FP2000

Analogue addressable Fire Panel

Reference Guide

LKFP2503

Revision 5 : September 1999

Downloaded from: http://www.guardianalarms.net

Copyright

© Aritech 1998. All rights reserved. No part of this publication may be reproduced, transmitted, stored in a retrieval system, or

transmitted in any form, or by any means – electronic, photocopying, recording, or otherwise – without the prior written permission of

Aritech.

Reference Guide 3

CONTENTS

Description ................................................................................................................................................................................7

Special features .......................................................................................................................................................................7

User friendliness ......................................................................................................................................................................7

Powerful maintenance features .........................................................................................................................................8

Networking ................................................................................................................................................................................8

General features......................................................................................................................................................................8

Standard I/O facilities ............................................................................................................................................................9

Mechanical data ......................................................................................................................................................................9

Led indications and controls.............................................................................................................................................. 11

General indicators................................................................................................................................................................. 11

Controls ....................................................................................................................................................................................13

Sounders.................................................................................................................................................................................. 13

Fire brigade ............................................................................................................................................................................. 14

Other..........................................................................................................................................................................................15

Zone indicators ...................................................................................................................................................................... 15

LCD and Keypad ...................................................................................................................................................................16

Alarm line................................................................................................................................................................................. 17

Valid entries line....................................................................................................................................................................18

Status line................................................................................................................................................................................19

System status menu............................................................................................................................................................ 19

Access to main menu..........................................................................................................................................................20

Main menu .................................................................................................................................................................. 21

System menu............................................................................................................................................................. 23

Configuration menu ................................................................................................................................................. 24

Hardware configuration 1 ...................................................................................................................................... 25

Hardware configuration 2 ...................................................................................................................................... 27

Board information.....................................................................................................................................................28

Memory allocation 1 ................................................................................................................................................29

Memory allocation 2 ................................................................................................................................................30

Panel ID ....................................................................................................................................................................... 31

Communication menu............................................................................................................................................. 33

Port setup ....................................................................................................................................................................34

Network menu ........................................................................................................................................................... 37

Panels ..........................................................................................................................................................................38

Local repeaters ......................................................................................................................................................... 39

Global repeaters ....................................................................................................................................................... 40

Modem menu............................................................................................................................................................. 41

Modem alarm report 1 ............................................................................................................................................ 42

Modem alarm report 2 ............................................................................................................................................ 43

Modem maintenance.............................................................................................................................................. 44

Modem setup 1 ......................................................................................................................................................... 45

Modem setup 2 ......................................................................................................................................................... 46

Modem setup 3 ......................................................................................................................................................... 47

CL devices .................................................................................................................................................................. 48

Access menu............................................................................................................................................................. 49

Access codes............................................................................................................................................................. 50

Field access...............................................................................................................................................................51

Clear site data 1 ........................................................................................................................................................52

Clear site data 2 ........................................................................................................................................................ 54

Set default................................................................................................................................................................... 55

Set times menu......................................................................................................................................................... 58

Set date and time.....................................................................................................................................................59

Output delays ............................................................................................................................................................. 60

Fire brigade delay off times .................................................................................................................................. 61

Sounder delay off times ......................................................................................................................................... 62

Zone off times ............................................................................................................................................................ 63

Zone on times ............................................................................................................................................................ 64

Day mode times ........................................................................................................................................................ 65

Night mode times .....................................................................................................................................................66

Restart menu............................................................................................................................................................. 67

Device menu.............................................................................................................................................................. 68

General setup and view (all types).....................................................................................................................69

Smoke and Heat detec tors...................................................................................................................................73

Manual Call Point.....................................................................................................................................................75

Sounder ....................................................................................................................................................................... 77

Indicating circuit controller.....................................................................................................................................79

Monitor units...............................................................................................................................................................80

Input/output units...................................................................................................................................................... 82

Gas unit I/O (GCU 1).............................................................................................................................................. 84

Zone menu.................................................................................................................................................................. 86

Area menu .................................................................................................................................................................. 89

Zone graphics ............................................................................................................................................................ 91

Zone graphic screen ...............................................................................................................................................92

Graphic device statistics........................................................................................................................................ 93

Device graphics ........................................................................................................................................................ 94

Device graphic screen ............................................................................................................................................ 96

Graphic device setup.............................................................................................................................................. 97

Input/output............................................................................................................................................................................. 98

Common facilities – all input types .....................................................................................................................99

Input definition – type General .......................................................................................................................... 102

Input definition – type Zone ............................................................................................................................... 104

Input definition – type Area................................................................................................................................ 105

Input definition – type Adjacent Area..............................................................................................................106

Input definition – type Internal........................................................................................................................... 107

Input definition – type Time................................................................................................................................108

Input definition – typ e Device Input................................................................................................................. 110

Input definition – type Device............................................................................................................................ 111

Input definition – type Network .........................................................................................................................112

Input definition – type Action............................................................................................................................. 113

Input definition – type Current Loop Device.................................................................................................114

Common facilities – all output types ............................................................................................................... 115

Output definition – type General ......................................................................................................................118

Output definition – type Zone ............................................................................................................................ 119

Output definition – type Area.............................................................................................................................120

Output definition – type Internal.......................................................................................................................121

Output definition – type Device Output.......................................................................................................... 122

Output definition – type Supervised In ternal................................................................................................123

Output definition – type Supervised Device Output..................................................................................124

Output definition – type Network ...................................................................................................................... 125

Output definition – type Current Loop Device.............................................................................................126

Output definition – type Supervised Current Loop.....................................................................................127

Output definition – type Event...........................................................................................................................128

Output definition – type Action.......................................................................................................................... 129

Output definition – link to equipment..............................................................................................................130

Logic .......................................................................................................................................................................... 132

CL devices ............................................................................................................................................................... 135

Event menu .......................................................................................................................................................................... 137

Display events ........................................................................................................................................................138

Clear event menu..................................................................................................................................................140

Clear all events menu .......................................................................................................................................... 141

Maintenance menu ............................................................................................................................................................142

Maintenance report menu..................................................................................................................................143

Device values .........................................................................................................................................................144

Device values [LCD].............................................................................................................................................145

Maintenance device.............................................................................................................................................146

Clear device statistics .......................................................................................................................................... 147

Hardware test .........................................................................................................................................................148

Maintenance times menu ...................................................................................................................................149

Options menu.........................................................................................................................................................150

Language menu.....................................................................................................................................................151

Operation menu.....................................................................................................................................................152

4 Reference Guide

Device protocol......................................................................................................................................................153

Loop test 1 ............................................................................................................................................................... 154

Loop test 2 ............................................................................................................................................................... 154

Loop test 1 – parameter screen 1 ...................................................................................................................155

Loop test 2 – parameter screen 2 ...................................................................................................................156

Loop test 3 – parameter screen 1 ...................................................................................................................157

Fast Compensation ..............................................................................................................................................158

Main menu ............................................................................................................................................................... 159

Test menu.............................................................................................................................................................................160

Zone test menu......................................................................................................................................................161

Zone test..................................................................................................................................................................162

Full test report .........................................................................................................................................................163

Test report [LCD] ...................................................................................................................................................164

Clear test results.................................................................................................................................................... 165

Exception test report............................................................................................................................................166

Exception test report [LCD]................................................................................................................................167

Test devices............................................................................................................................................................168

Output test ............................................................................................................................................................... 169

Lamp test.................................................................................................................................................................170

Alarm count.............................................................................................................................................................171

User log .................................................................................................................................................................... 172

Disable menu ......................................................................................................................................................................173

Zone disable............................................................................................................................................................174

Device disable menu ............................................................................................................................................175

Alarm device disable............................................................................................................................................176

Manual device disable.........................................................................................................................................177

Area disable............................................................................................................................................................178

Disabled report menu.......................................................................................................................................... 179

Disabled zones report.......................................................................................................................................... 180

Disabled device report.........................................................................................................................................181

Disabled areas report .......................................................................................................................................... 182

Output disable ........................................................................................................................................................183

FP2000 panel menus .......................................................................................................................................................184

Description ...........................................................................................................................................................................184

Reference Guide 5

I

NTRODUCTION

The purpose of this manual is to provide assistance during the installation and

commissioning of the FP2000 Series Fire Panels.

