Page 1

1 8 d e a g o s t o d e 2 0 1 6

DOCUMENT CODE: 602305M00**

Manual instructions

Manuel talimatları

Manual de instrucciones

Manuel d’instructions

Bedienungshinweise

Manual do instruções

Ręczny

ES

EN

DE

TK

FR

PT

PL

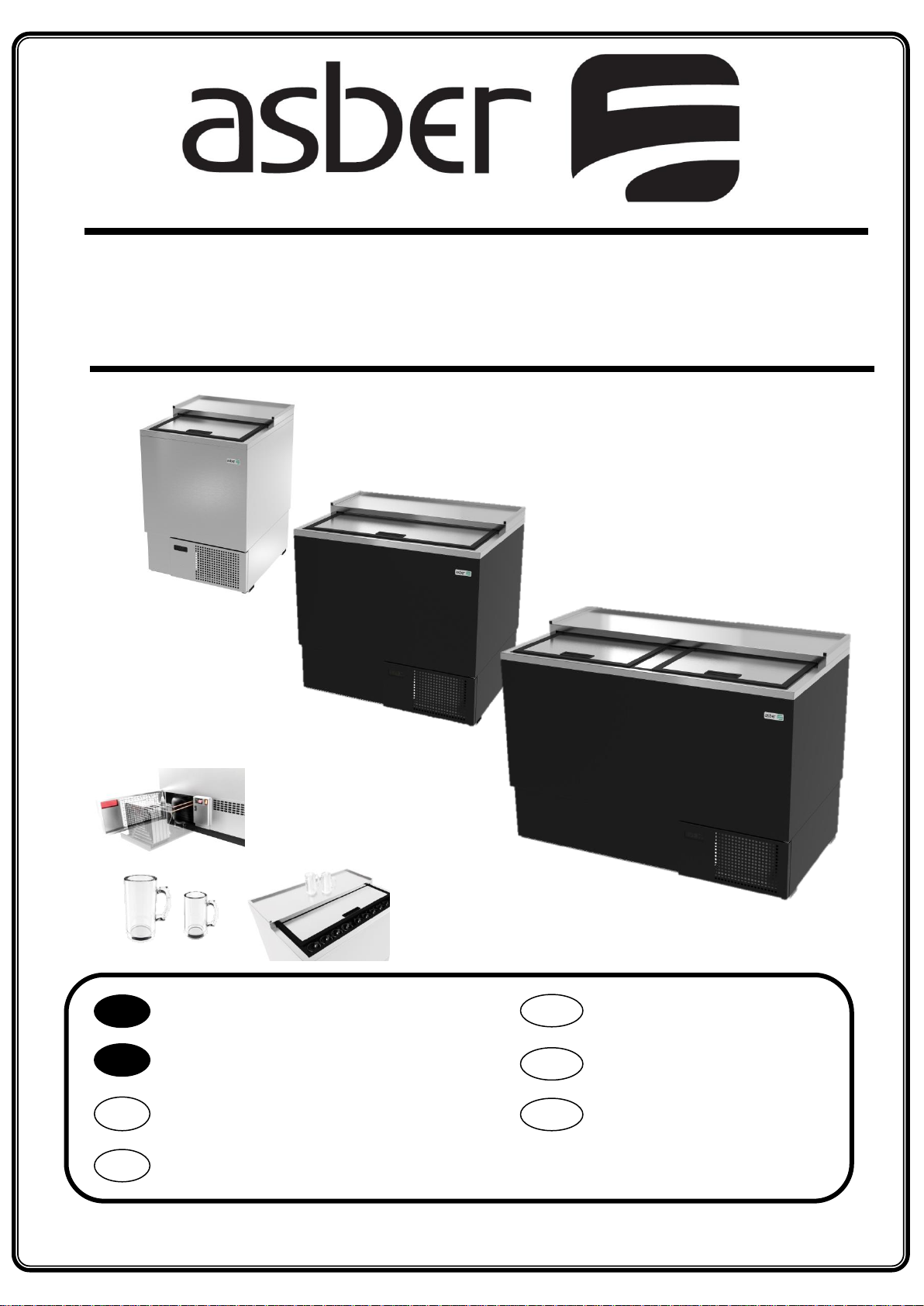

GLASS FROSTER LINE

Manual Instructions

AGF-24(S) AGF-36(S) AGF-50(S)

Installation and Operation

Uso y mantenimiento

Installation und Betrieb

Obsługa i konserwacja

Kurulum ve Çalıştırma

Installation et fonctionnement

Instalação e Operação

Page 2

asberprofessional.com

INDEX

ENGLISH

SPECIFICATION CHART/ TABLA DE ESPECIFICACIONES ...........................................................1

MACHINE INTRODUCTION ..........................................................................................................................1

1.1 Introduction to machine & models .......................................................................................1

1.2 Important safety information ..................................................................................................1

INSTALLATION .................................................................................................................................................2

2.1 General information .....................................................................................................................2

2.2 Transport, handling, unpacking, location ......................................................................2

2.3 Intended use and restrictions ...............................................................................................3

2.4 Manufacturer’s identification label description .........................................................3

2.5 Installation and assembly ........................................................................................................4

2.6 Connections ......................................................................................................................................4

OPERATION........................................................................................................................................................4

3.1 General information .....................................................................................................................4

3.2 Control panel description .......................................................................................................4

3.2.1 Electronic Control (IR33+) (apply freezer models) .........................................4

3.3 Machine settings and programs ............................................................................................5

MAINTENANCE .................................................................................................................................................6

4.1 General safety rules .................................................................................................................6

4.2 Machine cleaning and maintenance routine ....................................................................6

4.2.1 Cleaning the Condenser Coil ..........................................................................................7

4.2.2 Draining the Unit ...................................................................................................................7

4.3 Machine disposal ...........................................................................................................................7

TROUBLESHOOTING CHART .....................................................................................................................8

5.1 Trouble shooting chart .............................................................................................................8

ii

Page 3

asberprofessional.com

Model

Doors

Shelves

Mugs

HP

AMP

Crated Weight (LBS.)

Length

Width

Height

BTU

Refrigerant charge.

R-404 A

AGF-24 (S)

1 6 1

3/4

8.2

172

24"

26 3/4"

33 7/8"

850

6.7 oz

AGF-36 (S)

1 6 3

3/4

8.5

318

36 5/8"

26 3/4"

33 7/8"

2400

9.8 oz

AGF-50 (S)

2 6 3

3/4

8.5

359

50

26 3/4"

33 7/8"

2400

9.8 oz

SPECIFICATION CHART/ TABLA DE ESPECIFICACIONES

MACHINE INTRODUCTION

1.1 Introduction to machine & models

GLASS FROSTER LINE

ASBER GLASS FROSTER LINE presents design, performance and efficiency unlike

any of its kind.

