Armotech WG65 User Manual

ARMOTECH WG65 SERIES PAINTBALL MARKER OWNER’S MANUAL

WARNING

ARMOTECH PAINTBALL MARKERS ARE NOT A TOY. ANY MISUSE MAY CAUSE SERIOUS INJURY OR DEATH.

THE USER AND ANY PERSON WITHIN RANGE MUST WEAR EYE PROTECTION DESIGNED FOR PAINTBALL USE.

READ THIS OWNER’S MANUAL COMPLETELY BEFORE LOADING, PRESSURIZING, OR OPERATING YOUR

ARMOTECH PAINTBALL MARKER.

This paintball marker is intended for sale to adults only, for use in compliance with all applicable laws and regulations. Adult

supervision is recommended at all times whenever a minor is handling this paintball marker. All persons within range MUST wear

protective goggles & headgear specifically designed for paintball when a paintball marker is in use. Paintball safety rules must be

followed at all times.

ARMOTECH WG065 OWNER’S MANUAL, Compiled for ARMOTECH International, by

John L.R. Dovale, Dangerous Enterprises. Imagery by Mark Chance, Island Designs (ala Section 8)

Armotech International / Armotech Taiwan Ltd. http://www.armotech.net, http://www.armotech.us

6F No 10 Sec 4 Tzu Chiang Rd, San Chung, Taipei Hsien, Taiwan R.O.C.

Technical support forum http://www.armotech.us/forum

Table of Contents

CHAPTER 1

Paintball Safety Rules 1

Operating Instructions 3

Compressed Air/Gas 6

CO2 Safety 8

Velocity/PSI Adjust 10

E-Trigger Operations 12

CHAPTER 2

MARS Series Marker

Specifications 14

WG Parts & Diag. 15

Trigger Parts . 17

Maintenance &

Lubrication 18

Assembly/Adjust 20

Sight Adjustment 21

Handguard removal 21

Cleaning Lubing 22

Cupseal Maint. 25

CHAPTER 3

Troubleshooting 28

Tips, Hints ‘n Tricks

Warranty Info. 34

This owner’s manual is provided

with several models of the MARS

series paintball marker. Armotech

Inc reserves the right to modify or

change its markers without

incurring any obligation to

incorporate such modifications or

changes in any of its products

that were sold prior to the

modification. The information in

this owner’s manual may be

updated or changed without

notice.

This owner’s manual is intended

to remain with the paintball

marker upon any subsequent

transfer of the marker, whether

through sale, resale, or furnishing

in any manner.

Stock Adjustment 27

ARMOTECH WG065 OWNER’S MANUAL, Compiled for ARMOTECH International, by

John L.R. Dovale, Dangerous Enterprises. Imagery by Mark Chance, Island Designs (ala Section 8)

Armotech International / Armotech Taiwan Ltd. http://www.armotech.net, http://www.armotech.us

6F No 10 Sec 4 Tzu Chiang Rd, San Chung, Taipei Hsien, Taiwan R.O.C.

Technical support forum http://www.armotech.us/forum

ARMOTECH – THE PERFECT MARKER…THE PERFECT GAME

1

Paintball Safety Rules

Safety First!

Chapter

WARNING

ARMOTECH PAINTBALL MARKERS ARE NOT A TOY. ANY MISUSE MAY CAUSE

SERIOUS INJURY OR DEATH. THE USER AND ANY PERSON WITHIN RANGE MUST

WEAR EYE PROTECTION DESIGNED FOR PAINTBALL USE. READ THIS OWNERS’S

MANUAL COMPLETELY BEFORE LOADING, PRESSURIZING, OR OPERATING YOUR

ARMOTECH PAINTBALL MARKER.

• Always wear protective goggles & headgear designed for paintball when shooting this marker

• Everyone within range of an area where this paintball marker is used should wear protective

goggles and headgear specifically designed for paintball

• Operate this paintball marker only in areas where it is safe and lawful to do so

• Misuse of this marker may result in criminal charges or imprisonment

• This marker is intended for sale to adults. Adult supervision is recommended at all times

whenever a minor is handling this marker

• READ THIS OWNER’S MANUAL COMPLETELY BEFORE LOADING, PRESSURIZING, OR OPERATING THE

ARMOTECH WG SERIES PAINTBALL MARKER!

