Atd ATD-7432 User Manual

Telescopic

Transmission

Jack

Operating Instructions & Parts Manual

Model Number

Atd-7432

Capacity

1000 Lb.

This is the safety alert symbol. It is used to alert you to potential personal injury hazards.

!

Obey all safety messages that follow this symbol to avoid possible injury or death.

Atd Tools Inc.

160 Enterprise Drive, Wentzville MO 63385

ATD7432-M0 10/07

Printed in China

SAFETY and GENERAL INFORMATION

Save these instructions. For your safety, read, understand, and follow the information provided with and on this jack.

The owner and operator shall have an understanding of this jack and safe operating procedures before attempting

to use. The owner and operator shall be aware that use and repair of this product may require special skills and

knowledge. Instructions and safety information shall be conveyed in the operator’s native language before use of this

jack is authorized. If any doubt exists as to the safe and proper use of this jack, remove from service immediately.

Inspect before each use. Do not use if broken, bent, cracked, or damaged parts (including labels) are noted. Any

jack that appears damaged in any way, operates abnormally or is missing parts, shall be removed from service

immediately. If the jack has been or suspected to have been subjected to a shock load (a load dropped suddenly,

unexpectedly upon it), immediately discontinue use until jack has been checked by an Atd Tools authorized service

center (

inspection be done by qualified personnel. Replace worn or damaged parts and assemblies with Atd Tools Authorized

Replacement Parts only. Labels and Operator’s Manuals are available from manufacturer.

contact distributor or manufacturer for list of Authorized Service Centers)

. It is recommended that an annual

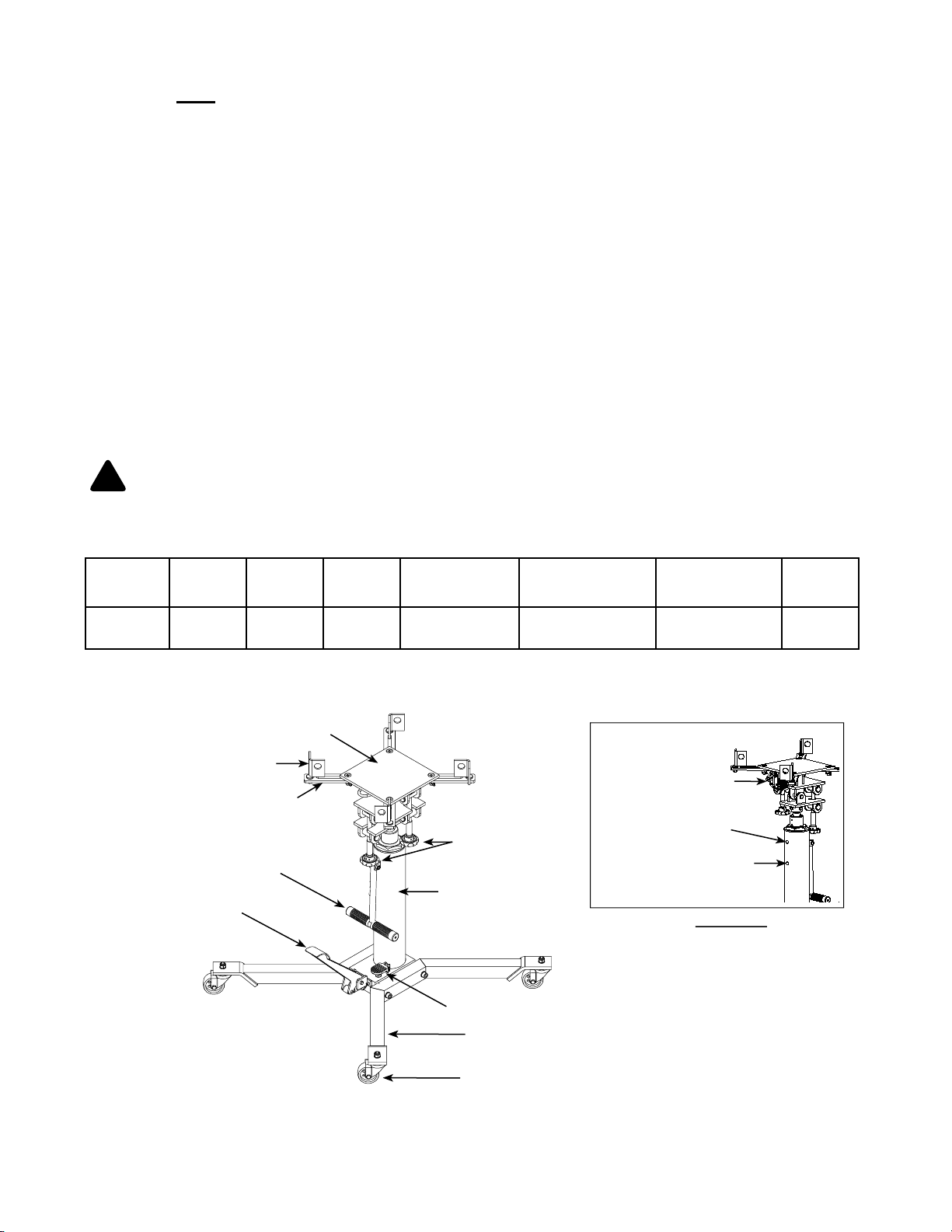

PRODUCT DESCRIPTION

Atd Tools Hydraulic Transmission Jack is designed to be used as an aid in the removal and installation of automotive

