Page 1

FP/FR2000 Series

Analogue addressable fire panels,

repeaters and emulators

Installation and

Commissioning Manual

Revision 4.5: October 1998

Downloaded from: http://www.guardianalarms.net

Page 2

ARCNET is a registered trademark of Datapoint Corporation.

Aritech is a division of SLC Technologies B.V.

Copyright

© SLC Technologies B.V. 1999. All rights reserved. No part of this publication may be reproduced, transmitted, stored in a retrieval system, or

transmitted in any form, or by any means – electronic, photocopying, recording, or otherwise – without the prior written permission of SLC

Technologies B.V.. SLC Technologies B.V. reserve the right to change information without notice.

Page 3

CONTENTS

Introduction ..............................................................................................................................................................3

1. General information......................................................................................................................................3

1.1. Product codes........................................................................................................................... 3

1.2. Design specifications................................................................................................................ 4

2. Technical specifications..............................................................................................................................5

3. Dimensions of the fire panel .....................................................................................................................10

4. Mounting instructions ................................................................................................................................11

4.1. Mounting instructions.............................................................................................................. 11

4.2. Panel layout ........................................................................................................................... 13

4.3. Repeater layout ...................................................................................................................... 14

5. Loop design .................................................................................................................................................15

5.1. Typical configuration .............................................................................................................. 15

5.2. Suitable cable types ............................................................................................................... 17

6. Field connections .......................................................................................................................................18

6.1. Loop, output and input connections......................................................................................... 18

6.2. Communication port connections (all models)......................................................................... 26

6.3. Power supply connections ...................................................................................................... 27

6.4. Installing a modem ................................................................................................................. 28

6.5. Network connections............................................................................................................... 29

6.6. Power supply.......................................................................................................................... 31

6.7. LCD display viewing angle...................................................................................................... 32

7. Country dependent selections..................................................................................................................33

7.1. Language selections............................................................................................................... 33

7.2. Operation mode...................................................................................................................... 33

7.3. Language inserts .................................................................................................................... 33

8. Commissioning a FP2000 Series fire panel ............................................................................................34

8.1. Before switching on ................................................................................................................ 34

8.2. Procedure for switching on ..................................................................................................... 35

Appendix A: DIP switch settings .........................................................................................................................37

Appendix B: Operation modes ...........................................................................................................................37