• Never aim or shoot this paintball marker towards anybody who is not wearing protective goggles

or headgear specifically designed for paintball

• During game play, follow referee’s instructions and all field safety rules. Avoid shooting at another

player’s head, neck or groin area

• Play paintball only where the rules of safety for paintball are followed

• All paintball markers must be chronographed regularly. Adjust the marker to shoot paintballs at a

velocity this is 300feet per second (fps) or less and that does not exceed the velocity limit set by

WG SERIES 1

ARMOTECH – THE PERFECT MARKER…THE PERFECT GAME

the Paintball Park or field where the marker is in use. Chronograph the marker at regular

intervals during the day, as well as any time the power source is refilled or changed, any time the

barrel or any part of the power system is changed, and upon request of any player or game

official

• This paintball marker operates using compressed gas or air at specified pressure ranges. Follow

safety procedures when handling compressed gas or air. All filling of compressed gas or air

cylinders must be done by qualified persons

• Follow the rules of safe marker handling: keep finger off the trigger until ready to shoot. Keep

muzzle pointed in a safe direction. In addition, firmly insert a barrel plug into the muzzle and push

the mechanical or electronic safety to “ON” or “SAFE” when the marker is not in use and when in

any non-shooting area

• Never shoot at domestic animals or wildlife

• Never mark objects outside the confines of the game or authorized shooting areas

• Never look down the barrel of a marker

• Before disassembly, storage, or transport of this marker, remove ALL paintballs from the

marker, barrel, and loader: remove power source: and remove all gas or air from the power

system. Insert a barrel plug and put the safety “ON”

• Carry your marker in a case or sturdy bag when transporting it in public

• Safely and securely store marker to prevent access to it by unauthorized persons or minors.

WG SERIES 2

ARMOTECH – THE PERFECT MARKER…THE PERFECT GAME

Operating Instructions

WARNING

Every person within range of this paintball marker must

wear protective goggles and headgear specifically

designed for paintball.

1. Before continuing with these instructions please refer to the section in

Chapter 2 on maintenance and lubrication (pg 16). Your marker should

first be properly cleaned internally & lubricated prior to firing to avoid

unnecessar y wear or damage on the internals. After completing that

task, return to this section and continue with step 2 if you have the

WG65E (which comes standard with electronic trigger). If you have a

WG65 skip to instruction point 5 and continue.

