Page 1

MERCHANDISER REFRIGERATORS AND FREEZERS

Manual for installation, use, and maintenance

Page 2

Page2

ASBER – MERCHANDISER: Operations and Service Manual/Rev. JUN. 2015

Contents

1 RECEIVING AND INSPECTING THE EQUIPMENT .................................................................................... 3

2 SPECIFICATIONS .................................................................................................................................... 4

3 INSTALLATION ....................................................................................................................................... 6

3.1 UNCRATING ................................................................................................................................... 6

3.2 LOCATION ...................................................................................................................................... 6

3.3 DATA PLATE ................................................................................................................................... 7

3.4 LEVELING ....................................................................................................................................... 7

3.5 ELECTRICAL CONNECTIONS ........................................................................................................... 7

3.6 SHELVING INSTALLATION .............................................................................................................. 8

4 OPERATION ........................................................................................................................................... 9

4.1 ANALOG THERMOSTAT ................................................................................................................. 9

4.2 ELECTRONIC CONTROLLER .......................................................................................................... 10

5 MAINTENANCE .................................................................................................................................... 11

5.1 GASKET ........................................................................................................................................ 12

5.2 DOORS/HINGES ........................................................................................................................... 13

5.3 DRAIN .......................................................................................................................................... 13

6 WIRING DIAGRAMS ............................................................................................................................. 14

7 TROUBLE SHOOTING ........................................................................................................................... 23

Limited Warranty ...................................................................................................................................... 24

Page 3

Page3

ASBER – MERCHANDISER: Operations and Service Manual/Rev. JUN. 2015

1 RECEIVING AND INSPECTING THE EQUIPMENT

Up on receiving your new Asber Refrigerator, check the package and the machine for any

damages that may have occurred during transportation. Visually inspect the exterior of the

package. I f damaged, open and inspect the contents with the carrier. Any damage should be

noted and reported on the delivering carrier’s receipt.

In the event that the exterior is not damaged, yet up on opening, there is concealed damage to

the equipment notify, the carrier immediately. Notification should be made verbally as well as

in written form. Request an inspection by the shipping company of the damaged equipment.

Retain all crating material until inspection has been made. Contact the dealer through which

you purchased the unit.

Check the compressor compartment housing and visually inspect the refrigeration package. Be

sure lines are secure and base is still intact.

A NOTE FROM OUR QUALITY CONTROL MANAGER

CONGRATULATIONS ON YOUR NEW PURCHASE. WE WOULD LIKE TO WELCOME

YOU TO THE ASBER TEAM. THE UNIT IN FRONT OF YOU IS A GREAT PIECE OF

EQUIPMENT THAT WILL BECOME ONE OF YOUR MOST RELAIBLE TOOLS IN YOUR

DAILY OPERATIONS FOR YEARS TO COME!

PRIOR TO SHIPPING YOUR UNIT, OUR TRAINED SERVICE TECHNICIANS TESTED

YOUR UNIT FOR A PERIOD OF 12 HOURS. THIS PERFORMANCE TEST WAS

RECORDED AND A COPY OF THE RESULTS IS INCLUDED WITH THIS SERVICE

MANUAL. DURING THIS TEST, OUR HIGHLY QUALIFIED PERSONNEL INSPECTED

YOUR MACHINE FOR LEAKS, LOSE COMPONENTS, AND IMPROPER NOISE

LEVELS. WE ALSO TESTED THE COOLING PERFORMANCE IN AN EFFORT TO GIVE

YOU THE BEST AND MOST RELAIBLE UNIT POSSIBLE.

