Page 1

••

Arri

Manual

35B

.L

INSTRUCTION MANUAL

Page 2

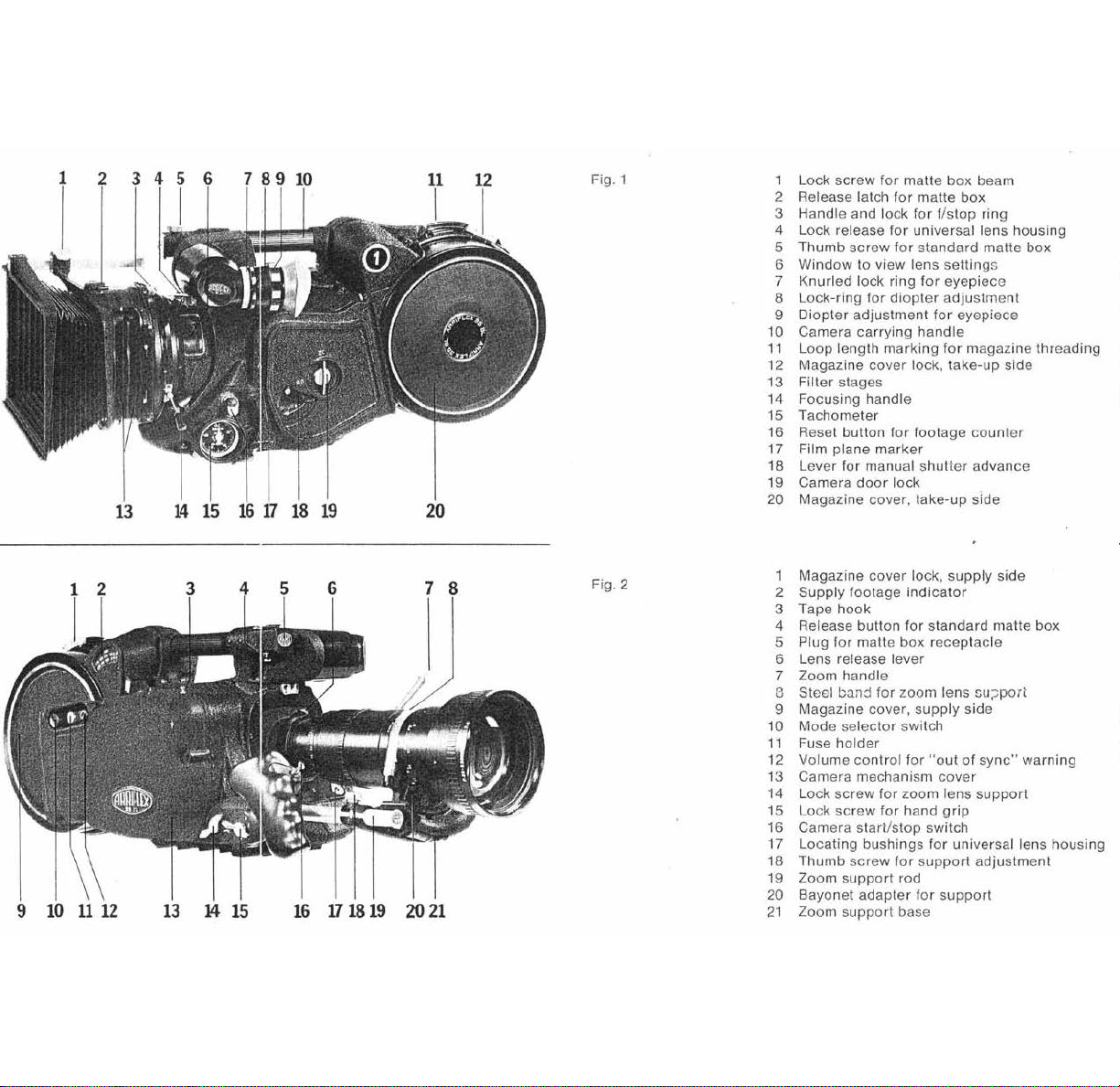

Fig.1

1 Lock

2 Release latch t

3 Hand le and lock for

4 Lock release

5 Thumb screw

6

7 Knurled lock ring

8 Lock-ring t

9 Diopte r adjustment

10 Camera carrying handle

11

12

13 Filter stages

14

15

16

17 Film plane

18

19

20

screw for matte box beam

Window

Loop length marking

Magazine cover lock, take-up side

Focusing hand le

Tachometer

Reset button for footage

Lever

for

Camera

Magazine cover, take-up side

or

matte

!/stop

for

universal lens housing

tor

to view lens

door

standard

sailings

for

diopter

lock

eyepiece

adjustment

for

eyepiece

for

or

marker

manual shutter advance

box

ring

malle

box

magazine threading

counter

Fig. 2

9

10

1112

13 14

15

16

17

18

19

20

21

1 2 Magazine cover lock,

Supply rootage

3 Tape hook

4 Release

5 Plug

6 Lens release

7 Zoom handle

B Steel

9 Magazine cover, supply side

10

Mode selec

11

Fuse

12

Volume contr

13

Camera mechanism

14

Lock screw f

15

Lock

16

Camera start/stop switch

17

Locat

18 Thumb screw for support adjustment

Zoom

19

20

Bayonet adapter

21

Zoom support base

bullon

for

malle

lever

b:1nd

for

tor

holder

ol

or

screw

for

ing bushings

support rod

supply

indicator

for

standard matte box

box receptacle

zoom

lens su;;port

switch

for "out of

cover

zoom lens support

hand grip

for

tor

support

side

sync"

universal lens housing

warning

Page 3

Content

s

Page

Magazine

Camera threading

Aperture

Ground

Mounting

Mount

Standard matte

Universal

Focus

Filters

Camera

Electronic/electrical

Camera speed selecti

Pil otone

El

ectronic

Preventive maintenance and

Cleaning

Lubrication

Other

Repl

Replacement

Maintenance

Magazine

Removal

Checking

Adjus

load

ing

plate

replacement

glass replacement

lenses

witho

ing lens

and

lubrication

acing

ting

support

box

hous

ing

f/stop

scales

power

connection

and

start

accessor

of

aperture plate

of

film

points

signal lamps

of electrical

of

the magazine

guide

roll

of

the camera mechanism cover

drive

belt

of

the drive belts

ut housing

brackets '

for fixed lenses

for

fixed lenses

features

on

marking system

ies

transport

fuses

ers

for high speed operation

tension

minor

and

film channel

mechani

service:

