Page 1

End User

Manual

SERIES

ACO 27 MFFIG.C.N: 47-116-34

ACO 32 MFFIG.C.N: 47-116-35

ACO 27 RFFI G.C.N: 41-116-09

ACO 32 RFFI G.C.N: 41-116-10

LEAVE THESE INSTRUCTIONS

WITH THE END USER

Country of destination: GB/IE

Page 2

Dear Customer,

ABLE OF CONTENTS

T

Thank you for choosing an ARISTON boiler.

e guarantee that your boiler is a reliable and

W

echnically sound product.

t

This manual provides detailed instructions and

recommendations for correct use.

Remember to keep this manual along with the

Installation and Servicing Instruction manual

in a safe place for future reference i.e. by the

gas meter.

our local MTS Servicing Centre is at your

Y

complete disposal for all requirements.

GUARANTEE

The guarantee on this appliance is valid for 60

months from the first day of installation by a

qualified CORGI registered engineer and

subject to an annual service carried out by a

qualified service engineer in line with MTS (GB)

LTD’s Servicing Schedule.

1.GENERAL INFORMATION p

2. CONTROL PANEL page. 4

3. OPERATING INSTRUCTIONS page. 6

4. US

5.MECHANICAL TIME CLOCK p

6. DIGITAL PROGRAMMER page. 10

IMPORTANT!

Please read this manual carefully.

For additional information, please consult the “Installation and Servicing

Instructions.”

Keep this manual along with the Installation & Servicing Instructions

manual in a safe place for future reference.

Every attempt has been made to avoid errors of any kind in this manual,

the Management invites customers to inform of any inaccuracies which

they may find. This will help to improve our service.

EFULINFORMATION

age. 3

page. 9

age. 10

Repairs to the electric, water or gas circuits may

only be carried out by your local authorised

MTS Servicing Centre.

2

Page 3

1. GENERAL INFORMATION

MTS (GB) Limited support the initiative. In the Installation

nd Servicing Instructions (Sections 11 and 12) you will find the

a

Commissioning Checklist and the Servicing Interval

Record, your installer must complete this, and show you how to

use it as it will give you important information about your boiler,

nd heating system. Also when the boiler is serviced annually the

a

Service Interval Record must be completed. Please have the

Installation and Servicing Instructions to hand whenever you contact a service engineer or us.

All CORGI Registered Installers carry a CORGI ID card, and

have a registration number. Both should be recorded in your

boiler Log Book. You can check your installer is CORGI reg-

stered by calling CORGI direct on :- (01256) 372300.

i

The ACO MFFI range of boilers are combined appliances for the

production of Central Heating (C.H.) and Domestic Hot Water

D.H.W.).

(

The ACO RFFI range of boilers are heating only boilers designed

for the production of Central Heating (C.H.) and Domestic Hot

ater (D.H.W.) in conjunction with an indirect storage cylinder.

W

By design, these appliances are for domestic use and must only

be used for this purpose.

The manufacturer declines all liability for damage caused by

improper or negligent use.

Do not allow children or inexperienced persons to use the appliance without supervision.

If you smell gas in the room,

the telephone or any other object which might cause sparks.

Open doors and windows immediately to ventilate the room.

Shut the gas mains tap (on the gas meter) or the valve of the gas

cylinder and call your Gas Supplier immediately.

If you are going away for a long period of time, remember to shut

the mains gas tap or the gas cylinder valve. (This may not be necessary if the appliance is to be left operational for frost protection).

Before any intervention within the boiler it is first necessary

to isolate the electrical power supply by turning the external

switch to “OFF”.

do not turn on light switches, use

3

Page 4

2. CONTROL PANEL

A

B

C

27/32 MFFI

I

H

G

F

E

Fig. 3.6

Button Description

ON/OFF Button

“COMFORT” Function Button

Reset Button/

Flue Test**/ scroll through Functions Menu

Menu Button

amming

r

Prog

Programming “-” key

“+”

D

Description

A

B

C

D

y

e

k

E

F

Green LED

(illuminated = burner on)

Time clock (Mechanical Version Shown)

Selector knob for Summer/Winter

Central Heating Temperature Adjustment Knob

Control Panel Cover

Domestic Hot Water Temperature Adjustment Knob

Heating System Pressure Gauge

** IMPOR

The Flue Test function will cause the boiler to run continuously on

maxim

rised engineer.

