Page 1

CS350

Installation Instructions

This manual contains installation details for

the CS350 control panels.

It provides the basic programming and installation information required by technicians and

engineers.

14 1791 999 1

Downloaded from: http://www.guardianalarms.net

Page 2

14 1791 9992

Page 3

CONTENTS

FEATURES .................................................................................................................................... 3

KEYPAD INSTALLATION ...........................................................................................................4-5

WIRING SPECIFICATIONS ...........................................................................................................5

POWERING UP PANEL ................................................................................................................. 6

HOW TO PROGRAMME ................................................................................................................7

PROGRAMMING MAP ................................................................................................................... 8

PROGRAMMING FUNCTIONS ................................................................................................... 11

PERIDIAX FEATURE ................................................................................................................... 19

PROGRAMMING TEXT ............................................................................................................... 20

RETURNING TO FACTORY DEFAULT ...................................................................................... 21

QUICK CODES ............................................................................................................................ 21

ZONE WIRING OPTIONS ............................................................................................................ 22

WIRING OF SIRENS .................................................................................................................... 23

WIRING OF OUTPUTS

RELAYS ........................................................................................................................... 24

DIGITAL COMMUNICATORS ......................................................................................... 24

FIRE DETECTORS ......................................................................................................... 24

LIST WITH SHORT CODES ........................................................................................................ 25

DEFAULT CHART ........................................................................................................................ 26

PROBLEM SOLVING ................................................................................................................... 27

TECHNICAL SPECIFICATION .................................................................................................... 29

MAIN PANEL WIRING DIAGRAM ............................................................................................... 30

Features

FEATURES

The CS350 is a microcomputer based alarm control panel operating from remote keypads, and has

the following features:

l Facility for up to 4 CD3008 remote keypads... one CD3008 is supplied with the panel.

l 6 freely programmable dual zones.

l Auxiliary tamper input.

l Supervised bell tamper input.

l Digital communicator fault input... reprogrammable to include remote engineer reset.

l New perimeter system capability which provides local alarms for perimeter zone activations.

This can reduce false alarms considerably. Exremely useful with inertia shock sensors.

l 4 freely programmable open collector outputs.

l 2 freely programmable high current outputs (eg. to control sirens).

l LCD with freely programmable zone names... up to 12 characters.

l Battery input monitored.

l Four user codes.

See Programming Functions on page 14 for zone (Input) and page 15 for output types.

14 1791 999 3

Page 4

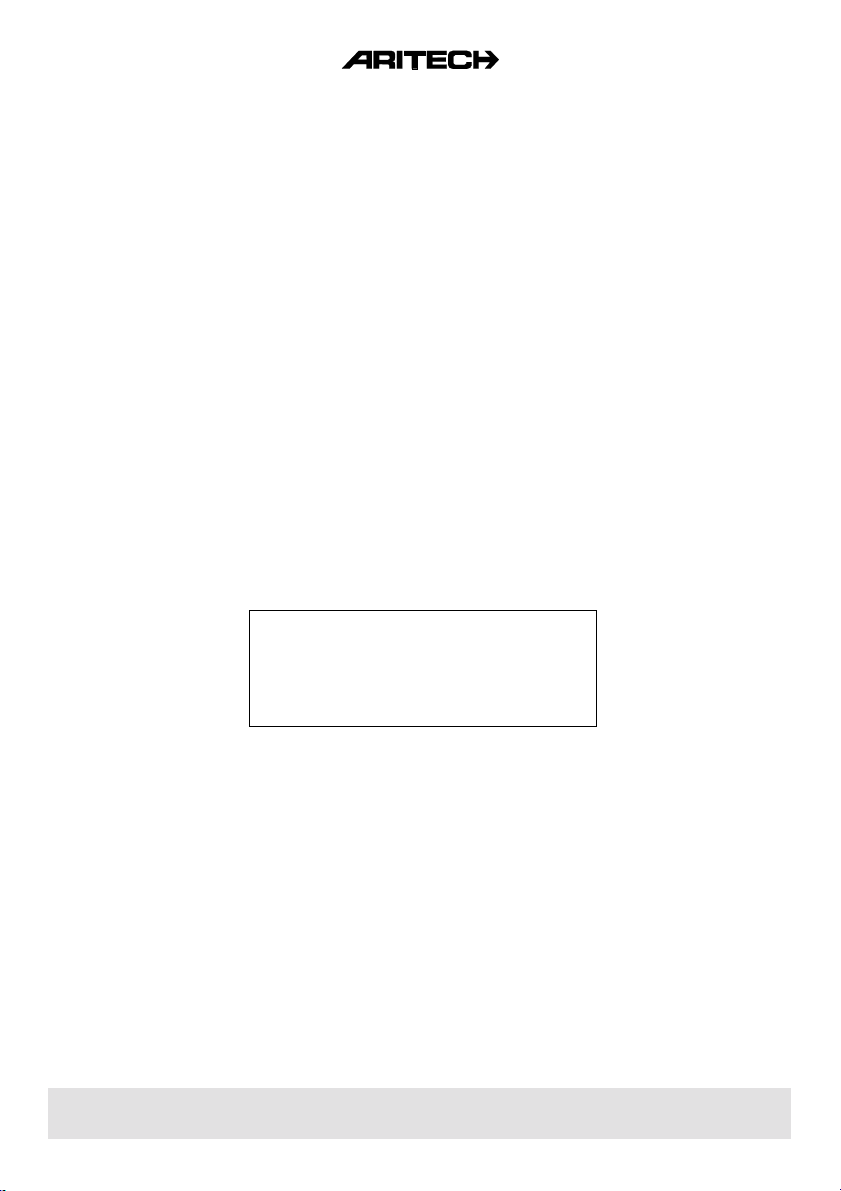

Keypad Installation

CD3008

CD3008

ADJUSTMENT

DISPLAY-CONTRAST

Figure 1.