Page 4

Page4

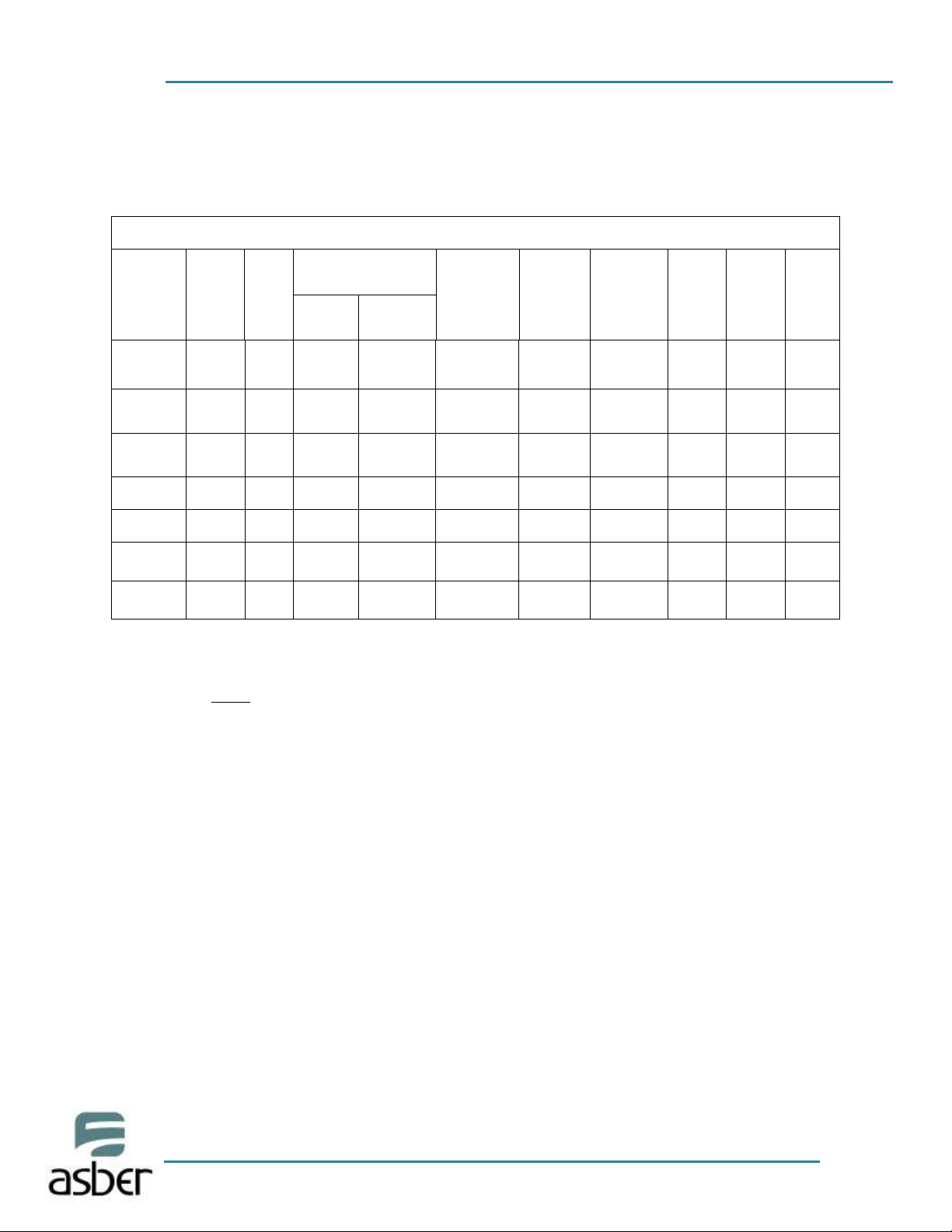

REACH IN MERCHANDISERS AND FREEZERS, GENERAL SPECS

Model

Capac.

(Cu.Ft.)

#of

Shvls

Temperature

Operation

Pressure

in

Suction Line*

Super-

Heat**

BTU

Ref.

Amount

Ref.

Type

Ship

Weight

Set

Point

Cut in

ARM-10

9.8

4

5°C/41°F

-3°C A 0°C

(27°F y 32°F)

10-16PSIG

7°C/13°F

1400

9.8 oz

R-134a

203

ARM-17

16

4

5°C/41°F

-3°C A 0°C

(27°F y 32°F)

10-16PSIG

7°C/13°F

1800

9.8 oz

R-134a

216

ARMD-23

23

4

5°C/41°F

-3°C A 0°C

(27°F y 32°F)

10-16PSIG

7°C/13°F

1800

9.8 oz

R-134a

262

ARMD-37

37

8

0°C/32°F

5°C/41°F

10-16PSIG

7°C/13°F

2400

17.28oz

R-134a

373

ARMD-49

49

8

0°C/32°F

5°C/41°F

10-16PSIG

7°C/13°F

2400

17.28oz

R-134a

424

AFM-17

16

4

-22°C/-8F

-18°C/0°F

12-16PSIG

4°C/7°F

1900

16.6oz

R-404A

216

AFMD-23

23

4

-22°C/-8F

-18°C/0°F

12-16PSIG

4°C/7°F

1900

16.6 oz

R-404A

262

2 SPECIFICATIONS

ASBER – MERCHANDISER: Operations and Service Manual/Rev. JUN. 2015

Note:

* The pressure in the suction line is recommended at 32°C / 90°F maximum of ambient

temperature.