FP/FR2000 V4.5: Installation and Commissioning Manual 1

Page 4

LIST OF FIGURES

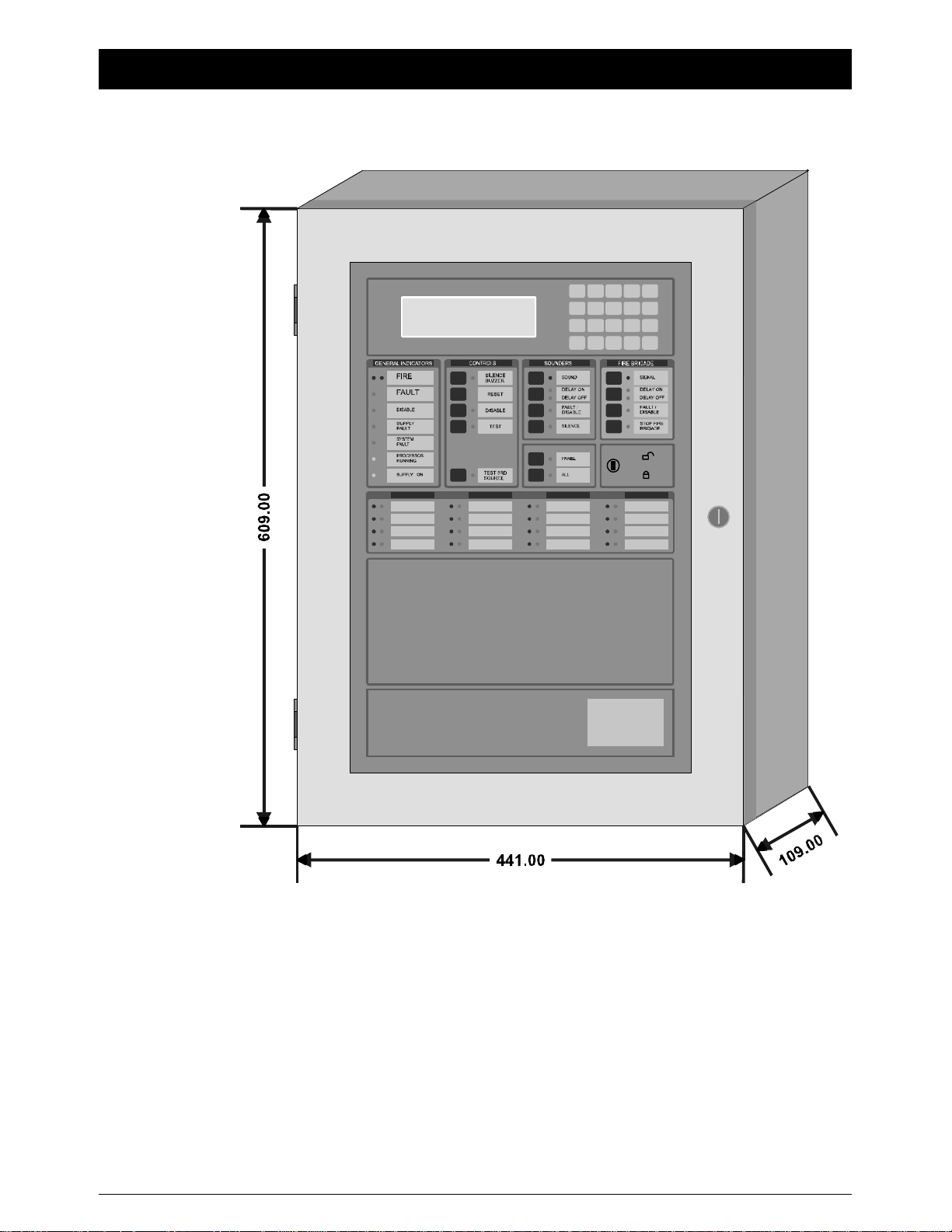

Figure 1: Panel dimensions (cabinet size A) .......................................................................................... 10

Figure 2: Mounting instructions.............................................................................................................. 11

Figure 3: Cable entries .......................................................................................................................... 12

Figure 4: Panel layout ........................................................................................................................... 13

Figure 5: Repeater layout ...................................................................................................................... 14

Figure 6: Class "A" return loop............................................................................................................... 15

Figure 7: Class "A" return loop with tee offs.......................................................................................... 15

Figure 8: Class "B" Single direction loop (Star configuration)................................................................. 16

Figure 9: Class B single direction loop with tee offs ............................................................................... 16

Figure 10: Position of inputs, loops and relay connections.......................................................................18

Figure 11: Class A loop connection ......................................................................................................... 19

Figure 12: Location of Class A - Class B jumpers .................................................................................... 19

Figure 13: Class B loop connection ......................................................................................................... 20

Figure 14: Class AB loop connection ....................................................................................................... 20

Figure 15: Programmable relay connections............................................................................................ 21

Figure 16: Supervised relay outputs A connections ................................................................................. 21

Figure 17: Two configurations for relay outputs 1-3 B .............................................................................. 22

Figure 18: Two configurations for relay output 4 B................................................................................... 22

Figure 19: Location of jumpers on sounder board .................................................................................... 23

Figure 20: Supervised inputs connections ............................................................................................... 23

Figure 21: Auxiliary inputs ....................................................................................................................... 24

Figure 22: Fire brigade transmitter connections....................................................................................... 24

Figure 23: Wiring when no feedback signal provided...............................................................................25

Figure 24: Dual tone siren connections.................................................................................................... 25

Figure 25: Current loop terminal connections .......................................................................................... 26

Figure 26: Connecting mains to mains terminal block..............................................................................27

Figure 27: Power-supply connections ...................................................................................................... 27

Figure 28: Battery connection.................................................................................................................. 28

Figure 29: Fault relay connections........................................................................................................... 28

Figure 30: Modem MOD2000 interconnection diagram............................................................................ 29

Figure 31: Network interface and associated connection ......................................................................... 30

Figure 32: The power supply and associated connections (230 V version)............................................... 31

Figure 33: Power supply connections (24 V version)................................................................................ 32

Figure 34: Adjustment of the LCD viewing angle ..................................................................................... 33

2 FP/FR2000 V4.5: Installation and Commissioning Manual

Page 5

INTRODUCTION

The purpose of this manual is to provide assistance during the installation and

commissioning of the FP/FR2000 Series fire panels, and repeaters/emulators.

Please note that the manual is intended as a guide only and is not to be used to replace

any local building and/or wiring codes.

Other manuals available are:

1. Aritech 900 Series detectors installation manual

2. Aritech 2000 Series detectors installation manual

3. FP2000 reference guide

4. FP2000 series network configuration guide

5. FP2000 end user instruction manual

1. GENERAL INFORMATION

1.1. Product codes

FIRE PANELS

FP2416: Cabinet size A*

FP2432: Cabinet size A*

FP2864: Cabinet size B*

REPEATERS / EMULATORS

FR2032: Cabinet size A*

2 loops extendible to 4 (class A)

16 zone - LED indication

Internal printer optional

2 loops extendible to 4 (class A)

32 zone - LED indication

No internal printer option

2 loops extendible to 8 (class A)

16 zone - LED indication, extendible to 64

Internal printer optional

16 zone/panel LED indication (max 32)

24 V DC supply

No internal printer option

FP/FR2000 V4.5: Installation and Commissioning Manual 3

Page 6

FR2064: Cabinet size B*

16 zone LED indication (max 64)

24 V DC supply

Internal printer optional

PERIPHERALS

ZE2016: 16 Zones LED extension (option)

NC2011: Network card RS485 (option)

NC2051: Network card optical (option)

NE2011: Network extension card RS485 (option)

NE2051: Network extension card optical (option)

PR2000: Internal printer (option) (40 column impact printer)

LC2002: Loop driver extension (option)

NA2004: 4-way network amplifier

*For cabinet sizes, see page 10.

1.2. Design specifications

The FP2000 series fire panels are designed to comply with the requirements of EN54-2

(control and indicating equipment) and EN54-4 (power supply equipment).

