Page 1

SALAMANDER/CHEESE MELTER

Manual instructions

Manueltalimatları

Manual de instrucciones

Manuel d’instructions

Bedienungshinweise

Manual do instruções

Ręczny

Obsługaikonserwacja

ES EN

DE TK

FR PT

PL

Manual Instructions

AESB-24, AESB-36, AECM-24, AECM-36,

Installation and Operation

Uso y mantenimiento

Installation und Betrieb

Kurulum ve Çalıştırma

Installation et fonctionnement

Instalação e Operação

Page 2

asberprofessional.com

DOCUMENTCODE:

INDEX

ENGLISH

MACHINE INTRODUCTION ................................................................................................................................ 1

1.1 INTRODUCTION TO MACHINE& MODELS ........................................................................................... 1

1.2 IMPORTANT SAFETY INFORMATION .................................................................................................. 1

1.3 SPECIFICATION CHART ....................................................................................................................... 1

INSTALLATION .................................................................................................................................................. 2

2.1 Transport, handling, unpacking, location ........................................................................................... 2

2.2 Manufacturer’s identification label description ................................................................................. 2

2.3 Installation and assembly .................................................................................................................. 3

2.3.1 UNCRATING ............................................................................................................................... 3

2.3.2 INSTALLATION ........................................................................................................................... 3

2.4 Gas Connections ................................................................................................................................ 4

2.4.1 MANUAL SHUT OFF VALVE ......................................................................................................... 5

2.4.2 PRESSURE REGULATOR .............................................................................................................. 5

2.4.3 THIS APPLIANCE IS EQUIPPED FOR NATURAL GAS. ..................................................................... 5

2.4.4 PRESSURE REGULATOR CONVERSION ........................................................................................ 6

2.5 Location ............................................................................................................................................ 6

2.6 CLEARANCES ..................................................................................................................................... 7

2.1 AIR SUPPLY & VENTILATION............................................................................................................... 7

OPERATION ...................................................................................................................................................... 8

3.1 General information. ......................................................................................................................... 8

3.2 ................................................................................................................................................................ 8

3.3 LIGHTING INSTRUCTIONS .................................................................................................................. 8

3.4 DAILY SHUT-DOWN ........................................................................................................................... 8

MAINTENANCE ................................................................................................................................................. 8

4.1 CLEANING.......................................................................................................................................... 8

4.1.1 DAILY ......................................................................................................................................... 9

4.1.2 STAINLESS STEEL PARTS ............................................................................................................. 9

TROUBLE SHOOTING........................................................................................................................................10

Page 3

BTU’S

10’’ W.C.

BTU’S

5’’ W.C.

MACHINE INTRODUCTION

1.1 INTRODUCTION TO MACHINE& MODELS

All equipment manufactured by ASBER is for use with the type of gas specified on the rating plate

and for installation will be in accordance with National Fuel Gas Code ANSI Z223.1 (latest edition)

Instruction to be followed in the event the user smells gas shall be posted in a prominent location.

This information shall be obtained by consulting the local gas supplier.

PLEASE RETAIN THIS MANUAL FOR FUTURE REFERENCES.

