Page 1

Agilent

E4416A/E4417A EPM-P Series

Power Meters and E-Series E9320

Peak and Average Power Sensors

Data Sheet

Page 2

EPM-P power meter specifications

Specifications describe the instrument’s warranted performance and apply after a 30 minute warm-up. These specifications are valid over its operating and environmental

range unless otherwise stated and after performing a zero

and calibration procedure.

Supplemental characteristics are intended to provide additional information; useful in applying the instrument by

giving typical (expected), but not warranted performance

parameters. These characteristics are shown in italics or

labeled as ‘typical’, ‘nominal’ or ‘approximate’.

Measurement uncertainties information can be found in,

Fundamentals of RF and Microwave Power Measurements

- Application Note 64-1, literature number 5965-6630E.

Compatibility, the EPM-P series power meters operate

with the E-series E9320 family of power sensors for peak,

average and time-gated power measurements. The EPM-P

series also operates with the existing 8480 and N8480

series, E-series CW and the E9300 range of power sensors

for average power measurements. For specifications pertaining to the 8480 and E-series CW and E9300 power sensors, please refer to the EPM Series Power Meters, E-

Series and 8480 Series Power Sensors, Technical

Specifications, literature number 5965-6382E. For specifications pertaining to the N8480 series power sensors, please

refer to the N8480 Series Thermocouple Power Sensors,

Technical Specifications, literature number 5989-9333EN.

Measurement modes, the EPM-P series power meters

have two measurement modes:

Single sensor dynamic range

E-series E9320 peak and average power sensors:

70 dB maximum (normal mode);

85 dB maximum (average only mode)

E-series CW power sensors: 90 dB

E-series E9300 average power sensors:

80 dB maximum

8480 series sensors: 50 dB maximum

N8480 series sensors: 55 dB maximum

Display units

Absolute: Watts or dBm

Relative: Percent or dB

Display resolution: Selectable resolution of 1.0,

0.1, 0.01, 0.001 dB in logarithmic mode, or 1 to 4 significant digits in linear mode.

Offset range: ±100 dB in 0.001 dB incre-

ments, to compensate for

external loss or gain

Video bandwidth: 5 MHz (set by meter and is

sensor dependent)

Note that the video bandwidth represents the ability of

the power sensor and meter to follow the power envelope

of the input signal. The power envelope of the input signal

is, in some cases, determined by the signal's modulation

bandwidth, and hence video bandwidth is sometimes

referred to as modulation bandwidth.

1. Normal mode (default mode using E9320 sensors)

for peak, average and time-related measurements,

and

2. Average only mode. This mode is primarily for

average power measurements on low-level signals,

when using E9320 sensors, and is the mode used

with 8480 and N8480 series sensors, E-series CW

sensors and E-series E9300 sensors.