Please note that the manual is intended as a guide only and is not to be used to replace

any local building and/or wiring codes.

Other manuals available are:

Product Code

F2000 Installation and Commissioning Manual LKFP2003

Series 950 Installation Guide LKFP2103

2000 Series Sensors Installation Guide LKFP2203

FP2000 Series Network Configuration Guide LKFP2303

FP2000 End User Instruction Manual LKFP2403

6 Reference Guide

1. P

Description

The FP2000 series of analogue addressable fire panels revolutionizes fire detection using

state of the art electronic technology.

Designed to meet the European Standard EN54 Parts 2 and 4, and tested to the

requirements of IEC801 Part 1-4, the FP2000 series provides one of the most versatile

and flexible systems available.

Special emphasis is placed on the design of the FP2000 in terms of aesthetics and

ergonomics, as well as technical features.

Special features

• False alarm checking on smoke and heat detectors.

• Fast scan algorithms for manual call points and pre -alarm.

• Memory allocation of the system is configurable to suit individual applications.

ANEL DEFINITION

• Powerful I/O programming including Boolean functions.

• Service/commission mode switch.

• Day/night zone operation.

• Zone on/off operation (for security applications).

• Selectable alarm level per device as well as automatic contamination adjustment.

• Event buffer to store up to 999 events.

• Extensive error checking.

• Coincidence mode for zones and areas.

User friendliness

The system is designed for ease of installation, operation and maintenance. A fully

implemented EN54 display and control lexan panel is provided. The display is an 8-line x

40-character backlit LCD display. Up to 2 lines x 40-character text is provided for field

devices, zones and areas; and 1 line x 40 characters of text for I/O.

Reference Guide 7

Powerful maintenance features

Extensive facilities are provided to help with the general use and maintenance of the

system.

• Separate ID codes to access maintenance menus.

• One -man-walk test for up to 4 zones simultaneously.

• Statistics per device:

− Maximum and minimum value with date and time

− Average value

− Number of alarms

− Communication quality

• Graphics screen for zones and individual sensors

− Actual value

− Average value

− Test values

− Maximum and minimum values

− Contamination levels

− Communication quality

• Self-test and sensor test

• Soak test per device

• Reporting to printer or modem

• Print screen facility

Networking

The FP2000 offers, as an option, unsurpassed networking capabilities with Arcnet using

RS485 for rugged, reliable and peerless operation. Devices can be added and removed

from the network , which allows for easy expansion of a system.

• RS485 nodes are available from the network for connection to building management

systems

• Remote maintenance

• Inter -panel I/O

• Remote upload/download capability

General features

The system is completely modular offering:

• Front end processor with separate host computer for high level functions

• 2, 4, 6 or 8 loops (Cla ss A)

• 4 or 8 loops (Class B)

• 16, 32 48 or 64 zones indicating fire and fault

Each two-wire loop is capable of addressing up to 126 addressable devices. System

configuration is easily achievable using menus, the RS232 ports, or by means of an

optional network. A default configuration is provided for instant programming.

8 Reference Guide

Standard I/O facilities

• Rugged loop driver optimised for

− EMC/EMI regulations

− Operation in worst case conditions of high capacitance and resistance which

makes it ideal for retrofit market.

• Current loop to drive up to 15 fireman’s panels

• 4x Programmable inputs and 1x Supervised input

• 4x Programmable relays

• Monitored alarm bell, fire brigade, fire protection and fault routing

• 3x Supervised inputs for fire brigade feedback, fire protection fault and fault routing

fault.

• Dual RS232 ports assigned to text, graphics, external printer or modem.

Mechanical data

Dimensions H W D

16 Zone Cabinet 609 441 109

64 Zone Cabinet 804 441 109

Mass (without batteries)

16 Zone Cabinet 11kg

64 Zone Cabi net 15kg

Reference Guide 9

2. P

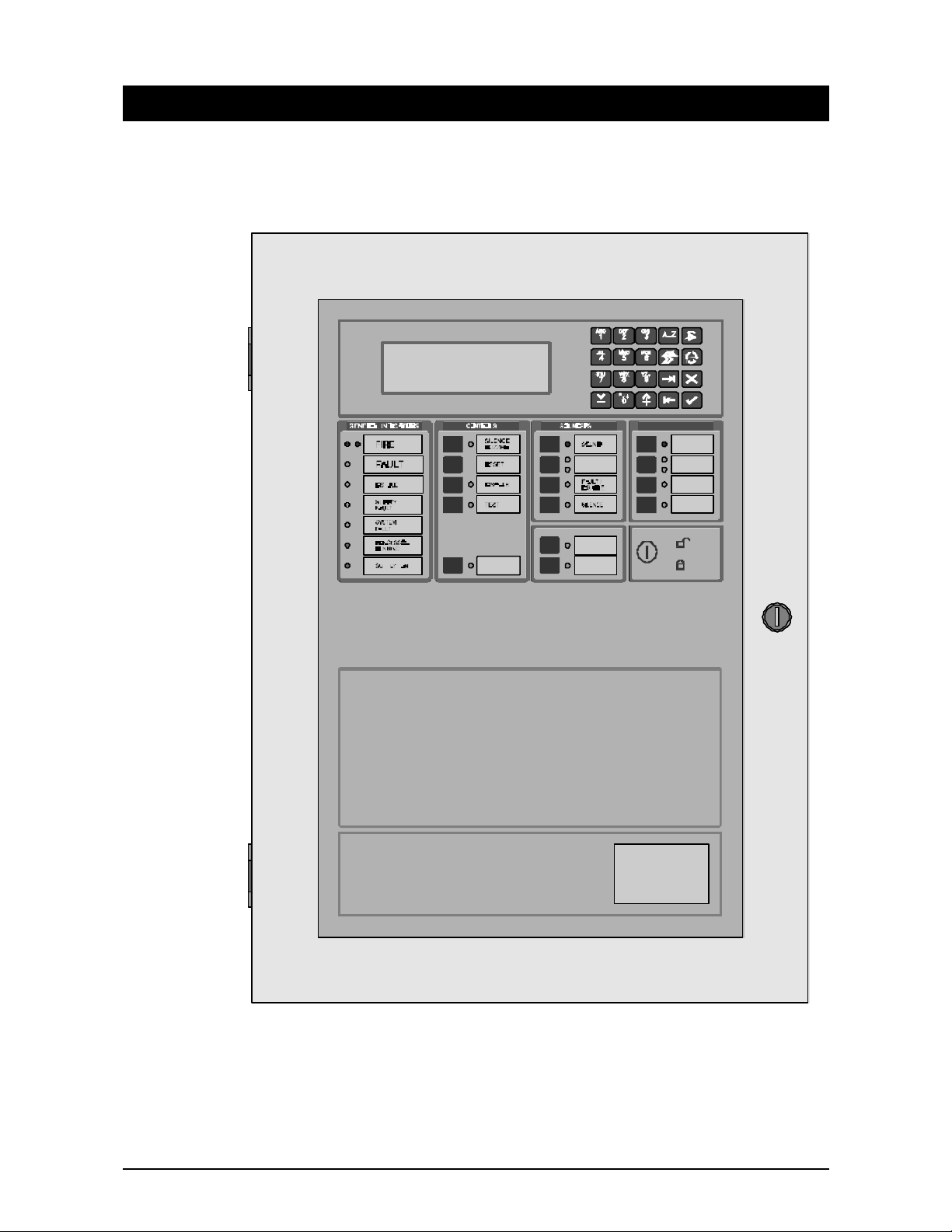

A view of the front of a typical FP2000 Series Fire panel is shown in Figure 1 below.