**Superheat measured in the outlet of the evaporator at 32°C / 90°F

Page 5

Page5

ASBER – MERCHANDISER: Operations and Service Manual/Rev. JUN. 2015

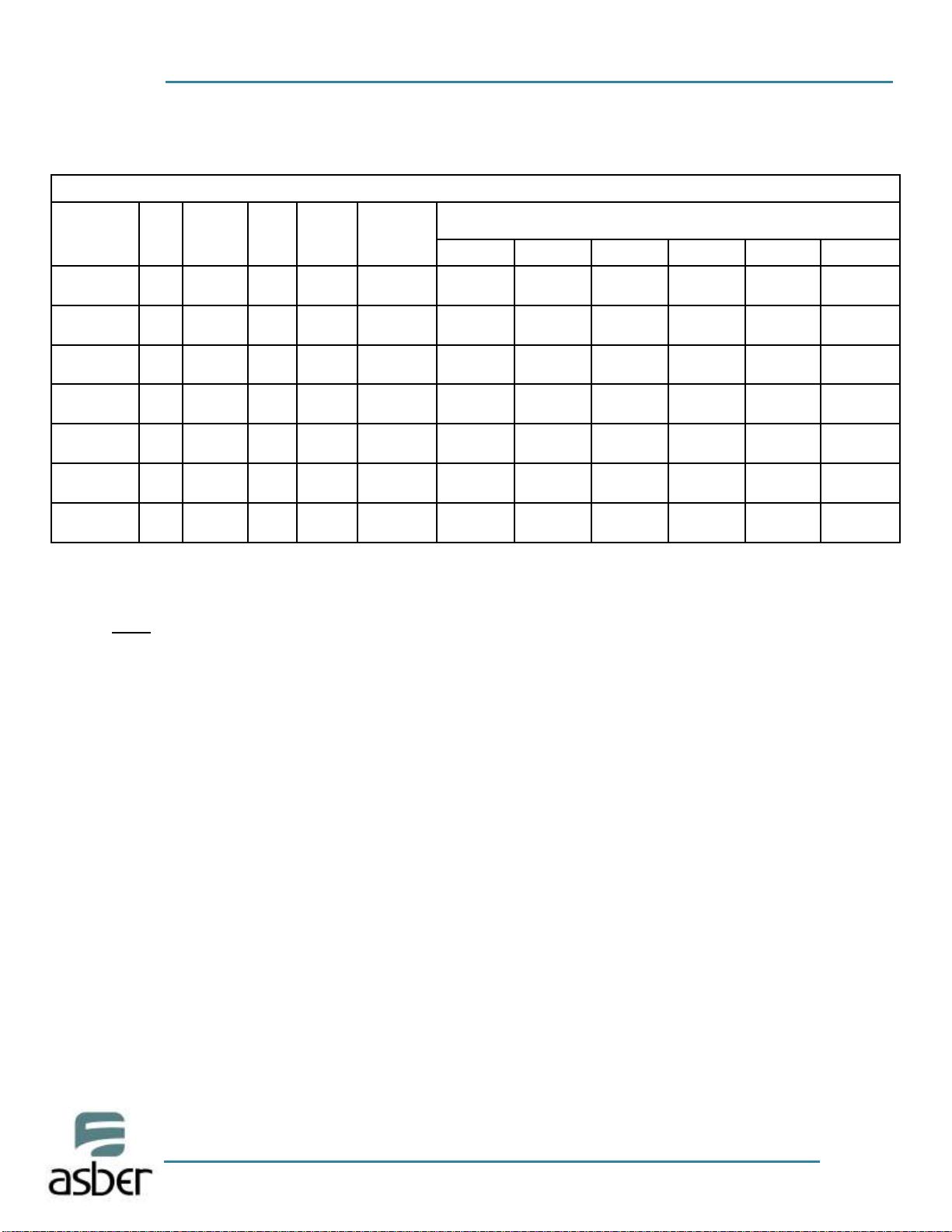

REACH IN MERCHANDISERS AND FREEZERS, ELECTRICAL SPECS

Models

HP Voltage

Amp.

Max.

NEMA

Plug

Breaker

Size*

Wire gauge recommended for 2% voltage drop in supply

circuits **

40 ft ***

60 ft

80 ft

100 ft

120 ft

140 ft

ARM-10

1/4

115

220

5.8

3.2

5-15P

2P+TT

15 amp

10 amp

14 AWG

14 AWG

14 AWG

14 AWG

12 AWG

14 AWG

12 AWG

14 AWG

12 AWG

14 AWG

10 AWG

12 AWG

ARM-17

3/4

115

220

5.8

3.2

5-15P

2P+TT

15 amp

10 amp

14 AWG

14 AWG

14 AWG

14 AWG

12 AWG

14 AWG

12 AWG

14 AWG

10 AWG

14 AWG

10 AWG

12 AWG

ARMD-23

1/4

115

5.8

3.2

5-15P

2P+TT

15 amp

10 amp

14 AWG

14 AWG

12 AWG

14 AWG

12 AWG

14 AWG

10AWG

14 AWG

10 AWG

14 AWG

10 AWG

12 AWG

ARMD-37

1/3

3/8

115

220

6.9

3.5

5-15P

2P+TT

15 amp

10 amp

14 AWG

14 AWG

12 AWG

14 AWG

12 AWG

14 AWG

10 AWG

14 AWG

10 AWG

12 AWG

8 AWG

12 AWG

ARMD-49

1/3

3/8

115

220

6.9

3.5

5-15P

2P+TT

15 amp

10 amp

14 AWG

14 AWG

12 AWG

14 AWG

10 AWG

14 AWG

10 AWG

12 AWG

8 AWG

12 AWG

8 AWG

12 AWG

AFM-17

3/4

115

220

8.8

4.5

5-15P

2P+TT

15 amp

10 amp

14 AWG

14 AWG

12 AWG

14 AWG

10 AWG

14 AWG

10 AWG

12 AWG

8 AWG

12 AWG

8 AWG

12 AWG

AFMD-23

3/4

115

220

8.8

4.5

5-15P

2P+TT

20 amp

10 amp

12 AWG

14 AWG

10 AWG

12 AWG

8 AWG

12 AWG

8 AWG

12 AWG

8 AWG

12 AWG

6 AWG

12 AWG

Note:

*Breaker sizes are recommended by the manufacturer to protect the equipment by

overload; this breaker only must be dedicated for the equipment.

** If the equipment is installed faraway of the circuit breaker, these are the wire gauge

recommend to connect the appliance; if the distance is higher that the chart values, please

contact an electrician.

***Distance in feet from the breaker or the power supply to the appliance.

Page 6

Page6

ASBER – MERCHANDISER: Operations and Service Manual/Rev. JUN. 2015

3 INSTALLATION

3.1 UNCRATING

Remove the outer packaging. Cut the 4 clamps that hold the refrigerator to the skid. Lift the

unit off the skid.

If machine was laid down during this operation, remember to leave the cabinet

up right for 24 hours before connecting to power source.

