User Manual

VingCard Essence (v2)

ASSA ABLOY Hospitality

1

66 1000 023-2

Copyrights

The information in this document is subject to change at the sole discretion of

ASSA ABLOY without notice.

Any use, operation or repair in contravention of this document is at your own risk.

ASSA ABLOY does not assume any responsibility for incidental or consequential

damages arising from the use of this manual.

All information and drawings in this document are the property of ASSA ABLOY.

Unauthorized use and reproduction is prohibited.

VingCard and Elsafe are registered trademarks of ASSA ABLOY.

ASSA ABLOY Hospitality

2

66 1000 023-2

Table of contents

.............................................................................................................................6 FCC and IC statements

FCC statements

.............................................................................................................................. 6

Industry Canada statements

.............................................................................................................................. 6

.............................................................................................................................7 1. Introduction

1.1 Lock Controller Unit (LCU) variants

.............................................................................................................................. 7

.............................................................................................................................8 2. Site survey

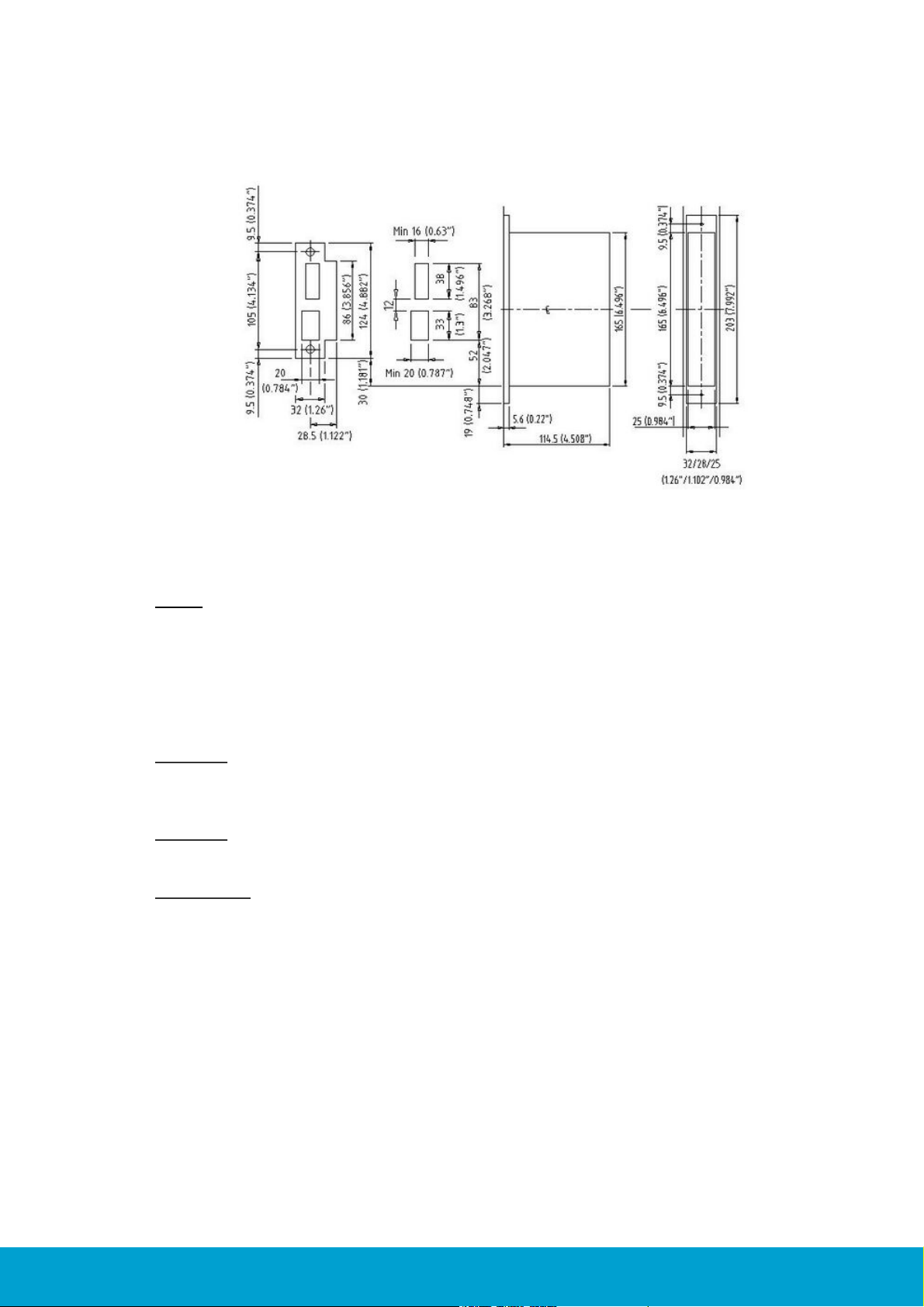

2.1 Door dimensions

.............................................................................................................................. 8

2.2 Door handing

.............................................................................................................................. 9

2.3 Type of lock case to be ordered (EURO/ANSI)

.............................................................................................................................. 10

................................................................................................................................................ 102.3.1 ANSI lock case orientation

2.4 Dimension requirements

.............................................................................................................................. 10

2.5 Check the door frames/striker plates

.............................................................................................................................. 11

2.6 Beveled doors

.............................................................................................................................. 11

2.7 Rebated doors

.............................................................................................................................. 12

.............................................................................................................................13 3. To mortise the door

3.1 Cut-outs

.............................................................................................................................. 13

3.2 To mortise for the lock case

.............................................................................................................................. 14

................................................................................................................................................ 143.2.1 Tools needed to make the cut-out for the lock case

3.3 To mortise for the striker plate

.............................................................................................................................. 15

................................................................................................................................................ 153.3.1 Tools needed to make the cut-out for the striker plate

.............................................................................................................................16 4. To install the lock

4.1 Necessary tools for the installation

.............................................................................................................................. 16

4.2 Door handle selection

.............................................................................................................................. 16

4.3 Exploded views

.............................................................................................................................. 18

................................................................................................................................................ 184.3.1 ANSI (DA)

................................................................................................................................................ 204.3.2 ANSI (DB)

................................................................................................................................................ 224.3.3 EURO

4.4 Parts included for a complete lock

.............................................................................................................................. 24

................................................................................................................................................ 244.4.1 ANSI specific parts

....................................................................................................................................... 25

4.4.1.1 ANSI (DA) specific part

....................................................................................................................................... 25

4.4.1.2 ANSI (DB) specific part

................................................................................................................................................ 254.4.2 EURO specific parts

4.5 Installation

.............................................................................................................................. 26

................................................................................................................................................ 354.5.1 To access the service jack

.............................................................................................................................36 5. To check the installation

5.1 Checklist for installation and cut-out

.............................................................................................................................. 36

................................................................................................................................................ 365.1.1 Lock mortise

ASSA ABLOY Hospitality

3

66 1000 023-2

................................................................................................................................................ 365.1.2 Cylinder

................................................................................................................................................ 365.1.3 Roses/door handles

................................................................................................................................................ 365.1.4 Striker plate

5.2 Operational check

.............................................................................................................................. 37

................................................................................................................................................ 375.2.1 Outside and inside handle

................................................................................................................................................ 375.2.2 Latch

................................................................................................................................................ 375.2.3 Thumbturn

................................................................................................................................................ 375.2.4 Cylinder

................................................................................................................................................ 375.2.5 Latch, auxiliary latch and deadbolt

5.3 Security function check

.............................................................................................................................. 38

................................................................................................................................................ 385.3.1 Auxiliary latch function

................................................................................................................................................ 385.3.2 Panic release function

5.4 Electronic check

.............................................................................................................................. 38

.............................................................................................................................39 6. Maintenance

6.1 Lubrication

.............................................................................................................................. 39

6.2 Loose screws and functional test

.............................................................................................................................. 39

6.3 To replace the batteries

.............................................................................................................................. 39

6.4 To troubleshoot the mechanical operation

.............................................................................................................................. 40

................................................................................................................................................ 406.4.1 Latch retraction

................................................................................................................................................ 406.4.2 Handle return

................................................................................................................................................ 416.4.3 Lock operation

................................................................................................................................................ 416.4.4 Thumbturn

................................................................................................................................................ 416.4.5 Auxiliary latch

6.5 To power open the lock

.............................................................................................................................. 41

6.6 Lock repair and part replacement

.............................................................................................................................. 42

................................................................................................................................................ 426.6.1 To replace the lock case

................................................................................................................................................ 426.6.2 To replace an LCU Essence RFID assy (3G) or LCA

.............................................................................................................................43 Appendix A: Part dimensions table

.............................................................................................................................44 Appendix B: Site survey form

.............................................................................................................................45 Appendix C: To install ADB

ANSI (DA) ADB

.............................................................................................................................. 45

ANSI (DB) ADB

.............................................................................................................................. 47

EURO ADB

.............................................................................................................................. 49

.............................................................................................................................50 Appendix D: Online

Introduction

.............................................................................................................................. 50

Technical specification

.............................................................................................................................. 50

Online kit

.............................................................................................................................. 51

To install an online lock

.............................................................................................................................. 52

Battery maintenance

.............................................................................................................................. 61

.............................................................................................................................62 Appendix E: Firmware change in LCU 5350

ASSA ABLOY Hospitality

4

66 1000 023-2

.............................................................................................................................63 Appendix F: Summary of notes

.............................................................................................................................66 Revision history

ASSA ABLOY Hospitality

5

66 1000 023-2

FCC and IC statements

FCC (Federal Communications Commission) statements

This device complies with Part 15 of the FCC Rules. Operation is subject to the

following two conditions:

(1) this device may not cause harmful interference, and

(2) this device must accept any interference received, including interference

that may cause undesired operation.

Note: This equipment has been tested and found to comply with the limits for a

Class A digital device, pursuant to part 15 of the FCC Rules. These limits are designed

to provide reasonable protection against harmful interference when the equipment

is operated in a commercial environment. This equipment generates, uses and can

radiate radio frequency energy and, if not installed and used in accordance with

the instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful

interference; in which case, correction of the interference is at the user's expense.

Important: Changes or modifications to an intentional or unintentional

radiator not expressly approved by the party responsible for compliance

could void the user's authority to operate the equipment.

The LCU (lock controller unit) must be labeled to say 'FCC ID: Y7V-4827610CC1'.

IC (Industry Canada) statements

This device complies with Industry Canada licence-exempt RSS standard(s).

Operation is subject to the following two conditions:

(1) this device may not cause interference, and

(2) this device must accept any interference, including interference

that may cause undesired operation of the device.

Le présent appareil est conforme aux CNR d’Industrie Canada applicables aux

appareils radio exempts de licence. L’exploitation est autorisée aux deux

conditions suivantes:

(1) l'appareil ne doit pas produire de brouillage, et

(2) l’utilisateur de l'appareil doit accepter tout brouillage radioélectrique subi,

même si le brouillage est susceptible d’en compromettre le fonctionnement.

The LCU (lock controller unit) is labeled 'IC:9514A-4827610CC1'.

The term "IC" before the equipment certification number only signifies that

the Industry Canada technical specifications were met.

Le terme "IC" devant le numéro de certification signifie seulement que les

specifications techniques Industrie Canada ont été respectées.

ASSA ABLOY Hospitality

6

66 1000 023-2

1. Introduction

The purpose of this document is to give the distributors of VingCard Essence (v2)

locks sufficient information to install and support this type of lock. This manual

contains descriptions and drawings needed for installation, maintenance and

troubleshooting of VingCard Essence (v2). Site survey before installation is also

covered in this document. The VingCard Essence (v2) lock can be used together

with the Visionline system. All dimensions in this manual (where applicable) are

given in mm and inches.

Important: VingCard Essence (v2) can only be installed in non-metallic doors.

Appendix F in this manual contains a summary of the tips, important notes and

cautions from the different sections of this manual. It can be used as an overview

and a reference for different phases of VingCard Essence (v2) installation, from site

survey to completion.

1.1 Lock Controller Unit (LCU) label

Figure 1: Labeling of LCU

ASSA ABLOY Hospitality

7

66 1000 023-2

2. Site survey

Before any order is placed, a site survey must be performed. Details which are

determined during the site survey are e.g.

length of screws, pins and cylinders

opening direction

lock case type

lock case dimensions

striker plate

A thorough and accurate site survey for every door is absolutely essential for the

successful execution of the order and the installation itself. Appendix B contains a

form where site survey notes can be filled in.

