Page 1

AGH41B

OPERATION MANUAL

APPLIANCES

FOR LIVING

Page 2

Congratulations, you are now the proud owner of an ARTUSI cooking appliance. Thank you for purchasing ARTUSI

and welcome to the ARTUSI Family.

This instruction manual has been specially created to inform you of the full range of features your ARTUSI appliance

has to offer and serves as an introduction to getting the very best out of your ARTUSI appliance.

We present detailed information on each of the features your ARTUSI appliance consists of. Once you have read

this section you will be able to choose the most appropriate settings for your appliance when cooking different

types of food.

We ask you to read the instructions in this booklet very carefully as this will allow you to get the best results from

using your appliance. KEEP THE DOCUMENTATION OF THIS PRODUCT FOR FUTURE REFERENCE.

TO REGISTER YOUR PRODUCT WITH ARTUSI, PLEASE FILL OUT THE WARRANTY CARD AT THE END OF

THIS BOOKLET AND POST IT TO: REPLY PAID 83617

LEICHHARDT NSW 2040

Dear Artusi Customer, please read this user manual carefully before using the product and, keep it permanently at

your disposal.

Note: This user manual is prepared for more than one model. Some of the features specified in this Manual may not

be available on your appliance.

All our appliances are only for domestic use, not for commercial use. Products marked with (*) are optional.

“THIS APPLIANCE SHALL BE INSTALLED IN ACCORDANCE WITH THE REGULA TIONS FORCE AND ONLY USED

IN A WELL VENTILATED SPACE. READ THE INSTRUCTIONS BEFORE INSTALLING OR USING THIS APPLIANCE”

“Conforms with the WEEE Regulations.”

Page 3

GENERAL NOTICE

We invite you to read this instruction booklet carefully, before installing and using the equipment.

It is very important that you keep this booklet together with the equipment for any future

If this equipment should be sold or transferred to another person, make sure that the new

user receives the booklet, so that they can learn how to operate the appliance and read the

This appliance complies with the following Directives:

EEC 2016/426/UE (Gas) EEC 2014/30/UE (Electromagnetic Compatibility)

EEC 2014/35/UE (Low Voltage) EEC 2004/1935/CE (Contact with foods)

WARNING

- The installation must be carried out by authorised personnel, in conformity with the regulations in force.

- CAUTION: The surface temperature of underbench components exceeds 95°C. To avoid a hazard,

underbench access must be restricted. Refer to the installation instructions.

- This appliance is not intended for use by persons (including children) with reduced physical, sensory or

mental capabilities, or lack of experience and knowledge, unless they have been given supervision or

instruction concerning use of the appliance by a person responsible for their safety.

- Children should be supervised to ensure that they do not play with the appliance.

- Before powering the equipment, check that it is properly adjusted for the type of gas at disposal (see the

“installation” paragraph).

- If the supply cord is damaged it must be replaced by a special cord or assembly available from the

manufacturer or its service agent.

- Before carrying out the maintenance or cleaning the equipment, cut off power supply and allow it cool

down.

- Make sure that air circulates around the gas equipment. Insufficient ventilation produces a lack of oxygen.

- In case of an intense or prolonged use of the equipment, it may be necessary to improve aeration, for

example by opening a window or increasing rangehood venting power, if it exists.

- The products of combustion must be discharged outside through a suction hood or an electric fan (see

the “installation” paragraph).

- For any possible operation or modification, apply to an authorized Technical Assistance Centre and

demand original spare parts.

- NOT FOR USE IN MARINE CRAFT, CARAVANS OR MOBILE HOMES UNLESS EACH BURNER IS

FITTED WITH A FLAME SAFEGUARD.

- DO NOT SPRAY AEROSOLS IN THE VICINITY OF THIS APPLIANCE WHILE IT IS IN OPERATION.

- DO NOT USE OR STORE FLAMMABLE MATERIALS IN OR NEAR THIS APPLIANCE.

- DO NOT PLACE ARTICLES ON OR AGAINST THIS APPLIANCE.

- DO NOT MODIFY THIS APPLIANCE.

- Not suitable for use with aftermarket lids or covers.

- REMOVE all transit material before installation and use.

consultation.

corresponding notice.

This is a Class 3 appliance.

Servicing shall be carried out only by authorised personnel.

The product label, with the serial number, is fixed to the underside of hob.

An additional label should be adhered to adjacent cabinetry for easy access- refer installation

instructions.

The manufacturer refuses all responsibility for possible damages to things or people, resulting

from incorrect installation or from an improper, incorrect or unreasonable use of this equipment.

2

Page 4

GENERAL NOTICE

CUSTOMER SERVICE

Before calling the customer service:

In case of failure of the plan we raccommend:

- check the correct insertion of the plug into the wall socket;

- check that the gas supply is regular.

If you do not locate the cause of the malfunction:

- switch the appliance of and call your service.

INSTRUCTIONS FOR THE USER

IT IS NECESSARY THAT ALL THE OPERATIONS REGARDING THE INSTALLATION, ADJUSTMENT

AND ADAPTATION TO THE TYPE OF GAS AVAILABLE ARE CARRIED OUT BY QUALIFIED

PERSONNEL, IN CONFORMITY WITH THE REGULATIONS IN FORCE.

THE SPECIFIC INSTRUCTIONS ARE DESCRIBED IN THE BOOKLET SECTION

INTENDED FOR THE INSTALLER

The symbols silk-screen printed on the side of the

knob indicate the correspondence between the

knob and the burner.