PUSH

1

DIPSWITCHES

FOR KEYPAD ID

3

LIFT

2

PUSH IN CLIP WITH

SCREW DRIVER AND

LIFT UP LID

REMOVE SCREW

IF FITTED

CABLE ENTRY

FROM TOP

MOUNTING HOLE

SPARE SCREW

TO FIX COVER

ONTO BASE

✓

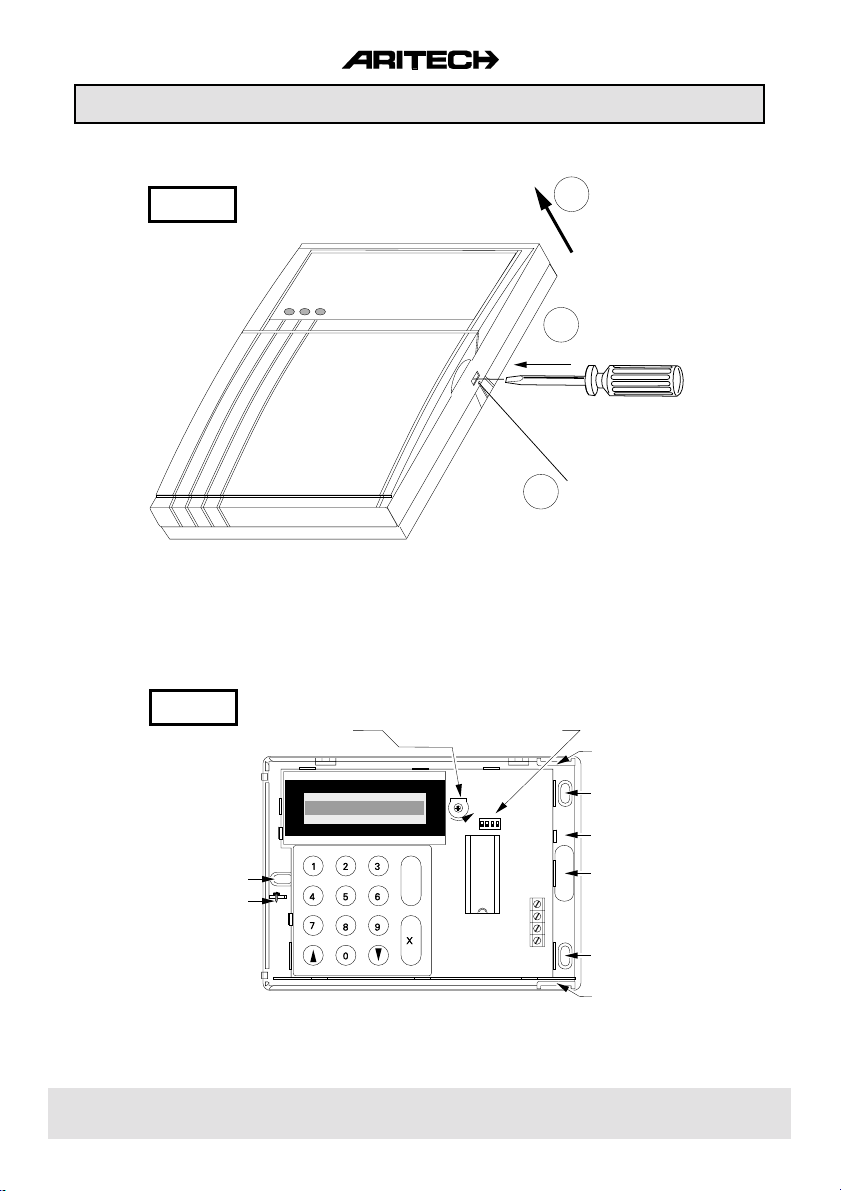

Figure 2.

MIN MAX

ON SD

1234

D

C

B

A

MOUNTING HOLE

PUSH CLAMP

GENTLY TO

REMOVE PCB

CABLE ENTRY

FROM BACK

MOUNTING HOLE

CABLE ENTRY

FROM BOTTOM

14 1791 9994

Page 5

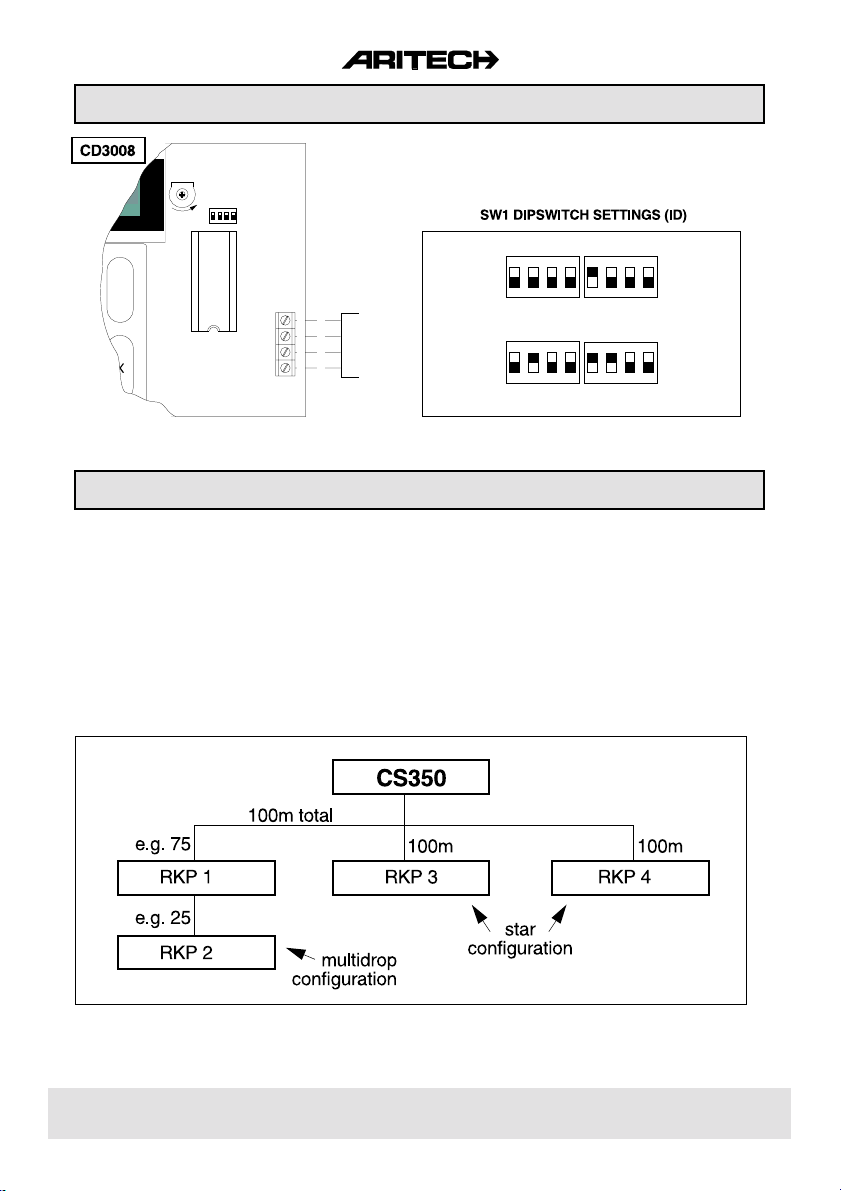

Keypad Installation

SW1

ON SD

MIN MAX

1234

ON

✓

CD3008

Control panel

Terminal 5

D

C

B

A

1234

OFF

Keypad 1

15

14

13

12

(all off)

ON

12341234

OFF

Keypad 3 Keypad 4

1234

Keypad 2

Figure 3.

Figure 4.

Wiring Specifications

Connect the additional keypads either using a STAR or MULTIDROP configuration.

MULTIDROP the keypads are 'daisy chained' together, each keypad being connected in parallel

STAR each keypad is wired back separately to the control panel terminals.

Any combination of the above wiring methods is allowed with the restriction that the total cable length

on each of the wiring loops (either multidrop or star) is restricted to 100m.

The following diagram shows how 4 RKPs may be connected using both methods.

to the one before it.

Figure 5.

14 1791 999 5

Page 6

Powering Up Panel

Connection of the control panel and the remote keypad in the following sequence allows the engineer

to establish that the control panel is working correctly.

Connection sequence:

1. Before installing the remote keypad (RKP) at it's designated position, it may be connected at

the control panel, to enable the engineer to commission the system.

2. Check that the ID for the RKP is set correctly... one keypad has to have ID1 (refer to Diagram

2).

3. Connect the RKP to the panel as shown in Diagram 3.

4. Replace the cover of the RKP and ensure that the tamper switch in the panel is closed.

5. Apply mains power to the panel. The system will power up in armed state (Factory Programme

Setting). If any zones are open at power up, the audibles will activate. The panel

defaults to the language select prompt when switched on for the first time [ UK/IRL Press é

1]. Enter [é] and [1] to select English language. Note that this also happens after returning to

factory default. See page 21 for more details.

6. Enter the Default User Security Code [1][1][2][2] at the keypad to disarm the system. The keypad

display shows DISARMING and the audibles, if sounding, will stop. Display then shows

any zones which are open and caused it to alarm. If [0] key is pressed at this stage, the display

will show FINISHED? . Enter ACCEPT [ü] to finish with operator menu.