With standard locks, robust units that it offer multiple feature rich

configurations: vinyl, stainless steel,

bin dividers,...

Details make this line unique .

• Standard locks per lid.

• Bottle opener & cap catcher.

• Heavy duty adjustable bin dividers.

Evaporator on the back for greater usable interior capacity.

• Self closing doors to ensure maximum efficiency.

• 18 gauge stainless steel top for greater durability.

• Slide out compressor rails for service ability.

• Locks for better inventory control.

• Automatic Evaporation for efficient condensation.

1.2 Important safety information

DANGER: Power must be turned off and disconnected from the power

source whenever performing maintenance, repair or cleaning the

condensing unit.

WARNING: Machine and compressor warranties are void if failure is

due to improper electrical installation.

Do not introduce hot foods, chemical or corrosive products, drugs,

or open beverage bottles.

1

Page 4

asberprofessional.com

INSTALLATION

2.1 General information

2.2 Transport, handling, unpacking, location.

2.3 Intended use and restrictions.

2.4 Manufacturer’s identification label description.

2.5 Installation and assembly.

2.6 Connections (electric, gas, water)

2.1 General information

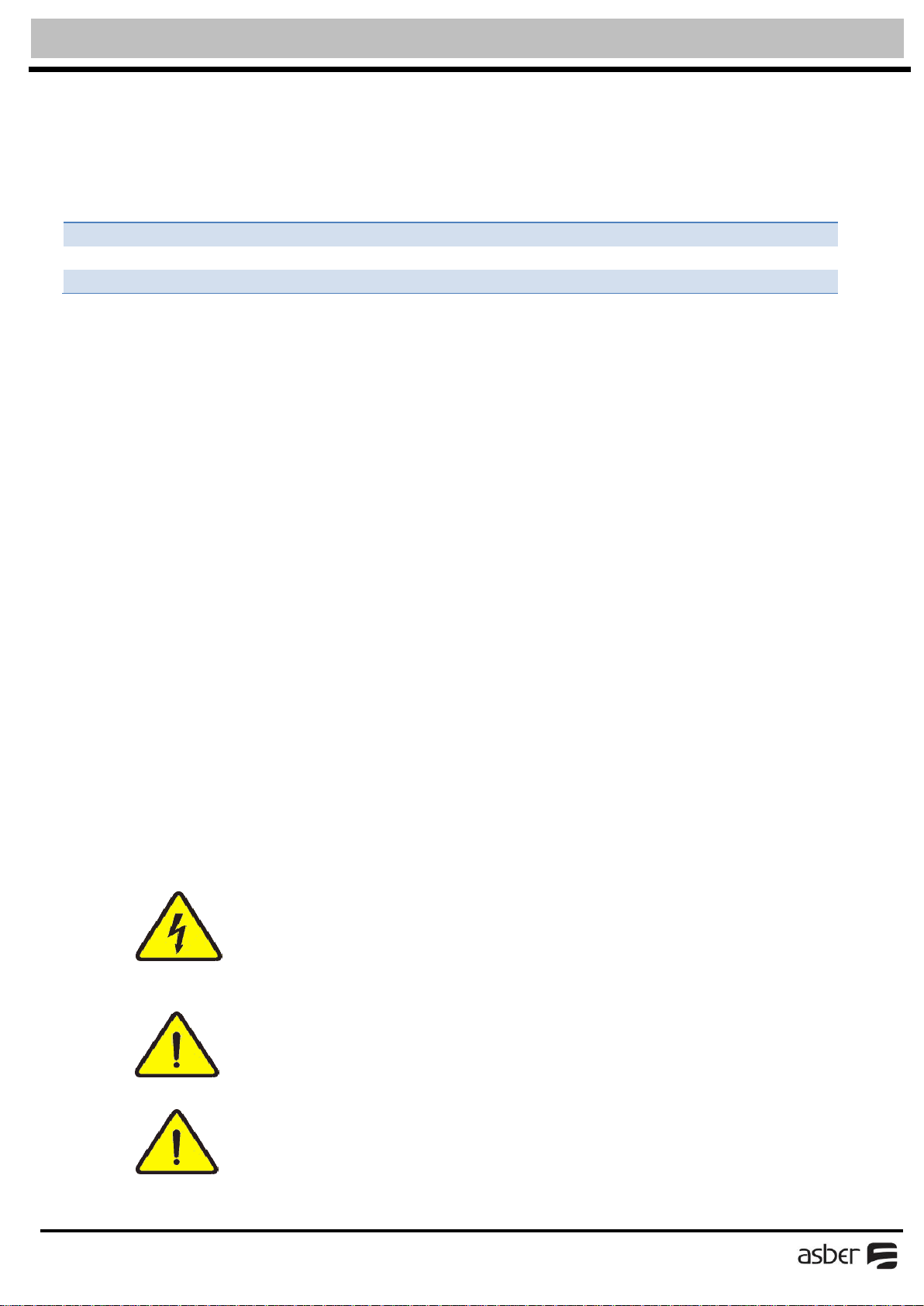

You can find in your equipment the following symbols, or stickers to identify some

type of warnings or useful information about your equipment.

2.2 Transport, handling, unpacking, location

Upon receiving your new ASBER GLASS FROSTER, check the package and the

machine for any damages that may have occurred during transportation. Visually

inspect the exterior of the package, if damaged, open and inspect the contents

with the carrier. Any damage should be noted and reported on the delivering

carrier’s receipt.

In the event that the exterior is not damaged, yet upon opening, there is concealed

damage to the equipment notify the carrier immediately. Notification should be

made verbally as well as in written form. Request an inspection by the shipping

company of the damaged equipment.

Retain all crating material until inspection has been made. Contact the dealer

through which you purchased the unit.

Check the compressor compartment housing and visually inspect the refrigeration

package. Be sure

lines are secure and base is still intact.