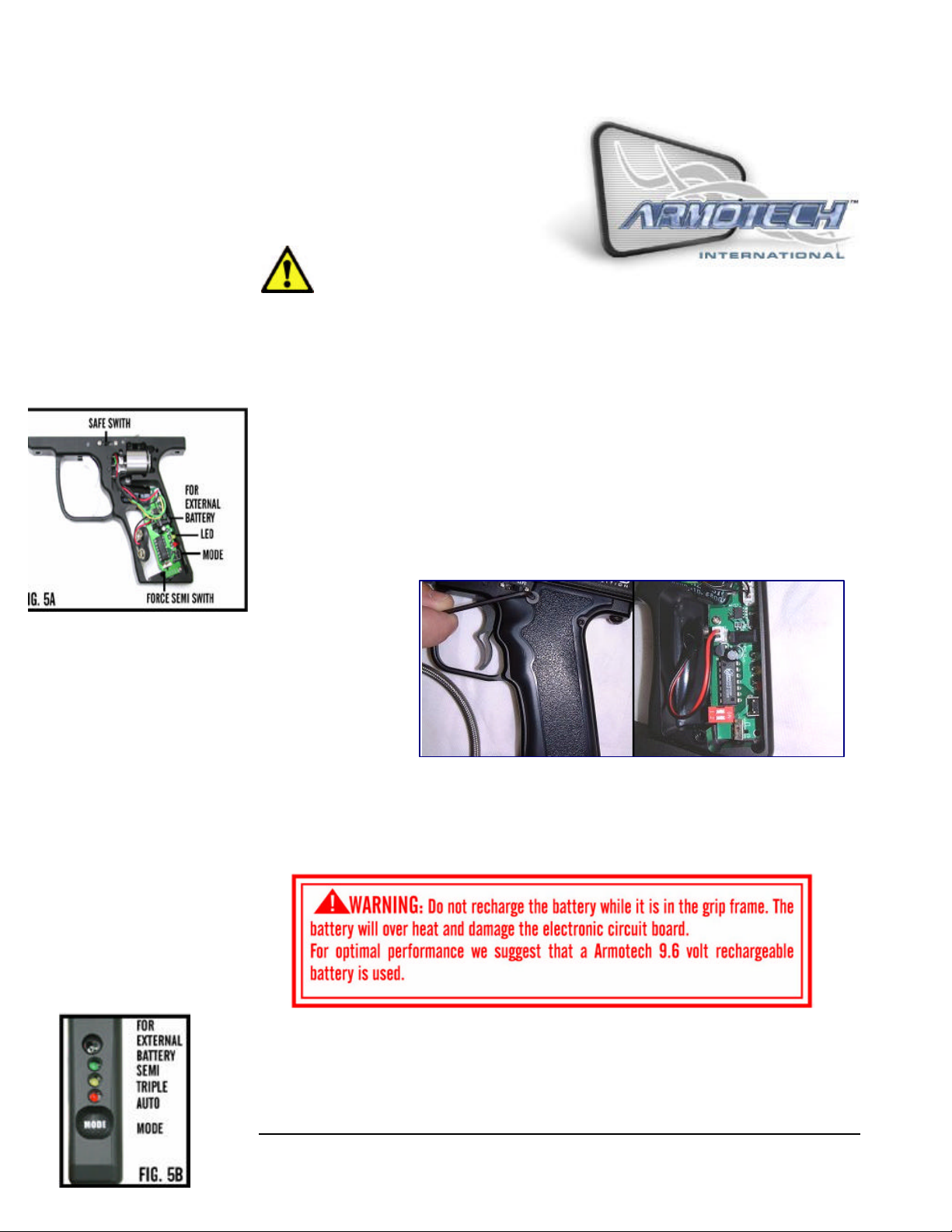

2. Use the

supplied hexwrench tools to

unscrew the

two screws on

the trigger

frame on the

left side of the

gun – (the side

with the pressure gauge) and remove the trigger frame cover.

3. Use a rechargeable 9.6v battery to power the trigger frame. Insert the

battery into the frame, and ensure that no wires are loose, pinched or

unsecured before replacing the frame cover.

4. Turn the trigger frame ON, by pressing the mode button at the back of

the trigger frame one time - the green LED should light up. This

signifies that the marker is in SEMI shot mode. Pressing the MODE

WG SERIES 3

ARMOTECH – THE PERFECT MARKER…THE PERFECT GAME

button again will put the marker in 3-BURST mode. Pressing MODE one

more time will put the marker in FULL AUTO mode. To turn off the

trigger frame, press and hold the MODE button for a few seconds until

ALL LEDs are off.

