Ariens 91140300 (2000-999999) Owner’s Manual

Wide Area Walk Mower

Owner/Operator Manual

Manuel du Proprietaire/Utilisateur

Models

911403 - WAW 1034

911407 - WAW 1034 CARB

ENGLISH

FRENCH

01290700A 8/09

Printed in USA

/ q:! :] III::1[o]_l [o[o] _,/ / :1_,/ Ig_

Safety ........................... 4

Assembly ........................ 9

Controls and Features ............. 11

Operation ....................... 12

Maintenance ..................... 16

Service and Adjustments .......... 19

II_Imd;[o]_lll[o,]ij[o] _I

Storage ......................... 23

Troubleshooting .................. 24

Service Parts .................... 25

Accessories ..................... 25

Specifications ................... 26

Warranty ........................ 27

NON-ENGLISH MANUALS

Manuals in languages other than

English may be obtained from

your Dealer. Visit your dealer or

w_v.ariens.com for a list of

languages available for your

equipment.

Manuals printed in languages

other than English are also

available as a free download on

our website:

http://www.ariens.co m

MANUALES EN IDIOMAS

DIFERENTES DEL INGLES

Puede obtener manuales en

idiomas diferentes del ingles en su

distribuidor. Visite a su distribuidor

o vaya a w_v.ariens.com para

obtener una lista de idiomas

disponibles para su equipo.

Tambien puede imprimir manuales

en idiomas diferentes del ingles

descargandolos gratuitamente de

nuestra pagina Web:

htt p://www.ariens.co m

MANUELS NON ANGLAIS

Des manuels dans differentes

langues sont disponibles chez

votre revendeur. Rendez-vous

chez votre revendeur ou allez sur

le site w_v.ariens.com pour

consulter la liste des langues

disponibles pour votre equipement.

Les manuels imprimes dans des

langues differentes de I'anglais

sont egalement disponibles en

t61echargement gratuit sur notre

site Web :

htt p://www.ariens.co m

THE MANUAL

Before using the unit, carefully and

completely read your manuals. The contents

will give you an understanding of safety

instructions and controls during normal

operation and maintenance.

All reference to left, right, front, or rear are

given from the operator's position, facing the

direction of forward travel.

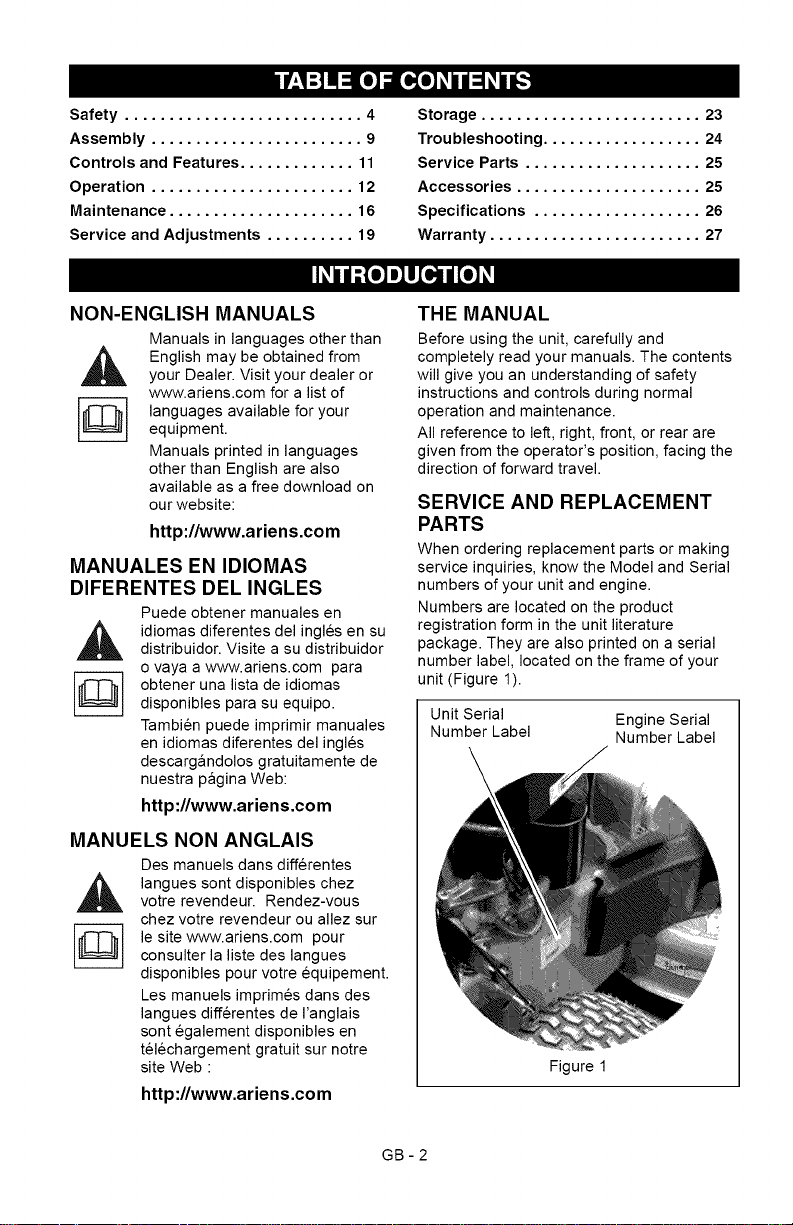

SERVICE AND REPLACEMENT

PARTS

When ordering replacement parts or making

service inquiries, know the Model and Serial

numbers of your unit and engine.