Frequency range: 9 kHz to 110 GHz,

sensor dependent

Power range: -70 to +44 dBm,

sensor dependent

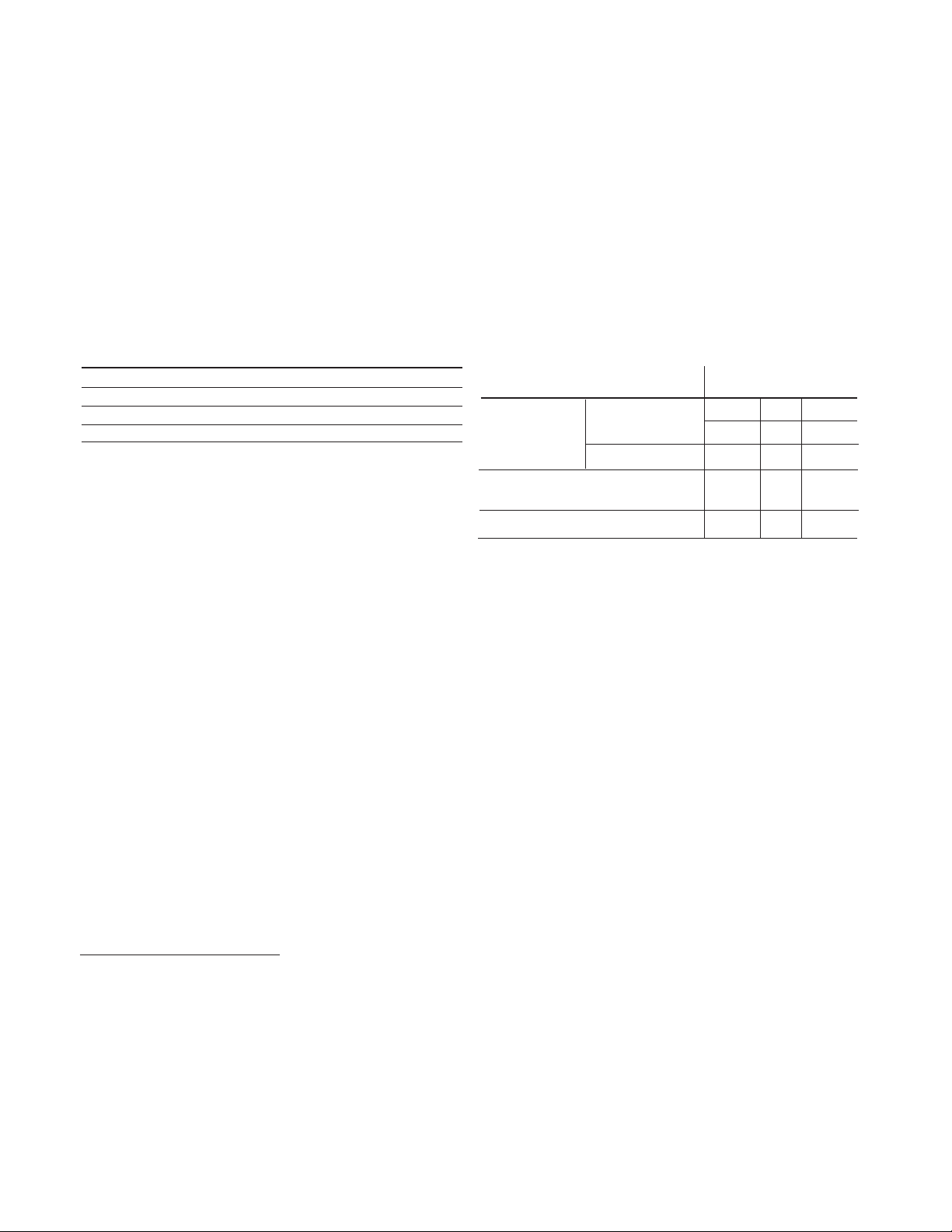

Table 1. Video bandwidth versus peak power dynamic range

Sensor model Video bandwidth/maximum peak power dynamic range

OFF High Medium Low

E9321A 300 kHz/ 300 kHz/ 100 kHz/ 30 kHz/

E9325A -40 dBm to +20 dBm -42 dBm to +20 dBm -43 dBm to +20 dBm -45 dBm to +20 dBm

E9322A 1.5 MHz/ 1.5 MHz/ 300 kHz/ 100 kHz/

E9326A -36 dBm to +20 dBm -37 dBm to +20 dBm -38 dBm to +20 dBm -39 dBm to +20 dBm

E9323A 5 MHz/ 5 MHz/ 1.5 MHz/ 300 kHz/

E9327A -32 dBm to +20 dBm -32 dBm to +20 dBm -34 dBm to +20 dBm -36 dBm to +20 dBm

Video bandwidth/

dynamic range optimization

The power measurement system, comprising the sensor

and meter, has its maximum video bandwidth defined by

the E9320 sensor. To optimize the system’s dynamic range

for peak power measurements, the video bandwidth in

the meter can be set to High, Medium and Low, as

detailed in the following table. The filter video bandwidths

stated in the table are not the 3 dB bandwidths as the

video bandwidths are corrected for optimal flatness. Refer

to figures 6 to 8 for information on the sensor’s peak flatness response. A filter OFF mode is also provided.

2

Page 3

Accuracy

Measurement characteristics:

Instrumentation

Please add the corresponding power sensor linearity percentage; see Tables 6a and 6b for the E9320 sensors.

Average only mode:

Absolute

Logarithmic: ±0.02 dB

Linear: ±0.5%

Relative Logarithmic: ±0.04 dB

Linear: ±1.0%

Normal mode:

Calibration temperature1Temperature

±5 °C 0 to 55 °C

Absolute accuracy (log) ±0.04 dB ±0.08 dB

Absolute accuracy (linear) ±0.8% ±1.7%

Relative accuracy (log) ±0.08 dB ±0.16 dB

Relative accuracy (linear) ±1.6% ±3.4%

Time Base Accuracy 0.01%

1 mW power reference

Power output: 1.00 mW (0.0 dBm). Factory

Accuracy: For two years

Frequency: 50 MHz nominal

SWR: 1.06 maximum (1.08 maximum

set to ±0.4% traceable to the

National Physical Laboratories

(NPL), UK

±0.5% (23 ± 3 °C)

±0.6% (25 ± 10 °C)

±0.9% (0 to 55 °C)

for Option E41xA-003)

2

Measurements: Average power

Peak power

Peak-to-average ratio

Measurements between two time

offsets (time-gating)

Averaging: Averaging over 1 to 1024 readings

is available for reducing noise

Measurement speed (GPIB)

Over the GPIB, three measurement speeds are available

(normal, x 2 and fast). The typical maximum speed is

shown in the table below.