Figure 1: Fire Panel Front View

ANEL OPERATION

In order to describe the operation of a FP 2000 series fire panel, the front panel has been

divided into two sections, these being:

• LED indicators and controls

• LCD and keypad

10 Reference Guide

Led indications and controls

The LED Indications and controls can further be broken down into:

• General indicators

• Controls

• Sounders

• Fire Brigade

• Enable/Disable keyswitch

• Zone indicators

Figure 2: General Indications and Controls

General indicators

COMMON FIRE

Two red LED's indicate that a fire has been detected.

COMMON FAULT

One or more of the follow ing may cause a common fault:

• Zone fault

• Supply fault

• Processor fault

• Sounder fault

• Fire Brigade fault

• Any test mode

• Any disable mode

Reference Guide 11

COMMON DISABLE

A yellow LED indicates that one or more of the following have been disabled:

• Devices on the loop

• Zone

• Sounders

• Fire Brigade

SUPPLY FAULT

A yellow LED will illuminate for:

• Mains failure

• Battery disconnect or not charging

SYSTEM FAULT

A yellow LED indicates that a system fault has occurred. A system failure can be one or

more of:

• Tamper switch

• Service switch

• Logic error

• Memory lock

• No checksums calculated

• Hardware test fault

• Fireman’s panel down

• Repeater down

• Panel down

• Global repeater down

• Input fault

• Output fault

• Configuration fault

• Checksum fault

• Protected memory overwritten

• Time date wrong

• Access fault

• FEP fault

• Watchdog time -out

PROCESSOR RUNNING

A flashing green LED indicates normal operation.

SUPPLY ON

A green LED indicates that the system is receiving 24V power.

12 Reference Guide

Controls

SILENCE BUZZER (Keyswitch Enabled or Disabled)

The internal panel buzzer is activated for any new condition. The buzzer will be

continuous for a fire alarm condition, intermittent for a fault warning and slow intermittent

for a condition warning.

The buzzer is silenced by pressing the Silence Buzzer Key. The yellow silence buzzer

LED will illuminate to indicate that the buzzer has been silenced.

RESET (Keyswitch Enabled)

This pushbutton will reset the fire panel.

DISABLE (Keyswitch Enabled)

This pushbutton calls up the Disable Menu (see Page 173). The yellow LED will indicate if

anything is disabled.

TEST (Keyswitch Enabled)

This pushbutton calls up the Test Menu (see Page 160). The yellow LED under General

Indicators will illuminate if the panel is put into a test mode.

Sounders

SOUND

Depends on operation selected by bits 5 and 6 of DIP switch on HOST PSU board. ( *See

Appendix B of the FP2000 Installation and Commissioning Manual: LKFP2003). A red

LED indicates that the sounders have been activated.

DELAY ON/OFF

The programmed Sounder Delay ( see Output Delays, Page 62) may be toggled ON or

OFF. Two LEDs indicate the state.

Depends also on operation selected by bits 5 and 6 of DIP switch on HOST PSU board.

(*See Appendix B of the FP2000 Installation and Commissioning Manual: LKFP2003 ).

FAULT/DISABLE (Keyswitch Enabled)

The Sounder Fault/Disable pushbutton allows the sounders to be disabled. The

associated LED indicates that the sounders have been disabled or that a sounder fault is

present.

The sounder fault can be:

• Sounder circuit open circuit

• Sounder circuit short circuit

• Bell fuse failure

Reference Guide 13

SILENCE (Keyswitch Enabled)

Depends on operation selected by bits 5 and 6 of DIP switch on HOST PSU board. ( *See

Appendix B of the FP2000 Installation and Commissioning Manual: LKFP2003). A yellow

LED indicates that the sounders have been silenced.

Fire brigade

SIGNAL (Keyswitch Enabled)

Depends on operation selected by bits 5 and 6 of DIP switch on HOST PSU board. ( *See

Appendix B of the FP2000 Installation and Commissioning Manual: LKFP2003). A red

LED will indicate that the signal has been activated.

DELAY ON/OFF

The programmed Fire Brigade Signal Delay ( see Output Delays, Page 60) may be

toggled ON or OFF. Two LEDs indicate the state.

Depends also on operation selected by bits 5 and 6 of DIP switch on HOST PSU board.

FAULT/DISABLE (Keyswitch Enabled)

✍

The Fire Brigade output may be disabled by using this pushbutton. When the signal is

disabled, then the disable LED will be illuminated.

The Fir e Brigade circuit is supervised. The Fire Brigade fault LED will flash when a fault is

detected in the circuit.

STOP FIRE BRIGADE (Keyswitch Enabled)

Depends on operation selected by bits 5 and 6 of DIP switch on HOST PSU board. ( *See

Appendix B of the FP2000 Installation and Commissioning Manual: LKFP2003). A yellow

LED will indicate that the Fire Brigade signal has been deactivated.

ENABLE/DISABLE KEYSWITCH

An Enable/Disable keyswitch is provided to either allow or prevent operation of the fire

panel controls. The Silence Buzzer and Test keys will operate with the keyswitch in any

position.

The different Sounder and Fire Brigade keys' operation depend on the operation selected

by bits 5 and 6 of the DIP switch on the HOST PSU board. (*See Appendix B of the

FP2000 Installation and Commissioning Manual: LKFP2003).

Level 1 for Disable and level 2 for Enable must not be confused with access levels 1 and

2. There is no relation between the Enable/Disable keyswitch and the allocated access

levels.

14 Reference Guide

Other

PANEL

This button is used by global and local repeaters for panel emulation. Emulation mode is

activated with a global repeater by pressing the Panel key, then entering the number of

the panel to be emulated, and Enter ( ).

To stop emulation, the Panel key is pressed and then "0" and Enter ( ).

When a global repeater is emulating a panel it is not necessary to stop emulation before

emulating another panel. The global repeater will automatically stop the emulation before

trying to emulate another panel.

With a local repeater, pressing the Panel key will start emulation of the panel. If the panel

is already emulated, pressing the Panel key will stop emulation.

The yellow LED indicates whether a panel is emulated or not.

ALL

Used by the global repeater panel to send a command to all the panels the global

repeater is communicating with. The yellow LED indicates that the key was pressed,

meaning that the following command button to be pressed will be sent to all the relevant

panels.

THIRD SOURCE TEST

This key tests the third source battery when the panel is powered on. Pressing the key

will sound the buzzer.

Zone indicators

Each zone has two indicators. A red LED indicates a fire and a yellow LED indicates a

fault, disablement or test. The zone fault LED will flash for a fault condition and be steady

on for disablement or test. The zones are numbered from the top left, from left to right.