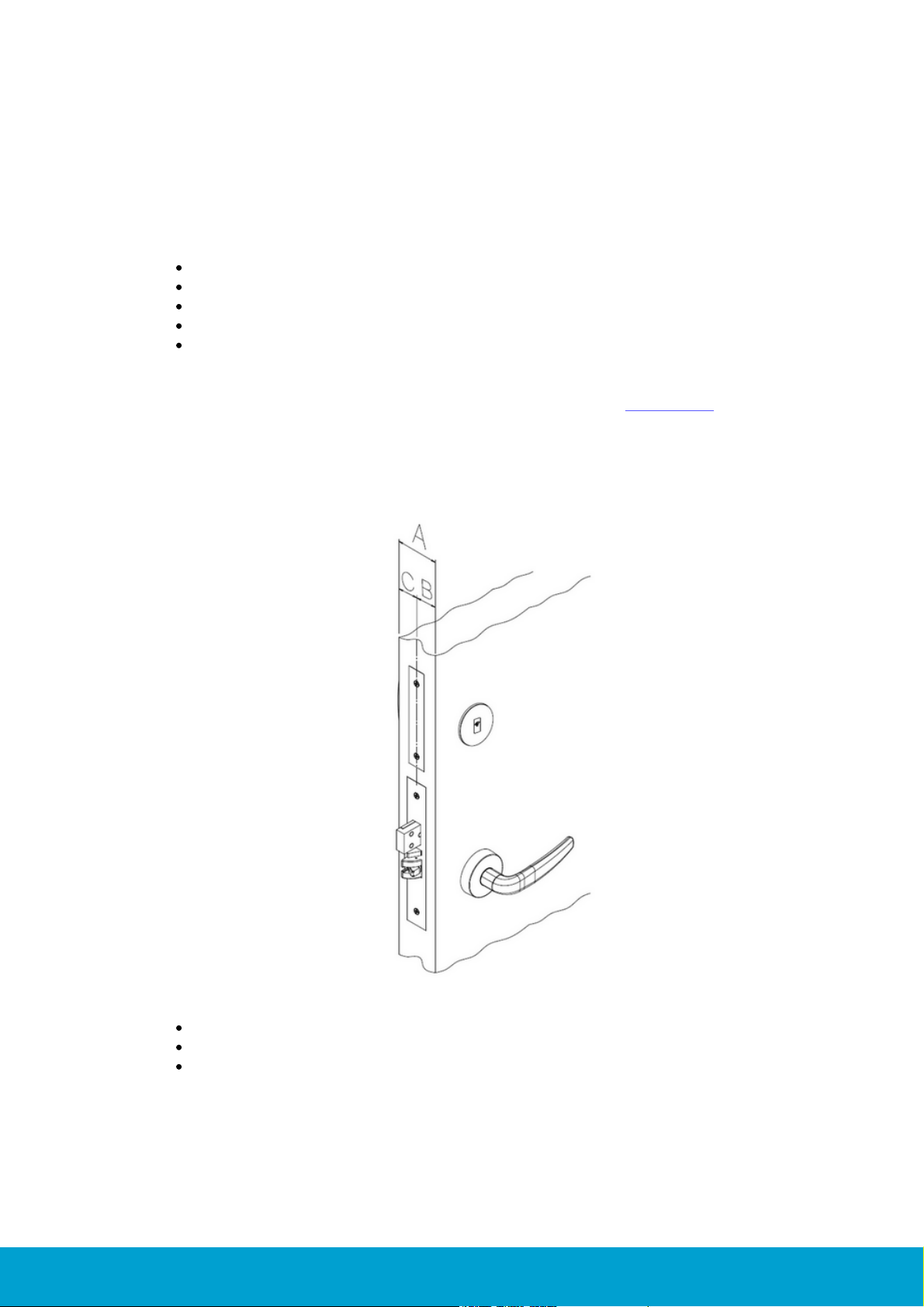

2.1 Door dimensions

The A-dimension is the entire door thickness.

The B-dimension is from the outside door edge to the center of the lock case.

The C-dimension is from the inside door edge to the center of the lock case.

ASSA ABLOY Hospitality

Figure 2: A-, B- and C-dimensions

8

66 1000 023-2

The A-, B- and C-dimensions are important to know when ordering VingCard Essence (v2)

A-Dimension

B-Dimension

38 mm; 1.50"

16 mm; 0.63"

A-Dimension

B-Dimension

129 mm; 5.087"

56 mm; 2.205"

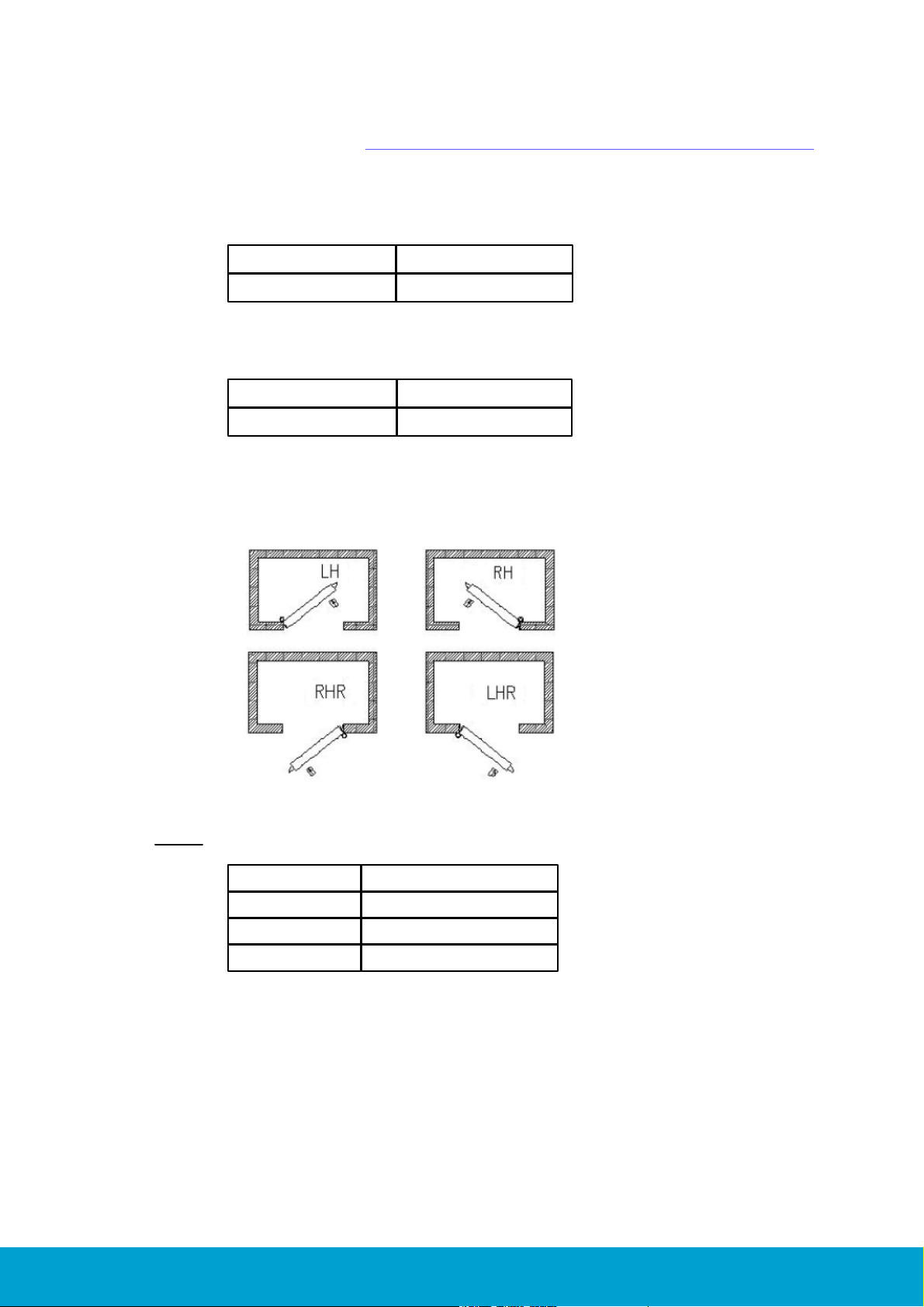

LH

Left handle

RH

Right handle

RHR

Right handle, retract

LHR

Left handle, retract

or certain parts for it. See Appendix A: Part dimensions table for Signature/Essence

for detailed information about length of screws, spindles etc according to the A-, Band C-dimensions.

Minimum door thickness:

Table 1: Minimum door dimensions; applicable for all ANSI types and all EURO types

Maximum door thickness:

Table 2: Maximum door dimensions; applicable for all ANSI types and all EURO types

2.2 Door handing

Figure 3: Door handing; for explanation, see Table 3 below.

Note: Always make sure to have the correct handing for all doors.

Table 3: Explanation of door handing abbreviations

ASSA ABLOY Hospitality

9

66 1000 023-2

2.3 Type of lock case to be ordered (EURO/ANSI)

Always take the A-dimension in account for the

type of lock case to be ordered. Find out which

standard (ANSI or EURO) that applies for the

property. If the door already has a cut-out,

check if the width and shape of the lock front

fit any of the standard ANSI or EURO lock

front dimensions.

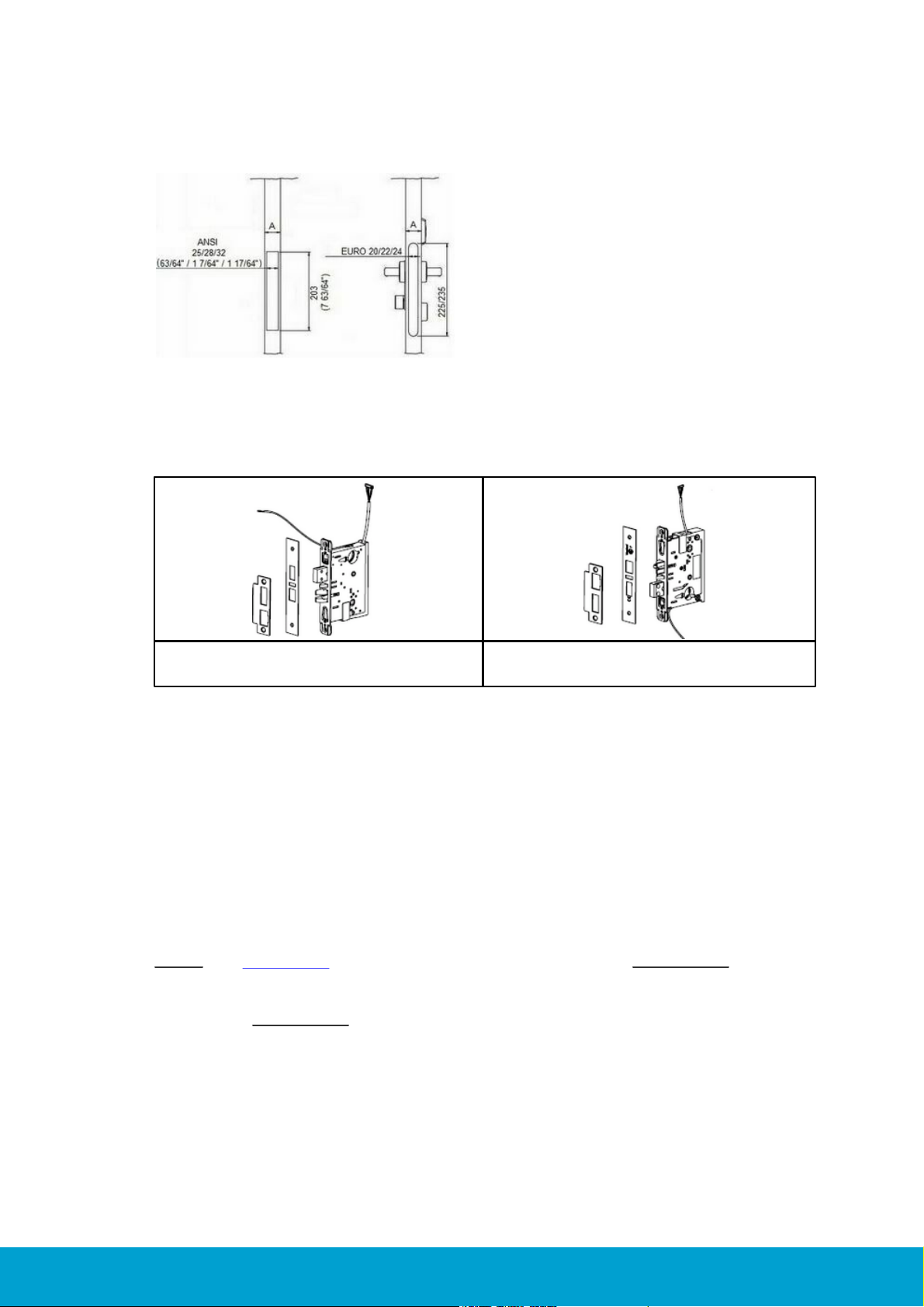

Figure 4: Available heights and widths for ANSI and EURO lock cases

Figure 5: ANSI (DA) lock case;

the Dead-bolt is Above the latch.