sm

3/4

4/5

6/7

10

10

11

11

11

/12/13

13

13/14

14/15/16

16

16/17

17/18

18

20/21

21/22

22

22

22

22/24/25

6

7

8

8

Page 4

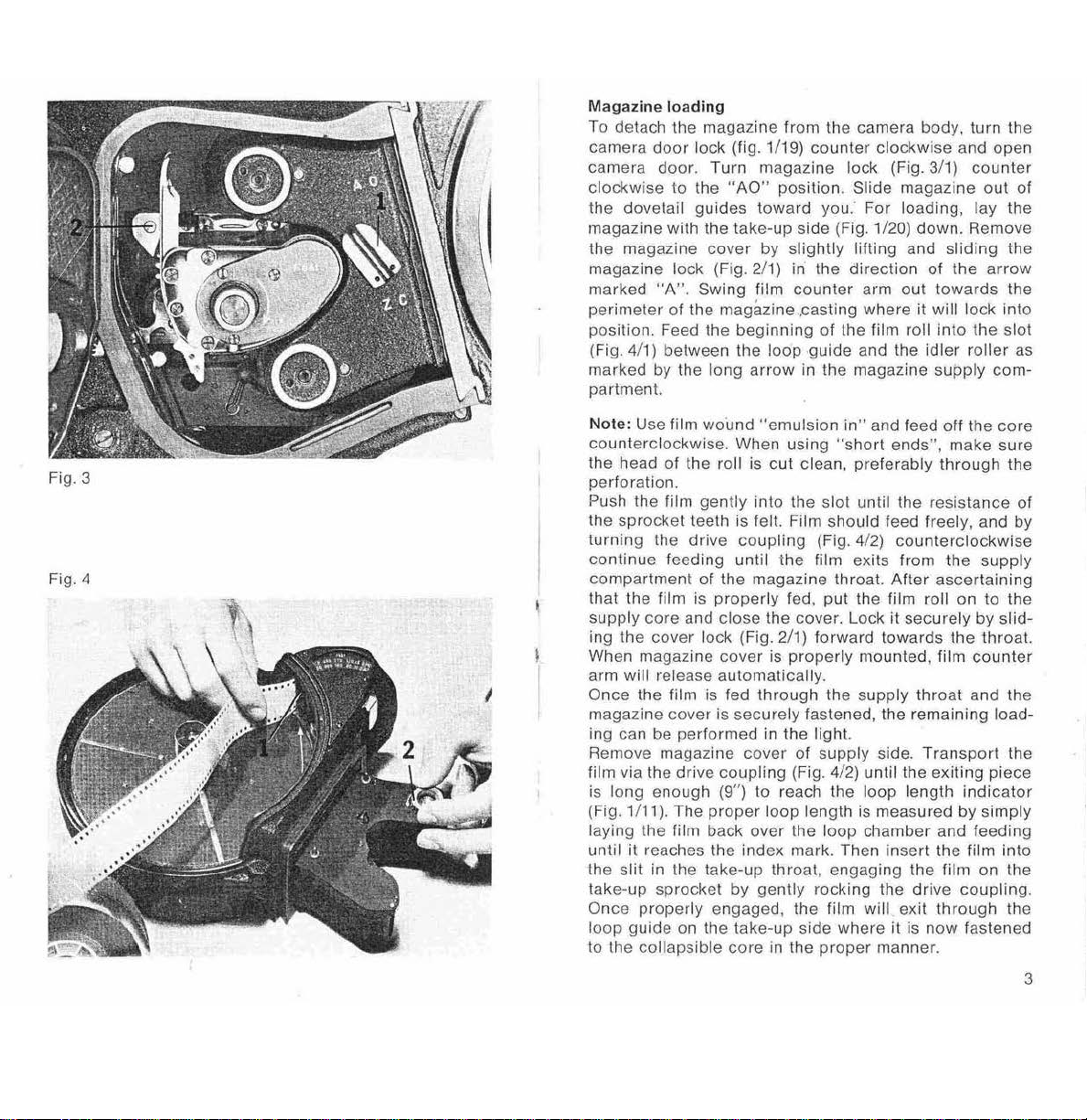

Magazine

loading

To detach the magaz ine from the camera body, turn the

camera

camera

clockwise to the

the dovetail guides

magazine with the take-up

the magazine

magazine

marked

perimeter

position. Feed the

(Fig. 4/

marked by the

partmen

door

lock (fig. 1/19)

door. Turn

magazine lock (Fig. 3/1)

"AO"

position. Slide magazine

toward

side (Fig. 1/20)

cover

by

slightly lifting

lock

(Fig. 2/1) in the

"A".

Swing film

of

the magazine .. casting where

counter

beginning

1)

between the

long

loop .guide

arrow

in the magazine supply

t.

counter

clockwise

you

.'

For loading, lay the

and

direction

arm

out

of

the film roll

and

the

and open

counter

down.

Remove

sliding

of

the

towards the

it

wi ll l

ock

into

the

idler

roller

out

the

arrow

into

slot

com-

of

as

Fi

g.

Fig. 4

Note: Use film wo'

counterc

the head

3

perforation.

lockwise. When using

of

Push the film

the sprocket teeth is fe l

turning the

continue

feeding until

compartment

that the film is

supply

ing the

core

cover Jock

When magazine

und

"emulsion

the roll is

gently

drive

cut

into the

t.

Film should feed freely,

coupling

the

of

the magazine throat.

proper

ly fed,

and

close

the cover. Lock it securely

(Fig. 2/1)

cover

is

properly

in"

and feed

"short

clean, preferably

slot

until the resistance

ends",

off

the

make

through

and

(Fig. 4/2)

counterclockwise

film exits from the supply

After

ascertaining

put

the film

roll

on

to the

by

forward

towards the throat.

mounted, fil m

counter

core

sure

the

of

by

slid-

arm will release automatically.

Once

the film is fed

magazine cover is

ing can

be

performed in the light.

Remove magazine

film via the

drive

is long enough (9") to reach the

(Fig.1 /11). The

laying the film back over the

until

it

reaches the i

the

slit

in the take-up throat, engaging the film

take-up sprocket

Once properly engaged, the film wi ll exit

loop

guide

on the take-up

to the

collapsible

secure

cover

coupling

proper

ndex

by

core

through

the supply thro at

ly fastened, the remaining

of

supply side.

(Fig. 4/

2)

until the exiting

loop

length

loop

length

is measured

loop

chamber

mark. Then Insert the fi lm

gently

rocking the drive

side

where

in the

proper

it

is

manner.

and

Transport

piece

indicator

by

simply

and

feeding

on

coupling.