This equipment is design engineered for commercial use only

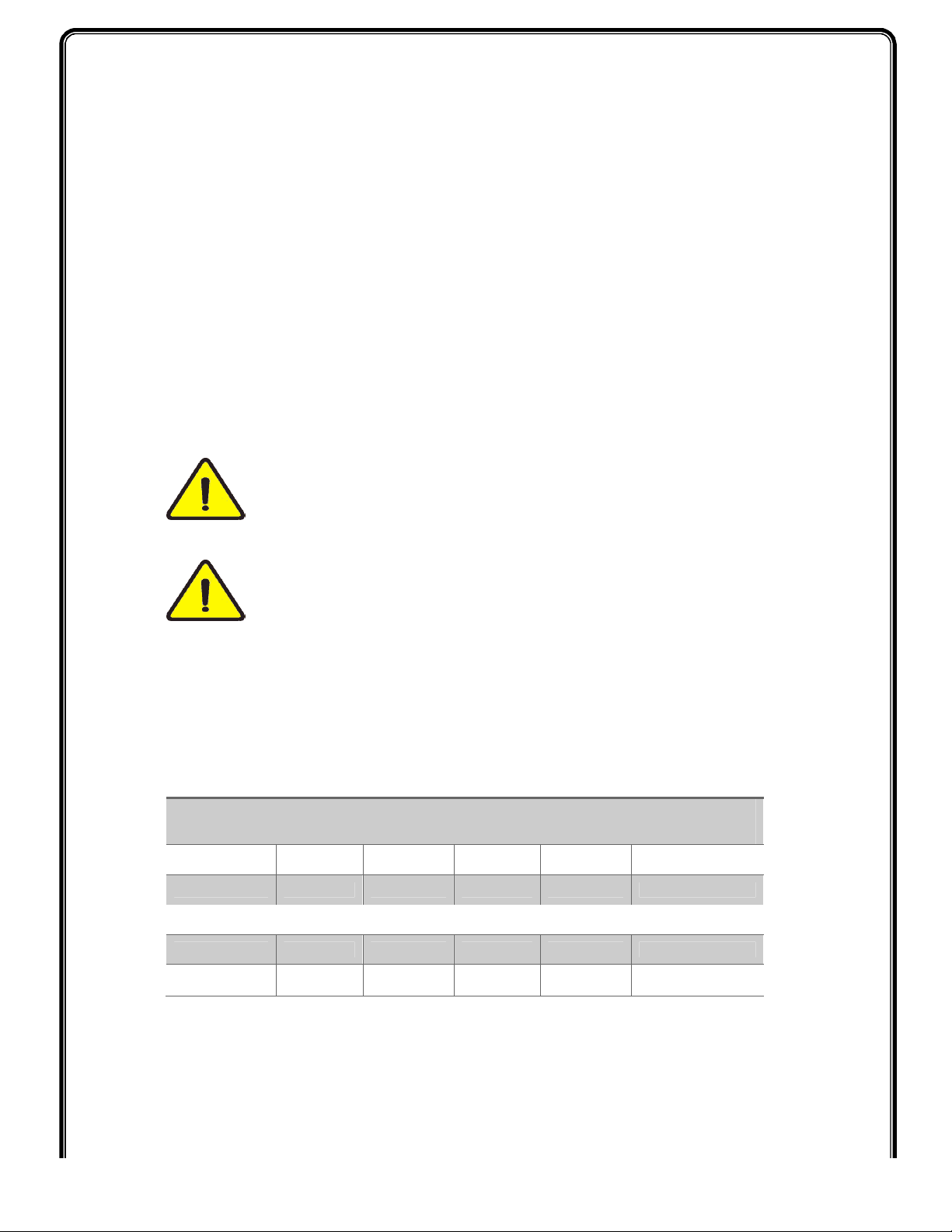

1.2 IMPORTANT SAFETY INFORMATION

WARNING: Improper installation, adjustment, alteration, service or maintenance

can cause property damage, injury or death. Read the installation, operating and

maintenance instructions thoroughly before installing or servicing this

equipment.

FOR YOUR SAFETY: Do not store or use gasoline or other flammable vapors or

liquids in the vicinity of this or any other appliance.

1.3 SPECIFICATION CHART

MODEL

AESB-24 20,000 56 20,000 50 1

AESB-36 40,000 56 40,000 50 1

AECM-24 20,000 56 20,000 50 1

AECM-36 40,000 56 40,000 50 1

LP AT

ORIFICE

SIZE LP

SALAMANDER

CHESSE MELTER

NG AT

ORIFICE

SIZE NG

BURNERS

Page 4

asberprofessional.com

Model

Serial Number

Orifice

INSTALLATION

2.1 Transport, handling, unpacking, location.

2.2 Manufacturer’s identification label description.

2.3 Installation and assembly.

2.4 Gas Connections

2.1 Transport, handling, unpacking, location

Upon receiving your new ASBER Equipment, check the package and the machine for any damages that

may have occurred during transportation. Visually inspect the exterior of the package. If damaged, open

and inspect the contents with the carrier. Any damage should be noted and reported on the delivering

carrier’s receipt.