The panels have the following options with requirements according to EN54-2:

• Output to fire alarm devices

• Output to fire alarm routing equipment (according to DIN VDE0833)

• Output to fire protection equipment (according to VdS-directive)

• Delays to outputs

• Coincidence detection

• Alarm counter

• Fault/disablements from addressable points

• Output to fault warning routing equipment

• Standardised input/output interface (according to DIN 14661)

• Test condition

• Total loss of power supply (option)

4 FP/FR2000 V4.5: Installation and Commissioning Manual

Page 7

2. TECHNICAL SPECIFICATIONS

Loop capacity:

• Every loop PCB can be configured as two class A loops or four class B loops

• Addressable devices per loop: 126 (900 Series) or 128 (2000 Series)

• Maximum 1008 (900 Series) or 1024 (2000 Series) addressable devices per panel

• Maximum eight loops per panel

• Loop overload: >500 mA

• Loop operating load: 100 mA max

Zone capacity:

• 16 zones (expandable to 32, 48 or 64 zones in cabinet size B)

• 112 zones for control purposes

LCD screen:

• Backlit alphanumeric 8 x 40 character LCD

Indicators:

• General indicators

Fire - 2 x LED - Red

Fault - 1 x LED - Amber

Disable - 1 x LED - Amber

Supply fault - 1 x LED - Amber

System fault - 1 x LED - Amber

Processor running - 1 x LED - Green

Supply On - 1 x LED - Green

• Control indicators

Silence buzzer - 1 x LED - Amber

Disable - 1 x LED - Amber

Test - 1 x LED - Amber

Third source test - 1 x LED - Amber

• Sounders indicators

Sound - 1 x LED - Red

Delay On - 1 x LED - Amber

Delay Off - 1 x LED - Amber

Fault/Disable - 1 x LED - Amber

Silence - 1 x LED - Amber

FP/FR2000 V4.5: Installation and Commissioning Manual 5

Page 8

• Fire brigade indicators

Signal - 1 x LED - Red

Delay On - 1 x LED - Amber

Delay Off - 1 x LED - Amber

Fault/Disable - 1 x LED - Amber

Stop fire brigade - 1 x LED - Amber

• Zone monitoring indicators

Fire - 16 x LED - Red (expandable to 32, 48 or 64)

Fault - 16 x LED - Amber (expandable to 32, 48 or 64)

• Indicators related to network facilities

All - 1 x LED - Amber

Panel - 1 x LED - Amber

Membrane keyboard:

1, 2, 3, 4, 5, 6, 7, 8, 9, 0, A .. Z

General control keys:

Silence buzzer

Reset

Disable

Test

Third source test

Sounders control:

Sound

Delay On/Delay Off

Disable

Silence

Fire brigade control:

Signal

Delay On/Delay Off

Disable

Stop fire brigade

Control keys related to network facilities:

All

Panel

Control key switch:

Prevents unauthorised resetting and programming of the fire panel.

6 FP/FR2000 V4.5: Installation and Commissioning Manual

Page 9

Tamper switch:

Fitted to the inside of the fire panel door to record any entry to the cabinet.

Third source (when implemented):

Test button and LED to test total loss of power supply.

Communication ports:

• 2 x RS232 serial port (set-up, upload/download, printer, graphics, remote

operation/graphic package)

• 1 x current loop (to connect repeaters and fireman’s panels)

Standard outputs

All standard outputs are located on the sounder board.

OUT 1: Output to the alarm devices (sounders)

A: 24 V - 0.8 A supervised

B: 3K3/680 Ohm switched output

OUT 2: Output to fire routing equipment (fire brigade)

A: 24 V - 0.8 A supervised

B: 3K3/680 Ohm switched output

OUT 3: Output to fire protection equipment

A: 24 V - 0.1 A supervised

B: 3K3/680 Ohm switched output

OUT 4: Output to fault warning routings equipment

A: 24 V - 0.1 A supervised

B: 3K3/680 Ohm switched output

OUT 5 - OUT 8: 4 programmable relays

Three terminals: COM - NO - NC

Maximum switching current: 2 A @ 24 V DC

Maximum power rating: 50 W DC

250 VA AC

Standard inputs (FP2xxx only)

4 x auxiliary inputs (15 V AC or 20-28 V DC) 3 mA (FEP board)

4 x supervised inputs (inputs 1-4). 3.3k Ohm termination (sounder board)

Current loop:

• Maximum 15 devices

• Maximum 1 km between 2 current loop devices

• Aritech FM800 / FR800 - German fire brigade panel (according to DIN 14661) can

be connected.

• Cable capacitance max. 150 nF

FP/FR2000 V4.5: Installation and Commissioning Manual 7

Page 10

Power supply characteristics (FP2xxx series):

INPUT: 230 V AC ± 15% 50 Hz ± 10% 200 V A

21 – 28 V DC (24 V standby battery)

OUTPUT: 27.6 V DC ± 1% 4 A total (battery charge and aux.)

with or without batteries

Supervisory: - mains fail

- battery disconnect

- battery flat

- flat battery cut-out

Fuses: AC fuse 2 A (20 mm STD fuse)

Aux. output 5 A (20 mm STD fuse)

Battery fuse 5 A 20 mm STD fuse)

Max. current drawn from the primary input: 1 A

Max. output ripple voltage: ± 300 mV

Normal Operation FP2416/32 FP2864

Mains load (max) 200 VA 200 VA

Total output current (27.6 V) 4 A 4 A

Battery capacity I

Battery capacity (max) 69 AH 69 AH

Required battery charging current (max. battery

capacity)

