Page 1

Owner's Operating

Service Instruction

Manual

• ASSEMBLY

lOtfc

Model Nos

136-480A

•OPERATION

• REPAIR PARTS

136-485A

MTD PRODUCTS INC

PRINTED IN U.S.A.

• 5389 tlEST 130th STREET •

P. 0. BOX 2741 CLEVELAND OHIO 44111

FORM NO. 770-6037

Page 2

IMPORTANT

It is suggested that this manual be read in its entirety before attempting to assemble or operate. Keep this

manual in a safe place for future reference and for ordering replacement parts.

This unit is shipped WITHOUT GASOLINE or OIL. After assembly, see operating section of this manuai for

proper fuel and amount.

SAFE OPERATION PRACTICES FOR RIDING VEHICLES

1. Know the controls and how to stop quickly—

READ THE OWNER’S MANUAL.

2. Do not allow children to operate vehicle. Do

not allow adults to operate it without proper

instruction.

3. Do not carry passengers. Keep children and

pets a safe distance away.

4. Clear work area of objects which might be

picked up and thrown.

5. Disengage all attachment clutches and shift

into neutral before attempting to start engine.

6. Disengage power to attachment(s) and stop

engine before leaving operator position.

7. Disengage power to attachment(s) and stop

engine before making any repairs or adjust

ments.

8. Disengage power to attachment(s) when

transporting or not in use.

9. Take all possible precautions when leaving

vehicle unattended such as disengaging

power-take-off, lowering attachments, shift

ing into neutral, setting parking brake,

stopping engine and removing key.

10. Do not stop or start suddenly when going

uphill or downhill. Mow up and down face of

steep slopes; never across the face.

11. Reduce speed on slopes and in sharp turns to

prevent tipping or loss of control. Exercise ex

treme caution when changing direction on

slopes.

12. Stay alert for holes in terrain and other hidden

hazards.

13. Use care when pulling loads or using heavy

equipment.

A. Use only approved drawbar hitch points.

B. Limit loads to those you can safely

control.

C. Do not turn sharply. Use care when

backing.

D. Use counterweight(s) or wheel weights

when suggested in owner’s manual.

14. Watch out for traffic when crossing or near

roadways.

15. When using any attachments never direct dis

charge of material toward bystanders nor

allow anyone near vehicle while in operation.

16. Handle gasoline with care—it is highly

flammable.

A. Use approved gasoline container.

B. Never remove cap or add gasoline to a run

ning or hot engine or fill fuel tank indoors.

Wipe up spilled gasoline.

C. Open doors if engine is run in garage—ex

haust fumes are dangerous. Do not run

engine indoors.

17. Keep the vehicle and attachments in good

operating condition, and keep safety devices

in place. Use guards as instructed in owner’s

manual.

18. Keep all nuts, bolts, and screws tight to be

sure the equipment is in safe working

condition.

19. Never store the equipment with gasoline in

the tank inside a building where fumes may

reach an open flame or spark. Allow engine to

cool before storing in any enclosure.

20. To reduce fire hazard keep engine free of

grass, leaves or excessive grease.

21. The vehicle and attachments should be

stopped and inspected for damage after

striking a foreign object, and the damage

should be repaired before restarting and

operating the equipment.

22. Do not change the engine governor settings or

overspeed the engine.

23. When using the vehicle with mower, proceed

as follows:

(1) Mow only in daylight or in good artificial

light.

(2) Never make a cutting height adjustment

while engine is running if operator must

dismount to do so.

(3) Shut engine off when removing grass

catcher and/or unclogging chute.

(4) Check blade mounting bolts for proper

tightness at frequent intervals.

24. Check grass catcher bags frequently for wear

or deterioration. Replace with new bags for

safety protection.

25. Look behind to make sure the area is clear

before placing the transmission in reverse and

backing up.

Page 3

INDEX

Safe Operation Practices.....

Index......................................................................... 3

Assembly and Battery Instructions

Controis.....................................................................6

Operating Instructions.............................................9

Maintenance

Lubrication............................................................. 10

Adjustments...........................................................11

Belt Replacement

Off-Season Storage................................................15

Trouble Shooting Chart for Recoil Start

Trouble Shooting Chart for Electric Start

Schematic for Recoil Start Unit.............................19

Schematic for Electric Start Unit

GRASS CATCHER Model No. 196-015A is

available as optional equipment for the mowers

shown in this manual.

...........................................................

...................................................

...................................

.....................

..............

............

..........................

2

4

10

13

16

17

20

\ warning )

The mower should not be operated

without the entire grass catcher or

chute deflector in place.

NOTE

Under normal usage bag material is

subject to wear, and should be

checked periodically. Be sure any

replacement bag complies with the

mower manufacturer’s recommen

dations.

For replacement bags, use only fac

tory authorized replacement bag No.

764-0121.

Differential Breakdown and Parts List

Deck Linkage

Transmission Breakdown......................................23

Transmission Parts List.........................................24

Wheel Chart.

Illustrated Parts for R.H. Side of Rider

Parts List for R.H. Side of Rider

Illustrated Parts for L.H. Side of Rider

Parts List for L.H. Side of Rider............................29

Illustrated Parts for Frame View

Parts List for Frame View

Illustrated Parts for Deck View

Parts List for Deck View

Parts Information....................................Back Cover

TIRE PRESSURE

FOR SHIPPING PURPOSES, THE TIRES ON

YOUR UNIT MAY BE OVER-INFLATED. TIRE

PRESSURE SHOULD BE REDUCED BEFORE

UNIT IS PUT INTO OPERATION. PRESSURE

SHOULD BE APPROXIMATELY 15 P.S.I. EQUAL

TIRE PRESSURE SHOULD BE MAINTAINED ON

ALL TIRES. MAXIMUM TIRE PRESSURE IS 30

P.S.I.

Reference to right-hand or left-hand

side of machine is from the driver’s

seat facing forward.

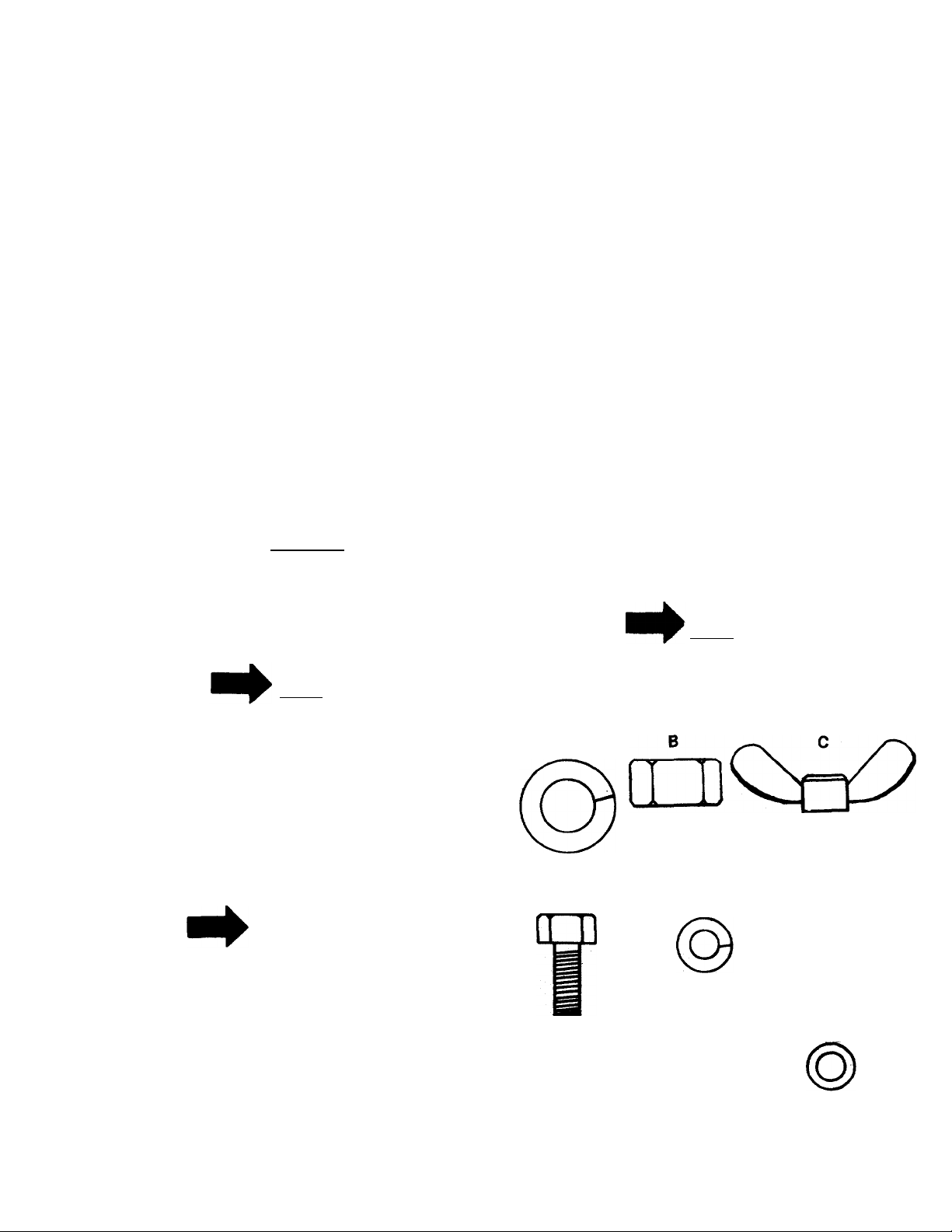

Lockwasher 1/2”

..........................................................

........................................................

...........

.............................

........................................

NOTE

Hex Nut

1/2—13

................

.25

................

..........

..................27

.................

...........................

...........................31

Wing Nut 1/4—20

21

22

26

28

30

32

33

IMPORTANT

After striking a foreign object, stop

the engine. Remove wire from spark

plug, thoroughly inspect the mower

for any damage, and repair the dam

age before restarting and operating

the mower.

The steering wheel and seat, with the necessary

hardware, are easily assembled to the machine.

On the electric starter models, the battery must be

activated and installed as outlined in this section.

D

Lock Washer 1 /4”

Hex Bolt

1/4—20x5/8

(ED

Hex Lock Nut

3/8—16 Belleville Washer 3/8”

FIGURE 1. HARDWARE SUPPLIED

¿D

Hex Nut

1/4—20

H

Page 4

ASSEMBLY

Step 1. Remove the lawn mower and all parts

from the carton. Make certain that all

loose parts and literature have been

removed before the carton is discarded.