4

TANT!!

um po

This function m

.

wer

ust only be activated by an autho-

G

H

“COMFORT” Function L.E.D

Red LED

(illuminated = boiler lockout)

I

Multi-function Display

Page 5

A

B

C

27/32 RFFI SYSTEM

I

H

G

F

FIG. 3.4

Button Description

ON/OFF Button

NOT USED

Reset Button/

Flue Test**/ scroll through Functions Menu

u Button

Men

Programming “+” key

ramming “-” key

Prog

A

B

C

D

F

G

Description

Green LED

(illuminated = b

Time clock (Mechanical Shown - Optional)

Selector knob for Summer/Winter

Central Heating Temperature Adjustment Knob

Control Panel Cover

Heating System Pressure Gauge

NOTUSED

urner on)

D

ANT!!

** IMPOR

The Flue Test function will cause the boiler to run continuously on

maxim

rised engineer

T

um power.This function must only be activated by an autho-

.

H

Red LED

(illuminated = boiler lockout)

I

Multi-function Display

5

Page 6

3. OPERATING INSTRUCTIONS

VALVES WITH 1/4

TURN HANDLES

O

MFFI

CAUTION!!

n the United Kingdom installation, start-up, adjustments

I

and maintenance must be performed by a CORGI registered

installer in accordance with the installation standards currently in effect, as well as with any and all local health and

afety standards i.e. CORGI

s

.

In the Republic of Ireland the installation, and initial start-up

of the appliance must be carried out by a Competent Person

n accordance with the current edition of I.S.813 “ Domestic

i

Gas Installations”, and the current Building Regulations, reference should also be made to the current ETCI rules for

electrical installation.

Improper installation may cause damage or injury to individuals,

animals and personal property, for which the manufacturer will

not be held liable.

o ensure efficient and safe operation and to maintain the 5 year

T

guarantee, the appliance

MUST be serviced annually by a compe-

tent person and the MTS Servicing schedule completed and

returned to MTS GB Limited.

f it is known or suspected that a fault exists on the appliance, it

I

must not be used until the fault has been corrected by a competent person.

Helpful Suggestions

To get the most out of your boiler, we have provided you with some useful advice on proper use and maintenance:

RFFI SYSTEM

FILLING LOOP

Filling Instructions

- Periodically check the system pressure using the pressure gauge “F”

and make sure that the pressure is between 1.0 and 1.5 bar when the

system is off and cool. If the pressure is below the minimum recommended value, the pressure must be brought into the acceptable

range. To refill the system, it will be necessary to connect the flexible

“P” to the cold water inlet and central heating flow connections

hose

(two black quarter turn handles underneath the boiler), then, open the

F

two black quarter turn handles, water will now be heard passing into

the appliance and the black needle on the pressure gauge will start

to rise. Once the pressure gauge

“F” reads 1.5 bar close the valves

again and disconnect the flexible hose.

If the pressure level drops on a frequent basis, it is likely that there is

a water leak in the system. If this is the case, your installer must

inspect the system.

NOTE:ON RFFI MODELS,THE INSTALLER MAY HAVE FITTED A REMOTE FILLING

LOOP THAT MAY NOT RESEMBLE THAT SHOWN IN

P

- The outer panels of the boiler's case must only be cleaned with a

DIAGRAM P.

damp cloth, do not use abrasive cleaners. The control panel can be

wiped with either a damp or dry cloth. Spray polishes must not be

used on the control panel surface or knobs. Care must be taken in

preventing any liquid entering the appliance.

- If the water is exceptionally hard, install a water softener so that the

efficiency of the boiler remains the same over time, as this will consume less gas.

- To improve comfort levels and take full advantage of the heat produced by the boiler, it is necessary that a room thermostat and an outdoor sensor be installed.

- When the boiler is not in use for prolonged periods shut it down by

pushing the button to the off position and close the gas and

ater isolation v

w

tant!)

Impor

(

period of disuse is v

alves.

This will disab

y cold it will also be necessar

er

le the anti-frost device (see page 9) - if the

ain the heat-

y to dr

ing system of water.

If you wish to leave the anti-frost device active, it is necessary to leave

the boiler on:

y impair this function.

ma

this will not saf

eguard from possib

le interventions which

- It is good practice to clean and service the appliance and Central

Heating System every year.

