Page 1

Installation

Instructions

Type C Boilers

G.C.N: 47-116-14

47-116-15

LEAVE THESE INSTRUCTIONS

WITH THE END-USER

Country of destination: GB

Page 2

2

TABLE OF CONTENTS

1. GENERAL INFORMATION

1.1 GENERAL INSTRUCTIONS

1.2 OVERALL VIEW

2. INSTALLATION

2.1 REFERENCE STANDARDS

2.2 SITING THE APPLIANCE

2.3 OVERALL DIMENSIONS

2.4 CLEARANCES

2.5 MOUNTING THE APPLIANCE

2.6 ELECTRICAL CONNECTION

2.7 GAS CONNECTION

2.8 WATER CONNECTIONS

2.9 FLUE CONNECTION

2.10 ROOM THERMOSTAT CONNECTION

2.11 ELECTRICAL/SYSTEM DIAGRAMS

2.12 WATER CIRCUIT DIAGRAMS

3. COMMISSIONING

3.1 INITIAL PREPARATION

3.2 CONTROL PANEL

3.3 REMOVING THE FRONT PANEL

3.4 INITIAL START UP

3.5 OPERATIONAL ADJUSTMENTS

3.6 COMBUSTION ANALYSIS

3.7 FUME DISCHARGE MONITORING

3.8 BOILER SAFETY SYSTEMS

3.9 DRAINING THE SYSTEM

4. GAS ADJUSTMENTS

GAS ADJUSTMENT TABLE

4.1 CHANGING THE TYPE OF GAS

5. MAINTENANCE

6. MISCELLANEOUS

6.1 WIRING DIAGRAM FOR TWO HEATING ZONES

6.2 WIRING DIAGRAM FOR CONNECTION TO AN ARISTON UNVENTED CYLINDER

7. TECHNICAL INFORMATION

Page 3

This manual is an integral and essential part of the product. It should be kept

with the appliance so that it can be consulted by the user and our authorised

personnel.

Please carefully read the instructions

and notices about the unit contained in

this manual, as they provide important

information regarding the safe

installation, use and maintenance of

the product.

For operating instructions please

consult the separate User’s Manual.

Read the instructions and recommendations in these Installation Instructions

carefully to ensure proper installation, use and maintenance of the appliance.

Keep this manual in a safe place.You may need it for your own reference while

our Servicing Centre technicians or your installer may need to consult it in the

future.

This is a combined appliance for the production of central heating (C.H.) and

domestic hot water (D.H.W.).

This appliance

must be used only for the purpose for which it is designed.

The manufacturer declines all liability for damage caused by improper or

negligent use.

No asbestos or other hazardous materials have been used in the fabrication of

this product.

Before connecting the appliance, check that the information shown on the data

plate and the table on pages 4-5 comply with the electric, water and gas mains

of the property.You will find the data plate on the reverse of the control panel.

The gas with which this appliance operates is also shown on the label at the

bottom of the boiler.

Do not install this appliance in a damp environment or close to equipment

which spray water or other liquids.

Do not place objects on the appliance.

Do not allow children or inexperienced persons to use the appliance without

supervision.

If you smell gas in the room,

do not turn on light switches, use the telephone or

any other object which might cause sparks.

Open doors and windows immediately to ventilate the room.

Shut the gas mains tap (on the gas meter) or the valve of the gas cylinder and

call your Gas Supplier immediately.

If you are going away for a long period of time, remember to shut the mains gas

tap or the gas cylinder valve.

Always disconnect the appliance either by unplugging it from the mains or

turning off the mains switch before cleaning the appliance or carrying out

maintenance.

In the case of faults or failure, switch off the appliance and turn off the gas

tap.Do not tamper with the appliance.

For repairs, call your local Authorised Servicing Centre and request the use of

original spare parts. For in-guarantee repairs contact MTS (GB) Limited.

Check the following at least once a year:

1 - Check the seals for the water connections; replacement of any faulty seals.

2 - Check the gas seals;replacement of any faulty gas seals.

3 - Visual check of the entire unit.

4 - Visual check of the combustion process or analysis of combustion by-

products (see section 3.6) and cleaning of the burner if needed.

1. GENERAL

INFORMATION

3

1.1 GENERAL INSTRUCTIONS

CO034A

Page 4

4

5 - If called for by point. 3, dismantling and cleaning of the combustion

chamber.

6 - If called for by point. 4, dismantling and cleaning of the burner jets.

7 - Visual check of the primary heat exchanger:

- check for overheating in the blade assembly;

- clean the exhaust fan if needed.

8 - Adjustment of the flow rate of the gas:flow rate for lighting, partial load and

full load.

9 - Check of the heating safety systems:

- safety device for maximum temperature;

- safety device for maximum pressure.

10- Check of the gas safety systems:

- safety device for lack of gas or flame ionisation (detection

electrode);

- safety device for gas cock.

11- Check of the electrical connection (make sure it complies with the instructions

in the manual).

12- Check of domestic hot water production efficiency (flow rate and temperature)

13- General check of the combustion by-products of the discharge/ventilation

system.

14- Check of the general performance of the unit.

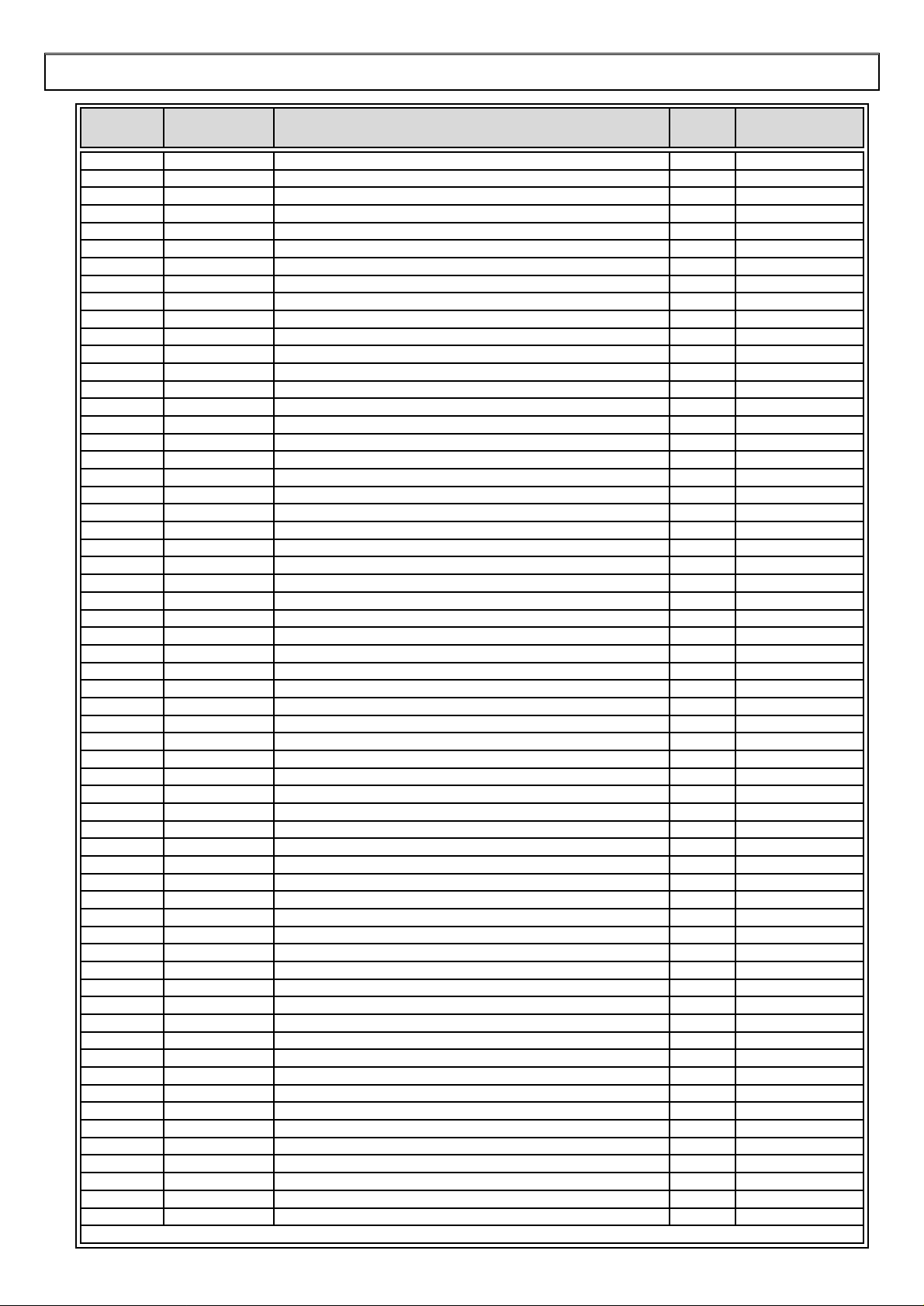

LEGEND:

1. Flue connector

2. Air intake for twin pipe flue systems

3. Fan

4. Combustion chamber hood

5. Main heat exchanger

6. Safety thermostat

7. Combustion chamber

8. Combustion chamber insulation panel

9. Burner

10. Detection electrode

11. Ignition electrodes

12. Motorised diverter valve

13. Main circuit temperature probe

14. Main circuit flow switch

15. Domestic hot water temperature probe

16. Gas valve

17. Spark generator

18. Domestic hot water flow switch

19. Domestic cold water inlet filter

20. Secondary heat exchanger

21. Circulation pump with automatic air release valve

22. Safety valve (3 bar)

23. Expansion vessel

24. Air pressure switch

25. Combustion analysis intakes

1.2 OVERALL VIEW

FIG. 1.0

IN013A

Page 5

5

The technical information and instructions provided herein below are

intended for the installer so that the unit may be installed correctly and

safely.

The installation and initial start up of the boiler must be by a CORGI

Approved Installer in compliance with the installation standards currently in

effect, as well as with any and all local health and safety standards i.e..

CORGI .

This appliance must be installed by a competent installer in

accordance with current Gas Safety (installation & use)

Regulations.

The installation of this appliance must be in accordance with the relevant

requirements of the current Gas Safety (installation & use) Regulations, the

Local Building Regulations, the current I.E.E. Wiring Regulations, the

byelaws of the local water authority, and in Scotland, in accordance with the

Building Standards (Scotland) Regulation and Health and Safety document

No.635 “Electricity at work regs.1989”.

Installation should also comply with the following British Standard Codes of

Practice:

The appliance may be installed in any room or indoor area, although

particular attention is drawn to the requirements of the current I.E.E. Wir ing

Regulations, and in Scotland, the electrical provisions of the Building

Regulations applicable in Scotland, with respect to the installation of the

combined appliance in a room containing a bath or shower.

Where a room-sealed appliance is installed in a room containing a bath

or shower the boiler and any electrical switch or appliance control,

utilising mains electricity should be situated so that it cannot be

touched by a person using the bath or shower.

The location must permit adequate space for servicing and air circulation

around the appliance as indicated in paragraph 2.4.

The location must permit the provision of an adequate flue and termination.

For unusual locations special procedures may be necessary.

BS 6798-1987 gives detailed guidance on this aspect.

A compartment used to enclose the appliance must be designed specifically

for this purpose. No specific ventilation requirements are needed for the

installation within a cupboard.

This appliance is not suitable for outdoor installation.

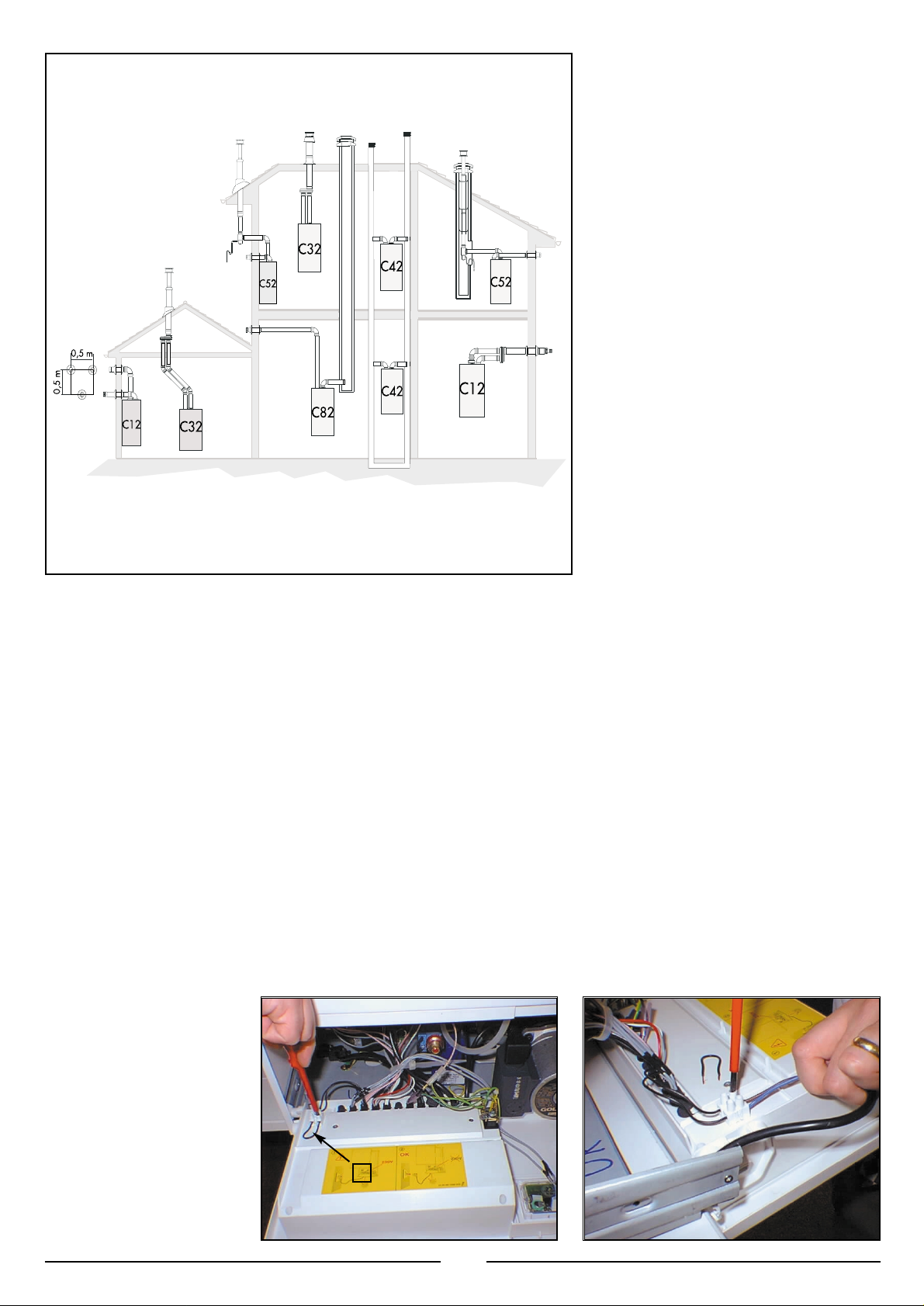

The type C appliances (in which the combustion circuit, air vent intake

and combustion chamber are air-tight with respect to the room in

which the appliance is installed) can be installed in any type of room.

There are no limitations with respect to ventilation and the volume of the

room itself.The boiler must be installed on a solid, permanent wall to prevent

access to the electrical parts (when live) through the aper ture on the back

frame.

2.1 REFERENCE STANDARDS

2. INSTALLATION

Low pressure

pipes BS 6891 1988

Boilers of rated input

not exceeding 60 kW BS 6798 1987

Forced circulation hot

water system BS 5449 1990

Installation of gas hot water

supplies for domestic purposes

( 2ndfamily gases) BS 5546 1990

Flues BS 5440-1 1990

Air supply BS 5440-2 1989

2.2 SITING THE APPLIANCE

Page 6

For safety purposes, have a competent person carefully

check the electrical system in the property, as the

manufacturer will not be held liable for damage caused by

the failure to earth the appliance properly or by anomalies

in the supply of power. Make sure that the residential

electrical system is adequate for the maximum power

absorbed by the unit, which is indicated on the rating plate.

In addition, check that the section of cabling is appropriate

for the power absorbed by the boiler.