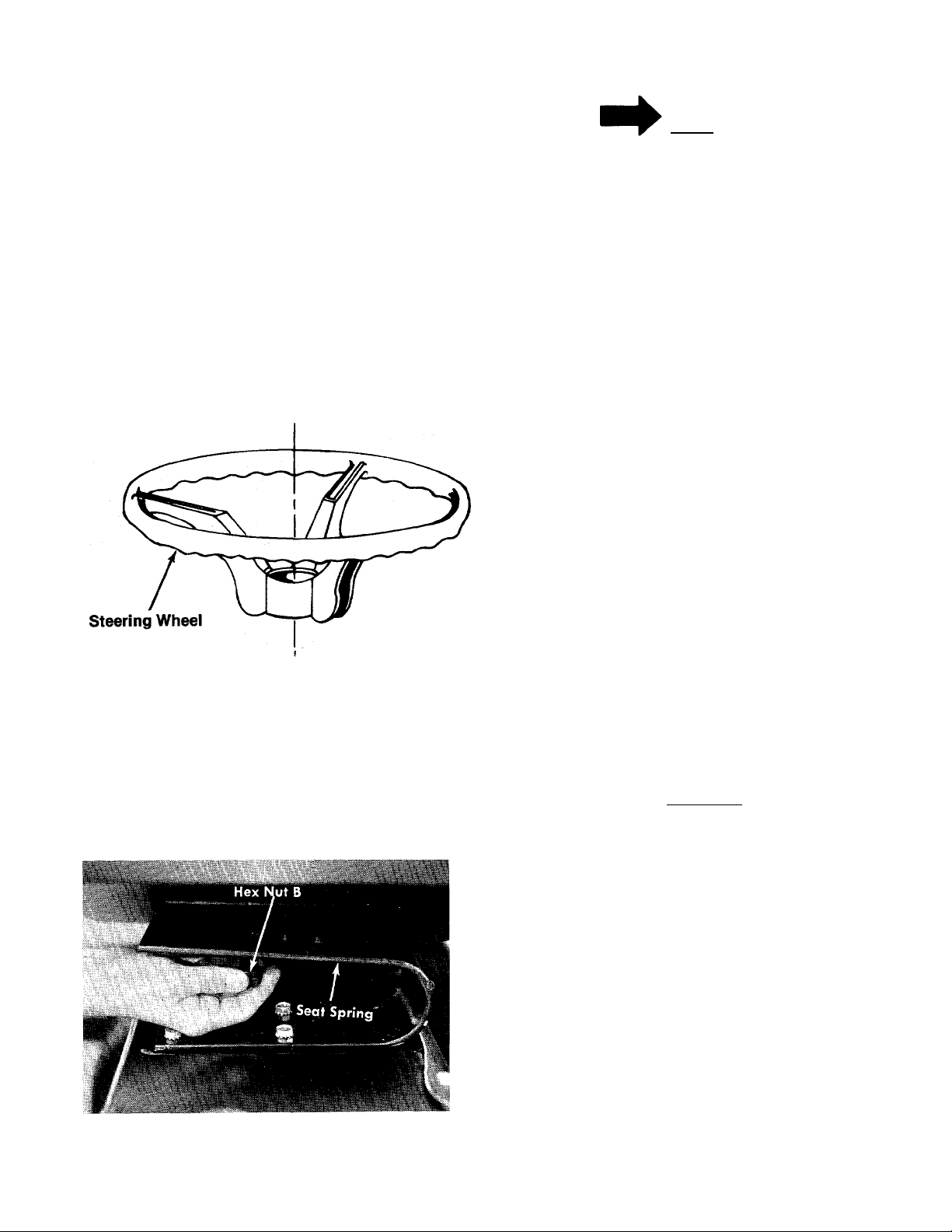

Step 2. Place steering wheel over steering shaft.

Step 3. Secure with Believille washer and hex

nut. See figure 2.

Step 4. Press the cap on the steering wheei by

hand. See figure 2.

Steering Wheel Cap—

NOTE

Check ALL nuts and bolts for cor

rect tightness.

BATTERY INFORMATION

FOR ELECTRIC START

MODELS

Hex Nut-

Belleville Washer ’

FIGURE 2. STEERING WHEEL ASSEMBLY

mounting bolt molded in the seat.

A. Select one of three hole locations on

seat spring.

B. Place seat on spring and secure with

lockwasher (A) and hex nut (B). See

figures 1 and3.

■G

■H

\ WARNING (

Battery acid must be handled with great care

A.

as it will blister the skin and damage clothing.

It is advisable to wear goggles, rubber gloves,

and a protective apron when working with it.

B.

Neutralize acid spilled on clothing with dilute

ammonia water or a water solution of baking

soda. If acid gets on clothes, dilute it with

clean water first, then neutralize.

C. If for any reason acid should be spattered in

the eyes, wash it out immediately with clean

cold water. Seek medical aid if discomfort

continues.

D. Since battery acid is corrosive to metals, do

not pour into any sink or drain. Rinse empty

theStep 5. Your molded seat comes with

electrolyte containers and mutilate before

discarding.

I DANGER \

BATTE-RIES CONTAIN SULFURIC

ACID AND MAY CONTAIN EXPLO

SIVE GASES (when electrolyte has

been added)

FIGURE 3. SEAT ASSEMBLY

A. Keep sparks, flame, cigarettes away.

B. Hydrogen gas is generated during charging

and discharging.

C. Ventilate when charging or using in enclosed

space.

D. When using a charger—to avoid sparks,

NEVER connect or disconnect charger clips to

battery while charger is turned on.

E. Always shield eyes, protect skin and clothing

when working near batteries.

Page 5

ACTIVATING THE

BATTERY

1. Place battery to be filled on bench or

workbench. NEVER activate battery in unit.

Remove vent caps from all cells.

2. Fill each cell carefully using battery grade

1.250-1.265 specific gravity. Sulfuric acid to

be 3/8” above the top of the separators or to

split ring.

3-. Allow battery to set for 20 minutes to I/2 hour.

Add additional acid if necessary to bring it up

to the proper levei.

4. Repiace the vent caps.

5. The battery can now be charged after the 20

minutes setting period. Battery can be SLOW

CHARGED (DO NOT FAST CHARGE) at a

maximum bench rate of 4-5 amperes until the

specific gravity reading is 1.265-1.275. A

charging rate in excess of this will buckle and

warp the positive plates and perforate the

separators. If electrolyte bubbles violently

while charging, reduce charging rate until

excessive bubbling action subsides, then

continue charging until specific gravity is

reached.

CAUTION

A

After battery has been in service,

add only approved water. DO NOT

ADD ACID.

B. TO INSTALL BATTERY

To install the battery in this unit, refer to next

column.

C. MAINTENANCE

1. Check periodically (every two weeks or

before and after charging) to be sure elec

trolyte level is 9/16” above separator

plates. Add only distilled water or good

quality drinking water. NEVER add addi

tional acid or other chemicals to battery

after initial activation.

2. The battery should be checked with a

hydrometer after every 25 hours of

operation. If the specific gravity is less than

1.225 remove battery and recharge.

3. Coat the terminals and exposed wiring with

a thin coat of grease or petroleum jelly for

longer service and protection against

electrolyte corrosion.

4. The battery should be kept clean. Any

deposits of acid should be neutralized with

soda and water. Be careful not to get this

solution in the cells.

D. STORAGE

1. Charge battery using normal methods.

NEVER store discharged battery as it will

not recover.

2. Store in cold, dry place.

3. Recharge battery whenever the specific

gravity is less than 1.225 before returning to

service or every two months, whichever

comes first.

E.

COMMON CAUSES FOR BATTERY FAILURE

ARE:

1. Overcharging

2. Undercharging

3. Lack of water

4. Loose hold downs and/or corroded con

nections

5. Excessive loads

6. Battery electrolyte substitutes

7. Freezing of electrolyte

NOTE

THESE FAILURES DO NOT CON

STITUTE WARRANTY.

LIMITED WARRANTY

For ninety (90) days of original retail purchase, the

battery carries a limited warranty against faulty

material or workmanship by the battery manufac

turer.

INSTALLING THE

BATTERY

1. Open the hood of the riding mower.

2. Place the battery in the battery case with the

terminal to the front. See figure 4.

Page 6

FIGURE 4.

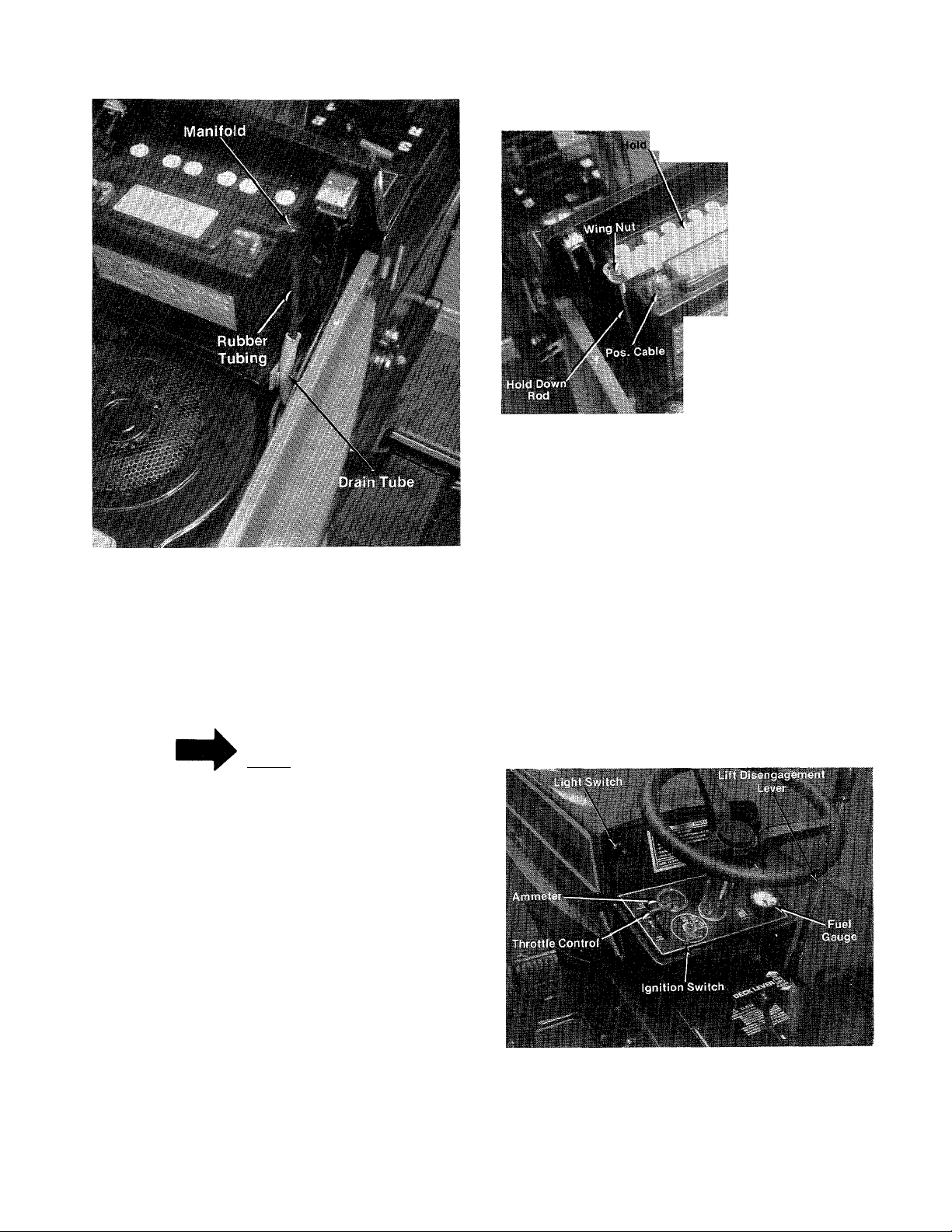

3. Cut the black rubber tubing approximately 4

Inches long.

4. Push the rubber tubing into the manifold of

the battery and place the other end into the

drain tube. See figure 4.

Dov.n

Neg.

i . .. .■,<

FIGURES.

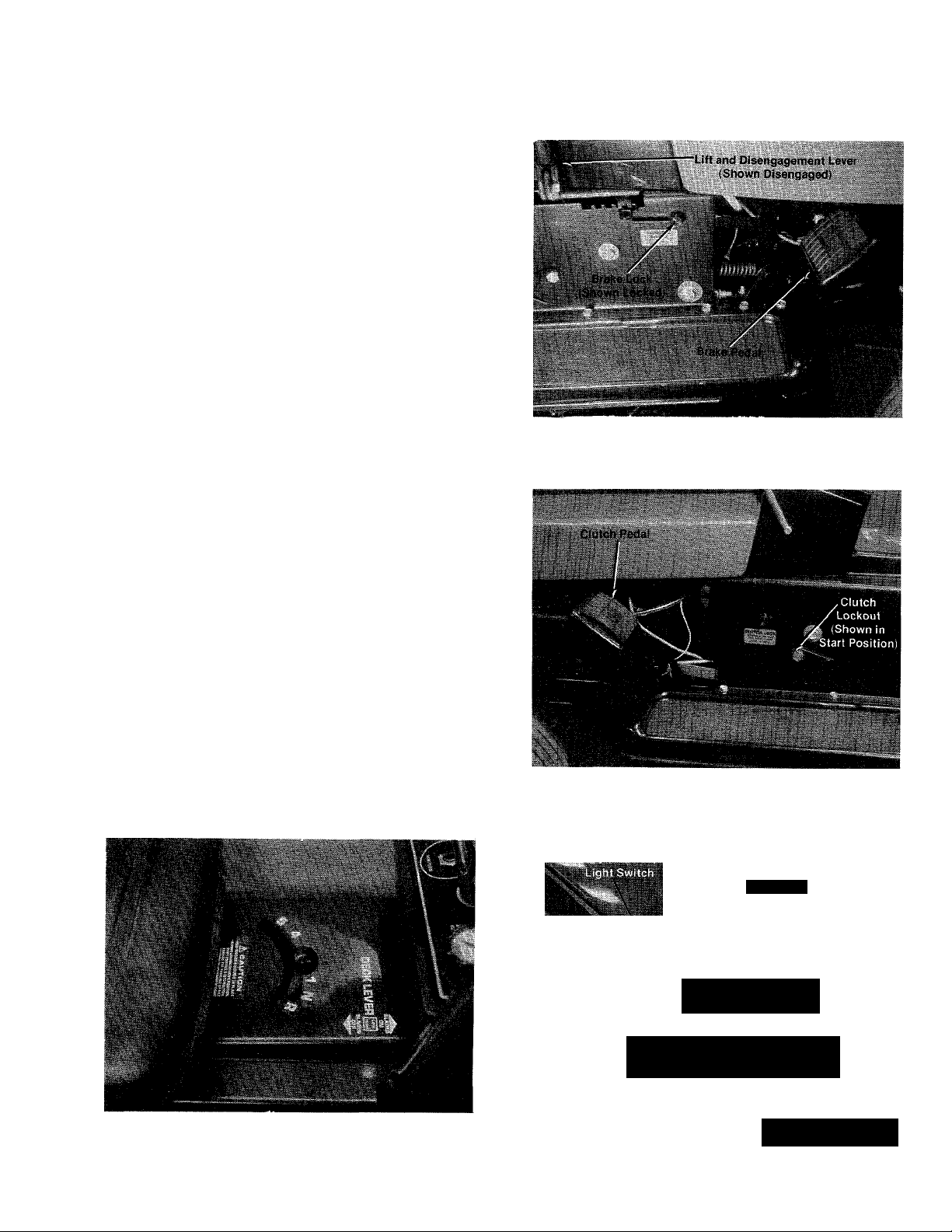

CONTROLS

The controls on both models may be considered

as the Drive Control and the Cutting Control as

follows:

a. Throttle Control. The throttle control is used to

regulate the engine speed and choke the engine.