Call a

CORGI registered gas installer.

6

Page 7

Adjusting the heating

t is possible to set the temperature of the Central Heating system

I

by adjusting the knob

“C”. By positioning the indicator somewhere between 1 and 6, a temperature may be obtained which

varies from approximately 38˚C to about 82˚C.

he water temperature in the primary circuit is shown on the dis-

T

play.

M

N

Start-up Procedure

Before starting the boiler, check the following:

- The water pressure on the pressure gauge “F” is between 1 and

1.5 bar;

- That the external gas cock

“M” and “N” and the inlet for domestic

water are open.

hese models are equipped with electronic ignition (there is no pilot

T

light).

To switch the boiler on, push the button. Turn the knob

A

the summer

nit will automatically light the main burner when needed without any

u

“ ” or winter position; a centralised electronic control

“C” to

intervention from the outside (green LED “A” will illuminate when the

burner is on).

f the burner does not light within the pre-set safety time limit, the dis-

I

play will show an error code and the red LED “H” will illuminate.

o reset the ignition system, the reset button must be pressed.

H

T

Should the system fail to light a second time, check to make sure that

the gas cock is open. If the problem persists, contact the Customer

Service Helpline.

summer

w

inter

Winter and Summer Operating Modes

In the “Winter”

operating mode, the boiler will produce both

Central Heating and Domestic Hot Water. In the “

Summer” operating mode, the boiler will produce only Domestic Hot Water.

Using the knob on the control panel, the user can select “winter”

or “summer” operating mode. Keeping the knob

“C” at the “ ”

position selects the “summer” operating mode. “Winter” operating

mode may be selected by positioning the knob “C” between the

C

C

min. and max. settings.

Note: The

“Summer” mode is only available for MFFI models.

External (room) thermostat control

C

If an external (room) thermostat is installed, it is recommended

that the temperature of the Central Heating system be set by

means of the knob

“C”, leaving it at max in order to obtain the

best performance from the boiler and to allow the regulation of the

room temperature to function efficiently.

Setting the hot water for domestic use (MFFI only)

C

Both in the winter and summer mode, the temperature of the

Domestic Hot Water may be adjusted by using knob

“E”. A delivery temperature for the water may be chosen in a range from 36˚C

to about 56˚C

, depending on the flo

position of the knob betw

o increase w

T

ater flo

the w

ater temper

w rate at the tap

w rate of the w

een the min. and max. settings.

, turn knob

ature

“E” to max. and reduce

.

ater and the

The water temperature in the primary circuit is shown on the

y.

displa

E

Comfort Function (MFFI only)

The supply of water for domestic use can become more conven-

y means of the

ient b

secondar

xchanger at a preset temper

y e

“COMFORT”function, which maintains the

ature when the boiler is

not running; thereby allowing a quicker delivery of domestic water

when required. This function is activated by pressing

the button on the control panel. When the function is on, a

y

ello

w L.E.D

.

“G” on the control panel will illuminate

.

7

Page 8

Note: If the “COMFORT” function is on during the pump overrun

G”

eriod, it will be temporarily deactivated. The yellow L.E.D.

p

“

will remain on to indicate that the boiler will resume the “COMFORT” mode once the pump overrun period is complete.

Periodic operation of the appliance will occur regardless of

emand on the boiler. This function is normal operation.

d

The COMFORT mode will automatically de-activate in low water

usage periods i.e. overnight. Turning on a tap will re-activate the

G

function.

Turning Off the Heating

nstallation without a room thermostat:

I

To turn off the heating, turn the selector knob “C” to “ ”. The

boiler will still provide domestic hot water.

nstallation with a room thermostat:

C

I

To turn off the heating, turn the selector knob “C” to “ ”. The

boiler will still provide hot water for domestic use. With a room

thermostat, turn the dial of the thermostat down to the lowest set-

ing.

t

Turning off the boiler

To turn the boiler off, push the button ; the display will go

off.

LEFT

RIGHT

Display: Viewing Normal Functions

When the system is operating, i.e. while the boiler is fulfiling its normal

functions, the left-hand display will show a letter indicating the following functions:

0

0

No Request for Heat (Stand By)

C

C

Central Heating

c

c

Pump Overrun for Heating

d

d

Domestic Hot Water

h

h

Pump Overrun for Domestic Hot Water

The right-hand display (two-digit) shows:

- in heating mode: temperature of heating system flow;

in domestic hot w

-

ater mode: temperature of the DHW leaving

the boiler (MFFI only)

Boiler Shutdown

The boiler is equipped with safety devices which intervene in

certain situations to shutdown the boiler. Some of these situations are signalled by the boiler and can be corrected by the

user.