The boiler operates with alternating current, as indicated in

the technical information table section in 6, where the

maximum absorbed power is also indicated. Make sure

that the connections for the neutral and live wires

correspond to the indications in the diagram. The

appliance electrical connections are situated on the

reverse of the control panel (see the servicing manual for

further information)

IMPORTANT!

In the event that the power supply cord must be changed,

replace it with one with the same specifications. Make the

connections to the terminal board located within the

control panel, as follows:

- The yellow-green wire should be connected to the

terminal marked with the

“”symbol; make sure to reuse the ferrule mounted on the other supply cord;- The

blue wire should be connected to the terminal marked “N”;

- The brown wire should be connected to the terminal

6

Fasten the boiler in place using the template and anchors

supplied with the unit. It is highly recommended that a

spirit level be used to position the boiler so that it is

perfectly level.

For additional information, please consult the instructions

contained in the connection kit and the flue kit.

2.7 ELECTRICAL CONNECTION

2.5 MOUNTING THE APPLIANCE

LEGEND:

A = Central Heating Flow (3/4”)

B = Domestic Hot Water Outlet (1/2”)

C = Gas Inlet (3/4”)

D = Domestic Cold Water Inlet (1/2”)

E = Central Heating Return (3/4”)

2.3 OVERALL DIMENSIONS

In order to allow for access to the interior of the boiler for

maintenance purposes, the boiler must be installed in

compliance with the minimum clearances indicated in FIG. 2.2

2.4 CLEARANCES

FIG. 2.1

F

IG. 2.2

F

IG. 2.3

QT002A

DM004A

VR001A

Page 7

VIEW OF THE BOILER CONNECTIONS

LEGEND:

A = Central Heating Flow

B = Domestic Hot Water Outlet

C = Gas Inlet

D = Domestic Cold Water Inlet

E = Central Heating Return

F = Safety Valve

CENTRAL HEATING

Detailed recommendations are given in BS 6798:1987 and BS 5449-1:1990,

the following notes are given for general guidance.

2.9 WATER CONNECTIONS

2.8 GAS CONNECTION

The local gas region contractor connects the gas meter to the service pipe.

If the gas supply for the boiler serves other appliances ensure that an

adequate supply is available both to the boiler and the other appliances

when they are in use at the same time.

Pipe work must be of an adequate size. Pipes of a smaller size than the

boiler inlet connection should not be used.

7

marked “L”.

Note:The diagrams for the electrical system are indicated in section 2.11.

Warning,this appliance must be earthed.

External wiring to the appliance must be carried out by a qualified technician

and be in accordance with the current I.E.E. Regulations and applicable

local regulations. The Genus range of boilers are supplied for connection to

a 230 V

~

50 Hz supply.

The supply must be fused at 3 A.

The method of connection to the electricity supply must facilitate complete

electrical isolation of the appliance, by the use of a fused double pole

isolator having a contact separation of at least 3 mm in all poles or

alternatively, by

means of a 3 A fused three pin plug and unswitched

shuttered socket outlet both complying with BS 1363.

The point of connection to the Electricity supply must be readily accessible

and adjacent to the appliance unless the appliance is installed in a bathroom

when this must be sited outside the bathroom.

FIG. 2.4

FIG. 2.5

KT002A

SC008A

Page 8

8

PIPE WORK:

Copper tubing to BS EN 1057:1996 is recommended for water pipes.

Jointing should be either with capillary soldered or compression fittings.

Where possible pipes should have a gradient to ensure air is carried

naturally to air release points and water flows naturally to drain taps.

The appliance has a built-in automatic air release valve, however it should

be ensured as far as possible that the appliance heat exchanger is not a

natural collecting point for air.

Except where providing useful heat, pipes should be insulated to prevent

heat loss and avoid freezing.

Particular attention should be paid to pipes passing through ventilated

spaces in roofs and under floors.

BY-PASS:

The appliance includes an automatic by-pass valve, which protects the main

heat exchanger in case of reduced or interrupted water circulation through

the heating system, due to the closing of thermostatic valves or cock-type

valves within the system.

SYSTEM DESIGN:

This boiler is suitable only for sealed systems.

Drain Cocks:

These must be located in accessible positions to permit the draining of the

whole system. The taps must be at least 15mm nominal size and

manufactured in accordance with BS 2870:1980.

SAFETY VALVE DISCHARGE:

The discharge should terminate facing downward on the exterior of the

building in a position where discharging (possibly boiling water & steam) will

not create danger or nuisance, but in an easily visible position, and not

cause damage to electrical components and wiring.

The discharge must not be over an entrance or a window or any other type

of public access.

AIR RELEASE POINTS:

These must be fitted at all high points where air naturally collects and must

be sited to facilitate complete filling of the system.

The appliance has an integral sealed expansion vessel to accommodate the

increase of water value when the system is heated.

It can accept up to 6 l (1.3 gal) of expansion water. If the heating circuit has

an unusually high water content, calculate the total expansion and add an

additional sealed expansion vessel with adequate capacity.

MAINS WATER FEED - CENTRAL HEATING:

There must be no direct connection to the mains water supply even through

a non-return valve, without the approval of the Local Water Authority.

FILLING:

A temporary method for initially filling the system and replacing lost water

during servicing in accordance with Water Supply Byelaw 14 must be

provided.

DOMESTIC WATER

The domestic water must be in accordance with the relevant

recommendation of BS 5546:1990. Copper tubing to BS EN 1057:1996 is

recommended for water carrying pipe work and must be used for pipe work

carrying drinking water.

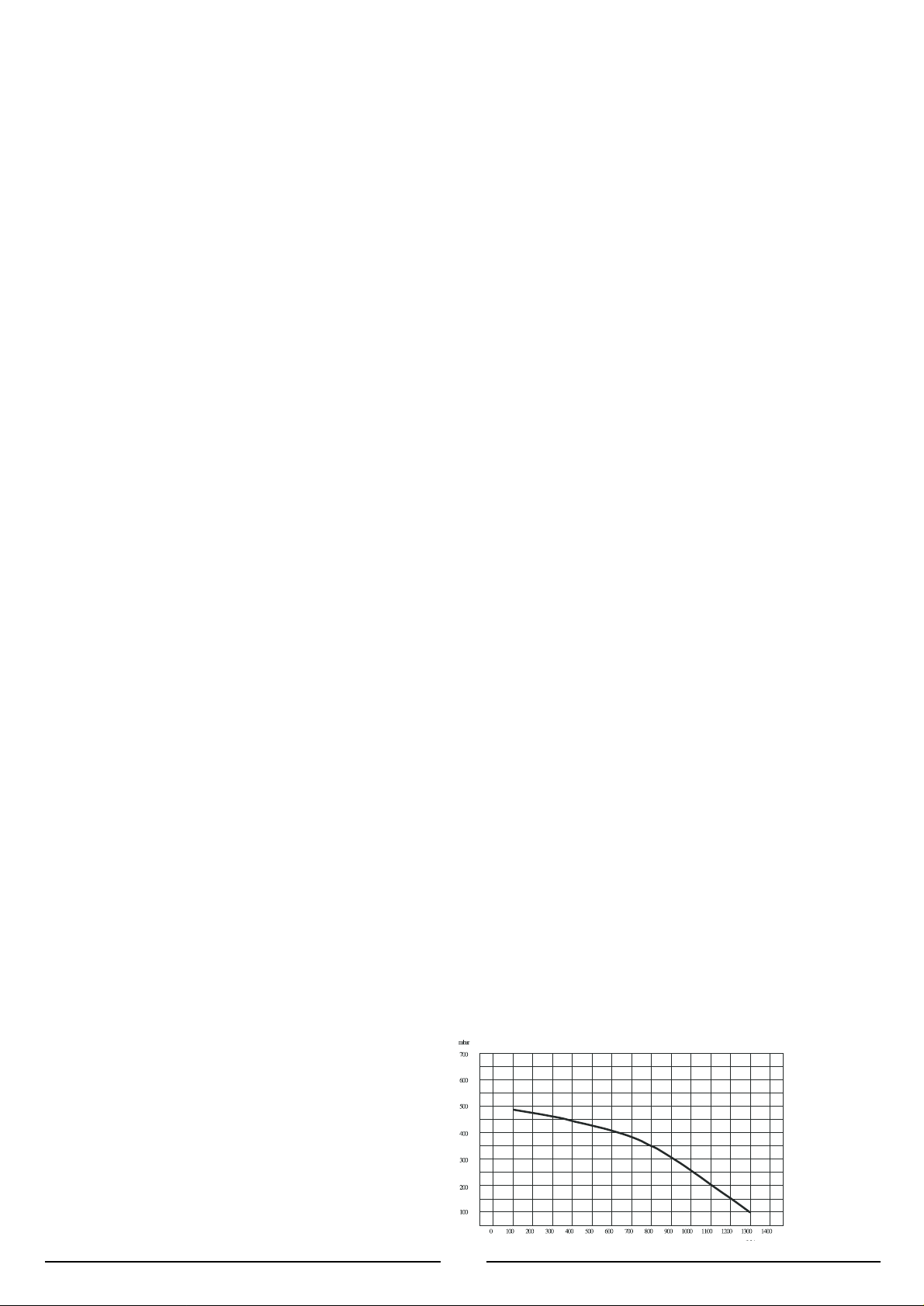

RESIDUAL HEAD OF THE BOILER

VR003A

Page 9

Ø 60/100 mm

FIG. 2.7

The boiler is designed to be connected to a coaxial flue discharge system.

9

2.9 FLUE CONNECTIONS

FLUE SYSTEM

The provision for satisfactory flue ter mination must be made as described

in BS 5440-1.

The appliance must be installed so that the flue terminal is exposed to outdoor air.

The terminal must not discharge into another room or space such as an

outhouse or lean-to.

It is important that the position of the terminal allows a free passage of air

across it at all times.

The terminal should be located with due regard for the damage or

discolouration that might occur on buildings in the vicinity.

In cold or humid weather water vapour may condense on leaving the flue

terminal.

The effect of such “steaming”must be considered.

If the terminal is less than 2 metres above a balcony, above ground or above

a flat roof to which people have access, then a suitable terminal guard must

be fitted. When ordering a ter minal guard, quote the appliance model

number.

A suitable terminal guard is available from:

TOWER FLUE COMPONENTS

Morley Road

Tonbridge

Kent TN9 1RA

The minimum acceptable spacing from the terminal to obstructions and

ventilation openings are specified in FIG. 2.6.

T

ERMINALPOSTION

mm

A - Directly below an open window or other opening 300

B - Below gutters, solid pipes or drain pipes 75

C - Below eaves 200

D - Below balconies or car-port roof 200

E - From vertical drain pipes and soil pipes 75

F - From internal or external corners 300

G - Above ground or below balcony level 300

H - From a surface facing a terminal 600

I - From a terminal facing a terminal 1200

J - From an opening in the car port

(e.g.door, window) into dwelling 1200

K - Vertically from a terminal in the same wall 1500

L - Horizontally from a terminal in the same wall 300

FIG. 2.6

FU010A

FU025A

FU002A

F

HI

BC

D

J

A

E

F

G

K

L

G

Page 10

Ø 80 mm

The components marked * in FIG 2.9 are present or absent

depending on the type of flue system used by the installer.

In addition, it is also possible to use a split (twin pipe)

system by fitting a special adaptor to the flue connector

and using the aperture for the air vent intake located on

the top part of the combustion chamber.

To utilise the air intake it is necessary to:

1. Remove the bottom of the air intake by cutting it with a

suitable knife (see

FIG.2.8);

2. Insert the elbow into the air intake until it reaches the

lower end.(There is no need to use gaskets or sealing

componds).

10

IMPORTANT!

For all flue systems, a restrictor

must always be inserted into the

boiler’s flue connector; the

restrictor must be ø 43 or ø 41 in

diameter depending on the length

of piping indicated in Table 2.1.

The diagrams illustrate some of the

various designs for coaxial or twin

pipe flue systems.

For further information on

discharge/ventilation accessories,

see the

FLUE PIPE ACCESSORIES

MANUAL.

COAXIAL SYSTEMS

FIG. 2.8

F

IG. 2.9

F

IG. 2.10

FU05A

FU004A

FU006A

FU001A

Page 11

Exhaust

Type

C12 (xy)

C32 (xy)

C42 (xy)

C52 (xy)

C82 (xy)

Restrictor

ø 43 mm

L max = 11.5 m

L max = 11,4 m

Maximum

Extension

Exhaust/Air

43 m

43 m

43 m

40 m

NO

Restrictor

L min = 11.5 m

L max = 43 m

L min = 11,4 m

L max = 40m

Risk of Condensation Forming

Twin Pipe

Systems

ø 80/80

Piping not insulated

ø 43 restrictor NO

4.3 m 6.9 m

4.3 m 6.9 m

Piping insulated

ø 43 restrictor NO

NONE NONE

5,7 m 21,7 m

L = Sum of the total length of exhaust + air intake piping.

11

Exhaust

Type

C12 (xx)

C32 (xx)

C42 (xx)

Restrictor

ø 43 mm

L min = 0.5 m

L max = 2 m

Maximum

Extension

Exhaust/Air

L = 4 m

NO

Restrictor

L min = 2 m

L max = 4 m

Risk of Condensation Forming

Coaxial

Systems

ø 60/100

Piping not insulated

ø 43 restrictor NO

NONE NONE

Piping insulated

ø 43 restrictor NO

NONE NONE

TABLE 2.1

Exhaust

Type

C12 (xy)

C32 (xy)

C42 (xy)

C52 (xy)

C82 (xy)

Restrictor

ø 41 mm

L max = 38 m

L max = 34 m

Maximum

Extension

Exhaust/Air

62 m

62 m

62 m

54 m

NO Restrictor

L min = 38 m

L max = 62 m

L min = 34 m

L max = 54 m

Risk of Condensation Forming

Twin Pipe

Systems

ø 80/80

Piping not insulated

ø 41 restrictor NO restrictor

8 m 11 m

8 m 11 m

Piping insulated

ø 41 restrictor NO restrictor

19 m 31 m

19 m 31 m

Exhaust

Type

C12 (xx)

C32 (xx)

C42 (xx)

Restrictor

ø 41 mm

L min = 0.5 m

L max = 1 m

Maximum

Extension

Exhaust/Air

L = 4 m

NO Restrictor

L min = 1 m

L max = 4 m

Risk of Condensation Forming

Coaxial

Systems

ø 60/100

Piping not insulated

ø 41 restrictor NO restrictor

NONE NONE

Piping insulated

ø 41 restrictor NO restrictor

NONE NONE

27 MFFI

23 MFFI

Page 12

12

To connect a room thermostat, it is necessary to:

1. - Open the control panel as indicated in section 3.3.

2.- Remove the link

“A” from the terminal block on the reverse of the control panel.

3. - Insert the thermostat cable through the cable grommet and fasten it by means of the

cable-clamp provided.

4. - Then connect the thermostat wires to the terminal block.

5.- If a remote time clock is to be fitted, disconnect the integral time clock from the P.C.B .

6. - Using a volt-free switching time clock, connect the switching wires from the time clock

following points 1-4 above.

7. - If using an external time clock and room thermostat, these must be connected in

series as points 1-7 above.

Note: Only a two-wire type room thermostat can be used.

An anti-frost device is built-in to the appliance’s electronic regulation

system.

2.10 ROOM THERMOSTAT

CONNECTION

A

TWIN PIPE

SYSTEMS

FIG. 2.11

In calculating the lengths of the pipes, the

maximum length “L” must also take into

consideration the values for the

exhaust/air intake end terminals, as well

as 90° elbows for coaxial systems.

The C52 types must comply with the

following requirements:

1 - The exhaust/ air intake pipes must

have the same diameter of

ø 80 mm.

2 - If elbows are to be inserted into the

air intake and/or exhaust system, the

calculation of the overall length must

take into consideration the values for

each elbow, see the

FLUE PIPE

ACCESSORIES MANUAL.

3 - The exhaust pipe must protrude by at

least 0.5 m above the top of the roof

in the event that it is located on the

opposite side to the side with the air

intake (this condition is not obligatory

when the air intake and exhaust are

located on the same side of the

building).

