes and 6 modules. The

N3300A mainframe is full rack width.

It has 6 slots. The N3301A mainframe

is half rack width. It has 2 slots.

Any assortment of the 6 different

modules can be configured into these

mainframes, up to the slot capacity.

The N3302A (150 watts), N3303A

(250 watts), N3307A (250 Watts) and

N3304A (300 watts) each require

one slot. The N3305A (500 watts)

and the N3306A (600 watts) each

require 2 slots. The electronic load

can be configured to supply exactly

what you need now, and this modular

design also allows for easy future

reconfiguration.

Test high current power supplies:

Electronic load modules can be operated in parallel to provide additional

current sinking capability.

2

Page 3

Control the electronic load how you

want to: GPIB, RS232, and manual

use of the front panel all provide

complete control of these electronic

loads. There are also analog programming and monitoring ports for those

applications that utilize nonstandard

interfaces, require custom waveforms, or utilize process control

signals. Custom waveforms can also

be created by downloading a “List” of

load parameters. In addition, there is

a built-in transient generator, which

operates in all modes.

Quickly create powerful and

consistent software: All Agilent

Technologies electronic loads use

the SCPI (Standard Commands for

Programmable Instruments) command set. This makes learning the

commands easy, because they are

the same format as all other SCPI

instruments. The resulting code is virtually self-documenting, and therefore

easier to troubleshoot and modify

in the future. Plug-n-Play drivers are

also available to help you to integrate

the loads into your standard software

packages.

Make Measurements

Easily and Accurately

The 16-bit voltage, current and power

measurement system provides both

accuracy and convenience. The

alternative is using a DMM (digital

multimeter) and MUX (multiplexer)

along with a precision current shunt

and a lot of extra wiring. Avoiding

this complexity increases system

reliability and makes the system

easier to design and support. Current

measurements in particular are

more consistently accurate using

the electronic load’s internal system,

because the wiring associated with

an external precision current shunt

may pick up noise.

Measure with all load modules

simultaneously: Testing multiple

output DC power supplies and DC

to DC converters can be very time

consuming if each output must be

tested sequentially. If measurements

are being made through a MUX using

one DMM, this is what will happen.

Using the built-in measurement

capabilities of the N3300 electronic

loads, all outputs can be measured

simultaneously. Alternatively, multiple

single output power sources can be

tested simultaneously.

Observe transient behavior using

waveform digitization: Transient

response and other dynamic tests

often require an oscilloscope. The

N3300 has a flexible waveform

digitizer with a 4096 data point

buffer for voltage and a 4096 data

point buffer for current. Under many

circumstances, this internal digitizer

will be adequate for power supply

test needs. Current and voltage are

digitized simultaneously, and the

sampling rate and sample window

are programmable. Some analysis

functions are provided, including

RMS, max and min.

Measure voltage and current

simultaneously: The N3300 measure-

ment system has individual but linked

current and voltage measurement

systems. This means that voltage

and current measurements are taken

exactly simultaneously, which gives

a true picture of the power supply

under test’s output at a particular

moment in time. Some other electronic loads which feature internal

measurement systems actually take

current and voltage measurements

sequentially, and therefore do not give

as accurate a picture of momentary

power.