Automatic start-up with valves

Turn the correspo nding kno b anticlockwise up

to the maximum position (large flame, fig.1) and

press the knob.

Once the burner has been started up, keep the

knob pressed for about 6 seconds.

Using the burners

In order to obtain the maximum yield without

waste of gas, it is important that the diameter of

the pot is suitable for the burner potential (see the

following table), so as to avoid that the flame goes

out of the pot bottom (fig.2).

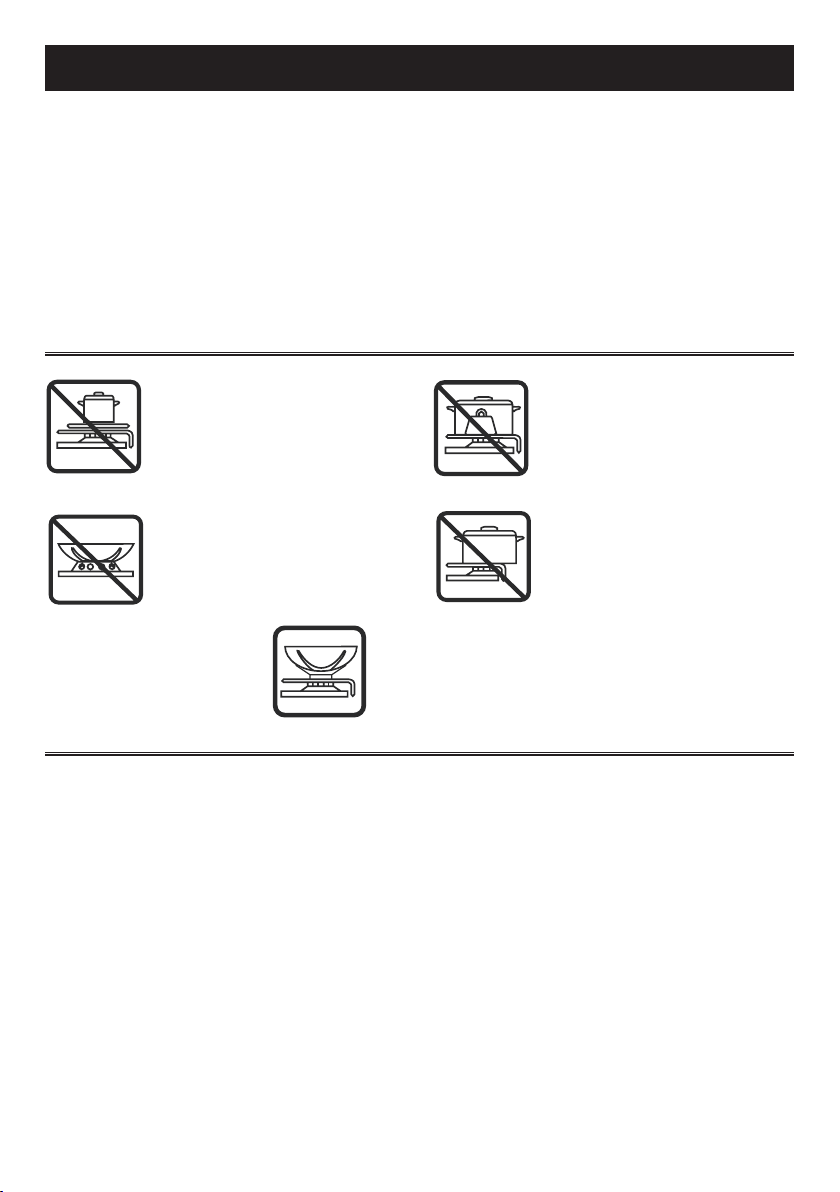

BURNERS

Double

crown

Power (MJ/h)

NG ULPG

28,0 25,0 28 - 30 cm

Ø of

cookware

Use the maximum capacity to quickly make the

liquids reach the boiling temperature, and the

reduced capacity to heat food or maintain boiling.

All of the operating positions must be chosen

between the maximum and the minimum ones,

never between the minimum position and the

closing point.

The gas supply can be interrupted by turning the

knob clockwise up to the closing position.

If there is no power supply, it is possible to light the

burners with matches, setting the knob to the startup point (large flame).

It is important to use cookware with the sizes

specified and ensure the cookware is always

correctly centred over the burner. Using

oversize cookware can potentially cause heat

damage to your benchtop and/or control knobs

which will not be covered under warranty.

3

Page 5

INSTRUCTIONS FOR THE USER

- Notice

- Whe n the equipment is not working, always

check that the knobs are in the closing position

(see fig.1).

- If the flame should blow out accidentally, the safety

valve will automatically stop the gas supply, after

a few seconds. To restore operation, set the

knob to the lighting point (large flame, fig.1).

- While cooking with fat or oil, pay the utmost

attention as these substances can catch fire

when overheated.