The engine should be operated from % to full

throttle when operating the cutting deck or snow

thrower (optional). See figure 6.

NOTE

The vented battery allows any gases

or liquid from the battery to be car

ried to the rear of the mower through

the drain tube.

5. Hook the hold down rods under the battery

case and place the hold down over the

manifold of the battery as shown In figure 5.

6. Secure the hold down with the wing nuts.

7. Attach the positive cable (from the starter

solenoid) and the small wire (from the

ammeter) to the positive battery terminal with

the bolt, lockwasher and nut in the assembly

pack.

8. Attach the negative cable, grounded, to the

negative battery terminal with the bolt,

lockwasher and nut in the assembly pack.

FIGURE 6. CONTROLS

b. Gear Shift Lever. The gear shift lever is used to

shift into one of four Forward Gears, NEUTRAL or

REVERSE. See figures 6 and 7.

Page 7

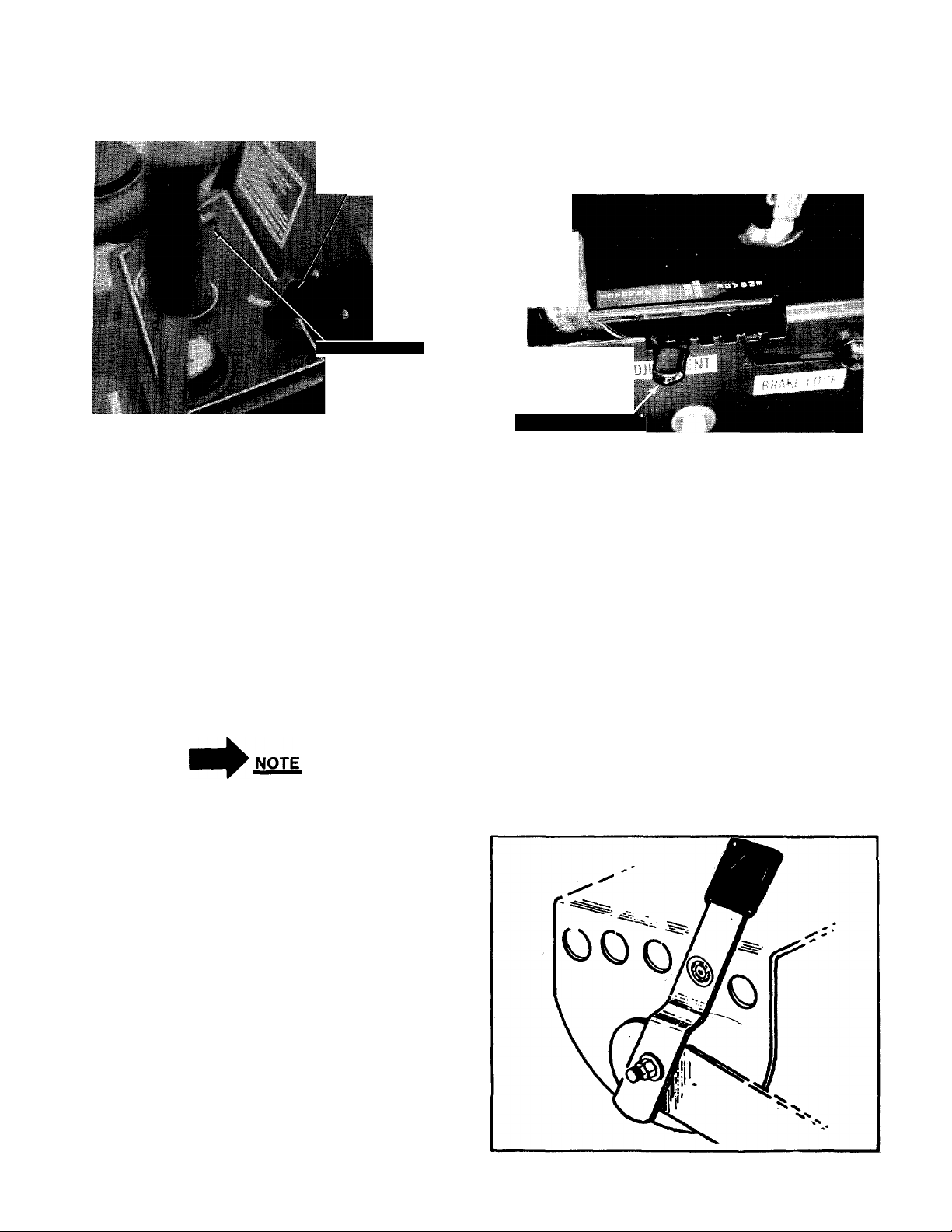

c. Brake. The brake pedal is located on the right

hand side of the mower and is operated by

depressing it with your right foot. See figure 8.

d. Brake Lock. The brake lock is located on the

right hand side of the mower. To lock the brake,

depress the brake pedal and lift up the lock

button. The pedal will stay depressed. To release,

depress the pedal. See figure 8.

e. Clutch Pedal. The clutch pedal is used to

disengage the drive mechanism. Depressing the

clutch pedal at any time will reduce mower speed.

If depressed all the way, it will stop the mower.

See figure 9.

f. Clutch Lockout. When the clutch pedal is

depressed all the way it can be locked by placing

the clutch lockout in the START position as

shown in figure 9. The clutch lockout must be in

this position before the engine will start.

g. Ammeter. (Electric Start Model Only.) The

ammeter registers the rate of battery charge or

discharge. The ammeter should register on the

plus ( + ) side when the engine is running in the

fast position until the battery is completely

charged. With a fully charged battery or with the

engine idling the ammeter will not show a charge.

See figure 10.

h. Light Switch. (Electric Start Only.) Pull the

light switch out to turn on the lights. The lights

will only operate when the engine is running. See

figure..

FIGURE 8. RIGHT HAND CONTROLS.

FIGURE 7. SHIFT PATTERN

FIGURE 9. LEFT HAND CONTROLS

Ammeter

• L * \

\ Gauge

Throttle ^ ,

Control Ignition Switch

’^¿iLift Disengagement

7 FIGURE 10. ELECTRIC START MODEL

' Lever ,

Page 8

R«coil Sta^qr

iShoiWH taeWrtjc”

k ^ Ignition Switch

I. Cutting Controls. The cutting controls consist

of the height of cut stop and the wheel height

adjusters.

Height of Cut Stop. See figure 12. Lift the stop

and set it at the desired cutting height.

r

Height of Cut Stop

FIGURE 11. RECOIL START MODEL.

i. Ignition Switch. The ignition switch is iocated

on the right side of the dashboard.

Recoil Model. See figure 11. Turn the key to the

ON position when starting the engine. To stop the

engine turn the key to the left to the OFF position

and remove the key to prevent accidental starting.

Electric Start. See figure 10. Turn the key to the

START positon to start the engine. When the

engine is running, let the key return to the ON

position. To stop the engine, turn the key to the

left to the OFF position and remove it to prevent

accidental starting.

The engine will not start unless the

clutch lockout is in the START posi

tion and the lift lever is in the DIS

ENGAGED position.

j. Recoil Starter. The recoil starter is located on

the right side of the dashboard. The recoil starter

can either be pulled while seated on the rider or

pulled while standing behind the rider. The

ignition key must be on before the engine will

start. After the engine starts, the recoil starter

handle must be returned and locked into the

dashboard before the blades or clutch are

engaged. The engine will stop if you do not follow

these instructions. See figure 11.

FIGURE 12. HEIGHT OF CUT SETTINGS

Wheel Height Adjuster. See figure 13. Move the

lever towards the wheel and set it in the desired

cutting height.

The cutting height of the mower can be set in two

different ways; FULL FLOAT position where the

deck follows the contour of the ground, and the

SUSPENDED position where the deck hangs

from the frame of the rider. The suspended

position is normally used for cutting rough

uneven ground.

To set the cutting deck in the full float position,

set the wheel height adjusters in the desired

cutting height as indicated in figure 13. Set height

of cut stop in the 1 Vz position. See figure 12.

To set the cutting deck in the suspended position,

set the height of cut stop in the desired cutting

height and then set the deck wheel so they just

dearths ground.

k. Lift and Disengagement Lever. It is used to

raise the cutting deck. Pulling it all the way back

and locking it disengages the blades. The engine

will not start unless the lift and disengagement

lever is in the disengaged position. See figure 10

S FIGUREIS. WHEEL HEIGHT ADJUSTER

Page 9

Parking Brake MUST be disengaged

before unit is put into motion.

Unit is equipped with separate brake

and ciutch pedals. To efficiently

stop, it is necessary to disengage

ciutch when applying brakes.

OPERATING

INSTRUCTIONS

STARTING THE ENGINE

Electric Start.

See figure 10. Turn the ignition key to

the START position. When the engine is

running, let the key return to the ON

position.

To stop either model, turn the key to the left to the

OFF position and remove the key to prevent

accidental starting.

A brief break-in period is essential

to ensure maximum engine and

mower life. This consists of running

the engine at half speed for a period

of time required to use one tank of

gasoline. It is also recommended to

change crankcase oil after the first 2

hours of operation.

Be sure to follow the instructions for the oil and

gasoline as described in the engine manual.