FU007A

Fo016A

Fo017A

Page 13

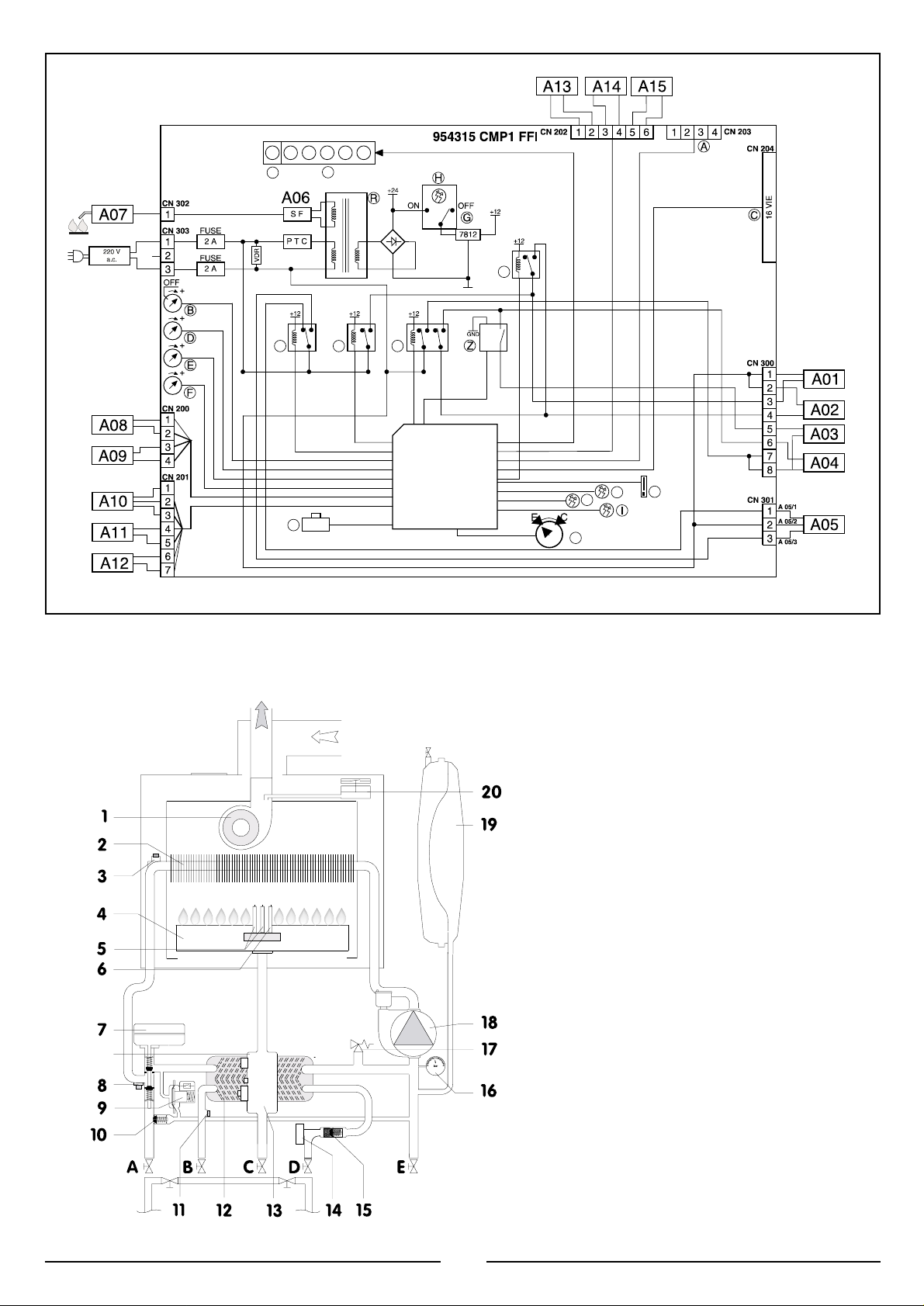

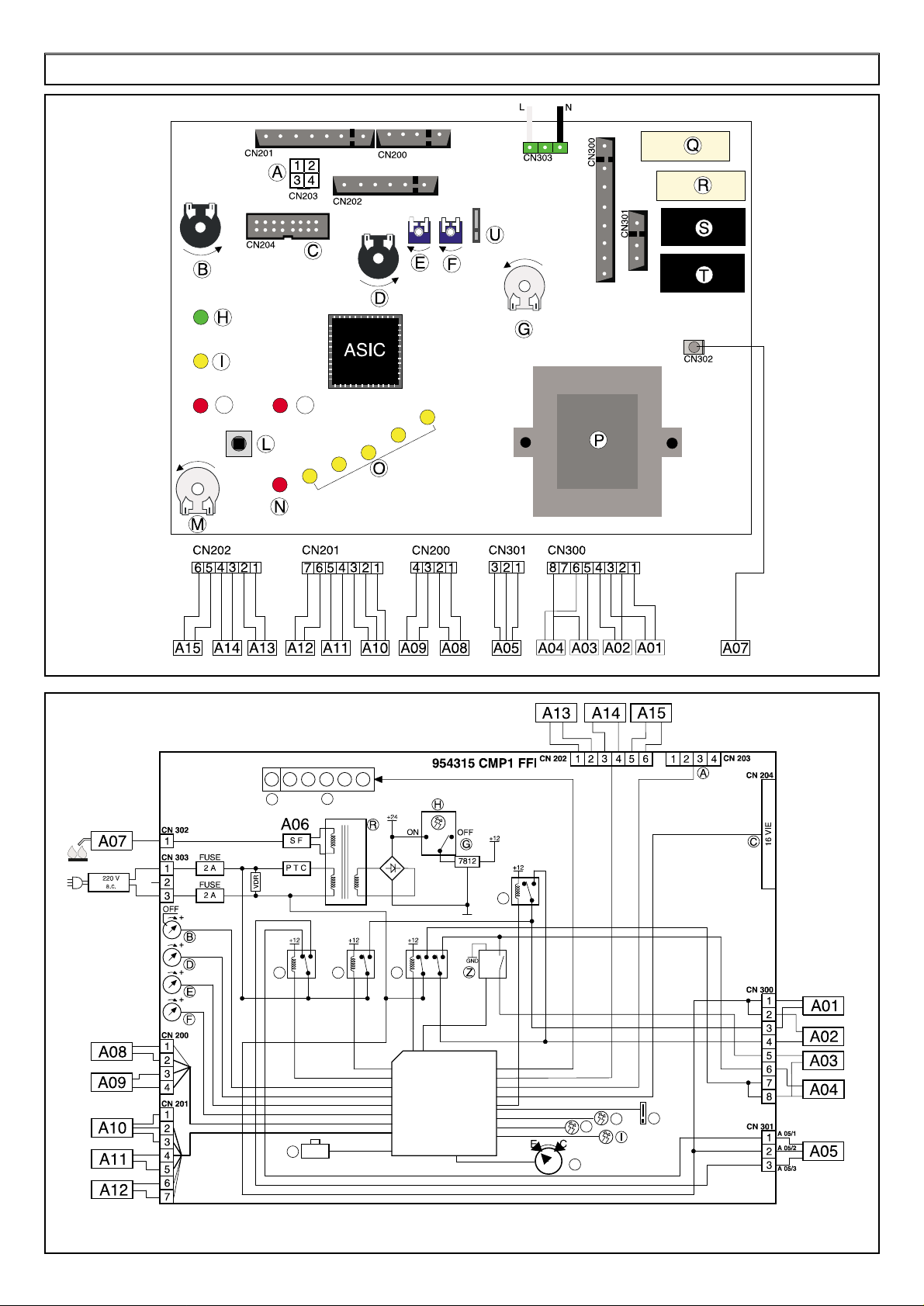

2.12 ELECTRICAL DIAGRAM

13

LEGEND:

A = Time Clock Connector

B = Central Heating Selection (Winter) and

Temperature Adjustment

C = Connector for Total Check System

D = Domestic Hot Water Temperature Adjustment

E = Soft-light Adjustment

F = Maximum Heating Adjustment

G = On/Off Switch

H = On/Off L.E.D.

I = Fume Sensor L.E.D.

J = Ignition Failure (Lockout) L.E.D.

K = Low System Water Level/Lack of Circulation L.E.D.

L = Reset Button

M = Economy/Comfort Selector

N = Overheat L.E.D.

O = Temperature L.E.D.s

P = Transformer

Q = Circulation Pump Relay

R = Fan Relay

S = Gas Valv e Relay

T = Motorised Diverter Valve Relay

V = Spark Generator

U = Anti-cycling Device Adjustment for Heating

A01 = Circulation Pump

A02 = Fan

A03 = Spark Generator/Gas Valve Supply

A04 = Motorised Diverter Valve

A05 = Flame Detection Circuit

A06 = Detection Electrode

A07 = Main Circuit Temperature Probe

A08 = Domestic Hot Water Temperature Probe

A09 = Domestic Hot Water Flow Switch

A10 = Main Circuit Flow Switch

A11 = Modulator

A12 = Air Pressure Switch

A13 = Safety Thermostat

A14 = External (Room) Thermostat

Colours:

Gry = Grey

Wh = White

Pnk = Pink

Brn = Brown

Bl = Blue

Blk = Black

Rd/Blk = Red/Black

FIG. 2.12

SE017A

JK

Blk

Blk

Gry

Gry

Pnk

Pnk

Blk

Blk

Wh

Gry

Gry

Rd/Blk

Pnk

Wh

Wh

Blk

Blk

Wh

Brn

Rd/Blk

Wh

Brn

Rd/Blk

Wh

Wh

Brn

Brn

Blk

Page 14

14

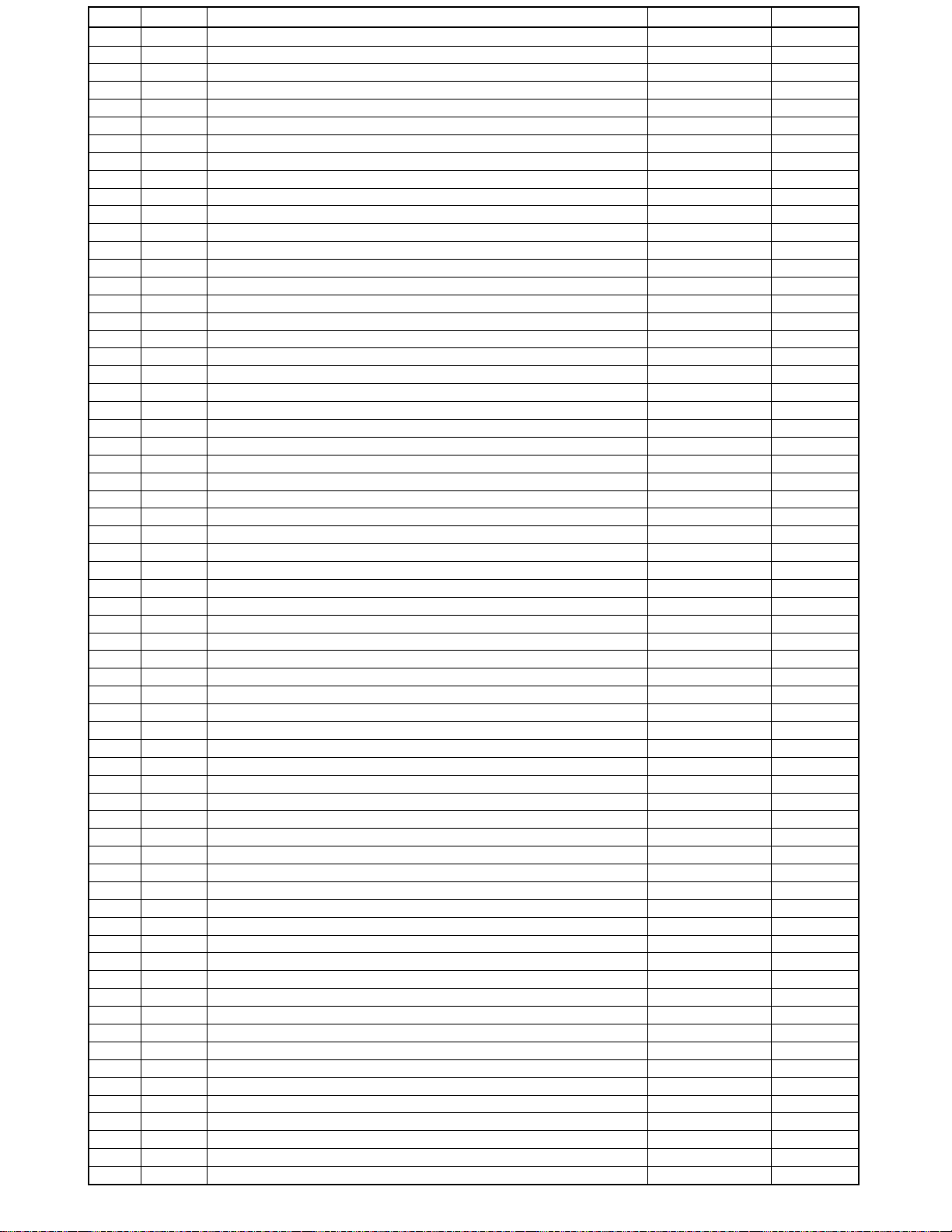

LEGEND:

1. Fan

2. Main Heat Exchanger

3. Overheat Thermostat

4. Burner

5. Ignition Electrodes

6. Detection Electrode

7. Motorised Valv e

8. Main Circuit Temperature Probe

9. Main Circuit Flow Switch

10. Automatic By-pass

11. Domestic Hot Water Temperature Probe

12. Secondary Heat Exchanger

13. Gas Valve

14. Domestic Hot Water Flow Switch

15. Domestic Water Inlet Filter

16. Pressure Gauge

17. Saf ety V alv e

18. Circulation Pump with Automatic

Air Release Valve

19. Expansion Vessel

20. Air Pressure Switch

A. Central Heating Flow

B. Domestic Hot Water Outlet

C. Inlet Gas

D. Domestic Cold Water Inlet

E. Central Heating Return

2.13 WATER CIRCUIT DIAGRAM

FIG. 2.14

FIG. 2.13

SF014A

SI017A

ON

R

SQT

K

L

M

UJ

Page 15

15

MTS (GB) Limited support the initiative.Within the information pack

you will find a copy of the logbook. It is important that this is

completed in the presence of your customer, they are shown how to us it,

and it is signed by them. Please instr uct your customer that they must have

their logbook with them whenever they contact a service engineer

or us.

Preliminary electrical system checks to ensure electrical safety must be

carried out by a competent person i.e. polarity, ear th continuity, resistance to

earth and short circuit.

FILLING THE HEATING SYSTEM:

Remove the panels of the case and lower the control panel (see section

3.3 for further information).

Open the central heating flow and return cocks supplied with the

connection kit.

Unscrew the cap on the automatic air release valve one full turn and leave

open permanently.

Close all air release valves on the central heating system.

Gradually open valve(s) at the filling point (filling-loop) connection to the

central heating system until water is heard to flow, do not open fully.

Open each air release tap starting with the lower point and close it only

when clear water, free of air, is visible.

Purge the air from the pump by unscrewing anticlockwise the pump

plug and also manually rotate the pump shaft in the direction

indicated by the pump label to ensure the pump is free.

Close the pump plug.

Continue filling the system until at least 1 bar registers on the pressure

gauge.

Inspect the system for water soundness and remedy any leaks

discovered.

FILLING OF THE D.H.W.SYSTEM:

Close all hot water draw-off taps.

Open the cold water inlet cock supplied with the connection kit.

Open slowly each draw-off tap and close it only when clear water, free of

bubbles, is visible

GAS SUPPLY:

Inspect the entire installation including the gas meter, test for soundness

and purge, all as described in BS 6891:1988.

Open the gas cock (supplied with the connection kit) to the appliance and

check the gas connector on the appliance for leaks.

When the installation and filling are completed turn on the central heating

system (section 3.4) and run it until the temperature has reached the boiler

operating temperature. The system must then be immediately flushed

through.

The flushing procedure must be in line with BS 7593:1992 code of practice

for treatment of water in domestic hot water central heating systems.

During this operation, we highly recommend the use of a central heating

flushing detergent (Fernox Superfloc or equivalent), whose function is to

dissolve any foreign matter that may be in the system.

Substances different from these could create serious problems to the

pump or other components.