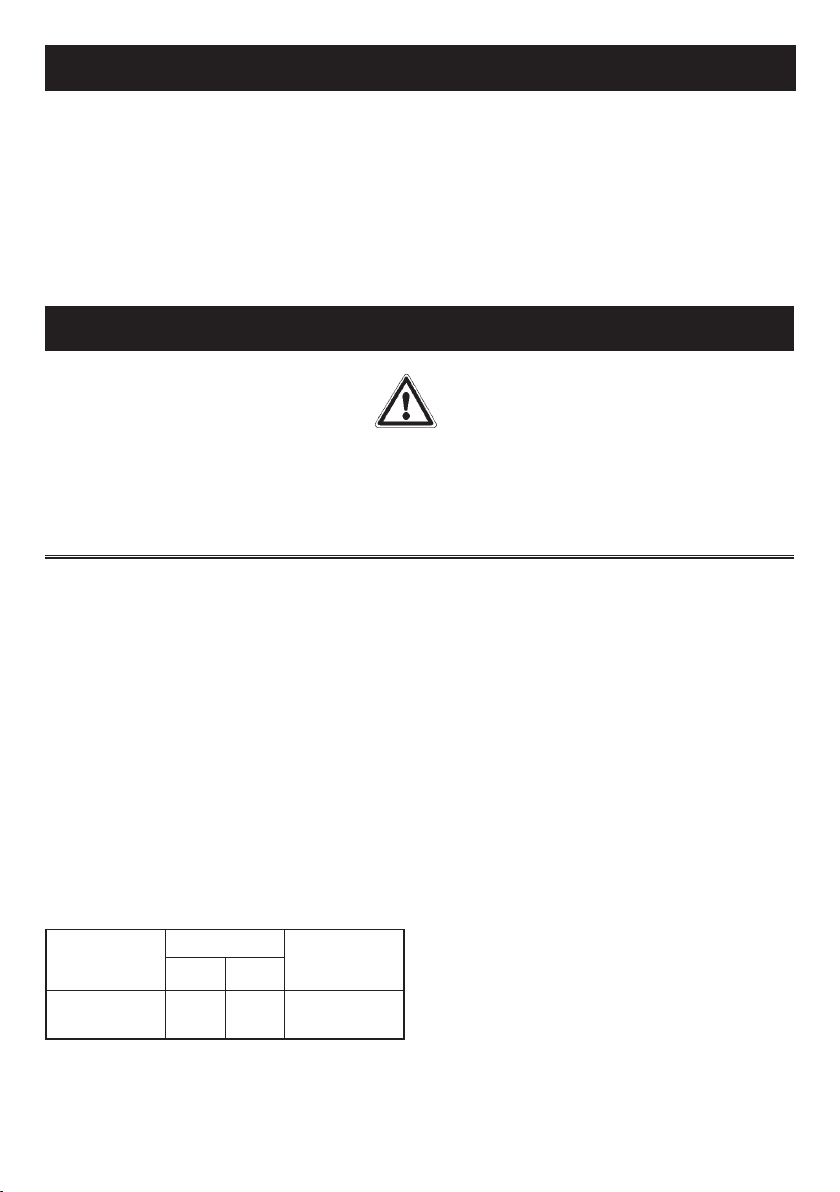

Do not place anything, e.g. flame

tamer, asbestos mat, between pan

and pan support as serious damage to the appliance may result.

Do not remove the pan support

and enclose the burner with a wok

stand as this will concentrate and

deflect the heat onto the hotplate.

Use only a wok support supplied or recommended by the

manufacturer or the appliance.

- Do not use sprays near the appliance in

operation.

- Do not place unstable or deformed pots on the

burner, so as to prevent them from overturning or

overflowing.

- Make sure that pot handles are placed properly.

- When the burner is started up, check that the

flame is regular and, before taking pots away,

always lower the flame or put it out.

D o n ot u se l arg e pots or

heavy weights which can bend

the pan support or deflect

the flame onto the hotplate.

Locate pan centrally over the burner so that it is stable and does

not overhang the appliance.

CLEANING

Before any operation, disconnect the appliance

from the electric grid. Don't use a steam

cleaner for the cleaning the hob.

It is advisable to clean the appliance when it is

cold.

Glass platform and enamelled parts

The glass platform and all of the enamelled parts

must be washed with a sponge and soapy water

or with a light detergent.

Do not use abrasive or corrosive products.

Do not leave substances, such as lemon or tomato

juice, salt water, vinegar, coffee and milk on the

enamelled surfaces for a long time.

Burners and racks

These parts can be removed to make cleaning

easier.

The burners must be washed with a sponge and

soapy water or with a light detergent, wiped well

and placed in their housing perfectly. Make sure

that the flame-dividing ducts are not clogged.

Check that the feeler of the safety valve and the

start-up electrode are always perfectly cleaned, so

as to ensure an optimum operation.

Gas taps

The possible lubrication of the taps must be carried

out by specialized personnel, exclusively.

In case of hardening or malfunctions in the gas

taps, apply to the Customer Service.