Table 2. Measurement speed for different sensor types

Sensor type Measurement speed

(readings/second)

Normal x 2 Fast

E-Series E9320 Average only mode 20 40 400

peak and average

sensors Normal mode

E-Series CW and E9300 average power 20 40 400

sensors

8480 and N8480 Series sensor 20 40 N.A.

5

20 40 1000

3,4

Channel functions A, B, A/B, B/A, A-B, B-A and

Relative

Storage registers 10 instrument states can be

saved via the Save/Recall menu.

Predefined setups

For common wireless standards (GSM900, EDGE, NADC,

iDEN, Bluetooth, IS-95 CDMA, W-CDMA and cdma2000),

predefined setups are provided.

Connector type: Type N (f), 50 ohms

1. Power meter is within ±5 °C of its calibration temperature.

2. National metrology institutes of member states of the Metre Convention, such as the

National Institute of Standards and Technology in the USA, are signatories to the

ComitÈ International des Poids et Mesures Mutual Recognition Arrangement. Further

information is available from the Bureau International des Poids et Mesures, at

http://www.bipm.fr/

3. Fast speed is not available for 8480 and N8480 series sensors.

4. Maximum measurement speed is obtained by using binary output in free run trigger.

5. For E9320 sensors, maximum speed is achieved using binary output in free run

acquisition.

3

Page 4

Trigger

Sources: Internal, External TTL,

GPIB, RS232/422,

Time resolution: 50 ns

Delay range: ±1.0 s

Delay resolution: 50 ns for delays < ±50 ms;

otherwise 200 ns

Hold-off:

Range: 1 us to 400 ms

Resolution: 1% of selected value

(minimum of 100 ns)

Internal trigger:

Range: -20 to +20 dBm

Level accuracy: ±0.5 dB

Resolution: 0.1 dB

Latency: 500 ns ± 100 ns

Trigger out: Outputs a TTL signal for synchronizing

with external equipment, BNC connector.

Ground: Binding post accepts 4 mm plug or bare wire

connection

Line power

Input voltage range 85 to 264 Vac,

automatic selection

Input frequency range 47 to 440 Hz

Power requirement approximately 50 VA

(14 Watts)

Remote programming

Interface: GPIB interface operates to IEEE 488.2 and

IEC-625. RS-232 and RS-422 serial interfaces supplied as

standard

Command language: SCPI standard interface

commands

GPIB compatibility: SH1, AH1, T6, TE0, L4, LE0, SR1,

RL1, PP1, DC1, DT1, C0.

Latency is defined as the delay between the applied RF

crossing the trigger level and the meter switching into

the triggered state.

External trigger range: High > 2.0 V, Low < 0.8 V;

BNC connector; rising or falling edge triggered; input

impedance > 1 kW.

Trigger out: Output provides TTL compatible levels

(high > 2.4 V, low < 0.4 V) and uses a BNC connector

Sampling characteristics

Sampling rate: 20 Msamples/second

Sampling technique: Continuous sampling

Rear panel inputs/outputs

Recorder output(s): Analog 0 to 1 V, 1 kW output

impedance, BNC connector. Two outputs are available

on E4417A (channels A and B).

Remote input/output:

TTL output: used to signal when mea-

surement has exceeded a

defined limit.

TTL input: initiates zero and calibration

cycle.

Connector type: RJ-45 series shielded modu-

lar jack assembly.

TTL output: high = 4.8 V max;

low = 0.2 V max.

TTL input: high = 3.5 V min, 5 V max;

low = 1 V max, -0.3 V min.

RS-232/422 interface: Serial interface for communi-

cation with an external controller. Male plug 9-pin

D-subminiature connector.

Trigger in: Accepts a TTL signal for initiating measure-

ments, BNC connector.

Environmental specifications

Operating environment

Temperature 0° to 55 °C

Maximum humidity 95% at 40 °C,

(non-condensing)

Minimum humidity 15% at 40 °C

Maximum altitude 3,000 meters

(9,840 feet)

Storage conditions:

Storage temperature -20 to +70°C

Non-operating maximum

humidity: 90% at 65 °C

(non-condensing)

Non-operating maximum

altitude: 15,420 meters

(50,000 feet)

Regulatory information

Electromagnetic compatibility: This product

conforms with the protection requirements of European

Council Directive 89/336/EEC for Electromagnetic

Compatibility (EMC). The conformity assessment

requirements have been met using the technical

Construction file route to compliance, using EMC test

specifications EN 55011:1991 (Group 1, Class A) and EN

50082-1:1992. In order to preserve the EMC performance

of the product, any cable which becomes worn or damaged must be replaced with the same type and specification.