Figure 3: Zone Fire and Fault Indication

Reference Guide 15

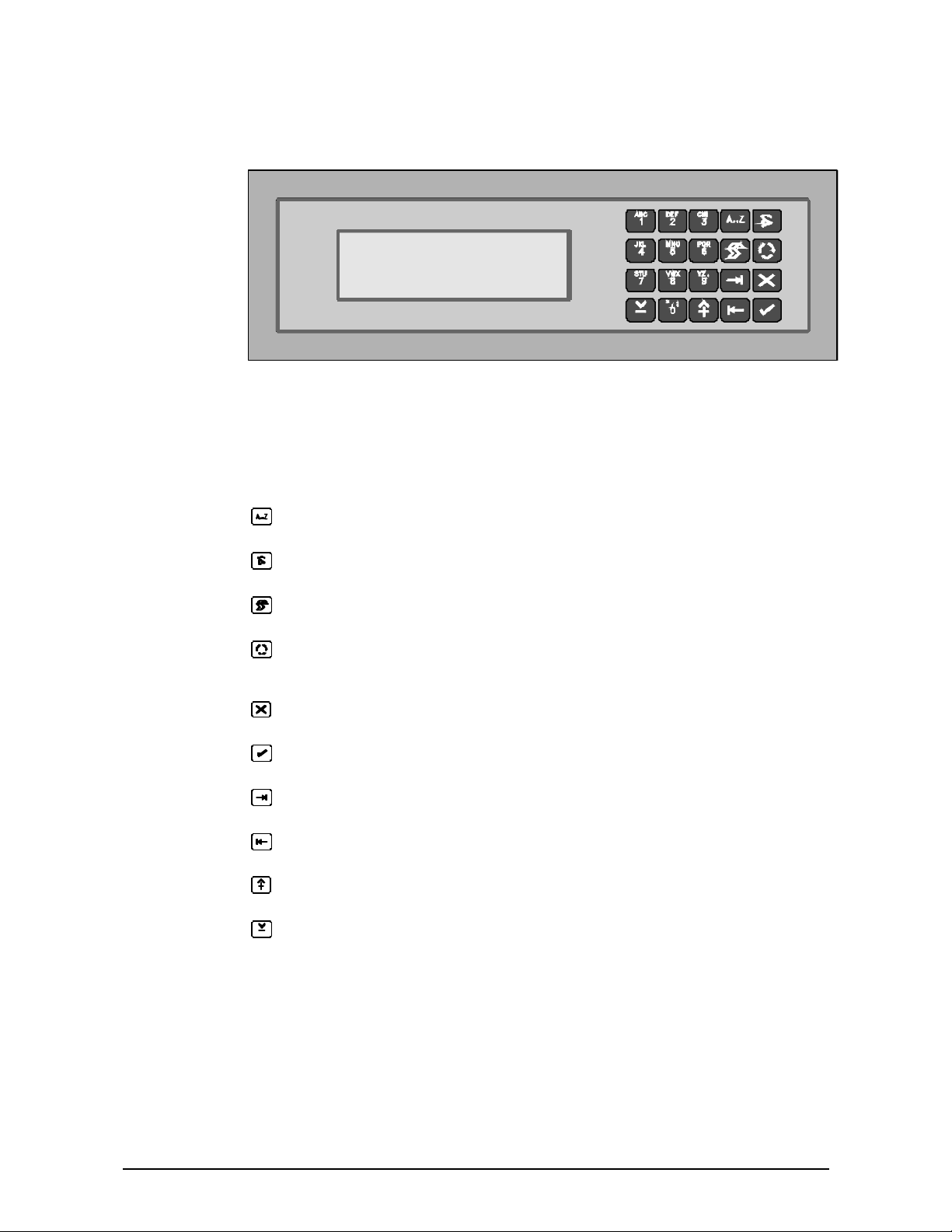

LCD and Keypad

Figure 4: LCD and Keypa d

The operation of the display is detailed in Chapter 3.

KEYPAD

The keypad consists of 20 keys, 10 of which are alphanumeric keys. The remaining 10

are assigned various functions as detailed below:

Alpha selection when using any of the 10 alphanumeric keys.

Used to display the latest alarm at any time.

Print screen function to print any screen to the internal or external printers.

Scroll key used to move between Alarm, Fault and Conditions, as well as to

view additional information when the "M ORE" prompt appears on the LCD.

Exit to previous menu

Enter or confirm

Move to the next field in the display

Move to the previous field in the display

Increment

Decrement

16 Reference Guide

Alarm line

EN54 Part 2 requires that the number of alarms, faults and conditions be displayed at all

times on the LCD screen. In the FP2000 product range this is accomplished by means of

the bottom line of the LCD Screen (called the ALARM LINE) as hig hlighted below:

The system status and mode is also summarised in the bottom right hand corner of the

alarm line.

The explanation of the initials used for this is as follows:

System Status System Mode

Idle I Day Mode D

Powerup P Night Mode N

Scanning S Security Zones On Z

Autosetup A Security Zones Off O

Sensor test T

3. LCD S

SYSTEM STATUS Fri 12/01/99 09:17:37

Scanning Day Mode Zones On

Alarms: 0 Faults: 0 Cond.: 0 P: 1 SDZ

CREEN OPERATION

E

For example

SDZ - Scanning, Day Mode, Zones On

SDO - Scanning, Day Mode, Zones Off

SNZ - Scanning, Night Mode, Zones On

etc.

If the panel is assigned a number, the number is displayed as part of the alarm line:

P - Fire panel

G - Global repeater or master panel

L - Local repeater panel

For example

P: 1 - Fire panel number 1

G: 1 - Global repeater panel number 1

L: 1/1 - Local repeater panel number 1 of fire panel 1

Reference Guide 17

Valid entries line

The second line from the bottom displays the valid keypad entries for the displayed menu,

as well as messages for the operator.

The following table describes these characters and messages and their relation to the

keypad:

MENU

KEYPAD DESCRIPTION

DISPLAY

<

>

∧

∨

E

X

0..9 0..9

A..z

Numeric

Alpha

More

Invalid Key -

Memory

Locked

Open Memory

Lock

Not in Service

Mode

No Access

0..9

a..z

A..Z

other1

-

-

-

-

Move backward between fields

Move forward between fields

i) Select available options – forward

ii) Increment numeric field values

iii) Move forward within a text line

i) Select available options – backward

ii) Decrement numeric field values

iii) Move backward within a text line

i) Start entry into FP2000 menu system - from the SYSTEM STATUS

Menu (highest level menu)

ii) Confirm selection

iii) Confirm field entry

i) Return to higher level menu

ii) Cancel changed field values

i) Selection of sub-menus

ii) Changing of numeric field value

Changing of test line (string) text - numeric characters 0 to 9, small capital

letters of alphabet and other ASCII characters1.

Indicates the keypad mode - pressing the [A..Z] key toggles between

numeric and alpha characters.

Indicates the keypad mode - pressing the [A..Z] key toggles between

numeric and alpha characters.

Toggle between different screens of a particular menu.

The pressed key has no meaning with regard to the displayed menu.

The Me mory Lock Switch on the Host PCB must be in the OPEN position

for the change to be accepted.

Place the Memory Lock Switch on the Host PCB in the OPEN position.

The Service Switch on the Host PCB must be in the OPEN position for the

operation to be executed.

i) A higher access level is needed to enter the selected menu

ii) While in the menu system, in other words access was granted, access

is disabled via a communication port. This is typically caused by the

up-/download software via a serial port (SER1/2).