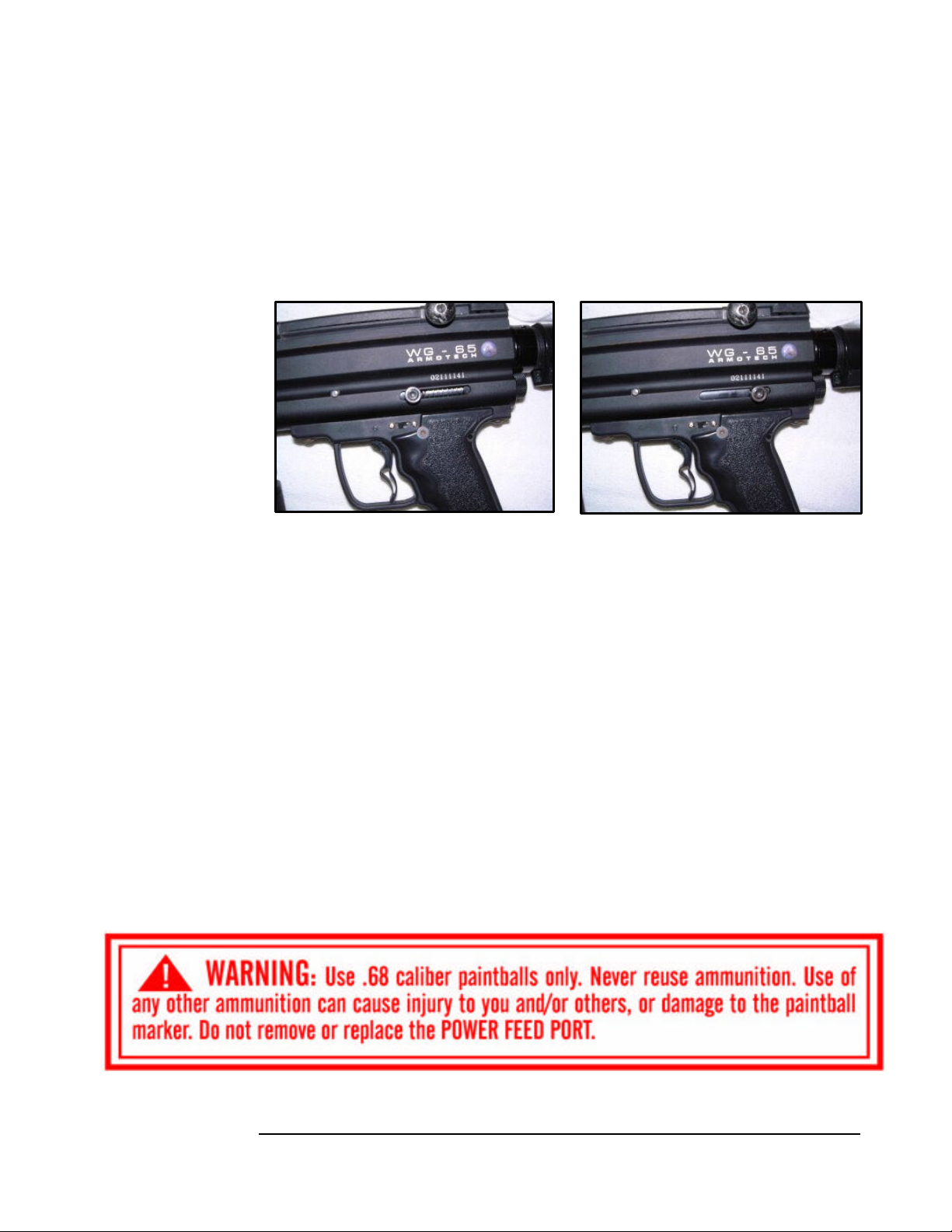

5. Make sure the safe switch is in the SAFE position. On the WG65E push

the switch to the right to turn safe ON, or the left to put marker in

active firing mode. On the WG Semi, press the button on the trigger

frame to the right for SAFE ON, and to the LEFT (red ring should be

visible on the button) for SAFE OFF.

6. Attach threaded barrel firmly to marker.

WG SERIES 4

ARMOTECH – THE PERFECT MARKER…THE PERFECT GAME

7. At this time do not attach power source or loader, and do not load any

paintballs into the marker.

8. Insert barrel plug firmly into the barrel.

9. Pull the cocking handle (left side as illustated) straight back until the

cocking mechanism locks back in the cocked position

10. Turn the safety switch to the

FIRE position and then squeeze the trigger with an even pressure. The

cocking knob should snap forward into the un-cocked position. You

have just dry-fired your Armotech marker. Do this a few times until you

are comfortable with this operation and the feel of the marker when

cocking, and firing it.

11. Using the supplied hex-wrench make certain to properly tighten all

screws on your marker. These include the trigger frame, the secure

positioning screws on the powerfeed, and the lug inside the cocking

knob. Do not overtighten and take care not to strip ANY of these

screws. Tighten the screw holding the cocking knob– DO NOT TIGHTEN

THIS ALL THE WAY DOWN – IT CAN CAUSE DAMAGE TO THE SPRING.

12. Attach the loader or hopper to the powerfeed via the supplied elbow .

Some loaders may require their feed-necks to be sandpapered in order

for them to fit properly in to the elbow or powerfeed of the marker. Do

not overtighten the screws on the elbow as you can crack it (its plastic)

WG SERIES 5

ARMOTECH – THE PERFECT MARKER…THE PERFECT GAME

Compressed Air/Gas

WARNING

The power system contains compressed gas or air

when pressurized. Never disassemble the marker until

removing ALL the gas or air from the power system.

Always keep hands away from escaping CO2 gas. It

can cause frostbite if allowed to come in contact with

skin.

• Before attaching any air or gas power source, read and understand this

section of the owner’s manual. Follow safety rules for handling

compressed air/gas. If any leaks occur in the power system, refer to

troubleshooting section or Armotech support. Use only cylinders for

compressed gas or air that comply with all applicable laws and

regulations, including but not limited to those of the US dept of

transportation, OSHA, Compressed Gas Association and/or American

Society for Testing and Materials.