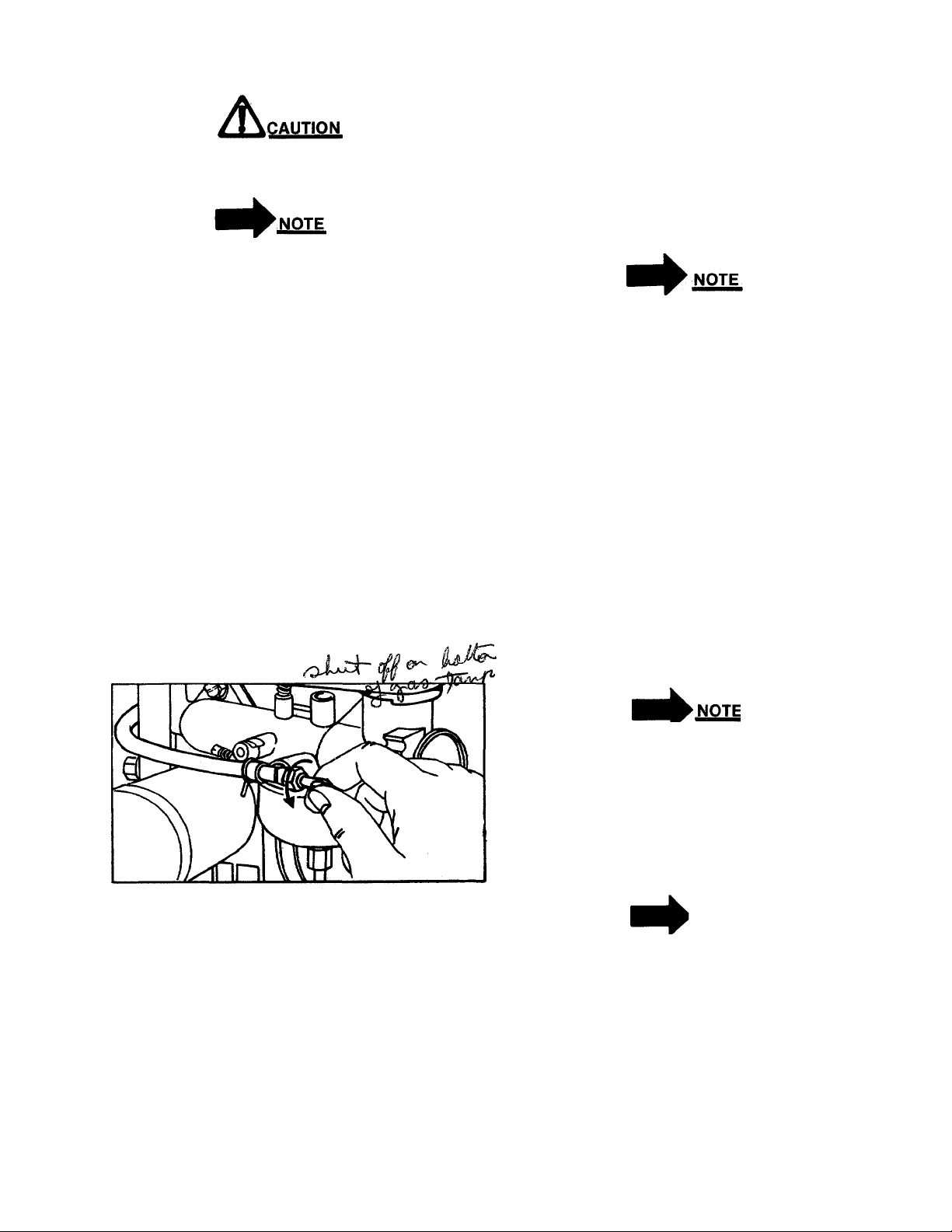

Step 1. Be sure the fuel shut-off valve is open.

See figure 14.

Step 2. Place the clutch lockout in the START

position. See figure 9.

Step 3. Place the lift and disengagement lever in

the DISENGAGED position. See figure

12.

FIGURE 14. FUEL SHUT-OFF VALVE

Step 4. Set the throttle control in the CHOKE

position. See figure 10.

Step 5. Recoil Starter.

a. Turn the ignition key to the ON

position. See figure 11.

b. Grasp the recoil starter, unlock it by

twisting it V4 turn and pull it out

sharply and hold it in the out position.

c. Slowly release the recoil starter and

lock it into the dashboard as shown in

figure 11.

STOPPING THE ENGINE

Turn the ignition key to the left to the OFF

position and remove the key to prevent accidental

starting.

OPERATING THE MOWER

Step 1. Set the desired cutting height.

Step 2. Start the engine as outlined on page 9.

Step 3. Select gear and shift.

As you become familiar with the op

eration of the mower you can move

the stop lever to a faster position.

Step 4. While holding down the clutch pedal,

move the clutch lockout lever forward.

Step 5. Put the gear shift lever into either

FORWARD or REVERSE.

'NOTE

DO NOT force the gear shift lever! If

the lever cannot be moved from

NEUTRAL to one of the drive posi

tions, release the clutch pedal slow

ly, depress it again, and then move

the gear shift lèveras required.

Step 6. Once the machine is in motion, remove

foot from the pedal. The mower will now

move ahead or to the rear, and the use of

the steering wheel will provide direction

al control.

Page 10

step 7. The mower is brought to a stop by

pressing your right foot against the brake

pedal and your left foot against the

clutch pedal. The drive belt will be disen

gaged and the brake will be applied.

A

Gear changing should be done only

after the mower has been brought to

a full stop. If the mower Is not to be

used for a long period, place the

gear shift lever in NEUTRAL and

stop the engine. DO NOT leave the

machine on an incline.

OPERATING THE CUTTER BLADE

The cutting blades may be engaged while the

mower is moving or standing still. DO NOT en

gage the cuttting blades abruptly as the sudden

belt tension on the pulley may cause the engine to

stall.

CAUTION

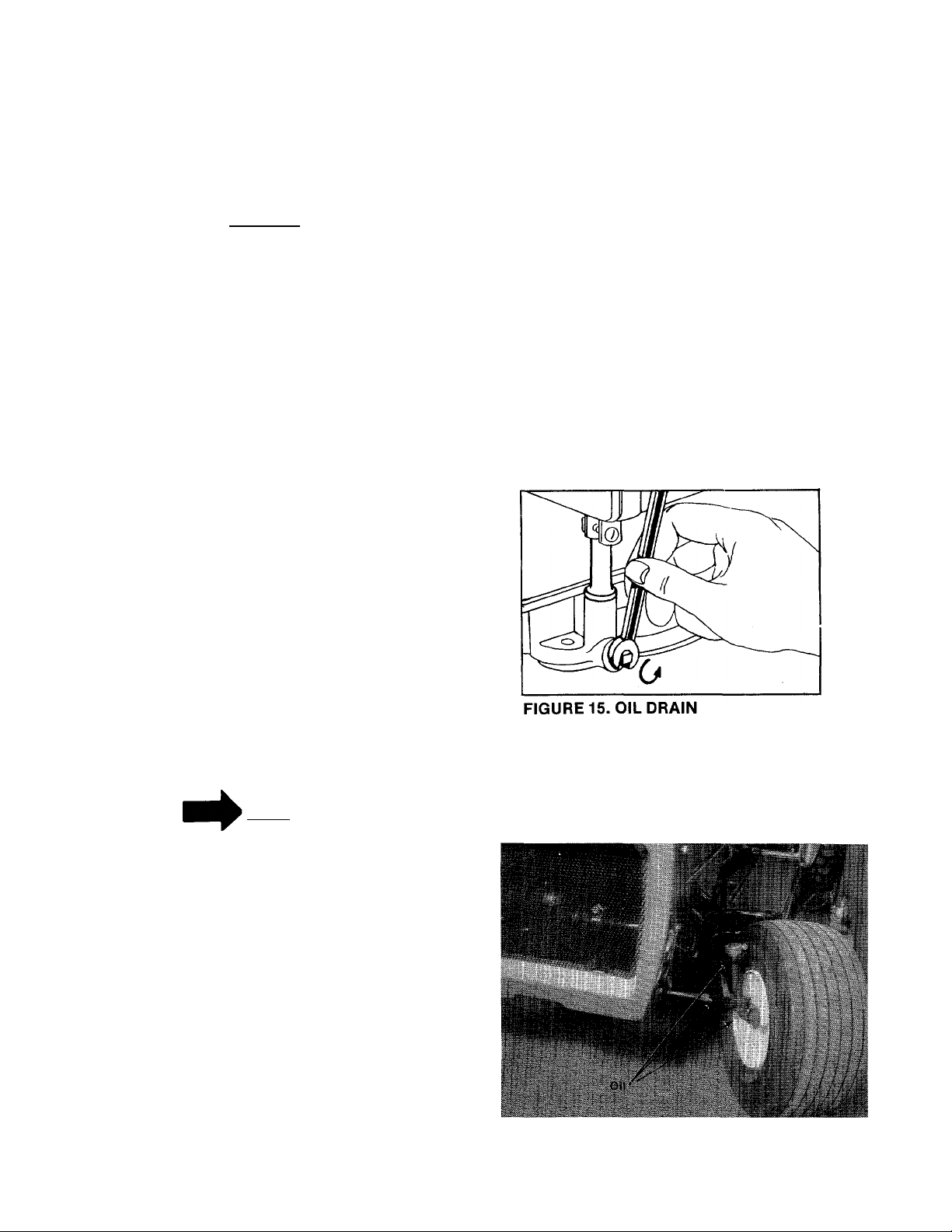

After the first five hours of operating a new

engine, drain the oil (see figure 15) from the

crankcase while engine is still hot and refill

crankcase with new oil; thereafter change the oil

every 25 hours of operation. This procedure

ensures for minimum wear of engine parts and

provides for virtually trouble-free operation. To

change the oii, proceed as foliows:

Step 1. With the machine on level ground, place

a suitable metal container under the oil

drain plug, then remove the drain plug.

See figure 15.

Step 2. After the oil has been drained complete-

iy from the crankcase, replace the drain

plug and tighten.

Step 3. Refill crankcase with IVa pints of good

quality, type MS, Engine oil into the

crankcase. Summer use SAE 30; Winter

(Below 40°F) use SAE 5W-20 or SAE

low.

WARNING

t

When the blade drive is engaged,

keep feet and hands away from the

discharge opening and from the

blade.

To stop the blades, move the lift and

disengagement lever (figure 10) into the DISEN

GAGED position. This raises the deck and

disengages the blades.

NOTE

When the machine is used for other

than mowing operations the blade

drive should be disengaged.

MAINTENANCE

CRANKCASE OIL

To ensure maximum engine performance, perform

the following periodic maintenance:

Oil Check

Check the oil level in the crankcase before each

use of the machine and after every five hours of

operation. Oil should b.e kept between the add and

full marks on the dipstick.

LUBRICATION

Lubricate the wheel bearings (2 per wheel) and the

upper and lower spindle bearings with SAE 30 oil

once a season. See figure 16.

FIGUREIS.

10

Page 11

The chain can be lubricated by wiping it with an

oily rag.

The differential and transmission are sealed at the

factory and require no further lubrication.

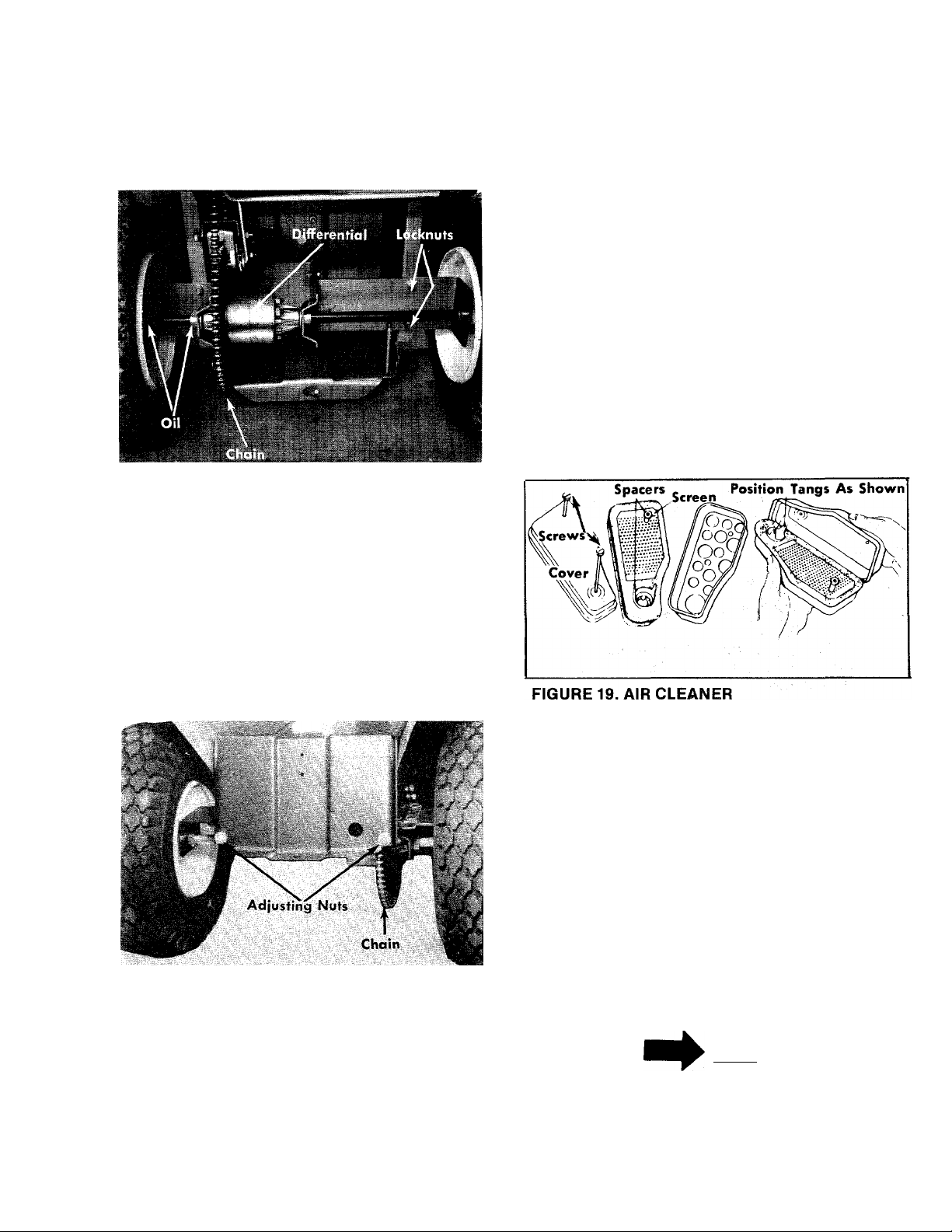

FIGURE 17. REAR AXLE ASSEMBLY

CHAIN ADJUSTMENT

To tighten the chain, loosen two locknuts on each

side of rear axie as shown in figure 17.