Product safety: This product conforms to the require-

ments of European Council Directive 73/23/EEC, and

meets the following safety standards:

IEC 61010-1(1990) + A1 (1992) + A2 (1995) /

EN 61010-1 (1993)

IEC 825-1 (1993) / EN 60825-1 (1994)

Canada / CSA C22.2 No. 1010.1-93

4

Page 5

Physical specifications

Dimensions: The following dimensions exclude front

and rear panel protrusions: 212.6 mm W x 88.5 mm

H x 348.3 mm D (8.5 in x 3.5 in x 13.7 in)

Weight

Net:

E4416A: 4.0 kg (8.8 lbs) approximate

E4417A: 4.1 kg (9.0 lbs) approximate

Shipping:

E4416A: 7.9 kg (17.4 lbs) approximate

E4417A: 8.0 kg (17.6 lbs) approximate

Ordering information

Standard-shipped accessories

Power sensor cable

E9288A 1.5 meter (5 ft). One per E4416A, two

per E4417A

Documentation

E441xA-0B0 Delete hard copy English language User’s

Guide

E441xA-0BF Hard copy English language Programming

Guide

E441xA-0BK Additional hard copy English language

User’s Guide and Programming Guide

E441xA-0B3 Hard copy English language Service

Manual

E441xA-ABD Hard copy German localization User’s

Guide and Programming Guide

E441xA-ABE Hard copy Spanish localization User’s

Guide and Programming Guide

E441xA-ABF Hard copy French localization User’s Guide

and Programming Guide

E441xA-ABJ Hard copy Japanese localization User’s

Guide and Programming Guide

E441xA-ABZ Hard copy Italian localization User’s Guide

and Programming Guide

Power sensor cables

E441xA-004 Delete power sensor cable

Power cord

One 2.4 meter (7.5 ft) cable. Power plug matches

destination requirements.

ANSI/NCSL Z540-1-1994 certificate of calibration

supplied as standard.

Manuals

• Hard copy English language User’s Guide and

Installation Guide

• Product CD-ROM (contains English and localized

User’s Guide and Programming Guide)

Warranty

Included with each EPM-P power meter is a standard 12month return-to-Agilent warranty and service plan. A

selection can be made to extend the initial warranty and

service plan to 3 or 5 years. Standard-shipped accessories

come with a 3-month warranty.

Power meter options

Connectors

E441xA-002 Parallel rear panel sensor input

connector(s) and front panel reference

calibrator connector

E441xA-003 Parallel rear panel sensor input

connector(s) and rear panel reference

calibrator connector

For operation with the E9320 power sensors:

E9288A Power sensor cable, length 5 ft (1.5 m)

E9288B Power sensor cable, length 10 ft (3 m)

E9288C Power sensor cable, length 31 ft (10 m)

Note: The E9288A, B, and C sensor cables will also

operate with 8480, N8480 and E-series power sensors.

For operation with 8480, N8480, E-series CW and E9300

power sensors:

11730A Power sensor and SNS noise source

cable, length 5 ft (1.5 m)

11730B Power sensor and SNS noise source

cable, length 10 ft (3 m)

11730C Power sensor and SNS noise source

cable, length 20 ft (6.1 m)

11730D Power sensor cable, length 50 ft (15.2 m)

11730E Power sensor cable, length 100 ft (30.5 m)

11730F Power sensor cable, length 200 ft (61.0 m)

Other sensor cable lengths can be supplied on request.

Accessories

E441xA-908 Rack mount kit (one instrument)

E441xA-909 Rack mount kit (two instruments)

34131A Transit case for half-rack 2U high instruments

34141A Yellow soft carry / operating case

34161A Accessory pouch

Calibration documentation

E441xA-A6J ANSI Z540 compliant calibration test

data including measurement uncertainties

1. CD includes EPM-P analyzer software.

5

Page 6

Service options

Warranty and Calibration

R-50C-011-3: Agilent Calibration Upfront

Plan 3-year coverage

R-50C-011-5: Agilent Calibration Upfront

Plan 5-year coverage

R-51B-001-3C: 1 year Return-to-Agilent

warranty extended to 3 years

R-51B-001-5C: 1 year Return-to-Agilent

warranty extended to 5 years

The E9320 Series power sensors have a

12-month return-to-Agilent warranty and

service plan. For more information,

contact your local sales and service office.