3.2 LOCATION

Units represented in this manual are intended for indoor use only. Be sure the location chosen

has a floor strong enough to support the total weigh to the unit and its contents. For the most

efficient operation, be sure to provide at least three (3) inches between sides, back and top of

the unit.

THE MACHINES NEEDS TO BE INSTALLED 2 FEET AWAY FROM ANY HEAT SOURCES.

The unit should not be installed under ambient temperatures higher than 100 °F.

If the relative humidity is higher than 60 %, the door frames may sweat water. This is not a

malfunctioning of the unit.

WARNING

The following actions will void your warranty:

Modification of power cord.

Connecting the unit to any extension cord.

Neglecting to install the castors or optional legs.

Inside cabinet:

The first cleaning must happen when you unpack the unit and before it is turned ON. For

this, you have to clean the unit with warm water and mild detergent. When it is cleaned and

dry, proceed to install accessories and plug your unit in to a dedicated outlet. WAIT 24 HOURS

BEFORE PLACING PRODUCT IN THE UNIT. This will guarantee that it is working properly.

Consequential damages are not covered under warranty.

Outside cabinet:

Be sure that the unit has access to ample air to breathe. Avoid hot corners and locations near

stoves and ovens. It is recommended the unit be installed no closer than 3” from any wall. The

place where the refrigerator is placed must be open and clean. This will reduce the amount of

debris and dirt on the condenser fan and coil.

Page 7

Page7

ASBER – MERCHANDISER: Operations and Service Manual/Rev. JUN. 2015

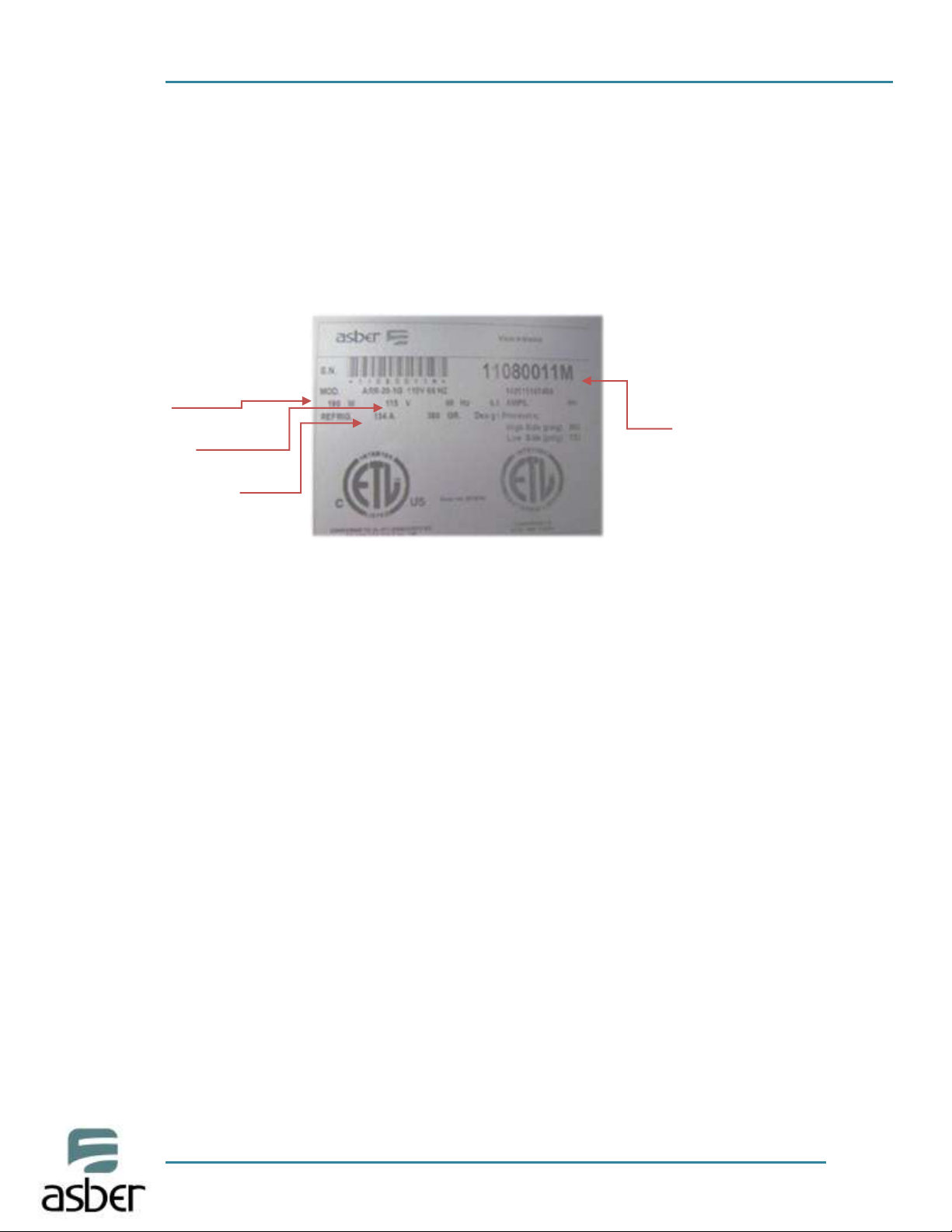

Model

Electrical

Refrigerant Type

SERIAL NUMBER FOR

THE EQUIPMENT

(8 digits and ends in

“M”)

3.3 DATA PLATE

The data plate is located inside the cabinet, near the top front, left corner. Under any

circumstances should the data plate be removed from the unit. The data plate is essential to

identify the particular features of your machine and i t is of great benefit to installers,

operators, and maintenance personnel. It is recommended that, in the event the data plate is

removed, you copy down the essential information in this manual for reference before

installation. Removal of data plate will void the warranty.