Tighten the adjusting nuts (figure 18) equally on

both sides. Tighten until the chain has Va inch

siack between the sprockets.

The adjusting nuts can be tightened individuaiiy

to aiign the axle.

Tighten the 4 locknuts after the adjustment is

made.

When assembling the air cleaner, make certain

the iip of the foam element extends over edge of

the air cleaner body. The foam element will form a

protective seal.

Step 1. Remove two screws and lift off complete

air cleaner assembly.

Step 2. Remove screen and spacers from foam

element.

Step 3. Remove foam element from air cleaner

body.

Step 4. a. Wash foam element in kerosene or

liquid detergent and water to remove

dirt.

b. Wrap foam in cloth and squeeze dry.

c. Saturate foam in SAE 30 engine oil,

then squeeze out excess oil.

d. Assemble parts, fasten to carburetor

with screw.

FIGURE 18. CHAIN ADJUSTMENT

AIR CLEANER

Under normal operating conditions, the air

cleaner, located on top of the carburetor, must be

serviced after every ten hours of use. Under

extremely dusty operating conditions the air

cleaner must be serviced after every hour of

operation. Refer to figure 19.

CLEANING ENGINE AND BLADE HOUSING

Any fuel or oil spilled on the machine should be

wiped off promptly. Grass, leaves, and other dirt

mustoot be left to accumulate around the cooling

fins of the engine or on any part of the machine.

Clean the underside of the blade housing after

each mowing.

BELTS

Check that belts are free of oil or dirt. Wipe the

belts periodically with a clean rag.

NOTE

Belt tension is automatically main

tained by the spring on the variable

speed bracket on the drive belts and

the belt tension on the deck belt is

maintained by the two deck springs.

11

Page 12

SPARK PLUG

WHEEL ADJUSTMENT

The spark plug gap should be cleaned and reset to

a 0.030-inch clearance every hours of engine

operation (See figure 20). Spark plug replacement

is recommended at the start of each mowing

season; check engine parts list for correct plug

type.

^NQTE

Whenever the spark plug is removed

for cleaning, it is advisable to re

place the spark plug gasket with a

new gasket.

FIGURE 20. SPARK PLUG CLEARANCE

REPLACING BLADE

The caster (forward slant of the king pin) and the

camber (tilt of the wheels out at the top) requires

no adjustment. Automotive steering principals

have been used to determine the caster and

camber on the tractor. The front wheels should

toe-in 1/8 inch.

To adjust the toe-in foilow these steps.

1. Remove the eiastic locknut and drop the tie

rod end from the wheel bracket. See figure 22.

2. Loosen the hex jam nut on tie rod.

3. Adjust the tie rod assembly for correct toe-in.

WARNING

Before beginning work on the cutter

blade, remove the spark plug from

the cylinder.

Removing and Sharpening Blades. Remove the

center bolt and lockwasher. See figure 21. Pull the

blade and blade adapter from the blade spindle.

The adapter can be removed from the blade by

removing the two adapter bolts, lockwashers and

nuts.

FIGURE 22. TIE ROD ADJUSTMENT

Dimension “B” should be approximately 118” less

than Dimension “A”. See figure 23.

A.) To increase Dimension “B”, screw tie rod into

12

tie rod end.

Page 13

B. ) To decrease Dimension “B”, unscrew tie rod

from tie rod end.

C. ) Reassmble tie rod. Check dimensions.

Readjust if necessary.

NOTE

To insure safe operation of your

unit, ALL nuts and bolts must be

checked periodicaliy for correct

tightness.

ADJUSTING CARBURETOR CHOKE

Proper choke adjustment is dependent upon

proper adjustment of remote controls on the

powered equipment.

To Check Operation of Choke-A-Matic Controls:

Move control lever to CHOKE position. (See figure

10.) The carburetor choke should be closed.

PREPARING FOR BELT REMOVAL

1

To prevent gasoline from leaking from the

engine, remove the fuel tank cap, place a

piece of thin plastic over the neck of the fuel

tank and screw on the cap.

2. Disconnect the spark plug wire and ground it

against the engine.

If the unit is equipped with a battery,

continue with Steps.

3. Remove the battery to prevent acid from

leaking.

NOTE

The air cleaner can be removed to

check the operation of the choke.

FIGURE 24. CARBURETOR ADJUSTMENT

To Adjust:

Place control lever on equipment in FAST (high

speed) position. Loosen control casing clamp

screw B. Move control casing A and wire until

lever D touches choke operating link at C. Tighten

casing clamp screw B. See figure 25.

I WARNING {

Disconnect the negatjve terminal

first and connect last when instal

ling the battery.

MOWING UNIT BELT REPLACEMENT

Step 1. Place the lift lever in the disengaged

position. See figure 10.

Step 2. Remove the belt keeper and large bolt on

the engine pulley. See figure 26.

FIGURE 26. BELT KEEPER

Step 3. Unhook the belt from the engine pulley.

See figure 27.

13

Page 14

■f

,r-

'i, .It»'.'"

FIGURE 27. REMOVING MOWER BELT

Step 4. Place the lift lever in the engaged

position. See figure 10.

Step 5. Unhook the tension springs on both

sides of the deck. See figure 27.

Deck,;, ■ ■

Links'“'...'

Deck Boll .0'

. V*-

FIGURE 29. DECK LINKS

“t'

TRANSMISSION BELTS

REMOVAL

Step 1. Place the lift lever in the disengaged

position. See figure 10.

Step 2. Remove the belt keeper and large bolt on

the engine pulley. See figure 26.

Step 3. Unhook the belt from the engine pulley.

See figure 27.

FIGURE 28. REMOVING TENSION SPRINGS

Step 6. Remove the front four deck links from the

cutting deck. See figure 29.

Step 7. Remove the belt guards from both deck

pulleys. See figure 29.

Step 8. Remove and. replace the belt and

reassemble.

Step 4. Place the lift lever in the engaged

position. See figure 10.

Step 5. Unhook the tension springs on both

sides of the deck. See figure 28.

Step 6. Remove the front four deck links from the

cutting deck. See figure 29.

Step 7. Tip the deck down as shown in figure 29.

NOTE

Leave the belt attached to the deck

pulleys unless you want to replace

it.

Step 8. Remove the engine belt guard by

removing the two front engine mounting

bolts. See figure 30.

14

Page 15

a.

Remove the entire belt guard from the

engine pulley by removing the two

front engine boits. See figure 30.

b.

Remove the transmisson pulley by

removing the hex nut and washer. See

figure 31.

c.

Remove the bolt and nut from the

steering rack and remove the belt.

Reassemble in reverse order with the

d.

new belt.

OFF-SEASON STORAGE

FIGURE 30. BELT GUARD REMOVAL

By working between the frame and

the deck, it is possible to remove

and repiace the deck belt without

removing the deck, however, the

working space is limited.

Belt Guard

If the machine is to be inoperative for a period

longer than 30 days, the following precautions are

recommended:

Step 1. Working outdoors, drain ail fuel from the

fuel tank. Use a clean dry doth to absorb

the small amount of fuel remaining in the

tank, then run the engine until all fuel in

carburetor is exhausted.

I WARNING I

C‘ # i^|>

Do not drain fuel while smoking, or

if near an open fire.

Step 2. Drain all the oil from the crankcase (this

should be done after the engine has been

operated and is still warm) and refill the

crankcase with clean new oil.

FIGURE 31. BOTTOM VIEW

Step 9. Removing the transmisión

figure 31.

Belt. See

Step 3. Disconnect the spark plug wire and

remove the spark plug from the cylinder.

Pour about six drops of engine oil into

the cylinder, and then pull the recoil

starter several times to spread the oil on

the cylinder wall. Replace the spark plug,

but DO NOT connect the wire.

Step 4. Clean the engine and the entire mower

thoroughly.

Step 5. Lubricate all lubrication points indicated

in figures 16 and 17 then wipe the entire

machine with an oiled rag in order to

protect the surfaces.

15

Page 16

TROUBLE SHOOTING CHART FOR RECOIL START MODELS

CAUTION: ALWAYS DISCONNECT SPARK PLUG BEFORE ATTEMPTING ANY REMEDY.

TROUBLE

Engine fails to start.

LOOK FOR

Safety System If the engine wili not start be sure the clutch control is dis

engaged; blade controls disengaged, the throttle control is

set and the key is turned on.

A. Disconnect the yellow wire from the engine. This comes

from the ignition switch.

B. If the engine fails to start the problem is with the engine,

not the safety system.

C. If the engine starts, the problem is with the safety system.

Check the yellow wire for a ground.

D. Check the operation of the switch behind the recoil start

er handle.

E. If the engine stops when the clutch or blade is en

gaged, the recoil handle is not pushed into the receptacle

and twisted a quarter turn.

Blocked fuel line or

empty gas tank.

Defective spark

plug.

Clean fuel line; check fuel supply. Also check fuel shut-off

valve.

Spark plug lead wire disconnected.

Faulty spark plug—spark should jump gap between control

electrode and side electrode. If spark does not jump, re

place spark plug.

NOTE: Use insulated pliers to hold the spark plug wire.

REMEDY

Hard starting or loss of

power.

Excessive vibration.

Unit fails to discharge

grass.

Engine overheats.

Throttle setting.

Loose connections

Dirty air cleaner.

Carburetor improp

erly adjusted.

Bent or damaged

blade spindle.

Discharge chute

clogged.

Foreign object

lodged in deck.

Obstructions in air

passages.

Oil level.

Throttle control lever not in the starting position.

Spark plug wire loose.

Remove air cleaner and clean as outlined in Engine

Manual.

Review paragraph Carburetor Adjustment.

Stop engine immediately; tighten all bolts and make all nec

essary repairs. If vibration continues, have the unit serviced

by a competent repairman.

Clean discharge chute artd inside of deck.

Remove object from deck. See CAUTION following step 1 in

paragraph Operation.

Remove any obstruction from air passages in shroud.

Grass and dirt in engine shroud.

Clean cooling fins.

Fill crankcase to proper oil level.

16

Page 17

TROUBLE SHOOTING CHART FOR ELECTRIC START MODEL

TROUBLE

Engine fails to start.

LOOK FOR

Safety System

Blocked fuel line or

empty gas tank.

Defective spark

plug.

REMEDY

A. Check for a blown fuse in the wire leading from the

positive terminal of the battery.

B. Before checking the safety system further, be sure the

clutch control and the blade control are disengaged; only

the starting system is being checked. Therefore remove

the spark piug lead and ground it to prevent the engine

from starting.

C. Attach a wire (minimum 18 gauge) to the positive ter

minal of the battery and touch the other end to the

small terminal (coil primary) of the solenoid. If the en

gine cranks, the problem is in the safety system.

D. Check for continuity from the battery to the solenoid.

NOTE: The positive terminal of the battery should have

a large cable (#8 guage) and a small wire (#18 gauge)

attached to it.

E. Check all wires and cable for tightness.

F. Use a #8 gauge wire and jump between the two large

terminals of the solenoid. If the unit starts, replace the

solenoid.

G. If the unit fails to start after following the above pro

cedure the problem is probably in the starting motor of

the engine.

Clean fuel line; check fuel supply. Also check fuel shut-off

valve.

Spark plug lead wire disconnected.