7. The display shows Time/Date and the system is now disarmed.

8. Enter [1][2][7][8] (Default Engineer Code) to enter Engineer Mode and to change programme

parameters. See the Programming Map and Programming Functions for operational details.

How to programme is detailed on page 7.

9. Each time the system is powered down the panel memorizes it's current state, i.e. whether

armed, disarmed, partguard, etc. and will restore to that state when powered-up again.

14 1791 9996

Page 7

HOW TO PROGRAMME

All programmed features can be changed. The structure and position of the programming options

are illustrated in the Programming Map on the next page. Features and options are grouped together

and allocated to 6 main menu blocks:

1 MAINTENANCE 4 ZONES

2 TIMERS 5 OUTPUTS/REMOTES

3 USERS 6 MISCELLANEOUS

Once in Engineer Mode, the blocks can be accessed by 'stepping' through the menu blocks and

accepting the option shown in the display. The keys used for programme selections are defined as

follows:

[ê] stepping forward to next block or programming option

[é] returning to previous block or programming option

[ü] enter programming block - enter programming option - confirm changes - accept option

[X] quit programming block - quit programming option - reject changes

PROGRAMMING EXAMPLE

Adding Additional Keypads

After have installed the additional keypads - mind the correct dipswitch ID setting - go to the Engineer

Programming Mode and proceed as follows:

1. Use the [ê] key till OUTPUTS/REMOTES is displayed then enter [ü] .

2. Use the [ê] key till INSTALL REMOTE is displayed then enter [ü] .

3. The display shows the keypads connected, eg. REMOTE k k ✱ ✱ . Confirm [ü] these changes

when they are correct. If not correct, verify the wiring to the keypad and dipswitch ID settings.

The keypad must be powerless when changing dipswitch settings.

4. The display now shows INSTALL REMOTE . Quit programming blocks [X] till GOODBYE is

displayed. Now accept [ü] to leave the Engineer Programming Mode.

14 1791 999 7

Page 8

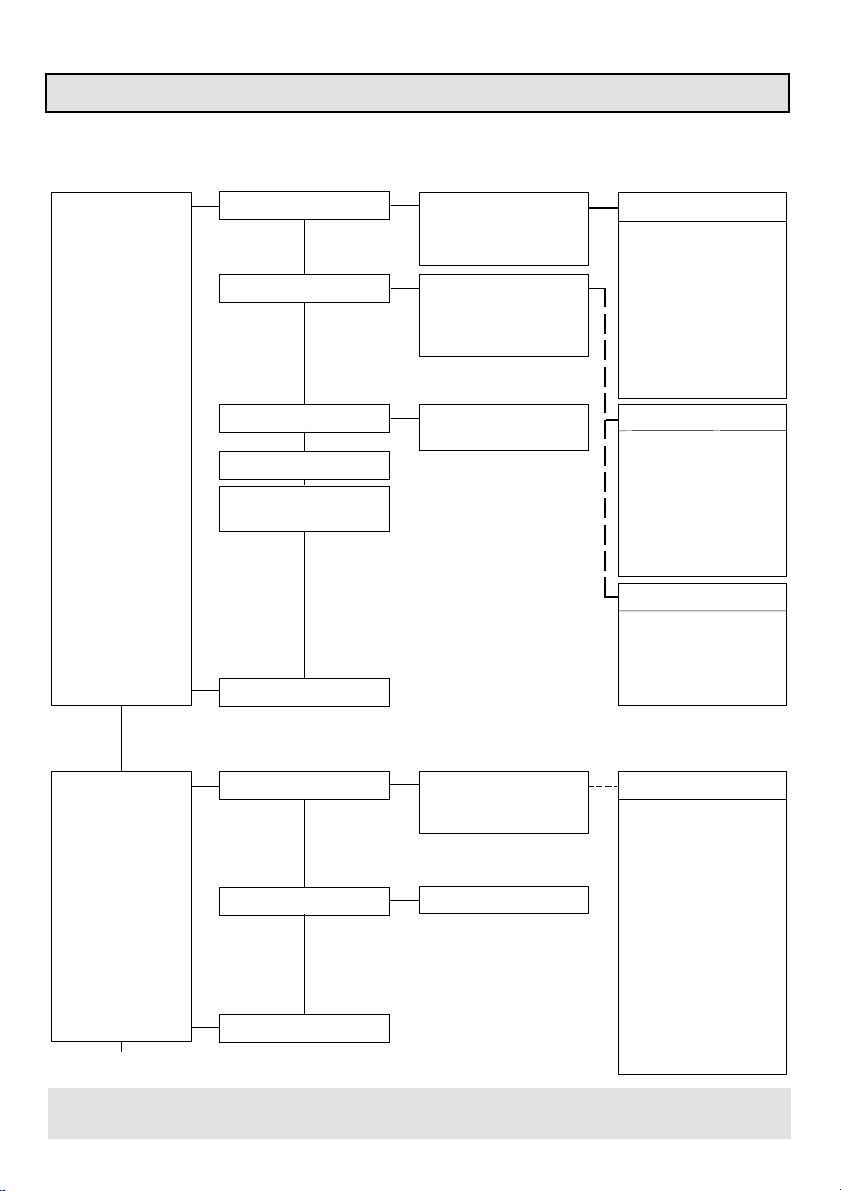

CS350 PROGRAMMIMG MAP V1.0

1 1 Engineer Log Display Log

Clear Log

Maintenance Menu

2 Output Test nn Low

nn High

MAINTENANCE 3 Show Open Zones All Closed

nn Zone

4 Walk Test Walk Test nn

5 LED Test Testing LEDs

Main Menu

2 1 Entry Time nn

2 Exit Time nn

3 Split Time OFF/ON

4 Bell Times Bell Cutout nn

Bel Delay nn

All Bells Cut ON/OFF

TIMERS Dig Cutout ON/OFF

Perim.Bell Cutout nn

Timers Menu

5 Time hh:mm Time hh:mm

6 Date dd/mm/yy Date dd/mm/yy

7 Summertime Forward Date

Backward Date

Summertime ON/OFF

Main Menu Timers Menu

or

or

3 1 Change Codes xx Code In Use

2 Code Privilege 01 Fs Us . . . . . . OK USER ATTRIBUTES

USERS Leave this Ps=Part Set

3 Engineer Code New Code Fs=Full Set

4 Duress Code New Code

5 Code Count nn

6

êê

Open Zones ON/OFF

Main Menu

xx Code Unused

New Code

Verify

Error

02 . . . . . . . . . . . OK

03 . . . . . . . . . . . OK Mn=Manager

04 . . . . . . . . . . . OK In=Inhibit

Us=Unset

Verify

Error

Verify

Error

14 1791 9998

Page 9

CS350 Programming Map

4 1 Zone Type 01 Alarm ZONE TYPES

2 Zone Attributes 01 In Key

ZONES 3 Shock Zones nn Gross. x Pls y ZONE ATTRIBUTES

4 Zone Name La=Local Alarm Contact

5 Loop Type : Alarm 24=24 hours

Loop Type : Dual Pg=Partguard

Main Menu Qs=Quick Set

0x . . . . . . . . . . . .

06 . . . . . . . . . . . . Unused

Leave this Tamper

PA

0x . . . . . . . . . . . . Fire

06 . . . . . . . . . . . . Exit/Entry

Leave this Alarm

Keypad Lock

Key Inf=Infinite Entry

Exit Trm=Exit Terminator

nn Wrong Type

Ls=Local Alarm Shock

In=Inhibit

So=Soak Test

Ac=Access

Ch=Chime

KEY ZONE ATTRIBUTES

Fs=Full Set

Ps=Part Set

Us=Unset

Pu=Pulsed

5 1 Output Type 01 Disarm/Arm OUTPUT TYPES

OUTPUTS / 2 Install Remote Remote kk** Latch

REMOTES Fire Detect Reset

Main Menu Perim.Alarm

0x . . . . . . . . . . . .