The use of an inhibitor in the system such as Fernox MB-1 or equivalent is

strongly recommended to prevent corrosion (sludge) damaging the boiler

and system.

Failure to carry out this procedure may invalidate the appliance

warranty.

3. COMMISSIONING

3.1 INITIAL PREPARA TION

Page 16

In order to access the inside of the boiler, it is necessary to unscrew

the fastening screws “A” of the control panel located on the lower part

of the panel itself.

The control panel moves downward and when pulled forward rotates

on two lateral hinges.

The panel stays in a semi-horizontal position, which allows access to

the inner parts of the boiler.

In order to increase the maneuvering space, it is possible to raise the

control panel and rotate it to a fully horizontal position.

16

3.3 REMOVING THE

FRONT PANEL

B

1

2

3

4

5

A

LEGEND:

A - On/Off knob

B - Domestic hot water temperature adjustment knob

C - Central heating selection (winter) and temperature

adjustment knob

D - On/Off L.E.D.(green)

E - Fume sensor L.E.D.(yellow)

F - Ignition failure (lockout) L.E.D.(red)

G-“Economy/Comfort” mode selection knob

H - Ignition failure (lockout) and/or overheat reset button

I - Overheat L.E.D.(red)

J - Low system water level L.E.D.(red)

K - Central heating temperature L.E.D (yellow)

L - Time clock

M - Heating system pressure gauge

3.2 CONTROL PANEL

FIG. 3.1

To dismantle the front

casing panel it is necessary

to:

1 - Remove the two screws

“B”;

2 - Lift the front casing panel

up and forward.

FR025A

FO006A

FO008A

FO009A

FO012A

FO013A

Page 17

17

3.4. INITIAL START-UP

(See section 3.2 for references) it is possible to:

- Set the temperature of the heating system by adjusting the knob “C”

- Set the temperature of the domestic hot water by turning knob “B”

- The selector knob “G” allows the user to choose the economy mode

(position “E”) or the comfort mode (position “C”).

The economy mode is the normal state for the operation of the boiler,

since the domestic water is heated up only when a tap is turned on.

The comfort mode is a special operating state, because the water

contained in the secondary exchanger and in the primary exchanger is

kept in a preheated condition, thereby allowing a quicker delivery of

domestic water when required. The latter is therefore the more

convenient choice.

To access the areas in which adjustments are made, it is necessary to open

the control panel, as indicated in section 3.3, then remove the rear

inspection cover by unscrewing the two screws. Access is thereby provided

to the P.C.B.and to the following components:

1. the power supply cable connector;

2. the fuses;

3. the soft-light potentiometer the setting for which can range from the

minimum thermal power to the maximum;

4. the maximum thermal heating power potentiometer adjustable by the

minimum to maximum power (already calibrated in the factory to 70% of

the maximum thermal power);

5. the potentiometer for adjusting the ignition delay (anti-cycling) feature,

which can be set from 0 to 2 minutes (set in the factory at one minute);

6. the time clock connector.

THE CHECKS TO BE RUN BEFORE INITIAL START-UP ARE AS FOLLOWS:

1. Make sure that:

- the screw on the automatic air valve has been loosened when the

system is full;

- If the water pressure in the system is below 1 bar, bring it up to the

appropriate level;

-Check to see whether the gas cock is closed;

- Make sure that the electrical connection has been made properly and

that the earth wire is connected to an efficient earthing system;

- Supply power to the boiler by turning the On/Off switch

“A” (see FIG.3.1)

- the L.E.D. “D” will illuminate - turn the selector knob “C” to the winter

/central heating position. This will start the circulation pump. After 7

seconds, the boiler will signal a shutdown due to ignition failure. Leave

the boiler as it is until all of the air has been bled from the lines.

-Loosen the cap on the head of the pump to eliminate any air pockets;

-Repeat the procedure for bleeding the radiators of air;

-Open the taps for a brief period;

- Check the system pressure and, if it has dropped, open the filling loop

again to bring the pressure back up to 1 bar.

2. Check the exhaust flue for the fumes produced by combustion.

3. Make sure that all gate valves are open;

4. Turn on the gas cock and check the seals on the connections, including

the one for the burner, making sure that the meter does not signal the

passage of gas.Check the connections with a soap solution and

eliminate any leaks.

5. Press the reset button

“A” for the lighting system; the spark will light the

main burner.If the burner does not light the first time, repeat the

procedure.

6. Check the minimum and maximum pressure values for the gas going to

the burner; adjust it if needed using the values indicated in the table in

section 4 (See the relative section for burner pressure adjustment within

the servicing manual).

3.5 OPERATIONAL

ADJUSTMENTS

Page 18

The boiler is fitted with the following devices (see section 3.2 for references).

1 - IGNITION FAILURE:

This control signals an ignition failure on the burner 7 seconds after a

lighting failure. The L.E.D. “F” will illuminate to signal the shutdown

status.

The system can be reset by pressing and releasing the button “H” after

checking to make sure that the gas cock is open.

2 - CIRCULATION FAILURE:

This control signals that the safety pressure switch on the primary

circuit has not sensed a pressure of at least 1 bar within 40 seconds of

the activation of the circulation pump; the circulation pump comes to a

halt and the red L.E.D. “J” illuminates.

The system may be reset, after re-establishing the correct level of

pressure in the boiler, turning the “A” knob.

3 - OVERHEATING:

This control shuts off the boiler in the case where the primary circuit

reaches a temperature in excess of 105°C.

The red L.E.D.s “I” and “F” will illuminate to signal this shutdown

status.

The system can be reset by waiting a few minutes for the primary

exchanger to cool down and then by pressing and releasing the “H”

button.

4. LIMESCALE BUILD-UP:

The boiler is equipped with a device that limits the formation of

Limescale in the secondary exchanger by controlling the temperature of

the domestic hot water (max 61°C) and also controlling the temperature

of the water in the primary heating circuit.

18

3.8 BOILER SAFETY SYSTEMS

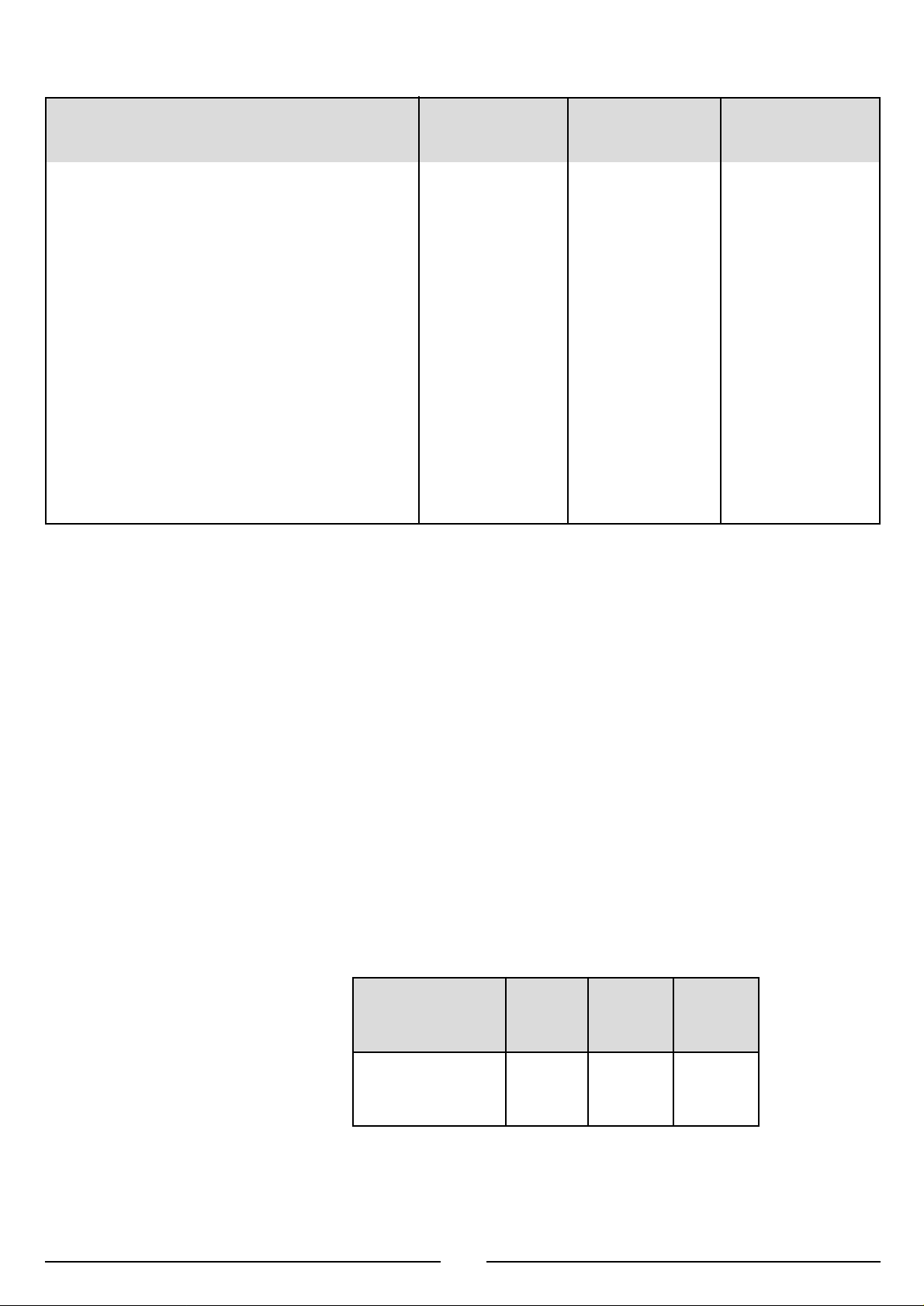

In the boiler, it is possible to monitor the correct operation of

the flue exhaust/air intake, checking for a loss of general

pressure in the system. Through the use of a differential

manometer connected to the test points of the combustion

chamber, it is possible to detect the ∆P of operation of the air

pressure switch.

The value detected should not be less than 0,55 mbar for

23kW and 0.75 mbar for 27kW under conditions of maximum

thermal power in order for the boiler to function properly and

without interruption.

The flue connector has two apertures, readings can be

taken for the temperature of the combustion by-products

and of the combustion air, as well as of the concentrations

of O

2

and CO2, etc. .

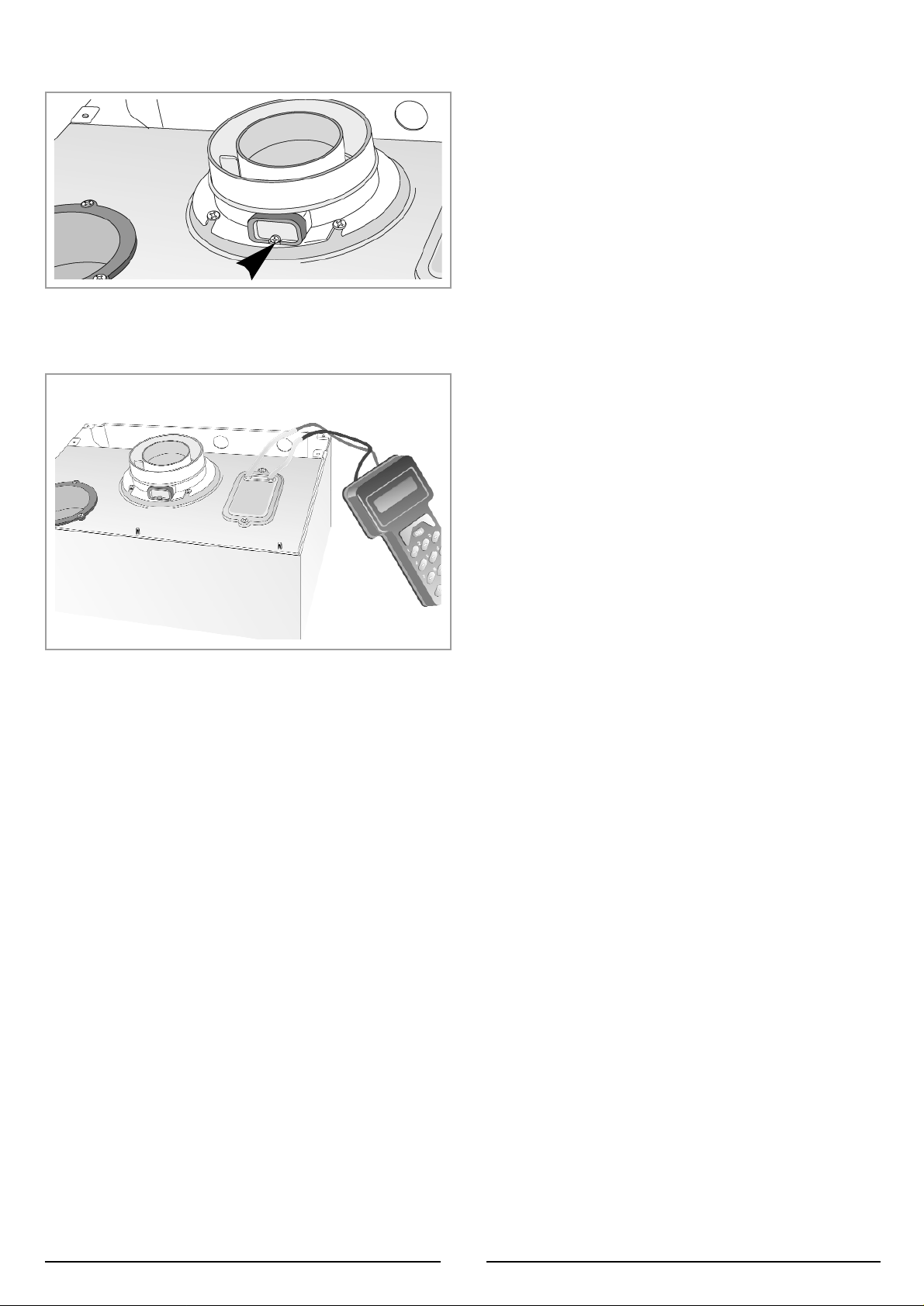

To access these intakes it is necessary to unscrew the front

screw and remove the metal plate with sealing gasket.

The best test conditions, with the maximum heating power,

are achieved by turning the selector knob “

C” to the “max”

position and removing the electrical connection to the heating

sensor (see section 6.).

3.6 COMBUSTION ANALYSIS

3.7 FUME DISCHARGE

MONITORING

FU008A

FU009A

Page 19

19

DRAINING THE HEATING SYSTEM

The heating system must be emptied as follows:

- Turn off the boiler;

- Open the drain valve for the system and place a container below to catch the

water that comes out;

- Empty the system at the lowest points (where present). If you plan on not

using the heating system for an extended period of time, it is recommended

that you add antifreeze with an ethylene glycol base to the water in the

heating lines and radiators if the ambient temperature drops below 0°C during

the winter.

This makes repeated draining of the entire system unnecessary.

DRAINING THE DOMESTIC HOT WATER SYSTEM

Whenever there is the danger of the temperature dropping below the freezing

point, the domestic hot water system must be drained as follows:

- Turn off the general water valve for the household plumbing system;

- Turn on all the hot and cold water taps;

- Empty the remaining water from the lowest points in the system (where

present).

3.9 DRAINING THE SYSTEM

5. ANTI-FROST DEVICE:

The boiler is equipped with a device that, in the event of the water

temperature going below 5°C, the 3-way diverter valve switches to

domestic hot water and the burner ignites at the minimum power until

the boiler water reaches a temperature of about 50°C.

This device operates only if the boiler is functioning perfectly and:

- the system pressure is sufficient;

- the boiler is powered electrically;

- the gas is distributed.

6 - EXHAUST DISCHARGE ANOMALY SHUTDOWN:

The boiler is fitted with safety devices, which in the event of defective

discharge of exhaust fumes, automatically interrupts the gas supply,

thereby shutting off the boiler.

The shutdown of the boiler is temporary and is indicated by the

illumination of the yellow L.E.D. “E” for a period of about 15 minutes.

Once this time period has passed and the discharge state of exhaust

fumes has returned to normal, the boiler automatically turns back on.

7 - SAFETY SHUTDOWN:

At the start of every lighting phase, the P.C.B. performs a series of

internal controls. If a malfunction occurs, the boiler will shutdown until

the problem has been resolved.