3.4 LEVELING

Set unit in its final location. A level cabinet looks better and will perform better. Effective

condensate removal and door operation will be effected by leveling. Machine must be leveled

front to back and side to side with a level tool. Castors ki t wi ll include shims for leveling.

Insert the shim between the castor and the frame rail. (See installation of castors). Lock front

castors so cabinet does not move. Ensure drain hose is inside drain pan.

3.5 ELECTRICAL CONNECTIONS

Refer to the amperage data in this manual, or on data plate, and your local code or the

National Electrical Code to be sure unit is connected to the proper power source. Verify

correct incoming voltage according to the Data Plate information.

Do not, under any circumstances, cut or remove the ground prong from the power cord.

Asber units must be properly grounded.

NEVER USE AN EXTENSION CORD! Asber will not warranty any unit that has been

connected to an extension cord.

Asber equipment must be grounded and connected in accordance with NEC Article 422

Appliances.

Page 8

Page8

ASBER – MERCHANDISER: Operations and Service Manual/Rev. JUN. 2015

DANGER:

Power must be turned off and disconnected from the power source whenever

performing maintenance, repair or cleaning the condensing unit.

If machine is still running when power is off, disconnect power at the circuit breaker

before unplugging the machine.

WARNING:

Machine and compressor warranties are void if failure is due to improper electrical

installation.

3.6 SHELVING INSTALLATION

Hook shelf rails onto shelf pilasters

Position all shelf rails equal in distance from the floor for level shelves

Wire shelves are oriented so that cross support bars are facing down

Note: Single door Reach-include an air flow guard on the rear of the shelves as well as a lip to

maintain an air space at the rear of the cabinet

Place shelves on shelf clips, making sure all corners are seated properly.

Page 9

Page9

ASBER – MERCHANDISER: Operations and Service Manual/Rev. JUN. 2015

Thermostat

Located inside

the unit in the

right side

Position

thermostat to

zero (0),

compressor will

not work.

For best

performance

knob should

be pointing

Knob to adjust

thermostat

setting.

4 OPERATION

4.1 ANALOG THERMOSTAT

Before y o u connect the unit to the power supply, verify the thermostat is NOT in the OFF

position (the position of the thermostat must be different than zero).If the thermostat is in

the OFF position, the compressor will not run. Keep in mind, the evaporator fan sand lights

will still have power while the thermostat is in the OFF position.

The knob of the thermostat is the temperature controller. T h i s is located inside the cabinet.

P

lease be sure that the knob of thermostat is pointing to the yellow arrow (figure # 3).This

position is recommended by the factory to assure correct function of the equipment (see the

figure #1 below).

Figure#1 Figure # 3

Note:

Keep in mind, if you move the knob to a different position that is recommend from factory, these temperature

will change, as well.

The knob position near the number one, gives you the warmest temperature and the knob position near the

number seven, gives you the coldest temperature.

Page 10

Page10

ASBER – MERCHANDISER: Operations and Service Manual/Rev. JUN. 2015

For Freezers or Refrigerators with electronic control

4.2 ELECTRONIC CONTROLLER

CAREL CONTROL

After connecting your unit, turn ON rocker switch located next to the controller. The display will light up

showing the temperature inside the unit. Also, the compressor and fan icons will flash for a period of

three minutes. After this delay the unit will start cooling.

Verify you don't have any alarms on the temperature controller. If after you turn ON the equipment the

controller shows the alarm icon or an error code, call for technical service. They will help you fix the

problem.

Changing the Set Point of the temperature on the controller

The unit comes with a factory default set point ( 32°F Refrigerators). These set values will make the unit

perform at its maximum capacity. Therefore, it is not recommended to change the set point. If set point

needs to be changed, follow the next steps.

1. Push the SET button for one second. You should see a flashing number. Release the button.

2. Press the up and down arrows to increase or decrease the set temperature. Then press the

set button to save the new set point.

Note:

The maximum value you can set in the controller is: For refrigerators: 5°C (40°F)

Page 11

Page11

ASBER – MERCHANDISER: Operations and Service Manual/Rev. JUN. 2015

3. If you wish decrease the value of the set point for a new temperature, press the button

DOWN arrow (see the picture below). Press this button to reach the desired value. Release

the button and then press the SET button to keep, and save, the new value.

Note:

The minimum value you can set in the controller is: For refrigerators: -1°C (30°F)

Manual Defrost

To select manual defrost, hold the button DOWN arrow for 5 seconds. The snow flake icon will appear

on the display. When this icon is solid it indicates that the equipment is in Defrost mode.

To exit manual defrost, hold the DOWN button arrow for 5 seconds. The snow flake icon will turn off.

Wait 2 minutes for the compressor to start

5 MAINTENANCE

Stainless Steel Care and Cleaning

Proper cleaning of stainless steel requires soft cloths or plastic scouring pads. Never use steel

pads, wire brushes, or scrapers!