3

Page 4

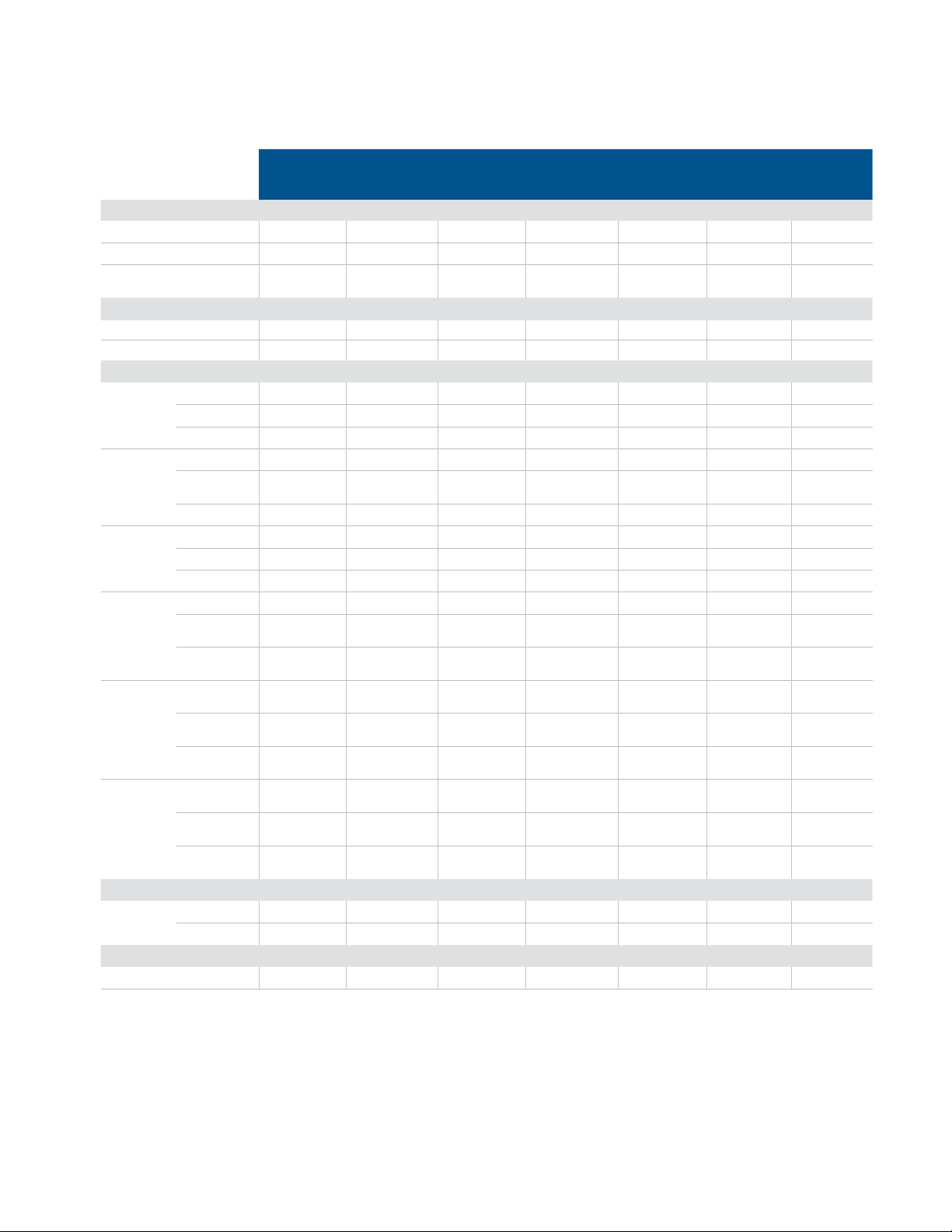

Specifications

Table A-1 lists the specifications for the different load models. Specifications

indicate warranted performance in the 25 °C ± 5 °C region of the operating

temperature range. Specifications apply to normal and transient modes unless

otherwise noted.