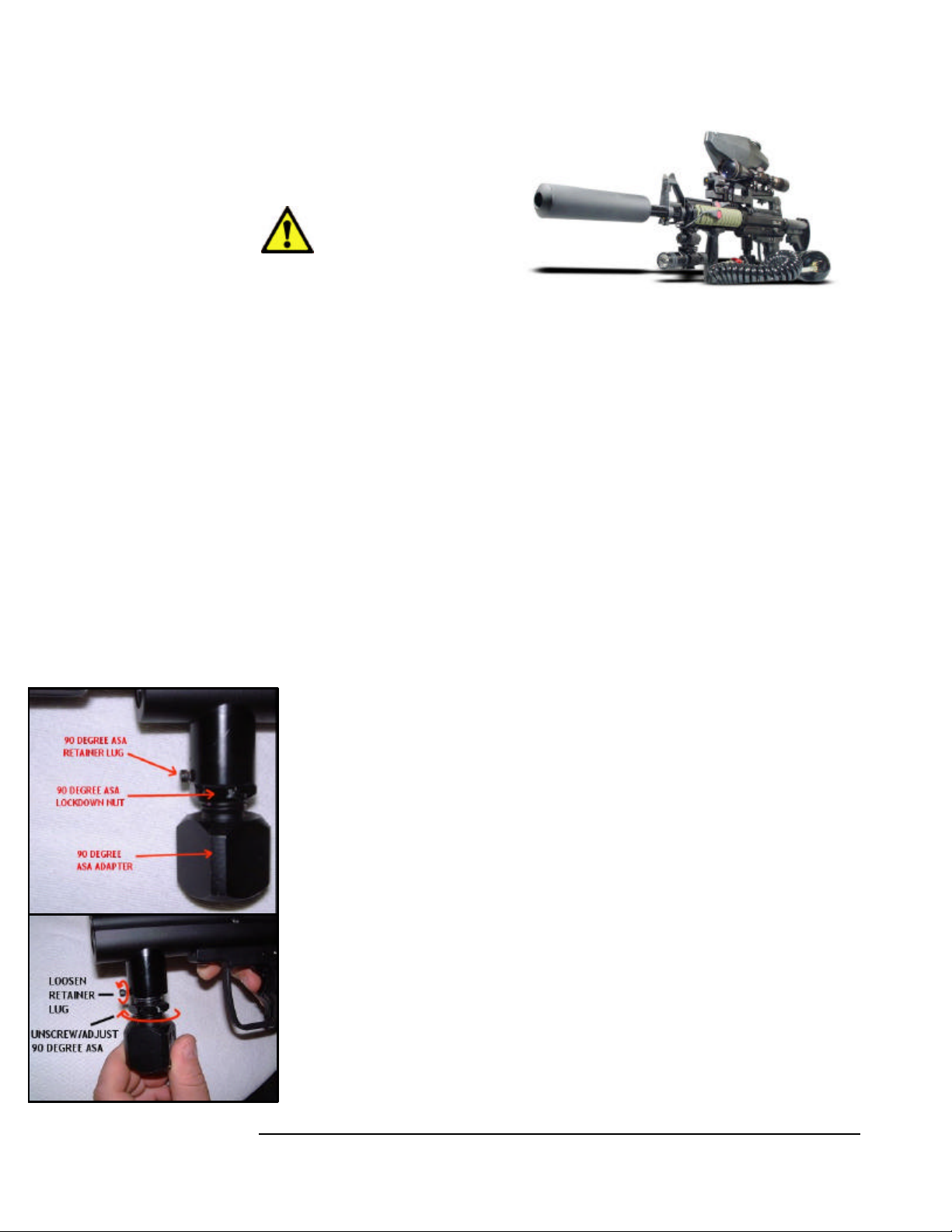

• VERTICAL AIR: The power source is attached by screwing the threads of

the tank or power source adapter into the threaded ASA in front of the

trigger frame – you can screw it into the 90 degree adaptor, or remove

that and screw into the vertical ASA directly.

• When cocking the pressurized marker do not release the cocking knob

until after the cocking mechanism has locked back into the cocked

position. The marker is now ready to fire.