Current required by system (I

Available auxiliary current 0.45 A 0.15 A

= 0 (72H standby) 36 AH 58 AH

AUX

3.05 A 3.05 A

) 0.5 A 0.8 A

SYS

−−

Charging current based to charge batteries up to 80% in 24 hours at 75% efficiency

Alarm Operation FP2416/32 FP2864

Mains load (max) 200 VA 200 VA

Total output current (27.6 V) 4 A 4 A

Required battery charging current (max. battery

capacity)

Current required by system 0.6 A 1 A

Available auxiliary current 3.4 A 3 A

Power supply characteristics

INPUT: 21 – 28 V DC (24 V standby battery)

I

calculated at 252 x 900 series ionisation detectors (FP2416) 1008 x 900

SYS

series ionisation detectors (FP2864)

0 A 0 A

8 FP/FR2000 V4.5: Installation and Commissioning Manual

Page 11

Supervisory

INPUTS: - Mains fail

- Charger fail

Fuses: Fuse 1 A (20 mm STD fuse)

Input current: 0.3 A (no options installed)

Environmental

Enclosure protection: IP54

Temperature

Optional: - 5 ºC — +40 ºC

Storage: - 20 ºC — +60 ºC

FP/FR2000 V4.5: Installation and Commissioning Manual 9

Page 12

3. DIMENSIONS OF THE FIRE PANEL

Figure 1: Panel dimensions (cabinet size A)

−− Cabinet size B: 804 x 441 x 109 (H x W x D)

Cabinet size C: 473.5 x 441 x 109 (H x W x D)

All dimensions are in mm

10 FP/FR2000 V4.5: Installation and Commissioning Manual

Page 13

4. MOUNTING INSTRUCTIONS

Cabinet size A

Cabinet size C

4.1. Mounting instructions

Figure 2: Mounting instructions

Cabinet size B

4 X 5 mm mounting holes

4 X 5 mm mounting holes

4 X 5 mm mounting holes

FP/FR2000 V4.5: Installation and Commissioning Manual 11

Page 14

The 5 mm mounting holes are located as shown in Figure 2.

y

Five 20 mm holes are provided for cable entry at the top and bottom of the panel.

The total panel weight equals: 11 kg for size A cabinet (excluding batteries)

15 kg for size B cabinet (excluding batteries)

9 kg for size C cabinet (excluding batteries)

Figure 3: Cable entries

Holes in roof X 4

Holes in base for mains entr

12 FP/FR2000 V4.5: Installation and Commissioning Manual

Page 15

4.2. Panel layout

Figure 4: Panel layout

1 23 4 5 6 26 78910

17

22

18

19

20

21

23

24

11 12 27 13 14 25 15 16

1. Numeric keypad 14. Optional ARCNET network card

2. Common LED board 15. Power supply and battery charger

3. LCD Display and backlight board 16. 2 x battery

4. Host processor board 17. Optional third source battery

5. Current loop terminal connections 18. Memory back-up battery jumper

6. RS232 ports (port 1-front; port 2-back) 19. Non-volatile memory lock

7. Front-end processor board 20. Service/commission mode switch

8. FEP power supply board 21. Optional printer (PR2000)

9. 2 Loop driver board (x2) 22. Auxiliary inputs terminal connections

10. Sounder relay board 23. Loop 1-4 terminal connections

11. Zone matrix display board 24. Terminal connections sounder board

12. DIP switch 25. Modem (optional)

13. Host power supply board 26. DB9-DB25 adapter (with modem)

27. Bus-termination card

FP/FR2000 V4.5: Installation and Commissioning Manual 13

Page 16

4.3. Repeater layout

Figure 5: Repeater layout

12 3 4 5 6 7

8

9

10

11

12

13 14 17 15 16

1. Numeric keypad

2. DIP switch

3. Current loop terminal connections

4. 24 V power supply

5. Memory back-up battery jumper

6. Service-commission mode switch

7. Common LED board

8. Host processor board

9. Zone matrix display board

10. Host power supply board

11. RS232 ports (port 1-front; port 2-back)

12. Optional 3rd source battery

13. Non-volatile memory lock

14. Optional printer (PR2000) (FR2064 only)

15. LCD display and backlight board

16. ARCNET network card

17. Bus termination card

14 FP/FR2000 V4.5: Installation and Commissioning Manual

Page 17

5. LOOP DESIGN

5.1. Typical configuration

The fire panel accepts the following loop configurations.

Figure 6: Class "A" return loop

Figure 7: Class "A" return loop with tee offs

FP/FR2000 V4.5: Installation and Commissioning Manual 15

Page 18

Figure 8: Class "B" Single direction loop (Star configuration)

Figure 9: Class B single direction loop with tee offs

A maximum of 126 detectors (900 Series) or 128 detectors (2000 Series) can be

connected to a loop. For combinations of fire sensing devices, monitoring controllers and

input/output devices, the maximum number of addressable units must be calculated.

Please refer to the Installation Manual of the 900 Series and 2000 Series detectors.

16 FP/FR2000 V4.5: Installation and Commissioning Manual

Page 19

−− EN54 specifies that a short circuit or an interruption in a detection circuit

cannot prevent the indication of a fire alarm from more than 32 fire detectors

and/or manual call points.

Therefore, when more than 32 detectors are connected to one loop, an

isolator should be placed at least at every 32 devices. In that case, a class A

configuration (no Tee Offs) should always be used.