through

now

fastened

the

load-

the

into

the

the

3

Page 5

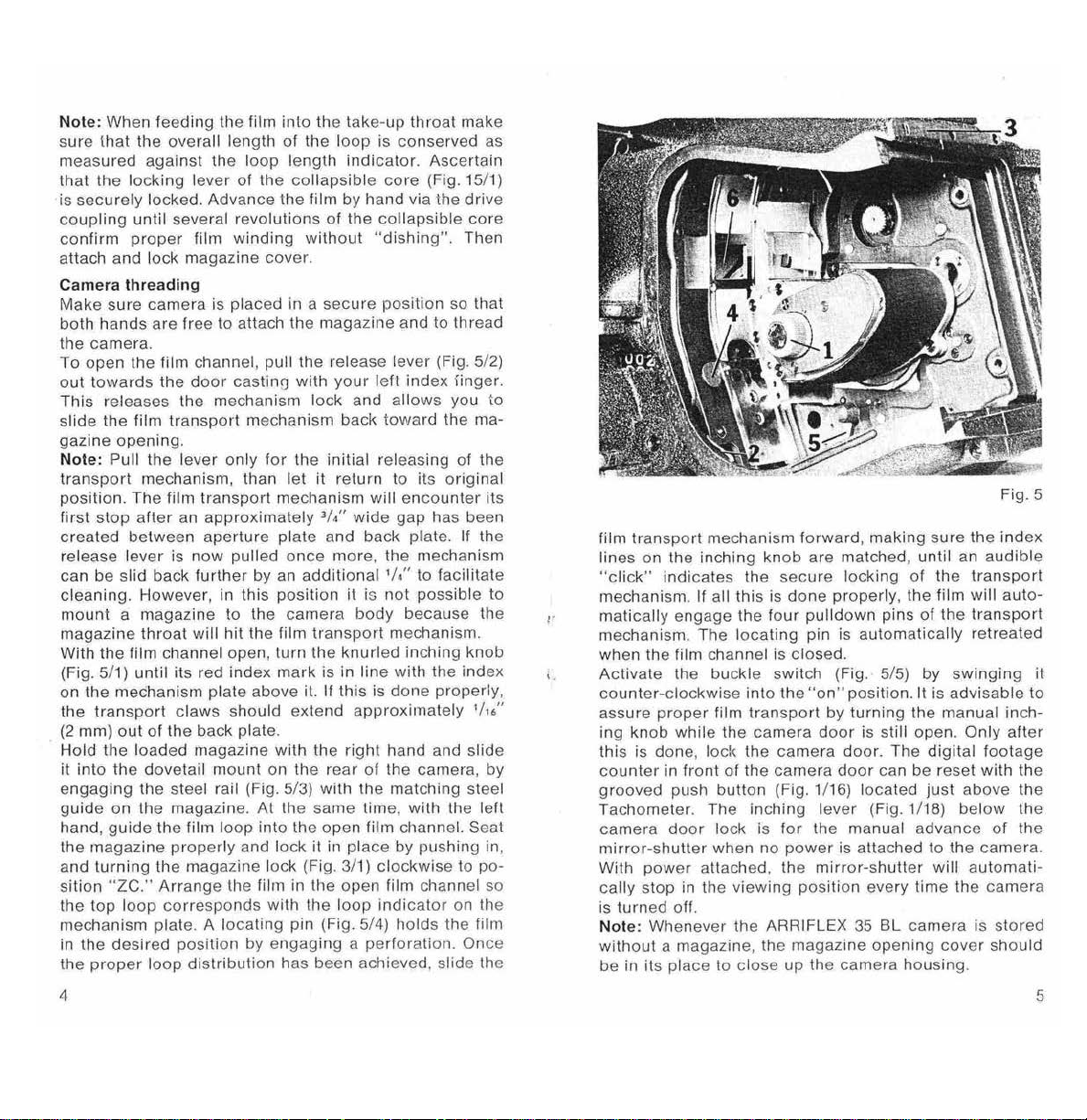

Not

e:

When feed ing the film into the take-

sure

that

the overall length

measured against the

that the

is

coupling

confirm

attach

Cam

Make

both

lock

ing lever

securely locked. Advance the film by

until

several revo lutions

proper

and lock

era thr

film

magazine

eading

sure camera is placed in a

hands

are

free to attach the magazine

of

loop

of

the

winding

cover

the

length

collapsible

without

.

of

secure

up

throat make

loop

is conserved as

indicator.

core

hand

via the drive

the

collapsible

"dishing

position

and

the camera.

To

open the film channel, pull the release lever (Fig. 5/

out

towards

This releases the mechanism

sl

ide

the

the

fi

lm

door

transport

castinC) with

your

lock

mechanism back

left

index

and

allows you to

toward

gazine opening.

Not

e:

Pull the lever

only

for the

initial

releasing

transport mechanism, than let it return to its

The

position.

first stop

created between aperture

release l

can be slid back f

cleaning.

mount

magazine

With the film channel open, turn the

(Fig. 5/1) unti l its red

film transport mechanism will

after

an approximately

plate

ever

is

now

pulled once

urther

by

an

However

a magazine to the

throat

, in this

will

hit

the film

index

position

camera

mark

3

/'

/

and

more

additiona

transport

knurled

is

in

on the mechanism plate above it. If this is

the

transport

(2

mm)

out

Hold the

it into the dovetail

engaging

guide

on

guide

hand,

the magazine

claws should extend

of

the back plate.

loaded

magazine

mount

with

on the rear

the steel rail (Fig. 5/

the right hand and

3)

with the matching steel

the magazine. At the same time,

the film

proper

loop

ly and

into

the open film channel. Seat

lock

it

in

and turning the magazine lock (Fig. 3/

sition

"ZC."

Arrang

the top

loop

mechanism plate. A

in the desired

the

proper

4

loop

e the film in the open film channel so

corresponds

position

with the loop

locating

by e

pin (Fig. 5/

ngaging a perfor

distribution has been achieved, slide the

encounter

wide

gap

back

plate. If the

, the mechanism

l '/

.''

to facilitate

it

is

not

possible to

body

because the

mechanism.

inching knob

line

with the ind ex

done

approximately '/""

of

the camera, by

with

place

by pushing in,

1)

clockwise to po-

indicator

4)

holds

ation.

Ascertain

(Fig. 15/

1)

core

". Then

so that

to thread

2)

linger.

the ma-

of

the

orig

inal

its

has been

properly

slide

the Jell

on the

the film

Onc

Fig. 5

fi

lm transport mechanism forward, making sure the

lines

on

the inching knob

"click" indicates

the secure locking

mechanism. If all this is

matically

mechanism. The

engage the four pull

locating

are

matched,

done

properly, the fi lm will autodown

pins

unti

of

of

the

the

pin is automatically retreated

index

l an audible

transport

transport

when the film channel is closed.

,

counter-clockwise

Activate

'·

assure

ing

this is

counter

grooved push

Tachometer. The inching lever (Fi

camera

mirror-shutter

With

cally stop in the viewing

is

turned off.

Not

e

without

be in its place to clos e

the buckle switch (Fig. 5/

into

the

proper

knob

done

while

, lock the

in front

film

transport

the camera

camera

of

the camera

button

(Fig. 1/16) located

"on" position.lt

by turning the manual inch-

door

door

5)

is

sti

ll open.

door. The

can be reset with the

g.

door

lock is

when

power

e:

attached, the mirror-shutter will automati-

Whenever the ARRIFLEX

for

the manual advance

no

power

is attached to the camera.

position

35

every time the camera

BL

a magazine, the magazine opening cover

up

the came

ra

by

swinging

is advisable to

Only

digital

just

above the

1/18)

below

camera

is

housing.

after

footage

the

of

the

stored

should

it

5

Page 6

Aperture

To remove the aperture plate for exchange

ment, the magazine should first

camera

escribed

d

lens

inching

area.

To

the rim

lower edge

pl

ate

i

ts

Retrieve the

scratching or damaging

Before

or

the cast in g.

To reinse rt the aperture plate, reverse t

cedure

loaded

parallel against the front castin

to engage the retaining wedges .