06 . . . . . . . . . . . . Disarm/Arm

Alarm

P.A.

Fire

Tamper

k=CD3008 Buzzer

Int.Bell

Ext.Bell

Partguard

System Clear

Trouble

Unused

Clear

14 1791 999 9

Page 10

CS350 Programming Map

6 1 Arm/Disarm Menu User Walk ON/OFF No Forced Arming

Forced Arm Opts Keep Inhibits

Rearm Options Clear when closed

ArmedDisplay ON/OFF Clear after exit

Exit Fault Buzzer/Bell

Final Door ON/OFF

Miscellaneous Menu Always rearm

2 P.A. Menu P.A. Silent/Bells

PA, LF Silent/Bells

éê PA ON/OFF

Miscellaneous Menu

3 Partgd/Chime Timed Partgd ON/OFF

Access>EE/Access

Partgd Digi ON/OFF

Latched Chime ON/OFF

Int.Bell Chime ON/OFF

Miscellaneous Menu

4 Eng. Reset Menu Reset Code/FTC or Code Only

P.A. Reset ON/OFF

Tamper Reset ON/OFF

MISCELLANEOUS Alarm Reset ON/OFF

Clear Engineer Reset

Miscellaneous Menu

5 Warnings PF Buzzer ON/OFF

LF Buzzer ON/OFF

Miscellaneous Menu

Never rearm

Rearm 1 to 8 Times

GOODBYE

6 Factory Prog Menu Engineer Lock ON/OFF

Miscellaneous Menu

7 Change Language English

Nederlands

Francais

Italiano

8 SysClear Inputs System Clear Mains ON/OFF

System Clear Battery ON/OFF

System Clear Fuse ON/OFF

System Clear Accs+EE ON/OFF

Main Menu Miscellaneous Menu

14 1791 99910

Page 11

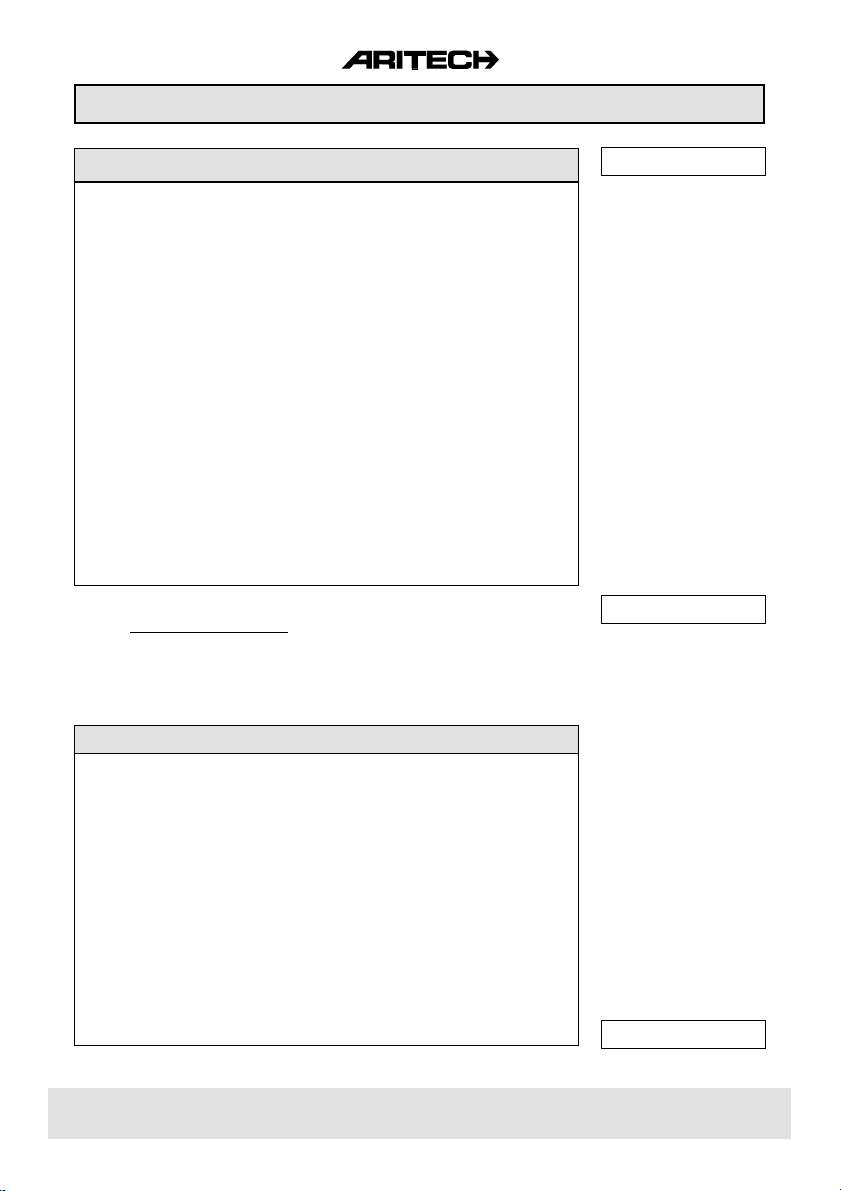

1. MAINTENANCE MENU

CS350 Programming Functions

1.1 Engineer Log

1.1.1 Display Log

Use this function to consult the 40 event log

1.1.2 Clear Log

Will clear all events in the Engineer Log

1.2 Output Test

Use the [é ] and [ê ] keys to select the desired output. Use the [ü]

key to toggle the output polarity. Will return to its programmed status

when you move to the next output.

1.3 Show Open Zones

Will show any zone which is open. This is a useful test function.

1.4 Walk Test

Used to test individual inputs. Triggering the input will activate the

interior bell for 4 seconds,as well as latch and walk test outputs.

1.5 Led Test

This option will perform a sequential test of all keypad LED's

2. TIMERS

2.1 Entry Time

Programmable between 0 to 99 seconds.

2.2 Exit Time

Programmable between 0 to 99 seconds.

Engineer Log

Output Test

Show open zones

Walk Test

Led Test

Entry Time

Exit Time

2.3 Split Entry Time

When this option is set and the entry time is exceeded, then only the

interior bells will sound. Only after the additional entry time expired,

which is half the time programmed in 2.1, will a full alarm be created.

2.4 Bell Times

2.4.1 Bell Cutout

Programmable between 0-99 minutes for exterior bell. When a

time limit is required for interior bell then see 2.4.3.

2.4.2 Bell Delay

Programmed delay in minutes for interior and exterior bells which

becomes operational only when the system is set and no digi

fault condition prevails (negative to terminal 20).

2.4.3 All Bells Cut

Select for ON if interior bell must be timed for duration of 'Bell Cutout'

time

14 1791 999 11

Split Entry Time

Bell Times

Page 12

CS350 Programming Functions

2.4.4 Digi Cutout

Select for ON if the output type 'Alarm' must reset with the Bell

cutout time. If set to OFF then this output resets when the system

is disarmed.

2.4.5 Perimeter Bell Cutout

Programmed alarm time in minutes for the 'Perim.Alarm' output

type. The exterior bell and Perimeter bell output types will reset

after this time alarm expired. See also Peridiax feature on page

19.

2.5 Time

Programme time in Hours and Minutes: hh:mm

2.6 Date

Programme date: dd / mm / yy

2.7 Summertime

2.7.1 Forward date

Date at which clock is advanced with 1 hour (start of summertime).