Table 3. Sensor specifications

1

E-series E9320 power sensor

specifications

The E9320 peak and average power sensors are designed

for use with the EPM-P series power meters. The E9320

sensors have two measurement modes:

Normal mode (default mode for E9320 sensors) for

peak, average and time-related measurements

Average only mode is designed primarily for average

power measurements on low-level signals. This mode is

the only mode used with 8480 and N8480 series sensors,

E-series CW sensors and E-series E9300 sensors.

The following specifications are valid after zero and calibration of the power meter.

Note: E9320 power sensors MUST be used with an

E9288A, B or C cable.

Sensor

model

E9321A

E9325A

E9322A

E9326A

E9323A

E9327A

Video

bandwidth

300 kHz

1.5 MHz

5 MHz

Frequency range

50 MHz to 6 GHz

50 MHz to 18 GHz

50 MHz to 6 GHz

50 MHz to 18 GHz

50 MHz to 6 GHz

50 MHz to 18 GHz

Power range

Average only mode Normal mode

-65 dBm to +20 dBm -50 dBm to +20 dBm

-60 dBm to +20 dBm -45 dBm to +20 dBm

-60 dBm to +20 dBm -40 dBm to +20 dBm

2

Maximum power

+23 dBm average;

+30 dBm peak

(< 10 msec duration)

Connector

type

Type N (m)

1. Options not available in all countries.

2. For average power measurements, free run acquisition.

6

Page 7

The E9320 power sensors have two measurement ranges

(lower and upper) as detailed in Table 4.

Table 4. Lower and upper measurement ranges

E9321A/E9325A

Normal Average only

Lower range

-50 dBm -65 dBm

(min. power)

Lower range

+0.5 dBm -17.5 dBm

(max. power)

Lower to upper

auto range point

Upper to lower

-9.5 dBm -18.5 dBm

auto range point

Upper range

-35 dBm -50 dBm

(min. power)

Upper range

+20 dBm +20 dBm

(max. power)

Table 5. Power sensor maximum SWR

Sensor model

E9321A,

E9325A

Maximum SWR (< = 0 dBm)

50 MHz to 2 GHz: 1.12

2 GHz to 10 GHz: 1.16

10 GHz to 16 GHz: 1.23

16 GHz to 18 GHz: 1.28

E9322A/E9326A

Normal Average only

-45 dBm -60 dBm

1

-5 dBm -13.5 dBm

-15 dBm -14.5 dBm

-35 dBm -45 dBm

1

+20 dBm +20 dBm

E9323A/E9327A

Normal Average only

-40 dBm -60 dBm

1

-5 dBm -10.5 dBm

-15 dBm -11.5 dBm

-30 dBm -35 dBm

1

+20 dBm +20 dBm

1

1

E9322A,

E9326A

50 MHz to 2 GHz: 1.12

2 GHz to 12 GHz: 1.18

12 GHz to 16 GHz: 1.21

16 GHz to 18 GHz: 1.27

E9323A,

E9327A

50 MHz to 2 GHz: 1.14

2 GHz to 16 GHz: 1.22

16 GHz to 18 GHz: 1.26

Figure 1. Typical SWR for the E9321A and E9325A sensors at various power

levels

Figure 2. Typical SWR for the E9322A and E9326A sensors at various power

levels

Figure 3. Typical SWR for the E9323A and E9327A sensors at various power

levels

1. Applies to CW and constant amplitude signals only above –20 dBm.

7

Page 8

Sensor linearity

Table 6a. Power sensor linearity, normal mode

(upper and lower range).

Sensor model Temperature Temperature

( 25 ± 10 °C) (0 to 55 °C)

E9321A and E9325A ±4.2% ±5.0%

E9322A and E9326A ±4.2% ±5.0%

E9323A and E9327A ±4.2% ±5.5 %

Table 6b. Power sensor linearity, average only mode

(upper and lower range).

Figure 4. Typical power linearity at 25 °C for the E9323A and

E9327A 5 MHz bandwidth sensors, after zero and calibration, with

associated measurement uncertainty.

Sensor model Temperature Temperature

( 25 ± 10 °C) (0 to 55 °C)

E9321A and E9325A ±3.7% ±4.5%

E9322A and E9326A ±3.7% ±4.5%

E9323A and E9327A ±3.7% ±5.0 %

If the sensor temperature changes after calibration, and

the meter and sensor is not re-calibrated, then the following

additional linearity errors should be added to the linearity

figures in Tables 6a and 6b.

Table 6c. Additional linearity error (normal and average only modes).