2

Page 5

asberprofessional.com

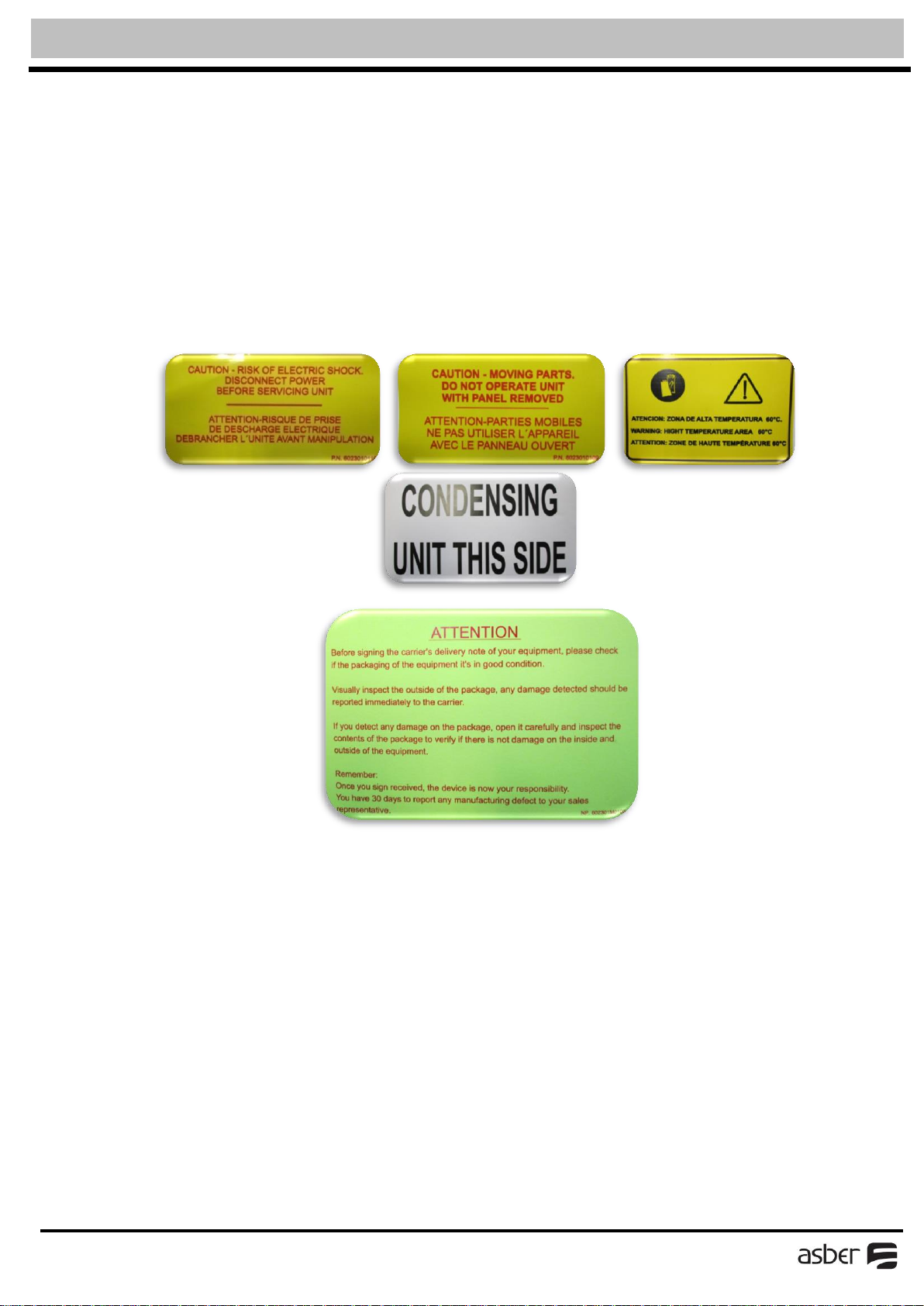

Model

Refrigerant Type

Eléctrical Specs

Serial Number

(8 dígits ending with “M”)

Code

2.3 Intended use and restrictions

ASBER equipment is not designed for personal, family, or household purposes,

and its sale for such purposes is not intended. In the event the equipment is so

used, this warranty shall be null and void, and the equipment is so used, this

warranty shall be null and void, and the equipment shall be deemed to have been

sold “as is-where is” without any warranty of any kind, including without limitation

any warranty of title, non-infringement, merchant-ability or fitness for a

particular purpose.

The equipments are conforms to UL and NSF- 7 standards.

If you want know more about other restrictions about your equipment see the

warranty that is located in the final part of your manual.

2.4 Manufacturer’s identification label description

The data plate is located inside the cabinet, near the top front, left corner.

Under no circumstances should the data plate be removed from the unit. The data

plate is essential to identify the particular features of your machine and it is of

great benefit to installers, operators, and maintenance personnel. It is

recommended that, in the event the data plate is removed, you copy down the

essential information in this manual for reference before installation. Removal of

data plate will void the warranty.

3

Page 6

asberprofessional.com

2.5 Installation and assembly

Units represented in this manual are intended for indoor use only. Be sure the

location chosen has a floor strong enough to support the total weight of the

unit and contents. For the most efficient operation, be sure to provide good air

circulation inside and outside of the unit.

INSIDE CABINET

The first cleaning must be made when you unpack the unit and before switching it

on. Clean it with water and a mild detergent. When it is clean and dry, insert the

accessories in the appropriate places, for the best use of the user.

OUTSIDE CABINET

Be sure the unit has good air circulation around it. Avoid hot corners and

locations near stoves and ovens. It is recommended the unit be installed no

closer than 2” from any wall. The place where the refrigerator is placed must be

open and clean, avoiding that de fan of the condensing unit absorbs materials

which are deposited then into the condenser blades and coil, which can produce

failures.

The unit should not be installed under ambient temperatures higher than 100 °F.

If the relative humidity is higher than 60 %, the door frames may sweat water. This

is not a

malfunctioning of the unit.

2.6 Connections

Refer to the amperage data in this manual or on data plate and your local code

or the National Electrical Code to be sure unit is connected to the proper power

source. Verify correct incoming voltage according to the Data Plate information.

The data plate in located inside the unit, near the top front left corner. Under

any circumstances should the data plate be removed from the unit.

The data plate is essential to identify the particular features of your unit and is

of great benefit to installers, operators and maintenance personnel. It is

recommended that, in the event the data plate is removed, you copy down the

essential information in this manual for reference before installation.

A protected circuit of the correct voltage and amperage must be run for

connection of the supply cord. Unit must be grounded and connected in

accordance with National Electrical Code.

OPERATION

3.1 General information.

3.2 Control panel description.

3.3 Machine settings and programs.

3.1 General information

Good air flow inside the cabinet is critical. Do not block air flow to the fans.

Allow three inches of space along the front, back, and sides.

3.2 Control panel description

3.2.1 Electronic Control (IR33+) (apply freezer models)

The operating parameters can be modified using the front keypad. Access

differs depending on the type: set point, frequently-used parameters (F) and

configuration parameters (C). The type of parameter is specified in the table

of parameters. Access to the configuration parameters is protected by a

password for the configuration parameters that prevents unwanted

modifications or access by unauthorized persons. The password can be used

to access and set all the control parameters.