2.7.2 Backward date

Date at which clock is returned with 1 hour (start of wintertime).

2.7.3 Summertime ON/OFF

Select for ON if automatic correction to summertime is required.

3. Users

3.1 Change Codes

Programme here user code 01 to 04. Use from 4 up to 6 digits with

the exception of '0'. Deleting a code is achieved by entering [ü]

after appearance of [New code _ ]. Code 4 can be used with a

code counter (see 3.5). Factory default code for user code01is

[1122].

Bell Times

Time

Date

Change Codes

Code Privileges

3.2 Code Privileges

Allocate operational functions to each code.

Attribute Function

. Mn change codes, time, date, read engineeer memory,

access to chime function

. In inhibit zones

. Ps part set of system

. Us unset of system

. Fs full set of system

3.3 Engineer Code

Programme here new Engineer code. Factory default is [1278].

Engineer Code

14 1791 99912

Page 13

CS350 Programming Functions

3.4 Duress Code

Programme here the code which will disarm the panel and activate

the Personal Attack output. The output restores after entering a

user code.

3.5 Code Count

Programme the amount of times code 4 can be introduced. When set

to '99' code 4 is always operational. Setting to '0' disables the code.

3.6 êêOpen Zones On/Off

When this option is programmed to 'On' then a keyswitch user will

be able to view any open zones by pushing twice the [ê ] button.

3.7 Quick codes On/Off

When this option is programmed to 'On' it is possible to fast arm the

panel.

The following three keystroke sequences are possible :

[0] [ê] [4] Arms system with exit time.

[0] [ê] [5] Arms system immediately (no exit time).

[0] [ê] [7] Arms system partially (Part Set).

4. ZONES

4.1 Zone Type

Define here the typical function of each input.

TYPE FUNCTION

. Unused Input is not operational

. Tamper Input is 24Hrs operational. Activation of input causes

'internal bell' alarm in disarmed state and full alarm in

armed state. The input is automatically bypassed after

an alarm till the second valid entry of a user code.

output : tamper, alarm, int.bell, ext.bell, system clear, fire

reset

. P.A. Input is 24Hrs operational. Silent or audible Personal

Attack alarm is determined in function 6.2.1.

output : P.A., system clear, fire reset

. Key Input is 24Hrs operational to arm/disarm system. The

exact operation will be determined by the attributes allocated in function 4.2. Use Pulse keyswitches if more

than one input is to be used as Key zone.

output : disarm/arm, buzzer, latch

. Fire Input is 24Hrs operational. Activation of zone will cause

the sirens to pulse on and of. The input is automatically

bypassed after an alarm till the second entry of a valid

user code.

output : fire, interior bell, exterior bell, system clear, fire

reset

Duress Code

Code Count

Open Zones

Quick Codes Off

Zone Type

14 1791 999 13

Page 14

CS350 Programming Functions

TYPE FUNCTION

. Exit/Entry Input is bypassed during exit time when arming the

system. If after the exit time the zone is still open, the

panel will not arm and act as programmed in

function 6.1.5. During the entry procedure the entry

timeris started which allows disarming.

output : buzzer, alarm, interior bell, exterior bell, fire

reset

. Alarm Input is only active when the system is armed and

it will act according to its programmed attributes.

outputs : alarm, interior bell, exterior bell, system

clear, fire reset

. Keypad Lockopening this input will disable access to the keypad.

. Key Infinite creates an infinite exit time. Only after opening and

closing this zone will the panel arm after four

seconds. Re-activation starts an infinite entry time.

. Exit The exit time stops and system arms 4 seconds

after Terminator closing the input.

4.2 Zone Attributes

Attributes define the operation of the zone type. Some types

have attributes inherent to them. Others can not be changed

which will be displayed by [No Option].

ATTRIBUTE FUNCTION

. In Allows inhibiting of alarm and exit/entry zones

. 24 Creates a 24Hrs zone. Only applicable for Alarm types.

. Pg Partguard. Zone is inhibited during partguard protection.

. So Soak Test. The related input will not activate any alarm output

but only log its events.

. Ac Access zone. Follows the exit/entry input. Will create a direct

alarm when triggered prior to the exit/entry input, except if programmed for Access/EE and the panel is in Partguard mode (see function

6.3.2.).

. Ch Chime. Input activates buzzer/ interior bell when in disarmed

state.

. Ls Local Shock. Shock sensor alarm triggers 'perimeter' output

instead of 'alarm' output. See also Peridiax programming on p.19.

. La Local Alarm. Both shock sensor and/or contact activation will

trigger the perimeter output. See also Peridiax programming on p.19.

Zone Type

Zone Attributes

Key Zones

14 1791 99914

Page 15

CS350 Programming Functions

KEY ZONE ATTRIBUTES

. Fs Full set. Keyswitch fully arms system.

. Ps Part set. Keyswitch partially arms system.

. Us Unset.Keyswitch disarms system.

. Pu Pulse.Keyswitch used must be a pulse type. Allows

arming/disarming with multiple keyswitches in a system.

. Qs Quick set. Keyswitch arms panel without exit time.

4.3 Shock Zones

Input 1 to 4 can be programmed to analyse enertia shocks (e.g. GS610).

Two types of attack can be calibrated for. Heavy attacks ( 'gross'

level) and small repetitive attacks ('pulse' count). The pulse count

ismonitored after the first triggering in a window of 30s with 1s

intervals.

4.4 Zone Names

Programme here personalised names for each input.

(See page. 20 for example.)

4.5 Loop Type

Inputs can be configured to detect alarm contact activations only

('Alarm') or alarm and tamper violations within the same loop ('Dual').

5. OUTPUTS / REMOTES

5.1 Output Type

Define here the typical function of each output (1 to 6).

TYPE FUNCTION

. Disarm/Arm Reflects the control panel's arm/disarm status.

. Alarm Switches with intrusion and tamper alarm

(Tamper only when armed).

. PA Switches with PA alarm and / or Duress alarm.

. Fire Switches with a fire alarm.

. Tamper Switches with a 24Hrs and / or a tamper alarm.

. Latch Switches after exit time and / or walk test. Resets

with disarm or start of entry time.

Used withlatching sensors.

. Fire Reset Switches with second entry of a valid user code

after an alarm or after leaving the user log.

. Buzzer Follows the buzzer operation of the keypad.

. Interior Bell Follows the interior bell status.

. Exterior Bell Follows the exterior bell alarm time.

. Partguard Switches when control panel is part set.

. System Clear Reflects the system status according to the

optionsprogrammed in function 6.8.

. Trouble Indicates a system error : E²PROM error, line fault,

RKP fault, low battery, mains failure. The RKP will

display the cause of trouble.

Zone Attributes

Shock Zones

Zone Names

Loop Type : Alarm

Output Type

14 1791 999 15

Page 16

CS350 Programming Functions

TYPE FUNCTION

. A Alarm Switches with a perimeter alarm for the duration as

programmed in function 2.4.5. In this case the

exterior bell follows the A Alarm.

. Unused Output is not used.

5.2 Install Remotes

Only one keypad is installed when the panel is powered-up from

factory default. Additional keypads must be initialised by the panel

before they become active. When selecting [ü] install remotes, the

display will show the keypads which it recognizes, for example two

keypads: [Remote kk**]. Now enter [ü] again to initialize the other

keypad(s).

6. MISCELLANEOUS

6.1 Arm / Disarm Menu

Programming of options associated with arming / disarming.

6.1.1 User Walk On/Off

When an input is open during arming of the panel, the interior

bell will give a short activation each time a zone is closed.