Page 20

20

The boiler can be converted to use either methane (natural) gas (G20)

or LPG (G30 - G31) by an Authorised Service Centre.

The operations that must be performed are the following:

1. Replace the jets on the main burner (see table in section 4);

2. Adjust the maximum and minimum thermal capacity values for the boiler

(see table in section 4);

3. Replace the gas rating plate;

4. Adjust the maximum thermal power setting;

5. Adjust the soft-light feature;

6. Adjust the ignition delay feature for the heating system (can be set from 0

to 2 mins.).

CATEGORY II2H3+

Recommended Softlight Pressure

(mbar)

Methane

Gas

G20

8.0

Liquid

Propane

Gas

G31

16.0

Liquid

Butane

Gas

G30

16.0

4.1 CHANGING THE

TYPE OF GAS

The outlet pressure of the gas cock is obtained by completely loosening the

screw on the solenoid. The maximum pressure of the gas to the burner will

be equal to the nominal delivery pressure minus the head loss within the

gas valve.

[1 mbar = 10,197 mmc.a.]

4. GAS ADJUSTMENTS

Lower Wobbe Index (15°C;1013mbar) MJ/m3h

Nominal Delivery Pressure mbar

Minimum Delivery Pressure mbar

23 MFFI

Main Burner: n. 13 jets (ø)mm

Consumption (15°C; 1013mbar) mc/h

Consumption (15°C; 1013mbar) Kg/h

Gas Cock Outlet Pressure

max - min mbar

27 MFFI

Main Burner: n. 15 jets (ø)

Consumption (15°C; 1013mbar) mc/h

Consumption (15°C; 1013mbar) Kg/h

Gas Cock Outlet Pressure:

max - min mbar

CATEGORY II2H3+ Methane Gas

G20

Liquid Butane Gas

G30

Liquid Propane Gas

G31

45.67

20

17

1.30

2.72

----

11.0 - 2.0

1.30

3.15

----

11.0 - 1.6

80.58

29

20

0.77

----

2.02

(*) - 6.0

0.77

----

2.34

(*) - 4.6

80.58

37

25

0.77

----

2.02

(*) - 6.0

0.77

----

2.31

(*) - 6.0

Page 21

21

It is recommended that the following inspections be carried out on the

boiler at least once a year:

1 - Check the seals for the water connections; replacement of any faulty

seals.

2 - Check the gas seals;replacement of any faulty gas seals.

3 - Visual check of the entire unit.

4 - Visual check of the combustion process or analysis of combustion by-

products (see section 3.6) and cleaning of the burner if needed.

5 - If called for by point. 3, dismantling and cleaning of the combustion

chamber.

6 - If called for by point. 4, dismantling and cleaning of the burner jets.

7 - Visual check of the primary heat exchanger:

- check for overheating in the blade assembly;

- clean the exhaust fan if needed.

8 - Adjustment of the flow rate of the gas:flow rate for lighting, partial load

and full load.

9 - Check of the heating safety systems:

- safety device for maximum temperature;

- safety device for maximum pressure.

10- Check of the gas safety systems:

- safety device for lack of gas or flame ionisation (detection

electrode);

- safety device for gas cock.

11- Check of the electrical connection (make sure it complies with the

instructions in the manual).

12- Check of domestic hot water production efficiency (flow rate and

temperature)

13- General check of the combustion by-products of the

discharge/ventilation system.

14- Check of the general performance of the unit.

5. MAINTENANCE

Page 22

22

7. MISCELLANEOUS

7.1 WIRING DIAGRAM FOR

TWO HEATING ZONES

Based on Honeywell controls

SH010A

BROWN

BLUE

GREY

ORANGE

GREEN/YELLOW

V4043H

VALVE

5

2

9

10

3

14

35

22

T6360B

ROOM

THERMOSTAT

ZONE1

BROWN

BLUE

GREY

ORANGE

GREEN/YELLOW

V4043H

VALVE

8

2

9

10

3

16

TYPICAL

JUNCTION BOX

• 1

• 2

• 3

• 4

• 5

• 6

• 7

• 8

• 9

1

BOILER ELECTRICAL SUPPLY CABLE

ENLmicroGENUS 23-27 MFFI

9 10 3 2

Remove internal time clock plug

from the the P.C.B. then connect

room stat terminal block on the

reverse of the boiler control panel

(see section 2.10)

the junction box.

25 ENL

14 N L

31 N L

74 E1 2

Sunvic ET 1451

Link 2-3-6

Sunvic DHP 2201 6 3 E 1 2

610 2 1

Towerchron FP

64321

Pegler Sunvic

SP 50/100 (Link L-3)

SWITCHMASTER 805, 900

Switchmaster

Symphony, Sonata

Switchmaster 400, 600 3 1 N L

to 9 + 10 on

NL

ON ON

610 2 1

Link 1-5/4-7-9

Towerchron MP

Link 1-4/6-11

Towerchron 2000 HW HTG

36 ENL

42 ENL

ACL LS522, LS722 3 4 N L

Randall 922, 972

Link L-2-5

Randall 3020 P

BOILER

ZONE 1

PROGRAMMER

and 3060

38

22

T6360B

ROOM

THERMOSTAT

ZONE 2

L1

N2

E3

240V

MAINS INPUT (3 AMP)

• 10

63 N L

64321

Honeywell ST 699B 1002

Link L-5-8

14 ENL

34 N L

ST 6400/ST 6300 ST 6200 3 4 N L

Drayton Tempus 7 3 4 N L

Horstmann 425, 525, 527

Link L-2-5

Landis & Gyr RWB2

Glowworm Mastermind

34 N L

Landis & Gyr RWB20

Microgyr

Potterton Miniminder 3 4 N L

Potterton EP2000/3000 - 3 4 N L

Link L-5 EP2001/3001

Randall 102/102 E 1 2 E 5 6

Link 3-6

Randall 4033

42 E7 6

31 ENL

Link 1-6

Randall 701, 702

Link L-6-5

Sangamo M5 1 8 E 4 3

Link 1-6

18 E4 3

Sangamo 410 Form 1

Link 3-6

If a room thermostat is not requied on Zone 1, insert a link

between 4 + 5 on the junction box.

If a room thermostat is not requied on Zone 2, insert a link

between 6 + 8 on the junction box.

ZONE 1

PROGRAMMER

ZONE 2 ZONE 2

Page 23

23

7.2 WIRING DIAGRAM FOR

CONNECTION TO AN

ARISTON UNVENTED

CYLINDER

Based on Honeywell controls

SH009A

14

35

22

T6360B

ROOM

THERMOSTAT

BROWN

BLUE

GREY

ORANGE

10

GREEN/YELLOW

V4043H

HEA TING V ALVE

BROWN

BLUE

GREY

ORANGE

10

GREEN/YELLOW

V4043H

HOT W A TER VALVE

1

BOILER ELECTRICAL SUPPLY CABLE

ENL

9 10 3 2

TYPICAL

JUNCTION BOX

5

2

9

3

• 1

microGENUS 23-27 MFFI

• 2

• 3

Remove internal time clock plug

from the the P.C.B. then connect

room stat terminal block on the

reverse of the boiler control panel

(see section 2.10)

to 9 + 10 on

the junction box.

NL

BOILER

• 4

610 2 1

ON ON

36 ENL

42 ENL

PROGRAMMER

8

2

• 5

25 ENL

14 N L

31 N L

74 E1 2

64321

610 2 1

9

• 6

3

• 7

Pegler Sunvic

SP 50/100 (Link L-3)

Switchmaster

Symphony, Sonata

Switchmaster 400, 600 3 1 N L

SWITCHMASTER 805, 900

Sunvic ET 1451

Link 2-3-6

Sunvic DHP 2201 6 3 E 1 2

Towerchron FP

Link 1-5/4-7-9

Towerchron MP

Link 1-4/6-11

Towerchron 2000 HW HTG

ACL LS522, LS722 3 4 N L

Randall 922, 972

Link L-2-5

Randall 3020 P

and 3060

L1

N2

E3

240V

MAINS INPUT (3 AMP)

Cylinder

thermostat

1

C/P

2

Thermal

cut-out

1 C/P

• 8

• 9

• 10

63 N L

64321

1

P

2

8

6

Not

used

Honeywell ST 699B 1002

Link L-5-8

14 ENL

34 N L

ST 6400/ST 6300 ST 6200 3 4 N L

Drayton Tempus 7 3 4 N L

Horstmann 425, 525, 527

Link L-2-5

Landis & Gyr RWB2

Glowworm Mastermind

34 N L

Landis & Gyr RWB20

Microgyr

Potterton Miniminder 3 4 N L

Potterton EP2000/3000 - 3 4 N L

Link L-5 EP2001/3001

Randall 102/102 E 1 2 E 5 6

Link 3-6

Randall 4033

42 E7 6

31 ENL

Link 1-6

Randall 701, 702

Link L-6-5

Sangamo M5 1 8 E 4 3

Link 1-6

18 E4 3

Sangamo 410 Form 1

Link 3-6

PROGRAMMER

Page 24

Manufacturer: Merloni TermoSanitari SpA - Italy

Commercial subsidiary: MTS (GB) LIMITED

MTS Building

Hughenden Avenue

High Wycombe

Bucks HP13 5FT

Telephone:(01494) 755600

Fax:(01494) 459775

internet: http://www.mtsgb.ltd.uk

E-mail: info@mtsgb.ltd.uk

Technical Service Hot Line: (01494) 539579

23 99 84 1469 312 - Stampa: bieffe RECANATI

CE Certification

Heat Input max/min kW

Heat Output max/min kW

Efficiency of Nominal Heat Input %

Efficiency at 30% of Nominal Heat Input %

Heat Loss to the Casing (∆T=50°C) %

Flue Heat Loss with Burner Operating %

Flue Heat Loss with Burner Off %

Maximum Discharge of Fumes (G20) Kg/h

Residual Discharge Head mbar

Consumption at Nominal Capacity(G20) m3/h

Gas Consumption after 10 Minutes* m

3

(15°C, 1013 mbar) (G30-G31) Kg/h

Temp. of exhaust fumes at nominal capacity °C

CO

2

Content %

O

2

Content %

CO Content ppm

Minimum Ambient Temperature °C

Head Loss on Water Side (max) (∆T=20°C) mbar

Residual Head of System bar

Heating Temperature max/min °C

Domestic Hot Water Temperature max/min °C

D.H.W.Flow Rate ∆T=35°C l/min

D.H.W.Flow Rate ∆T=35°C gal/min

D.H.W. Minimum Flow Rate l/min

Pressure of Domestic Hot Water max/min bar

Expansion V essel Capacity l

Expansion Vessel Pre-load Pressure bar

Maximum Water Content of System l

Maximum Heating Pressure bar

Nominal Pressure Natural Gas (G20) mbar

LPG (G30-G31) mbar

Electrical Supply V/Hz

Power Consumption W

Protection Grade of Electrical System IP

Internal Fuse Rating

Weight Kg

G.C. Number

27 MFFI

7. TECHNICAL INFORMATION

63AU4549

25.6/11.0

92.9

91.1

1.0

6.1

0.4

49.5

0.96

2.72

0.32/0.39

2.02/2.00

123

7.2

7.5

51.9

+5

200

0.25

82/42

56/36

9.7

2.2

2.6

8/0.2

6

1

130

3

20

30-37

230 / 50

140

X4D

FAST 2 AT

38

47-116-14

63AU4549

29.8/12.0

93.5

90.7

0.2

6.3

0.4

60

1.60

3.15

0.37

2.34/2.31

128.8

6.9

8.1

48

+5

200

0.25

82/42

56/36

11.4

2.6

2.6

8/0.2

6

1

130

3

20

30-37

230 / 50

155

X4D

FAST 2 AT

39

47-116-15

23 MFFI

*Calculated at 70% maximum output

Page 25

Servicing

Instructions

Type C Boilers

G.C.N: 47-116-14

47-116-15

LEAVE THESE INSTRUCTIONS

WITH THE END-USER

Country of destination: GB

Page 26

2

B063

1. SERVICING INSTRUCTIONS

1.1 REPLACEMENT OF PARTS

1.2 TO GAIN GENERAL ACCESS

- Removing the front panel

- Removing the sealed chamber frontal cover

- Removing the side panels

1.3 ACCESS TO THE COMBUSTION CHAMBER

- Removing the combustion cover

- Removing the burner and jets

- Removing the electrodes

- Removing the main heat exchanger

- Removing the air pressure switch

- Removing the fan

- Removing the venturi device

1.4 SERVICING AND REMOVAL OF THE GAS VALVE

- Setting the gas pressures

- Removing the spark generator

- Removing the gas valve

1.5 ACCESS TO THE WATER CIRCUIT

- Removing the D.H.W.(secondary) exchanger

- Removing the safety valve

- Removing the automatic air vent

- Removing the main circuit flow switch

- Removing the pump

- Removing the pressure gauge

- Removing the expansion vessel

- Removing the overheat thermostat

- Removing the heating temperature sensor (N.T.C.)

- Removing the D.H.W.temperature sensor (N.T.C.)

- Removing the divertor valve actuator

- Removing the D.H.W.flow switch

1.6 ACCESS TO THE CONTROL SYSTEM

- Checking the fuses

- Removing the time clock

- Removing the P.C.B.

2. FAULT FINDING

2.1 FAULT FINDING GUIDE (FLOW-CHART)

3. ELECTRICAL DIAGRAMS

4. SHORT SPARE PARTS LIST

TABLE OF CONTENTS

Page 27

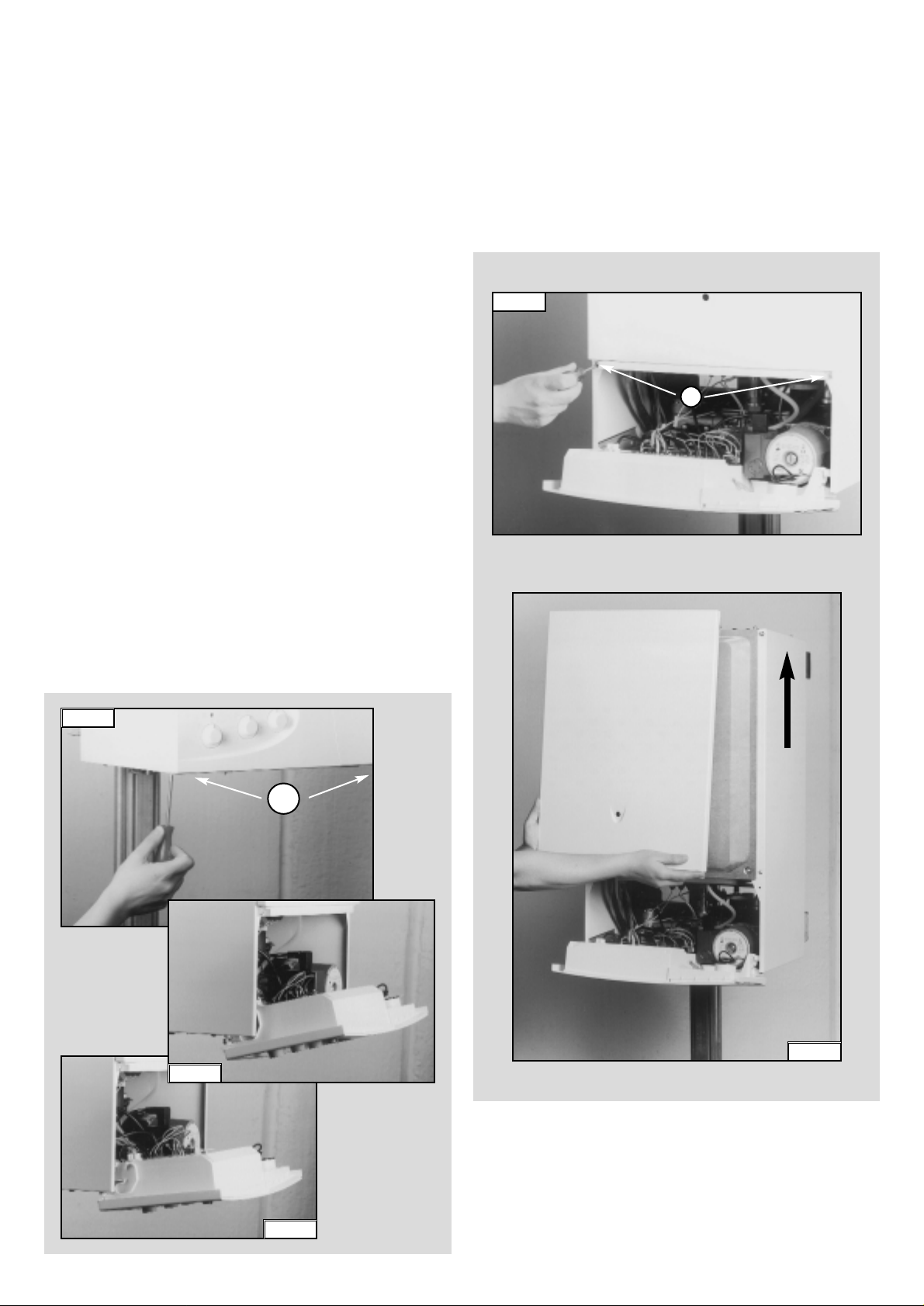

2. The control panel moves downward and when pulled forward,

rotates on two lateral hinges; the panel stays in a semihorizontal position, which allows access to the inner parts of

the boiler (F

IG. 1.2);

3. In order to increase the manouvering space, it is possible to

raise the control panel and rotate it to a fully horizontal position

(F

IG. 1.3);

4. Remove the screws “B” from the front panel bottom lip

(F

IG. 1.4);

5. Lift the front panel from the raised screws at the the top of the

casing (FIG. 1.5).