4

Page 7

asberprofessional.com

3.3 Machine settings and programs

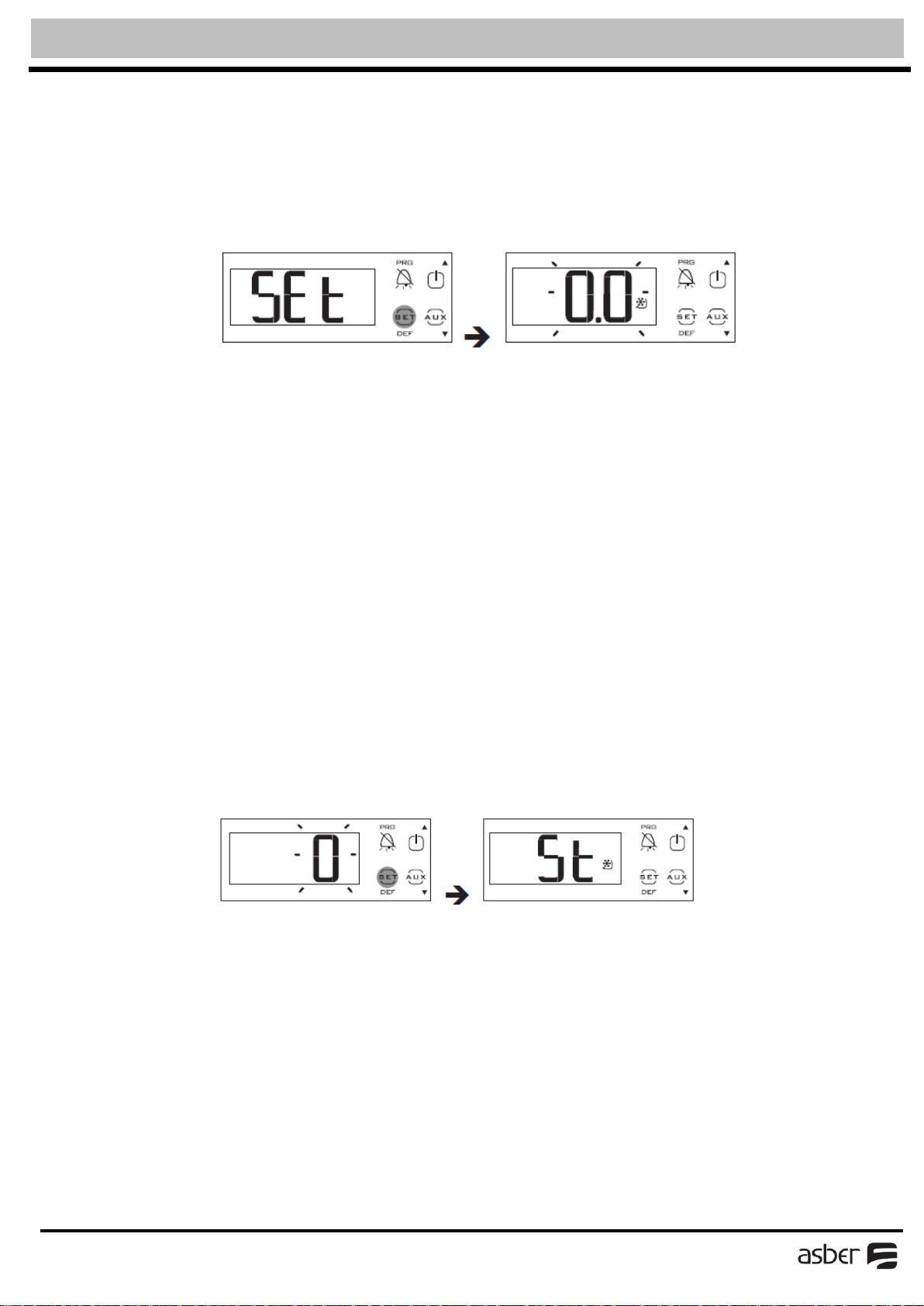

Setting the set point

To change the set point St (default -8°C)

1. Press Set for more than 1 s: the display shows Set and then the

current value of St;

2. Press UP/DOWN until reaching the desired value;

3. Press Set to save the new value of St.

Setting type F parameters

Type F parameters include the set point, differential, temperature

monitoring interval, interval between defrosts, end defrost temperature,

dripping time, alarm thresholds, alarm bypass times, etc. See the parameter

table.

Procedure:

1. Press Prg/Mute one or more times to return to the standard display;

2. Press Prg/Mute for more than 3 seconds (if an alarm is active, the

Buzzer is muted): the display will show the code PS (Password) and

The number 0;

3. Press Set, the display shows parameter St;

4. Press UP or DOWN until reaching the desired parameter: when

Scrolling, an icon is displayed that represents the category the

Parameter belongs to (see the table below and the parameter table);

5. Press Set to display the value of the parameter;

6. Press UP/DOWN until reaching the desired value;

7. Press Set to temporarily save the new value and display the

parameter Code again;

8. Repeat steps 4) to 7) to set other parameters;

9. To permanently save the new values of the parameters, press Prg/

Mute for 5 seconds. This exits the parameter setting procedure.

Setting type C parameters

Type C parameters include the type F parameters plus all the other control

parameters.

Procedure:

1. Press Prg/Mute one or more times to return to the standard display;

2. Press Prg/Mute for more than 3 seconds (if an alarm is active, the

Buzzer is muted): the display will show the code PS (Password) and

The number 0;

3. Press UP/DOWN and enter the password: 22. Press Set, the display

Shows parameter/2;

4. Press UP or DOWN until reaching the desired parameter: when

Scrolling, an icon is displayed that represents the category the

Parameter belongs to (see the table below and the parameter table);

5

Page 8

asberprofessional.com

5. Press the SET button to display the value of the parameter;

6. Press UP/DOWN until reaching the desired value;

7. Press Set to temporarily save the new value and display the

parameter Code again;

8. Repeat steps 4) to 7) to set other parameters;

9. To permanently save the new values of the parameters, press

Prg/Mute for 5 seconds. This exits the parameter setting procedure.

Important:

• If the controller is powered down before pressing Prg/mute, all the

changes made to the parameters will be lost;

• In the two parameter setting procedures (F and C), the new values are only

saved after having pressed Prg/mute for 5 seconds. When setting the set

point, the new value is saved after confirming with Set.