6.1.2 Forced Arm Opts

Determine here the' forced arming' conditions. Input(s) and

code(s) must have the 'In' attribute to be able to force arming of

the panel. Forced arming can be achieved in three ways.

a) Go to the [Forced Arm ] menu in the user mode and accept.

b) Arm the panel and enter [éé] when the display shows [Open

Zone(s)].

c) Arm the panel with a keyswitch while a 'forced arm' option

has been programmed.

Option Operation

. No forced arming Forced arming is not possible.

. Keep inhibits Open zones are omitted till the panel is dis-

armed.

. Clear when closed Open zones are omitted till they close

again. From that moment on they can detect

again.

. Clear after exit Open zones are omitted till the exit time has

expired, after which they can detect again.

Output Type

Install Remotes

Arm/Disarm Menu

6.1.3 Rearm Options

Define the condition of retriggering of bells.

Option Operation

. Always Rearm The same input when activated, will al-

ways retrigger sirens.

. Never Rearm The same input will not re-trigger the sirens.

. Rearm 1 to 8 times Limits the number of re-triggerings as

programmed.

14 1791 99916

Page 17

CS350 Programming Functions

6.1.4 Armed Display On / Off

Determines if the display will show the armed status or time & date

when armed.

6.1.5 Exit Fault Buzzer/Bell

Deterines if the buzzer only or buzzer + interior bell will activate

with an exit fault.

6.1.6 Final Door On / Off

After introducing the code, the panel will arm 4s. after having opened

and closed the exit zone or access zone even before the exit time

has expired.

6.2 P.A. Menu

6.2.1 P.A. Silent/Bells

Programme if a PA alarm must be silent or loud.

6.2.2 PA,LF Silent/Bells

Programme if a PA alarm must be silent or loud when a phone line

fault is present.

6.2.3 éê PA On/Off

Programme if the keypad panic buttons are operational or not.

6.3 Partguard / Chime

6.3.1 Timed Partguard On/Off

Define if the panel is armed with or without exit time.

6.3.2 Access zones with Partguard

Define if an access zone becomes an entry/ exit zone when

partially armed or not.

Armd/Disarm Menu

P.A. Menu

Partguard/Chime

6.3.3 Partguard Digi On/Off

Define if the alarm output operates when partially armed or not.

6.3.4 Latched Chime On/Off

If Latched Chime is set to On, the chime will remain operational

each time the system is disarmed untill manually canceled by user.

6.3.5 Interior Bell Chime On/Off

Define if the interior bell follows the chime function or not.

6.4 Engineer reset menu

Define the conditions which will call for an engineer reset. When

a panel asks for [Call Engineer nn], were nn is a number, the user

can't arm his panel.

6.4.1 Reset Code/FTC input or Code only

When made negative,Input 20 (Fail To Communicate or Digi Fault)

may be used to clear engineer reset. When only a code is allowed

to reset, programme for [Reset Code Only].

14 1791 999 17

Engineer reset

Page 18

CS350 Programming Functions

6.4.2 P.A. Reset On/Off

Define if PA alarm requires engineer reset or not.

6.4.3 Tamper Reset On/Off

Define if Tamper alarm requires engineer reset or not.

6.4.4 Alarm Reset On/Off

Define if Alarm type input (including Tamper when armed)

requires engineer reset or not.

6.4.5 Clear Engineer Reset

Clear an engineer reset request. [Reset Cleared !] will be

displayed.

6.5 Warnings

6.5.1 PF Buzzer On/Off

Define if a 230V mains failure must trigger the buzzer output.

6.5.2 LF Buzzer On/Off

Define if a Digi Fault (via input 20) must trigger the buzzer output.

6.6 Engineer Lock

Define if an engineer code is required to factory default the

panel. See also the chapter returning to factory default.

6.7 Change Language

Change the language used by the panel to Dutch, French or Italian.

6.8 System Clear Inputs

Define the parameters which will determine the function of the

System Clear output.

P.A. Menu

Warnings

Engnr. Lock Off

Change Language

System Clear

Inputs

6.8.1 System Clear Mains On/Off

Will a 230V mains failure switch the output off or not.

6.8.2 System Clear Battery On/Off

Will a battery failure switch the output off or not.

6.8.3 System Clear Fuse On/Off

Will a fuse failure switch the output off or not.

6.8.4 System Clear Access + EE On/Off

Will an open access or EE zone switch the output off or not.

14 1791 99918

Page 19

Peridiax Feature

The CS3503 control panel has been equipped with Aritech's new Perimeter and Dialler eXtended

programming option.

How It Works

When the panel is armed and not in alarm state, activating a perimeter zone will cause a PerimeterAlarm or Local Alarm. This means that both internal and external bells sound for a programmable

number of minutes (perimeter bell time).

l A Perimeter Alarm digi output will turn on and reset at the end of the perimeter bell cutout time.

l The main alarm digi will not turn on.

l Engineer reset and rearm option are not activated by Perimeter-Alarm.

l Perimeter-Alarms that occur during exit time, after silent PA etc. are treated like normal alarms.

l Perimeter-Alarms that occur during bell delay/cutout will merely set Perimeter-Alarm digi output.

l The output functionality is fixed... both bells go for the Perimeter-Time when a Perimeter-Alarm

happens.

Typical Application Example

WIRING

Figure 6.

PROGRAMMING AND OPERATION

PROGRAMMING

Zone Attribute

NO La

NO La

La

La

For programming see Programming

Shock Option

Ls

No Ls

Ls

No Ls

Inertia Activation

'Perimeter' Alarm

'Full' Alarm

'Perimeter' Alarm

'Perimeter' Alarm

Zones è Zone attributes Ls for Shock (Zone 1-4)

Map:

è Bell times è perim. bell cutout ON/OFF

Timers

WEAPON AGAINST FALSE ALARMS

Consider, for example, the situation where the inertia sensor and magnetic contact are wired in series

and mounted on a window. When only the zone attributes Ls is added , then the panel will cause

a local alarm for inertia sensor activations and a full alarm when the window opens.

14 1791 999 19

OPERATION

Contact Activation

'Full' Alarm

'Full' Alarm

'Perimeter' Alarm

'Perimeter' Alarm

La for Contacts(Zone 1-6)

Page 20

Programming Text

Literal text is available for programming customized zone and user names. The keypad digits each

represent a set of characters.

KEYPAD CHARACTER SET

ABC DEF GHI

JKL

STU

MNO

VWX YZ

PQR

✓

The [9] key has a blank space and

CURSOR

LEFT

HOME

CURSOR

RIGHT

punctuations (eg. full stop, comma,

etc.).

The [0] key has a blank space.

SCROLL

UP

SCROLL

DOWN

HOW TO PROGRAM NAMES

Function keys used:

ê key Move to next character.

é key Move to previous character.

4 key . Confirm to reprogram current text

. Confirm changes to the description shown on the

display after programming.

key . Restart the programming of a name

X

. Return to previous menu section.

EXAMPLE

Reprogram zone 1 01 zone to 01 Door .

l Enter engineer mode [0][1][2][7][8]

l Jump to zones - zone name [4][4] - display shows 01 zone

l Confirm to reprogram 4 - display shows 01 _

l Start programming capital letter'D' [2] - display shows 01 2

Repeat steps till 'D' appears [2]+[2]+.. - display shows 01 D

l Move to next character ê - display shows 01 D_

l Repeat programming sequence for all characters.

l Confirm new name when the last character shows on the display 4 you can now proceed with

the next name ê or return to the previous menu section X .