Cleaning solutions need to be alkaline or non-chloride cleaners. Any cleaner containing

chlorides will damage the protective film of the stainless steel. Chlorides are commonly found

in hard water, salts, house hold and industrial cleaners. If a cleaner containing chloride is used,

be sure to rinse repeatedly and dry thoroughly up on completion.

Stainless steel mu st b e cl ean ed e ver y da y with soap and water. Extreme stains or grease

should be cleaned with a non-abrasive cleaner and plastic scrub pad. When using a stainless

steel chemical cleaner, make sure it is recommended for commercial applications.

Never use an acid based cleaning solution! Many food products have an acidic content which

can deteriorate the stainless steel finish. Be sure to clean ALL food products from any stainless

steel surface. Failure to do so, will result in spots and rust on the surface affected.

Cleaning the Condenser Coil

DANGER: Power must be turned off and disconnected from the power source whenever

performing maintenance, repair or cleaning the condensing unit.

Page 12

Page12

ASBER – MERCHANDISER: Operations and Service Manual/Rev. JUN. 2015

Disconnect machine. Remove front bottom panel and carefully slide out the condensing unit.

The condenser coil requires regular cleaning. It is recommended every 30-60 days, depending

on the accumulation of dust and grease.

If the build up on the coil consists of only light dust and debris, the condenser coil can be

cleaned with a simple brush. Heavier dust build up may require a vacuum or even compressed

air to blow though the condenser coil.

If heavy grease is present, there are de-greasing agents available for coils. The condenser coil

may require to be sprayed with de-greasing agent and then to be dried with compressed air.

Be sure all electrical and mechanical parts are dry before turning ON the power.

Never use high pressure water for cleaning the co nd en se r coi l. Water can damage the

electrical components located near or at the condenser coil. Do not place filter material in

front of condenser coil. This material blocks air-flow to the coil similar to having a dirty coil!

If you keep the Condenser clean, you will minimize your service expense and lower your

electrical costs. Failure to maintain a clean condenser coil can initially cause high temperatures

and excessive runtimes. Continuous operation with dirty or clogged condenser coils can result

in compressor failures. This will not be covered under warranty.

Neglecting the condenser coil cleaning procedures WILL VOID YOUR WARRANTY

To put back the condensing unit, slide in the unit carefully in. BE SURE THE DRAIN PIPEIS

LOCATED OVER THE DRAIN PAN. Replace front bottom panel.

5.1 GASKET

Gaskets require regular cleaning to prevent mold and mildew build up and to keep the

elasticity of the gasket. Gasket cleaning can be done with the use of warm soap and water.

Avoid the use of chemical cleaning products on gaskets as this can cause them to become

brittle and prevent proper sealing. Also, never use sharp tools or knives to scrape or clean the

gasket which could possibly tear the gasket and rip the bellows.

Gaskets can easily be replaced and do not require the use of tools or authorized service

personnel. To remove the gasket, pull the gasket towards you. To replace gasket, press the

gasket against the groove of the door the gasket will “snap” back into place.

Page 13

Page13

ASBER – MERCHANDISER: Operations and Service Manual/Rev. JUN. 2015

5.2 DOORS/HINGES

During transportation the doors hinges may become loose. If the door(s) don’t look aligned,

tighten the screws that hold the hinge brackets to the frame of the unit. If the doors are loose

or sagging, this can cause the hinge to pull out of the frame which may damage the doors and

the door hinges. In some cases, this fix or adjustment may require a qualified service agent or

maintenance personnel.

5.3 DRAIN

Each unit comes equipped with a drain pan located outside the unit. The drain pan catches the

condensation produced inside the evaporator coil. If the drain hose become loose or

disconnected from moving or bumping the unit, you may find a puddle of water inside/outside

of the unit. Replace or fix any lose connections. IF YOU NOTICE EXCESSIVE WATER

ACCUMULATIONON THE INSIDE OF THE UNIT, be sure the drain tube is connected firmly and

not kinked or bent. It is the owner’s responsibility to maintain the drain pan leveled, and with

the drain hose inside of the pan.

Units installed in a humid environment will produce large amounts of water in

the drain pan. This is NOT a malfunction of the unit. It is the customer’s

responsibility to clear the drain pan as necessary to avoid puddles of water

underneath the unit.

Do not store open containers with liquids inside the unit. This will increase the

amount condensation inside and outside of the unit, and the evaporator coil

will freeze up.

Do not store hot products inside the unit. This will increase the amount of

condensation inside and outside of the unit, and the evaporator coil will freeze

up.