IF YOU NEED MORE INFORMATION PLEASE CONTACT THE TECHNICAL SUPPORT

MAINTENANCE

4.1 General safety rules.

4.2 Machine cleaning and maintenance routine.

4.3 Machine disposal.

4.1 General safety rules

DANGER: Power must be turned off and disconnected from the power

source whenever performing maintenance, repair or cleaning the

condensing unit.

Neglecting the condenser coil cleaning procedures WILL VOID YOUR WARRANTY

associated with the compressor or cost to replace the compressor!

Proper cleaning of stainless steel requires soft cloths or plastic souring pads.

Never use steel pads, wire brushes or scrapers!

4.2 Machine cleaning and maintenance routine

Cleaning solutions need to be alkaline or non-chloride cleaners. Any cleaner

containing chlorides will damage the protective film of the stainless steel.

Chlorides are also commonly found in hard water, salts, and household and

industrial cleaners. If cleaner containing chlorides are used be sure to rinse

repeatedly and dry thoroughly upon completion.

Routine cleaning of stainless steel can be done with soap and water. Extreme

stains or grease should be cleaned with a non-abrasive cleaner and plastic scrub

pad. There are also stainless steel cleaners available which can restore and

preserve the finish of the steels protective layer.

Never use and acid based cleaning solution! Many food products have an acidic

content which can deteriorate the finish. Be sure to clean the ALL food products

6

Page 9

asberprofessional.com

from any stainless steel surface. Common items include peppers, tomatoes and

other vegetables.

4.2.1 Cleaning the Condenser Coil

Disconnect machine. Remove front bottom panel and carefully slide out the

condensing unit.

The condenser coil requires regular cleaning; recommended every 30-60

days, depending of the accumulation of dust and grease. If the buildup on

the coil consists of only light dust and debris the condenser coil can be

cleaned with a simple brush. Heavier dust build up may require a vacuum or

even compressed air to blow though the condenser coil. If heavy grease is

present there are de-greasing agents available for refrigeration use and

specifically for the condenser coils. The condenser coil may require a

spray with the de-greasing agent and then blown through with compressed

air.

Be sure all electrical and mechanical parts are dry before turning on the

power.

Never use a high pressure water wash for this cleaning procedure as water

can damage the electrical components located near or at the condenser

coil. Do not place filter material in front of condenser coil. This material

blocks air-flow to the coil similar to having a dirty coil!

If you keep the Condenser clean you will minimize your service expense and

lower your electrical costs. Failure to maintain a clean condenser coil can

initially cause high temperatures and excessive run times. Continuous

operation with dirty or clogged condenser coils can result in compressor

failures.

To put back the condensing unit in its place, slide in the unit carefully. BE

SURE DRAIN PIPE IS LOCATED OVER THE PAN. Replace front bottom panel

4.2.2 Draining the Unit

Each unit has a drain located inside the unit which removes the

condensation from the evaporator coil and evaporates it at an external

condensate evaporator pan. Each drain can become loose or disconnected

from moving or bumping the drain.

IF YOU NOTICE EXCESSIVE WATER ACCUMULATION ON THE INSIDE OF THE

UNIT be sure the drain tube is connected from the evaporator housing to

the condensate evaporator drain pan.

IF WATER IS COLLECTED UNDERNEATH THE UNIT you may want to check the

condensate evaporator drain tube to be sure it is still located inside the

drain pan. The leveling of the unit is important as the units are designed to

drain properly when on a level surface, if your floor is not level this can

also cause drain problems. Be sure all drain lines are free of

obstructions; typically food product is found blocking drain lines causing

water to back up and overflow the drain pans.

4.3 Machine disposal

The product’s life-cycle is around 7 to 10 year from the intalation and operation

date.

ASBER equipment is manufactured without dangerous or toxic materials. Some

parts of the equipments are biodegradable.

The disposing after the product’s life-cycle shall be determined according to the

rules and laws established in the city or State of residence related refrigaration

equipments

REMEMBER TO TAKE CARE OF THE ENVIRONMENT.

7

Page 10

asberprofessional.com

TROUBLESHOOTING CHART

5.1 Troubleshooting guide chart

5.1 Trouble shooting chart

Follow the next steps before requesting warranty service. Failure to do

so, may result in service charges for you and may void your warranty:

1)

Refrigerator doesn’t work:

a. Check that the machine is still connected.

b. Check that the ON/OFF button is in the ON position.

2)

Refrigerator doesn’t reach temperature :

a. Verify unit is not on saving mode

b. Check that the thermostat is not in OFF position.

c. Ensure Equipment is in a ventilated place and removed

minimum of 2 inches from any other appliance and away

from any heat source.

d. The environment maximum temperature must be 38 °C/ 100°F.

e. To insure proper air flow, product must not be placed

higher than the maximum level mark located on the internal

wall of the unit.

f. Check that the fan is moving.

3)

There is water inside the refrigerator:

a. Check that the drain pan inside the cabinet is in position.

b. Check that there is not food clogging the drain line.

4)

There is water under the refrigerator:

a. Check that the drain pipe is over the pan.

Warning: To in s u r e proper operation of equipment, it is recommended

that the unit is on for 24 hours prior to the introduction of

perishables.

8

Page 11

asberprofessional.com

ESPAÑOL

INDEX

ENGLISH

1 INTRODUCCION ................................................................................................................................ 10

1.1 Introducción a los equipos y modelos ........................................................................... 10

1.2 Información de seguridad ...................................................................................................... 10

INSTALACION ................................................................................................................................................ 10

2.1 Información General ................................................................................................................. 10

2.2 Transporte, manejo, desempaque y localización ...................................................... 11

2.3 Uso y restricciones ................................................................................................................... 11

2.4 Placa de identificación del Fabricante .......................................................................... 11

2.5 Instalación y Ensamble ........................................................................................................... 12

2.6 Conexiones ...................................................................................................................................... 13

OPERACION .................................................................................................................................................... 13

3.1 Información General ................................................................................................................. 13

3.2 Descripción del panel de control ..................................................................................... 13

3.2.1 Control electronico (IR33+) ....................................................................................... 13

3.3 Configuraciones del Equipo ................................................................................................. 14

MANTENIMIENTO ......................................................................................................................................... 16

4.1 Reglas de seguridad general .............................................................................................. 16

4.2 Rutina de limpieza y mantenimiento del equipo ........................................................... 16

4.2.1 Limpiando el condensador ............................................................................................. 16

4.2.2 Limpieza del empaque plástico ..................................................................................... 17

4.2.3 Drenado ................................................................................................................................... 17

4.3 Disposición del equipo ............................................................................................................. 17

SOLUCIONANDO PROBLEMAS ............................................................................................................. 18

5.1 Solucionando problemas........................................................................................................ 18

ELECTRIC DIAGRAM / DIAGRAMA ELECTRICO .............................................................................. 19

9

Page 12

asberprofessional.com

ESPAÑOL

1 INTRODUCCION

1.1 Introducción a los equipos y modelos

LINEA GLASS FROSTERS

Línea GLASS FROSTERS de ASBER presenta mejor diseño, rendimiento y eficiencia

a diferencia de su competencia.