Faulty spark plug—spark should jump gap between control

electrode and side electrode. If spark does not jump, re

place spark plug.

NOTE: Use insulated pliers to hold the spark plug wire.

Hard starting or loss of

power.

Excessive vibration.

Unit fails to discharge

grass.

Engine overheats.

Throttle setting.

Loose connections

Dirty air cleaner.

Carburetor improp

erly adjusted.

Bent or damaged

blade spindle.

Discharge chute

clogged.

Foreign object

lodged in deck.

Obstructions in air

passages.

Oil level.

Throttle control lever not in the starting position.

Spark plug wire loose.

Remove air cleaner and clean as outlined in Engine

Manual.

Review paragraph Carburetor Adjustment.

Stop engine immediately; tighten all bolts and make all nec

essary repairs. If vibration continues, have the unit serviced

by a competent repairman.

Clean discharge chute and inside of deck.

Remove object from deck. See CAUTION following step 1 in

paragraph Operation.

Remove any obstruction from air passages in shroud.

Grass and dirt in engine shroud.

Clean cooling fins.

Fill crankcase to proper oil level.

17

Page 18

NOTES

18

Page 19

PARTS LIST FOR MODEL 136-480A ONLY

REF. PART

NO.

NO.

SCHEMATIC FOR ELECTRICAL SYSTEM

DESCRIPTION

NEW

PART

725-0269

1

725-0266

2

3

712-0121

4

710-0425

5

736-0338

6

732-0257

7

736-0225

8

Safety Switch Norm

Closed—Red

Magneto Igntion Switch

w/Nut

Wire Harness

Hex Nut #10-24

Truss Mach. Scr. #10-24 x .62

Fiber Washer

Switch Spring

internai L-wash. 5/8 i.D.

19

Page 20

136-485A

PARTS LIST FOR MODEL 136-485A ONLY

REF.

NO.

PART

NO.

1

725-0201

2 725-0267

3 725-0119

COLOR

CODE

DESCRIPTION

Ignition Key

Ignition Switch

Ammeter

4 725-0202 Headlight Switch

5 725-0486

Wire Harness N

6 725-0480 Vinyl Sealing Tape

7 725-0268 Safety Switch

8 725-0270

Solenoid

9 725-0298 Fuse7V2 Amp. V4 Dia. x

1.25 Lg.

10

725-0268

Safety Switch

NEW

PART

N

PARTS LIST FOR MODEL 136-485A ONLY

1

731-0333

2

726-0141

3

725-0453

PART

NO.

REF.

NO.

4

5 725-0^ Ì»

6 725-0480

COLOR

CODE

DESCRIPTION

NEW

PARI

Convoluted Conduit

Mtg. Clamps 3/8 I.D.

Battery 12 V.—Manifold

Vented

Battery Cable Harness

Electric Wire

Vinyl Sealing Tape N

N

20

Page 21

136-480A 136-485A

PARTS LIST FOR DIFFERENTIAL ASSEMBLY 717-0330

Ref.

No.

,'3 738-0249

8 736-0187

9

10 711-0276

11

^13

Part

No.

1

715-0247

2

748-0185

4

736-0188

5 717-0341

6

736-0119

7

710-0363

748-0158

712-0237

09133

738-0250

737-0120

Qty.

Req’d.

2

Spring Pin Spir. 3/16” Dia.

2 Gear—Doubie “D” Hoie ,,

Shaft—Long t&:8§” Lg.

1

2

FI-Wash. .760I.D. X1.49

O.D.

2

Housing Haif

2

L-Wash.5/16” Scr.*

2

Hex Scr. 5/16-24x4.00”

2

FI-Wash. .640 I.D. X 1.24

2 Gear—Round Hole

1

Drive Pin

2 Hex Cent. L-Nut 5/16-24

1

Sprocket—60 Tooth

1

Shaft—Short 9r53” Lg.

Grease—High Temp. 450®F.

2oz.

Description

X1.00” Lg.

Lg.*

O.D.

Thd.

SHORT SHAFT

New

Part

N

*For faster service obtain standard nuts, boits and washers iocaiiy. If these items cannot be obtained locally, order by part

number and size as shown on parts list.

21

Page 22

DECK LINKAGE

NOTE

Refer to illustration below for proper deck link

hook-up. if the deck is removed for any reason use

the illustraton below for correct assembly.

22

Page 23

REVERSING TRANSMISSION (PEERLESS 701)

44 36

23

Page 24

PARTS LIST FOR FIVE SPEED TRANSMISSION PEERLESS MODEL 701

REF.

NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

27

28

29

30

31

32

33

34

35

36

37

40

41

42

43

44

PART

NO.

Pc-770061 Case, Transmission

PEt772070

PE-776164 Shaft, Output and Brake

PE-778121

PE-778122 Gear, Spur (22 teeth)

PE-778123

PE-778124

PE-778125

PE-784266

PE-786060

PE-786061

PE-776134 Shaft, Counter

PE-778109

PE-778126

PE-778127

PE-778128

PE-778129

PE-776140 Shaft, Input

PE-778113

PE-786049

PE-780105

PE-786062

PE-780072

PE-780106 Bearing, Needle

PE-792072

PE-792035

PE-780109

PE-788040

PE-784271 Rod and Fork Ass'y., Shift

PE-792073

PE-792089

PE-792077 Ball, 5/16" Steel

PE-792078

PE-792079 Spring

PE-780'l 08

PE-792074

Cover, Transmission

Gear, Spur (20 teeth)

Gear, Spur (25 teeth)

Gear, Spur (30 teeth)

Gear, Spur (35 teeth)

Collar, Shift

Sprocket (14 teeth)

Sprocket (10 teeth)

Gear, Bevel (42 tooth and 15 tooth spur gear)

Gear, Spur (20 teeth)

Gear, Spur (25 teeth)

Gear, Spur (28 teeth)

Gear, Spur (30 teeth)

Bevel Pinion, Input

Sprocket (8 teeth)

Bushing, Flanged

Chain, Roller (No. 41 chbin, 22 links)

Race, Thrust

Ring, Retaining *

Ring, Retaining

Washer

Ring, Retaining

Scr., ’^-20 X IVi hex hd. tap-tite

Key

Screw, %-16 y. % set

Washer, Thrust

Plug

DESCRIPTION

NOTE; This unit is not under warranty by

the mower manufacturer. All Part Orders

and Service must be handled through the

Local Authorized Tecumseh Service Deoler.

Find Us Fast

In The

YeHow Pages

This unit it undar warranty by TtcvmMh

Products Company. Parts and Sorvice ara

ovaiiobla through all Tacumtah, Lauton

Power Products Sarvica Oaalart. ¿hack tha

"Yallow Pagas" of your talaphona dirac-

tory under "Engines—Gasolina."

PEERLESS MODEL 701

24

Page 25

WHEELCHART

FRONT WHEEL

PART

NO.

DESCRIPTION

734-0494 Wheel Ass’y-—Comp.

734-0520 .

Rim Ass’y. Only

734-0495 Tire Only 13x5.00

734-0255 Air Valve

734-0249

Inner Tube (Service Only)

PART

NO.

734-0592

734-0594

734-0294

734-0255

734-0310

REAR WHEEL

DESCRIPTION

Wheel Ass’y.—Comp.

Rim Ass’y. Only

Tire Only 18 X ’i-B

Air Valve

Inner Tube (Servi

25

Page 26

136-480A

136-485A

RIGHT HAND VIEW

26

Page 27

J»ef.

NO.

PART

NO.

COLOR

CODE

PARTS LIST FOR MODEL 136-480A AND 136-485A

NEW

DESCRIPTION

PART

REF.

NO.

PART

NO.

COLOR

CODE

DESCRIPTION

NEW

PART

1 11263

2 710-0351

Plastic Handle (480A only)

Truss Mach. Scr. #10x .50”

Lg. (480A only)

3 710-0425

Truss Mach. Scr. #10-24 x

.62” Lg.(480Aonly)

4 736-0338

712-0121

5

Fiber Wash. (480A only)

Hex Nut #10-24 Thd.* (480A

only)

6 11053 Switch Brkt. Ass’y- (480A

only)

7

712-0147

Speed Nut #10-24 U-Type

(480A only)

725-0266

8

9 732-0257

10 725-0128

712-0287 Hex Nut 1/4-20Thd.* (485A

11

Ignition Switch (480A only)

Switch Spring (480A only)

Ignition Key (480A only)

only)

12 736-0329

L-Wash. 1/4” Scr. *(485A

only)

13 710-0258

Hex Scr 1/4-20 X. 62” Lg.*

(485A only)

14 711-0222

Battery Hold Down Rod

(485A only)

725-0453 Battery 12-volt Manifold

15

Vented (485A only)

16

712-0113

Wing Nut Solid V4-20 Thd.

(485A only)

1 17

12614 Battery Hold Dow'n (485A

only)

18 731-0333

Convoluted Conduit (485A

only)

710-0286 Truss Mach. Scr. V4-20 x

19

.50” Lg. (485A only)

20 736-0329

L-Wash. 1/4” Scr.* (485A

only)

21

712-d^

Hex Nut 1/4-20 Thd.*(485A

only)

22

710-0258

Hex Scr. 1/4-20 X.62” Lg.*

(485A only)

23 12811

Battery Brkt. Brace (485A

only)

24 736-0329

L-Wash. 1/4” Scr.* (485A

only)

712-0287 Hex Nut 1/4-20 Thd.* (485A

25

only)

26

12747

Battery Brkt. (485A only)

27 710-0289 Hex Scr. 1/4-20 X.50” Lg.*

28 723-0296 Hood Latch Ass’y-

29 736-0329 L-Wash. 1/4” Scr.*

712-0287

30

Hex Nut V4-20Thd.*

31 11027 Handle Stop Brkt. Ass’y.

32 726-0121 Push Cap V4” Dia. Black

736-0192

33

FI-Wash. .531 I.D. xl.13

O.D.

34 712-0287

Hex Nut 1/4-20 Thd.* (485A

only)

35 736-0329, L-Wash. 1/4” Scr.* (485A

only)

36 Head Lamp Bezel (485A

only)

N

37 Head Lamp Retainer (485A

only)

N

12781 Head Lamp Bezel (480A

only)

N

38 714-0101 Inter. Cot. Pin 1/2” Dia.

39 10346

40 720-0157

Lockout Link Ass’y.

Grip

41 749-0212 Lift Handle

42 11032

43 736-0219

Lift Handle Brkt. Ass’y.

Bel I.-Wash. .400 I.D. x1.130

O.D.

44

710-0201 Hex Scr. 3/8-16 X.62” Lg.*

45 11029

Handle Pivot Brkt.

46 735-0180 Rubber Wash. .75 I.D. x

1.25 O.D.

47 748-0201

Spacer .635 I.D. x .88 O.D.

X .57

10904

48

Deck Link Ass’y.

49 710-0195 Hex Scr. 1/4-28 X.62” Lg.*

711-0577

50

51 726-0106

52

11399 Adapter Plate Ass’y.

Pivot Pin

Push-on Flange Palnut

53 732-0261 Torsion Spring

54 11574

Chute Cover Ass’y.

55 10349 Deck Link Ass’y.

56 710-0627

57 736-0242

Hex Scr. 5/16-24 X .75” Lg.*

Bell.-Wash. .345I.D. x.88

O.D.

734-0592

N

58

Rear Wheel Ass’y.—Comp.

18x6.50-8

59

738-0140 Shid. Scr. .437 Dia. x .180

736-0264

N

60

61 712-0267

62 09735

FI-Wash. .344 I.D. x .62 O.D.

Hex Nut 5/16-18 Thd.*

Connecting Rod 3/16x1 x

12.5” Lg.

09721

63

Pivot Link Ass’y.

*For faster service obtain standard nuts, bolts and washers locally. If these items cannot be obtained locally, order by part

number and size as shown on parts list.

(462—Red Flake)

When ordering parts if color or finish is important, use color code shown at left,

(e.g. Red Flake Finish—11839 (462).)

27

Page 28

co co

o> o>

I I

È

00 00

СЛ о

>>

IO

00

<0 Od

Cb \)

Page 29

PARTS LIST FOR M

REF.

NO.

1 731-0220

2 712-0158

736-0242

" 3

PART

NO.

COLOR

CODE

DESCRIPTION

Steering Wheel Cap

Hex Cent. L-Nut 5/16-18 Thd

Bell.-Wash. .345I.D.X.88

O.D.