Table A-1

N3302A N3303A N3304A N3304-J01

Special

order option

N3305A N3306A N3307A

Input ratings

Current 0–30 A 0–10 A 0–60 A 0–60 A 0–60 A 0–120 A 0–30 A

Voltage 0–60 V 0–240 V 0–60 V 0–80 V 0–150 V 0–60 V 0–150 V

Maximum power @ 40 °C

1

150 W 250 W 300 W 300 W 500 W 600 W 250 W

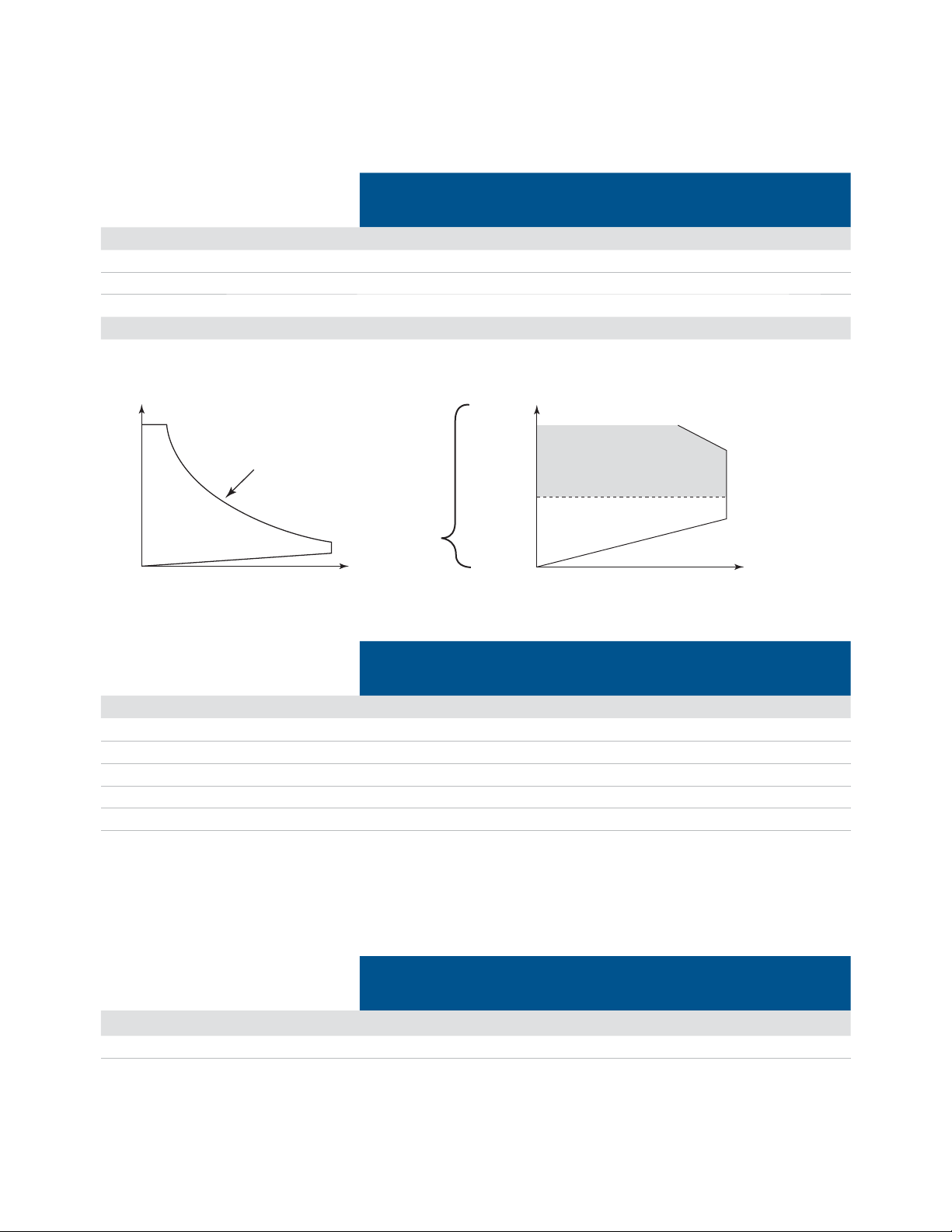

Input characteristic

Operating contour Derated current detail

Voltage

Full

scale

Max. power contour

0

Current

Full

scale

Voltage

Full

scale

All specifications apply

3

Slew rate limitations apply

2

(see Table A-2)

1

0

Current

Full

scale

N3302A N3303A N3304A N3304-J01

Special

order option

N3305A N3306A N3307A

Specified current @ low voltage operation

2.0 V

1.5 V

1.0 V

0.5 V 7.5 A 2.5 A 15 A 15 A 15 A 30 A 7.5 A

0 V 0 A 0 A 0 A 0 A 0 A 0 A 0 A

1. Maximum continuous power available is derated linearly from 100% of maximum at 40 °C, to 75% of maximum at 55 °C.

30 A 10 A 60 A 60 A 60 A 120 A 30 A

22.5 A 7.5 A 45 A 45 A 45 A 90 A 22.5 A

15 A 5 A 30 A 30 A 30 A 60 A 15 A

Table A-1 states that maximum current is available down to 2 volts. Typically,

however under normal operating conditions, the load can sink the maximum

current down to the following voltages:

N3302A N3303A N3304A N3304-J01

Special

order option

N3305A N3306A N3307A

Typical minimum operating voltage @ full scale current

1.2 V 1.2 V 1.2 V 1.2 V 1.4 V 1.4 V 1.4 V

4

Page 5

Table A-1

Specifications (continued)

Constant current mode

Low range/High range

Regulation

Low range accuracy 0.1% +

High range accuracy

0.1% +

Constant voltage mode

Low range/High range

Regulation

Low range accuracy 0.1% +

High range accuracy

0.1% +

Constant resistance mode

Range 1

(I > 10% of current rating)

Range 2

(I > 1% of current rating)

Range 3

(I > 0.1% of current rating)

Range 4

(I > 0.01% of current rating)