Figure 6: ANSI (DB) lock case;

the Dead-bolt is Below the latch.

2.3.1 ANSI lock case orientation

2.4 Dimension requirements

Check the following dimension requirements:

1. The gap between lock front cover and striker plate must not exceed 3 mm; 0.118".

2. For all types of ANSI lock cases, allow at least 25.4 mm (1") depth behind the

striker plate hole for the deadbolt. (Except ANSI AUS = 0 mm and ANSI JPN =

21 mm). Allow 21 mm for EURO lock cases.

3. For all types of ANSI lock cases, allow at least 19 mm (0.748") depth behind the

striker plate hole for the latch. Allow 14 mm for EURO lock cases.

4. Make sure that the lock case, door handles or cylinder does not get in conflict

with i.e. glass windows or ornaments/decor on the door.

Note: See section 3.1 for an overview of available cut-outs. Important: The hole for

the cylinder is optional and is only to be cut out for locks equipped with cylinders and

only from the outside of the door to the center of the lock case; i.e. not through the

entire door. Important: If you are going to install the security cylinder Hydra,

remember to make space for the cylinder fastening clip when making the cut-out

for the lock case.

ASSA ABLOY Hospitality

10

66 1000 023-2

2.5 Check the door frames/striker plates

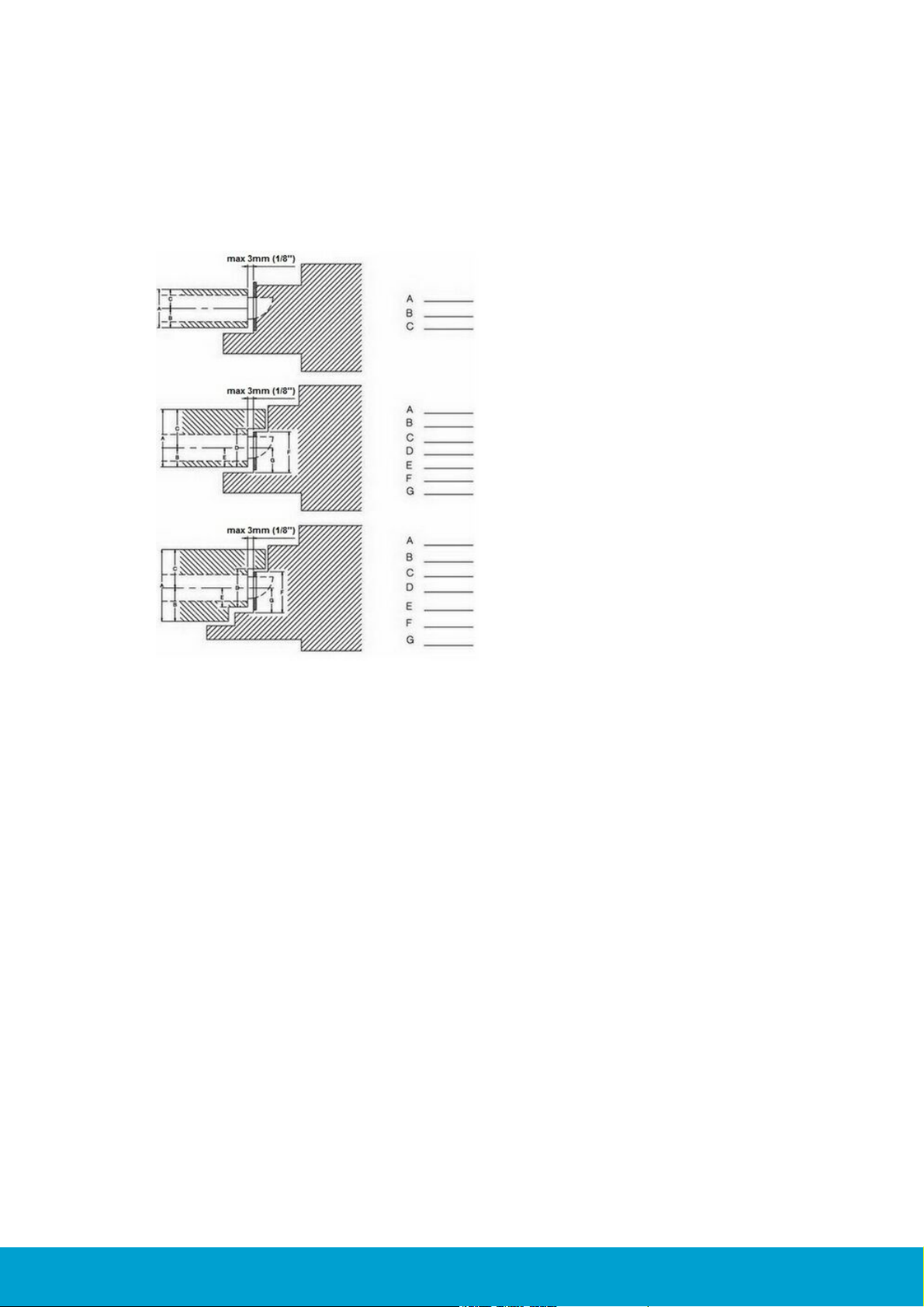

Figure 8: Beveled doors

Check if you can use ANSI or EURO standard striker plate or if you need to order a

customized striker plate. Check if the door frame is a wooden frame or a steel frame.

This will decide what kind of tools you will need for the installation.

Figure 7: Positioning of ANSI (DA) standard striker plate.

Note the dimension 30 mm (1.181") from the edge

of the lock case to the edge of the striker plate.

Figure 7 above shows the lock case center line (CL); see dot and dash line through the

figure above. The CL is important for the positioning of the lock case, striker plate and

escutcheon onto the doors.

Position of the ANSI standard striker plate:

The striker plate is positioned in the frame so that the bottom of the striker plate

is 30 mm (1.18'') above the bottom of the lock case; see Figure 7. Horizontally,

the B- or C-dimension (see Figure 2) will apply depending on the direction of

the door and the center/rebate orientation.

Note: Be aware if there is any door gasket.

2.6 Beveled doors

If the door is beveled (edge is not at 90º to door), the dimensions should be based

on the shortest side. Standard beveling is 3.2 mm; 1/8".

ASSA ABLOY Hospitality

11

66 1000 023-2

2.7 Rebated doors

Figure 9: Examples of rebated doors

and door frames

When it comes to rebated doors and rebated frames, be extra observant regarding

protrusion for the deadbolt on the frame side. See Figure 9 for examples of rebated

doors and door frames.

ASSA ABLOY Hospitality

12

66 1000 023-2

3. To mortise the door

Description

Online/offline

Document number

ANSI (DA) with cylinder

Online

AN-236

ANSI (DA) with cylinder

Offline

AN-244

ANSI (DA) without cylinder

Online

AN-238

ANSI (DA) without cylinder

Offline

AN-243

ANSI (DB) with cylinder

Online

AN-241

ANSI (DB) without cylinder

Online

AN-239

EURO with cylinder

Online

AN-242

EURO without cylinder

Online

AN-240

Table 4

Before installing the lock in the door, the door and door frame must be mortised

to fit this type of lock. The mortising should be based on the dimensions shown

in the applicable cut-out; see section 3.1 for an overview of available cut-outs.

The position of the lock case (lock case center line) has to be set according to

the ANSI standard and be level from the floor. American Disabilities Act (ADA)

requirements demand a maximum of 1220 mm (48") height to the highest point

of operation.

3.1 Cut-outs

The following cut-outs are available:

ASSA ABLOY Hospitality

13

66 1000 023-2

3.2 To mortise for the lock case

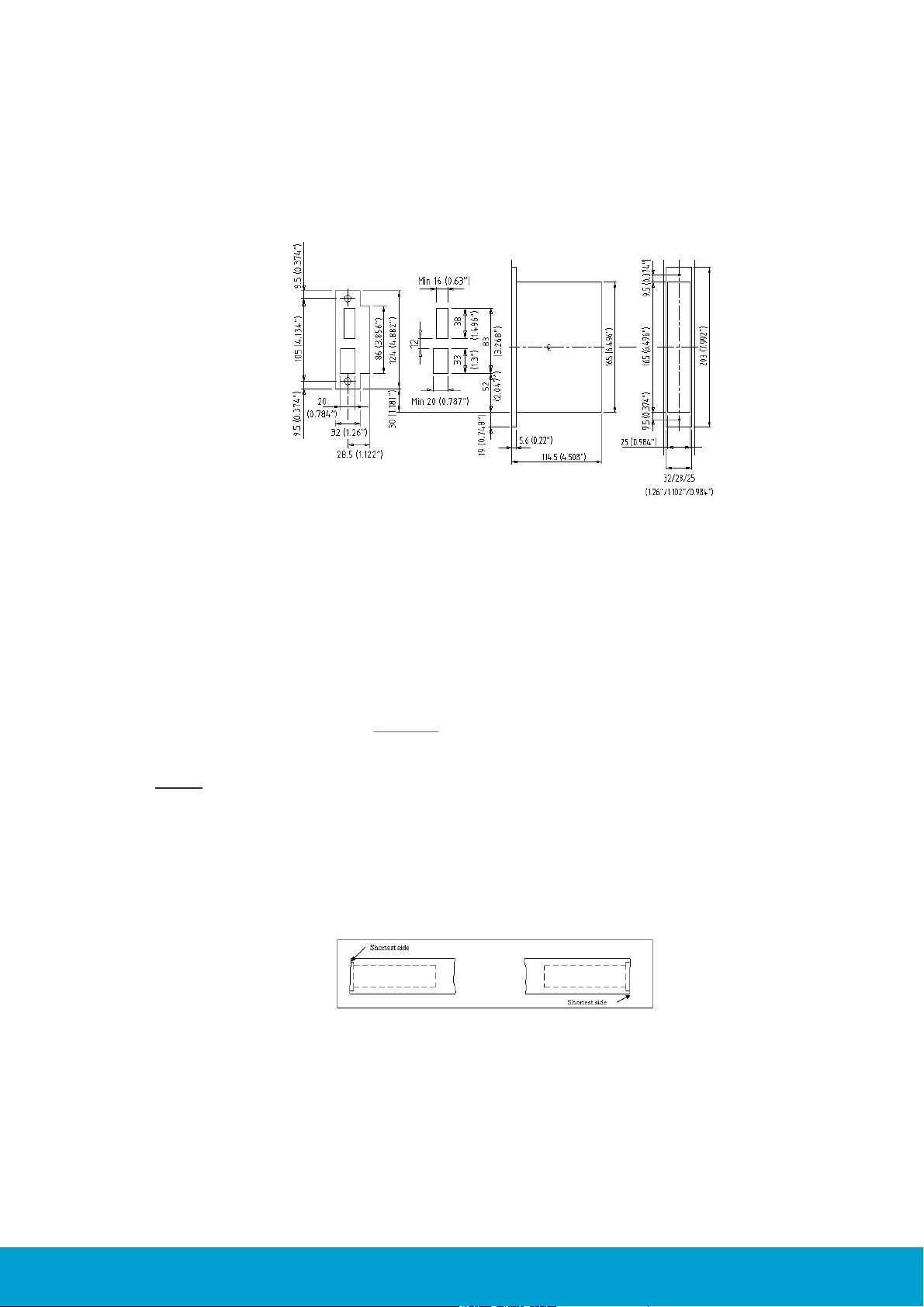

Figure 10: Cut-out for

ANSI (DA) lock case

Determine where the positioning of the lock case center line (CL) shall be, and make

the cut-out according to Figure 10.