Con cerraduras estándar, estas unidades robustas ofrecen múltiples

configuraciones: vinilo, acero inoxidable, parrillas divisores…

Los detalles hacen que esta línea única.

• Destapador & colector de tapa.

• Divisores ajustables y resistentes.

Evaporador en la parte posterior para mayor capacidad interior utilizable.

• Puerta gruesa con incrustaciones de diseño para proteger las juntas.

• Calibre 18 en parte superior de acero inoxidable para mayor durabilidad.

• Rieles para deslice del compresor para capacidad de servicio.

• Puertas de cristal con doble panel de eficiencia térmica.

• Cerraduras y luces para un mejor control de inventario.

• Evaporador de gas caliente en la bandeja recolectora para una

condensación eficiente.

1.2 Información de seguridad

El quipo debe ser apagado y desconectado de la fuente de

alimentación cuando realizar el mantenimiento, reparación o limpieza

de la unidad condensadora.

Si la máquina sigue funcionando cuando está apagado, desconecte la

alimentación principal antes de desenchufar la máquina.

.

La garantía de la maquina y el compresor se anulan debido a la

instalación eléctrica inadecuada.

No introdusca alimentos calientes, productos quimios o corrosivos,

drogas o botellas destapadas.

INSTALACION

2.1 Información General

2.2 Transporte, manejo, desempaque y localización

2.3 Uso y restricciones

2.4 Placa de identificación del Fabricante

2.5 Instalación y ensamble

2.6 Conexiones (eléctricas, agua, gas)

2.1 Información General

En el equipo usted ecnontrara los siguientes simbolos y/o etiquetas que le

ayudaran a identificar peligros y/o informacion util relacionada con su equipo.

10

Page 13

asberprofessional.com

2.2 Transporte, manejo, desempaque y localización

Al momento de recibir su equipo ASBER, verifique el empaque en búsqueda de

daños que pudieran haber ocurrido durante el transporte. Inspeccione de manera

visual el exterior del empaque, si encuentra dañado, abra e inspeccione, delante

de la empresa transportadora, todo el equipo. Cualquier daño debe ser anotado y

reportado en el recibo de entrega de la empresa transportadora.

IMPORTANTE: Una vez que se haya retirado todo el material del empaque, revise

por la parte posterior del equipo el compartimiento del compresor. Inspeccione

visualmente el sistema de refrigeración y asegúrese que las tuberías no estén

dobladas y que no presenten alguna fisura, asegúrese que la base esté intacta.

Si al momento de abrir el empaque existe un daño oculto en el equipo, notifíquelo

de inmediato a la empresa transportadora mediante un llamado telefónico así

como también de manera escrita. Solicite una inspección por parte de la compañía

transportadora si el equipo está dañado. Conserve todo el material de embalaje

hasta que se haya realizado la inspección, contacte al proveedor con el que

adquirió su equipo ASBER.

2.3 Uso y restricciones

EL equipo ASBER no está diseñado para uso con fines personales, familiares o del

hogar, y su venta para esos fines no está prevista. En el caso de que el equipo se

utiliza con tal fin, esta garantía será nula de pleno derecho, y el equipo se

considerará que se han vendido "como es, donde es" sin garantía de ningún tipo,

incluyendo, sin limitación, cualquier garantía de título, no infracción, los

comerciantes la capacidad o aptitud para un propósito en particular.

Los equipos cumplen con los estándares de las normas UL y NSF-7

Si usted quiere saber más acerca de otras restricciones relacionadas con el

equipo ver la garantía que se encuentra localizada al final del manual.

2.4 Placa de identificación del Fabricante

11

Page 14

asberprofessional.com

Modelo

Tipo

Refrigerante

Especificaciones

eléctricas

Número de Serie

(8 dígitos con terminación en

Código

La placa de datos se encuentra dentro del gabinete, en la parte superior

izquierda. Bajo ninguna circunstancia debe quitar la placa de datos de la unidad.

La placa de datos es esencial para identificar las características particulares de

su equipo y es de gran beneficio para los instaladores, operadores y personal de

mantenimiento. Se recomienda que, en caso de que sea retirada la placa de datos,

copie la información esencial en este manual como referencia antes para futuras

aclaraciones.

La Remoción de la placa de datos anulará la garantía.

2.5 Instalación y Ensamble

Los equipos englobados en este manual están diseñados solamente para uso

interior. Asegúrese de que la ubicación elegida tiene un piso lo suficientemente

fuerte para soportar el peso total del equipo y su contenido. Para la operación

más eficiente, asegúrese de proveer buena circulación de aire dentro y fuera de la

unidad.

Dentro del gabinete:

La primera limpieza debe hacerse cuando desempaque el equipo y antes de

encenderlo. Limpie con agua y un detergente suave. Cuando esté limpio y seco,

inserte los accesorios en los lugares apropiados, para el mejor aprovechamiento

del usuario.

Tome cuidado con el contro de temperaura de su equipo, algunos liquidos

pudieran dañarlo y componentes ELECTRICO/ ELECTRONICOS no cuentan con

garantia.

12

Page 15

asberprofessional.com

Fuera del gabinete:

Asegúrese que la unidad tenga buena circulación de aire alrededor de él. Evite

rincones calientes y lugares cerca de estufas y hornos. Se recomienda instalar la

unidad a no menos de dos pulgadas (2 ") de cualquier pared. El lugar donde se

coloca el refrigerador debe estar ventilado y limpio, evitando que el ventilador

de la unidad condensadora absorba materiales que luego se depositan en las

aletas del condensador y motor lo que puede producir fallas.

La unidad no debe ser instalada bajo temperaturas ambientales superiores a 100 °

F.

Si la humedad relativa es superior al 60%, los marcos de las puertas pueden

presentar condensacion. Esto no es un mal funcionamiento de la unidad.

2.6 Conexiones

Tome en cuenta los datos sobre el amperaje y voltaje que aparecen en la placa

matricula del equipo. Es indispensable que la instalación eléctrica del usuario

cumpla con los requerimientos y normatividades eléctricas nacionales y locales

correspondientes al lugar donde se instalara el aparato.