−− EN54 specifies that in case of a system fault, not more than 512 fire detectors

and/or manual call points and their associated mandatory functions shall be

affected. Taking this into consideration, the amount of detectors per panel

should be limited to 512.

5.2. Suitable cable types

Most types of cables are acceptable. 126 detectors can be operated over 2 km of 1 mm

mineral insulated cable (maximum capacitance = 300 nF/km, total maximum resistance

=

100 Ohm)

−− The cable resistance limit is calculated to maintain the minimum required

supply - voltage in the presence of the worst case load conditions.

FP/FR2000 V4.5: Installation and Commissioning Manual 17

Page 20

6. FIELD CONNECTIONS

4

6.1. Loop, output and input connections

Figure 10: Position of inputs, loops and relay connections

1

FEP

FEP power supply board

2

3

4 X auxiliary inputs

LC2002

LC2002

SD2000

Programmable relays

Fault routing (J)

Fire protection (G)

Fire routing (E)

Fire alarm devices (C)

Line driver

Line driver

EN VDS common I/O

A

A

A

2 X class A loops

or

4 X class B loops

(FP2000 only)

2 X class A loops

or

4 X class B loops

(FP2000 only)

Fire routing (E) feedback input

Fire protection (G) fault input

Fault routing (J) fault input

General input

A

18 FP/FR2000 V4.5: Installation and Commissioning Manual

Page 21

6.1.1. Loop connections

Standard, the panel is configured in a class A set-up (see also Chapter 5, Loop design):

Figure 11: Class A loop connection

When class B operation is required, the A-jumpers should be removed to double the

amount of loops. The B-jumpers should be put in.

Figure 12: Location of Class A - Class B jumpers

FP/FR2000 V4.5: Installation and Commissioning Manual 19

Page 22

Figure 13: Class B loop connection

FWD.

RET.

++

Loop 1

Loop 2

The FWD and Return of each class A loop used must be linked in the

correct polarity

Isolators are polarity dependant (see Detector Installation and

Commissioning Manual)

Preferably loop boards must be configured for class A

A and B loops can be combined in the following way:

a) Configure as class A

b) Class B loops are connected as follows:

Figure 14: Class AB loop connection

FWD.

RET.

Loop 1

The maximum of loops (either A or B) in one panel is limited to eight.

All loop cards in a panel must be configured in the same way (either A or

B).

Loop devices

The FP2000 Series of analogue addressable fire panels are fully compatible with the

Aritech 900 range of detectors and manual call points, as well as with the Aritech range

of monitoring controllers and input/output devices. They are also fully compatible with

the Aritech Intrinsically Safe range of fire detectors.

The FP2000 Series of fire panels are also fully compatible with the Aritech 2000 range of

detectors, manual call points and input/output devices.

Dip switch 7 on the Host PSU board must be in the ON (up) position when using Aritech

900 devices and in the OFF (down) position when using the Aritech 2000 devices. (See

Appendix A).

For information on any devices, refer to the appropriate Installation and Commissioning

Manual.

20 FP/FR2000 V4.5: Installation and Commissioning Manual

Page 23

6.1.2. Programmable relay

y

Each of the four programmable relays has a change over contact. The relay is shown in

the NORMAL state. A red LED indicates the state of the relays.

Figure 15: Programmable relay connections

Section of the sounder board

LED 8 7 6 5

shown in the normal state

Rela

6.1.3. Supervised relay outputs A

When active, these outputs provide 24 V DC. A red LED indicates the state of the

outputs.

Figure 16: Supervised relay outputs A connections

FP/FR2000 V4.5: Installation and Commissioning Manual 21

Page 24

6.1.4. Relay outputs B

OUT1 / OUT2 / OUT3

Two configurations are available. The configuration is determined by jumper settings.

An LED indicates the state of the output (LED ON = output active).

Figure 17: Two configurations for relay outputs 1-3 B

Configuration 1

Outputs CONF 1 CONF 2

Sounders OUT 1 J12 in

J13 out

FB OUT 2 J2 in

J3 out

Fire Protection OUT3 J4 in

J5 out

OUT 4

The configurations for OUT 4 is shown below (FAIL SAFE). The switch is closed when

there is a fault. The LED is ON when there is no fault.

J12 out

J13 in

J2 out

J3 in

J4 out

J5 in

Configuration 2

− J18 out

J19 out

− J18 out

J19 out

Figure 18: Two configurations for relay output 4 B

Configuration 1

Outputs CONF 1 CONF 2

Fault routing OUT4 J6 in

J7 out

J6 out

J7 in

Configuration 2

22 FP/FR2000 V4.5: Installation and Commissioning Manual

Page 25

Figure 19: Location of jumpers on sounder board

6.1.5. Supervised inputs IN5 - IN8

The supervised inputs are located on the sounder PCB.

The function of these inputs is determined by the operation mode of the FP2000 (see

Appendix B). In NEN and EP operation mode these inputs have no dedicated function

and are freely programmable through I/O logic.

Figure 20: Supervised inputs connections

FP/FR2000 V4.5: Installation and Commissioning Manual 23

Page 26

6.1.6. Auxiliary inputs

Four auxiliary inputs are provided on the FEP-PCB. Each input is opto-isolated and

independent of polarity. These inputs are not supervised and can be used through I/O

programming.