4 731-0219

750-0319

5

722-0115

6

710-0351

7

Steering Wheel

Steering Tube

Knob—Throttle Control

Truss Mach. Scr. #10 x .50”

Lg.*

746-0160 Throttle Control Ass’y-

8

Comp.

9 12790

710-0599

10

Upper Frame Cover

Hex C-Tap Scr. V4-20 x .50”

Lg.

757-0264 Seat Assembly

11

12

13

15

736-0921

712-0206

710-0198

L-Wash. V2”Scr.*

Hex Nut 1/2-13Thd.*

Hex Sems Scr. 5/16-18 x

.75” Lg.*

736-0119

16

712-0267

17

11839

18

19 710-0259

L-Wash. 5/16” Scr.*

Hex Nut 5/16-18 Thd.*

Rear Fender

Hex Sems Scr. 5/16-18 x

.62” Lg.*

20 11090

21 723-0241

22 712-0798

736-0105

23

Frame Assembly

Foot Pad 15.75x4.00”

Hex Nut 3/8-16 Thd.*

Bell.-Wash. .400I.D. x.88

O.D.

24 738-0317

12748

25

748-0227

26

27 748-0237

736-0264

28

29 748-0236

30 710-0180

31 736-0tJ3'

710-0494

32

S'

Steering Shaft

Steering Gear Support

Hex Flange Bearing .630 I.D.

Pinion Gear

FI-Wash. .344 I.D. x .62 O.D.

Side Gear

Hex Scr. 3/8-24 X .75” Lg.*

FI-Wash. .406 I.D. X 1.25

O.D.

Sq. Hd. Set Scr. 5/16-18 X

.38 Cup

34

35

711-0169

734-0494

Collar5/8” I.D.

Front Wheel Ass’y-—Comp.

13x5.00

723-0156

36

37 712-0711

711-0613

38

736-0156

39

Ball Joint Ass’y. 3/8-24 Thd.

Hex Jam Nut 3/8-24 Thd.

Tie Rod

FI-Wash. .6351.D.x 1.20

O.D.

40

41

748-0151

710-0670

Flange Brg.w/Flats.75 I.D.

Hex Nylon Scr. 3/8-16 X

1.25” Lg.

42 12749

43 736-0%aS“

44 710-0180

747-0186

45

714-0507

46

Steering Arm Shaft Ass’y.

Fi-Wash. .406 I.D.x 1.25 O.D.

Hex Scr. 3/8-24 X.75” Lg.*

Steering Rod

Cotter Pin 3/32” Dia. X.75”

Lg.*

712-0923

47

48 736-0158

12406

49

c, 50

712-0711

12755

51

52 736-0169

j

________________

*For faster service obtain standard nuts, boits and washers

iocaily. If these items cannot be obtained locally, order by

part number and size as shown on parts list.

Hex Cent. L-Nut 5/8-16 Thd.

L-Wash. 5/8” Scr.*

Front Pivot Bar Ass’y.

Hex Jam Nut 3/8-24 Thd.

Axle Ass’y.—Front R.H.

L-Wash. 3/8” Scr.*

L136-480AAND 136-4

ODE

NEW

PART

REF.

NO.

53

PART

NO.

712-0241

54 12752

COLOR

CODE

35A

DESCRIPTION

Hex Nut 3/8-24 Thd.*

Axle Ass’y.—Front L.H. N

55 748-0193 Spacer .380 I.D.x .630 O.D.

X .575 Lg.

56 12411 Front Pivot Bracket

57 710-0622

N

58 12791

59

■\

60 712-0121

61

62

N

✓

710-0192

736-0722 L-Wash. #10 Scr.*

12782 Lower Side Panel R.H.

Hex Scr. 5/8-18x1.62” Lg.*

Grille Screen N

Truss Scr. #10-24 X .375”

Lg.*

Hex Nut #10-24Thd.*

63 12781 Lower Grille Panel

64

65

712-0375

12814

Hex Cent. L-Nut 3/8-16 Thd.

Front Grille Upper Ass’y.

(485A only)

12808 Front Grille Upper (480A

only) N

66 727-0199 Hood Stop

67

736-0463 FI-Wash. .25 I.D. x .62 O.D.

68 736-0722 L-Wash. #10 Scr.*

69 712-0121 Hex Nut #10-24 Thd.*

70 736-0101

FI-Wash. .380 I.D. X 1.00

O.D.

71

735-0126 Rubber Wash. .3? ^ x .87

O.D.

72

710-0253 Hex Scr. 3/8-16 X i

73

710-0258 Hex Scr. V4-20X.62” Lg.

74

12780

75 723-0155 Fuel Gauge—Cap

N

76 735-0179

N

Front Hood

Rubber Grommet (Fuel Tank

Neck)

77

731-0345 Dash Panel Insert (480A

only) N

N

731-0346 Dash Panel Insert (485A

only) N

78 12795 Dash Panel Ass’y. (480A

only) N

12798 Dash Panel Ass’y. (485A

only)

79 712-0222

80

72&=048O Vinyl Sealing Tape'^'=‘ ''s

81 12784

—462 Side Panel R.H.

82 712-0287

Speed Nut Push On 5/8” Dia.

Hex Nut 1/4-20 Thd.*

83 736-0329 L-Wash. 1/4” Scr.*

84

12785 —462 Side Panel L.H.

85 710-0621

86 12783 —462

87 726-0157

712-0147

88

89 751-0182 Fuel Tank

N

90

N

732-0255 Seat Spring 4.50” High

91 751-0183

92

710-0289

93 11852

N

94

751-0173 Fuel Line

95 751-0171

96 735-0149

97

710-0342

Hex Scr. 5/16-18 X.50” Lg.*

Lower Side Panel L.H.

Speed Nuti /8” Stud

Speed Nut #10-24 “U”-Type

Engine Brace

Hex Scr. 1/4-20 X.50” Lg.*

Upper Frame

Fuel Shut-Off Valve

Bushing—Fuel Tank (Valve)

Hex Scr. 3/8-16x1.25” Lg.*

98 725-0270 Solenoid (485A only)

99 736-0222

N

100 748-0228

(462—Red Flake)

When ordering parts, if color or finish is important use the

Ext. L-Wash. 1/4”Scr.*

(485A only)

Hex Flange Brg. .5(X)” I.D.

29 appropriate color code shown above (e.g. Red Flake

Finish—11839(462).)

NEW

PART

N

N

N

N

N

i^^N

N

N

N

N

N

Page 30

136-480A 136-485A

NOTE: If for any rea

son disc brake is dis

assembled, be sure

round end of push

pin (Ref. No. 97) is

toward the cam lever

(Ref. No. 93).

FRAME VIEW

30

Page 31

PARTS LIST FOR MODEL 136-480A AN

NO.

....

COLOR

CODE

DESCRIPTION

Enqine

Hex Scr. 5/16-18x1.50” Lg.*

Part of Engine

Muffler Strap

L-Wash.5/16” Scr.*

Hex Nut 5/16-18 Thd.*

Hex Drill Scr. #10x.50” Lg.

L-Wash. 1/4” Scr.*

Hex Scr. 1/4-20 X .62” Lg.* Lg.

Hose Clamp

Muffler w/1.120 I.D. Inlet

Clutch Pedal Pad

Clutch Pedal Ass’y.

Cotter Pin 3/32” Dia. x .75”

REF.

PART

NO.

1

710-0442

^ 3

4 751-0188

5 736-0119

712-0267

6

710-0456

7

736-0329

8

710-0258

9

751-0186 Exhaust Pipe Ass’y-

10

11 726-0132

751-0190

12

11057 Parking Brake—Lever Ass’y-

13

14 12379

11037

15

714-0507

16

Lg.*

17

18

19

20

12654

11090

712-0267

736-0105

Belt Guard Ass’y. —Engine

Frame Ass’y.

HexNut5/16-18Thd.*

Bell.-Wash. .400I.D. X.88

O.D.

21 738-0215

Shid. Scr. .489” Dia. x 3.00”

Lg.

22 710-0259

Hex Sems Scr. 5/16-18 x

' .62” Lg.*

23 12160

24 747-0112

25 12448

26 712-0158

27 12806

X

712-0375

28

29 711-0630

Belt Keeper Ass’y.

Clutch Rod

Idler Brkt. Ass’y.

Hex Cent. L-Nut 5/16-18 Thd

Parking Brake—Lever

Ass’y.

Hex Cent. L-Nut 3/8-16 Thd.

Spacer .380 I.D. x .50 O.D. x

.562

30 11039

750-0298

31

32 736-0119

712-0267

33

34

710-0193

Pedal ‘‘U”-Brkt. Ass’y.

Spacer .384 1.D. x .500 O.D.

X1.43” Lg.

L-Wash. 5/16” Scr.*

Hex Nut 5/16-18Thd.*

Hex Sems Scr. 5/16-18 x

.75” Lg.*

35 11845

710-0194

36

37 714-0129

Transmission Belt Guard

Hex Scr. 3/8-16 X 3.00” Lg.*

#4Hi-ProKey3/32”x5/8”

Dia. Hdn.

712-0287

38

736-0329

39

40 761 -0148

Hex Nut 1/4-20 Thd.*

L-Wash. 1/4” Scr.*

Blade Brake Ass’y. 1.38”

High

41 710-0198

Hex Sems Scr. 5/16-18 x

.75” Lg.

42 12813

43 12378

710-0134 Carriage Bolt V4-20 x .62”

44

Brake Pedal Ass’y.

Brake Pedal Pad

Lg.*

726-0121

45

712-0267

46

47 736-0119

48 738-0140

- 49

732-0245

Push Cap Va” Dia. Black

Hex Nut5/16-18Thd.*

L-Wash. 5/16” Scr.*

ShId. Scr. .437 Dia. x .180

Extension Spring .90 O.D.

X3.75” Lg.

'For faster service obtain standard nuts, bolts and washers

locally. If these items cannot be obtained locally, order by

part number and size as shown on parts list.

NEW

PART

N

N

N

N

N

D 136-485A

REF.

PART

NO.

50 736-0119

NO.

COLOR

CODE

DESCRIPTION

L-Wash. 5/16” Scr.*

51 712-0267 Hex Nut 5/16-18 Thd.*

52 732-0191

53 736-0119

Spring .75 O.D. x 11.00” Lg.

L-Wash. 5/16” Scr.*

54 712-0267 Hex Nut 5/16-18 Thd.*

55 710-0322 Hex Sems Scr. 5/16-18 x

1.00” Lg.*

56 747-0106 Brake Rod .25” Dia. x 23.50”

57 710-0198 Hex Sems Scr. 5/16-18 x

.75” Lg.*

58 10398 Disc Brake Brkt. Ass’y.

712-0287 Hex Nut 1/4-20Thd.*

59

60 736-0329

61 10410

62

710-0258

L-Wash. 1/4” Scr.*

Spring Brkt.

Hex Scr. 1/4-20 X .62” Lg.*

63 713-0163 #420 Chain Vz” Pitch x 79

Links

64 741-0199 Plastic Flange Brg. w/Flats

65 10364 Rear Axle Plate

710-0437 Chain Adj. Link 5/16-18 x

66

4.38” Lg.

67

712-0429 Hex Ins. L-Nut 5/16-18 Thd.

732-0157

68

Spring .38 O.D. x 3.25” Lg.

69 10360 Axle Bolt Plate Ass’y.

10362 Rear Axle Brkt. Ass’y.

70

71 710-0198

Hex Sems Scr. 5/16-18 x

.75” Lg.*

72 736-0119

L-Wash. 5/16” Scr.*

73 712-0267 Hex Nut 5/16-18 Thd.*

74 710-0412 Hex Scr. 1/4-28 X .75” Lg.

736-0242

75

Bell.-Wash. .345 I.D. x.88

O.D.

710-0237 Hex Scr. 5/18-24 X.62” Lg.*

76

77 735-0126 Rubber Wash. .33 I.D. x .87

O.D.

712-0158

78

Hex Cent. L-Nut 5/16-18 Thd.

79 736-0159 FI-Wash. .344 I.D. x.88 O.D.

80 11846 Shift Lever Brkt. Ass’y.

81 11545

82

720-0165

Shift Lever

Knob (For Transmission

Lever)

83 736-0329 L-Wash. 1/4” Scr.*

84

712-0138 Hex Nut 1/4-28 Thd.

12797

85

761-0137 Disc Brake Ass’y.—Comp.