Ground glass replaceme nt

The gr

plays the fu ll apertur

position

and

gro

mirror

tected against scratching. Engage

the

instrument

leased.

hol

Before

ground

clean, si

ness

gro

seated, pull it forward

properly

plate

replacement

or

be

detached from the

head. Then open film channel

previously. As a safety measure, remove the

and

advance the

knob

(Fig. 5/

unlock

lower end

dust

und glass, first remove the lens and advance the

der

und glass has been inserted

the aperture pl

of

the

aperture

of

the aper t

is pushed

mounting the aperture plate

has

by

prongs

ound

areas are e

are

avail

shutter

ground

Be

so

insertin g a ground gl.ass,

glass

nce impr

and

.

up

back

aperture

accumulated

engag ing the

and push vertica lly up

glass

able

away from the

glass

and

pull

sure to have a

it

wi ll

not

and

parallax adjustment

mirror-shutter

1)

until

it

is away from the aperture

ate

, push

(Fig. 5/6) or the

ure

plate. Once the

by

approximately

towards the transport mechanism.

plate from the film channe l

any

part

in the process.

on the back

upper

image area in the ARRIFLEX 35 BL

e.

The

tch

ed

directly

for

all

popular

frame (Fig.

down

slightly until the frame is re-

good

drop

and

the ground glass frame

oper

seatin g

ge

ntly to

edge with the spring

g.

markings

formats. To

aperture

6)

grip

get chip

might

of

mak

all

the way as

with the manual

vertically

1

/1/'

make

he

unt

Then l

for

onto the ground glass

the small eyelet

with an appropriate

on the

ped

ascer

impair

the finder. Arter the

into the

e sure

up against

cut-out

1

/2

(1

mm), sl

sure

or

on

its seal in

desc

rib ed

il the plate lies

et

it

sli

different

retr

area

so

ground

or

scratched.

tain that the

are

absolutely

the sharp-

frame and

it

is

pos

G

repl

ace-

on the

ape

rtur

without

no

pro-

de

down

dis-

com

ieve the

it is

pro-

glass

itioned

e

ant

dirt

on

Fig . 6

Note: All

precision mounted

camera to

indeed properly,

f

ocal

-

mencmg

Mounting

The ARR IFLEX

Bayonet"

mounted lenses can

they are designed to

necessary when using lenses of extremely short focal

length which

ARRIFL

the

Heavy zoom and tete lenses can

FL

EX

lens

wi ll sag and compress the camera sound insul

material, possibly raising the camera noise level

siderably

groun

d glasses

cam~nl.To

!ength

le~s

shootm

of

lenses

35

lens mount. Th

might

EX

35

II C, s

mirror shutter

35

BL

only when

support

brackets. If

.

on

th

,

e,..ARRlt~BL

aQ>!

.•

are·rea

sEJaif~d

~'6,

24 m,n:l.

g.

witho~t

BL

is·

be

cover

have been especially adapted for the

ince

in the ARRIFLEX

supporting

dil

y

interch~~

insure that

in .

-i,

ts.

};P.

' . •·

(

~

l

e-~s

equ

ipped with the "ARRI

erefdre

used on the came r

the

they mi'ght touch and damage

not

.the-

~oJder

!

'tt!J::Jj

:

inf~n

:;. ,('."~:'{

:

.;·

··

. '···'~·~f

·

.:

·

~ous

i

ng

, virtual ly all ARRIFLEX

35

mm format. Caution is

35

be

them

properly

.