• Test for function – now that the power source is loaded and the marker

cocked, turn the trigger frame ON (for electronic triggers), and flip the

safety switch to the FIRE position and squeeze the trigger. The marker

should shoot air, and the cocking knob should cycle back to the cocked

position ready to fire again. Repeat this several times to get used to

the action of the marker. You have now fired your marker WITH loaded

power source.

WG SERIES 6

ARMOTECH – THE PERFECT MARKER…THE PERFECT GAME

The ARMOTECH paintball marker may be powered by CO2, regulated

compressed air (HPA), or regulated nitrogen. From the source of gas or air

through the entire power system, there are varying pressures that are applied

to the marker and the components of the power system.

The marker requires a minimum of 450psi for proper operation – if you are

using CO2 please refer to the manufacturer’s information to learn how to

adjust, control and properly maintain your input pressure. The WG marker

does not have an inline regulator system.

If you are using HPA please ensure that the HPA bottle regulator output is at

least 550 PSI.

WG SERIES 7

ARMOTECH – THE PERFECT MARKER…THE PERFECT GAME

SAFETY RULES FOR HANDLING COMPRESSED

AIR OR GAS MUST BE FOLLOWED AT ALL TIMES!

OPERATING PRESSURES AND INPUT PRESSURE

• Operating pressure range 450 p.s.i. to 1150 p.s.i. (Although some

markers have been known to operate at pressures as low as 330 p.s.i.

or pressures over 1200 p.s.i. it is recommended that the specified

operating pressure of the Armotech marker be used in order to avoid

problems.)

• Never exceed recommended pressures, as this may be dangerous to

you and damaging to the marker.

• Do not leave a pressurized marker or cylinder in direct sunlight or

exposed heat source. Increased temperatures will increase the internal

pressure of the compressed gas or air and could cause problems.

VALVE CYLINDER CONNECTION

• The Valve on a cylinder is to remain screwed into the cylinder. Should it

loosen, the cylinder may detach from the valve with an extremely

dangerous force.

• Every time a cylinder is fill ed, the connection between the valve and

cylinder must be inspected. If any looseness or leak is detected

between the valve and the cylinder, do not fill. Drain the cylinder and

have it inspected by qualified persons.

• During filling if any looseness or leak is detected between the valve

and the cylinder, filling should be stopped and the cylinder should

immediately be drained to avoid problems.

FILLING COMPRESSED AIR/GAS

• An overfill of any compressed air or gas cylinder can cause the safety

burst disk on the cylinder to rupture. A cylinder may rupture with

excessive force. Use properly rated disk only for the burst disk.

• A scale must be used for ALL CO2 fills to prevent an overfill. A pressure

gauge must be used for all compressed gas or air fills to prevent

overfills.

WG SERIES 8

ARMOTECH – THE PERFECT MARKER…THE PERFECT GAME

• Many cylinders are required to have US Department of Transportation

hydrostatic tests done at periodic intervals. This interval varies

depending on the cylinder type. The date of the cylinder’s initial or last

testing appears on the cylinder. Out of date cylinders should not be

used.

• Installing the Gas/Air Power Source

o Make sure the BARREL PLUG is placed in the barrel

o Put the trigger frame on SAFE

o Screw the compressed air/gas source into the ASA Adapter

o Tighten until you feel a solid stop

o Turn the gas/air on if it has an on/off valve, otherwise it should

be active and ready to go.

o Do not store the marker with power source installed and full

• Removing the Gas/Air Power Source

o Always remove power source before performing disassembly of

marker

o Unload all paint from the marker and detach the hopper/loader

o Put the trigger frame on SAFE, (or turn trigger frame OFF if it’s

the electronic version)

o If the power source has an on/off valve– shut it OFF. Otherwise

point the marker in a safe position and slowly unscrew the

power source.

o You will hear some compressed gas/air escaping via a bleed-

hole while unscrewing the power source. If you prefer you can

fire the marker to release ANY pressure in the system, while

continuing to unscrew the power source.

o If the unscrewing is difficult the system still has too much

pressure in it – check to make sure the power source is OFF (if

it has an on/off valve), or to ensure it is completely discharged

before continuing. CO2 can cause damage to O-rings. These

need to be inspected regularly to avoid leaks.

WG SERIES 9

Loading...

Loading...