FIG. 1.4

B

FIG. 1.5

3

B063

1. SERVICING INSTRUCTIONS

The life of individual components varies and they will need

servicing or replacing as and when faults develop.

The fault finding sequence chart in chapter 2 will help to locate

which component is the cause of any malfunction, and instructions

for removal, inspection and replacement of the individual parts are

given in the following pages.

1.1 REPLACEMENT OF PARTS

1.2 TO GAIN GENERAL ACCESS

All testing and maintenance operations on the boiler require the

control panel to be lowered. This will also require the removal of

the casing.

Removing the front panel

1. Loosen the fastening screws “A”of the control panel located on

the lower part of the panel itself. (F

IG. 1.1);

A

FIG. 1.3

FIG. 1.1

FIG. 1.2

To ensure efficient safe operation, it is recommended that the

boiler is serviced annually by a competent person.

Before starting any servicing work, ensure both the gas and

electrical supplies to the boiler are isolated and the boiler is

cool.

Before and after servicing, a combustion analysis should be made

via the flue sampling point (please refer to the Installation Manual

for further details).

After servicing, preliminary electrical system checks must be

carried out to ensure electrical safety (i.e.polarity, earth continuity ,

resistance to earth and shor t circuit).

19.eps

14.eps

13.eps

FO016A/15.eps

16.eps

Page 28

4

B063

Removing the sealed chamber frontal cover

1. Remove the screws “C” (FIG. 1.6);

2. Lift the sealed chamber frontal cover from the locating pins

(FIG. 1.7).

FIG. 1.6

C

C

FIG. 1.7

Removing the side panels

1. Remove the four screws “D” for each side panel (FIG.1.8);

2. Pull the panel away from the boiler, then lift the panel up and

remove from the boiler (FIG.1.9).

D

D

D

FIG. 1.8

FIG. 1.9

18.eps

98.tif

17 eps 97.tif

Page 29

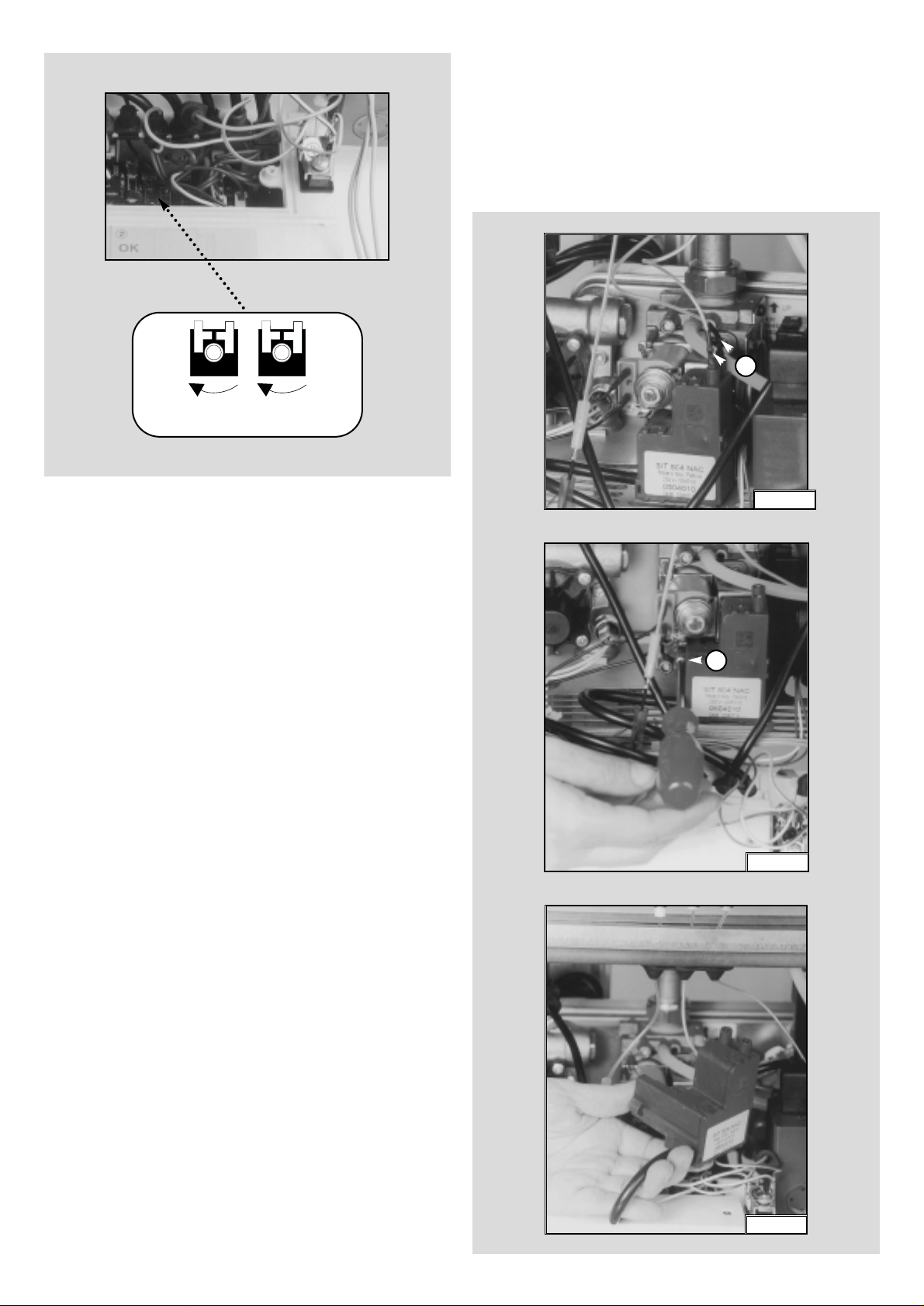

Removing the electrodes

Before carrying out this procedure, unscrew and slide the

burner forward (see previous section).

1. Remove rubber gasket “G”(Fig. 1.13);

2. To remove the detection electrode disconnect the cable

at its connection point close to the P.C.B. (Fig. 1.14);

FIG. 1.13

G

FIG. 1.14

Removing the burner and jets

1.

Remove the screws “F” from the burner (FIG. 1.11);

2. Remove the burner (FIG. 1.12);

3. Remove the jets using a No.7 socket spanner;

4. Replace in reverse order.

5

B063

Removing the combustion cover

1.

Remove the screws “E” (FIG. 1.10);

2. Lift off the combustion cover.

1.3 ACCESS TO THE COMBUSTION CHAMBER

E

E

E

FIG. 1.10

FIG. 1.11

Fig. 1.12

F

F

99.tif

12 eps

78 eps

49 eps

50 eps

Page 30

6

B063

3. Remove screw “H” (FIG. 1.15);

4. Gently slide the electrode downward (FIG.1.16).

To replace, repeat the steps in reverse order, paying

particular attention to the following:

a -Centre the electrode in the positioning hole carefully,

otherwise the electrode may break;

b -Check that the cables have been connected correctly;

c -Check that the rubber gasket covers the cable/ electrode

connection point completely.

FIG. 1.15

FIG. 1.16

H

1. Drain the boiler of water;

2. Release the overheat thermostat sensor “I” (FIG. 1.17);

3. Release the two connection nuts “J” connecting the

exchanger to the flow and return pipes (FIG. 1.18);

4. Pull it straight out (FIG. 1.19).

Removing the main heat exchanger

FIG. 1.18

J

Fig. 1.17

I

FIG. 1.19

51 eps

11 eps

52 eps

75 eps

76 eps

6 eps

Page 31

1. Disconnect electrical connections “N” and silicon pipes

“O” (FIG.1.23);

2. Remove screw “P” and remove the fan collar clamp “Q”

(FIG.1.24);

3. Remove screws “R” (FIG.1.25);

4. Remove fan and mounting plate (FIG.1.26).

Removing the fan

1. Disconnect the electrical connections “K” and silicon pipes

“L” from their connection points (F

IG. 1.20);

2. Remove screws “M” on the top of the sealed chamber

(FIG. 1.21);

3. Unscrew to remove switch from the plate (FIG. 1.22).

FIG. 1.21

FIG. 1.20

7

B063

Removing the air pressure switch

L

K

M

M

FIG. 1.22

FIG. 1.25

R

R

FIG. 1.24

P

Q

FIG. 1.23

N

N

O

FIG. 1.26

91.tif

90.tif

93.tif

94.tif

95.tif

96.tif

Page 32

8

B063

1.4 SERVICING AND REMOVAL

OF THE

GAS VALVE

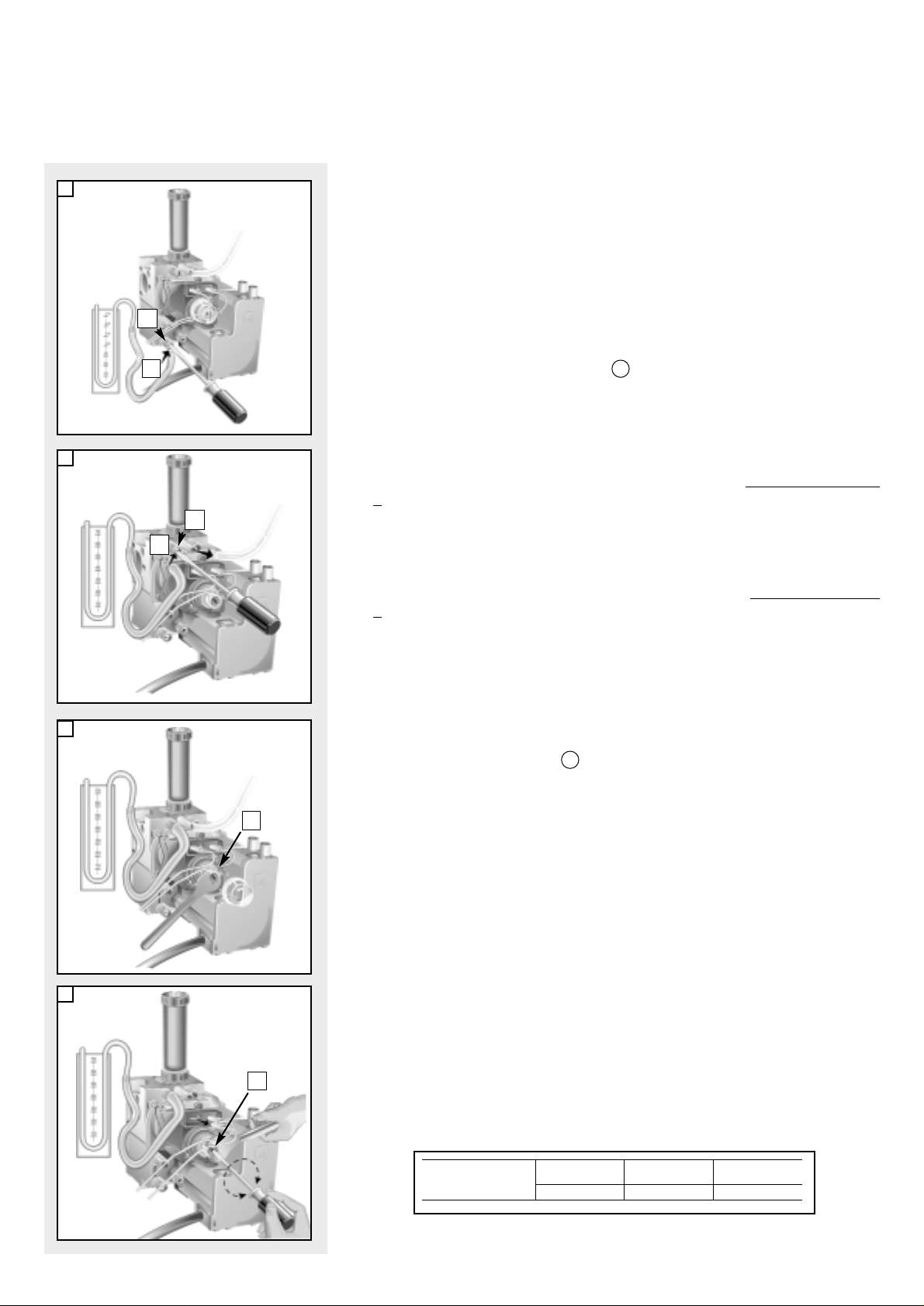

Setting the gas pressures

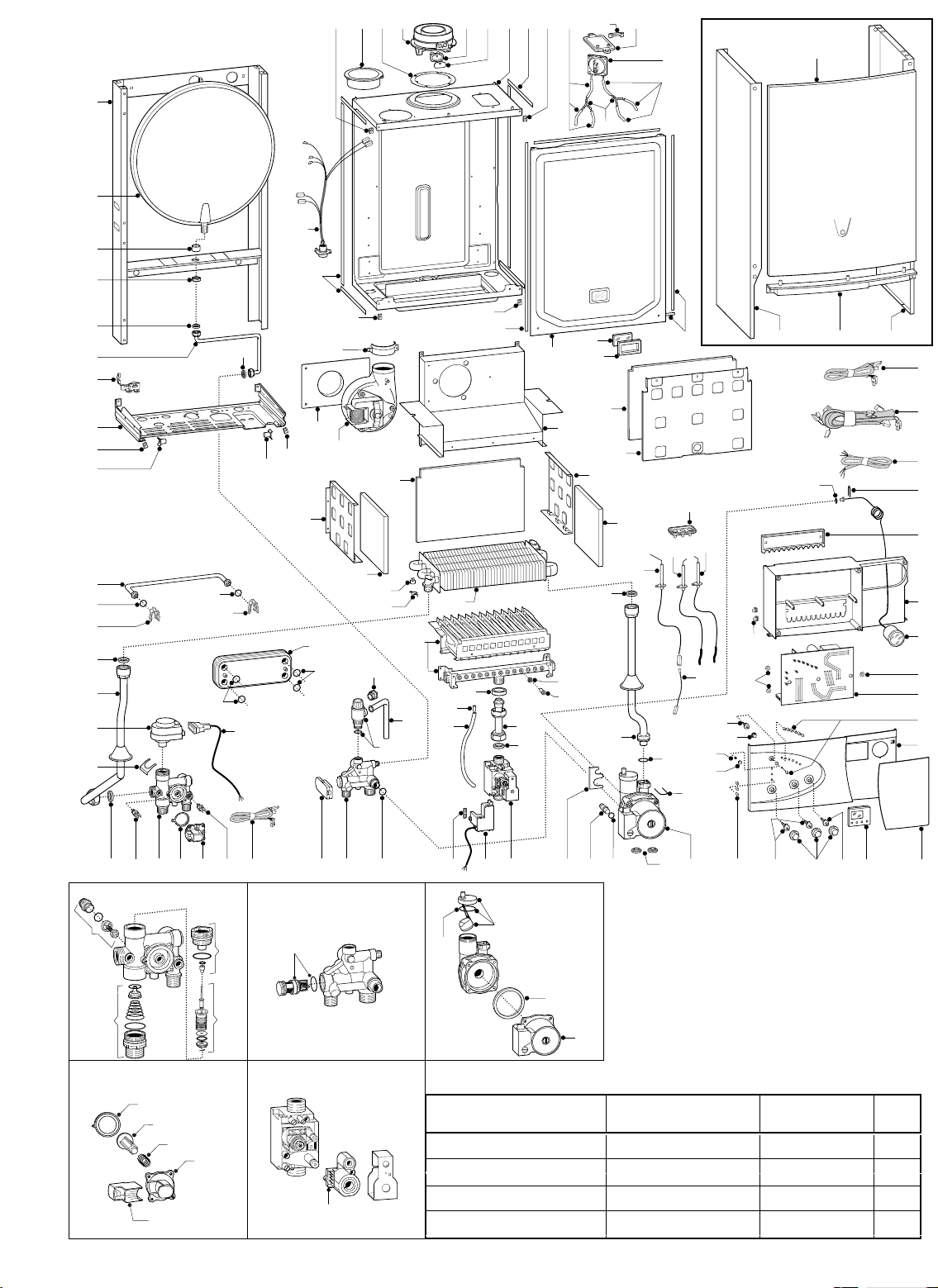

1

2

3

4

A

B

C

E

F

D

Setting the minimum and the maximum power of the boiler

1. Check that the supply pressure to the gas valve is a minimum of 20 mbar

for natural gas.