1

Keypad characters: 0 to 9

✍

a to z

A to Z

.=*,;~#$%^&`{}[]()<>:"/

space

18 Reference Guide

Status line

The status line is the third line from the bottom (see highlighted line) and the system

status, as summarised in the alarm line, is displayed in full. Note that the system status

line is not present in all menus:

SYSTEM STATUS Fri 12/01/99 09:17:37

Scanning Day Mode Zones On

E

Alarms: 0 Faults: 0 Cond.: 0 P: 1 SDZ

System status menu

Under normal operating conditions the LCD Screen shows the System Status Menu as

given below:

SYSTEM STATUS Fri 12/01/99 09:17:37

Scanning Day Mode Zones On

E

Alarms: 0 Faults: 0 Cond.: 0 P: 1 SDZ

Reference Guide 19

4. P

ROGRAMMING MENUS

Access to main menu

Main Menu obtained from the System Status Screen after entering an access code.

If the fire panel is currently displaying alarms, faults, or conditions on the screen, then

press to obtain the System Status Screen.

SYSTEM STATUS Fri 12/01/99 09:17:37

Scanning Day Mode Zones On

E

Alarms: 0 Faults: 0 Cond.: 0 P: 1 SDZ

Press to obtain the access code prompt.

Enter Access Code:

0. .9, <>, E, X

Alarms: 0 Faults: 0 Cond.: 0 P: 1 SDZ

Enter a one to four digit code and press .

The Main Menu will be displayed, provided one of six correct codes has been entered.

Different codes may have different access levels . This means that some facilities may

not be available to users with a code of lower access level.

*See Access Menu, Page 49

20 Reference Guide

Main menu

(SYSTEM STATUS, , CORRECT CODE, )

MAIN MENU

1 System 2 Devices

3 Input/Output 4 Events

5 Maintenance 6 Test/Disable

0. .9, <>, E, X

Alarms: 0 Faults: 0 Cond.: 0 P: 1 SDZ

Select number or use and press

Return to System Status *See Chapter 3.

1 System Menus Page 23

2 Device Menus Page 68

3 Input, Output and Logic

Page 97

4 Event Log Page 137

5 Maintenance Menus Page 142

6 Test and Disable Functions Page 160 (Test menu)

Page 173 (Disable Menu)

All data of the fire panel may be viewed and/or changed by persons authorised to do so.

In order to view any screen requires the correct access code(s). In order to change data,

the user requires both the correct access code and the memory must be unlocked. The

memory lock switch is located on the Host CPU board and thus access is required within

the cabinet in order to change data.

The Main Menu provides a logical subdivision of the fire panel data and facilities.

• System - The viewing/programming of the fire panel internal system. Items such as

the serial ports, RAM memory, operation, date/time and timings are accessed.

• Devices - The viewing/programming of all facilities of the devices connected to the

loops of the fire panel. This includes the zoning and statistics of each device as well

as graphic screens.

• Input/Output - The definition of inputs and outputs, as well as the logic defining the

operation of the fire panel according to input/output. Inputs and outputs are derived

from the internal system, I/O devices on the loop, and network.

• Events - The examination and selective printing of the event log. The event log is also

cleared in this menu.

• Maintenance - The facilities provided in order to completely maintain the fire panel

system and the devices on the loop. This includes a host of reporting facilities.

Reference Guide 21

• Test/Disable - Zones and individual devices can be selectively tested and disabled.

Test features include one-man test of zones and soak test of individual devices. The

Test and Disable Menus are not directly available from the Main Menu, but are

accessed by using the Test and Disable keys on the front panel. These menus do not

require any access code, but do r equire that the enable/disable keyswitch is enabled.

Selecting Test/Disable from the Main Menu causes a prompt to operate the desired

keyswitch.

22 Reference Guide

System menu

(MAIN MENU, 1, )

SYSTEM MENU

1 Configuration 2 Access

3 Clear Site Data 4 Set Default

5 Set Times 6 Restart

0. .9, <>, E, X

Alarms: 0 Faults: 0 Cond.: 0 P: 1 SDZ

Select number or use and press

The System Menus are used to configure and display the internal operation of the fire

panel. That is, all parameters other than the loop devices and input output programming.

The menu selections are:

1 Configuration Page 24

Hardware configuration

Memory allocation

Panel ID

Communication including port, serial, printer and network set-ups

Return to Main Menu Page 21

2 Access Page 49

Set user access codes

Set access levels of the menus

3 Clear Site Data Page 52

Clear the site programmable data

4 Set Default Page 55

Set the site programmable data to default values

5 Set Times

Fire panel date and time

Sounder and Fire Brigade Delay

Sounder and Fire Brigade Delay on/off times

Zone on and off times

Day/night mode times

Page 58

6 Restart Page 67

The fire panel will perform a cold start as if it had been switched off and

then on. Restart will only operate if the Memory Lock/Unlock switch located

on the Host CPU board is in the LOCK position.

Reference Guide 23

Configuration menu

(SYSTEM MENU, 1, )

CONFIGURATION MENU

1 Hardware 2 Allocation

3 ID 4 Communication

0. .9, <>, E, X

Alarms: 0 Faults: 0 Cond.: 0 P: 1 SDZ

Select number or use and press

Return to System Menu Page 23

1 Hardware Page 25

View the fire panel internal configuration, software version, ports and PCB's.

2 Allocation Page 29

Memory allocation for field devices, I/O and logic, text, and event buffer

3 Panel ID

Set the ID number of the fire panel

Page 31

4 Communication Page 33

Port setup

Network

Modem

Current loop devices

24 Reference Guide

Hardware configuration 1

(CONFIGURATION, 1, )

Version: 5.00NKF 23.05.99/5.00-8 29.05.99

Ports: 5 Zones : 112 Loops : 2A

Unlocked : 256k Locked RAM : 128k

Relays Sup.Rel. Inputs

Backpanel: 4 4 8

Frontpanel: 0 0 0

more X

Alarms: 0 Faults: 0 Cond.: 0 P: 1 SDZ

Press [More ] to view Hardware Configuration 2 Page 27

Return to Configuration Menu Page 24

This display and the Hardware Configuration 2 display show the hardware configuration

of the fire panel. The particular configura tion will be determined by the model number of

the FP2000 as well as any optional boards that may have been installed.

The screen will show:

Version -

The version number and the compilation date of the installed HOST and FEP software.

Ports -

The number of ports installed.

The standard ports are:

FEP Port (not accessible to the user)

Current Loop (for fireman’s panels)

Ser1 RS232 Serial port 1

Ser2 RS232 Serial port 2

ARC 1 Arcnet port 1

Zones -

The number of displayable zones equipped.

Loops -

The number of loops equipped and whether the loop driver boards are connected in

Class A or Class B configuration. Each loop board accommodates two Class A loops or

four Class B loops.

Unlocked RAM -

The amount of RAM installed that is not controlled by the memory lock switch.

Locked RAM -

The amount of RAM installed that is controlled by the memory lock switch. Locked RAM

is used for site data.

*See Memory Allocation, Page 29 for more information relating to memory size.

Reference Guide 25

Backpanel and Frontpanel Input and Output Equipped -

The FP2000 contains, as standard, relays and input ports. The back panel refers to the

boards plugged into the FEP section in the base of the fire panel. The front panel refers

to the boards plugged into the HOST section in the door of the fire panel. The HOST

section contains two layers of board plug -in positions.

The standard equipped I/O is:

• Four Inputs IN1 - IN4 located on the FEP board These inputs are freely programmable by the user.

• Sounder board:

- Four monitored relays (OUT1 - OUT4)

- Four unmonitored relays (OUT5 - OUT8)

The monitored relays have dedicated functions:

OUT1 - Sounder

OUT2 - Fire Brigade

OUT3 - Fire Protection

OUT4 - Fault Routing

- Four supervised inputs (IN5 - IN8)

IN8 is a general programmable input, but the others have dedicated functions:

IN5 - Fire brigade feedback (EN54-mode only)

IN6 - Fire protection fault (EN54-mode only)

IN7 - Fault routing fault (EN54-mode only)

All relays are programmable by means of the I/O programming menus, but care should

be taken when programming the dedicated relays above.