Sensor model Temperature Temperature

( 25 ± 10 °C) (0 to 55 °C)

E9321A and E9325A ±1.0% ±1.0%

E9322A and E9326A ±1.0% ±1.5%

E9323A and E9327A ±1.0% ±2.0 %

Power range –30 to –20 to –10 to 0 to +10 to

–20 dBm –10 dBm 0 dBm +10 dBm +20 dBm

Measurement ±0.9% ±0.8% ±0.65% ±0.55% ±0.45%

uncertainty

Figure 5. Relative mode power measurement linearity with an

EPM-P series power meter, at 25 °C (typical).

Figure 5 shows the typical uncertainty in making a relative

power measurement, using the same power meter channel

and the same power sensor to obtain the reference and the

measured values. It also assumes that negligible change in

frequency and mismatch error occurs when transitioning

from the power level used as the reference to the power

level measured.

8

Page 9

Peak flatness

The peak flatness is the f latness of a peak-to-average ratio

measurement for various tone-separations for an equal

magnitude two-tone RF input. Figures 6, 7 and 8 refer to

the relative error in peak-to-average measurement as the

tone separation is varied. The measurements were performed at –10 dBm average power using an E9288A sensor

cable (1.5 m).

Calibration Factor (CF) and

Reflection Coefficient (Rho)

Calibration Factor and Reflection Coefficient data are provided at frequency intervals on a data sheet included with

the power sensor. This data is unique to each sensor. If you

have more than one sensor, match the serial number on

the data sheet with the serial number of the power sensor

you are using. The CF corrects for the frequency response

of the sensor. The EPM-P series power meter automatically

reads the CF data stored in the sensor and uses it to make

corrections.

For power levels greater than 0 dBm, add to the calibration factor uncertainty specification:

±0.1%/dB (for E9321A and E9325A sensors),

±0.15%/dB (for E9322A and E9326A sensors) and

±0.2%/dB (for E9323A and E9327A sensors).

Reflection Coefficient (Rho) relates to the SWR according

to the formula:

SWR = (1 + Rho) / (1 – Rho)

Figure 6. E9321A and E9325A Error in peak-to-average measurements for a

two-tone input (high, medium, low and off filters).

Figure 7. E9322A and E9326A error in peak-to-average measurements for a

two-tone input (high, medium, low and off filters).

Figure 8. E9323A and E9327A error in peak-to-average measurements for a

two-tone input (high, medium, low and off filters).

Maximum uncertainties of the CF data are listed in Table 7.

The uncertainty analysis for the calibration of the sensors

was done in accordance with the ISO Guide. The uncertainty data, reported on the calibration certificate, is the

expanded uncertainty with a 95% confidence level and a

coverage factor of 2.

Table 7. Calibration factor uncertainty at 0.1 mW (-10 dBm).

Frequency

50 MHz

100 MHz

300 MHz

500 MHz

800 MHz

1.0 GHz

1.2 GHz

1.5 GHz

2.0 GHz

3.0 GHz

4.0 GHz

5.0 GHz

6.0 GHz

7.0 GHz

8.0 GHz

9.0 GHz

10.0 GHz

11.0 GHz

12.0 GHz

12.4 GHz

13.0 GHz

14.0 GHz

15.0 GHz

16.0 GHz

17.0 GHz

18.0 GHz

Uncertainty (%)

(25 ±10°C)

Reference

±1.8

±1.8

±1.8

±1.8

±2.1

±2.1

±2.1

±2.1

±2.1

±2.1

±2.1

±2.1

±2.3

±2.3

±2.3

±2.3

±2.3

±2.3

±2.3

±2.3

±2.5

±2.5

±2.5

±2.5

±2.5

Uncertainty (%)

(0 to 55°C)

Reference

±2.0

±2.0

±2.0

±2.0

±2.3

±2.3

±2.3

±2.3

±2.3

±2.3

±2.3

±2.3

±2.5

±2.5

±2.5

±2.5

±2.5

±2.5

±2.5

±2.5

±2.8

±2.8

±2.8

±2.8

±2.8

9

Page 10

Zero set

This specification applies to a ZERO performed when the

sensor input is not connected to the POWER REF.

Table 8. Zero set

Sensor model Zero set Zero set

(normal mode) (average only mode)

E9321A, E9325A 5 nW 0.17 nW

E9322A, E9326A 19 nW 0.5 nW

E9323A, E9327A 60 nW 0.6 nW

Example:

E9321A power sensor, number of averages = 4, free run

acquisition, normal mode, x 2 speed.

Measurement noise calculation:

(< 6 nW x 0.88 x 1.2) = < 6.34 nW

Effect of video bandwidth setting: The noise per sample

is reduced by applying the meter video bandwidth reduction filter setting (High, Medium or Low). If averaging is

implemented, this will dominate any effect of changing the

video bandwidth.

Table 11. Effect of video bandwidth on noise per sample.