Important: The lock front can be delivered with a width of 32 mm (1.26"), 28 mm

(1.102") or 25 mm (0.984"). Make sure that you mortise the door to the correct

dimensions for your lock dimensions. Check the dimensions of the lock before you

start cutting.

Important: If you are going to install the security cylinder Hydra, remember to

make space for the cylinder fastening clip when making the cut-out for the lock case.

3.2.1 Tools needed to make the cut-out for the lock case

Hammer and chisel are needed to make the corners for the lock front.

ASSA ABLOY Hospitality

14

66 1000 023-2

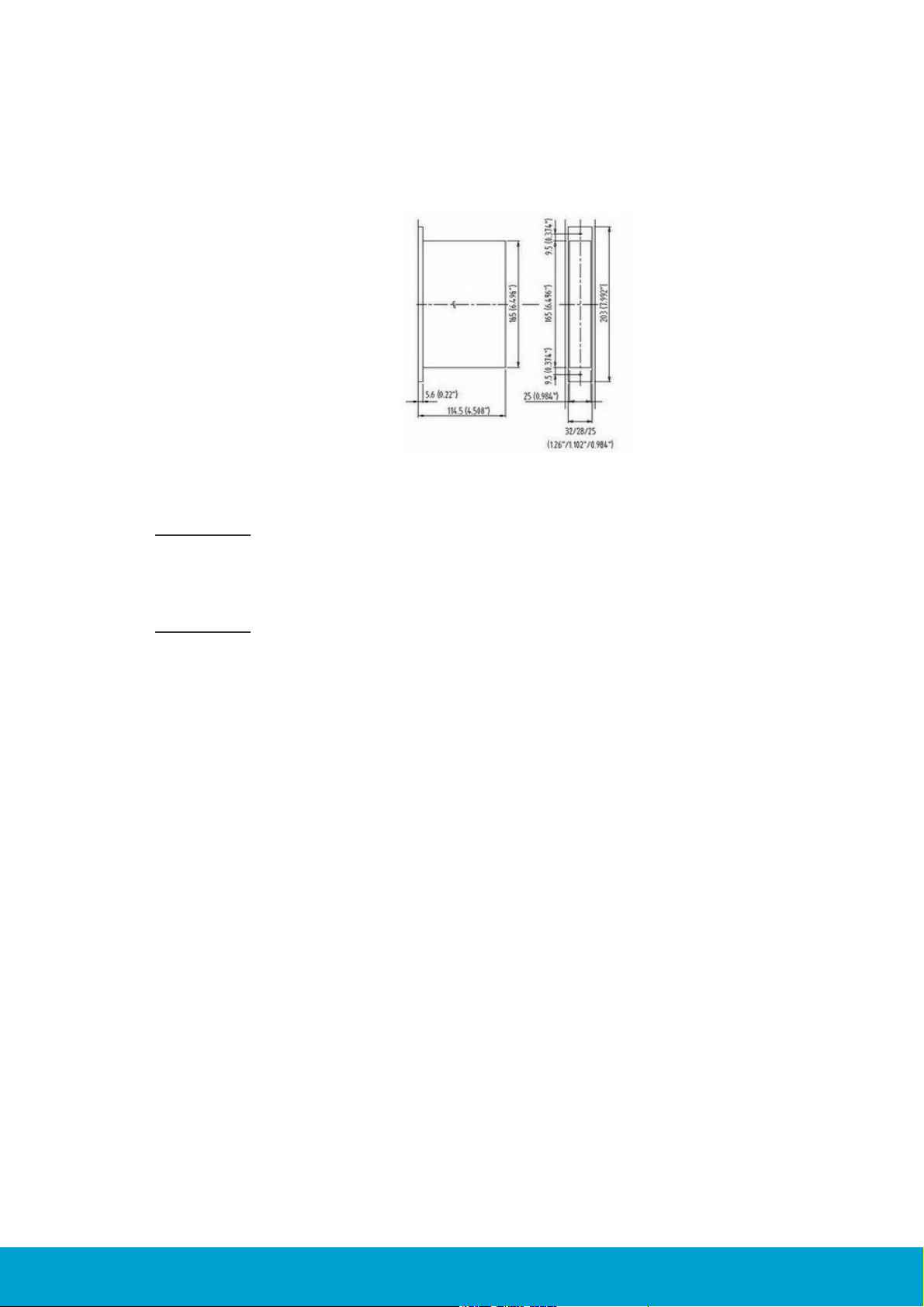

3.3 To mortise for the striker plate

Figure 11: External striker plate dimensions and

cut-out dimensions for ANSI (DA).

Note: Be aware of the dimension 30 mm (1.181'') from the edge of the lock case to

the edge of the striker plate.

Before mortising for the striker plate, make sure to align the side template vertically

and horizontally according to Figure 11. Use the center line (CL) for the lock case as

a reference. Position the striker plate so that the bottom of the striker plate is 30 mm

(1.18") above the bottom of the lock case.

Caution: If the cut-out for the deadbolt is less than 25.4 mm (1") deep, the deadbolt

may not be retracted by use of a metal key in case of an emergency when the door is

double locked (ANSI AUS = 0, ANSI JPN = 21).

Caution: Be aware if there is any door gasket. If so, compensation must be made by

adjusting the horizontal positioning of the striker plate.

Important: If the striker plate is not used (example: steel frame), it is important

that the distance between the latch (lower) cut-out and the deadbolt cut-out must

be 12 mm (0,47") in order for the auxiliary latch to work.

3.3.1 Tools needed to make the cut-out for the striker plate

Use an ordinary drilling machine, hammer and chisel.

ASSA ABLOY Hospitality

15

66 1000 023-2

4. To install the lock

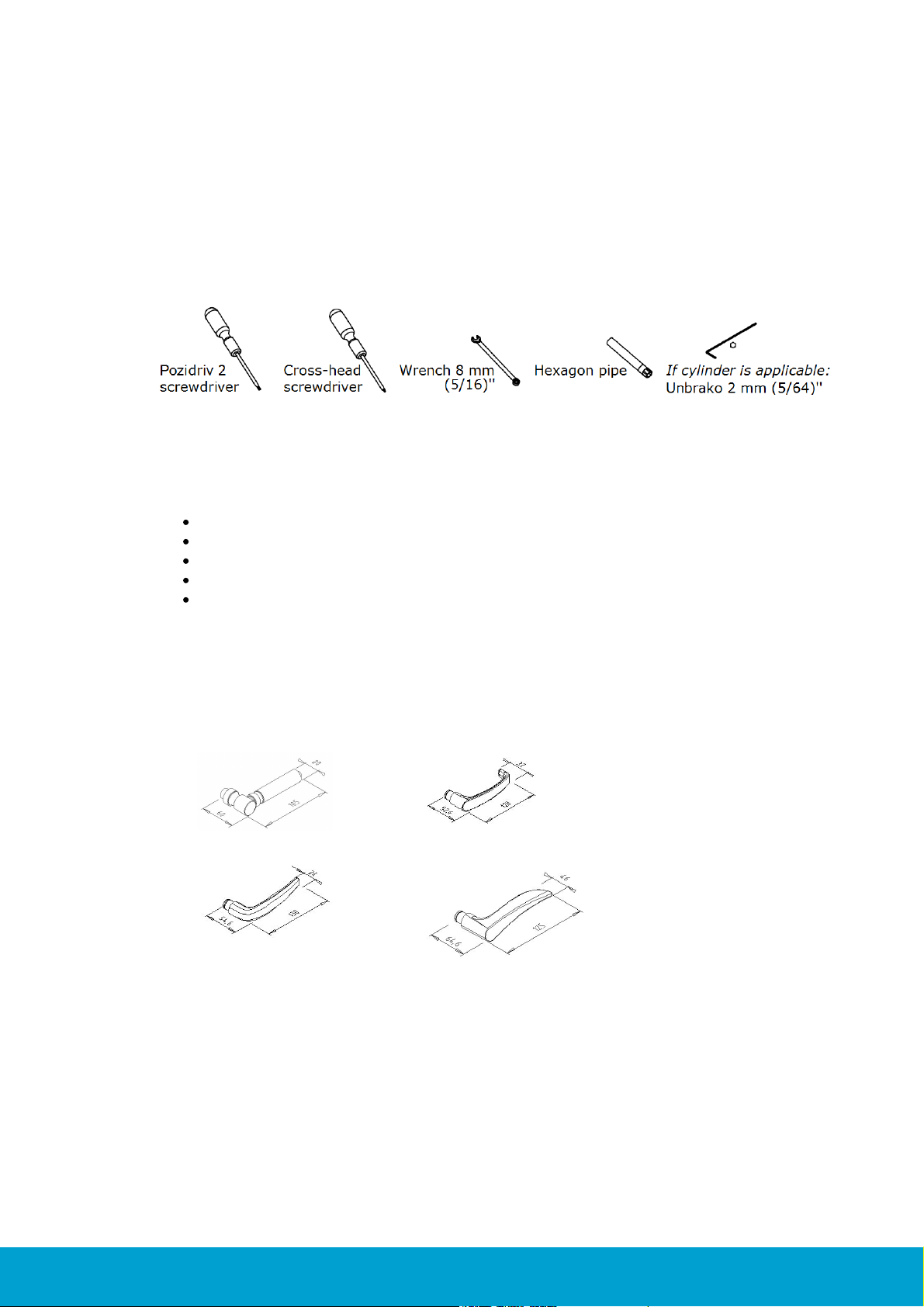

Gothic

ANSI

Straight

Wing

Figure 13: Standard Essence door handles

4.1 Necessary tools for the installation

Figure 12: Tools needed for installing the lock;

the Unbrako is only needed if cylinder is applicable

The tools shown in Figure 12 are needed for assembly of the lock:

Pozidriv 2 screwdriver

Cross-head screwdriver

Wrench 8 mm (5/16)''

Hexagon pipe

If cylinder is applicable: Unbrako 2 mm (5/64)''; only used to fasten the

cylinder fastening screw

4.2 Door handle selection

It is possible to choose between a variety of standard door handles and a variety

of door handles from the Designers Collection from Valli & Valli.

ASSA ABLOY Hospitality

16

66 1000 023-2

AC Nonvantuno

GP Novantotto

H123 R8 (Valli &

Valli)

K1160 R8 (Valli & Valli)