In the event that the exterior is not damaged, yet upon opening, there is concealed damage to the

equipment notify the carrier immediately. Notification should be made verbally as well as in written form.

Request an inspection by the shipping company of the damaged equipment. Retain all crating material

until inspection has been made. Finally, contact the dealer through which you purchased the unit.

2.2 Manufacturer’s identification label description

Information on this plate includes the model, serial number, BTU / hour input of the burners operating

gas pressure in inches WC, and whether the appliance is orifices for natural or propane gas.

When communicating with factory about a unit or requesting for special parts or information,

Rating plate data is essential for proper identification.

ASBER COOKING APPLIANCES MUST BE CONNECTED ONLY TO THE TYPE OF GAS

IDENTIFIED ON THE RATING PLATE

Gas Type

2asberprofessional.com

Page 5

asberprofessional.com

2.3 Installation and assembly

SHIPPING DAMAGE CLAIM PROCEDURE

The equipment is inspected and crated by skilled personnel before leaving our factory. The

transportation company assumes full responsibility for safe delivery upon acceptance of this equipment.

If shipment arrives damaged:

Visible loss or damage: Note on freight bill or express delivery and signed by person making

delivery.

File claim for damages immediately: Regardless of extent of damages.

Concealed loss or damage: If damage is noticed after unpacking, notify Transportation

Company immediately and file “Concealed Damage “claim with them. This should be done

within (15) days from date of delivery made to you. Retain container for inspection.

2.3.1 UNCRATING

Cut and remove the outer packaging. Cut the (4) clamps that hold the equipment to the skid lift the unit

off the skid.

2.3.2 INSTALLATION

WALL MOUNTING

3asberprofessional.com

Page 6

asberprofessional.com

1. - Place the support to the wall

2. - Put the equipment and use the screw to fasten the equipment to the support.

2.4 G

a

s

C

o

n

n

e

c

t

i

o

4asberprofessional.com

Page 7

asberprofessional.com

2.4 Gas Connections

The gas supply (service) line must be the same size or greater than the inlet line of the appliance.

ASBER appliances use a ¾” NPT inlet.

Pipe joint compound must be resistive to Natural or LP gas.

For equipment using propane gas do not install supply lines with a diameter less than ½ under any

circumstances.

All connections must be tested with a soapy water solution before lighting any pilots.

The appliance shall be connected to the fuel gas for which it was designed. No attempt shall be made to

convert the appliance from the gas specified on the rating plate for use with a different gas without

consulting the installation instructions, the serving gas supplier, or the appliance manufacturer for

complete instructions.

2.4.1 MANUAL SHUT OFF VALVE

This installer supplied valve must be in the gas service line ahead of the appliance regulator in

the gas stream and in a position accessible in the event of an emergency.

2.4.2 PRESSURE REGULATOR

Commercial cooking equipment must have a pressure regulator on the incoming service line for

safe and efficient operation; the gas pressure regulator supplied by ASBER must be installed at

the gas inlet of each piece of equipment.

The regulators supplied along with ASBER appliances, will have 3/4”inlet/outlet openings and

are adjusted at the factory for 5” WC (natural gas) or 10” WC (propane gas) depending on

customer’s ordering instructions.

Prior to connecting the regulator, check the incoming line pressure, as these regulators can only

withstand a maximum pressure of ½” PSI (14”WC). If the line pressure is beyond this limit, a

step down regulator will be required.

The arrow shown on the bottom of the regulator body shows the gas flow direction, it should

point downstream to the appliance. The BLUE air vent cap on the top is part of the regulator

and should not be removed.

Any adjustments to the regulator should be made by qualified service personnel only with the

proper equipment.

2.4.3 THIS APPLIANCE IS EQUIPPED FOR NATURAL GAS.

This appliance is equipped with orifices for operation with natural gas.For conversion to LP

(PROPANE) change the orifice selected in the table according burner type. Orifices necessary

for LP (PROPANE) conversion are provided on accessory box.Gas conversion must be

performed by qualified or authorized personnel

5asberprofessional.com

WARNING: To avoid the risk of serious personal injury or property damage, the range must be

converted correctly. Improper conversion or flame adjustment will produce carbon monoxide,

which is a poisonous gas.