Any additional optional I/O that is equipped within the FP2000 will be shown on this

screen.

*See I/O Menus, Page 97 for the programming of Inputs and Outputs.

26 Reference Guide

Hardware configuration 2

(CONFIGURATION 1, )

HARDWARE CONFIGURATION

Host :DEN ZON ARC . . . . . . . . . . . . . . .

PSH . . . . . . . . . . . . . . . . . . . . .

FEP :LPA REL VDS . . . . . . . . . . . . . . .

ADD :FEP HST KBD LCD PSF . . . . . . . . .

more <>, E, X

Alarms: 0 Faults: 0 Cond.: 0 P: 1 SDZ

Press [More ] to view Hardware Configuration 1 Page 25

Return to Configuration Menu Page 24

Select the PC Board code using the cursor

View additional details of the selected PC Board

This menu is used to display the details of the printed circuit boards (PC Boards) installed

in the FP2000 system. The PC Board summary is shown in three sections:

1 Addressable boards located in the Host CPU (front panel) section.

2 Addressable boards located in the FEP (back panel) section.

3 Additional non -addressable boards located in both the Host and FEP system

Reference Guide 27

Board information

(CONFIGURATION 2, or, , )

BOARD INFORMATION

Addr. :17 Sup1:passive Inp5:passive

ID :20 Sup2:passive Inp6:passive

Type :VDS Sup3:passive Inp7:passive

Sup4:passive Inp8:passive

X

Alarms: 0 Faults: 0 Cond.: 0 P: 1 SDZ

Return to Hardware Configuration Page 25

This includes:

• Board description

• Actual board address

The board address is used in certain I/O programming

The board description and address in a two loop, 16 zone FP2000 is given below. Note

that board addresses are changed automatically when additional PC boards are added or

removed. When more than one loop driver or zone board is present in a system, then

each one of these boards assumes a unique address.

PC Board Description Address

DEN Common Display (EN Type) 0

ZON 16 Way Zone Board 1

PSH Host Power Supply 8

LPA 2 Loop Class A Driver 16

VDS Common Input/Output 18

FEP Front End Processor 24

HST Host CPU 25

KBD Keypad 26

LCD Liquid Crystal Display 27

PSF FEP Power Supply 28

28 Reference Guide

Memory allocation 1

(CONFIGURATION, 2, )

MEMORY ALLOCATION Free unlocked :175238

Free locked :84042

Logic :600 Input Text :40

Inputs :200 Output Text :40

Outputs :200 Zone Text :40

Events :999 Area Text :40

more 0. .9, ^V, <>, E, X

Alarms: 0 Faults: 0 Cond.: 0 P: 1 SDZ

Press [More ] to view Memory Allocation 2 Page 29

Return to Configuration Menu Page 24

Select item to be changed

or 0..9 change data in item (Unlock memory!)

Confirm change

Changing memory allocation will clear all existing programmed data from memory!

✍

The user must reprogram all site data after changing any items in memory allocation.

The random access memory (RAM) of the fire panel is partitioned for different types of

data. Some of this data is contained within locked memory; other data is in unlocked

memory.

The default memory allocation for the FP2000 is shown. Further information is obtained

by using [More ] (Page 30). The default memory allocation should be correct for most

applications and should only be changed if the user has particular requirements that

exceed the parameters given.

The amount of free locked and unlocked memory is dynamically displayed on the screen

as allocations are increased or decreased.

!

W hen exiting from this menu, the user is prompted as to whether the allocation is to be

saved or not. This prompt will occur even if no parameters have been changed. If the

allocation is saved then all RAM is cleared and the fire panel must be reprogrammed.

Press for no save

Press for YES and then in order to save the allocation (Unlock memory!)

Reference Guide 29

Memory allocation 2

(CONFIGURATION, 2, , )

MEMORY ALLOCATION

Loop Devices Text Loop Devices Text

1 128 80 5 0 0

2 128 80 6 0 0

3 0 0 7 0 0

4 0 0 8 0 0

more X

Alarms: 0 Faults: 0 Cond.: 0 P: 1 SDZ

Press [More ] to view Memory Allocation 1 Page 29

Return to Configuration Menu Page 24

The amount of RAM memory allocated to field devices on the loops is viewed with this

screen. Provision is made for 80 characters of user text for each device. It is not possible

to change the amount of memory allocated. Allowance is always made for 126 or 128

devices per loop irrespective of the number of devices actually installed. The amount of

memory used is dependent only on the number of loops equipped within the fire panel.

!

When exiting from this menu, the user is prompted as to whether the allocation is to be

saved or not. This prompt will occur even if no parameters have been changed. If the

allocation is saved then all RAM is cleared and the fire panel must be reprogrammed.

Press for no save

Press for YES and then in order to save the allocation (Unlock memory!)

30 Reference Guide

Panel ID

(CONFIGURATION, 3, )

IDENTIFICATION

Change of Node ID Clears Eventbuffer!

Node : 1 / 0 Max. Config.:15/15

Panel : 1

0. . 9, ^V, E, X

Alarms: 0 Faults: 0 Cond.: 0 P: 1 SDZ

Return to Configuration Menu Page 24

Select item to be changed

or 0..9 change data in item (Unlock memory!)

Confirm change

For Panel ID Text Fields (2 lines x 40 characters):

Use to obtain the text line to be changed

Press (Unlock memory!)

Use to toggle between alpha and numeric text

Press the alpha/numeric button required

Use to move the cursor within the line

Press when completed

Default:

ID: 0/0

Panel: 0

Max. Config.: 15/15

Each FP2000 fire panel, as well as global repeaters and local repeaters in a network

system, can be uniquely identified by means of the panel ID. The panel ID is used for the

upload/download of data via the serial ports, as well as information transfer on the

network. In addition to the panel ID, two lines of user text can be assigned t o each fire

panel or repeater. The user text is displayed on the System Status Screen and for the

logging of all system (general) fault warnings of the panel.

The Panel ID consists of two digits: fire panel number/repeater number (p/r).

For fire panels the repeater number is always Ø

e.g.: 0/0 - fire panel Ø

12/0 - fire panel 12

For global repeaters (network systems only) the fire panel number is zero, and the

repeater number defines the global repeater

e.g.: 0/1 - global repeater number 1

0/3 - global r epeater number 3

For local repeaters attached to a particular fire panel on the network, the fire panel

number and the repeater number defines the repeater

e.g.: 1/3 - repeater 3 of fire panel 1

3/1 - repeater 1 of fire panel 3

Reference Guide 31

The field "Panel" confirms the fire panel number. The panel ID is also shown on line 8 of

the display: P:p. For global repeaters the word "Panel" becomes "G -Repeater" and line 8

displays G:r. For local repeaters the display is "repeater" and L:p/r is displayed on line 8.

The field Max. Config. : Panel/repeater show the maximum number of panels and

repeaters, local or global that can be configured. The

options are: 7/31

15/15

31/7

When transferring data from a computer to the fire panel, the fire panel ID of the data file

must match the fire panel ID.

When setup as a Global Repeater, additional Universal Node settings are possible:

un-n for a Universal Node on the Setup/NET1/NET2 Port

un-m for a Universal Node on the Modem Port

• If set to 0/0, the Universal Node ID will automatically assume the ID of the connected

PC or Panel.

• If set to 0/x (x = valid repeater number) then the Universal Node functions will only

work if the connected PC or Panel will have the same ID.