a~

~~~

~

·

g-"r'Q~ugjass

ch:E?ck

with

c\

_

i!>\

b~!~te\

.'·

' · .

·.

~·:.

-> "7' ,

. .._

..

., ·

'\

a,

provi

BL.

used

on

the ARRI-

on

the avail

supported

are

e

from

is

short

~com

-

~

~

Steel

ding

able

, they

ation

con-

7

Page 7

Mounting

To

hand

which contarns

and the

bracket.

Attach to the

band

bracket has a bayonet lock

ponds

bayonet lens mount. Thus.

aligned,

camera while at the same time sl

of

the zoom

to the right

mount

The

along the support r

various lens types. Very 11eavy zoo m lenses, for example

the Ang

special heavy

support

of

lens sup

attach the lens support bracket, remove the camera

grip

and

hand

zoom lens

(Fig.

218), or a similar

in its rotational angle with that

slide

suppor

until

and

in the

support

base (Fig. 2/21)

enieux

rod.

port

brackets

mount

in

its

place

(Fig. 2/14) the extension

both

the lens

gnp

mount. Refit the

the zoom lens into the lens

t base (Fig. 2/21

it

is

securely locked in the camera lens

suppor

od

20- 120

duty

support arm whrch

support

either

the bracket with the steel

arrangement

once

t base.

of

the bracket can be moved

(Fig. 2/19)

or

the

Cooke

bracket receptacle

handgrip

screw-on

the bracket has been

iding

it

).

Then twist the lens

so

it

can

20-100,

will

to the

bracket. This

which

corres-

of

the ARRI

mount

into

be

lit

of

the keyway

aligned f

require a

t11e

standa rd

the

or

Fig. 7

Fig. 8

Standard

This

length

matte

or

graduated

matte box,

camera

runner

knurled thumb

runner.

pos

frame

knurled

matte

casting and push the

casting (Fig. 7/

matte

box

for fixed lenses

matte

box

is very

lenses from

box

has two filter

four inch filters. The rear frlter stage, intended for

or

polarizing filters, is rotatable. To

simply

handle

of

After the rear frame

itioned

out

screw

box, un l

casting (Fig. 2/5)

the

malte

screw

and

tl1e

to the desired

on

ock

2)

practical

16

mm to

remove the

box

(Fig. 7/ 1) serves to lock the square

square runner is locked,

top

of the

the knurled

button

to release the square

when usrng fixed focal

approximately

holders

into

pos

adaptable

blind

cap

at

and

slide

the square open in

of

the matte

ition

and

lock

rear frame.

t11umb

screw

on

the underside

runner

150 mm. The

the end

the square

box

pull

it

To

remove the

on

the handle

for three

mount

has been

the front

with the

.

8

g.

of

of

the

the

The

the

9

Page 8

Universal hous i

The universal lens housing is designed to keep camera

noise emissi

sound filming.

focus

device

To

mount

lens must

the two

sl

ight

ly. Once seated. swing it

the

face

latch (Fig. 1/4

door

filter

ocusing

the f

follower

ring,

also

housing, simultaneously engaging the

followers

lens mount. With one hand, activate the scissor-l

(F1g. 19/2)

certain

tely

locks

are

mounted, turn the

with the coupl ing

engage it.

Focus and

As mentioned, the universal lens

than one

device

changeable distance and rlstop scales can

on the

lens.

For

~erial

numbe~

mg a lens

and slide them

diaphragm rings until they

Up

Note:

are

fastened to

In

addition

for random

Wherever

diaphragm

small w1ndow in the lens housmg (Fig. 1/6) Lenses not

equipped

ng

lor 1ixed lenses

on

to an absolu te

At

the same time

and a filter stage.

the universal

be

removed first. Engage the lens housing

loca

ting bushin

of

the camera until

& Fig.

by

unlocking the swivel latch (Fig. 19/1), turn

ring to infinity (Fig. 1/14) and flip the iris

(Fig. 8/1) forward. Now the lens

set

at

of the focusing ring (Fig. 8/2)

for

the lens locking mechanism.

that the lens

~ngaged

fls

top scales

function

for

two-man camera operation.

hous

ing, matchi ng

utmost

of

, s1mply select the

to camera serial

to the pre-marked.scales,

mark

the

circumstances

setting or the lens can be checked through a

with

lens

19

infinity,

properly.

!/stop

wedge

. Among others,

accuracy, all scales

their co

into

t11e slots

spring-loaded

ing are al

the special di

minimum

housing

gs (Fig. 2/17) tilting it

up

it

locks

/3).

To

mount

can

be entered

is

seated

After

foll

ower

on

the front ring

exactly

rresponding

appropriate

(Fig. 19/4)

"click"

number

hooks

so

availabl

allow,

aphragm

for

crillcal

it

serves as a follow

on

the camera, the

and

press it

in

the

spring loaded

a lens. open the

with

into

rubber

and

Make

correctly

the lens is securely

(Fig.

8/

1) un

of

housing

il

is a follow

For

each fixed l

are

mark

lens. When chang-

of

into place.

35060. these scales

on

the lens housing.

blank

e.

both

coupling

its focusing

the camera

and the

ti

the lens and

serves

this,

be

ocal

ed with the

set

the focus

white

focusing and

sync

into

down

aga

inst

the lens

padded

ike

grip

absolu-

lens

l it meets

mor

locus

inter-

mounted

length

of

scales

and

scales

ring can

10

be

used, but require

of

the f/stop setting.

ing

Filters

The universal

fixed focal length lenses

two

4 x 4" filters.

order

to

In

mended that eith

flat, delivered with the camera, is mounted

filter

stage.

i~g

and flip

filter, simply swing the

and

close the

holder

from 16 mm to

series Ill.

nical construc

holder

it, remove the matte

(Fig. 1/2), open the

and depress

holder

holder

be

used in

Cooke

C

am

\

e

era p

Connect

battery cable (Type KCU

pin

Cannon

latch should

wedge

batteries

5 Ah) should

drop

Note: Batteries which have either a dead cell, or

age

or

be

used

cation

either

Wprning buzzer whi le running .

Electron

Once

the

bridge

get

To

down

can be used

This

which

can

be

in the reverse order. A special

both

is

being

ower con

the camera to a 12 volt

engages the

of

b31ow 10.5 volts

misuse

with

of

insufficient

does

not

ic/el

the camera is con

plug

opening

lens

housing

minimum

er

a 3 x

reach this stage, open the lens

the fi.

door.

85 mm

lens, because

tion, requires a special two-s tage filter

accepts

both

ends

disengage

filter

used.

nection

plug

on

be

pointing

a reasonably large capacity

be

used.

do

not reach their full

the ARRIFLEX 35

reach speed,

ectrical

features

(Fig.

of

the filter

serves as a filter stage for

and

can

camera

3"

fil ter

!ter

holder.

holder

The standard three stage filter

for

except

only

box

housing

holders

the flange receptacle, the

upward

gui

de sl

The

or

exceed

battery

nected

9/4

back up

all fixed focal

for the

of

two 4 x

by

releasing

swivel latch (Fig. 19/

of

the

d. Remount the replacement

except when the

or

KCUSp). To

so tha t the raise d

ot

In the

battery

16

BL

voltage is when the

or

sounds the

to the

a)

is in place,

door

for

chang-

accept

one 3 x

noise, il

or the

After

18

its extended mecha-

4"

filters. To

fi ller

hinge

polarizing

3"

is

recom-

clear opt

in

the 3 x

inserting

until

it locks,

length

mm

its

snap lock

until

filter

hous-

lenses

Cooke

mount

18

battery

with the

insert

the four-

receptac

(recommended

voltage

volts.

capacity

camera. A sure

power

it

le.

should

, should

"out

of

supply,

is advisable to

proper

lockmg

du

camera

guide

and

ica

l

3"

the

1)

the

can

mm

Only

never

e to

not

indi-

sync"

and

11

Page 9

Fig. 9

check all

turn

(l

amp

Camera should

camera

mode

check)

functions for

selector

and

now

switch (Fig. 9/10) to position

activate

(Fig. 5/5) is in the :.OFF"

forward

Running

"L" , two

area. In the

frame st

ower

l

AI

cal "out

whose

knob

matic

fi

lm

to the r

The

turned

quency) combinat

be

switched

into

the "ON" position.

the

camera,

indicator

center

art

mark

right corner, the red

the

same

time, (f

of

sync"

volume can

(Fig. 9/12).

start

channe

ight

mode

to

active

for

"ON"

The

mark

system can

l which should

of

the

select

the

desired

approxima

, as

with

lamps

of the finder,

lamp shou ld

rom

monitor

be

edge

aperture

or switch (Fig. 9/1 0) must

ion.

The

well

12

proper

camera

run unless

pos

ition. If this is so, move

the

mode

should

ope

ration. For this,

switch (Fig. 2/16).

the

buckle switch

selector

be

visible

the bright, white, full

be

visible, and in the

,out

of

sync"

warning

came

ra No. 35026 on) an acousti-

should

regulated by

deliver

marking

be

checked by

a buzz

the volume

lamp for the

show the illuminated

. .

fps/Hz

tely 500 ms

as

(frames

"out

of

sync"

afler

immediately

per

mon i

the

after

in position

in the

finder

er

signal

control

ope

ning the

pin hol e

now

second

tor

will

camera

switching

"L"

light.

auto-

be

/fre-

only

is

it

it

"OF

F"

while

the

camera

of

sync"

lhe

volume

just

ment

Position

Volume

warning

of

Knob:

0 0 0

1

/4

turn loud

1

h

turn

of

the

of

the

start

buzzer

warning

full turn loud

If the

camera

warning

and

the buckle-switch

lhe

camera

position.

buckle-swiich

buz

zer

will

mirror-shutter

It

is advisable

buckle-switch is checked by

before

running the

has a

mark

Start

'so

und

returned

camera

is

coasting

doub

buzzer, and s

ing signal.

Marker

:

loud

is

tripped

unt

il the

to

its "ON"

can

pulse back

that

proper

simply

wit

h film.

to a stop. The

le

potentiometer for

imult

aneous

"Out

of

Warning:

low

me

loud

duri

ng a take, the

problem

is

position

to

the viewing

funct

ion

tripp

ing

it

From camera No. 35080 on, a blinking running

installed

Camera speed