4

Page 6

INSTRUCTIONS FOR THE USER

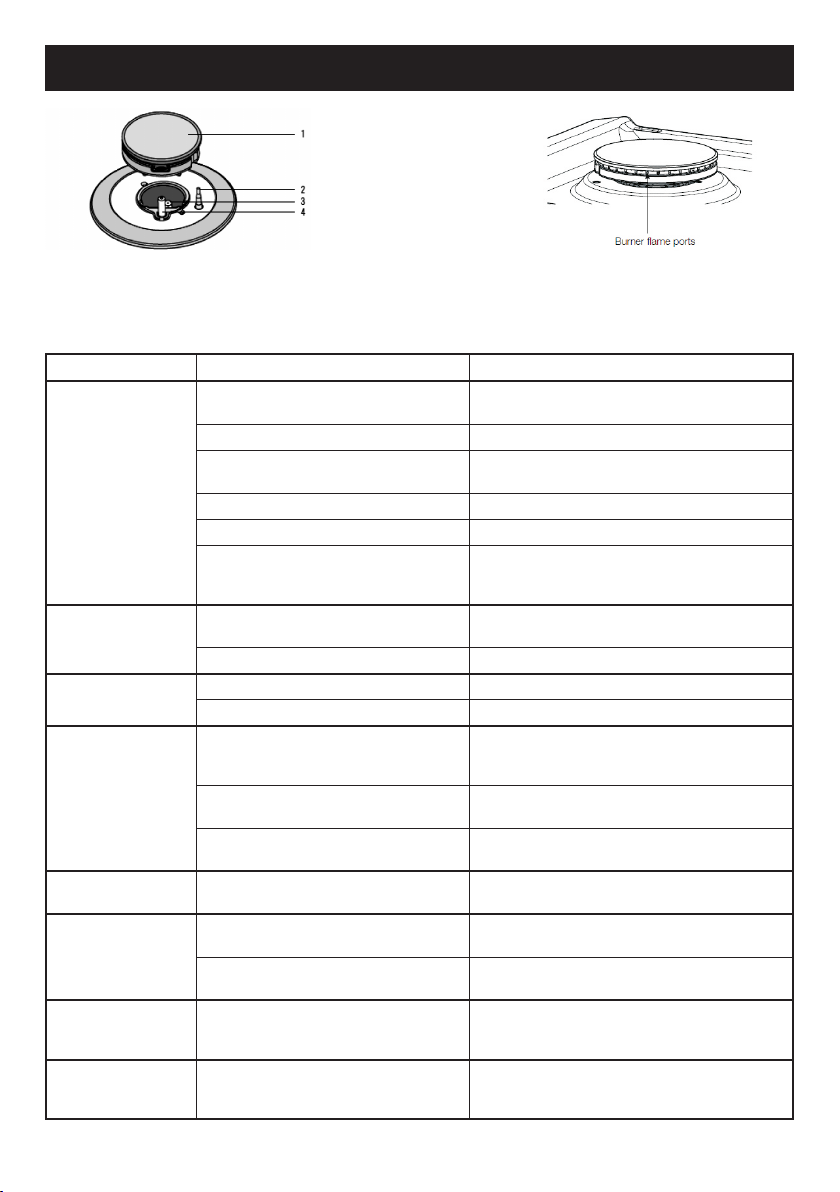

1 Burner 3 Injector

2 Flame safeguard sensor 4 Ignition spark plug

If you have a problem with the cooktop, check the table below. You may be able to solve the problem and this will save

you from paying for a service call. You will have to pay for a service call even in the warranty period if the problem is one

listed below

FAULT POSSIBLE CAUSES REMEDY

Burner will not light

even though the

sparker is working.

No spark is obtained

when control knob is

activated

Flames uneven or

tending to lift

Flames not staying on

when knob released

Low heat, slow

cooking

Benchtop or knobs

overheating

Cooktop stainless

steel discoloured

Outer ring of wok

burner goes out

when set to low

Knob not held down long enough in ‘High’

position for flame safeguard to engage

Gas supply valve turned off Turn on gas supply to appliance

Wrong knob turned Ensure the knob you are turning corresponds to the

Port blockage in ignition area Ensure that ports in ignition area are clean and dry

Ignition spark plugs wet or dirty Dry or clean ignition spark plugs

Injector blocked

El ec tri ci ty su pply is di sc onnec ted o r

switched off"

Ignition spark plugs wet or dirty Dry or clean ignition spark plugs

Flame ports blocked or wet Clean or dry flame ports

Burner incorrectly fitted Ensure this component is fitted correctly

Knob not held down long enough

in ‘High’ position for flame safeguard

(where fitted) to engage

Knob not set between ‘High’ and

‘Low’

Dirt or spillage on flame safeguard

sensor (where fitted)

Incorrect cooking pot or pan being used Refer to table page 3

Incorrect cooking pot or pan used Check table on page 3 for correct pot or pan to be

Pot or pan not located on burner

properly

Pot or pan being is too large Ensure pot sizes used are as per user manual

This is not a failure. This is a function of the

dual wok burner to give a very low power

flame option

Repeat lighting procedure and hold knob down for 6

seconds in ‘High’ position (refer page 3)

burner you want to light

Ensure the injector remains free of any foreign

material. If necessary, use a thin piece of wire to

clear the orifice.

Switch on electricity or check fuses

Repeat lighting procedure and hold knob

down for 6 seconds in ‘High’ position

(refer page 3)

Knob MUST be set between these positions

Clean flame safe guard sensor tip

used

Ensure pot or pan is centrally located

on burner

requirements. Clean with STEEL POWER (available

through spare parts).

No remedy - burner is functioning as intended

If the above points have been checked and there is still a problem with the cooktop, please call the Service Centre.

5

Page 7

INSTRUCTIONS FOR THE INSTALLER

Important notice:

The operations indicated below must be followed by authorised personnel exclusively, in

conformity with the regulations in force.

The manufacturing firm refuses all responsibility for damages to people, animals or things,

resulting from the failure to comply with such provisions.

This appliance shall be installed only by authorised persons and in accordance with the

manufacturer’s installation instructions, local gas fitting regulations, municipal building codes,

electrical wiring regulations, and any other statutory regulations. For Australia and New Zealand

this appliance must be installed by an authorised person in compliance with AS/NZS 5601.1 Gas

installations part 1: general installations, and AS/NZS 5601.2 Gas installations part 2: LP GAS

installations in caravans and boats for nonpropulsive purposes. For outside of Australia/New

Zealand refer to the relevant installation code for gas appliances in your country.