2

2

1

1

0.05% +

0.05% +

1

0.05% +

0.1% +

Current measurement

Low range/High range

Low range accuracy

High range accuracy

Voltage measurement

Low range/High range

Low range accuracy 0.05% +

High range accuracy

Power measurement

Accuracy

N3302A N3303A N3304A N3304-J01

N3305A N3306A N3307A

Special order

option

1

3 A/30 A 1 A/10 A 6 A/60 A 6 A/60 A 6 A/60 A 12 A/120 A 3 A/30 A

10 mA 8 mA 10 mA 10 mA 10 mA 10 mA 10 mA

5 mA 4 mA 7.5 mA 7.5 mA 7.5 mA 15 mA 7.5 mA

10 mA 7.5 mA 15 mA 15 mA 15 mA 37.5 mA 15 mA

1

6 V/60 V 24 V/240 V 6 V/60 V 8 V/80 V 15 V/150 V 6 V/60 V 15 V/150 V

5 mV 10 mV 10 mV 10 mV 10 mV 20 mV 10 mV

3 mV 10 mV 3 mV 5 mV 10 mV 3 mV 10 mV

8 mV 40 mV 8 mV 12 mV 20 mV 8 mV 20 mV

1

0.067–4 Ω 0.2–48 Ω 0.033–2 Ω 0.033–2.6 Ω 0.033–5 Ω 0.017–1 Ω 0.067–10 Ω

3.6–40 Ω 44–480 Ω 1.8–20 Ω 2.4–26 Ω 4.5–50 Ω 0.9–10 Ω 9–100 Ω

36–400 Ω 440–4800 Ω 18–200 Ω 24–260 Ω 45–500 Ω 9–100 Ω 90–1000 Ω

360–

2000 Ω

4400–

12000 Ω

180–

2000 Ω

240–

2600 Ω

450–

2500 Ω

90–

1000 Ω

900–

2500 Ω

3 A/30 A 1 A/10 A 6 A/60 A 6 A/60 A 6 A/60 A 12 A/120 A 3 A/30 A

3 mA 2.5 mA 5 mA 5 mA 5 mA 10 mA 3 mA

6 mA 5 mA 10 mA 10 mA 10 mA 20 mA 6 mA

6 V/60 V 24 V/240 V 6 V/60 V 8 V/80 V 15 V/150 V 6 V/60 V 15 V/150 V

3 mV 10 mV 3 mV 5 mV 8 mV 3 mV 8 mV

8 mV 20 mV 8 mV 12 mV 16 mV 8 mV 16 mV

0.4 W 1.2 W 0.6 W 0.8 W 1.6 W 1.3 W 0.9 W

1. Specification is ± (% of reading + fixed offset). Measurement is 1000 samples. Specification may degrade when the unit is subject to an RF field of

3 V/meter, the unit is subject to line spikes of 500 V, or an 8 kV electrostatic discharge.

2. DC current accuracy specifications apply 30 seconds after input current is applied.

5

Page 6

Supplemental

Characteristics

Table A-2 lists the supplemental characteristics, which are not warranted but are

descriptions of typical performance determined either by design or type testing.

Table A-2

N3302A N3303A N3304A N3304A-J01

N3305A N3306A N3307A

Special order

option

Programming resolution

Constant current mode

Constant voltage mode

Constant resistance mode

0.05/0.5 mA 0.02/0.2 mA 0.1/1 mA 0.1/1 mA 0.1/1 mA 0.2/2 mA 0.05/0.5 mA

0.1/1 mV 0.4/4 mV 0.1/1 mV 0.135/1.35 mV 0.25/2.5 mV 0.1/1 mV 0.25/2.5 mV

0.07/0.7/7/

70 mΩ

0.82/8.2/

82 mΩ

0.035/0.35/

3.5/35 mΩ

0.05/0.5/5/

50 mΩ

0.085/0.85/

8.5/ 85 mΩ

0.0175/0.175/

1.75/17.5 mΩ

0.17/1.7/

17/170 mΩ

Readback resolution

Current

Voltage

Programmable slew rate

Current

ranges

Voltage

ranges

Resistance

range 1

Resistance

range 2

Resistance

range 3

Resistance

range 4

Slow band 500–25 kA/s 167–8330 A/s 1 k–50 kA/s 1 k–50 kA/s 1 k–50 kA/s 2–100 kA/s 500–25 kA/s

Fast band ≥3 V 50 k–2.5 MA/s 16.7 k–833 kA/s 100 k–5 MA/s 100 k–5 MA/s 100 k–5 MA/s 200 k–10 MA/s 50 k–2.5 MA/s