2. To do this, remove the screw “A”.

Fit the pipe of the pressure gauge to the pressure connection of the gas

valve “B”.

When you have completed this operation, replace the screw

“A” securely

into its housing to seal off the gas.

3. To check the pressure supplied by the gas valve to the burner, remove the

screw “C”. Fit the pipe of the pressure gauge to the pressure outlet of the

gas valve

“D”.

Disconnect the compensation pipe either from the gas valve or from the

sealed chamber.

4. Set the On/Off button to position < I > and the “summer/winter” switch to

the winter position.

To set the maximum power, turn on the hot water tap and allow the hot

water tap to run at a rate of about 8 litres/minute so that the main burner

lights.

Adjust nut

“E” on the modureg to set the gas pressure (displayed on the

pressure gauge) corresponding to the maximum power (see

TABLE “A” page

9).

5. To set the minimum po wer, disconnect a supply terminal from the modureg

and adjust screw “F”.

Turn the screw clockwise to increase the pressure and counter-clockwise to decrease the pressure (displayed on the

pressure gauge) corresponding to the minimum power (see

TABLE “A” page

9).

6. When you have completed the above operations, turn off the

hot water tap, re-connect the supply terminal to the modureg

on the gas valve and replace the cap on the screw of the

modureg.

Setting the maximum heating circuit power

7. To set the maximum heating circuit power, place the

On/Off button to position < I > and the “summer/winter” switch to winter

position.

Turn the knob of the heating thermostat clockwise to maximum.

8. Remove the inspection panel of the P.C.B. and fit a small cross-head

screwdriver in to the right hand potentiometer.Turn clockwise to increase

the pressure or counter-clockwise to reduce the pressure. Adjust the

setting to the required heating pressure value (displayed on the pressure

gauge), as indicated in the diagrams shown in page 10.

9. Turn off the boiler by placing the main switch to the "Off" position.

Setting pressure for soft ignition.

Disconnect the detection electrode connection from the P.C.B..

Start the boiler and during the ignition sequence adjust the left hand

potentiometer until the gas pressure reads the required gas pressure as

per the table below.

Once the gas pressure is set turn off the boiler and re-connect the

connection to the P.C.B.

NB.:It may be necessary to reset the flame failure reset a number of times

during this operation.

VG001Aa

VG001Ac

VG001Ab

VG001Ad

NATURAL GAS (G20) BUTANE GAS (G30) PROPANE GAS (G31)

Recommended pressure for

soft-light ignition

8 mbar

16 mbar

16 mbar

Page 33

9

B063

Regulating the heating power for

natural gas (G20)

Regulating the heating power for

butane gas (G30)

Regulating the heating power for

propane gas (G31)

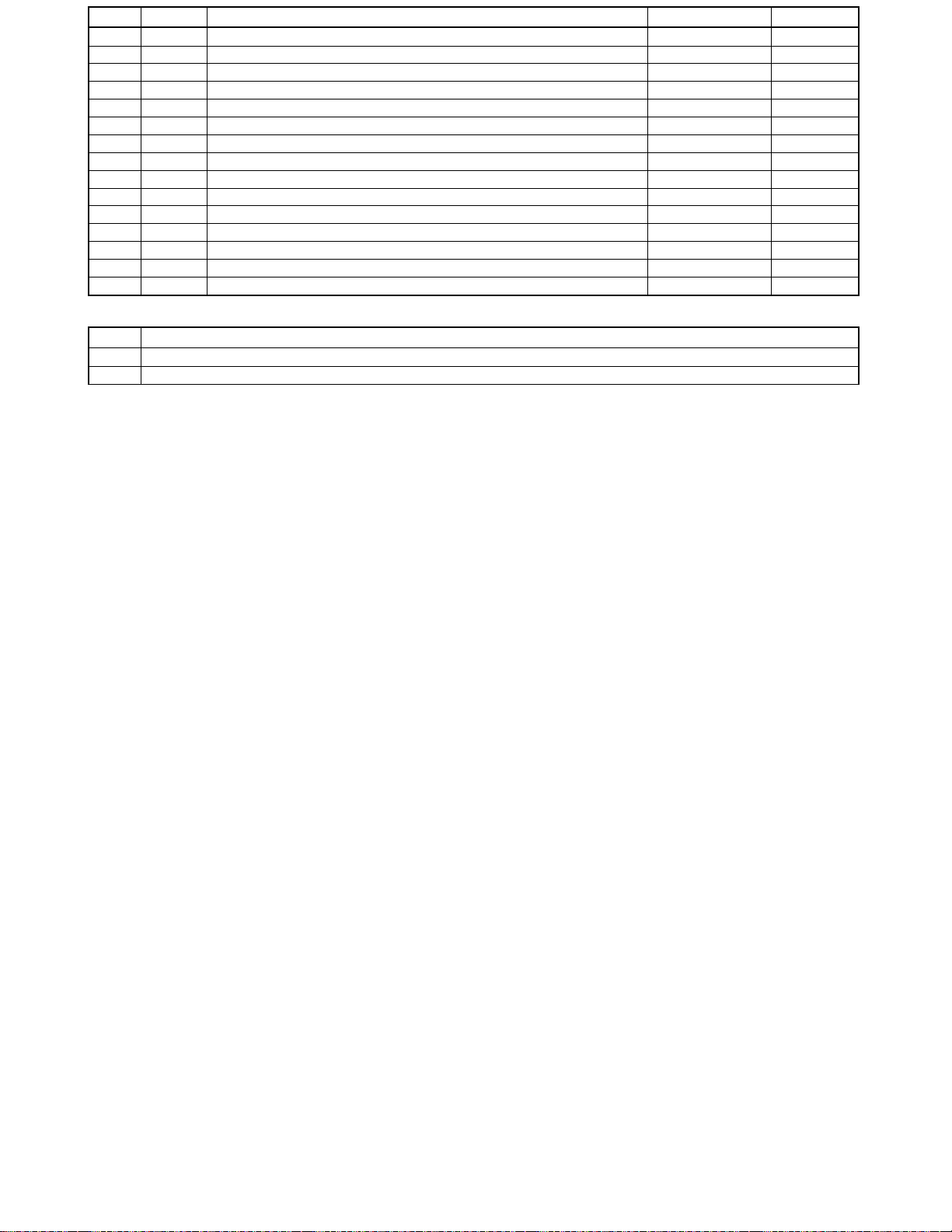

TABLE “A”

CG007A

CG008A

CG009A

TB012A

model 23

model 27

model 23

model 27

23 MFFI

2.70

1.16

20

11.0

2.0

40

38

36

34

model 23

model 27

2.01 Kg/h

0.87 Kg/h

28 mbar

27.7 mbar

6.0 mbar

2.00 Kg/h

0.85 Kg/h

37 mbar

35.5 mbar

7.3 mbar

27 MFFI

3.15

1.26

20

11.0

1.6

14 x 1.30

12 x 0.77

2.34 Kg/h

0.94 Kg/h

28 mbar

27.7 mbar

4.6 mbar

14 x 0.77

12 x 0.77

2.31 Kg/h

0.93 Kg/h

37 mbar

35.5 mbar

6.0 mbar

14 x 0.77

Page 34

10

B063

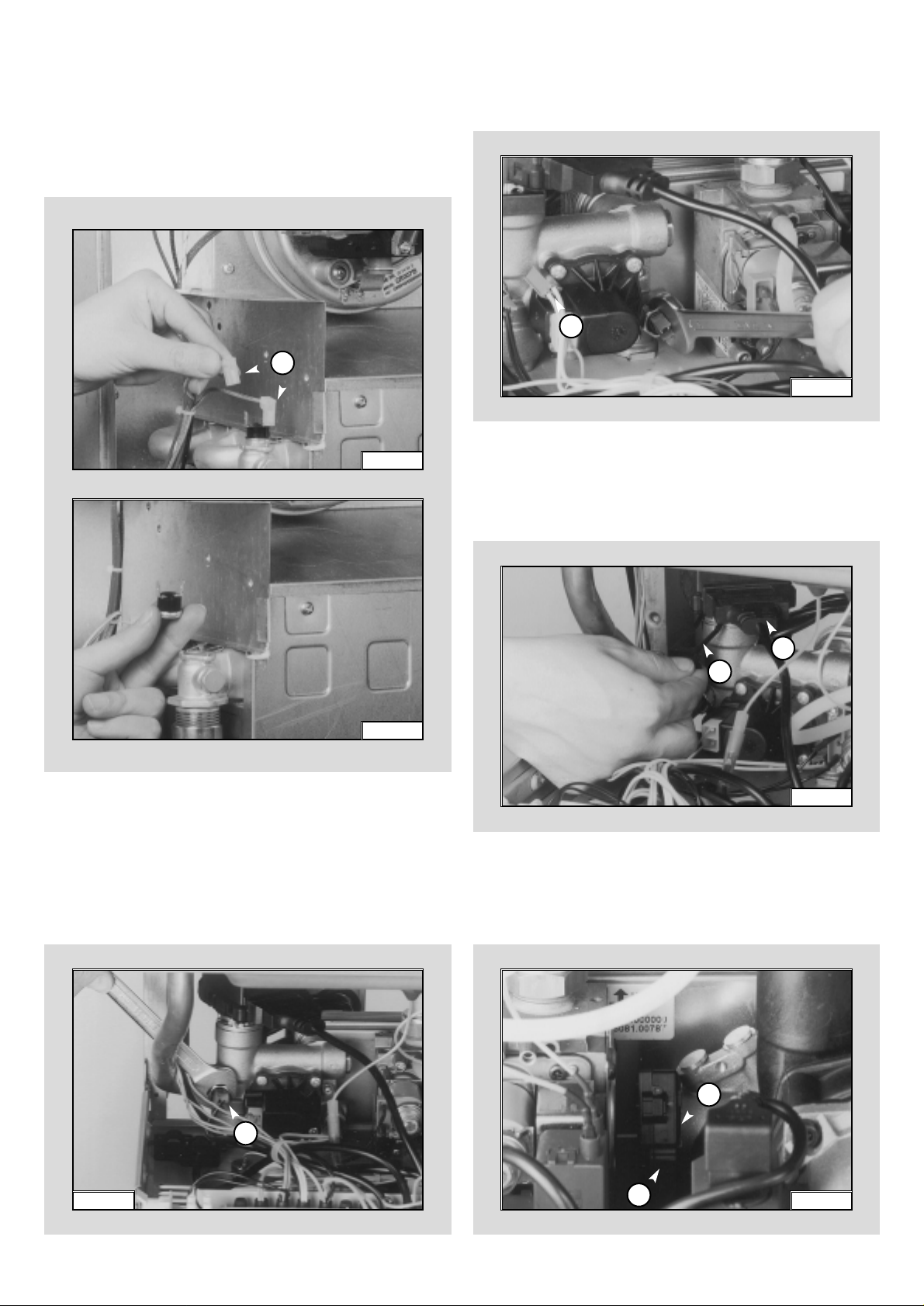

Removing the spark generator

1.

Disconnect ignition leads “T” by pulling upward

(FIG. 1.27);

2. Remove the screw “V”(FIG. 1.28);

3. Remove the spark generator (FIG. 1.29).

10. Remove the pipe from the pressure gauge and connect

screw “C” to the pressure outlet in order to seal off the

gas.

11.Carefully check the pressure outlets for gas leaks (v alve

inlet and outlet).

IMPORTANT!

Whenever you disassemble and reassemble the gas

connections, always chec k f or leaks using a soap and water

solution.

FIG. 1.27

FIG. 1.28

FIG. 1.29

T

V

Soft-light

Adjustment

Max Heating

Adjustment

61.eps

45.eps

43.eps

44.eps

VR015A.eps

Page 35

11

B063

Important! Before any component is removed, the boiler

must be drained of all water.

Removing the D.H.W. (secondary) exchanger

1.Remove the screws “Y” (FIG 1.33 + FIG 1.34);

2.Push the exchanger tow ards the rear of the boiler , and lift

upwards and remove out of the front of the boiler

(FIG 1.35);

3.Before replacing the exchanger ensure that the O-rings

are in good condition and replace if necessary.

1.6 ACCESS TO THE WATER CIRCUIT

FIG. 1.30

FIG. 1.31

FIG. 1.32

FIG. 1.33

W

X

X

Removing the gas valve

1.

Disconnect all the cables from the solenoid and

modureg;

2. Remove the spark generator (see previous section);

3. Release the top nut “W” (FIG. 1.30);

4. Remove the screws “X” from the bottom of the gas valve

pipe (FIG. 1.31);

5. Remove the gas valve (FIG. 1.32).

Y

FIG. 1.34

FIG. 1.35

Y

47.eps

48.eps

38.eps

22.eps

21.eps

68.eps

Page 36

12

B063

Removing the safety valve

1.

Loosen nut “Z” (FIG. 1.36);

2. Unscrew and remove the valve (FIG. 1.37).

Removing the automatic air vent

1. Unscrew valve top “A1” (FIG. 1.38);

2. Remove valve (Fig 1.39).

Removing the main circuit flow switch

1.

Remove the cable of the main circuit flow switch “B1”

(FIG. 1.40);

2. Remove the screws “C1”(FIG. 1.41);

3. Remove the main circuit flow switch.

FIG. 1.36

Fig. 1.38

FIG. 1.40

Z

B1

C1

C1

FIG. 1.37

A1

Fig. 1.39

FIG. 1.41

40.eps

37.eps

39.eps

41.eps

53.eps

54.eps

Page 37

13

B063

Removing the pump

1.

Remove the U-clip “ D1” (FIG. 1.41);

2. Remove the retaining clip “E1” (FIG. 1.42);

3. Remove the U-clip “ F1” (FIG. 1.43);

4. Release the nut “G1” (FIG. 1.44);

5. Remove the pipe “H1” (FIG. 1.45);

6. Remove the screws “I1” (FIG. 1.46);

7. Remove the pump (FIG. 1.47).

D1

FIG. 1.41

FIG. 1.42

FIG. 1.43

FIG. 1.44

E1

F1

FIG. 1.45

FIG. 1.46

FIG. 1.47

G1

H1

I1

I1

31.eps

33.eps

34.eps

42.eps

32.eps

35.eps

25.eps

Page 38

14

B063

Removing the expansion vessel

1.

Loosen nuts “K1” and remove the gas pipe (FIG. 1.50);

2. Loosen nut “L1” (FIG. 1.51);

3. Remove back nut “M1” (FIG. 1.52);

4. Remove the expansion vessel (FIG. 1.53).

Removing the pressure gauge

1.

Remove the U-clip “J1” and remove the pressure gauge

coupling (FIG. 1.48);

2. Push the pressure gauge through the control panel from

the rear (FIG. 1.49).

FIG. 1.48

FIG. 1.50

J1

FIG. 1.49

K1

L1

FIG. 1.51

FIG. 1.52

FIG. 1.53

K1

M1

34.eps

27.eps

77.eps

57.eps

58.eps

59.eps

Page 39

15

B063

Removing the overheat thermostat

1.