14 1791 99920

Page 21

Returning to Factory Default

Without Engineer Lock programmed

1. Remove all power from the panel. Mains and the battery.

2. Remove the plug-on link (JP1) on the panel.

3. Restore the mains power.

4. The Display will prompt for the Language Default prefered. The display will change every two

seconds.

UK/IRL Press é1

NL Toets é2

F Taper é3

I Ins. é4

4. Enter at Keypad 1 the default operators code [0][1][1][2][2].

5. Enter at Keypad 1 the default engineer's code [0][1][2][7][8].

6. Replace the plug-on link and reconnect the battery.

With Engineer Lock programmed

1. Enter Engineer Mode using EXISTING Engineer code at Keypad 1.

2. Select 'Factory Prorgram Menu' from the miscellaneous section and scroll down to 'Default

Settings'. Enter accept ✔ .

NOTE: . When the existing engineer code is unknown, then the control panel must be

returned to the factory for reprogramming.

. The panel always powers up in Armed condition.

Quick Codes

The use of operator "Quick Codes" can be enabled or disabled by setting "Quick Code" to ON or

OFF in the Use Menu.

The quick codes are as follows:

0¯4 Normal Set.

0¯5 Alarm Set (No Buzzer).

0¯7 Alarm Partguard Set.

14 1791 999 21

Page 22

Zone Wiring Options

General

The main control panel inputs are set up as standard EOL (4K7) zones which are freely

programmable to whichever type is required. However, by selecting option 'dual' from the

'zones' menu all main control panel zone inputs can be programmed to give ALARM and

TROUBLE indication ON THE SAME ZONE (Fig. 7.).

Wiring

1. The ALARM devices are wired as normal and a 4K7 resistor is fitted in PARALLEL with

the complete loop.

2. The TAMPER switches/devices are wired as normal and a 4K7 resistor is fitted in series

with this loop.

Principles of Dual Operation

All devices closed ....... loop resistance is 4K7

TAMPER device open loop is open circuit

ALARM device open ... loop resistance is 9K4 (ie EOL resistor PLUS parallel resistor)

Example 1

Four wire application for powered motion sensors

Example 2

Multiple sensors wired in a single zone

Figure 7.

Figure 8.

14 1791 99922

Page 23

AS290 / AS390

BEACON CONTACTS

SPEAKER

TAMPER

SWITCH

-

(black)

BATTERY

(red)

+

+

-

-+ -+

1 2 3 4 5 6 7 8 9 10

Wiring of Aritech Sirens

16

TAMPER LOOP

-

INPUT POWER (13.0-14.2)

+

SIREN HOLD-OFF VOLTAGE (*)

BEACON HOLD-OFF VOLTAGE (*)

*) Program Internal (5) and External (7)

Bell outputs for positive (+) trigger

4K7

17

3

2

5

7

CUT-OFF

TIMER

Figure 9.

J2 J1

JUMPERS CUT-OFF TIMER: (minutes)

J1

J2

✲= cut link

✲

✲

✲

✲

10’:

20’:

3’:

5’:

14 1791 999 23

Page 24

Wiring of Outputs

Principle of operation from outputs.

Output as shown is 'High'. When programmed for '-'

trigger

the output will switch to '-' with an alarm condition.

Figure 10.

Wiring to Digital Communicator

Figure 11.

Figure 12.

Wiring of Fire Detectors

14 1791 99924

Page 25

List with Short Codes

A

Armed display on ................................ 61 4

B

Bell cut-out time, program ................... 24 1 mm

Bell delay, program ............................ 24 2 mm

Bell option, exit fault ........................... 61 5

Bells cut option, all ............................. 24 3

Buzzer option, line fault ...................... 65 2

Buzzer option, power failure ............... 65 1

C

Change of hour backward .................. 27 2

Change of hour forward ...................... 27 1

Chime option, latched ........................ 63 4

Chime, internal bell on........................ 63 5

D

Date, program curren ................. 26 DD MM YY

E

Engineer code, program ..................... 33

Engineer lock select ........................... 66 2

Engineer reset clear ........................... 64 5

Engineer reset PA .............................. 64 2

Engineer reset tamper ....................... 64 3

Engineer reset (Alarm) ....................... 64 4

Entry time, program ............................ 21 SS

Exit time, program .............................. 22 SS

F

Factory default program select .......... 66 N

Final door set ...................................... 61 6

Forced arm select ............................... 61 2

I

Input attibute, program ....................... 42 NN

Input name, program .......................... 44 NN

Input option, A/T dual ......................... 45

Input type, program ............................ 41 NN

Input values, program inertia.............. 43 NN

Input walk test .................................... 14 NN

Inputs, show open .............................. 13

Install new remotes ............................ 52

L

Log, clear ............................................ 112

Log, display the .................................. 111

O

Output type, program .......................... 51 NN

Output, test .......................................... 12 NN

P

PA at keypad, select ...........................62 3

PA option, lien fault silent .................... 62 2

PA option, silent .................................. 62 1

Partguard, access to exit on ............... 63 2

Partguard, digi options ........................ 63 3

Partguard, timed/instant ......................63 1

R

Rearm options select ..........................61 3

S

Split entry time, program .....................23 SS

Shock perimeter select........................ 46

T

Time, program current......................... 25 HH

MM

U

User attributes, change .......................32 N

User code, program.............................31 N

User walk test, select .......................... 61 1

Key to Abbreviations:

HH Enter number of hours

mm Enter number of minutes

N Enter number of User Code

NN Enter number of output/zone

SS Enter number of seconds

DD Enter number of days

YY Enter year

MM Enter month

HOW TO WORK WITH SHORT CODES

Instead of using the - ¯ ✔ keys to access

programming options, it is possible to directly

jump to the menu section required. Immediately after you enter the engineer code, keyin one of the digit sequences as indicated in

the Short Code List.

14 1791 999 25

Page 26

Default Chart

No. Default Required

ZONE TYPES

1 Exit/Entry

2 Alarm

3 Alarm

4 Alarm

5 Alarm

6 Alarm

OUTPUT TYPES

No. Default Required

1 Arm/Disarm

2 Partguard

3 Latch

4 Tamper

5 Int. Bell

6 Ext. Bell

TIMERS

Description Default Required

Exit time 30 sec.

Entry time 30 sec.

Split ent. time off

Bell delay 0 min.

Bell cut off 30 min.

OTHER OPTIONS

Function Default Required

Buzzer for line ON

fault

Buzzer for pow- ON

er failure

Latched chime OFF

Chime rings Int. OFF

bell

Current date 01Jan92

Current time 00 00

Engineer lock

Engineer reset Code+FTC

option

Engineer reset OFF

Select

Type In Pg Ch 24 Ac

ZONE ATTRIBUTES

So

Alarm l

Tamper x x x x x x

PA x x x x x x

Fire x x x x x x

E/E l x l x x x

CODES & PRIVILEGES

No. Default Fa Ps Us In Mn Cn

1 1 1 2 2 llll x

2 Unused x

3 Unused x

4 Unused l

Duress Unused xx xxx x

Ud code Unused xxxxx x

Eng. 1 2 7 8 xxxxx x

Pu Qs Fs Ps Us

Key ll

OTHER OPTIONS cont'd

Function Default Required

Exit fault of buz- BUZZER

zer/bell

Final door set OFF

Forced arming OFF

Inputs alarm or ALARM

dual

Keyswitch PULSED

option KEY

PA at keypad OFF

PA with line fault BELLS

bells or silent

PA activations BELLS

bells or silent

Partguard OFF

acces to E/EE

Partguard OFF

activates digi

Partguard INSTANT

time/instant

Auto rearm NEVER

option

x = Not Available (for attributes and privileges charts) l = Default

14 1791 99926

Page 27

Problem Solving

Bells do not ring at 1. Check bell fuse.

bell test. 2. Disconnect bell cable from control panel and connect across battery

Alarm zone does not Arm system and remove wires from the terminal block. If the system does

activate system. not activate, disarm and enter Engineer Mode.