Zero drift and measurement noise

Table 9. Zero drift and measurement noise.

Sensor

Zero drift

1

Measurement noise

model

E9321A

Normal Average only

mode mode

< ±5 nW < ±60 pW

Normal Normal Average only

mode

3

mode

4

< 6 nW < 75 nW < 165 pW

E9325A

E9322A

< ±5 nW < ±100 pW

< 12 nW < 180 nW < 330 pW

E9326A

E9323A

< ±40 nW < ±100 pW

< 25 nW < 550 nW < 400 pW

E9327A

Effect of averaging on noise: Averaging over 1 to 1024

readings is available for reducing noise. Table 9 provides

the measurement noise for a particular sensor. Use the

noise multipliers in Table 10, for the appropriate speed

(normal or x 2) or measurement mode (normal or average

only) and the number of averages, to determine the total

measurement noise value.

In addition, for x 2 speed (in normal mode) the total measurement noise should be multiplied by 1.2, and for fast

speed (in normal mode), the multiplier is 3.4.

Note that in fast speed, no additional averaging is

implemented.

2

mode

Noise multipliers

Sensor

E9321A

Low

0.32

Medium

0.50

High

0.63

E9325A

E9322A

0.50

0.63

0.80

E9326A

E9323A

0.40

0.63

1.0

E9327A

Example:

E9322A power sensor, triggered acquisition, video bandwidth = High.

Noise per sample calculation:

(< 180 nW x 0.80) = < 144 nW

Effect of time-gating on measurement noise

The measurement noise will depend on the time gate

length, over which measurements are made. Effectively

20 averages are carried out every 1 us of gate length.

Table 10. Noise multipliers

Mode

Number of

1

4

2

8

16

32

64

128

256

512

averages

Average

-only

Noise multiplier

(normal speed)

Noise multiplier

5.5

6.5

3.89

4.6

2.75

3.25

1.94

2.3

1.0

1.63

0.85

1.0

0.61

0.72

0.49

0.57

0.34

0.41

0.24

0.29

(x 2 speed)

Normal

Noise multiplier

1.0

0.94

0.88

0.82

0.76

0.70

0.64

0.58

0.52

0.46

(normal speed;

free run acquisition)

1. Within 1 hour after zero set, at a constant temperature, after a 24 hour warm-up of the power meter.

2. Measured over a one-minute interval, at a constant temperature, two standard deviations, with averaging set to 1

(for normal mode), 16 (for average only mode, normal speed) and 32 (for average only mode, x 2 speed).

3. In free run acquisition mode.

4. Noise per sample, video bandwidth set to OFF with no averaging (i.e. averaging set to 1) - see the note “Effect of

Video Bandwidth Setting” and Table 11.

10

1024

0.17

0.2

0.40

Page 11

Settling times

Average-only mode:

In normal and x 2 speed, manual filter, 10 dB decreasing power

step refer to Table 12.

Table 12. Settling time (average only mode)

Number of average 1 2 4 8 16 32 64 128 256 512 1024

Settling time(s) normal 0.08 0.13 0.24 0.45 1.1 1.9 3.5 6.7 14 27 57

Settling time(s) x 2 0.07 0.09 0.15 0.24 0.45 1.1 1.9 3.5 6.7 14 27

In fast speed, within the range –50 to +20 dBm, for a 10 dB

decreasing power step, the settling time is 10 ms (for the E4416A)

and 20 ms (for the E4417A).

When a power step crosses the power sensor’s auto-range switch point,

add 25 ms.

Normal mode:

In normal, free run acquisition mode, within the range –20 to +20 dBm,

for a 10 dB decreasing power step, the settling time is dominated by

the measurement update rate and is listed in Table 13 for various filter settings.

Table 13. Settling time (normal mode)

Number of averages 1 2 4 8 16 32 64 128 256 512 1024

Settling time free run 0.1 0.15 0.25 0.45 0.9 1.7 3.3 6.5 13.0 25.8 51.5

acquisition, normal speed (s)

Settling time free run 0.08 0.1 0.15 0.25 0.45 0.9 1.7 3.3 6.5 13.0 25.8

acquisition, X2 speed (s)

Table 14. Rise and fall times versus sensor bandwidth

In normal mode, measuring in continuous or single acquisition mode,

the performance of rise times, fall times and 99% settled results are shown

in Table 14. Rise time and fall time specifications are for a 0.0 dBm pulse,

with the rise time and fall time measured between 10% to 90% points and

upper range selected.