Page 8

asberprofessional.com

A. Remove cap and snap out plastic plunger from bottom of cap.

To convert your range, follow the directions below

1. Check that the main gas supply has been shut off and the power supply cord is

disconnected.

2. Remove main top.

3. Convert pressure regulator. Your range is equipped with a convertible pressure regulator.

To convert, follow the illustrations below for the type of regulator on your range.

2.4.4 PRESSURE REGULATOR CONVERSION

B. Turn plunger over and snap back in original location.

Failure to install the pressure regulator will void the appliance warranty

2.5 Location

• Installation of the equipment should be performed by qualified, certified, and authorized personnel

who are familiar and experienced with local installation codes.

• Before Installation please read instructions completely and carefully.

• Do not remove permanently affixed labels, warnings or plates from the product.

• Please observe all local and national codes and ordinances

• Installation must conform with local codes, or in the absence of local codes, the National

Fuel Gas Code, ANSI Z223.1 (latest edition)

• The appliance must be isolated from gas supply piping system, by closing its individualmanual shut off

valve during any pressure testing of the gas supply piping system at test pressure equal to or less than

½ psi (3.45kpa)

6asberprofessional.com

Page 9

asberprofessional.com

MODEL

NON COMBUSTIBLE

COMBUSTIBLE

2.6 CLEARANCES

The appliance area must be kept free and clear of all combustibles

REAR SIDES REAR SIDES

SALAMANDRA 0Inches 0Inches 4Inches 4Inches

CHEESE MELTER 0Inches 0Inches 4Inches 4Inches

2.1 AIR SUPPLY & VENTILATION

The area in front of, around and above the appliance must be kept clear to avoid any obstruction of the

flow of combustion and ventilation air.

Adequate clearance must be maintained around the appliance for easy servicing. Provision should be

made for any commercial, heavy-duty cooking appliance exhaust combustion waste products to the

outside of the building. Usual practice is to place the appliance under an exhaust hood, which should be

constructed in accordance to the local codes. Strong exhaust fans in this hood or in the overall air

conditioning system can produce a slight vacuum in the room and / or cause air drafts, either of which

can interfere with the pilot or burner performance and could be difficult to diagnose. Air movement

should be checked during installation. Air openings or baffles may have to be provided in the room, if

pilot or burner outage problem persists.

7asberprofessional.com

Page 10

asberprofessional.com

WARINING

OPERATION

3.1 General information.

3.2Lighting Instructions.

3.3Daily Shut-Down.

3.1 General information.

Operation of this equipment must be performed by qualified or authorized personnel who have read and

are familiar with the functions of the equipment.

Hot oil and hot surfaces can cause severe burns. Use caution when operating the fryer.

Do not attempt to move the fryer filled whit hot oil or shortening.

Do not go near the area directly above the flue when fryer is operation.

Severe burns may be caused.

Drain hot oil in metal containers, do not use plastic buckets or glass containers.

3.2 LIGHTING INSTRUCTIONS

· Tum all valves or thermostats to the OFF position.

· Wait 5 minutes.

· Turn main gas supply ON and light pilot valves(s)

· Adjust pilot valve(s) screw counter clockwise more flame, screw clockwise less flame

· Adjust pilot flame ¼ inch high.

· Turn ON gas valve(s) to light main burner.

· For complete shutdown, shut OFF gas valve(s) and turn pilot valve(s) adjusting screw

clockwise to shut off gas to the pilot(s).

3.3 DAILY SHUT-DOWN

At the end of the day, turn the gas tap dial on the combination gas valve and the thermostat to OFF

position. Where applicable turn the power switch to OFF position. Filter the oil in all fryers.

MAINTENANCE

4.1 CLEANING

For continued performance efficiency and longevity of your Fryer it is essential to carry out a good

maintenance program.

8asberprofessional.com

Page 11

asberprofessional.com

4.1.1 DAILY

OPEN BURNERS / HOT PLATES

1. Remove all top grates.

2. Lift off the burners heads and venturies by raising the head slightly, sliding to the

rear andlifting upwards.

3. Wash off the above in hot soapy water.

4. Re-install parts in the reverse order.

GRIDDLES

1. Scrape with a nylon griddle scraper to remove the cooked spills.

When absolutely necessary use a fine grained stone to scrape.