The unit must be level and on a strong surface. When moving the unit, check

the drain piping to make sure it was not disconnected or moved out of the

drain pan. This will not be covered under warranty

Page 14

Page14

6 WIRING DIAGRAMS

ARM-17/ ARMD-23

ASBER – MERCHANDISER: Operations and Service Manual/Rev. JUN. 2015

Page 15

Page15

ARM-10 / ARMD-37 / ARMD-49

ASBER – MERCHANDISER: Operations and Service Manual/Rev. JUN. 2015

Page 16

Page16

ARMD 35 SD_ ARMD 47 SD

ASBER – MERCHANDISER: Operations and Service Manual/Rev. JUN. 2015

Page 17

Page17

AFM-17/ AFMD-23

ASBER – MERCHANDISER: Operations and Service Manual/Rev. JUN. 2015

Page 18

Page18

AFMD-37

ASBER – MERCHANDISER: Operations and Service Manual/Rev. JUN. 2015

Page 19

Page19

ARM 17 A_ ARM 23A

ASBER – MERCHANDISER: Operations and Service Manual/Rev. JUN. 2015

Page 20

Page20

ARM 35 SD-A_ ARM 47 SD-A

ASBER – MERCHANDISER: Operations and Service Manual/Rev. JUN. 2015

Page 21

Page21

ARM 10-A_ ARMD 37 –A _ARMD 49 A

ASBER – MERCHANDISER: Operations and Service Manual/Rev. JUN. 2015

Page 22

Page22

ARMD 72

ASBER – MERCHANDISER: Operations and Service Manual/Rev. JUN. 2015

Page 23

Page23

ASBER – MERCHANDISER: Operations and Service Manual/Rev. JUN. 2015

7 TROUBLE SHOOTING

Follow the next steps before requesting warranty service. Failure to do so, may

result in service charges for you and may void your warranty:

1) Refrigerator doesn’t work:

a. Check that the machine is still connected.

b. Check that the ON/OFF button is in the ON position.

2) Refrigerator doesn’t reach temperature :

a. Verify unit is not on saving mode

b. Check that the thermostat is not in OFF position.

c. Check that the machine is not in the defrost cycle.

d. Ensure Equipment is in a ventilated place and removed minimum of

2 inches from any other appliance and away from any heat source.

e. The environment maximum temperature must be 38 °C/ 100°F.

f. To insure proper air flow, product must not be placed higher than

the maximum level mark located on the internal wall of the unit.

g. If FREEZER, check that the temperature is not Celsius.

h. Check that the gasket is in good condition and door is sealed.

i. Check that the fan is moving. Open the door and press and hold

doors witch for verification.

j. Don’t put any food inside until the unit has reached the proper temperature.

k. If FREEZER, food must be previously frozen before being placed inside the

cabinet.

l. Be sure castors or legs were installed.

3) There is water inside the refrigerator:

a. Check that the drain pan inside the cabinet is in position.

b. Check that there is not food clogging the drain line.

4) There is water under the refrigerator:

a. Check that the drain pipe is over the pan.

Warning: To in sur e proper operation of equipment, it is recommended that the

unit is on for 24 hours prior to the introduction of perishables.

b. Check that the cabinet is level.

Page 24

Limited Warranty

One Year Parts & Labor Warranty: Asber Commercial, Inc. (“Asber”) Warrants

to the fist-end-user purchaser (the “User) that the Asber brand equipment sold

hereunder, except for parts and accessories which carry the warranty of a

supplier (the “Equipment”) will be free from defects in material and factory

workmanship under normal conditions of use and maintenance for a period of

one (1) years from the date of installation (Warranty commencement date), but

in no event to exceed eighteen (18) months from the date of shipment from the

factory. Warranty is Not Transferable.

Warranty Coverage: If there is a defect in material or factory workmanship

covered by this Warranty reported to Asber during the period the applicable

Warranty is in force and effect, Asber will repair or replace, at Asber’s option,

that part (ground shipping only) of the Equipment that has become defective and

will cover labor cost (straight time only) within the corresponding warranty

period of time Asber shall bear all labor costs (straight time only) in connection

with the installation of these replacement parts, provided that, the installation is

conducted by Asber or its authorized representative. Charges for warranty travel

time round trip, total two (2) hours or up to 100 miles total. Any charges

exceeding those stated herein must have prior authorization by Asber. Travel

outside of the two (2) hours or 100 miles, and any work performed at overtime

or weekend rates, would be the responsibility of the owner/user. In the case

Asber deems the equipment non-repairable, said equipment will be replaced and

the replacement unit(s) will carry the same warranty period from the original

unit’s installation date (original Warranty Commencement Date).

Additional Three Year Compressor Part Warranty: In addition to the

warranty set above, Asber warrants the sealed compressor (part only) for an

additional four (4) years based on the installation date. This warranty is for

defects, both in workmanship and material, under the normal and proper use

and maintenance service. The four (4) year extended warranty only applies to

sealed parts of the compressor and does not apply to any other part or

component, including, but not limited to cabinet, temperature control,

refrigerant, motor starting equipment, fan assembly, or any other electrical or

mechanical component.

Exclusions from and Conditions to Warranty Coverage: This Warranty does

not cover parts or accessories, which (a) carry the warranty of a supplier or (b)

are abused. Application of this Warranty is further conditioned upon the

following:

Installation: The Equipment must be properly installed in accordance with

Asber’s installation procedures and by a professional technician.

No Alteration: The Equipment must not have been modified or altered from

its condition at the date of original installation.

Use: ASBER EQUIPMENT IS NOT DESIGNED FOR PERSONAL, FAMILY, OR

HOUSEHOLD PURPOSES, AND ITS SALE FOR SUCH PURPOSES IS NOT

INTENDED. IN THE EVENT THE EQUIPMENT IS SO USED, THIS

WARRANTY SHALL BE NULL AND VOID, AND THE EQUIPMENT SHALL

BE DEEMED TO HAVE BEEN SOLD “AS IS-WHERE IS” WITHOUT ANY

WARRANTY OF ANY KIND, INCLUDING WITHOUT LIMITATION ANY

WARRANTY OF TITLE, NON-INFRINGEMENT, MERCHANT-ABILITY OR

FITNESS FOR A PARTICULAR PURPOSE.