8

Page 9

4. USEFUL INFORMATION

Shutdown Due to Ignition Failure

his anomaly is indicated by “A01”on the display. To reset the

T

boiler, press and then release the reset button .

At this point, the electronic ignition system will attempt to light the

burner again.

hould the boiler fail to ignite a second time, check that the

S

external gas cock is open. If the problem persists, contact an

Authorised Service Centre.

hutdown Due to Overheating

S

This anomaly is indicated by “A 03” on the display. The boiler has

shutdown because the safety thermostat detected that the boiler

temperature has exceeded the maximum limit.

o reset this state, wait until the boiler has cooled and press

T

the button.

If the safety thermostat operates on a frequent basis, contact an

Authorised Service Centre.

Shutdown Due to Insufficient Water Circulation

This anomaly is indicated by “A 02” on the display.

One of the possible causes of this shutdown situation could be the

ack of water in the boiler or water circulation failure in the primary

l

heating circuit.

Check the system pressure on the pressure gauge

“F” and, if it is

less than 0.5 bar, try bringing the system pressure up to a mean

value of 1.0 bar by opening the water inlet valve (see page 6 for

further instructions). Then reset by pressing the button.

Other Shutdown Situations

Should a shutdown situation indicated on the left display by the

letter E (E 04, E 05, E06, .....etc.) occur, contact an Authorised

Service Centre.

If instead the display shows one of the shutdown situations indicated by the following letters and figures, A 07, A 33, A 97, A 98,

A 99, try resetting the boiler by pressing the reset button . If

the boiler shuts off again, contact an Authorised Service Centre.

Anti-frost device

The anti-frost function acts on the central heating flow temperature probe, independently from other regulations, when the electrical supply is turned on.

If the primary circuit temperature falls below 8°C the pump will run

for 2 minutes.

After the two minutes of circulation (fixed) the boiler will check the

following:

a) if the central heating flow temperature is > 8°C, the pump stops;

b) if the central heating flow temperature is between 3 and 8°C,

or another two minutes;

the pump will r

un f

c) if the central heating flow temperature is < 3°C, the burner will

fire (heating position) at minimum power until the temperature

reaches 33°C, the burner will go out and the pump will continue to

run for two minutes.

If the flow temperature remains between 3-8°C the pump will continue to run for two minutes for a maximum of 10 times unless a

temperature above 8°C is detected in the central heating flow,

after this the the burner will fire.

If lockout is caused by overheat the burner is kept OFF.

NOTE: In all cases, the circulation takes place in the central

heating system.

The anti-frost device activates only when (with the boiler operating correctly):

- the system pressure is correct;

- the boiler is electr

ically pow

ered;

- there is a supply of gas.

IMPORTANT!

THE

O

T

DUE

ODUCE

PR

ATION FOR A CONDENSING BOILER.