2. Wipe away any griddle stone dust and food particles with burlap.

3. Wash with hot, soapy water, and then rinse with vinegar and water.

4. Rinse again with clear water.

5. Re-oil with shortening or liquid frying compound.

6. DO NOT FLOOD A HOT GRIDDLE WITH COLD WATER. This could cause

warping and griddle plate to crack.

BROILER

1. Remove large pieces of food residue and carefully scrape spillovers from the

drip tray below the cooking surface.

2. Wash all exterior and interior surfaces with hot soapy water solution. Do not use

any abrasives on any portion of the stainless or painted surfaces.

3. Cast iron grates should be scraped frequently with a wire brush and periodically

soaked in hot water solution to remove grease particles.

Never expose the grates to excessive heat for the purpose of burning excess

grease. Thispractice could shorten the useful life of the grates.

9asberprofessional.com

4.1.2 STAINLESS STEEL PARTS

Do not use steel wool, abrasive cloths, cleansers or powders to clean stainless steel surfaces.

All stainless steel parts should be wiped regularly with hot soapy water during the day and a

stainless steel liquid cleaner at the end of the day. To remove encrusted materials, soak in hot

water to loosen the material, and then use a wood or nylon scraper. NOT USE a metal knife,

spatula, or any other metal tool to scrape stainless steel. Scratches are almost impossible to

remove.

Page 12

asberprofessional.com

Pilot will not

a. No gas

a. Turn main gas valve “ON”

Pilot will not

a. Gas

tap dial not depressed

a. Depress and hold for at

Main burners

a. Pilot not lit

a. Light the pilot

Oil/shortening

a. Operating temperature too

a. Set at proper temperature.

Fryer shut

-

off,

a. Hi-limit cut off.

a. Note: cannot re

-

light the

TROUBLE SHOOTING

PROBLEM PROBABLE CAUSE REMEDY

light

stay lit

will not ignite

Fryer does not

heat up fast

b. Gas tap dial not set at “Pilot”

position and depressed.

and held long enough

b. Defective thermopile

c. Pilot flame not properly

adjusted

b. Thermopile not properly

installed in the pilot.

c. Gas tap dial not set at “ON”

position.

d. Thermostat not set at any

temperature.

e. Defective gas valve.

f. Defective hi-limit switch.

a. Insufficient gas.

b. Line clogged

c. Overloading the fryer.

b. Set gas tap dial on

combination gas valve to

“Pilot”. Depress and hold

while lighting.

least 30 sec.

b. Replace

c. Adjust pilot flame whit

pilot adjustment screw on

the combination valve.

b. Push in ad tightens. Pilot

flame should engulf the

thermopile.

c. Turn and set gas tap dial to

“ON” position.

d. Set thermostat to desired

temperature.

e. Replace

f. Replace.

a. Check gas pressure.

b. Remove and clean gas line

c. Cook smaller loads. Need

larger fryer!

scorches and

breaks down.

Temperature

cannot be

controlled

cannot re-light

pilot

10asberprofessional.com

high.

b. Thermostat out of calibration

c. Oil/shortening overused.

d. Oil/shortening not filtered

frequently.

a. Thermostat bulb out of proper

position.

b. Thermostat out of calibration.

c. Defective thermostat.

d. Defective gas valve.

b. Defective thermostat.

c. Thermostat out of calibration.

d. Hi-limit switch defective.

b. Re-calibrate

c. Replace

d. Replace

a. Relocate and secure at the

proper position.

b. Re-calibrate.

c. Replace.

d. Replace.

pilot until temperature of

oil drops to about 325°F.

call service, if uncertain.

b. Replace.

c. Re-calibrate

d. Replace.

Page 13

asberprofessional.com

ASBER

Circuito Exportación N° 201

Parque Industrial Tres Naciones

San Luís Potosí, S.L.P. México

13105 NW 47th Ave

Miami, Fl. 33054

www.asberprofessional.com

MULTI-SOLUTION MANUFACTURER OF FOODSERVICE EQUIPMENT

11asberprofessional.com

Loading...

Loading...