Figure 21: Auxiliary inputs

6.1.7. Connection of fire brigade transmitter (according to DIN VDE0833)

Figure 22: Fire brigade transmitter connections

EOL position B

EOL position A

Position of end-of-line

resistor

A : for supervised lines

B : for non-supervised lines

− The wiring must be changed when there is no feedback signal.

24 FP/FR2000 V4.5: Installation and Commissioning Manual

Page 27

Figure 23: Wiring when no feedback signal provided

OUT 2 B must be set up according to Configuration 1 (see 6.1.4)

6.1.8. Connection of dual tone siren AS263/AS264

The Aritech dual-tone siren can be connected on Sounder (out 1) and Fire Brigade (out

2) in the following way:

Figure 24: Dual tone siren connections

OUT 2 OUT 1

Common

1 Sound

2 Sound

Common

1 Sound

2 Sound

Set jumpers as follows: J2 in, J3 in, J18 in, J19 in

−− This set-up should only be used when operation mode is "EP"

(see Appendix B).

FP/FR2000 V4.5: Installation and Commissioning Manual 25

Page 28

6.2. Communication port connections (all models)

6.2.1. Current loop

A current loop output is provided as a standard feature on the FP2000 Series of fire

panels. The current loop is used to drive up to 15 fireman’s panels and conventional

repeaters. Each fireman’s panel/repeater has its own unique address, by means of

resistor settings at that panel. Please refer to the appropriate Installation Manual for the

correct settings.

The location of the current loop terminal connections is shown in Figure 4.

The connections between the FP2000 Series fire panels and the FM800 Series fireman’s

PCBs and FR800 Series repeater are as shown below.

Figure 25: Current loop terminal connections

Host CPU board

++

6.2.2. RS232 ports

The two RS232 ports are provided with DB25 male connectors. The location of the

connectors is shown in Figure 4. The signals at both the connectors are as follows:

Repeater 1 Repeater 2

To route the current loop wires inside the cabinet refer to section 4.2, Item 32.

PIN NR Signal name

1DCD

2 RXD

3 TXD

4DTR

5 GND

6DSR

7 RTS

8 CTS

9RI

++

26 FP/FR2000 V4.5: Installation and Commissioning Manual

To route the RS232 cable inside the cabinet, refer to section 4.2, Item 32.

Page 29

6.3. Power supply connections

y

(

)

p

6.3.1. Mains power connection

Figure 26: Connecting mains to mains terminal block

Mains

terminal

block

To ground stud on panel

Transformer

230 V mains

A mains terminal block with fuse is provided for connecting the panel to the mains.

Please note the polarity of live, mains and earth.

During installation the 230 VAC should be fed directly from a separate group in the

distribution board. This group should have a bi-polar disconnect device, be clearly

marked and only be used for fire detection equipment.

The recommended mains cable is 3 x 1.5 mm² (live, neutral, earth).

6.3.2. Power supply

Figure 27: Power-supply connections

TRM1

Batter

Neutral

Ground

Live

Modem connections

MOD2000

Modem

Gnd. +5 V

Mains switch with fuse

Fault

Aux.

NC

Com

+

-

Fault relay

Aux.

ower

FP/FR2000 V4.5: Installation and Commissioning Manual 27

Page 30

6.3.3. Battery connection

Figure 28: Battery connection

Link

Blue

Red

Bat

Vin

Bat 12 V

++

Observe the correct polarity when connecting the battery!

6.3.4. Connecting the fault relay

1. Ensure that the mains power is disconnected before opening the unit.

2. Connect the fault relay as shown in Figure 29.

3. Route the wires away from sharp edges and corners and fix them into position.

Figure 29: Fault relay connections

Fault relay

contacts shown

in fault

condition

Bat

6.4. Installing a modem

The installation of the MOD2000 modem is described below. The modem is provided

with a bracket for wall mounting. To install this bracket, please refer to Figure 4 and

Figure 30.

1. Remove the protective cover from the double-sided self-adhesive tape on the rearmounting surface of the bracket supplied with the modem.

2. Position the mounting bracket inside the fire panel as shown in Figure 4 and fix it

into position using the double-sided self-adhesive tape.

3. Before connecting the modem to the fire panel ensure that the battery and the

mains power are isolated.

4. Carefully read the Modem User’s Manual. To connect the modem to the fire panel

and telephone line, refer to Figure 4 and Figure 30.

5. Connect the green earth wire leading from the modem to the earth stud inside the

fire panel. Please note that the modem and associated circuitry are only protected if

this connection is made.

28 FP/FR2000 V4.5: Installation and Commissioning Manual

Page 31

6. Connect the power harness leading from the modem to the power supply. Observe

correct polarity. Please note that the connector leading to the printer is not used. It

must be tied down using the mounting studs provided inside the fire panel.

7. Connect the RS232 input on the modem to the serial port.

8. Connect the telephone line to the modem protection board (use the telephone cable

adapter supplied if required).

9. Slide the modem into the bracket inside the panel and fix all cables in position using

the hardware supplied (P-Clips and nuts). Ensure that the modem cannot slide out

of the bracket.

10. Restore battery and mains power to the fire panel and turn the modem power switch

the ON.