Fast band <3 V 50 k–250 kA/s 16.7 k–83.3 kA/s 100 k–500 kA/s 100 k–500 kA/s 100 k–500 kA/s 200 k–1 MA/s 50 k–250 kA/s

Slow band 1 k–50 kV/s 4 k–200 kV/s 1 k–50 kV/s 1.33 k–66.6 kV/s 2.5 k–125 kV/s 1 k–50 kV/s 2.5 k–125 kV/s

Fast band ≥3 V 100 k–

Fast band <3 V 100 k–50 kV/s 400 k–200 kV/s 100 k–50 kV/s 133 k–66.6 kV/s 250 k–125 kV/s 100 k–50 kV/s 250 k–125 kV/s

Slow band 44–1125 Ω/s 540–13.5 kΩ/s 22–560 Ω/s 30–745 Ω/s 55–1400 Ω/s 11–280 Ω/s 110–2800 Ω/s

Fast band ≥3 V 2250–34 kΩ/s 27 k–408 kΩ/s 1120–17 kΩ/s 1500–22.6 kΩ/s 2800–42.5 kΩ/s 560–8.5 kΩ/s 5600–85 kΩ/s

Fast band <3 V 2250–3.4 kΩ/s 27 k–40.8 kΩ/s 1120–1.7 kΩ/s 1500–2.26 kΩ/s 2800–4.25 kΩ/s 560–850 Ω/s 5600–8.5 kΩ/s

Slow band 440–11.25 kΩ/s 5.4 k–135 kΩ/s 220–5600 Ω/s 300–7450 Ω/s 550–14 kΩ/s 110–2800 Ω/s 1.1 k–28 kΩ/s