MDF Duemiladue

NF Novantotto

Quattro S

Quattro S

S Novanta

Figure 14: Door handles from the Designers Collection from Valli &Valli

ASSA ABLOY Hospitality

17

66 1000 023-2

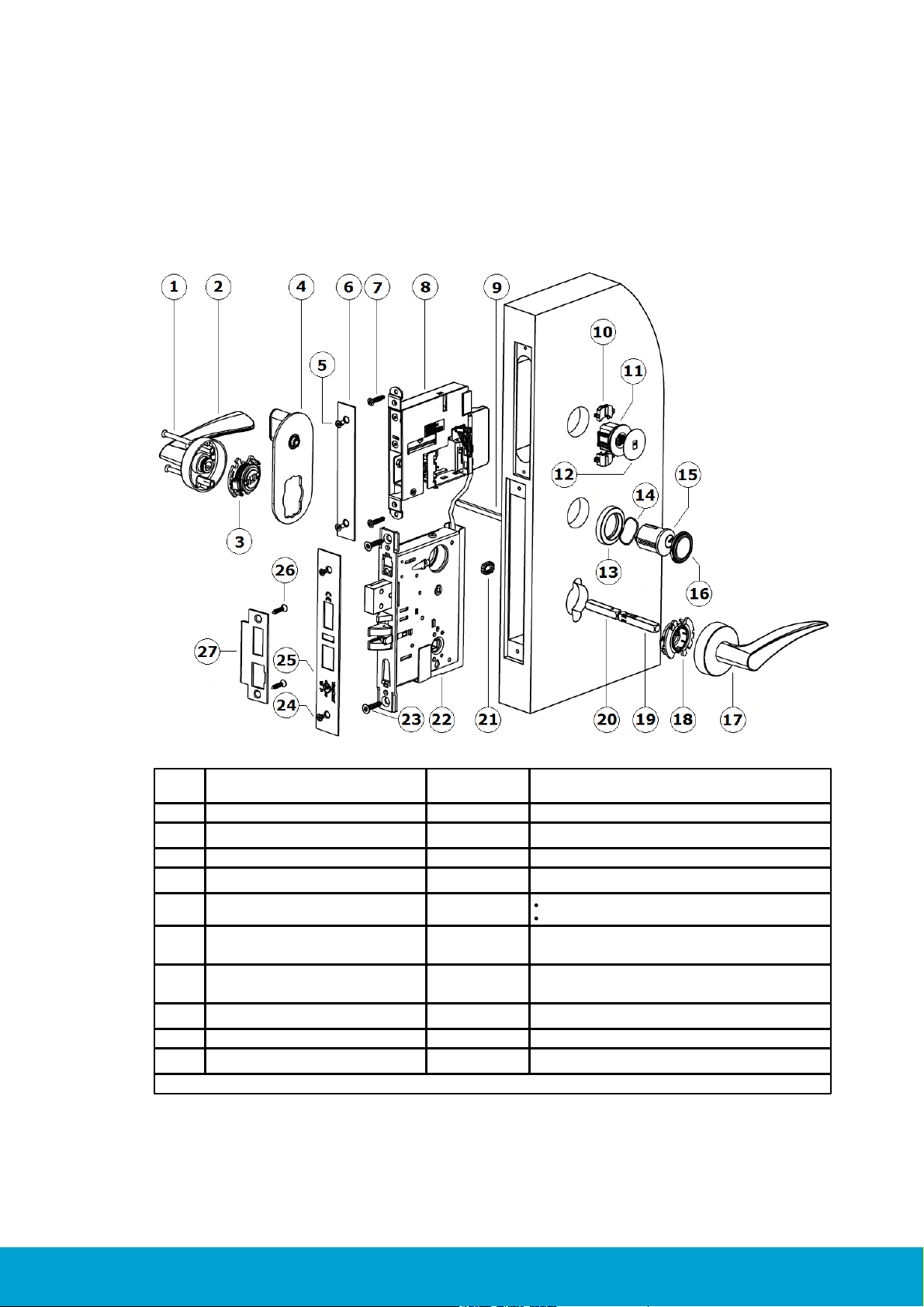

4.3 Exploded view

Pos

Description

Available as

single item

Available as kit

1

Screw Signature M5

X

HW kit Essence/Sig 1000-series

2

Handle on inside rose Signature

X

3, 18

Handle retainer*Signature

X

HW kit Essence/Sig 1000-series

4

Escutcheon thumbturn Signature

X

5

Screw, M4x5

X

Front end kit, square, for Essence

Screw kit for ANSI lock case, brass & chrome

6

Front for Essence cassette

X

Front end kit, square, for Essence cassette

7

Screw 4,5 x 22

Front end kit, square, for Essence cassette

8

Essence cassette

X

VingCard Essence (v2) main assembly

9

Thumbturn spindle Signature

X

HW kit Essence/Sig 1000-series

10

Spacer

X

VingCard Essence (v2) main assembly

Table is continued on next page

4.3.1 ANSI (DA)

Figure 15: Components for a VingCard Essence (v2) lock, ANSI (DA) variant with cylinder

ASSA ABLOY Hospitality

18

66 1000 023-2

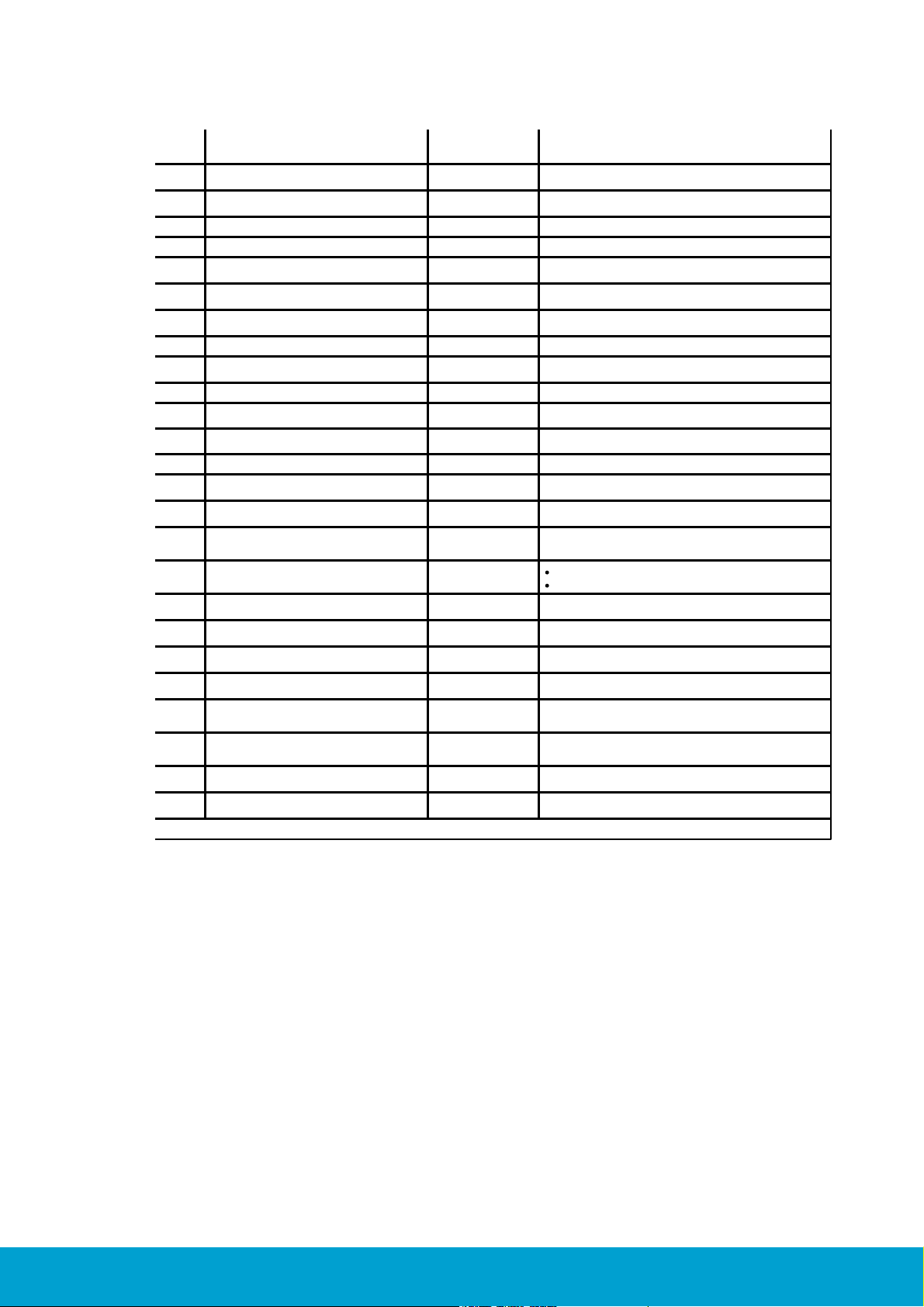

Pos

Description

Available as

single item

Available as kit

11

LCU 5350

X

VingCard Essence (v2) main assembly

12

Service cover

X

VingCard Essence (v2) main assembly

13

Cylinder rose

X

Cylinder ring kit Signature

14

Spring cylinder rose Signature

X

Cylinder ring kit Signature

15

Cyl 5-lev Std thread front prof R

X

Cyl 5-lev A ADB thread front prof R

X

Cyl 5-lev E ADB thread front prof R

X

16

Cylinder sealing assy

X

Cylinder ring kit Signature [finish] XXmm w/seal

17

Handle on outside rose Signature

X

18

See 3, 18

X

HW kit Essence/Sig 1000-series

19

Spindle handle male Signature

X

Square spindle assy Signature

*)

20

Spindle handle female Signature

X

Square spindle assy Signature

*)

21

Spindle locking clip

X

HW kit Essence/Sig 1000-series

22

Lock case ANSI DA

X

Lock case ANSI DA ADB

X

23

Screw wood, countersunk 5X25 mm

X

Screw kit for ANSI lock case, brass & chrome

24

Screw, M4x5

X

Front end kit, square, for Essence cassette

Screw kit for ANSI lock case, brass & chrome

25

Lock front ANSI

X

Lock front ANSI ADB

X

26

Screw 5,00x12 st 4,8 Zinc color

Screw kit for ANSI lock case, brass & chrome

Screw 5,00x12 st 4,8 Yellow color

Screw kit for ANSI lock case, brass & chrome

Screw, wood, countersunk, 5x25mm,

Metal zinc color

Screw kit for ANSI lock case, brass & chrome

Screw, wood, countersunk, 5x25mm,

Metal yellow color

Screw kit for ANSI lock case, brass & chrome

27

Striker plate ANSI

X

Striker plate ANSI ADB

X

Table 5

*) 'Square spindle assy Signature’ is sold as a separate kit, but is also included in 'HW kit Essence/Sig 1000-series'.

ASSA ABLOY Hospitality

19

66 1000 023-2

4.3.2 ANSI (DB)

Pos

Description

Available

as

single item

Available as kit

1

Screw Signature M5

X

HW kit Essence/Sig 1000-series

2

Handle on inside rose Signature

X

3, 18

Handle retainer*Signature

X

HW kit Essence/Sig 1000-series

4

Escutcheon thumbturn Signature

X

5

Screw, M4x5

X

Front end kit, square, for Essence

Screw kit for ANSI lock case, brass & chrome

6

Front for Essence cassette

X

Front end kit, square, for Essence cassette

7

Screw 4,5 x 22

Front end kit, square, for Essence cassette

8

Essence cassette

X

VingCard Essence (v2) main assembly

9

Thumbturn spindle Signature

X

HW kit Essence/Sig 1000-series

10

Spacer

X

VingCard Essence (v2) main assembly

Table is continued on next page

Figure 16: Components for a VingCard Essence (v2) lock, ANSI (DB) variant with cylinder

ASSA ABLOY Hospitality

20

66 1000 023-2

Pos

Description

Available

as

single item

Available as kit

11

LCU 5350

X

VingCard Essence (v2) main assembly

12

Service cover

X

VingCard Essence (v2) main assembly

13

Cylinder rose

X

Cylinder ring kit Signature

14

Spring cylinder rose Signature

X

Cylinder ring kit Signature

15

Cyl 5-lev Std thread front prof R

X

Cyl 5-lev A ADB thread front prof R

X

Cyl 5-lev E ADB thread front prof R

X

16

Cylinder sealing assy

X

Cylinder ring kit Signature [finish] XXmm w/seal

17

Handle on outside rose Signature

X

18

See 3, 18

X

HW kit Essence/Sig 1000-series

19

Spindle handle male Signature

X

Square spindle assy Signature

*)

20

Spindle handle female Signature

X

Square spindle assy Signature

*)

21

Spindle locking clip

X

HW kit Essence/Sig 1000-series

22

Lock case ANSI DB

X

Lock case ANSI DB ADB

X

23

Screw wood, countersunk 5X25 mm

X

Screw kit for ANSI lock case, brass & chrome

24

Screw, M4x5

X

Front end kit, square, for Essence cassette

Screw kit for ANSI lock case, brass & chrome

25

Lock front ANSI

X

Lock front ANSI ADB

X

26

Screw 5,00x12 st 4,8 Zinc color

Screw kit for ANSI lock case, brass & chrome

Screw 5,00x12 st 4,8 Yellow color

Screw kit for ANSI lock case, brass & chrome

Screw, wood, countersunk, 5x25mm,

Metal zinc color

Screw kit for ANSI lock case, brass & chrome

Screw, wood, countersunk, 5x25mm,

Metal yellow color

Screw kit for ANSI lock case, brass & chrome

27

Striker plate ANSI

X

Striker plate ANSI ADB

X

Table 6

*) 'Square spindle assy Signature’ is sold as a separate kit, but is also included in 'HW kit Essence/Sig 1000-series'.