INSTALLATION

The installation kit contains the following:

- 1 natural gas regulator

- 1 elbow

- 1 manifold

- 1 fibre sealing washers

- 4 brackets for assembly

- 4 bracket screws

- 1 pack of cooktop to benchtop seals

- 1 duplicate rating label

Adjacent walls, cupboards and protection for

combustible materials.

Ensure that the appliance is installed in

accordance with clauses 6.2.5 and 6.10.1.1 of AS/

NZS5601.1, or clauses 6.9.1 and 6.9.5 of

AS/NZ S5 601.2 wi th r eg ard t o cl ea rance s

to combustible surfaces and materials, and

clearances to rangehoods and exhaust fans.

Clearance of 200mm from the periphery of

bu rners to vert ic al combu st ible sur fa ces is

requir ed. Clearances to combustibl e surfaces

may be reduced only if combustible surfaces are

protected in accordance with clause 6.10.1.2 of

AS/NZS5601.1, or clause 6.9.2 of AS/NZS5601.2.

For conversion to ULPG

- 1 Universal LPG sticker

- 1 injectors

Additional accessory for cooking with vessel s

diameter 120mm or below

- 1 mini trivet

- 1 wok trivet

Installing the top

The appliance is designed to be embedded into heatresistant benchtop capable of withstanding 95°C.

minimum distance of at least 50 mm from the back

edge of the installed device and 100 mm of the

adjacent side walls.

Rangehoods and exhaust fans* shall be installed

in accordance with the manufacturer’s relevant

instructions. However, in no case shall the

clearance between the highest part of the hob

of the gas cooking appliance and a range hood

be less than 600mm or, for an overhead exhaust

fan, 750mm. (*An exhaust fan is defined as a

mechanical device other than a rangehood for

moving air from one interior space to another, or

to outside of the space) Refer (fig. 4).

Th e eq ui pment must n ot be in st alled n ear

inflammable materials, such as curtains,

cloths,etc. Make a cut out in the benchtop, with

the dimensions indicated in fig.3, respecting a

6

Page 8

INSTRUCTIONS FOR THE INSTALLER

IMPORTANT:

A separation pa nel at least 10m m from the

bottom of the cooktop must be included during

installation to prevent access to the underside

of the appliance. This panel can be made of any

non-combustible rigid material.

If the hob is going to be installed on the top of an

oven, precautions must be taken to guarantee an

installation in accordance with current accident

prevention standards. Pay particular attention to

the position of the electric cable and gas pipe: they

must not touch any hot parts of the oven.

Moreover, if the hob is going to be installed on

the top of a built in oven without forced cooling

ventilation, proper air vents must be installed to

guarantee an adequate ventilation, with the lower

air entering with a cross section of at least 200cm2,

and the higher air exiting with a cross section of at

least 60 cm2.

Fastening the top

Every cook-top is equipped with a special washer.

A set of hooks is also su ppl ied for mounting the

cook-top.

Depending on the type of mounting surface, the

suitable type of mounting hook is supplied (hook A

or hook B).

For the installation proceed as follows:

- Remove all loose components from the top.

- Turn the appliance upside down lay it's edges on

foam packaging blocks to prevent damage to the

ignition spark plugs and lay the seal S along the

external border (fig. 5).

- Introduce and place the cook-top in the hole

made in the piece of furniture, then fasten it

with the screws and fastening brackets supplied

(fig.6).

WARNING: Failure to fix the cooktop to the bench

could result in loosening of the gas connection

through movement of the cooktop and a gas leak

may result.

A duplicate rating label is included with these

instructions. Ensure this is attached to a readily

accessible surface, so that the cooktop can be

easily identied in the case of a service call.

INSTALLATION ROOM

This appliance is not provided with a device for

exhausting the products of combustion.

Therefore, it is necessary to discharge these

outside.

The room where this appliance is installed

must have a natural air inflow, so as to ensure

a regular gas combustion and room ventilation:

the necessary air volume must not be lower than

20m3.

Air must come from permanent openings made on

the room walls that communicate with the outside.

The section of these openings shall correspond to

at least 200 cm2.

OPERATION ON N.G / S.N.G.

Regulator

An appliance regulator is provided. The regulator

must be positioned so that the pressure test nipple

is accessible when the appliance is installed.

Connect the gas supply to the 1/2" B.S.P. internal

thread inlet of the regulator. Refer to page 9 for

connection point position.

Regulators are supplied pre-adjusted and

configured by the component maker for use with

Natural Gas. The appliance installer is not required

to make an adjustment to obtain the correct outlet

pressure setting.

An arrow on the base of the regulator indicates

the direction of gas flow when the inlet and outlet

of the regulator is orientated correctly. When the

regulator has been fitted check for leaks from the

connections with soapy water.

Gas Connection

This appliance is supplied for use with Natural

Gas. However, it can be converted for use with

LPG. Refer to LP conversion chapter.

Supply pipe sizing

The total hourly gas consumption for the appliance

is shown on the data label. The required supply

pressure (i.e. at inlet to appliance regulator) for

each gas type is shown on the data label, and

given in page "TECHNICAL CHARACTERISTIC

TABLES". Use this information in conjunction with

the length of run, number of elbows, tees and

bends, the available service pressure and the

supply requirements of other installed appliances

to determine a suitable pipe size. For assistance

in this matter refer to the appropriate section of the

Installation Code AS/NZS5601.