Figure 30: Modem MOD2000 interconnection diagram

ℵ To 5 V on power supply

(modem terminal)

ℑ 5 V to printer (not used –

fix in position to prevent

contact)

ℜ Telephone line adapter (if

required)

R

℘ To telephone line

⊗ To Serial 2

⊕ Not used

∅ Power harness

∩ To earth

∪ Green

⊃ Phone

Ρ Line

6.5. Network connections

6.5.1. NC2011/NC2051 ARCNET network cards

The NC2011 and NC2051 are interface cards required to network FP2000 Series fire

panels and FR2000 Series repeaters/emulators. All network nodes communicate via the

ARCNET protocol, using RS485 electrical (NC2011) or optical medium (NC2051). Every

node on the network - except the UN2000 - must have a network card installed as a

standard. The PCB is delivered with the necessary washers, nuts and spacers to allow

for proper mounting. All repeaters/emulators are supplied with a standard NC2011

(RS485) network card. For more information refer to the Network Configuration Guide.

FP/FR2000 V4.5: Installation and Commissioning Manual 29

Page 32

Figure 31: Network interface and associated connection

)

NC2051 (optical

¯

¯

ℵ Jumper –

termination

end-of-line

ℑ Channel A

ℜ Jumper-earth

connection

℘ Channel B

⊗ Repeater

selection

n

ℵ Repeater mode

selection

ℑ TX – Transmit A

ℜ Optical fibre

connections

channel A

℘ RX – Receive A

⊗ TX – Transmit B

⊕ Optical fibre

connections

channel B

6.5.2. NE2011/NE2051 ARCNET network extension cards

The NE2011 (RS485) and NE2051 (Optical) are network interface modules that are

mounted directly on the NC2011 or NC2051 network card. The modules provide the user

the ability to implement a wide range of network topologies when networking FP2000

Series fire panels and FR2000 Series repeaters/emulators. The modules are delivered

with the necessary washers, nuts and spacers to allow for proper mounting. For more

information refer to the Network Configuration Guide.

30 FP/FR2000 V4.5: Installation and Commissioning Manual

Page 33

6.6. Power supply

6.6.1. 230 V version

Figure 32: The power supply and associated connections (230 V version)

24 V auxiliary

power

Live

Earth

Neutral

M5 earth stud mounted on

back panel

12 V

battery

12 V

battery

REV 1.1

230 VAC

The DOL power supply PSU-2000 has been designed according to EN54-4. A mains

switch (on the bottom) is provided, as well as a battery ON/OFF switch. Three LED’s on

top of the power supply indicate the following:

- Charger On

- Battery On

- Battery fail

On top there is a 24 Volt auxiliary output for other fire panel equipment.

As part of the building installation, the 230 V AC should be derived directly from a

separate group in the distribution board. This group should have a bi-polar disconnect

device, clearly marked and only used for fire detection equipment.

FP/FR2000 V4.5: Installation and Commissioning Manual 31

Page 34

The recommended mains cable is 3 x 1.5 mm² (live, neutral, earth).

Two 12 V batteries have to be put in series and connected to the battery terminals. No

other equipment may be connected to the battery terminations.

The PSU-2000 is designed for use in Aritech fire panel housing only.

An optional third source battery (9 V, PP3) can be installed as a third source of power.

The location of the third source battery is shown In Figure 4.

6.6.2. 24 V VERSION

The FR2000 is delivered with a 24 V connection board.

Figure 33: Power supply connections (24 V version)

24 V DC terminator board

ℵ +24 V

ℑ -24 V

ℜ Earth

℘ Chrg. fail

⊗ Mains fail

⊕ Normally shorted inputs

`´ˆ˜

6.7. LCD display viewing angle

The LCD display may be set to obtain maximum contrast by adjusting the viewing angle

of the LCD display. This viewing angle is set by adjusting potentiometer VR 1 located on

the LCD display and backlight board.

32 FP/FR2000 V4.5: Installation and Commissioning Manual

Page 35

Figure 34: Adjustment of the LCD viewing angle

LCD display and backlight board

LCD contrast control

7. COUNTRY DEPENDENT SELECTIONS

7.1. Language selections

The DIP switch on the inside of the panel is used to select the language. Please refer to

Appendix A.

SW1/SW2/SW3 determine the language.

7.2. Operation mode

NEN - EN or EP mode of operation is selectable. The operation of Sounder, Fire Brigade

Outputs and Inputs from Fire Brigade, Fire Protection and Fault Routing are influenced

by these settings. Please refer to Appendix B.

7.3. Language inserts

Inserts are available in several languages and need to be slipped into the inside of the

panel.

FP/FR2000 V4.5: Installation and Commissioning Manual 33

Page 36

8. COMMISSIONING A FP2000 SERIES FIRE PANEL

8.1. Before switching on

1. Visually check the fire panel for any damage that might have occurred during

installation. In particular, check for loose pieces that could have fallen in the

electronics.

2. Check that all harnesses are securely plugged into the correct plug positions on the

printed circuit boards.

3. Ensure that both the mains switch and the battery on/off switch are in the OFF

position.

4. Enable the lithium battery by linking the jumper J5 (located above the battery on the

host CPU board) to the ON position.

5. Unlock the memory.

6. Set the panel to service mode (this prevents any output from switching during

commissioning).

7. Connect the main supply to the power supply input terminals or connect the 24 V to

the 24 V supply board.

8. Connect the batteries to the battery terminals of the power supply. Observe correct

polarity!