Proper Maintenance and Operation: The Equipment must be properly

maintained and operated in accordance with Asber’s maintenance and

operating procedures. All service, labor and parts must be acquired

from Asber or its authorized service representative for the User’s area.

This warranty is void if failure is a direct result of handling and/or

transportation, fire, water, accident, misuse, acts of god(s), attempted

repair by unauthorized persons, improper installation, if serial number

has been removed or altered, or if unit is used for purpose other than it

was originally intended.

Failure to comply with any of these conditions will void this Warranty. In

addition, this Warranty does not cover defects due to apparent abuse, misuse or

accident.

Parts Warranty Coverage: Asber warrants all new machine parts produced or

authorized by Asber to be free from defects in material and workmanship for a

period of 90 days from the Warranty Commencement Date. If any defect in

material and workmanship is found to exist within the warranty period, Asber

will replace the defective part without charge. Defective parts become the

property of Asber.

Asber will have no responsibility to honor claims received after the date the

applicable Warranty expires. Notwithstanding the foregoing , any claim with

reference to the Equipment or any parts therefore for any cause shall be deemed

waived unless submitted by the User to Asber within (30) days after the date the

User discovered, or should have discovered, the claim. In connection with all

claims under this Warranty, Asber will have the right, at its own expense, to have

its representatives inspect the Equipment at the User’s premises and to request

all of the User’s records pertaining to the Equipment to determine whether a

defect exists, whether the co nditions set forth in this Warranty have been

satisfied, and whether or not the applicable Warranty is in effect.

THE FOREGOING WARRANTY IS IN LIEU OF AND EXCLUDES ALL OTHER

WARRANTIES NOT EXPRESSLY SET FORTH HEREIN, WHETHER EXPRESS OR

IMPLIED BY OPERATION OF LAW OR OTHERWISE, INCLUDING BUT NOT

LIMITED TO ANY REPRESENTATION OF PERFORMANCE AND ANY IMPLED

WARRANTIES OF TITLE, NON-INFRINGEMENT, MERCHANTABILITY OR

FITNESS FOR A PARTICLULAR PURPOSE. NO OTHER WARRANTIES ARE

AUTHORIZED ON BEHALF OF ASBER UNLESS SPECIFICALLY ISSUED BY

ASBER.

Asber shall have no liability for incidental or consequential losses, damages

including without limitation or expenses, loss of sales, spoiled food, profits or

goodwill, claims whether or not on account of refrigeration failure or punitive or

exemplary damages directly or indirectly arising from the sale, handling or use of

the Equipment or from any other cause relating thereto, whether arising in

contract, tort, warranty, strict liability or otherwise. Asber’s liability hereunder

in any case is expressly limited, at Asber’s election, to repair or replacement of

Equipment or parts therefore or to the repayment of, or crediting the user with,

an amount equal to the purchase price of such goods.

Prices & Specifications: Asber reserves the right to change the prices and

specifications of the equipment and/or material without notice. Prices are FOB

Asber warehouses. All orders are subject to acceptance by Asber Commercial,

Inc.

Terms: All orders are subject to credit approval. All Invoices not paid within the

specified terms will be subject to a 1.5% per month delinquency charge. Buyer

agrees to pay all costs of collection including such attorney’s fees as may be

allowed by law.

Taxes: This price list does not include any Federal, State, City or Local taxes,

which may apply and are subject thereto.

Shipment: Requested carrier will be used upon request. Asber has the right to

ship via any responsible carrier if requested carrier is unavailable. Shipping

charges are payable by consignee and any claims arising as such charges shall be

resolved between the carrier and the consignee. Shipping dates are

approximates. Asber is not responsible for any delays in deliveries that are

beyond our control.

Damaged Merchandise: Inspect shipment for any damage, before accepting it. If

damaged, open and inspect the contents with the carrier. Any damage should be

noted and reported on the delivering carrier’s receipts. Asber does not assume

responsibility for damages while in transit.

Concealed Damage: If there is concealed damage to the equipment, notify the

carrier immediately. Notification should be made verbally as well as in written

form. Request an inspection by the shipping company of the damaged

equipment. Retain all crating material until inspection has been made.

Cancellations & Returns: Cancelled orders and returned merchandise are

subject to a 25% restocking and handling charge. Written authorization is

required for a return of any equipment. All equipment returned must be in it s

original factory crate; freight prepaid and must be in the same condition as

originally shipped by Asber. Returns will only be authorized within 30 days of

invoice date.

Warranty: Register your product with Asber Commercial to validate you

warranty. Service calls must be made directly through Asber service department.

1-(866)-463-2467 or e-mail:

*You may register your product online at http//:www.Asbercommercial.com

servicerequest@Asbercommercial.com

Page 25

ASBER

13105 NW 47th Ave

Miami, Fl. 33054

Phone: (305) 477 1680

http//:www.Asbercommercial.com

Circuito Exportación N° 201

Parque Industrial Tres Naciones

San Luís Potosí, S.L.P. México

C.P. 78395

Teléfono Planta S.L.P.: + 52 (444) 137 0500

Teléfono México D.F.: + 52 (55) 5082 5825

Sin costo: 01 800 00 ASBER

Página Web: www.asberprofessional.com

Loading...

Loading...