Fast band ≥3 V 22.5 k–

Fast band <3 V 22.5 k–

Slow band 4.4 k–

Fast band ≥3 V 225 k–

Fast band <3 V 225 k–

Slow band 44 k–

Fast band ≥3 V 2.2 M–

Fast band <3 V 2.25 M–

0.05/0.5 mA 0.02/0.2 mA 0.1/1 mA 0.1/1 mA 0.1/1 mA 0.2/2 mA 0.05/0.5 mA

0.1/1 mV 0.4/4 mV 0.1/1 mV 0.135/1.35 mV 0.25/2.5 mV 0.1/1 mV 0.25/2.5 mV

1

500 kV/s

340 kΩ/s

34 kΩ/s

112.5 kΩ/s

3.4 MΩ/s

340 kΩ/s

1.125 MΩ/s

34 MΩ/s

3.4 MΩ/s

400 k–

2 MV/s

270 k–

4.08 MΩ/s

270 k–

408 kΩ/s

54 k–

1.35 MΩ/s

2.7 M–

40.8 MΩ/s

2.7 M–

4.08 MΩ/s

540 k–

13.5 MΩ/s

27 M–

408 MΩ/s

27 M–

40.8 MΩ/s

100 k–

500 kV/s

11.2 k–

170 kΩ/s

11.2 k–

17 kΩ/s

2.2 k–

56 kΩ/s

112 k–

1.7 MΩ/s

112 k–

170 kΩ/s

22 k–

560 kΩ/s

1.12 M–

17 MΩ/s

1.12 M–

1.7 MΩ/s

133 k–

666 kV/s

15 k–

226 kΩ/s

15 k–

22.6 kΩ/s

3 k–

74.5 kΩ/s

150 k–

2.26 MΩ/s

150 k–

226 kΩ/s

30 k–

745 kΩ/s

1.5 M–

22.6 MΩ/s

1.5 M–

2.26 MΩ/s

250 k–

1.25 MV/s

28 k–

425 kΩ/s

28 k–

42.5 kΩ/s

5.5 k–

140 kΩ/s

280 k–

4.25 MΩ/s

280 k–

425 kΩ/s

55 k–

1.4 MΩ/s

2.8 M–

42.5 MΩ/s

2.8 M–

4.25 MΩ/s

100 k–

500 kV/s

5600–

85 kΩ/s

5600–

8.5 kΩ/s

1.1 k–

28 kΩ/s

56 k–

850 kΩ/s

56 k–

85 kΩ/s

11 k–

280 kΩ/s

560 k–

8.5 MΩ/s

560 k–

850 kΩ/s

250 k–

1.25 MV/s

56 k–850 kΩ/s

56 k–

85 kΩ/s

11 k–

280 kΩ/s

560 k–

8.5 MΩ/s

560 k–

850 kΩ/s

110 k–

2.8 MΩ/s

5.6 M–

85 MΩ/s

5.6 M–

8.5 MΩ/s

Programmable short

Maximum 66 mΩ 200 mΩ. 33 mΩ 33 mΩ 33 mΩ 17 mΩ 33 mΩ

Typical 40 mΩ 100 mΩ 20 mΩ 20 mΩ 25 mΩ 12 mΩ 20 mΩ

Programmable open

≥ 20 kΩ ≥ 80 kΩ ≥ 20 kΩ ≥ 20 kΩ ≥ 20 kΩ ≥ 20 kΩ ≥ 80 kΩ

1. Slew rate bands are the ranges of programmable slew rates available. When you program a slew rate value outside the indicated bands, the electronic

load will automatically adjust the slew rate to fit within the band that is closest to the programmed value. It is not necessary to specify the band, only the

slew rate itself.

Below 3 volts, the maximum bandwidth of the electronic load is reduced by a factor of ten to one. For example, in the current range for Model N3302A,

the maximum slew rate is specified as 2.5 MA/s, below 3 volts the maximum slew rate would be 250 kA/s. Any slew rate programmed between

2.5 MA/s and 250 kA/s would produce a slew rate of 250 k/s. Slew rates programmed slower than 250 kA/s would still correctly reflect their

programmed value. Note that if you are using transient mode to generate a high frequency pulse train, a reduced slew rate might cause the load to

never reach the upper programmed value before beginning the transition to the lower programmed value. So even though the transient mode is still

operational at lower voltages, a fast pulse train with large transitions may not be achievable.

6

Page 7

Supplemental

Characteristics

Table A-2 (continued)

N3302A N3303A N3304A/

N3305A N3306A N3307A

N3304A-J01

Ripple and noise (20 Hz–10 MHz)

Current (rms/peak to peak) 2 mA/

20 mA

Voltage (rms) 5 mV rms 12 mV rms 6 mV rms

1 mA/

10 mA

4 mA/

40 mA

4 mA/

40 mA

2

10 mV rms 8 mV rms 10 mV rms

6 mA/

60 mA

External analog programming

Voltage programming accuracy10.5% + 12 mV 48 mV 12 mV 30 mV 12 mV 30 mV

Current programming accuracy

1

0.25% + 4.5 mA 1.5 mA 9 mA 9 mA 18 mA 4.5 mA

External monitor ports

Voltage monitor accuracy 0.25% + 12 mV 48 mV 12 mV 30 mV 12 mV 30 mV

Current monitor accuracy 0.1% + 4.5 mA 1.5 mA 9 mA 9 mA 18 mA 4.5 mA

1. Applies to all ranges.

2. Ripple and noise for N3304-J01 = 8 mV rms.

Table A-3

Table A-3 lists the supplemental

characteristics for the different mainframes

N3300A N3301A

Operating temperature range

0 °C to 55 °C 0 °C to 55 °C

Input ratings

Operating range

Input current

Input VA

Inrush current 38 A 18 A @ 115 VAC; 36 A @ 230 VAC

100–250 VAC; 48–63 Hz 100–250 VAC; 48–63 Hz

4.2 A @ 100–127 VAC;

2.2 A @ 200–250 VAC

440 VA 230 VA

2.3 A @ 100–250 VAC

2 mA/

20 mA

Table A-4 Measurement time

Number of samples

or points

Measurement time Additional fixed

offset (in addition to

measurement accuracy

1000 samples (default) 20 ms none

200 samples 10 ms < 6%

100 samples 9 ms < 10%

20 points 7 ms < 30%

< 20 points 7 ms > 30%

7

Page 8

Supplemental

Characteristics for All

Model Numbers

Command processing time:

Average time for the output voltage to

change after getting a GPIB command

is 3 ms for discrete commands, 1 ms

for list commands

List dwell characteristics:

Range: 0 - 10 s

Resolution: 1 ms

Accuracy: 5 ms

Transient generator:

Frequency range: 0.25 Hz - 10 kHz

Frequency accuracy: 0.5%

Duty cycle range:

3 to 97% (0.25 Hz - 1 kHz);

6 to 94% (1 kHz - 10 kHz)

Duty cycle accuracy: 1%

Pulse width: 50 μs ± 1% to

4 seconds ± 1%

Analog programming bandwidth:

10 kHz rms (-3 db frequency)

Analog programming voltage:

Voltage: 0 - 10 V

Current: 0 - 10 V

Analog monitor ports:

Voltage: 0 - 10 V

Current: 0 - 10 V

DC floating voltage: Output terminals

can be floated up to ± 300 VDC from

chassis ground

Remote sensing:

5 V DC between sense and load input

Digital/Trigger inputs:

Vil = 0.9 V max at Iil = -1 mA

Vih - 3.15 V min (pull-up resistor on

input)

Digital/Trigger outputs:

Vol = 0.72 V max at Iol = 1 mA

Voh = 4.4 V min at Ioh = -20 μA

GPIB interface capabilities:

SH1, AH1, T6, L4, SR1, RL1 DT1, CD1

Software driver:

VXIplug&play

Regulatory compliance:

UL 61010B-1, IEC 61010-1/EN 61010-1,

CSA C22.2 No. 1010.1

Net weight:

N3300A: 13.2 kg (29 lb);

N3301A: 7.3 kg (16 lb);

N3302A, N3303A, N3304A,

N3304A-J08 or N3307A: 2.7 kg (6 lb);

N3305A or N3306A: 4.6 kg (10 lb)

Shipping weight:

N3300A: 17 kg (38 lb);

N3301A: 9.1 kg (20 lb)

N3302A, N3303A, N3304A,

N3304A-J08 or N3307A: 4.1 kg (9 lb)

N3305A or N3306A: 6.8 kg (15 lb)

Calibration interval: One year for

modules, mainframes do not require

calibration

Warranty: One year

Ordering Information

N3300A & N3301A mainframes ship

with product reference CD-ROM

including: VXIplug&play drivers, user’s

guide, programming guide, and

application notes

Module options:

Opt. A6J: Certificate of calibration

Opt. UK6: Commercial calibration

Opt. UJ1: 8 mm screw terminal

connector

Chassis options:

Opt. 0L1: Printed user’s guide and

programming guide

Note: no service manual available for

this product

Accessories

1CM020A* (N3300A)

Rackmount flange kit 88.1 mm H (2U)

– four brackets (4U total); 1.75 inch

hole spacing

1CP012A* (N3300A)

Rackmount flange and handle kit

88.1 mm H (2U) – four brackets (4U

total); front handles

1CM001A* (N3301A)

Rackmount flange kit 177.0 mm H (4U)

– one bracket, one half-module

bracket

1CM034A* (N3301A)

Rackmount flange kit 177.0 mm H

(4U) – two flange brackets and lock

link kit for mounting two units side by

side. Equivalent to 1CM023A plus

p/n 5061-9694 lock link kit.

E3663AC

Support rails for Agilent rack cabinets

* Support rails or slides are required.