7

Page 9

INSTRUCTIONS FOR THE INSTALLER

Only install with a hose assembly that complies

with AS/ANZ 1869 (AGA Approved), 10mm ID,

class B or D, no more than 1.2m long and in

accordance with AS/NZS 5601. and in particular

section 4.8. Where a hose assembly is used and

the cooktop is in the installed position, the hose

assembly shall be suitable for connection to a fixed

consumer piping outlet located at a point 800 850mm above the floor and in the region outside

the width of the appliance to a distance of 250mm.

The point of connection to consumer piping must

be accessible with appliance installed.

Elbow positioning

It is possible to reposition the elbow if required by

loosening the locking nut and elbow by using two

spanners. Re-tighten the entire assembly after the

elbow has been repositioned. When fitting elbow to

appliance, ensure that the sealing washer is fitted.

Regulator

An appliance regulator is provided. The regulator

must be positioned so that the pressure test nipple is

accessible when the appliance is installed. Connect

the gas supply to the ½” B.S.P. internal thread inlet

of the regulator. Refer page 10 for connection point

position.

Assembly of Regulator

The assembly of the regulator to the cooktop

manifold is achieved via the elbow union and

sealing washersupplied.

The ½” parallel thread connects to the manifold, and

the sealing washer is placed between the manifold

end and the flat face on the elbow.

The ½” tapered thread connects to the outlet of the

regulator, and is sealed on the thread using

approved thread sealing tape or approved thread

sealing compound.

The inlet of the regulator is a ½” parallel thread and

is connected to consumer piping or hose assembly.

Regulators are supplied pre-adjusted and

configured by the component maker for use with

Natural Gas.

The appliance installer is not required to make an

adjustment to obtain the correct outlet pressure

setting.

An arrow on the base of the regulator indicates the

direction of gas flow when the inlet and outlet of the

regulator is orientated correctly. When the regulator

has been fitted check for leaks from the connections

with soapy water.

Checking the gas supply

1. Check the manometer zero point is correct.

2. Connect the manometer to the cooktop

pressure point. This is located on the

regulator.

3. Turn on the gas supply and electricity and try

to ignite the gas. NOTE! lt will take additional

time to light the gas for the first time as air

needs to be purged from the pipes.

4. With the appliance operating check the outlet

pressure

5. when all burners of the appliance are

operating at maximum,

6. when the smallest burner of the appliance is

operating at minimum.

Under these conditions the outlet pressure should

not vary from the nominal outlet pressure of

1.00kPa by more than ± 0.20kPa

If th e reg ula to r app ear s to no t per for m

satisfactorily, then check the following points:

1. If the outlet pressure is consistently too low

then the inlet pressure may be too low and

adjustment of an upstream regulator may be

needed, or an upstream regulator or valve

with insufficient flow capacity may be present

in the gas supply line. If this is suspected then

it may be necessary to repeat fhe checks

whilst measuring both the inlet and outlet

pressure to determine if the inlet pressure is

in the range 1.13 - 5kPa.

2. Check that the regulafor has been fitted to the

gas supply line in the correct orientation, the

arrow on the base of the body indicates the

direction of gas flow.

Once these checks have been completed, if the

regulator still fails to perform in a satisfactory

manner it should be replaced.

Electrical connection

The appliance is supplied with a standard 10

Amp service cord terminated by a 3-pin plug for

connection to a standard household socket. The

electrical supply is required to power the electronic

ignition system.

NOTE: It will be necessary for servicing purposes

to disconnect the electrical power supply. The

power point should therefore be accessible after

the appliance is installed, as specified in the local

wiring regulations.

TESTING APPLIANCE OPERATION

After installation the installer must fully test the

appliance and ensure it operates correctly before

handing it over to the customer.

8

Page 10

GAS TRANSFORMATIONS AND ADJUSTMENTS

GAS CONVERSIONS AND ADJUSTMENTS

Data Label

A duplicate Data Label is supplied to adhere in an

accessible area next to the appliance.

This appliance is suitable for Natural Gas and

Universal LPG; en sure that the available gas

supply matches the Data Label.

When converting from Natural Gas to Universal

LPG ensure that the NG regulator is removed

and replaced with the Test Point Assembly. An

AGA Approved gas regulator suitable for a supply

pressure of 2.75kPa should be part of the gas

tank supply and the test point pressure should be

adjusted to 2.75kPa.

Replacing double crown burner nozzle

If the equipment is adjusted for a type of gas that is

different from the one available, it is necessary to

replace the burner injectors.

The choice of the injectors to replace must be

made according to the table of the “technical

characteristics” as enclosed.

To replace the nozzle is necessary to remove the

glass or open the panel under the hob (fig.7):

- Remove the nozzle "U" (see picture below) and

insert the new nozzle with the diameter specified

in the "TECHNICAL CARACTERISTIC TABLES".

- Adjust the air by loosening the screw on the door

venturi tube (fig.8). Once loosened the screw

you can proceed to the venturi air adjustment as

explained in the table (dimension "A").

After changing the injector, it is necessary to

eliminate residual natural gas in the system.

To do this you have to turn to the maximum

position then press the knob of each burner and

wait few seconds.

Adjusting the burners

The lowest flame point must always be properly

adjusted and the flame must remain on even if

there is an abrupt shift from the maximum to the

minimum position.

If this is not so, it is necessary to adjust the lowest

flame point as follows:

- start the burner up

- turn the tap up to the minimum position (small

flame)

- remove the knob from the tap rod

- introduce a flat-tip screwdriver in the hole F of

the tap (fig.8) and turn the by-pass screw up to a

proper adjustment of the lowest flame point.