9. Connect the repeaters (Fireman’s panels) to the current loop terminals. For detail

refer to the FM800 Installation, Configuration and Detailed Operation Manual.

10. Connect the network card (if necessary) - for detail refer to the Network

Configuration Guide.

11. Ensure that the fire panel is well earthed at the earth terminals provided. The earth

must be directly wired to the distribution board earth. This is required for reasons of

both safety and interference suppression.

12. Ensure that all field devices are connected and that their addresses are correctly

set.

−− Loop isolators must have the correct polarity wired.

13. Use a multimeter to check all field wiring for short circuits, continuity, and earth

faults. If isolators have been used in the loop wiring, then one wire of the loop will

not have continuity. Continuity, earth fault and short circuit must be checked

between each isolator.

DO NOT MEGGER THE LOOPS - This will damage devices connected to the loops.

14. Connect all field wiring to the fire panel. The service switch ON will prevent outputs

from switching.

34 FP/FR2000 V4.5: Installation and Commissioning Manual

Page 37

15. Ensure that NO loose bare wiring exists in the fire panel cabinet. This can cause

damage to the electronics.

8.2. Procedure for switching on

1. Switch the main power on at the power supply or connect the 24 V to the 24 V

supply board.

2. The internal buzzer will sound and the message "STARTING FP2000" will appear

on the LCD display.

If the above does not occur, DO NOT proceed. Check that the mains supply is

present and that the fuses are good.

3. Switch the battery On/Off switch to the ON position (230 V model only).

4. Check that the battery float voltage is 27.6 V. If the voltage is significantly less, then

check:

• Are the batteries flat?

• Are there possible overloads in the field?

5. If there are visible signs of the power supply overheating, then do not proceed.

Disconnect the field wiring and batteries, and eliminate the cause of the problem.

6. The fire panel will perform internal checks. Any failures occurring will be reported on

the LCD screen.

Observe the total number of faults reported on line 8 of the LCD screen.

It is expected to have at least two faults reported:

• Memory unlocked

• Service switch ON

7. Use the

8. All faults (except for the two above) should be eliminated before proceeding further.

Use the [RESET] button to obtain a new fault report each time.

Possible faults that can occur on switch ON are:

Loop overload - Check the affected loop for short circuits

Earth fault - Check/eliminate the fault

Battery fail - Check battery charging

Sounders or fire brigade - Check polarity reversal diodes and 5K6

Short circuit or open circuit termination resistors

key to view the faults existing.

Specific device faults - Check device

Double address - Note address of device and check

9. Enable the loop devices of the FP2000 fire panel in one of three methods:

• Individually manually using the Device Set-up Menu.

• Set default using the System Default Set-up.

• Program by means of a laptop computer using the RS232 port.

FP/FR2000 V4.5: Installation and Commissioning Manual 35

Page 38

10. Eliminate any fire alarms and comms alarms reported.

11. Investigate all devices that are reported Disabled.

12. Check all output relays for correct switching.

13. Configure your Panel ID.

IF A NETWORK IS INSTALLED:

1. Configure network set-up with one of two methods:

• Manually using LCD menus.

• Program by means of a laptop computer using the RS232 port.

2. Investigate all panel and repeater faults that are reported.

3. Check status of the systems on the ARCNET network that are configured to

communicate with the repeater. Faults regarding communication with repeater node

identification address should disappear when the ARCNET network is operational.

4. Check all connections to panels by emulating them.

5. Check panel fault reporting by switching the panel off.

6. Check fire and fault reporting.

7. Once all of the above is correct, then:

1. Switch the service switch to OFF

2. Check all network I/O for correct functioning

3. Switch the memory lock switch to locked

8. Reset the repeaters and panels.

36 FP/FR2000 V4.5: Installation and Commissioning Manual

Page 39

APPENDIX A: DIP SWITCH SETTINGS

On host PSU board:

SW1 SW2 SW3 SW4 SW5 SW6 SW7 SW8 OPTION

ON Aritech (900 Series)

OFF Sentrol (2000 Series)

OFF OFF EN Operation

OFF ON

ON OFF NEN Operation

ON ON EP Operation

Language Group

1 2 3

OFF OFF OFF English English English

OFF OFF ON Italian Lithuanian Danish

OFF ON OFF Dutch (Belgium) Polish Swedish

OFF ON ON Portuguese Hungarian Norwegian

ON OFF OFF Dutch (Holland) Czech Finish

ON OFF ON German Slovakian

ON ON OFF French

ON ON ON Spanish

ON = Upper position

OFF = Lower position

The location of the DIP switch is shown in Figure 4.

APPENDIX B: OPERATION MODES

Mode EN NEN EP

Sounders:

Sound Resound (level 2) Resound (level 2) Sound (level 2)

Silence Silence (level 2) Silence (level 1) Silence (level 2)

Delay Allowed Not allowed Allowed

1 min. time-out FB

signal time-out stopped

by silence bell

Fire Brigade:

Signal No No Signal (level 2)

Stop No No Stop (level 2)

Delay Allowed Allowed Allowed

VDS Inputs:

inp 5 Fire brigade return Logic Logic

inp 6 Fault routing return Logic Logic

inp 7 Fire protection return Logic Logic

inp 8 Logic Logic Logic

FP/FR2000 V4.5: Installation and Commissioning Manual 37

Page 40

14 3252 999-2

Loading...

Loading...