The ARRIFL

is

per second.

tone

in the

EX

equipped to

The

frequency

rear plate

of

selection

35

BL, wi

thout

run

crystal controlled

des

ired

combination

is select

ed

with

the camera.

any additional

at

of

the

mode

accessories,

24

or

speed and Pli

selector

(Fig. 9/10).

With the

speeds (24/25 fps) as

approximate

to

page 14)

Pilotone

The ARRIFLEX

dr

ive system

appropriately

tor

ever,

use a

also

When sel

switch (Fig. 9/10)

bination

desired one.

as

follows:

The

variab

ly 5 f

and

wireless

double

for

those instances

conventional

equipped

ecting a camera

of

speed and Pi l

25/50, 24/50, 24/60.

Pilotone

le

speed

ps

start

marking

35

BL is

and

can

equipped

with

it

is

Frame

output

attachment (VS

well

as variable

to

30 fps can be

35

BL), f

speeds

obtained.

system

equipped

therefore, in

sync sound

system sync sound

where

Pilotone

cab

with

it

might

le

a crystal

con

juncti

recorder,

recording.

set-up,

controlled

on with

be

necessary

the

came

the stan dard Pilotone system.

importan

rate

and

is

provided

speed on t

t to

otone

frequency

he

asce

rtain that

frequency

combinations

via t

he

mode

is indeed the

5-pin flange

"out

ad-

Sync"

diu

m

corrected

so

of

the

by

hand,

light

is

25

frames

o-

swit

ch

ixed

from

(Refer

any

be

used

How-

to

ra is

selector

the

com-

are

13

Page 10

mounted

as all

The

60 ohm.

feed back

receptacle

Pilotone

Pilotone

The

circuit

connectors

voltage

Pilotone

and is a

(Fig. 9/3)

on

conforms

frequ

ency

and

other

:s

direct

speed.

The

ARRIFLEX

start

mark

receptacle, delivers

tion

of a start

taneously,

start

mark

the

camera

12 volt DC

the

Pilotone

Pilotone

able

from stock.

KPN 1 (15 feet) and KPN

with

all ARRIFLEX cameras in

ARRIVOX-TANDBERG,

Pilot 1000"

KPN 4 (15feet)

FLEX

cafl'eras

1 (15 feet) is su ited

KPS

nection

Stell

Electronic

with the Stellavox

avox

Several

availableattached· via

the rear connector

A)

Remote

The

panhandle

switch

the

position

B)

Variable

A

variable

(5-30

tps) is -available

oys a clamping arrangement similar

pl

panhandle

pos

ition.

tains a

remote

35

BL

is

also

system which,

mark

during

lamp

the run up

in the

has reached

and

the

frequency

cables

for

the 12

oscillator

aperture

fogging

is del i

the

mo_st

the

through

volt

sync

1L (30 feet)

Nagra 3

and "1200".

and

KPN

4L

in

connection

for

SM 5 and

reco

rder

s are

special orde

accesso

important

fur

the

the

ries

and useful

ARRIFLEX

flange

receptac

board.

control/panhandle swit

switch (Type RCS) makes it possible to

camera

when

speed

speed

"ON"

operating

control

control

and " OFF

off

for

switch

so

it

can

The

variable

speed

camera

"ON/OFF

equ ipped

DC

of

the

lamp

vered

popular

(30 feet) is suited

with

ARRIFLEX

35

a tripod.

for

the ARRIFLEX 35

be

contro

14

is wired the same way

ARRIFLEX

to

the

der

ived from the

indication

with

pin 3

current for

in

the

recorder.

camera

will

fog

sound

speed, both the

are

switched off, and

through

recorders

are

conjunction

and

the

the Nagra

SP 7. (All

came

standard 1 Veff

motor

of

camera

the

standard

of

the

Pilotone

the

opera-

Simul-

, the full frame

the film .

Once

pins 1 and

are

avail-

suitable for use

with

Uher

"Report

for

aiiARRI-

4.

cameras

cab

in

les for

r items.)

power

BL,

accessor

most

le (Fig. 9

of

/2)

ies

which

on

top

ch

"·

the

from a conv

lower

framing rates

to

the

BL

one

enient

It em-

on

fastened in a conveni

l (Type VS

35

BL)

" switch as well as a

ras.

the

con

are

are

the

ent

con-

2.

of

selector

for

variab

le speed

or

crys

tal

controlled

fixed

speeds.

/

C) External

With

to

synchron ize the

pre-recorded

as

cameras

forms

the

to

sync

external

or

any

the

current

input

synchronizer

camera

Pilotones, Pi l

other

external signal

and

frequency

(Type EXS) it is

from external

otone

camera. This includes, fo r example,

of the

came

ra

with

a television

sig

nal

possible

sources

signals

source

requirements

the

synchronization

from

which

such

other

con-

of

through a suitable

the

circuit.

D) Multi-camera synchronizat i

To

run

two

ARRIFLEX

with

each

other

cable also

seconda

camera

High speed

The

to

100 frames

36

a

from three 12

-

The hi gh-speed attachment fits in pl

plug

all

ry,

the

.

accessory

ARRIFLEX

volt

operating

(Fig. 9/4

ows

"slave

per

volt

a)

35

requ ires a special

for

the remote

d"

35

BL

can be

second.

current

batteries

in

the

on

BL

cameras in

cable

start

camera

ope

, from

rated

For this, the

wh i

ch

can

or

one

special

ace

fla nge mounted

synchronization

type KSY.

and

stop

of

the

primary

at

speeds

camera

either

36

of

be

volt

the

of

requires

derived

battery.

bridge

receptacle

This

the

sync

up

(Fig. 9/4).

It

is imp

ortant

connected

the standard

damage to

Emergen

It the

35

be

bridge

cy

electronic

BL fails, a

connected

plug.

from the

the

control

for

speed

manner, the

this

and synchronous

Converter

A) For the stationary, in

the ARRIFLEX

that

whenever

to

this

battery

the

plug , all

circuit

cable

or

the

other

are

power

operation

motor

control

spec

ial

emergency

to the

receptacle

This

cable

is

wired

battery

is fed

direct

to

circuits. A potentiometer

adjustments

power

according

camera

sound

takes

supplies

motor

are

door

35

BL

it

is poss ible to use a

the high-speed

power

connections

disconnected

to prevent

source.

circuit

of

the ARRIFLEX

cable

(Type KCN) can

(Fig. 9/4) in

so the 12

the

motor, bypassing

on

the

cable

place

volt

to the Tachometer. In

runs as a

not

operation

"wi

possible.

up

to

ld"

conve

cable

of

current

allows

motor

30

tps

is

via

the

all

of

rter

15

Page 11

power

this

rating is required. Star t

possible

for

connectors,

should

B) For the stationary,

the ARRIFLEX 35

supply of 36 volt/10 amp rating is required. Start-up

currents

In both cases the ARRI mains unit NG4

stabilizer

the

be

Pr

Cleaning

To clean the film channe l

the transport mcvement back to its end stop as described

in previous paragraphs. II is advisable to

tration

Note: To

only recommended

sary,

plate.

which can

screwdriver

supply instead

be

desirable, a

and

thus should

high speed operation

the maximum

never

be

of

up to

of

another

maximum

exceeded.

eventive maintenance

pins

tools.

Soft

a

mild

used to remove emulsion

Lubri

cation

Both the

FLEX 35

system. 0

of

the shaft. To gain access to these

remove the magazine from the

(Fig. 10/

mching

be

brought

l

ow temperature

cant. The

entirely

small quantities

16

perm1ssible

of

aperture plate

during

clean the

cotton

solution

of

the film

pull

down

BL

are

11

wicks

be

loaded through small

1)

off

the mechanism. If necessary use a small

and

knob

(Fig. 10/2) the

into a convenie

amount

on

the saturation

of

rechargeable batteries. Should

power

exceeded.

BL

using a high-speed cable, a

15

amps should

make can

cleaning to avoid

f1lm

swabs

clean ing utensils. Should

of

transport

and registration

equipped with a reservoir

are

positioned

carefully

oil

(PDB38) should be used

of

oil

of

oil are required to load the reservoir.

supply

-up

cur

rents

not

overload the

through

supply

indoor

operation

supply

and

minor

and

film channel

of

the ARRIFLEX 35 BL,

channel, NEVER use any metal

or

lens c leaning cl

50/50

water

deposits

camera

pry

lubrication

nt

position.

that should

of

the wicks . In general, very

of

12 volt/10 amp

of

up

to

15

amp are

circuit.

the

proper

voltage

up to 100 Ips

not

overload the

or

be

recommended, but

voltage

service

retract

damaging

and

alcoho

from the aperture

mechanism

cams

inside

bot

holes

lubrication

and

it loose. By rotating the

access

Only

be

applied depends

Except

cable

and

of

16

volts

power

circuit.

a similar DC

should

of

h cam shafts

111

pull

never

slide

the regis-

them.

oth

are

it

be

neces

l can be

the ARRI-

lubrication

the center

points,

the

cover

holes can

high

grade

as a lub

the

of

ri-

Fig. 10

and .,drop

apply it.

The cam shaft

-

cated at intervals

camera has been

6000

speeds.

Never over

wicks can easily

off

the cams

ning , and can

Other

In addition to the

the two

followers

Here,

All excess

cloth.

The parallel

and

precision steel guides. one dovetail shaped, the

flat rail. Inside the

filled

oilers"

or

8000 feet if the camera has been used at high

lubri

cation

phenolic

should be

lubrication

the

drive

w1th a h1gh

or

syringe

reservoir

of

operated

oil

the reservo1rs, feed

absorb

owing

to the centrifugal

splatter

oil

must be removed with a clean, lint-free

slide

into

points

two

transport

lubricated

is best

to which the transport mechanism

motor

guide

grade,

type

oilers

are

best used to

should

approx

. All excess

the film compartment.

oil

applied

are mounted is made up

rails. small round cavities are

low

be

checked

imately 60,000 feet

at normal speed, and every

only

as much

oil

forces

reservoirs in the cam shafts

and

two registr

with a thin f

with a small,

temperature grease. If the

will

and

oil

be

during

ation

ilm

soft

lubri-

if

the

as the

thrown

run-

cam

of

oil.

brush.

of

two

other

a

17

Page 12

slide tightens up, small amounts