As regards U-LPG gas burners, the by-pass

screw must be tightened completely.

WARNING !!

AL L GAS TR AN SF OR MAT IO NS MUST B E

CARRIED OUT ONLY BY AUTHORISED

PERSONNEL

ADJUSTMENT

AIR

DOUBLE RING

GAS

Natural Gas 8

ULPG 13

SETTING

mm (A)

U

9

Page 11

MAINTENANCE

Maintenance Schedule

No regular maintenance is required for the hotplates except cleaning.

Replacing the power supply cable

If the power supply cable should be replaced, it is necessary to use a cable with a section of 3x0.75mm2,

type H05VV-F or H05RR-F, complying with the regulations in force.

The connection to the terminal board must be effected as shown in fig.11.

brown cable L (phase)

blue cable N (neutral)

green-yellow cable (ground)

11

TECHNICAL CARACTERISTIC - TABLES

1

8

MODEL:

AGH41B

Depth of cooktop casing

from benchtop surface : 130 mm

NG Universal LPG

1 Double ring burner 28.0 MJ/h 25.0 MJ/h

8 Control knob for burner

BURNERS

N° DESCRIPTION KPa 1/100 mm 1/100 mm

DOUBLE

1

CROWN

GAS

Universal LPG 2.75 1,40 60 25,0

Natural 1.00 2,50 Adjust. 28,0

NORMAL

PRESSURE

INJECTOR

DIAMETER

10

TAPE BY

PASS

DIAMETER

NOMINAL

HEAT INPUT

(MJ/h)

Page 12

Maximum

Close

350

Minimum

1 2

495

3 4

5 6

SCREW ADJUSTMENT

TUBE VENTURI

A

7 8

11

Page 13

C

B

A

9 10

WIRING DIAGRAM

MODEL: AGH41B

The manufacturing firm refuses all responsibility for any possible imprecision in this booklet, due to

misprints or clerical errors. It reserves the right to make all the changes that it will consider necessary in

its own products, without affecting the essential characteristics of functionality and safety.

12

Page 14

13

Page 15

FOR SPARE PARTS OR TO FIND THE ADDRESS OF

YOUR NEAREST STATE SPARE PARTS CENTRE IN AUSTRALIA

Distributes by Eurolinx pty Ltd

Street: 48-50 Moore Street, Leichhardt N.S.W 2040

Suburb / City: SYDNEY

State / Country:

Postcode: 2040

Telephone: +1 300 85 64 11

14

Page 16

Warranty Card

Worldwide Appliances Pty Limited

A.B.N. 45868077422

Oce:

48-50 Moore Street, Leichhardt N.S.W 2040

Post:

Locked Bag 3000, Annandale, N.S.W 2038

P: 1300 694 583

WARRANTY REGISTRATION

Your ongoing satisfaction with your artusi

product is important to us. We ask that you

complete the enclosed Warranty Registration

Card and return it to us so that we have a record

of the artusi product purchased by you.

PRIVACY

Worldwide Appliances respects your

privacy and is committed to handling your

personal information in accordance with the

National Privacy Principles and the Privacy

Act 1988 (Cth). A copy of the Worldwide

Appliances Privacy Policy is available at

www.artusi.com.au. Worldwide Appliances will

not disclose any personal information set out

in the Warranty Registration Card (“Personal

Information”) without your consent unless

required by:

1. law;

2. any Worldwide Appliances related company;

3. any service provider which provide services

to artusi or assist artusi in providing services

(including repair and warranty services) to

customers. Our purpose in collecting the

Personal Information is

to keep a record of the artusi product purchased

by you, in order to provide a better warranty

service to you in the unlikely event that there is

a problem with your artusi product. Worldwide

Appliances may contact you at any one or more

of the address, email address or telephone

numbers set out in the Warranty Registration

Card. Please contact artusi on 1300 694

583 should you not wish to be contacted by

Worldwide Appliances.

WARRANTY

1. Warranty

Worldwide Appliances warrants that each artusi

product will remain, for a period of either 12

months or 24 months of warranty. All Warranties

are valid from the original date of purchase, And

warranty claims must be accompanied by the

proof of purchase.

24 months warranty products:

All Built-in Appliances – Limited to Ovens,

Gas, Induction and Electric Cooktops, and All

Rangehoods

Freestanding Cookers - Gas and Electric Models

(900mm Width)

artusi.com.au

Dishwashers - Freestanding, Fully Integrated,

Semi Integrated and built-in

12 months warranty products:

Freestanding Cookers - Gas and Electric Models

in 50cm, 54cm and 60cm Widths

Portable Appliances* – Benchtop Models and

Portable Gas Models

2. What is not Covered by the Warranty.

The Warranty does not apply if an artusi product

is defective by a factor other than a defect arising

in the manufacture of the artusi product, including

but not limited to:

(a) damage through misuse (including failure

to maintain, service or use with proper care),

neglect, accident or ordinary wear and tear

(including deterioration of parts and accessories

and glass breakage);

(b) use for purpose for which the artusi product

was not sold or designed;

(c) use or installation which is not in accordance

with any specied instructions for use or

installation;

(d) use or operation after a defect has occurred or

been discovered;

(e) damage through freight, transportation or

handling in transit (other than when Worldwide

Appliances is responsible);

(f) damage through exposure to chemicals, dusts,

residues, excessive voltage, heat, atmospheric

conditions or other forces or environmental

factors outside the control or Worldwide

Appliances;

(g) repair, modication or tampering by the

purchaser or any person other than Worldwide

Appliances, an employee of Worldwide

Appliances or an authorised artusi service

contractor*;

(h) use of parts, components or accessories

which have not been supplied or specically

approved by artusi.