8

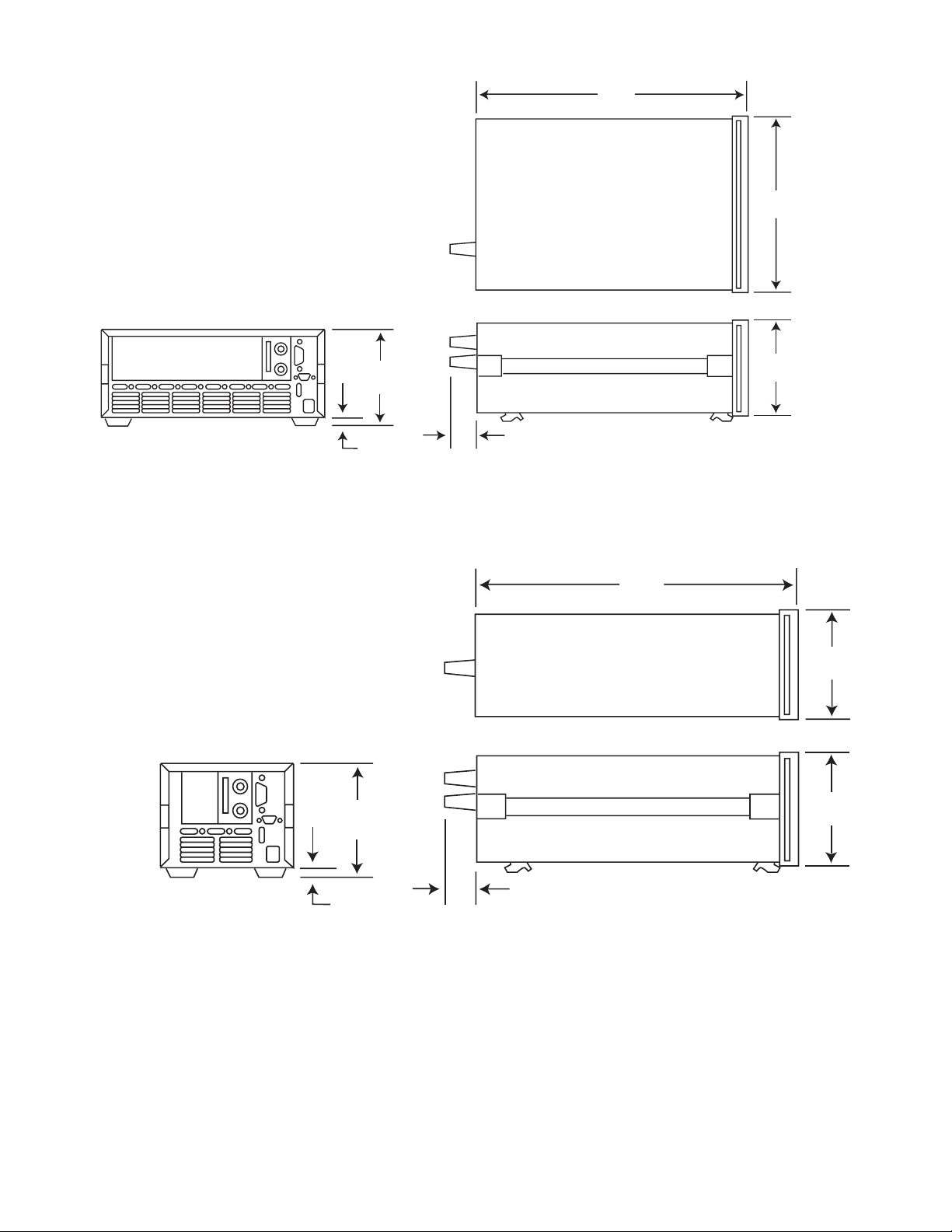

Page 9

Agilent N3300A

To p

624.8mm

24.6"

425.5mm

16.75"

Agilent N3301A

Rear

190.5mm

12.7mm

190.5mm

7.5"

7.5"

0.5"

50.8mm

2.0"

Side

624.8mm

24.6"

To p

177.8mm

7.0"

213.4mm

8.4"

177.8mm

7.0"

Rear

12.7mm

0.5"

50.8mm

Side

2.0"

9

Page 10

s

myAgilent

www.agilent.com/find/myagilent

A personalized view into the information

most relevant to you.

Agilent Channel Partners

www.agilent.com/find/channelpartners

Get the best of both worlds: Agilent’s

measurement expertise and product

breadth, combined with channel

partner convenience.

Agilent Advantage Services is committed

to your success throughout your equipment’s lifetime. To keep you competitve,

we continually invest in tools and

processes that speed up calibration and

repair and reduce your cost of ownership.

You can also use Infoline Web Services

to manage equipment and services more

effectively. By sharing our measurement

and service expertise, we help you create

the products that change our world.

www.agilent.com/find/advantageservices

Agilent Electronic Measurement Group

DEKRA Certified

ISO 9001:2008

Quality Management SystemQuality Management Sy

www.agilent.com/quality

www.agilent.com

For more information on Agilent

Technologies’ products, applications or

services, please contact your local Agilent

office. The complete list is available at:

www.agilent.com/find/contactus

Americas

Canada (877) 894 4414

Brazil (11) 4197 3600

Mexico 01800 5064 800

United States (800) 829 4444

Asia Pacific

Australia 1 800 629 485

China 800 810 0189

Hong Kong 800 938 693

India 1 800 112 929

Japan 0120 (421) 345

Korea 080 769 0800

Malaysia 1 800 888 848

Singapore 1 800 375 8100

Taiwan 0800 047 866

Other AP Countries (65) 375 8100

Europe & Middle East

Belgium 32 (0) 2 404 93 40

Denmark 45 45 80 12 15

Finland 358 (0) 10 855 2100

France 0825 010 700*

*0.125 €/minute

Germany 49 (0) 7031 464

6333

Ireland 1890 924 204

Israel 972-3-9288-504/544

Italy 39 02 92 60 8484

Netherlands 31 (0) 20 547 2111

Spain 34 (91) 631 3300

Sweden 0200-88 22 55

United Kingdom 44 (0) 118 927

6201

For other unlisted countries:

www.agilent.com/find/contactus

Revised: January 6, 2012

Product specifications and

descriptions in this document subject

to change without notice.

© Agilent Technologies, Inc. 2012

Published in USA, December 5, 2012

5980-0232E

Loading...

Loading...