Disconnect the overheat thermostat electrical

connections “N1” (FIG. 1.54);

2. Then remove the thermostat from its mounting by

releasing the securing clip (FIG. 1.55).

Removing the heating temperature sensor (N.T.C.)

1.

Pull off the electrical connector “P1” and unscrew the

sensor probe using a suitable spanner (FIG. 1.56).

FIG. 1.54

FIG. 1.55

Removing the D.H.W. temperature sensor (N.T.C.)

1.

Pull off the electrical connector “Q1” and unscrew the

sensor probe using a suitable spanner (FIG. 1.57).

FIG. 1.57

Removing the divertor valve actuator

1. Unplug the electrical connector “R1” (FIG. 1.58);

2. Release the retaining clip “S1” and remove the divertor

valve actuator.

FIG. 1.58

Removing the D.H.W. flow switch

1. Unplug the electrical connector “T1” (FIG. 1.59);

2. Release the retaining clip “V1” and remove the D.H.W.

flow switch.

FIG. 1.59

N1

P1

Q1

S1

R1

FIG. 1.56

T1

V1

80.eps

83.eps

87.eps

60.eps

74.eps

30.eps

Page 40

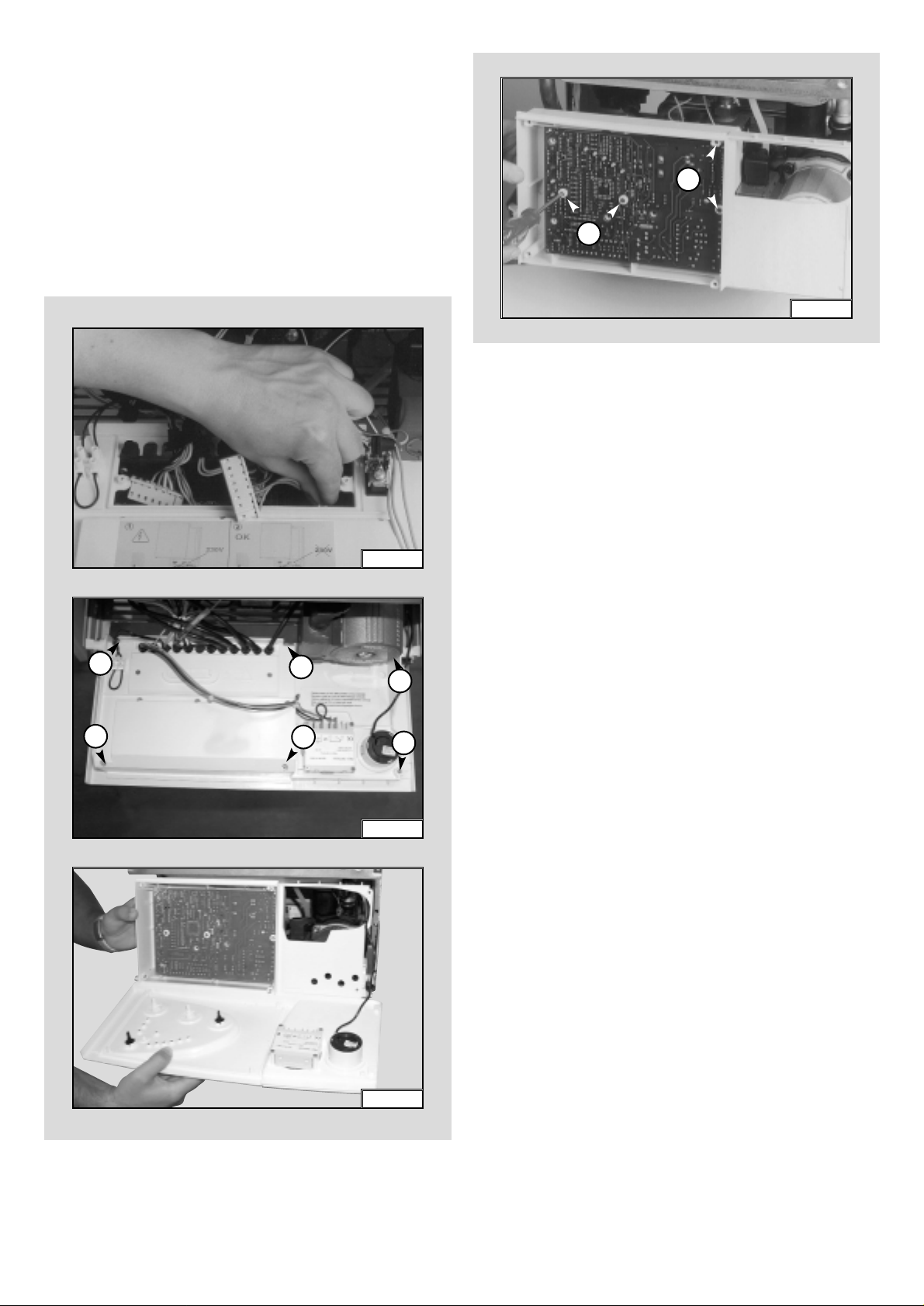

16

B063

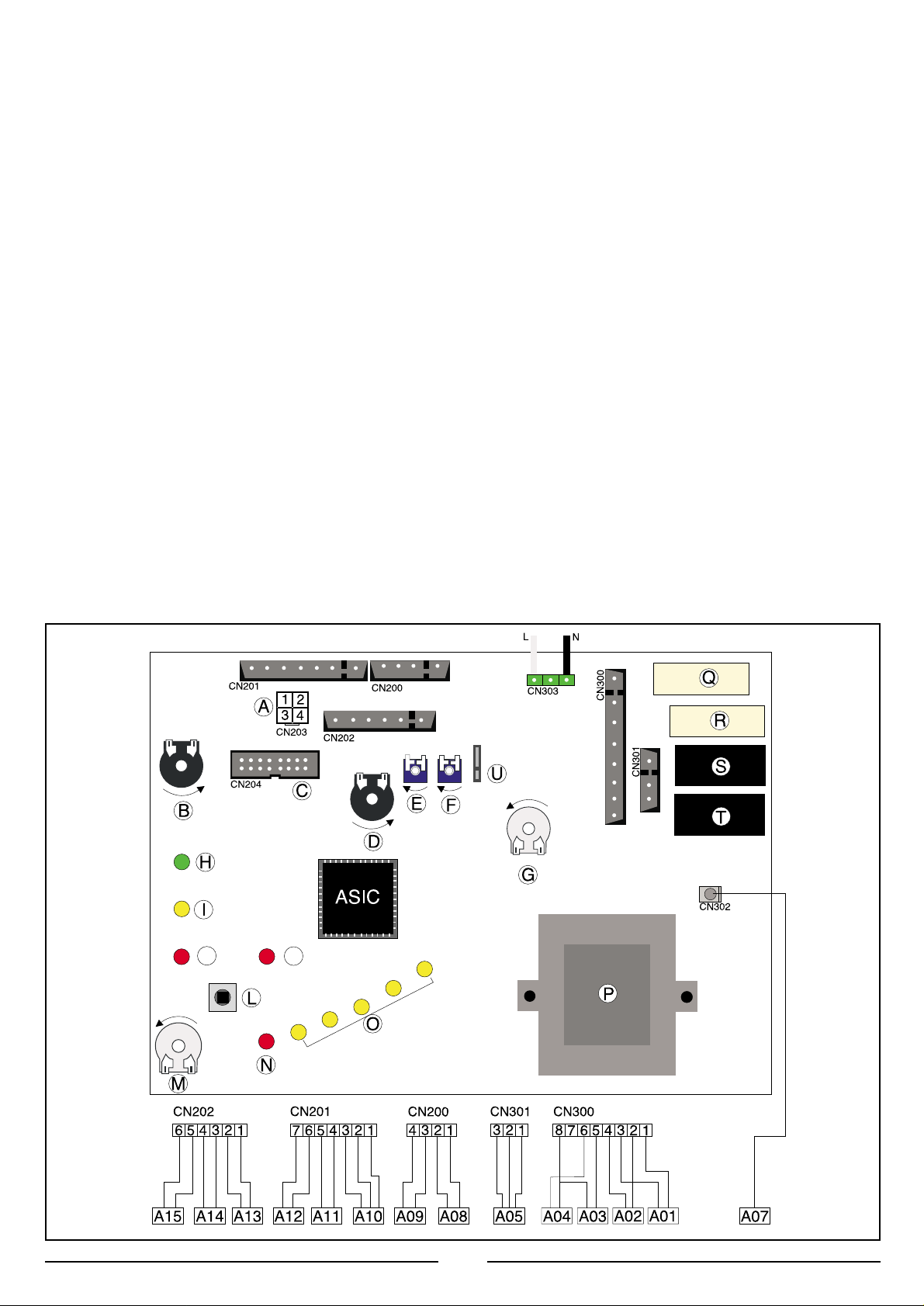

Checking the fuses

1.

Remove the inspection cover on the reverse of the

control panel (FIG. 1.60);

2. Remove the fuses (FIG. 1.61).

1.6 ACCESS TO THE CONTROL SYSTEM

Removing the time clock

1.

Unplug electrical connection “W1” from the clock (FIG.

1.62);

2. Remove the screws “W2”(see fig. 1.63);

3. Remove the clock from the panel (see fig. 1.64).

FIG. 1.60

FIG. 1.62

FIG. 1.61

FIG. 1.64

W1

72.eps

61.eps

69.eps

1190.tif

FIG. 1.63

1189.jpg

W2

Page 41

17

B063

Removing the P.C.B.

1.

Isolate electricity;

2. Remove the inspection cover from the reverse of the

control panel;

3. Unplug all electrical connections from the P.C.B. (FIG.

1.65);

4. Remove the screws “X1” (FIG. 1.66);

5. Separate the facia panel from the rear of the control

panel (FIG. 1.67);

7. Remove the screws “Y1” and remove the P.C.B. (FIG.

1.68).

FIG. 1.66

X1

X1

X1

X1

X1

X1

FIG. 1.65

FIG. 1.67

FIG. 1.68

Y1

Y1

64.eps

1187.eps

65.eps

82.eps

Page 42

18

B063

2. FAULT FINDING

PRELIMARY CHECKS

MAKE SURE THAT:

IS

THE POWER

L.E.D.

ON?

POSTION

OF THE

SELECTOR

NO

NO

WINTERES TAT ESUMMER

NONO

YESYES

YESYES

YESYES

YESYES

YESYES

NONO

NONO

NONO

NONO

NONO

NONO

NONO

YESYES

YESYES

YESYES

1 - Check the fuses

2 - Check the power supply

cable, plug and outlet

3 - Check/replace the power

supply to the P.C.B.

TURN ON THE ON/OFF

SWITCH

D.H.W. IS

BEING DRAWN?

D.H.W. IS

BEING DRAWN?

FOR BOILERS

WITH ELECTRONIC

ANTI-FROST DEVICE:

PROTECTION IS ACTIVATED

IF HEATING TEMP

IS < 5

°

C

FOR BOILERS

WITH ELECTRONIC

ANTI-FROST DEVICE:

PROTECTION IS ACTIVATED

IF HEATING TEMP

IS < 5

°

C

MUST

TIME CLOCK

AND/OR ROOM

THERMOSTAT

BE ACTIVATED?

A

ECONOMY/

COMFORT

SELECTOR

TEMP.

C.H. < 34°C

Comfort

Comfort

Economy

Economy

1 - There is sufficient water in

the system

2 - The gas is turned on

3 - The electrical supply is

turned on

1 - Check/reset system

pressure

2 - Check/restore gas

supply

3 - Check/replace short circuited heating probe

4 - Check/replace siezed

pump

1 - Check/reset the

system pressure

2 - Check/restore

gas supply

3 - Check/replace short circuited heating probe

4 - Check/replace

siezed pump

TEMP.

C.H. < 34°C

ECONOMY/

COMFORT

SELECTOR

It is possible to detect and correct any defect by using the standard fault

finding diagrams described in this chapter.

2.1 FAULT FINDING GUIDE

(FLOW-CHARTS)

FC004Aa

Page 43

19

B063

IS THE PUMP

RUNNING?

YES

NO

NO

NO

YES

YESYES

POWER T O

THE PUMP?

DOES THE

"NO WA TER" L.E.D.

ILLUMINATE

(WITHIN 40 SECS)?

1 - Check if there is air in the

system

2 - Check main circuit flow switch

operation

3 - Check pressure on the water

gauge and fill system to return

to 1 bar

1 - Turn the boiler off then on

(protection reset)

1 - Check that the pump

is not stuck

2 - Release/replace pump

1 - Check pump cable

2 - Check/replace P.C.B.

3 - Check main flow main

switch operation when

drawing D.H.W.

A

B

FC004Ab

Page 44

20

B063

IS THE FAN

RUNNING?

BOILER

SHUTDOWN?

POWER

TO FAN?

NO

YES

YES

YES

NO

YES

NO

NO

NO

YES

1 - Check/replace main

circuit flow switch

2 - Check/replace

connection cable

3 - Check/replace P.C.B.

1 - Check/replace air

pressure switch

2 - Check if reset button

is jammed

3 - Check/replace flame

detection electrodes

1 - Check/replace

connection cable

2 - Check/replace P.C.B.

3 - Check/replace air

pressure switch

1 - Replace fan

1 - Reset the boiler

PUMP PROTECTION

ACTIVATED?

INTERNAL

P.C.B. PROTECTION

ACTIVATED?

B

C

FC004Ac

Page 45

21

B063

IS THE BURNER

ALIGHT?

YES

NO

YES

YES

YES

NO

NO

NO

NO

YES

1 - Check/replace ignition

electrode

2 - Check ignition cable

3 - Check spark generator

4 - Check ignition electrode

cable

5 - Check/replace P.C.B.

1 - Check if flame strikes

detection electrode

2 - Check soft-light gas

pressure

3 - Check/replace detection

electrode

4 - Check/replace P.C.B.

1 - Check power supply of

gas valve

2 - Check/replace P.C.B.

3 - Check efficiency of

gas valve

4 - Replace gas valve

Shutdown L.E.D. off

fan restarts

IS THE

AIR PRESSURE SWITCH

ACTIVATED?

CHECK

∆P ON TEST

PRESSURE

INTAKE

IS FLUE

DISCHARGE

NORMAL?

HAS THE

BOILER SAFETY

SHUTDOWN BEEN

ACTIVATED?

HAS THE

BOILER SAFETY

SHUTDOWN BEEN

ACTIVATED?

1 - Check exhaust discharge

2 - Check venturi & pipes

3 - Check fan efficiency

1 - Check A.P. switch cable

2 - Check/replace A.P. switch

3 - Check/replace P.C.B.

C

D

P 1.2 mbar

P 1.2 mbar

∆

∆

∅

≤

FC004Ad

Page 46

22

B063

IS

THERE STILL

A PROBLEM?

NORMAL

OPERATION

NO

YES

FAULTS

POSSIBILE CAUSES

1

2

3

4

5

6

7

8

9

D

Drawing D.H.W:

When you turn on a tap

burner switches off

Drawing D.H.W:

radiators heat up in summer mode

Drawing D.H.W:

insufficient hot water

temperature

Drawing D.H.W:

noisy operation

Decrease/increase

heating circuit pressure

Repeated shutdowns

Repeated intervention of safety thermostat

When cold water tap turned off, the boiler

ignites

Insufficient radiator temperature

- air in secondary heat exchanger

- faulty main circuit flow switch

- faulty D.H.W. flow switch

- faulty 3-way valve

- check C.H./D.H.W. temperature probes

- check gas pressures

- check water flow rate

- check secondary heat exchanger

- primary heat exchanger faulty or

lime-scale deposits

- low heating system water pressure

- check gas pressures

-

check C.H./D.H.W. temperature probes

- check for leaks on the heating circuit

- faulty filling-loop

- faulty secondary heat exchanger

- expansion vessel faulty

- faulty detection electrodes

- check gas settings

- check flame detection electric circuit

- C.H./D.H.W. temperature probes open circuit

- overheat thermostat not calibrated correctly

- air in primary water circuit

- drop in pressure in the water mains, with

consequent water hammer

- check C.H. temperature probe

- check by-pass