32 Reference Guide

Communication menu

(CONFIGURATION, 4, )

COMMUNICATION MENU

1 Port Setup 1 Network

3 Modem 4 CL Devices

0. . 9, <>, E, X

Alarms: 0 Faults: 0 Cond.: 0 P: 1 SDZ

Select number or use and press

Return to Configuration Menu Page 24

1 Port Setup Page 34

Set the communication ports to the functions required.

2 Network Page 37

Panels

Local Repeaters

Global Repeaters

3 Modem Page 41

Alarm Report

Maintenance

Setup

4 Current Loop Devices

Set up the panel number and mode of operation.

Page 48

Reference Guide 33

Port setup

(COMMUNICATION, 1, )

PORT SETUP

Port :INT Baudrate :9600

Allocation :FEP Protocol :8, 1, n

^V, <>, E, X

Alarms: 0 Faults: 0 Cond.: 0 P: 1 SDZ

Return to Communication Menu Page 33

Select item to be changed

Change data in the item (Unlock memory!)

Confirm change

This menu is used to set the function and, if applicable, the data rate (Baudrate) of the

physical communication ports.

1. Select the required port (only installed ports can be selected):

INT

CL The current loop port used for local fireman’s panels

SER1

SER2

ARC1 Arcnet network board 1 (optional).

2. Select the function to be assigned to the port using the allocation field:

None The selected port has no function. This is the default

NET1 The FP2000 will support two networks simultaneously.

NET2 All communication assigned to NET1 (see Network

Ev. pri Set the selected port as an event printer. All events of

Not available to the user.

only.

The Baudrate must be 600.

The standard serial ports provided on the FP2000 fire

panel.

setting with the exception of the CRL and FEP ports that

have predefined functions.

Menu, Page 4-18) will be sent to the ports allocated to

the NET1 function. Similarly all communication assigned

to NET2 will be sent via the NET2 port. Generally the

ARC1 port will be set to NET1. In the case of a graphic

system connected to the serial port (SER1, say) the

SER1 port is assigned the function NET1, ARC1, SER12 are the only ports that support NET1 and NET2.

the fire panel are sent to the port when they occur. Any

information that is manually sent to Ev.Pri by the user

will also be printed. The fire panel will give a fault if the

device connected to the event printer port is not

connected or not ready (e.g. paper out).

34 Reference Guide

3. Select the Baudrate for the serial ports (default 9600)

Rp.Pri Set the selected port as a report printer. The report

printer port is used to manually sent report to a device

such as a printer or laptop computer. It is primarily used

for selected printing of the event buffer, test reports and

such. No fault is given if a report printer is off line or not

plugged in. Thus, a report printer can be removed at any

time. Reports are held in a buffer when the device

connected to the port is not on -line. The type of printer

(e.g. internal) can be defined.

VDU This function operates in the same manner as Rp.Pri

above, except that the report is halted every 20 lines

(one VDU screen). Pressing any character on the VDU

device will allow the report to be continued for a further

20 lines. This function is particularly useful for viewing

reports on the screen of a laptop computer. Only the

serial ports support VDU.

EMU The port is set to emulation mode. Only the serial ports

support EMU. This allows the fire panel to be operated

remotely by means of a computer. The entire fire panel

front panel keyboard and display is accessible via the

serial port in this mode. Special software (PC2000

series) is required at the computer to operate in

emulation mode.

CL Device This is the default function for the current loop port. It is

used to communicate to fireman’s panels connected to

the current loop port. This function should not be

assigned to any other port.

Setup Allows remote upload and download of site via the serial

port. This function is used to program site data into the

fire panel. Upload/download software is required at the

computer. Only the serial ports support Setup.

FEP The FEP function is used for the INT port only.

Modem This function assigns one of the serial ports as an

300

600

1200

2400

4800

9600 Default

19200

38400

interface to a modem.

Reference Guide 35

Select the mode of operation for the ARCNET ports:

4. The protocol of the serial ports is fixed: Eight data bits, one stop bit, and no parity

Example:

To activate the built-in printer as an event printer: Ser2 must be allocated to Ev.Pri.

Bus

Dual Bus

Ring Half Duplex

Ring Half Duplex (Master)

Ring Full Duplex

Only for CE-FP -344-x

36 Reference Guide

Network menu

(COMMUNICATION, 2, )

NETWORK MENU

1 Panels 2 L-Repeaters

3 G-Repeaters

0. . 9, <>, E, X

Alarms: 0 Faults: 0 Cond.: 0 P: 1 SDZ

Select number or use and press

Return to Communication Menu Page 33

1 Panels Page 38

Define other fire panels on the network that will communicate with this fire panel.

2 L-Repeaters Page 39

Define local repeaters on the network that will communicate with this fire panel.

3 G-Repeaters Page 40

Define the global repeaters that will communicate with the fire panel on the network.

Reference Guide 37

Panels

(NETWORK, 1, )

PANELS

Panel No. :1

Status :dis

0. . 9, ^V, <>, E, X

Alarms: 0 Faults: 0 Cond.: 0 P: 1 SDZ

Return to Network Menu Page 37

or 0..9 to select panel number

Move to status field

Toggle dis/NET1 check/NET2 check/ NET1 no check/NET2 no check (Unlock

memory!)

Confirm entry

The fire panels that will communicate with this FP2000 fire panel on the network must be

assigned.

Fire panels that are assigned to the network will be checked for communication on the

system. If a panel is assigned to "NET1/2 check", a fault warning will be displayed in the

event of a failure, but if assigned to "NET1/2 no check" the failure will only be an action

logged in the event buffer.

Each fire panel on the system must have the correct ID set (see Page 31).

✍

The fire panel that is being programmed must be set at disable, i.e. a fire panel does not

check itself: assign only other fire panels.

38 Reference Guide

Local repeaters

(NETWORK, 2, )

LOCAL REPEATERS

L-Repeater No. :1

Status :dis

^V, <>, E, X

Alarms: 0 Faults: 1 Cond.: 0 P: 1 SDZ

r Return to Network Menu Page 37

or 0..9 to select repeater number

Move to status field

Toggle dis/NET1 check/NET2 check/NET1 no check/NET2 no check (Unlock

memory!)

Confirm entry

The local repeater that will communicate with this FP2000 panel on the network, must be

assigned.

Local repeaters that are assigned to the network will be checked for communication on

the system. If a local repeater is assigned to "NET1/2 check", a fault warning will be

displayed in the event of a failure, but if assigned to "NET1/2 no check", the failure will

only be an action logged in the event buffer.

Reference Guide 39

Global repeaters

(NETWORK, 3, )

GLOBAL REPEATERS

G-Repeater No. :1

Status :dis

^V, <>, E, X

Alarms: 0 Faults: 1 Cond.: 0 P: 1 FDZ

Return to Network Menu Page 37

or 0..9 to select master number

Move to status field

Toggle NET1 check/NET2 check/NET1 no check/NET2 no check (Unlock memory!)

Confirm entry

The global repeaters that will communicate with this FP2000 panel on the network, must

be assigned.

Global r epeaters that are assigned to the network will be checked for communication on

the system. If a global repeater is assigned to "NET1/2 check", a fault warning will be

displayed in the event of a failure, but if assigned to "NET1/2 no check", the failure wi ll

only be an action logged in the event buffer.

40 Reference Guide

Modem menu

(COMMUNICATION, 3, )

MODEM MENU

1 Alarm Report 2 Maintenance

3 Setup

0. . 9, <>, E, X

Alarms: 0 Faults: 1 Cond.: 0 P: 1 SDZ

Select number or use and press

1 Alarm Report Page 42

Set up the conditions for alarm reporting and the destination telephone numbers.

2 Maintenance Page 44

Enable or disable of remote maintenance.