used in the reservoirs of the cam shaft should be applied.

From time to time the dovetail guide

zine opening should be cleaned.

light film

and remove the excess with a clean lint-free cloth.

The same cleaning and lubricating pr

mended

zines: the lock wedge on the magazine lock; the three

bayonet clips on each magazine cover and their counter-

parts, the locking latches on the magazine; the

wedges on the camera

camera housing; the

of the camera handle and the threads of the electrical

con

A minute amount of oil should be applied to the hinges

of the camera

Preventive maintena

or

f

support,

be a conscientious process of cleaning, checking and

lubricating.

every time before the equipment is stored for long

periods.

Replacing signal lamps

To replace any of the signal lamps, slide back the trans-

port movem ent, rotate the

tur

e area and remove the aperture plate. Then pu ll out

the lamp

suitable tool.

Caution

and the tool do not

plate in case it suddenly releases.

After removal

the two locating pins on the carrier, making the lamps

accessible (Fig. 12

1 =

2

= Full frame fog lamp.

3

= Edge fog lamp.

Replace lamps as required. When re-in serting the lamp

carrier, make sure everything

sure

place, re-insert the aperture plate and test the lamps

proper

of

high grade grease (ARRI special grease)

for

the following parts

door

3

/8' tripod screw;

nect

ors on the rear of the camera.

door

whenever necessary.

nc

e of this type is also recommended

all camera accesso ries, the lens housing, the zoom

etc

., etc. Equipment care

It should be done at regular intervals and

carrier

:-

Pull

"Ou

t of syn

good

function (refer to lamp test in earlier paragraph).

using a metal

only

with a short stroke so the lamp

of

the carrier, pull th e

).

c"

monitor

electrical

hit

and damage the back pressure

contact. When the

of

oil of the same type

of

the camera maga-

Aller

cleaning, apply a

ocedure

of

the camera and maga-

and their receptacles on the

the

of

this nature should

mirror

shutter out

hook

{Fig. 11)

contac

lamp {red glass).

is

seated properly to

is recom-

locking screw

of

the aper-

or

any other

t block off

carrier

is back in

carrie

lock

in-

lo

r

r

11

Fig.

Fig. 12

18

19

Page 13

Fig.

13

Fig.

14

4

Fig.

15

Replacement

The camera

15 amp

power

to the 15 amp

(Fig. 2/13)

Caution:

disconnect

solutely sale, there should

of the sockets

Arter the mechanism cover has been removed, unscrew

the

printed

the way

screwdriver,

remove the

of

the same rating (miniature

32 volt

).

From

came

replaced

No

. 4

Arter the fuse has been replaced

power

circuit

20

of electri

circuit

power fuse, the

supply

leads

of

power

must

Before

all

power

on

circuit

so

the fuse (Fig. 14/1) is accessible. With a

loosen

de

fective fuse

ra No. 35060

without

are

plate

No. 4. Before the mechanrsm cover is put

cal fuses

is

protected

other

the

drive

control

fuse, the

be removed.

removing the mechanism cover, always

supplies to the camera. To

be

the rear co

plate

No.4

two

cylinder

and

onwa

removing the

securely fastened . remount the

with two ruses, one a

a 0.75 amp fuse

circuit.

camera

no

cab

nnector

(Fig. 13)

head

replace

glass

rds, the

To gain access

mechanism cover

le

connected

plate.

and

screws

rt

with a

tube fuse 15 amp,

15

amp fuse can

printed

and

the red insulated

lor

be

swing out

(Fig. 14/2),

new

circuit

printed

the

ab-

to

any

of

one

be

board

back on, rnake sure

between any el

position

connector

are

The

located

the

unscrew

fuse 0.75 amp 1

(F

rg. 9/11

Up

located

Ma

To garn access to the magazrne throat, loosen the two

self

Pu

dovetail guide. C!ean

ing with a soft, clean brush.

on

C~ution

thrng

the mechanism cover, slidin g it

plate, again watching carefully that no

pinched

other

"out

to

intenance

retaining, reset scr

ll the cover off straight nnd parallel to the magazin e

and

or

damaged in the process.

fuse. a 0.75 amp minralure

under

the cap between the

of

sync'' volume

the fuse

).

camera No. 35020 this fuse is a

in the

lower

of the magazine

fasten it wrth the two screws.

:

Never clean the magazine sprockets

other

than a brush .

none

of

the wi res are squeezed

ect

ric

al

components.

control. To replace it, simply

cap

and

plug in a repl

25

volt) fuse of the same type

left

portion

ews

(Fig. 15/2) in the

out

the

interior

Slide

Under

Then carefully re-

mode

of

printed

of the throat cast-

the throat

no

circums

over

plug-in

selector

acement

1

h amp

circuit

throat

the r

ear

wires

ruse , is

and

(micro

and

rating

Pico

fuse,

No.3.

cover

cover

back

with

any-

tances use

21

.

Page 14

any metal tools to clean the sprockets. Do

assemble the magazine any further than described ,

remove any sprockets.

guide

Magazine

60 Ips

to

100 fps

When using the ARRIFLEX

speed operation, it is essential that they

with

high speed guide rollers as

attach t

"top"

gaging

fastening them with the

he

and

the locating pin

rollers

guide rollers , simply fasten the arms marked

"bo

ttom" in

for high

35

their

appropriate

in

the

knurled

speed operation

BL

shown

corresponding

thumb

not

magazines

be

m Fig. 15. To

location by en-

screws

try to

for

equipped

hole and

(Fig. 15/3).

dis

or

from

high

-

Removal

To

or

mechanism

self-retaining screws around its perimeter and slide

the

Before remounting the mechanism cover, be sure the

hard

selector

around the perimeter or the

seals tightly, otherwise the camera noise level

substantially.

Checking drive

To check drive belt tension . the mechanism

be

drive belt and the magazine drive

by

dr

drive

sufficient

by

this

wheel (Fig.

Caution: The drive belt must have sufficient tension to

clear

Adjusting

Note: The following paragraph

should

of

the came

inspec

t the came

to adjust the drive belts,

cover

cover

olf

its groove around the rear

rubber

removed. The tension is

approx

iver

or

bells at the positions marked A and

braking

case

gasket around the

is in place. Also

imately

any other suitable

tension on the mam drive

the tension

the belt would ride

bell

•/s

ra

mechanism

ra

mechanism, to r

it

is

necessary to remove the

(Fig.

2113).

To

do

be

certain

cover

tension

correct

of

an inch. To test this, use a screw-

object

roller

(Fig. 16/1) with a finger, in

up

on the teeth

16/4).

the mounting flange f

of

the drive bells

not

be performed in the field. It should only be

or

the tension roller(Fig.17/1).

cover

eplace

so, loosen the seven

cut-out for

is

in

when both the main

bell

can

and press against the

belt

descnbcs

the fuses,

connector

that the gasket

good

Bin

can

the mode

order

could

cover

be

deflected

Fig.

be

detected

of

the drive

work

plate.

and

rise

must

16.

which

In-

Fig.

Fig.

16

17

22 23

Page 15

performed

the

proper

ARRIFLEX service agency

tees

To

adjust

For the main

cover,

the tension

fuliy press the tencion arm until the

tension,

screws

described

The magazine

by

adjusting

might

loosen

hold

ore

by

knowledgeable service tec

tool

s.

Unless performed

it

will void whatever guaran-

be

valid

for

the

camera

the tension

drive

arm

it

securely fastened. test the

in

ihe

tens:on roller No. 1 (Fig. 16).

of

the

drive

belt,

after

removing the mechanism

two

screwc

in position. Then,

there,

previous paragraph.

drive

(Fig. 16/3) which

and

retighten the screws. When the

belt

is

adjusted

belt

hnicians

by

an authorized

at

the time.

proceed

with

be

lt has the d0sired

in a

as follows.

are

one finger, care-

belt

tension as

similar

with

holding

fash:on

f

..

.,

I

Caution:

leaves

the

rechecked

To

removed from its mount.

door and

then open the film channel and

(F

ig. 3/2)

transport

Note: All

be

When the three screws

its

to the camera body. Note the

connects

When reassemb ling the drive, this

engage the

on

Make

drive

cessary until the timing between the shutter and the

claws

edge

the

the lens side)

mechanism

When

mount the

[f

during

any

of

the drive couplings,

mirror

shutter, etc., the

and

if necessary readjusted.

adj

ust the timing

loosen the two chromed

located

mechanism.

three

screws are

completely

coupling

the film

sure the

members. Check

is correct. Proper

of

the mi

upper

proper

removed from the

and

the

motor

motor

transport

rror

right edge

are

belt tension and

motor

th:s adjustment the ma'n

e.

g.

timing

of

the camera must be

of

the camera. the

To

do

this,

open

screws

loosen

forward of, and sli

self-retaining

are

loosened,

lay it, attached to its

to the film

and its

drive

shutter, rotating clocl<wise, just cove rs

and

lined

as

corresponding

mechanism.

bell

is

properly

and

realign the

liming

is

of

the

aperture

the

index

marks

up

(with the film channel closed).

iollows.

ghtly

motor

pull

cable

rubber

transport

rubber

engaged

obtained

plate (looking from

on

timing

drive

the movement,

motor

must

the camern

(Fig. 17/2, 3),

the third

above, the

and should

earner.

the

motor

harness, next

coupling

mechanism.

coup

ling must

flange (Fig.

with

drive

belt

when the right

the transport

are

correct, re-

belt

be

screw

not

orr

which

'16

/2)

all

as ne-

AAAI

adv!•rtlsong dep<:rtmem

wothout oblogation. Modilocatoons

may be

Prinled

reproduced

in

West GPrmany •

only

with

WA

Ted

our

j 1 1 1 ·