ASSA ABLOY Hospitality

21

66 1000 023-2

4.3.3 EURO

Pos

Description

Available as

single item

Available as kit

1

Screw Signature M5

X

HW kit Essence/Sig 1000-series

2

Handle on inside rose Signature

X

3, 18

Handle retainer*Signature

X

HW kit Essence/Sig 1000-series

4

Escutcheon thumbturn Signature

X

5

Screw, M4x5

X

Front end kit, square, for Essence

Screw kit for ANSI lock case, brass & chrome

6

Front for Essence cassette

X

Front end kit, square, for Essence cassette

7

Screw 4,5 x 22

Front end kit, square, for Essence cassette

8

Essence cassette

X

VingCard Essence (v2) main assembly

9

Thumbturn spindle Signature

X

HW kit Essence/Sig 1000-series

10

Spacer

X

VingCard Essence (v2) main assembly

Table is continued on next page

Figure 17: Components for a VingCard Essence (v2) lock, EURO variant with cylinder

ASSA ABLOY Hospitality

22

66 1000 023-2

Pos

Description

Available as

single item

Available as kit

11

LCU 5350

X

VingCard Essence (v2) main assembly

12

Service cover

X

VingCard Essence (v2) main assembly

13

Cylinder rose

X

Cylinder ring kit Signature

14

Spring cylinder rose Signature

X

Cylinder ring kit Signature

15

Cyl 5-lev Std thread front prof R

X

Cyl 5-lev A ADB thread front prof R

X

Cyl 5-lev E ADB thread front prof R

X

16

Cylinder sealing assy

X

Cylinder ring kit Signature [finish] XXmm w/seal

17

Handle on outside rose Signature

X

18

See 3, 18

X

HW kit Essence/Sig 1000-series

19

Spindle handle male Signature

X

Square spindle assy Signature

*)

20

Spindle handle female Signature

X

Square spindle assy Signature

*)

21

Spindle locking clip

X

HW kit Essence/Sig 1000-series

22

Lock case EURO

X

Lock case EURO ADB

X

23

Screw wood, countersunk 5X25 mm

X

Screw kit for ANSI lock case, brass & chrome

24

Not applicable for EURO

25

Not applicable for EURO

26

Screw 5,00x12 st 4,8 Zinc color

Screw kit for ANSI lock case, brass & chrome

Screw 5,00x12 st 4,8 Yellow color

Screw kit for ANSI lock case, brass & chrome

Screw, wood, countersunk, 5x25mm,

Metal zinc color

Screw kit for ANSI lock case, brass & chrome

Screw, wood, countersunk, 5x25mm,

Metal yellow color

Screw kit for ANSI lock case, brass & chrome

27

Striker plate EURO

X

Table 7

*) 'Square spindle assy Signature’ is sold as a separate kit, but is also included in 'HW kit Essence/Sig 1000-series'.

ASSA ABLOY Hospitality

23

66 1000 023-2

4.4 Parts included for a complete lock

Figure 18: Parts included for a complete Essence lock; see details in Table 6 (ANSI DA),

Table 7 (ANSI DB) and Table 8 (EURO). The online kit and cylinder kit are purchased

separately, when applicable.

4.4.1 ANSI specific parts

The below parts are specific for ANSI (DA) and ANSI (DB); the striker plate is

however turned the other way for ANSI (DB).

Figure 19, from the left: front for Essence cassette, striker plate ANSI,

lock front ANSI and cylinder set screw for cylinders ex threaded ANSI ADB.

ASSA ABLOY Hospitality

24

66 1000 023-2

4.4.1.1 ANSI (DA) specific part

Figure 20: The lock case is the only part which is specific for ANSI (DA).

4.4.1.2 ANSI (DB) specific part

Figure 21: The lock case is the only part which is specific for ANSI (DB).

4.4.2 EURO specific parts

Figure 22, from the left: front cover rounded, striker plate EURO 5994 steel,

cylinder set screw for cylinders ex threaded ANSI ADB and lock case EURO.

ASSA ABLOY Hospitality

25

66 1000 023-2

4.5 Installation

Figure 23

Figure 24

Figure 25

Note: For information about online

related parts of the installations,

see Appendix D.

Note: The position numbers in bold refer

to the exploded views in section 4.3.

1. Position the cables into the door

before inserting the lock case (22).

The connector on the cable must be

bent before being threaded into the

hole through the door. Important:

Do not lubricate the lock case.

2. Position the lock case into the edge

of the door and fasten it with two

screws wood, countersunk 5X25 mm

(23).

Note: If applicable, do not forget to

install the cylinder fastening clip

before inserting the lock case.

ASSA ABLOY Hospitality

26

66 1000 023-2

Figure 26

Figure 27

3. Before inserting the spindle handle female Signature (20) and the spindle

handle male Signature (19) into the lock case, check that the spindle threads

are lubricated with grease.

4. Screw the spindle handle female Signature onto the spindle handle male Signature

and then reverse it (3/4 turn).

5. Insert the spindle handles into the lock case from the outside of the door so that

the hole that goes through the spindle handle is visible on the inside (room side)

of the door. Note: The spindle handle marked 'EXT' must be on the outside of

the door.

ASSA ABLOY Hospitality

27

66 1000 023-2

Figure 28

6. Thread the spindle locking clip (21) onto

the spindle handle female Signature (20;

on the inside of the door) by squeezing

hard on the spindle locking clip. Make

sure that the clip clicks onto the hole

in the spindle handle.

Figure 29

Figure 30

7. At delivery, the handle retainers*

Signature (3 and 18) are not mounted

into the handle on inside rose Signature

(2) and handle on outside rose Signature

(17), and they must be prepared

according to the door handing. If the

handle on inside rose Signature is a

left handle (i.e. pointing to the left),

the white retainer should be mounted

on the inside handle. If the handle on

inside rose Signature is a right handle,

the black retainer should be mounted

on the inside handle.

Important: For both left handles

and right handles, make sure that

the handle retainer*Signature is in

the "click" position within the groove

on the shank of the handle.

ASSA ABLOY Hospitality

28

66 1000 023-2

Figure 31

8. Insert the thumbturn spindle Signature

(9) into the lock case from the inside.

The marked end on the spindle handle

must be inserted into the thumb turn

knob. Important: For ANSI (DB) and

EURO, the thumb turn knob should be

pointing downwards. Insert the inside

handle onto the spindle handle and

screw the handles together.

Important: For ANSI (DA), the thumb

turn knob should be pointing upwards.

Insert the inside handle onto the spindle

handle and screw the handles together.

9. Insert the inside handle including the

handle retainer*Signature (3) onto

the spindle handle. Fasten the handles

together using screws Signature M5 (1).

ASSA ABLOY Hospitality

29

66 1000 023-2

Figure 32

Figure 33

Figure 34

10. If cylinder is used:

- Thread the spring cylinder rose

Signature (14) onto the cylinder

(15; see full names of the

cylinder variants here) from

the cylinder-arm side.

- Insert the cylinder into the

cylinder rose.

- Use a key and screw the cylinder

into the lock case.

- Tighten the cylinder until the

cylinder rose is tight to the door.

- Fix the cylinder into the lock case.

- The keyhole should always point

towards the handle.

11. There are two ways for installing

the cylinder fastening screw:

- The nomal way; insert the

2 mm Unbrako into the screw,

and insert the screw in the hole

facing towards the lock front.

Tighten the cylinder in the

lock case as illustrated in

Figures 32-34.

ASSA ABLOY Hospitality

30

66 1000 023-2

Figure 35

- A more secure way; fix the cylinder in

place by using the fixing-screw tool kit.

Use the L-shaped Allen key to lock the

headless fixing screw (cylinder screw

is turned upside down) to the T-shaped

tool as illustrated in Figure 35. Using the

T-tool, screw the fixing screw in place as

shown earlier to fix the cylinder in place.

Make sure that the cylinder fixing screw

is tightened in the cylinder. Release the

T-tool from the fixing screw by holding

the T-tool rigid while turning the Allen

key counter-clockwise until the Allen key

is released from the screw; then unscrew

the T-tool.

12. After installation of the cylinder, fix for

ANSI (DA) and ANSI (DB) the face plate

to the lock case after installation of

the cylinder.

Figure 36

13. Assemble the Essence cassette (8)

before installation.

14. Depending on whether the handing is

left or right (see details here), the fire

shield plate shall be attached on the

opposite side of the LCU (the drawing

shows right handing).

Figure 37

15.To match the B-measurement of the

door leaf, it is possible to increase the

length of the LCU in order to reach the

sprocket*) inside the Essence cassette.

This can be done by adding spacers

(expansion modules), which consist

of two halfs sliding into the slot on the

back of the LCU. The two halfs will meet

and by a “snap-lock” functionality lock

onto the LCU. Additional spacers can

be added on top of the other spacers.

*) The sprocket is only partly locking the LCU in

place after installation.

ASSA ABLOY Hospitality

31

66 1000 023-2

Figure 38

16.Connect the lock case cable to the

Essence cassette (I in Figure 38).

Important before mounting the

Essence cassette in the door:

Make sure that the LCU cable is well

positioned in the space marked with

II in Figure 38, to avoid pinching of

the cable.

Figure 39

17.Insert the Essence cassette into

the door.

Figure 40

18.Loose the bracket with a wrench (8 mm)

until it moves freely.

Figure 41

19.Connect the LCU cable to the LCU and

adjust the bracket in order to enter the

LCU against the sprocket.

Important: Arrange the cables to

prevent pinching them.

ASSA ABLOY Hospitality

32

66 1000 023-2

Figure 42

20.Fasten the bracket with the

wrench (8 mm).

Note: Tighten gently.

Figure 43

21.When the LCU has entered the bracket,

use the hexagon pipe to turn the

sprocket in order to pull the LCU

in place.

Note: Tighten gently.

Figure 44

22.When the LCU is pulled all the way

into the door leaf, fasten the screw

in the centre of the sprocket by using

a Pozidriv 2 screwdriver.

Note: Tighten gently.

Figure 45

23.Insert 3 AA batteries.

24.Fix the face plate of the case, upload

the firmware and attach the service cover

of the LCU. The service cover shall be

inserted 90 degrees to the left and then

be turned 90 degrees clockwise in order

to fasten.

ASSA ABLOY Hospitality

33

66 1000 023-2

Figure 46

25. To install the strike: The depth

in the frame must be sufficient

(min 25,4 mm/1'') for throwing

the deadbolt.

ASSA ABLOY Hospitality

34

66 1000 023-2

Figure 47

26. Make a full test of the lock.

Important: Do not close the door

before the lock has been tested.

Note: If cylinder with cap is used,

the installation of the cap should

be the last operation in the mounting

of the lock.

Figure 48

When access to the service jack is needed, twist by hand

the service cover counterclockwise and lift it off. To mount

it again, twist it clockwise until the RFID card symbol looks

as in Figure 48.

ASSA ABLOY Hospitality

4.5.1 To access the service jack

35

66 1000 023-2

5. To check the installation

A quick check of the installation and operation is important in order to

discover any problems related to the installation or the lock itself.

5.1 Checklist for installation and cut-out

5.1.1 Lock mortise

The lock front/face plate should be flush with the door edge.

5.1.2 Cylinder

The cylinder should be flush with the cylinder rose and properly fixed.

5.1.3 Roses/door handles

All should be aligned vertically, horizontally and firmly tightened. Make sure there

are no gaps between the door surface and the lock installation.

5.1.4 Striker plate

The depth in the frame must be sufficient for throwing the deadbolt with small

clearance (min. clearance 26.4 mm; 1.04") and releasing the latch (min. clearance

20 mm; 0.79").

ASSA ABLOY Hospitality

36

66 1000 023-2

5.2 Operational check

5.2.1 Outside and inside handle

Handles must return to a horizontal position after being depressed and slowly

released. The handle on outside rose Signature (see pos 17 in the exploded views

of section 4.3) can only be depressed when the lock is in an unlocked position.

5.2.2 Latch

The latch must release freely into the striker plate. When the latch is released

into the striker plate there should be minimal door movement.

5.2.3 Thumbturn

The escutcheon thumbturn Signature (pos 4 in the exploded views of section 4.3)

must throw and retract the deadbolt freely, also when thrown into the striker plate.

5.2.4 Cylinder

When using an emergency key (mechanical), the latch and the deadbolt must

throw and retract freely.