Return to Communication Menu Page 33

3 Setup

Modem setup commands.

Page 45

Reference Guide 41

Modem alarm report 1

(MODEM, 1, )

MODEM ALARM REPORT

Tel. No. Fire Fault Cond. Disc.

dis dis dis rem

dis dis dis local

dis dis dis local

dis dis dis local

more Numeric, A. . z, ^V, <>, E, X

Alarms: 0 Faults: 1 Cond.: 0 P: 1 SDZ

Return to Modem Menu Page 41

Select field to be changed

To change selection (Unlock memory!)

Confirm entry

For telephone numbers:

Use to move to the required telephone number line

Use to toggle between alpha and numeric text when necessary and press the

required button

Use to move the cursor within the line

Press when complete (Unlock memory!)

Press to go to Modem Alarm Report 2 Page 43

The telephone numbers whereto alarm reports must be sent and the conditions that

causes the reports to be sent, are set up with this menu.

The device that has to disconnect can be selected in the last column:

rem: The "remote device" (PC) has to disconnect.

local: The panel/global repeater will disconnect automatically when the message

has been broadcasted.

42 Reference Guide

Modem alarm report 2

(MODEM ALARM REPORT 1, )

MODEM ALARM REPORT

Fire Delay :60 s Report :dis

Fault Delay :60 s Test Call :dis

Cond. Delay :60 s Test Line :dis

more 0. . 9, ^V, <>, E, X

Alarms: 0 Faults: 1 Cond.: 0 P: 1 SDZ

Return to Modem Menu Page 41

Select field to be ch anged

To change selection (Unlock memory!)

Confirm entry

Press to go back to Modem Alarm Report 1 Page 42

Fire, Fault and Cond. Delay:

Delays reporting to control station. If the panel gets reset before the delay has elapsed,

no alarm/fault condition will be reported. The shortest delay will start the reporting to the

central station and will report all pending alarms/faults/conditions.

Report:

Instead of report disabling by using the previous menu (Modem Alarm Report 1), this

menu supplies a quick disable mechanism. Disabling reports on this menu will disable all

reports regardless of the setup on the previous menu (Modem Alarm Report 1).

Test Call:

This menu enables a test call at every maintenan ce time.

Test Line:

This menu enables a line test with hardware test, manually or every hour automatically.

Reference Guide 43

Modem maintenance

(MODEM, 2, )

MODEM MAINTENANCE

Maintenance :dis

Dial back :dis

^V, <>, E, X

Alarms: 0 Faults: 1 Cond.: 0 P: 1 SDZ

Return to Modem Menu Page 41

To change selection (Unlock memory!)

Confirm entry

Remote maintenance via the modem can be disabled while the modem interface is

operational.

When Dial Back is disabled, the dial back command from the remote location (PC) will be

ignored.

44 Reference Guide

Modem setup 1

(MODEM, 3, )

MODEM SETUP

Wait for Connection :60 s

Pause between Calls :60 s

Max. dialling attempts :99

more 0. . 9, ^V, <>, E, X

Alarms: 0 Faults: 1 Cond.: 0 P: 1 SDZ

Return to Modem Menu Page 41

Select field to be changed

To change selection (Unlock memory!)

Use 0..9 or To change field values

Confirm entry

Press to go to Modem Setup 2 Page 46

Set the modem time-outs and the maximum dialling attempts.

Reference Guide 45

Modem setup 2

(MODEM SETUP 1, )

MODEM SETUP

Init :AT&FØMØ\NØ\JØ\Q3&QØ

SØ=1&WØ

Dial :ATDWT

Escape :+++

more Numeric, A. . z, ^V, <>, E, X

Alarms: 0 Faults: 0 Cond.: 0 P: 1 SDZ

Return to Modem Menu Page 41

Select field to be changed

Use to toggle between alpha and numeric text when necessary and

press the required button

Press to confirm (Unlock memory!)

Press to go to Modem Setup 3 Page 47

Set up the modem command strings.

Refer to your Modem manual for detailed description of the commands:

Init: Initialisation string for modem

for US Robotics : AT& F1MØ L1&MØ&KØ

SØ=1&WØ

Fast link: AT&FØMØL1\NØ\JØ\Q3&QØ%CØ

SØ=1&WØ

Datasystems: AT&FØMØ\NØ\JØ\ Q3&QØ%CØ

SØ=1&WØ

Bausch : AT&F1MØL1&CØ

SØ=1&WØ

Dial: Dial prefix for modem

Escape: Escape sequence for modem

46 Reference Guide

Modem setup 3

(MODEM SETUP 2, )

MODEM SETUP

Hangup :ATHØ

Test :ATDWT,

ID :

more Numeric, A. . z, ^V, <>, E, X

Alarms: 0 Faults: 1 Cond.: 0 P: 1 SDZ

Return to Modem Menu Page 40

Select field to be changed

Use to toggle between alpha and numeric text when necessary and

press the required button

Press to confirm (Unlock memory!)

Press to go to Modem Setup 1 Page 45

Set up the modem command strings

Hangup: Puts the modem on hook

Test: Test string for line test

ID: A String to identify the modem to the maintenance programs.

Reference Guide 47

CL devices

(COMMUNICATION MENU, 5, )

CL DEVICES

Panel :0 Inputs :0

Mode :dis Outputs :0

0. . 9, ^V, <>, E, X

Alarms: 0 Faults: 1 Cond.: 0 P: 1 FDZ

Return to Communication Menu Page 33

Select field to be changed

Enter number 0..9 or to change panel field

Select mode

Confirm entry (Unlock memory!)

Current Loop Devices:

All fireman’s panels connected to the current loop of the FP2000 fire panel are enabled

with this menu. Each fireman’s panel must have a unique address (see FM800

Installation, Configuration & Detailed Operation Manual or FR800 Installation,

Configuration & Detailed Operation Manual . Fireman’s panels that are enabled are

checked for communication, and a fault warning will occur in the event of a failure.

Mode:

The fireman’s panel can be assigned as Zone, Device , I/O or Area. (See also CL Devices

Menu under Input/Output Menu, page 98).

Input and Output:

Display the number of inputs/outputs available on the fireman’s panel. (Communication

between the two systems must of course be established for the panel to acquire this

information.)

48 Reference Guide

Access menu

(SYSTEM MENU, 2, )

ACCESS MENU

1 Access Codes 2 Field Access

0. . 9, <>, E, X

Alarms: 0 Faults: 1 Cond.: 0 P: 1 SDZ

Select number or use and press

1 Access Codes Page 50

Examine or change user access codes and the access level of any these codes.

2 Field Access Page 51

Set the access level of individual menus. This allows selected menus to be excluded from

access codes that have lower access levels.

Return to System Menu Page 23

Reference Guide 49

Access codes

(ACCESS MENU, 1, )

ACCESS CODES

Access No. :1

Access Code :1

Access Level :1

0. . 9, ^V, <>, E, X

Alarms: 0 Faults: 1 Cond.: 0 P: 1 FDZ

*See also Page 51

Six access codes are allowed in order to use the menu screens viz. Access No 1 to

Access No 6. Each of these access numbers can be assigned a numeric code of 1-4

digits. Each access number 1-6 is also allocated an access level: 1-Low level; 2-High

level; Ø-No access.

Return to Access Menu Page 49

Select item to be changed

or 0..9 change data in item (Unlock memory!)

Confirm entry

The access number of the entry code used to gain access to the menus is logged in the

event buffer. After 3 unsuccessful attempts to gain access, an Access Fault messag e is

given.

Each menu screen of the FP2000 fire panel has an access level. Access numbers that