86

87

710-0316 Hex Scr. 3/8-16x3.50” Lg.*

88 761 -0138 Spacer for Disc Brake 5/8

transmission Support Brkt.

O.D.

HH-12-03045 Casting—Carrier Side

89

90

HH-11

-03436

Spacer

91 HH-12-03041 Casting—Cam Side

92

712-0375 Hex Cent. L-Nut 3/8-16 Thd.

93 HH-18-02770

94

HH-03-03032 Thrust Wash. 5/16” I.D.

712-0134 Hex Top L-Nut

95

Cam Lever

96 HH-06-03031 Spring

97 HH-05-03034 Push Pin

HH-03-03097 Disc—Back Up

98

99 HH-15-02533

(462—Red Flake)

When ordering parts, if color or finish is important us® the

31

appropriate color code shown above (e.g. Red Flake

Finish—11839(462).)

Pad—Friction

NEW

PART

N

N

Page 32

136-480A

136-485A

IMPORTANT

Belts listed by Part Number are of

special construction and should be

used when replacement is necessary.

The dimensions and description given

are for general reference only and belts

purchased by description and dimen

sion generally will only provide tempo

rary service.

DECK VIEW

32

Page 33

PART

REF.

L,no.

1

756-0174

NO.

COLOR

CODE

Transmission Split Pulley

.50 I.D.

2 712-0261

736-0158

3

4 754-0191

5 756-0124

754-0151

6

756-0253

7

736-0235

8

Hex Jam Nut 5/8-11 Thd.

L-Wash. 5/8” Scr.* C.D.

“V”-Belt Vz x65” Lg. 34

Deck Pulley 4.75” O.D.

“V”-Belt21 /32x67” Lg.

Two Step Engine Pulley

FI-Wash. .406 I.D. X 1.25

O.D.

9

10

11

12

13

14

736-0169

710-0152

12672

09164

12674

710-0322

L-Wash. 3/8” Scr.*

Hex Scr. 3/8-24x1.00” Lg.*

Belt Guard—L.H.

Deck Reinforcement Plate

34” Deck Ass’y. 42

Hex Sems Scr. 5/16-18 x

1.00” Lg.* 44 732-0307 Spring (Deck)

710-0289

15

712-0123

16

17 736-0119

742-0120

18

710-0117

19

Hex Scr. V4-20X.50” Lg.*

Hex Nut 5/16-24 Thd.*

L-Wash. 5/16” Scr.*

17” Blade 47 09321

Hex Scr. 5/16-24x1.00” Lg.

H.T. C.D.

20

710-0459

Hex Scr. 3/8-24 X1.50” Lg.

H.T.

736-0217

21

22 10769

710-0289

23

4 24

711-0571

11399 Adapter Plate Ass’y-

25

710-0195

26

27 732-0261

11574

28

726-0106

29

736-0329

30

L-Wash. 3/8” Scr. H.D.

Blade Adapter Kit 52

Hex Scr. 1/4-20 X.50” Lg.* 53 756-0217 Fl-ldler 2.75” C.D.

Pivot Pin

Hex Scr. 1/4-28 X.62” Lg.* 56 712-0922

Torsion Spring

Chute Cover Ass’y.

Push Nut 1/4” Rod

L-Wash. 1/4” Scr.*

PARTS LIST FOR MODEL 136-480A AND 136-485A

DESCRIPTION

NEW

PART

REF.

NO.

PART

NO.

712-0287 Hex Nut 1/4-20 Thd.*

31

32

10949

COLOR

CODE

33 736-0105

712-0116 Hex Ins. L-Nut 3/8-24 Thd.

35 738-0119 Shid. Scr. .625” Dia. xl.75”

36 734-0295 Wheel Ass’y. 5.0” Dia.

37 736-0105 Bell.-Wash. .400I.D. x.88

10937

38

11236 Wheel Brkt. Ass’y.—R.H .

39

40 736-0329

41 712-0287 Hex Nut 1/4-20 Thd.*

12673

43 711-0255 Blade Spindle

45 714-0365

46 08253

48 741-0919

49 736-0329

50 712-0287 Hex Nut 1/4-20 Thd.*

11237

51

712-0116 Hex Ins. L-Nut 3/8-24 Thd.

54

756-0116

55 09322 Blade Brake Disc

57

736-0921 L-Wash. 1/2” Scr.*

58 11917 34” Deck Ass’y. Comp.

"2 % *'^■3

DESCRIPTION

Spring Lever Ass’y. w/Knob

Bell. Wash. .400 I.D. x .88

Lg.

C.D.

Wheel Pivot Bar

L-Wash. 1/4” Scr.*

Belt Guard—R.H.

#6Hi-Pro Key 5/32” X 5/8”

Dia.

Bearing Housing

Blade Spindle Ass’’.'. Comp.

Ball Brg. .787 I.D «‘i

L-Wash. 1/4” Scr.*

Wheel Brkt. Ass’y. L.H.

“V”-Belt ldler3.06”C.D.

Hex Jam Nut 1/2-20 Thd.

(For Service Cniy)

1i

NEW

PART

*For faster service obtain standard nuts, bolts and washers locally. If these items cannot be obtained locally, order by part

number and size as shown on parts list.

(462—Red Flake)

When ordering parts if color or finish is important, use color code shown at left,

(e.g. Red Flake Finish—11839(462),)

33

Page 34

PARTS INFORMATION

POWER EQUIPMENT PARTS AND SERVICE

BRIGGS & STRATTON, TECUMSEH AND PEERLESS

PARTS AND SERVICE

Ports and service for all MTD manufactured power

equipment are available through the authorized service

firms listed below. All orders should specify the model

number of your unit, parts numbers, description of parts

and the quantity of each part required.

ALABAMA BIRMINGHAM

Auto Electric&Carburetor Co...2625 4th Ave. S.......................... 35233

ARKANSAS NORTH LITTLE ROCK

Sutton's Lawn Mower Shop

Mity Mite Motors, Inc; .....................2515 Towson Ave

CALIFORNIA SAN BERNARDINO

Lawn Mower Supply Co................... 25608 E. Baseline .... 92410

J.W. Jewett Co.................................. 981 Folsom St......................94107

Luttig 8i Severson ........................... 2030 28th St....................... 95818

COLORADO DENVER

South Denver Lawn Equip

CONNECTICUT SUFFIELD

The Jones 8i Ramsey Co

FLORIDA JACKSONVILLE

Rodeo Distributors

Moz-AII of Florida, Inc

GEORGIA EAST POINT

East Point Cycle & Key

ILLINOIS !

Keen Edge

INDIA‘S' ■ ELKHART

^ & Sales Inc

Brown Equip. Dist., Inc

IOWA DUBUQUE

Power Lawn 8i Garden Equip. .2551 J.F. Kennedy —52001

KANSAS WICHITA

Hixon, Inc

LOUISIANA NEW ORLEANS

Suhren Engine Co

MARYLAND ТАКОМА PARK

Center Supply Co

MASSACHUSETTS SPRINGFIELD

Morton B. Collins Co

MICHIGAN MOUNT CLEMENS

Power Equipment Dist

Lorenz Service Co

MINNESOTA MINNETONKA

Hance Distributing Inc......................11212 Wayzata Blvd. ..55343

MISSISSIPPI BILOXI

Biloxi Sales & Service, Inc. ....506 Caillavet St

MISSOURI KANSAS CITY

Automotive Equip. Service

Henzier, Inc

NEBRASKA OMAHA

R.P.W., Inc

............................

...........................................

.............................

..........................

.............................

.......................................

.........................................

.............

FORT SMITH

SAN FRANCISCO

SACRAMENTO

..............

..................

..........................

CORAL GABLES

.....................

..........

......... 2834 Church St....................30344

...............

CORYDON

....................

.......................

.....................

LANSING

..............

ST. LOUIS

Rt. 4, Box 368

527 West Evans

850 Thompsonvi He Rd. 06078

2403 Market St

365 Greco Ave

8615 Ogden Ave

2101 Industrial Pkwy. ..46514

110 Beech St

3030 Mascot

8330 Earhart Blvd

6867 New Hampshire Ave. 20012

300 Birnie Ave

36463 South Gratiot... 48043

2500 S. Pennsylvania.. 48900

3117 Holmes St

2015 Lemay Ferry Rd. 63125

7402 "L" St......................... 68127

...................

..............

..................

..................

....................

.................

.......................

.....................

..............

.....................

............................

..................

72117

72901

80223

32206

33146

60534

47112

67204

70118

01107

39533

64109

Briggs & Stratton, Tecumseh and Peerless parts anV

service should be handled by your nearest authorize

engine service firm. Check the yellow pages of your

telephone directory under the listing Engines

Goso/irae, Briggs & Stratton or Tecumseh Lauson

NEW YORK CARTHAGE

Gamble Dist., Inc

Kimber's, Inc......................................115 N. Geddes St

Henry W. O'Neil8> Associates ..410 N. Goodman St. ... 14609

NORTH CAROLINA GREENSBORO

Dixie Sales Company

Smith Hordware Co

OHIO WADSWORTH

National Central .................................687 Seville Rd,

Bleckrie, Inc

Stebe's Mid-State Mower Supply Box 366

Sunshine Wholesale Tire Outlet Route 224.................................44890

McClure Lawn & Garden Supply...1114 Lexington Ave. . 44903

OKLAHOMA MUSKOGEE

Victory Motors, Inc

Ada Auto Supply

OREGON PORTLAND

Kenton Supply Co

PENNSYLVANIA LANCASTER

Raub Supply Co................................ James8iMulberry Sts...17604

Bluemont Co

TENNESSEE KNOXVILLE

Master Repair Service

Memphis Cycle & Supply Co

American Sales 8t Service, Inc.. 1922 Lynnbrook

TEXAS DALLAS

Marr Brothers, Inc............................ 423 E. Jefferson ..................75203

Bullard Supply Co

Catto & Putty, Inc............................. P.O. Box 2408

Woodson Sales Corp

UTAH SALT LAKE CITY

A-1 Engine & Mower Co.................. 437 E. 9th St

VERMONT BURLINGTON

Vermont Appliance Co.......................44 Lakeside Ave

VIRGINIA RICHMOND

RBI Corp............................................. 963 Myers St

WASHINGTON SEATTLE

Bailey’s Rebuild, Inc

WEST VIRGINIA CHARLESTON

Young's, Inc........................................233 Virginia St., E. ...25301

WISCONSIN APPLETON

Automotive Supply Co

...............................

SYRACUSE

ROCHESTER

.......................

GOLDSBORO

..........................

.......................................

....................................

CLEVELAND

CARROL

WILLARD

MANSFIELD

...........................

ADA

....

..........................301 E. 12th St..................... 74820

..............................

PITTSBURGH

....................

MEMPHIS

HOUSTON

........................ 2409 Commerce St

SAN ANTONIO

FORT WORTH

........................

........................

.....................

West End Ave

327 Battleground Ave.. 27402

515 N. George St

7900 Lorain Ave

605 S. Cherokee

8216 N. Denver Ave. . 97217

11125 Frankstown Rd.. 1523f' 2423 Broadway, N.E. ..37917

...........

421 Monroe Ave..................38103

1702 N. Sylvania ............. .76111

1325 E. Madison St. ...98102

123 S. Linwood Ave. ..54911

-------------------------

-----------------

....................

..............

.............

...............

.................

.................................

.............

......................

................

....................

.......................

................

......................

13619

13204

27530

44281

44102

43112

74401

38117

77003

78206

84111

05401

23260

WARRANTY PARTS AND SERVICE POLICY

The purpose of warranty is to protect the customer from defects in workmanship and materials, defects which are NOT detected

at the time of manufacture. It does not provide for the unlimited and unrestricted replacement of parts. Use and maintenance are

the responsibility of the customer. The manufacturer cannot assume responsibility for conditions over which it has no control.

Simply put, if it's the manufacturer’s fault, it's the manufacturer’s responsibility; if it's the customer's fault, it’s the customer’s

responsibi lity.

CLAIMS AGAINST THE MANUFACTURER'S

WARRANTY INCLUDES

1. Replacement of Missing Ports on new equipment. 1. Model Number of unit involved.

2. Replacement of Defective Parts within the warranty period. 2. Dote unit was purchased or first put into service.

3. Repair of Defects within the warranty period. 3. Dote of failure.

All claims MUST be substantiated with the following

information:

4. Nature of failure.

Loading...

Loading...