El equipo debe ser instalado en un circuito protegido por sobrecargas y/o cortos

circuitos así como por variaciones de voltaje.

IMPORTANTE: El contacto o enchufe debe tener conductor de tierra física

obligatoriamente.

La unidad debe ser conectada a tierra y conectado según la normativa electrica

vigente nacional y local.

OPERACION

3.1 Información General

3.2 Descripción del panel de control.

3.3 Configuraciones del Equipo.

3.1 Información General

La buena circulación de aire dentro del gabinete es crítico. No obstruya el

flujo de aire de los ventiladores. Coloque el equipo a no menos de 3

pulgadas de espacio a lo largo del frente, parte posterior y los lados

como separacion para una ventilacion adecuada.

3.2 Descripción del panel de control

3.2.1 Control electronico (IR33+)

Los parámetros pueden modifi carse por medio del teclado frontal.

El acceso varía en función del tipo de parámetro de que se trate: punto de

ajuste, parámetros de uso frecuente (F) o parámetros de configuración (C).

En la tabla de parámetros se indica el tipo de parámetro. El acceso a los

parámetros de confi guración está protegido con una contraseña que impide

que se modifi quen de manera accidental o que los modifi quen personas no

autorizadas. Con la contraseña de los parámetros de configuración también

es posible acceder a todos los parámetros del controlador y modificarlos.

13

Page 16

asberprofessional.com

3.3 Configuraciones del Equipo

Modifi cación del punto de ajuste

Para modifi car el punto de ajuste St (predeterminado = 0°C):

• Pulse Set durante más de 1 segundo;en el display aparece Set

seguido del valor actual de St.

• Pulse UP/DOWN para desplazarse hasta el valor que desee.

• Pulse Set para guardar el nuevo valor de St.

Modificación de los parámetros de tipo F

En los parámetros de tipo F se incluyen el punto de ajuste, el

diferencial,el intervalo de monitorización de la temperatura, el

intervalo entre desescarchados, la temperatura de fi nal de

desescarchado, el tiempo degoteo, los umbrales de alarma, los

tiempos de omisión de las alarmas, etc.

Véase la tabla de parámetros.

Procedimiento:

1. Pulse Prg/Mute una o varias veces para que se muestre la vista

estándar del display.

2. Mantenga pulsado Prg/Mute más de 3 segundos (en caso de

alarma,primero se silencia el zumbador);en el display se mostrará el

código PS (contraseña) y el número 0.

3. Pulse Set para que aparezca el parámetro St.

4. Pulse UP o DOWN hasta que aparezca el parámetro cuyo valor

quiera modificar.Conforme se desplace por el display, se iluminará el

icono que representa la categoría a la que pertenece el parámetro

(véanse la tabla siguiente y la tabla de parámetros).

5. Pulse Set para ver el valor del parámetro.

6. Pulse UP/DOWN hasta que aparezca el valor deseado.

7. Pulse Set para guardar provisionalmente el nuevo valor en la

memoria y regresar a la vista del código del parámetro.

8. Repita las operaciones de la 4) a la 7) para modificar otros

parámetros.

9. Para guardar defi nitivamente los nuevos valores de los

parámetros y salir del procedimiento de modifi cación de parámetros,

pulse Prg/Mute durante 5 segundos.

14

Page 17

asberprofessional.com

Modifi cación de los parámetros de tipo C

En los parámetros de tipo C se incluyen los parámetros de tipo F y

todos los demás parámetros del controlador. Procedimiento:

1. Pulse Prg/Mute una o varias veces para que se muestre la vista

estándar del display.

2. Mantenga pulsado Prg/Mute más de 3 segundos (en caso de

alarma, primero se silencia el zumbador);en el display se mostrará el

código PS (contraseña) y el número 0.

3. Pulse UP/DOWN e introduzca la contraseña: 22. Pulse Set para

que aparezca el parámetro /2.

4. Pulse UP o DOWN hasta que aparezca el parámetro cuyo valor

quiera modificar.Conforme se desplace por el display, se iluminará el

iconoque representa la categoría a la que pertenece el parámetro

(véanse la tabla siguiente y la tabla de parámetros).

5. Pulse la tecla Set para ver el valor del parámetro.

6. Pulse UP/DOWN hasta que aparezca el valor deseado.

7. Pulse Set para guardar provisionalmente el nuevo valor en la

memoria y regresar a la vista del código del parámetro.

8. Repita las operaciones de la 4) a la 7) para modifi car otros

parámetros.

9. Para guardar defi nitivamente los nuevos valores de los

parámetros y salir del procedimiento de modifi cación de parámetros,

pulse Prg/Mute durante 5 segundos.

Atención:

• Todos los cambios realizados se perderán si se interrumpe el

suministro eléctrico del controlador antes de pulsar Prg/mute.

• En ambos procedimientos de modifi cación de parámetros (F y C)

es preciso pulsar Prg/mute durante 5 segundos para que los valores

nuevos se guarden en la memoria. En el procedimiento de modifi

cación del punto de ajuste, el nuevo valor se guarda en la memoria

una vez que se pulsa Set para confi rmar la operación.

15

Page 18

asberprofessional.com

MANTENIMIENTO

4.1 Reglas de seguridad general.

4.2 Rutina de limpieza y mantenimiento del equipo

4.3 Disposición del equipo

4.1 Reglas de seguridad general

El quipo debe ser apagado y desconectado de la fuente de

alimentación cuando realizar el mantenimiento, reparación o limpieza

de la unidad condensadora.

Cualquier negligencia con los procedimientos de limpieza del compresor puede

anular la garantía y generar un costo del remplazo del compresor.

Para la limpieza del acero inoxidable use paños suaves o esponjas. Nunca usar

esponjas metalicas, cepillos de alambre o algun tipo de lija.

4.2 Rutina de limpieza y mantenimiento del equipo

La limpieza debe ser a base de limpiadores alcalinos o libres de cloro. Cualquier

limpiador que contiene cloruros dañará la película protectora del acero

inoxidable. Cloruros son también comúnmente encontrados en agua dura, sales y

productos de limpieza domésticos e industriales. Si se utilizan limpiador que

contienen cloruros asegúrese de enjuagar varias veces la superficie y seque bien

al finalizar. La limpieza de rutina del acero inoxidable puede hacerse con agua y

jabón.

Las manchas de grasa deben limpiarse con un paño no abrasivo exfoliante

limpiador. También hay limpiadores de acero inoxidable disponibles que se pueden

restaurar y conservar el acabado de la capa protectora de los aceros.