Alarm zone name will 1. Enter Engineer mode and open panel.

not clear from the 2. Disconnect the alarm zone wires from the terminal block and replace with

display when attempt- a 4K7 resistor.

ing to arm the system. 3. Enter 'Show Open Zones' in 'Maintenance Menu' and observe that the

Control panel activates 1. Check that the battery is connected correctly.

during a short power 2. Check that the battery fuse is not blown.

failure. 3. Ensure that the battery is fully charged and is large enough to carry the

load of the system.

observing correct polarity. If wiring is correct the bell should ring.

1. Check if bell delay time is programmed for [00] ('Timers Menu' at 'Bell

Times').

2. Check if zone is not in soak test ('Zones Menu' at 'Zone Attributes').

3. If PA zone, check that it is programmed as audible ('Miscellaneous Menu'

at 'PA Menu').

zone name in question does not come up on the display. This proves

that the panel is functioning correctly.

4. Check the zone wiring to ensure that the circuit is closed and that there

are no shorts on the cables. Reconnect the wires back to the panel and

retest.

System returns to Check that jumper is on link LK1 on the main control panel.

factory setting when

mains and battery

powre are removed.

System activates Before leaving engineer mode check that no PA, FIre, Medical, or Tamper

when leaving engineer zones are open. Use 'Show Open Zones' menu to do this.

mode.

System does not

activate when Tamper

opens during day

(ie when system is

disarmed).

14 1791 999 27

Check that the internal sounder is connected.

NOTE: the external bell only sounds on tamper fault when the system is

armed. If using dual loops, check that the zone type is programmed for

DUAL (in 'Zones' menu) and that the Tamper devices are wired in series with

the EOL resistor.

Page 28

Problem Solving

Alarm zones cannot

be inhibited.

Bell fuse blows when

bells are sounding.

PA is activating when

alarm is switched off.

'No panel data' shows

on the display.

Check that the 'In' attribute is set for this zone number

('Zone Attribute' in 'Zones' menu). Check that the user code has 'In' privilege

('Code Privileges' in 'Users' menu).

Check that there is no short circuit in bell wiring.

Disconnect bell wires from terminal and, observing correct polarity, connect

across battery. If bells ring, wiring is correct. The load of the bells is greater

than the fuse rating, inserting a higher value fuse may damage the panel.

Spread the load of the bells across the bell outputs or fit a relay and use the

auxiliary power output to provide some of the current.

Ensure that the operator is not entering the duress code when switching off

the system.

This happens when the keypad is not receiving correct data from the panel.

Check wiring to the keypad, especially for swapped wires.

Check that the address is correctly set on the keypad.

14 1791 99928

Page 29

Technical Specification

Power Input 230 V AC ±10%, 50Hz, 14.5 VA

Current CS350 Quiescent: 30mA Alarm: 50mA

Consumption CD3008 Quiescent: 30mA Alarm: 50mA

Output Voltage 13.8 V DC ±5%

Signalling Output Internal bell 800mA 2A

External bell 800mA 2A

Programmable 50 mA each

Outputs

Loop 6 inputs, configurable as double-pole loops using 4K7 resistors.

characteristics Response time: 300 ms.

Battery 12 V lead acid rechargeable battery (not supplied)

Backup Float charging method at 13.8 V ±5%, 800mA max.

charging current. 6.5 Ah recommmended

Auxiliary Power 13.8 V DC fused at 800mA.

Output

Note: if the combined current is greater than 800mA for the above devices, the load will be shared

by the standby battery.

Normal Surge

14 1791 999 29

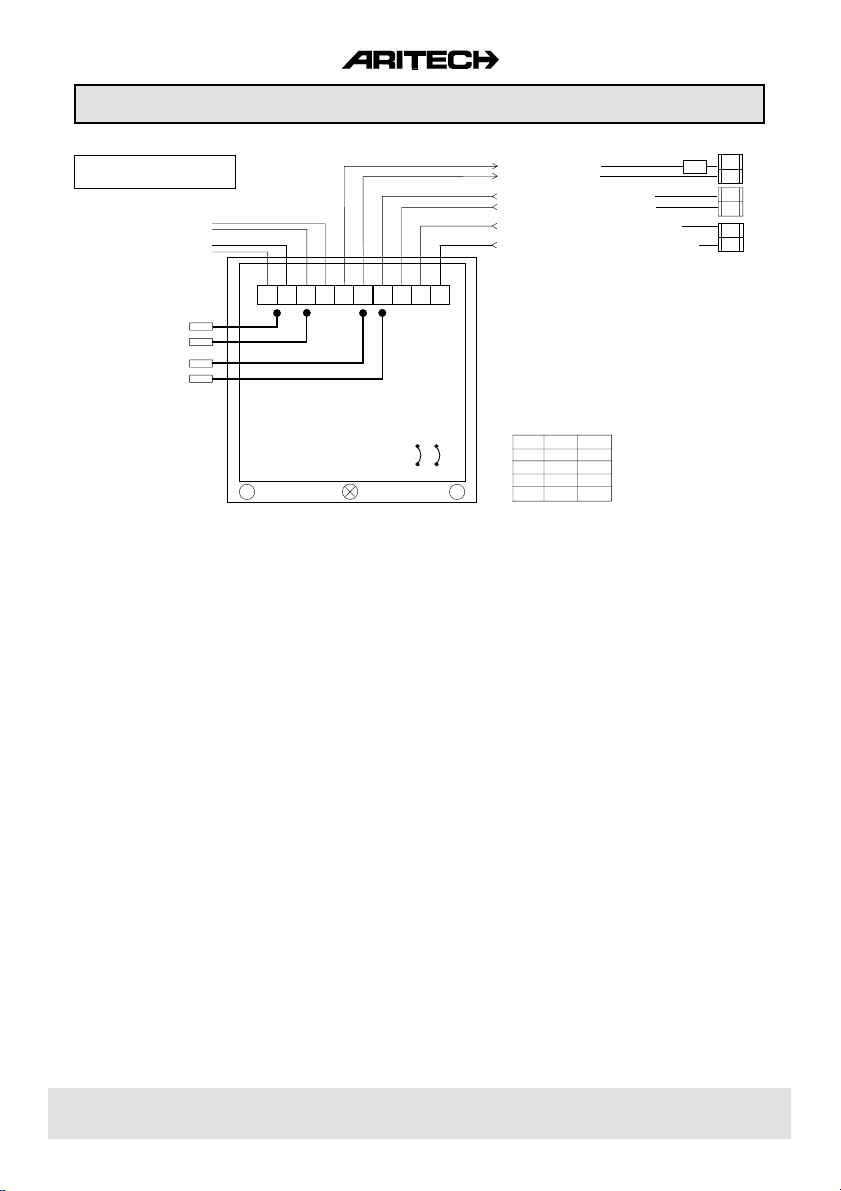

Page 30

FACTORY

SETTINGS

CS350 WIRING DIAGRAM

E.O.L.

N.C.

N.C.

N.C.

N.C.

N.C.

N.C.

A B C D

+

-

Figure 13.

- +

1 2 3 4

+ - + - + -

✆

14 1791 99930

Page 31

14 1791 999 31

Page 32

Aritech is an ISO 9001 certified manufacturer.

14 1791 99932Aritech reserves the right to change specifications without notice. .4

Loading...

Loading...