~~~;;~cdn

will.tcn

HO

~~mato~n

autho~i~~~~~':;aloon

097308

and

spocolocaloons ore

covered

Fig.

herein

18

211

Page 16

Move the film transport mechanism back to the loading

position

is in the

supply to the

pulse

that the camera will

shutter

the

mechanism. Fasten the

located in front

film

remai

Important:

fore

transport mechanism

Important

ot

mg.

all

electric

move freely and bend

the sl

and turn the inchi

position

the

motor

in

the viewing position. Once this is

motor

via the rubber

transport

ning motor

remounting

that the

her

parts

The

motor

other

components

cable

ide

is moved back

ng

knob

until

the

mirror

shown in Fig.

came

ra,

hold

the

18.

Then, attach

motor

with one hand

with the camera switch. This is to insure

later alw

ays

stop

with the

done

coupling

of

the

claw

mechanism forward

lock

screws

After

the

motor

moto

with the film transport

r lock

screw

mechanism. Then, slide the

and

fasten the two

(Fig. 17/2, 3).

has

been

attached, and be-

the camera mechanism cover, test the

slide

for

motor

does

not

which are in

should have a

of

no

contact

minimum

less than •/u

harness attached to the

without

and

kinking

forth.

proper

with the camera hous-

operation.

pinch any cables

distance from

of

an inch. The

motor

or

squeezing when

shutter

power

and

mirror

, engage

(Fig. 3/

It

should

2)

is

or

Fig. 19

1

Swivel latch for filter

door

2 Lens release latches

3 Look/release for universal lens

4

Mounting

5 F/stop odju:>tmcn\

grooves

for

and

scales

lock

housing

knob

6 Focus handle

Fig.

Fig.

19

20

20

Fig.

1 Flange receptacle for

2 Flange receptacle

3

Pilotone

outlet

4 Flange receptacle

emergency

10

Mode

11

Fuse

12

Volume

operation

selector

holder

control

switch

for

lor

lor

cable

··out

power

various

bridge

or

sync

cable

electronic

plug

, high speed

"'

buzzer

systems

and

Loading...

Loading...