Nunca use una solución de limpieza a base de ácido. Muchos productos

alimenticios tienen un contenido ácido que puede deteriorar el acabado. Asegúrese

de limpiar los todos los residuos de productos alimenticios de cualquier

superficie de acero inoxidable.

4.2.1 Limpiando el condensador

El condensador “SE DEBE LIMPIAR REGULARMENTE”, por lo menos cada 3

meses y/o según se requiera (dependerá de la acumulación de polvo y

grasa).

PELIGRO: Se tiene que apagar y desconectar el aparato de suministro de

energía eléctrica cuando se realicen procedimientos de mantenimiento,

reparación o limpieza.

Desconecte el equipo, retire los tornillos que sujetan la rejilla inferior

frontal, remueva los dos tornillos que sujetan la base del compresor a la

base del equipo y con extremo cuidado deslice la base del compresor hacia

afuera.

Si la acumulación de polvo y pelusa en el condensador es mínima, esta

puede ser limpiada con un cepillo sencillo. La acumulación de polvo más

espeso requiere de una aspiradora o de aire comprimido para pasar por los

tubos del condensador.

Si hay grasa espesa presente, existen agentes desengrasantes para uso en

refrigeración y más específicamente para condensadores. El condensador

puede requerir de un spray con agente desengrasante y luego ser soplado

con aire comprimido.

Asegúrese de que todas las partes mecánicas y eléctricas estén secas antes

de encender la máquina.

16

Page 19

asberprofessional.com

NOTA: nunca utilice agua a alta presión para procedimientos de lavado ya

que el agua puede dañar los componentes eléctricos localizados cerca del

condensador. No coloque filtros delante del condensador ya que este

material obstruye el flujo de aire hacia los tubos provocando un efecto en

el sistema de refrigeración similar a un condensador sucio.

ATENCIÓN: mantener el condensador limpio tiene grandes ventajas, tales

como: alargar la vida útil del equipo, mejorar el funcionamiento del

aparato, minimizar los costos de servicios y disminuir los costos de

electricidad. Si no mantiene el condensador limpio, inicialmente puede

causar tiempos de abatimiento de temperatura excesivos, excesivo consumo

de energía eléctrica, etc. La operación continua del equipo con el

condensador sucio puede dar como resultado daños en el compresor.

LA FALTA DE LIMPIEZA DE LA UNIDAD CONDENSADORA ANULARÁ LA

GARANTÍA ASOCIADA AL COMPRESOR O A LOS COSTOS DE REEMPLAZO DEL

MISMO.

Para volver a colocar la unidad condensadora en su lugar, deslice con

extremo cuidado la base del compresor hacia adentro sobre las guías.

ASEGÚRESE DE QUE LOS TUBOS NO SE DOBLEN Y/O DAÑEN EN ESTA

OPREACIÓN. Coloque los tornillos que sujetan la unidad condensadora a

la base del equipo y coloque la rejilla frontal con sus tornillos.

4.2.2 Limpieza del empaque plástico

El empaque requiere una limpieza regular para evitar la acumulación de

moho arriba y también para mantener la elasticidad del mismo. La limpieza

puede realizarse con el uso de agua caliente y jabón. Evitar productos de

limpieza ya que esto puede causar que se tornen quebradizos y evitar el

sellado adecuado. Además, nunca utilice herramientas o cuchillos para

raspar o limpiar el empaque, posiblemente podrían romper el empaque y

rasgar el fuelle.

Los empaques pueden ser reemplazados fácilmente y no requieren el uso de

herramientas o personas autorizadas de servicio.

4.2.3 Drenado

Cada unidad tiene un drenado ubicado dentro de la unidad que elimina la

condensación de la bobina del evaporador y lo evapora en un exterior

condensado del evaporador. Cada drenaje puede ser removido o

desconectado.

Si percibe excesiva acumulación de agua en el interior de la unidad

asegúrese de que está conectado el tubo de desagüe del evaporador a la

bandeja de drenaje de condensado del evaporador.

La nivelación de la unidad es importante, ya que las unidades están

diseñadas para drenar adecuadamente cuando sobre una superficie

nivelada, si el piso no está nivelado esto también puede causar problemas

de drenaje. Asegúrese de que todas las líneas de desagüe estén libres de

obstrucciones.

4.3 Disposición del equipo

El ciclo de vida promedio de los productos ASBER es de 7 a 10 años apartir de

la fecha de instalcion y uso del equipo.

Los equipos ASBER son fabricados sin materiales toxicos o peligorosos. Algunas

partes son biodegradables.

La disposicion final del equipo despues del termino del ciclo de vida sera definido

de acuedo a las reglas, y leyes vigentes establecidas en la ciudad y/o estado de

residencia.

RECUERDE CUIDAR EL MEDIO AMBIENTE.

17

Page 20

asberprofessional.com

SOLUCIONANDO PROBLEMAS

5.1 SOLUCIONANDO PROBLEMAS

5.1 Solucionando problemas

Algunas veces, las fallas son debido a causas simples que pueden ser

solucionadas por el usuario. Antes de pedir ayuda a un técnico calificado,

debe hacer algunas verificaciones. Estas fallas no están cubiertas por la

garantía:

1) El refrigerador no funciona:

a. Verifique que la maquina esté conectada de forma correcta y que

exista el voltaje correcto para el equipo.

b. Verifique que el “Botón Encendido/Apagado” este en la posición de

“Encendido”.

2) El refrigerador no da la temperatura adecuada:

a. Verifique que el equipo no está en el ciclo de deshielo.

b. Verifique que el control no marque alguna alarma.

c. Verifique que el SET POIT de temperatura es el correcto.

d. Verifique que no existe obstrucción al flujo del aire en el interior

del equipo.

e. Verifique que el ventilador ó los ventiladores funcionan

correctamente.

f. Asegúrese que el condensador este limpio y que no haya objetos

que obstruyan el paso de aire por las tuberías del condensador.

g. Verifique que el ventilador del condensador funciona.

3) Hay agua dentro del equipo:

a. Asegúrese que el panel de drenaje que se encuentra en el interior

del gabinete esté en su posición correcta.

b. Verifique que no haya alimento obstruyendo la línea del drenaje.

18

Page 21

asberprofessional.com

ELECTRIC DIAGRAM / DIAGRAMA ELECTRICO

19

Page 22

1 8 d e a g o s t o d e 2 0 1 6

ASBER PROFESSIONAL

Parque Industrial Tres Naciones

San Luís Potosí, S.L.P. México

Teléfono Planta S.L.P.: + 52 (444) 137 0500 Ext.538

Sin costo: 01 800 00 ASBER

13105 NW 47th Ave

Miami, Fl. 33054

Loading...

Loading...