HIGH EFFICIENCY

CONDENSED

PLUMES

OF

NA

TURE

W

TER VAPOUR

A

OF THE APPLIANCE

, THIS

, THE

NORMAL

IS

FLUE

WILL

OPER

-

9

Page 10

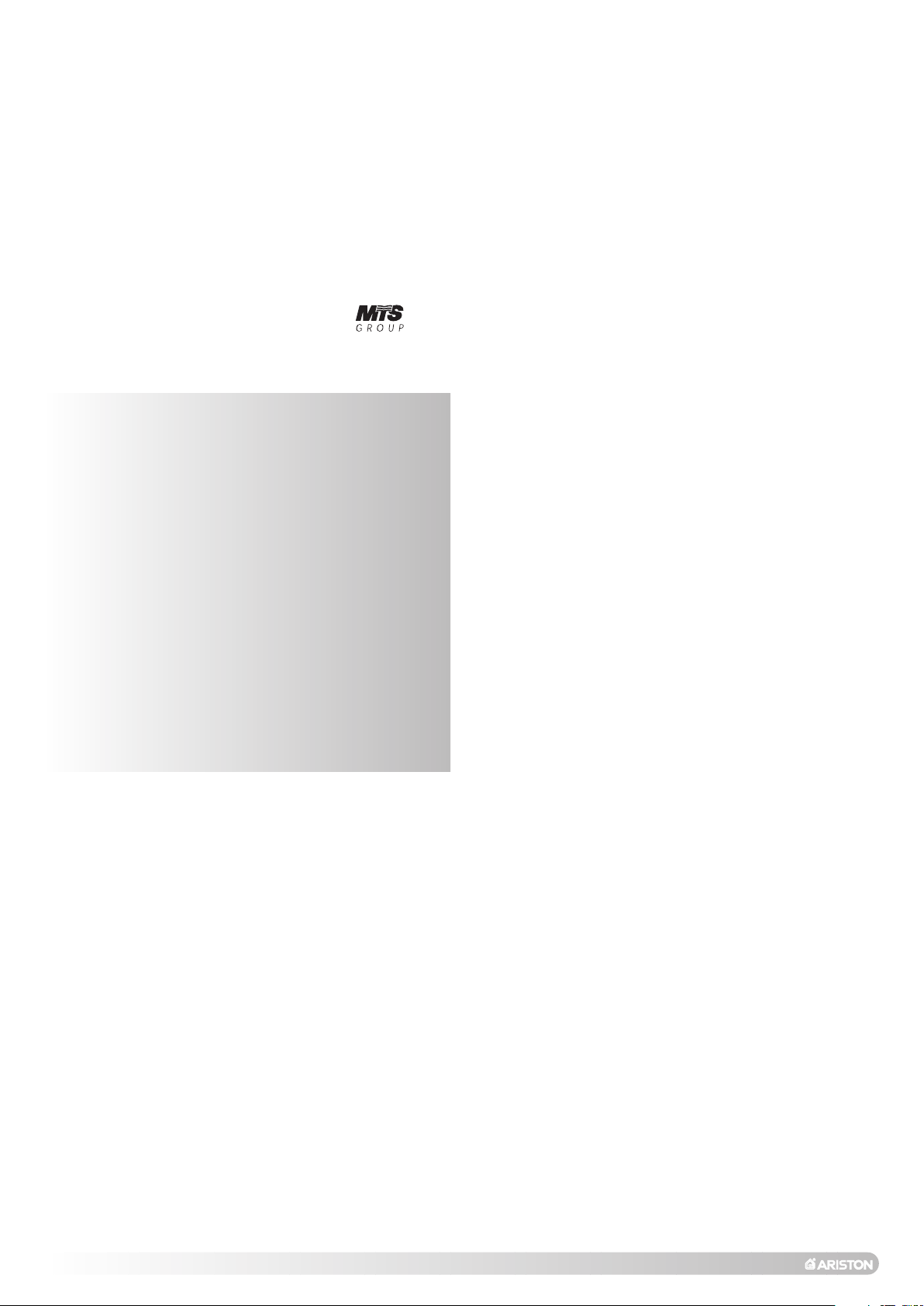

5.TIME CLOCK

P

r

o

g

.

Day

Manual switch

Summer and

winter time

setting

Reset

Enter

weekday/s

Enter

the hours

Weekdays

flash

Enter

minutes

Enter

switching

times

Imput

time

Status

NOTE: the time clock is for central heating control only.

The time clock is provided with 96 switches, called riders, each of

which covers a time interval of 15 minutes (four per hour).

hen a rider is switched from the inside (off setting) to the outside

W

of the clock border (on setting), the circuit is closed (switch on) for

a period of 15 minutes and then the boiler starts if the room thermostat (if installed) or the heating thermostat require heat (heat-

ng function on).

i

EXAMPLE

To set the heating of your home in the time interval from 7.00

m to 8.00 am and from 7.00 pm to 10.00 pm every day (see

a

diagram):

- rotate the outer ring of the clock in a clockwise direction until the

correct time of day (24h) lines up with the arrow on the clock (at

approx. 2 o’clock position);

-

under no circumstances should the minute hand be moved

manually

;

- make sure all the switches, i.e. the riders, are placed on the

inside of the clock border;

- pull outward the riders for 7.00 am and 8.00 am, and then all riders between these two;

- repeat this for 7.00 pm and 10.00 pm.

Other heating intervals may be set in the same way.