Sensor model Parameter Video bandwidth setting

E9321A, Rise time (< μs) 2.6 1.5 0.9 0.3

E9325A Fall time (< μs) 2.7 1.5 0.9 0.5

Settling Time (rising) (< μs) 5.1 5.1 4.5 0.6

Settling Time (falling) (< μs) 5.1 5.1 4.5 0.9

E9322A, Rise time (< μs) 1.5 0.9 0.4 0.2

E9326A Fall time (< μs) 1.5 0.9 0.4 0.3

Settling Time (rising) (< μs) 5.3 4.5 3.5 0.5

Settling Time (falling) (< μs) 5.3 4.5 3.5 0.9

E9323A, Rise time (< μs) 0.9 0.4 0.2 0.2

E9327A Fall time (< μs) 0.9 0.4 0.2 0.2

Settling Time (rising) (< μs) 4.5 3.5 1.5 0.4

Settling Time (falling) (< μs) 4.5 3.5 2 0.4

Overshoot in response to power steps with fast rise times, i.e. less than the

sensor rise time, is < 10%. When a power step crosses the power sensor’s

auto-range switch point, add 10 μs.

1

Low Medium High Off

1. Rise and fall time specifications are only valid when used with the E9288A sensor cable (1.5 meters).

11

Page 12

Physical specifications

Dimensions: 150 mm L x 38 mm W x 30 mm H

(5.9 in x 1.5 in x 1.2 in)

Weight: Net: 0.2 kg (0.45 lbs)

Shipping: 0.55 kg (1.2 lbs)

Ordering information

E9321A 50 MHz to 6 GHz; 300 kHz BW

E9322A 50 MHz to 6 GHz; 1.5 MHz BW

E9323A 50 MHz to 6 GHz; 5 MHz BW

E9325A 50 MHz to 18 GHz; 300 kHz BW

E9326A 50 MHz to 18 GHz; 1.5 MHz BW

E9327A 50 MHz to 18 GHz; 5 MHz BW

Accessories supplied

Operating and Service Guide (multi-language)

ANSI/NCSL Z540-1-1994 Certificate of Calibration

supplied as standard

Power sensor options

E932xA-A6J Supplies ANSI/NCSL Z540-1-1994

test data including measurement

uncertainties

E932xA-0B1 Add manual set

12

Page 13

www.agilent.com

For more information on Agilent

Technologies’ products, applications

or services, please contact your local

Agilent office. The complete list is

available at:

www.agilent.com/find/contactus

Americas

Canada (877) 894-4414

Latin America 305 269 7500

United States (800) 829-4444

Asia Pacific

Australia 1 800 629 485

China 800 810 0189

Hong Kong 800 938 693

India 1 800 112 929

Japan 0120 (421) 345

Korea 080 769 0800

Malaysia 1 800 888 848

Singapore 1 800 375 8100

Taiwan 0800 047 866

Thailand 1 800 226 008

Europe & Middle East

Austria 43 (0) 1 360 277 1571

Belgium 32 (0) 2 404 93 40

Denmark 45 70 13 15 15

Finland 358 (0) 10 855 2100

France 0825 010 700*

*0.125€/minute

Germany 49 (0) 7031 464 6333

Ireland 1890 924 204

Israel 972-3-9288-504/544

Italy 39 02 92 60 8484

Netherlands 31 (0) 20 547 2111

Spain 34 (91) 631 3300

Sweden 0200-88 22 55

Switzerland 0800 80 53 53

United Kingdom 44 (0) 118 9276201

Other European Countries:

www.agilent.com/find/contactus

Revised: October 1, 2009

Product specifications and descriptions in this document subject to

change without notice.

© Agilent Technologies, Inc. 2009

Printed in USA, November 2, 2009

5980-1469E

www.agilent.com/find/EPM

Agilent Email Updates

www.agilent.com/find/emailupdates

Get the latest information on the products

and applications you select.

www.lxistandard.org

LXI is the LAN-based successor to GPIB,

providing faster, more efficient connectivity. Agilent is a founding member of the LXI

consortium.

Agilent Channel Partners

www.agilent.com/find/channelpartners

Get the best of both worlds: Agilent’s

measurement expertise and product

breadth, combined with channel partner

convenience.

Remove all doubt

Our repair and calibration services will get

your equipment back to you, performing like

new, when promised. You will get full value

out of your Agilent equipment through-out

its lifetime. Your equipment will be serviced

by Agilent-trained technicians using the latest factory calibration procedures, automated repair diagnostics and genuine parts.

You will always have the utmost confidence

in your measurements. For information

regarding self maintenance of this product,

please contact your Agilent office.

Agilent offers a wide range of additional

expert test and measurement services for

your equipment, including initial start-up

assistance, onsite education and training,

as well as design, system integration, and

project management.

For more information on repair and

calibration services, go to:

www.agilent.com/find/removealldoubt

Loading...

Loading...