and light truck transmissions, transfer cases and transaxles. It is intended for use under an overhead lift or in a

garage pit.

Do not use for any purpose other than those uses outlined above.

!

SPECIFICATIONS

Model Capacity

Atd-7432 1000-lb 36" 73" 9 7/8" x 9 7/8" 18 1/2" x 18 1/2"

Saddle Bracket

Bracket Bar

Position Handle

Lift Pedal

Min.

Height

Saddle Base

Max.

Height

Saddle Base

Tilt Adjustment

Knobs

Hydraulic Unit

Release Valve Pedal

Extended Saddle

Area

*Shipping/Vent Plug

*replace w/ vent plug

before initial use

Jack Size

(L x W)

34 1/2" x 34 3/8"

Nylon Strap

Oil Filler Plug

Rear View

Net

Weight

141 lb.

Base half

Caster

Figure 1 - Transmission Jack Components

2

ASSEMBLY (Refer to Figure 1)

Estimated Assembly Time:

20 minutes.

Tools Required for Assembly:

A big Philips Screwdriver, 19mm wrench, socket

wrench and torque wrench.

1. Package contents:

(a) Hydraulic unit,

(b) Saddle unit,

(c) Base half 2 pieces,

(d) Caster 4 pieces,

(e) Saddle bracket & bracket bar 4 sets,

(f) Position handle, and

(g) hardware

2. Attach all four casters to the base halves and secure

with washers and M12 locknuts.

3. Attach either one of the two base halves to the base

of the hydraulic unit, then secure using M12x70 bolts

and lock washers. Apply the same procedure to the

other base half. Use torque wrench to tighten to 30

lb.ft.. Do not overtighten.

4. Attach the position handle onto Hydraulic unit with

M10x40 bolt and locknut.

5. Position the saddle unit above the ram plunger, place

the saddle socket onto the ram plunger. Secure with

two M12x20 bolts provided.

6. Secure all four bracket bars to the saddle with

M12x40 screws and wing nuts. Then attach saddle

brackets onto the bracket bars with M10 nuts.

BEFORE USE

1. Verify that the product and the application are

compatible, if in doubt call Atd Tools Technical

Service (636)327-9050.

2. Before using this product, read the operator's manual

completely and familiarize yourself thoroughly with

the product, its components and recognize the

potential hazards associated with its use.

3. Press the release valve pedal, ensure that saddle is

fully lowered. Remove shipping plug (shipping plug

is located above the oil filler plug). Ensure oil level

is just below the rim of the oil filler hole. Reinstall

with vent plug provided.

4. Check to ensure that jack rolls freely, that the pump

and release valve operate smoothly. Raise and lower

the unloaded jack throughout the advertised lift range

before putting into service.

5. Replace worn or damaged parts and assemblies

with Factory Authorized Replacement Parts only.

Lubricate as instructed in Maintenance Section.

! WARNING

• Study, understand, and follow all printed materials

provided with/on this product before use.

• Do not exceed rated capacity.

• Use only on hard, level surface.

• Use of this jack is limited to the removal,

installation and transportation of transmissions,

transfer cases and transaxles. Do not use a

transmission jack to tilt or support a vehicle.

• Use only the saddle assembly to lift. Never use

any other part of the jack as a lifting surface.

• Ensure the center gravity of load is centered on

the saddle.

• For your safety, do not exceed 10 degree tilt angle

of the saddle assembly in all directions.

• Adequately support the vehicle before servicing.

• Use only strap, attachments and/or adapters

supplied by the manufacturer.

• If loaded jack must be moved, make sure that the

load is secured, stable and in lowest position.

• This is a lifting device only.

• Transfer load immediately to appropriate support

device for service or repair.

• Shock loads may cause the sudden loss of load

and/ or cause the jack to tip or flip over violently,

bend or break.

• No alterations shall be made on this product.

• Failure to heed these markings may result in

personal injury and/or property damage.

! WARNING

To avoid crushing and related

injuries:

NEVER work on, under or

around a load supported

only by transmission jack.

Immediately transfer the load to

an appropriate support device.

3

Loading...

Loading...