The clock is provided with a selector switch with three positions

(see figure):

Position “I” CONSTANT: in this position, the clock circuit is

1.

always closed (switch on), therefore the boiler will constantly be

on and will only shut off upon the request of the room ther

mo-

stat (if installed) or the heating thermostat;

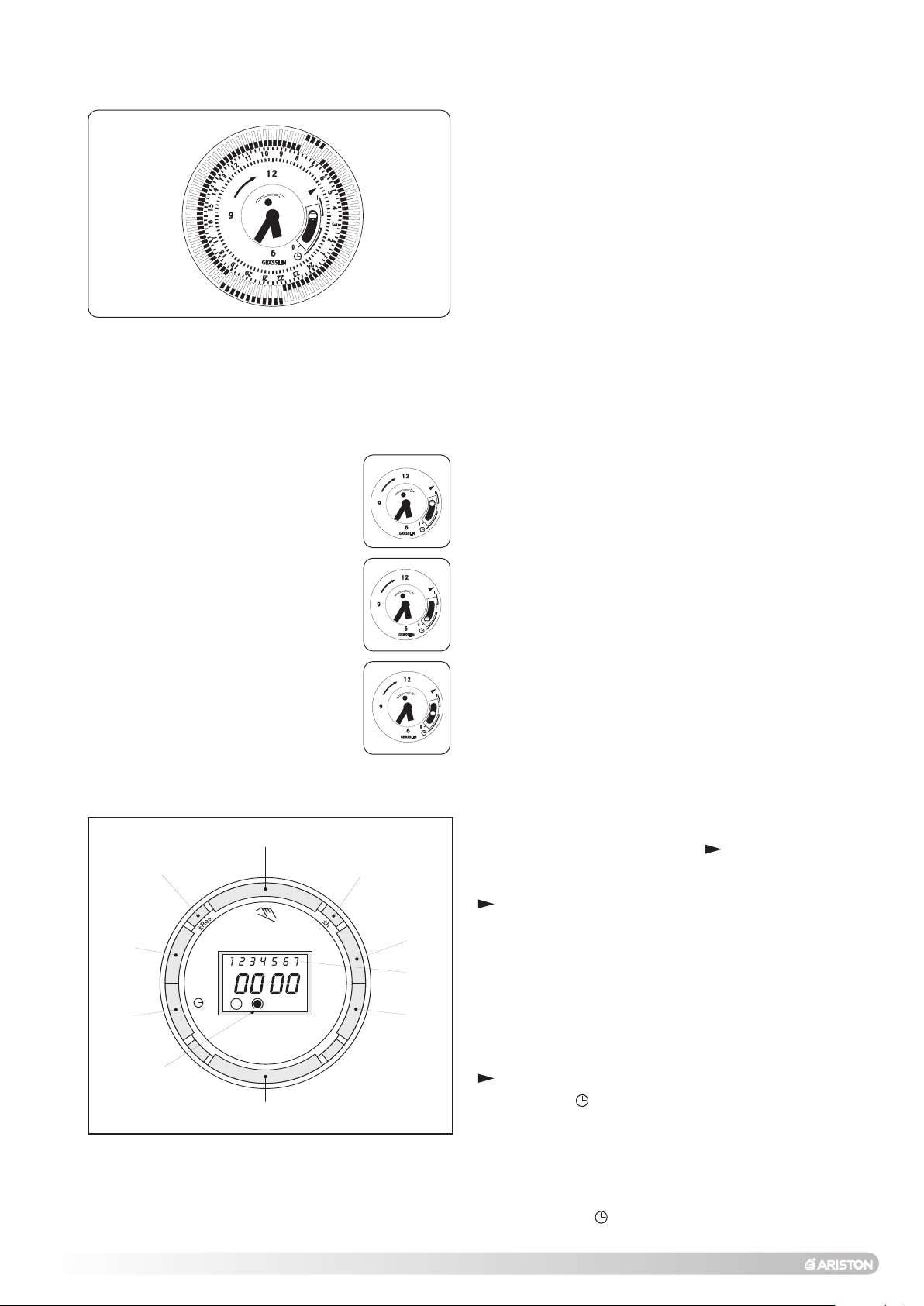

6. DIGITAL PROGRAMMER

Position “O” HEATING OFF: in this position, the clock circuit is

2.

always open (switch off) and the boiler will therefore never ignite

for heating;

3.

“Central” Position

PROGRAMMING ACTIVE: in this position,

the programming set by the user is active.