(i) damage to surface coatings caused by cleaning

or maintenance using products not recommended

in the artusi product handbook provided to the

purchaser upon purchase of the artusi product;

(j) damage to the base of an electric oven due to

items having been placed on the base of the oven

cavity or covering the base, such as aluminium

foil (this impedes the transfer of heat from the

element to the oven cavity and can result in

irreparable damage); or

(k) damages, dents or other cosmetic

imperfections not aecting the performance of the

artusi in respect of an artusi product purchased

as a “factory second” or from display

The Warranty does not extend to light globes

used in artusi products.

3. Domestic Use

Each artusi product is made for domestic use.

This Warranty may not extend to artusi products

used for commercial purposes.

Continued over...

Page 17

Warranty Card continued

artusi.com.au

4. Time for Claim under the Warranty

You must make any claim under this Warranty

within twenty eight (28) days after the occurrence

of an event which gives rise to a claim pursuant

to the Warranty, by booking a service call on the

telephone number below.

5. Proof of Purchase

Customers must retain proof of purchase in order

to be eligible to make a warranty claim in respect

of an artusi product.

6. Claiming under the Warranty

Customers will bear the cost of claiming under

this Warranty unless Worldwide Appliances

determines the expenses are reasonable, in which

case the customer must claim those expenses

by providing written evidence of each expense

to Worldwide Appliances at the address on the

Warranty Registration Card.

7. Statutory Rights

(a) These terms and conditions do not aect your

statutory rights.

(b) The limitations on the Warranty set out in this

document do not exclude or limit the application

of the consumer guarantees set out in the Act or

any other equivalent or corresponding legislation

in the relevant jurisdiction where to do so would:

(i) contravene the law of the relevant jurisdiction;

or

(ii) cause any part of the Warranty to be void.

(c) Worldwide Appliances excludes indirect or

consequential loss of any kind (including, without

limitation, loss of use of the artusi product) and

(other than expressly provided for in these terms

and conditions) subject to all terms,

conditions and warranties implied by custom, the

general law, the Act or other statute.

(d) The liability of Worldwide Appliances to you

Warranty Card tear off

for a breach of any express or non-excludable

implied term, condition or warranty is limited at

the option of Worldwide Appliances to:

(i) replacing or repairing the defective part of the

artusi product;

(ii) paying the cost of replacing or repairing the

defective part of the artusi product;

(iii) replacing the artusi product; or

(iv) paying the cost of replacing the artusi

product.

(e) Our goods come with guarantees that cannot

be excluded under the Australian Consumer

Law. You are entitled to a replacement or refund

for a major failure and for compensation for any

other reasonably foreseeable loss or damage.

You are also entitled to have the goods repaired

or replaced if the goods fail to be of acceptable

quality and the failure does not amount to a

major failure.

8. Defects

Any part of an artusi product deemed to be

defective and replaced by Worldwide Appliances

is the property of Worldwide Appliances.

Worldwide Appliances reserves the right to

inspect and test artusi products in order to

determine the extent of any defect and the

validity of a claim under the Warranty.

*To locate your closest artusi authorised service

agent please contact us on 1300 652 100 or visit

www.artusi.com.au

ALL SERVICE CALLS MUST BE BOOKED

THROUGH AN AUTHORISED DEALER OR

WARRANTY DEPARTMENT ON 1300 652 100

OR stokesaps.com.au/artusi-service

01032014

WARRANTY REGISTRATION CARD

01052013

Last Name: First Name:

Address:

State: Postcode: Email:

Home Phone: Mobile:

Purchase Date: / / (Please attach proof of purchase to validate warranty)

MODEL NUMBER

1

2

3

4

Please complete and send to ARTUSI at: REPLY PAID 83617

LEICHHARDT NSW 2040

SERIAL NUMBER

(if you cannot locate the serial number please call ARTUSI on 1300 694 583)

01032014

4

Page 18

Page 19

DISCLAIMER

Worldwide Appliances PTY LTD, trading as ARTUSI, is continually seeking ways to improve the design specifications, aesthetics and production

techniques of its products. As a result alterations to our products and designs take place continually. Whilst every effort is made to produce

information and literature that is up to date, this brochure should not be regarded as an infallible guide to the current specifications, nor does it

constitute an offer for the sale of any particular product. Product dimensions indicated in our literature is indicative only. Actual product only

should be used to define dimension cutouts. Distributors, and retailers are not agents of ARTUSI and are not authorised to bind ARTUSI by any

express or implied undertaking or representation.

ARTUSI OFFICES ARE OPEN DAILY FROM 9AM–5PM AND SATURDAYS 10AM–4PM

NSW & ACT (HEAD OFFICE)

48-50 MOORE STREET

LEICHHARDT

F 02 8569 4699

P: 13 00 6 49 5 83

VIC, TAS & SA

1211 TOORAK ROAD

CAMBERWELL

F 03 9809 2155

QLD

1/42 CAVENDISH ROAD

COORPAROO

F 07 3397 0850

WA & NT

UNIT 10/55 HOWE STREET

OSBORNE PARK

F 08 9201 9188

NZ

PO BOX 11.160

SOCKBURN CHRISTCHURCH

F 03 344 5906

ARTUSI.COM.AU

Loading...

Loading...