5.2.5 Latch, auxiliary latch and deadbolt

When the deadbolt has been retracted by the escutcheon thumbturn Signature

(pos 4 in the exploded views of section 4.3) - or the handle on inside rose Signature

(pos 2 in the exploded views of section 4.3) - and the handle on inside rose Signature

is fully depressed, the latch, auxiliary latch and deadbolt should be flush with the

lock front.

ASSA ABLOY Hospitality

37

66 1000 023-2

5.3 Security function check

5.3.1 Auxiliary latch function

When depressing the auxiliary latch, the latch should be blocked. Make sure the

latch is not snagged by the striker plate when the door is closed. According to

the ANSI standard, the latch shall be blocked when depressing the auxiliary latch

0-9.5 mm (0-0.37") measured from lock front. For EURO locks, the requirement

is 0-3 mm (0-0.118"); the actual dimension is typically 0-6 mm (0-0.236").

5.3.2 Panic release function

When the door is closed and the deadbolt is thrown, depress the inside handle.

The deadbolt and the latch must be retracted.

5.4 Electronic check

Always check that the electronics works before closing the door.

To check the privacy function you need to have a card without deadbolt override,

use a staff card issued when the Visionline system setup has been performed.

If the deadbolt is thrown, you should get three very short yellow flashes.

The outside door handle should still be blocked. If the deadbolt is not thrown,

you should get a green light. The outside door handle can easily be depressed.

ASSA ABLOY Hospitality

38

66 1000 023-2

6. Maintenance

For a reliable operation of the lock, a certain level of maintenance is required.

6.1 Lubrication

All parts that need lubrication are already lubricated by ASSA ABLOY Hospitality.

No parts should therefore need any further lubrication.

Caution: The use of lubricants containing solvents or graphite will void the warranty

on the lock.

6.2 Loose screws and functional test

Check for loose screws, especially the door handle fastening screws, at scheduled

times. Also, perform a functional test (see chapter 5) at scheduled times; at least

once per year is recommended.

6.3 To replace the batteries

The LCU 5350 (pos 11 in the exploded views of section 4.3) checks the battery

voltage when a staff card is used. The check is performed when the lock motor is

activated. If the battery voltage is below the acceptable, the LCU 5350 signals with

four short yellow flashes. The door will still unlock as long as the battery voltage is

high enough to operate the lock motor; this gives a green flash. If there is no green

flash at the end, the battery voltage is below next critical level and will not operate

the lock motor.

Important: Battery check and/or replacement should be performed at

scheduled intervals.

Important: It is recommended to always make a read-out of the time in the lock

after a battery exchange to make sure that it is correct. Use a service cable and a

service PC with the software Lock Service 3G; see Quick reference guide Lock Service

3G for details. If the time is not correct, a soft reset has occurred; see details on how

to proceed in step 9 below.

To replace the batteries:

1. Important: Make sure to have fresh batteries ready since the battery holder

4.5V with new batteries must be connected as quickly as possible after the

old batteries have been disconnected, else a soft reset may take place.

Do not present any card during the battery exchange. If other batteries than

those provided by ASSA ABLOY Hospitality are used, make sure that they

ASSA ABLOY Hospitality

39

66 1000 023-2

are alkaline or long life batteries.

2. Remove the front end by loosening the two screws.

3. Drag out the battery holder 4.5V.

4. Exchange the batteries in the battery holder 4.5V with fresh ones.

Important: The old batteries should be treated in accordance with local

regulations regarding recycling.

5. Reinstall the battery holder 4.5V.

Important: If a short green flash is seen when the battery is connected,

a soft reset has been done since the lock has been without power too long.

Be observant on the green flash; it can be hard to see due to surrounding light.

See in step 9 below how to proceed if a soft reset has taken place.

6. Mount the front end with the two screws.

7. Make a read-out of the time in the lock with Lock Service 3G to make sure

that the time is correct. If it is not, use Lock Service 3G to set the time. If stand

open and/or privacy are applicable, these parameters must by set in the lock

again; if the Online option is applicable in Visionline, they are sent online,

but not instantly. These parameters can also be set with a stand open card

and privacy card respectively; see User manual Visionline for details.

6.4 To troubleshoot the mechanical operation

If a lock does not work properly when a card is used, you must determine whether

the malfunction is due to a card error or to a mechanical error. Many mechanical

malfunctions can be detected by a visual inspection. If a lock cannot be operated

when a card is used – even though the reader displays a green LED – or if the lock

is difficult to operate, check the items stated in the following sections.

6.4.1 Latch retraction

Depress the latch with your thumb. If it does not depress easily, either the lock case

is in binding lock case components are malfunctioning. Remove the lock case from

the door and depress the latch. If the latch depresses easily when the lock case is

removed from the door, reinstall the lock case carefully testing at each stage of

assembly. After installation of a lock, check for full extension of the latch. If the

latch does not extend completely, binding between the lock case and the mortise

pocket or other lock parts may be interfering with operation.

6.4.2 Handle return

If the handle on outside rose Signature (pos 17 in the exploded views of section 4.3)

does not return to a horizontal position after the door has been operated, the handle

return spring (which is located inside the handle on outside rose Signature) may

be broken or displaced. Remove the door handle roses to check the handle

return spring.

ASSA ABLOY Hospitality

40

66 1000 023-2

If the handle on inside rose Signature (pos 2 in the exploded views of section 4.3) sags,

door alignment may be causing binding. In this case, loosen the door handle screws and

depress the handle. If the handle returns freely with the screws Signature M5 (pos 1 in

the exploded views of section 4.3) loosened, align the lock so that the handle continues

to return after the screws are tightened. The handle may also sag because the hub

spring, in the lock case, is broken or weak.

6.4.3 Lock operation

If it is difficult to depress the handles, loosen the door handle screws and try again.

If the lock is still difficult to operate, loosen the lock case screws. This procedure may

help detect binding. Sometimes binding is caused by improperly drilled holes for the

door handle screws. Be careful if enlarging the screw holes to reduce the binding.

The door handle roses may not cover enlarged screw holes, and the enlarged holes

could cause recurring alignment problems.

6.4.4 Thumbturn

The escutcheon thumbturn Signature (pos 4 in the exploded views of section 4.3)

should extend and retract the deadbolt easily. Difficulty in turning usually results from

poor striker plate alignment. Operate the escutcheon thumbturn Signature with the door

open. If the escutcheon thumbturn Signature operates easily with the door open but is

difficult to operate with the door closed, the striker plate is not well aligned. Reduce or

add door silencing pads to avoid re-positioning the striker plate. Sometimes filing the

striker plate slightly can alleviate striker plate binding. Adjusting the striker plate may

be a good solution.

Loosening the door handle screws and re-tightening may correct the alignment.

However, escutcheon thumbturn Signature difficulty can indicate more serious lock

case malfunction. If the deadbolt is difficult to operate, even when the lock case is

removed from the door, replace the lock case.

6.4.5 Auxiliary latch

Press and hold the auxiliary latch and then try to press the latch. You should not be

able to depress the latch bolt when the auxiliary latch is engaged. If the auxiliary bolt

never disengages (the latch bolt cannot be retracted), check for binding. If the mortise

pocket is not wide enough, the auxiliary latch cannot move correctly.

6.5 To power open the lock

It is possible to power open the LCU 5350 (pos 11 in the exploded views of section

4.3) with a service cable and a service PC with the Lock Service 3G software; see

Quick reference guide Lock Service 3G for detailed information.

ASSA ABLOY Hospitality

41

66 1000 023-2

6.6 Lock repair and part replacement

6.6.1 To replace the lock case

In order to replace the lock case, refer to the Installation section, but do everything

in the reverse order. Everything except the striker plate must be removed from

the door.

Tip: Use a long set of pliers to remove the spindle locking clip.

6.6.2 To replace an LCU Essence RFID assy (3G) or LCA

To replace an LCU Essence RFID assy (3G) or LCA, see the Installation section.

ASSA ABLOY Hospitality

42

66 1000 023-2

Appendix A: Part dimensions table for

Figure A1

Signature/Essence

ASSA ABLOY Hospitality

43

66 1000 023-2

Appendix B: Site survey form

Figure B1

ASSA ABLOY Hospitality

44

66 1000 023-2

Appendix C: To install ADB

Figure C1: Striker plate and cut-out

Door handing

Striker plate L

Striker plate R

LH (Rx)

X

RHR (Ro)

X

RH (Lx)

X

LHR (Lo)

X

This appendix contains drawings needed for an installation or upgrade of

ANSI (DA) ADB, striker plate

ANSI (DA) ADB, mortise

ANSI (DB) ADB, striker plate

ANSI (DB) ADB, mortise

EURO ADB lock case

ANSI (DA) ADB, striker plate

When installing or upgrade to ANSI DA ADB lock case, the external striker plate must be

installed as shown in Figure C1; dimensions in mm (inches).

Important: When installing an ADB lock case, the ADB striker plate with

curved lip must always be used (hands of door L and R).

Table C1: Striker plates for different door handings

All frames (wooden and steel frames)

1. Install the lock in the door according to the Installation section.

2. Place the ADB striker plate in the frame as shown in Figure C1, 49 mm

(1 30/32") above the bottom of the lock front (30mm + 19mm, i.e. 3/4"+1 3/16").

ASSA ABLOY Hospitality

45

66 1000 023-2

Appendix C: To install ADB

Figure C2: Remove the

hatched area

ANSI (DA) ADB, mortise

If the frame is mortised for a standard ANSI striker plate, the frame must be modified

as shown in Figure C2.

ASSA ABLOY Hospitality

46

66 1000 023-2

ANSI (DB) ADB, striker plate

Figure C3: Striker plate and cut-out

Door handing

Striker plate

L

Striker plate

R

LH (Rx)

X

RHR (Ro)

X

RH (Lx)

X

LHR (Lo)

X

When installing or upgrade to ANSI DB ADB lock case, the external striker plate must

be installed as shown in Figure C3; dimensions in mm (inches).

Important: When installing an ADB lock case, the ADB striker plate with curved lip

must always be used (hands of door L and R).

Table C2: Striker plates for different door handings

All frames (wooden and steel frames)

1. Install the lock in the door according to the Installation section.

2. Place the ADB striker plate in the frame as shown in Figure C3, 49 mm

(1 30/32") below the top of the lock front (30mm + 19mm, i.e. 3/4"+1 3/16").

ASSA ABLOY Hospitality

47

66 1000 023-2

Appendix C: To install ADB

Figure C4: Remove the

hatched area

ANSI (DB) ADB, mortise

If the frame is mortised for a standard ANSI striker plate, the frame must be modified

as shown in Figure C4.

ASSA ABLOY Hospitality

48

66 1000 023-2

Appendix C: To install ADB

ADB lock case, EURO

When installing or upgrade to EURO lock case, the external striker plate must be

installed as shown in Figure C5; dimensions in mm.

Figure C5: EURO ADB lock case

The notes below refer to Figure C5.

Note 1: Latch - same function as standard ASSA ABLOY Hospitality EURO lock.

Note 2: Auxiliary latch/deadbolt trigger - when the door is closed and the auxiliary

latch hits the striker plate/frame, the automatic deadbolt will be thrown and the latch

will be blocked. Always install a striker plate before installing the lock case in the

door. If the door with lock case is closed without a striker plate, the auxiliary latch

will be jammed in the frame cut-out. The dimension from the front of the lock case

to the striker plate must not exceed 4mm to obtain automatic deadbolt function.

Note 3: Automatic deadbolt - the deadbolt throws automatically when the door

is closed.

Note 4: Privacy hub - with the thumbturn, the privacy hub can be rotated 45°.

When the escutcheon thumbturn Signature (pos 4 in the exploded views of

section 4.3) is pointing downwards, the privacy function is off. When the escutcheon

thumbturn Signature is rotated 45°, the privacy function is on. The deadbolt cannot

be retracted with the thumbturn.