Operating the time switch

The steps marked with the symbol “ ” are necessary to carry

out a switching program.

Preparing f

or Operation

Activate the “Res” switch (=RESET) to reset the time switch to

its default setting (activate using a pencil or similar pointed

instrument). Do this:

- every time you wish to “reset” the time switch

- to erase all switching times and the current time of day.

After approximately two seconds the following display

appears:

10

Enter current time and weekday

- Keep the “ ” key pressed down

During the summer time period press the +/- 1h key once.

Enter the hour using the “h” key

Enter the minutes using the “m” key

Enter the day using the “Day” key

1 =

“Monda

y”..............7 = Sunda

y

- Release the “ ” key.

Page 11

Changing the programmed switching times

Press the “Prog” key repeatedly until the switching time you want

to change is displayed.You can now enter the new data. See point

“

Entering the switching times”.

otes on storing switching times:

N

f you end your entry of the switching times by pressing the “Prog”

I

key, then the switching time you have entered will be stored and

the next memory location displayed.

ntering the switching times

E

You have 20 memory Iocations available. Each switching time

takes up one memory location.

Keep pressing the “Prog” key until a free memory location is

shown in the display “– –:– –”.

Programme ON or OFF with the “ ” key:

“ ”= OFF; “ ”= ON

Enter the hour using “h”

Enter the minutes using “m”

If a switching command is to be carried out every day (1 2 3

4 5 6 7) then store using the “ ” key, otherwise select the

day(s) it is carried out by using the “Day” key.

When the day seIection is left bIank, the programmed switching instruction operates at the same time every day

1 2 3 4 5 6 = Monday – Saturday

1 2 3 4 5 = Monday – Friday

6 7 =Saturday – Sunday

In addition, a complete switching command is stored

after around 90 seconds provided no other key is pressed.

cally

The time switch then enters the automatic operating mode and

isplays the current time again.

d

eleting individual switching times

D

ress the “Prog” key repeatedly until the switching time you wish

P

to delete is shown in the display. Then set to “– –” using the “h” or

“m” key and keep the “ ” key pressed down for around 3 seconds.The switching time is now erased and the current time is dis-

yed.

pla

AM / PM time display

ou press the “+/-1h” and “h” keys at the same time, the time dis-

If y

play switches into the AM/PM mode.

automati-

Selection of single days: 1 = Mon. .............. 2 =Tues.

Save the switching time with the “ ” key.

The time switch enters the automatic operating mode and displays the current time of day.

Begin any further entry of a switching time with the “Prog”

If your entry is incomplete, the segments not yet

witch.

s

After prog

selected will b

pleted, and you return the time clock to the current time display with the “ ” key, the time clock will not activate any

switching instruction required for the current time. You may

need to manually select the desired switching state with the

“ ” key. Thereafter, as the unit encounters further switching instructions in the memor

vate all subsequent switching instructions.

ual Override Switch

Man

With the “ ” you can change the current setting at any time.The

switching program already entered is not altered.

Reading the programmed switching times

Pressing the “Prog” key displays the programmed switching times until

the first free memor

If you now press the “Prog” key once again, the number of free

y Iocations will be displa

memor

tions are occupied, the display “

link in the display

“

y location appears in the displa

.

y in real time

”

yed, e.g. “

00” appears.

ramming is com-

, it will correctly acti

– –”.

“– – :

y

If all memor

18”.

y loca-

-

11

Page 12

acturer:

uf

Man

Commercial subsidiaries: MTS (GB) Limited MTS Heating Limited

Merloni

MTS Building Damastown Industrial Park

Hughenden A

High

Bucks HP13 5FT Dublin 15

Telephone: (01494) 755600 Telephone: (01) 810 3723

ax:

F

Internet: www.mtsgroup.com/uk Internet: www.mtsgroup.com/ie

E-mail: info@uk.mtsgroup.com E-mail: info@ie.mtsgroup.com

ec

T

Customer Ser

ermoSanitari SpA - Italy

T

venue Damastown Avenue

ycombe

W

(01494) 459775

0870 241 8180

hnical Ad

vice:

vice:

0870 600 9888 Customer Service: (01) 437 0121

Mulhuddart

ax: (01) 810 3727

F

hnical Ad

ec

T

vice:

(01) 437 0121

099841833112

Loading...

Loading...