Figure C6: Thumb turn position at

'privacy off’ and ’privacy on'

ASSA ABLOY Hospitality

49

66 1000 023-2

Appendix D: Online

Power

4.5V - 3AA batteries

Reader option

RFID

Online type

RF

Lock case options

(all 4.5V)

ANSI (DA) with

2 switches

70 (2 3/4'') 25/28/32 (63/64'' 1 7/64'' 1 17/64'')

ANSI (DA) with ADB

70 (2 3/4'') 25/28/32 (63/64'' 1 7/64'' 1 17/64'')

ANSI (DA) with

4 switches

70 (2 3/4'') 25/28/32 (63/64'' 1 7/64'' 1 17/64'')

ANSI (DB) with

2 switches

70 (2 3/4'') 25/28/32 (63/64'' 1 7/64'' 1 17/64'')

ANSI (DB) with ADB

70 (2 3/4'') 25/28/32 (63/64'' 1 7/64'' 1 17/64'')

ANSI (DB) with

4 switches

70 (2 3/4'') 25/28/32 (63/64'' 1 7/64'' 1 17/64'')

ANSI AUS

70 (2 3/4'') 25/28/32 (63/64'' 1 7/64'' 1 17/64'')

ANSI JPN

70 (2 3/4'') 25/28/32 (63/64'' 1 7/64'' 1 17/64'')

EURO with 2 switches

65/80 20/22/24

EURO with ADB

65 20/22/24

Audit trail

2000 events

Cylinder option

Yes

System compatibility

Visionline

Table D1

Introduction

This appendix contains information about the online variant of Essence.

For general information about Essence, see earlier in this manual. There is

also an easy 4-page quick reference, covering both online and offline version.

For full online functionality, Essence is used with an ANSI 4-switch lock case.

If full online functionality is not needed, Essence can be used with lock cases

that are not 4-switch.

A battery holder 4.5V with 3AA batteries is used.

Technical specification

ASSA ABLOY Hospitality

50

66 1000 023-2

Appendix D: Online

Online kit

Figure D1: The online kit is purchased separately and

contains ZigBee endnode, plastic cover, Y-cable and cooling material.

ASSA ABLOY Hospitality

51

66 1000 023-2

Appendix D: Online

Figure D2

Figure D3

Figure D4

Note: The position numbers in bold refer

to the exploded views in section 4.3.

1. Position the cables into the door

before inserting the lock case (22).

The connector on the cable must be

bent before being threaded into the

hole through the door. Important:

Do not lubricate the lock case.

2. Position the lock case into the edge of

the door and fasten it with two screws

wood, countersunk 5X25 mm (23).

If applicable, do not forget to install

the cylinder fastening clip before

inserting the lock case.

To install an online lock

Note: The position numbers in bold refer to the exploded views in section 4.3.

ASSA ABLOY Hospitality

52

66 1000 023-2

Figure D5

Figure D6

3. Before inserting the spindle handle female Signature (20) and the spindle

handle male Signature (19) into the lock case, check that the spindle threads

are lubricated with grease.

4. Screw the spindle handle female Signature onto the spindle handle male Signature

and then reverse it (3/4 turn).

5. Insert the spindle handles into the lock case from the outside of the door so that

the hole that goes through the spindle handle is visible on the inside (room side)

of the door. Note: The spindle handle marked 'EXT' must be on the outside of

the door.

ASSA ABLOY Hospitality

53

66 1000 023-2

Figure D7

6. Thread the spindle locking clip (21) onto

the spindle handle female Signature (20;

on the inside of the door) by squeezing

hard on the spindle locking clip. Make

sure that the clip clicks onto the hole

in the spindle handle.

Figure D8

Figure D9

7. At delivery, the handle retainers*

Signature (3 and 18) are not mounted

into the handle on inside rose Signature

(2) and handle on outside rose Signature

(17), and they must be prepared

according to the door handing. If the

handle on inside rose Signature is a

left handle (i.e. pointing to the left),

the white retainer should be mounted

on the inside handle. If the handle on

inside rose Signature is a right handle,

the black retainer should be mounted

on the inside handle.

Important: For both left handles

and right handles, make sure that

the handle retainer*Signature is in

the "click" position within the groove

on the shank of the handle.

ASSA ABLOY Hospitality

54

66 1000 023-2

Figure D10

8. Insert the thumbturn spindle Signature

(9) into the lock case from the inside.

The marked end on the spindle handle

must be inserted into the thumb turn

knob. Important: For ANSI (DB) and

EURO, the thumb turn knob should be

pointing downwards. Insert the inside

handle onto the spindle handle and

screw the handles together.

Important: For ANSI (DA), the thumb

turn knob should be pointing upwards.

Insert the inside handle onto the spindle

handle and screw the handles together.

9. Insert the inside handle including the

handle retainer*Signature (3) onto

the spindle handle. Fasten the handles

together using screws Signature M5 (1).

ASSA ABLOY Hospitality

55

66 1000 023-2

Figure D11

Figure D12

Figure D13

10. If cylinder is used:

- Thread the spring cylinder rose

Signature (14) onto the cylinder

(15; see full names of the

cylinder variants here) from

the cylinder-arm side.

- Insert the cylinder into the

cylinder rose.

- Use a key and screw the cylinder

into the lock case.

- Tighten the cylinder until the

cylinder rose is tight to the door.

- Fix the cylinder into the lock case.

- The keyhole should always point

towards the handle.

11.There are two ways for installing

the cylinder fastening screw:

- The nomal way; insert the 2 mm

Unbrako into the screw, and insert

the screw in the hole facing towards

the lock front. Tighten the cylinder in

the lock case as illustrated in Figures

D11-D13.

ASSA ABLOY Hospitality

56

66 1000 023-2

Figure D14

- A more secure way; fix the cylinder in

place by using the fixing-screw tool kit.

Use the L-shaped Allen key to lock the

headless fixing screw (cylinder screw is

turned upside down) to the T-shaped tool

as illustrated in Figure D14. Using the

T-tool, screw the fixing screw in place as

shown earlier to fix the cylinder in place.

Make sure that the cylinder fixing screw

is tightened in the cylinder. Release the

T-tool from the fixing screw by holding

the T-tool rigid while turning the Allen

key counter-clockwise until the Allen

key is released from the screw; then

unscrew the T-tool.

12. After installation of the cylinder, fix for

ANSI (DA) and ANSI (DB) the face plate

to the lock case after installation of

the cylinder.

Figure D15

13. Assemble the Essence cassette (8)

before installation.

14. Depending on whether the handing

is left or right (see details here),

the fire shield plate shall be attached

on the opposite side of the LCU (the

drawing shows right handing).

15. Connect the Y-cable to the endnode

and LCU and also to the 7-pin connector

at the LCA.

16. Snap the plastic cover with ZigBee

endnode inside onto the Essence cassette

until the locking mechanism locks.

17. When the lock case cable has been

connected, fasten the cooling material

on the Essence cassette.

ASSA ABLOY Hospitality

57

66 1000 023-2

Figure D16

18.To match the B-measurement of the

door leaf, it is possible to increase the

length of the LCU in order to reach the

sprocket*) inside the Essence cassette.

This can be done by adding spacers

(expansion modules), which consist

of two halfs sliding into the slot on

the back of the LCU. The two halfs will

meet and by a “snap-lock” functionality

lock onto the LCU. Additional spacers

can be added on top of the other

spacers.

*) The sprocket is only partly locking the LCU in

place after installation.

Figure D17

19.Connect the lock case cable to the

Essence cassette (I in Figure D17).

20.Snap the lock case cable into the cable

gateway in the endnode housing

(II in Figure D17).

21.Fasten the cooling material in the area

marked with III in Figure D17.

Important before mounting the

Essence cassette in the door:

Make sure that the LCU cable is well

positioned in the space marked with

IV in Figure D17, to avoid pinching

of the cable.

Figure D18

22.Insert the Essence cassette into

the door.

Figure D19

23.Loose the bracket with a wrench (8 mm)

until it moves freely.

ASSA ABLOY Hospitality

58

66 1000 023-2

Figure D20

24.Connect the LCU cable to the LCU and

adjust the bracket in order to enter the

LCU against the sprocket.

Note: Arrange the cables to prevent

pinching them.

Figure D21

25.Fasten the bracket with the

wrench (8 mm).

Note: Tighten gently.

Figure D22

26.When the LCU has entered the bracket,

use the hexagon pipe to turn the

sprocket in order to pull the LCU

in place.

Note: Tighten gently.

Figure D23

27.When the LCU is pulled all the way

into the door leaf, fasten the screw

in the centre of the sprocket by using

a Pozidriv #2 screwdriver.

Note: Tighten gently.

Figure D24

28.Insert 3 AA batteries.

29.Fix the face plate of the case, upload

the firmware and attach the service cover

of the LCU. The service cover shall be

inserted 90 degrees to the left and then

be turned 90 degrees clockwise in order

to fasten.

ASSA ABLOY Hospitality

59

66 1000 023-2

Figure D25

30. To install the strike: The depth

in the frame must be sufficient

(min 25,4 mm/1'') for throwing

the deadbolt.

ASSA ABLOY Hospitality

60

66 1000 023-2

Figure D26

31. Make a full test of the lock.

Important: Do not close the door

before the lock has been tested.

Note: If cylinder with cap is used, the

installation of

the cap should be the last operation in

the mounting of the lock.

Battery maintenance

The procedure to replace batteries is the same for online locks as for offline locks;

see section 6.3.

ASSA ABLOY Hospitality

61

66 1000 023-2

Appendix E: Firmware change in LCU 5350

If a lock needs to have its firmware upgraded due to new firmware features etc,

follow the steps below:

1. Choose Upload firmware in the Lock Service 3G software 1).

2. Mark the applicable lock firmware (and if you have touchpad, move the cursor

to be over the Upload button).

3. Connect the service cable to the lock; after a few seconds, the lock LED will

be green. Step 4 below must be performed directly after this 2).

4. Click Upload; a progress bar will show how the upgrade proceeds. When the

upgrade is complete, a message will be shown.

1)

Always make sure that the lock firmware which is already included in Lock Service

3G is the latest version. If it is not, see the appendix about firmware upgrade in

Setup manual Visionline for information on how to prepare for lock firmware upgrade,

then choose Download firmware in Lock Service 3G to download the firmware

from the Visionline server to Lock Service 3G. It is also possible to browse to the

firmware file directly from the Upload firmware dialog, but it is recommended

to go via Visionline.

2)

If Upload is not clicked within 4 seconds, there will be a timeout and the

service cable must be disconnected and then connected again.

ASSA ABLOY Hospitality

62

66 1000 023-2

Appendix F: Summary of notes

Below is a summary of the important notes etc in this manual. It therefore gives

a condensed overview of what to think of in different phases for the Essence lock,

such as site survey and lock installation. Some tips appear in more than one manual

section; they are then only mentioned once in this appendix. Some tips have been

slightly rewritten to be understandable outside their original context.

1. Introduction

Important: VingCard Essence (v2) can only be installed in non-metallic doors.

2. Site survey

Note: Always make sure to have the correct handing for all doors.

Note: See section 3.1 for an overview of available cut-outs.

Important: The hole for the cylinder is optional and is only to be cut out for locks

equipped with cylinders and only from the outside of the door to the center of the

lock case; i.e., not through the entire door.

Important: If you are going to install the security cylinder Hydra, remember to

make space for the cylinder fastening clip when making the cut-out for the lock case.

Note: Be aware if there is any door gasket.

3. To mortise the door

Important: The lock front can be delivered with a width of 32mm (1.26"), 28mm

(1.102") or 25 mm (0.984"). Make sure that you mortise the door to the correct

dimensions for your lock dimensions. Check the dimensions of the lock before you

start cutting.

Note: Be aware of the dimension 30 mm (1.181'') from the edge of the lock case to

the edge of the striker plate.

Caution: If the cut-out for the deadbolt is less than 25.4 mm (1") deep, the deadbolt

may not be retracted by use of a metal key in case of an emergency when the door is

double locked. (ANSI AUS = 0, ANSI JPN = 21).

Caution: Be aware if there is any door gasket. If so, compensation must be made by

adjusting the horizontal positioning of the striker plate.

Important: If the striker plate is not used (example: steel frame), it is important

that the distance between the latch (lower) cut-out and the deadbolt cut-out must

be 12 mm (0,47") in order for the auxiliary latch to work.

ASSA ABLOY Hospitality

63

66 1000 023-2

4. To install the lock

Note: The online kit and cylinder kit are purchased separately, when applicable.

Important: Do not lubricate the lock case.

Note: If applicable, do not forget to install the cylinder fastening clip before

inserting the lock case.

Note: The spindle handle marked 'EXT' must be on the outside of the door.

Important: For both left handles and right handles, make sure that the handle