Numbers are located on the product

registration form in the unit literature

package. They are also printed on a serial

number label, located on the frame of your

unit (Figure 1).

Unit Serial Engine Serial

Number Label Number Label

Figure 1

GB-2

•RecordUnitModelandSerialnumbers

here:

l ]

• Record Engine Model & Serial numbers

here:

[ J

PRODUCT REGISTRATION

The Ariens dealer must register the product

at the time of purchase. Registering the

product will help the company process

warranty claims or contact you with the latest

service information. All claims meeting

requirements during the limited warranty

period will be honored, whether or not the

product registration card is returned. Keep a

proof of purchase if you do not register your

unit.

Customer Note: If the Dealer does not

register your product, please fill out, sign and

return the product registration card to Ariens

or go to www.ariens.com on the internet.

UNAUTHORIZED REPLACEMENT

PARTS

Use only Ariens replacement parts.

Replacing any part on this vehicle with

anything other than an Ariens authorized

replacement part may adversely affect the

performance, durability, or safety of this unit

and may void the warranty. Ariens disclaims

liability for any claims or damages, whether

warranty, property damage, personal injury or

death arising out of the use of unauthorized

replacement parts. To locate your nearest

Ariens Dealer, go to www.ariens.com on the

internet.

DEALER DELIVERY

Dealer should:

1. Check that all assembly and

adjustments have been properly

completed.

2. Fill out Original Purchaser Registration

Card and return the card to Ariens.

3. Explain Ariens Limited Warranty Policy.

4. Explain recommended lubrication and

maintenance. Advise customer on

adjustments. Remind customer to

change oil in 4 cycle engine crankcase

after first five (5) hours of operation.

5. Instruct customer on controls and

operation of unit. Discuss and

emphasize the Safety Rules. Give

customer Owner/Operator, Parts, and

Engine manuals. Advise customer to

thoroughly read and understand them.

DISCLAIMER

Ariens reserves the right to discontinue,

make changes to, and add improvements

upon its products at any time without public

notice or obligation.The descriptions and

specifications contained in this manual were

in effect at printing. Equipment described

within this manual may be optional. Some

illustrations may not apply to your unit.

GB-3

[,:'Y-,1_1=1i'i

WARNING: This cutting machine

,&

is capable of amputating hands

and feet and throwing objects.

Failure to observe the safety

instructions in the manuals and

on decals could result in serious

injury or death.

Slopes are a major factor related

to slip and fall accidents.

Operation on all slopes requires

extra caution.

Tragic accidents can occur if the

operator is not alert to the

presence of children. Never

assume that children will remain

where you last saw them.

Gasoline is extremely flammable

and the vapors are explosive,

handle with care.

Stop unit and engine, remove key

(if equipped) and allow moving

parts to stop before leaving

operator's position.

SAFETY ALERTS

Look for these symbols to point

,_ out important safety precautions.

The safety alert symbols above and signal

words below are used on decals and in this

manual.

Read and understand all safety messages.

They mean:

Personal Safety Is Involved!

Attention!

Become Alert!

Obey The Message!

CAUTION: POTENTIALLY

A

HAZARDOUS SITUATION! If not

avoided, MAY RESULT in minor or

moderate injury. It may also be

used to alert against unsafe

practices.

NOTATIONS

NOTE: General reference information for

proper operation and maintenance practices.

IMPORTANT: Specific procedures or

information required to prevent damage to

unit or attachment.

PRACTICES AND LAWS

Practice usual and customary safe working

precautions, for the benefit of yourself and

others. Understand and follow all safety

messages. Be alert to unsafe conditions and

the possibility of minor, moderate, or serious

injury or death. Learn applicable rules and

laws in your area.

REQUIRED OPERATOR

TRAINING

Original purchaser of this unit was instructed

by the seller on safe and proper operation. If

anyone other than the original purchaser will

use the unit, ALWAYS provide this manual

and any needed safety training before

operation.

DANGER: IMMINENTLY

HAZARDOUS SITUATION! If not

avoided, WILL RESULT in death or

serious injury.

WARNING: POTENTIALLY

HAZARDOUS SITUATION! If not

avoided, COULD RESULT in

death or serious injury.

GB-4

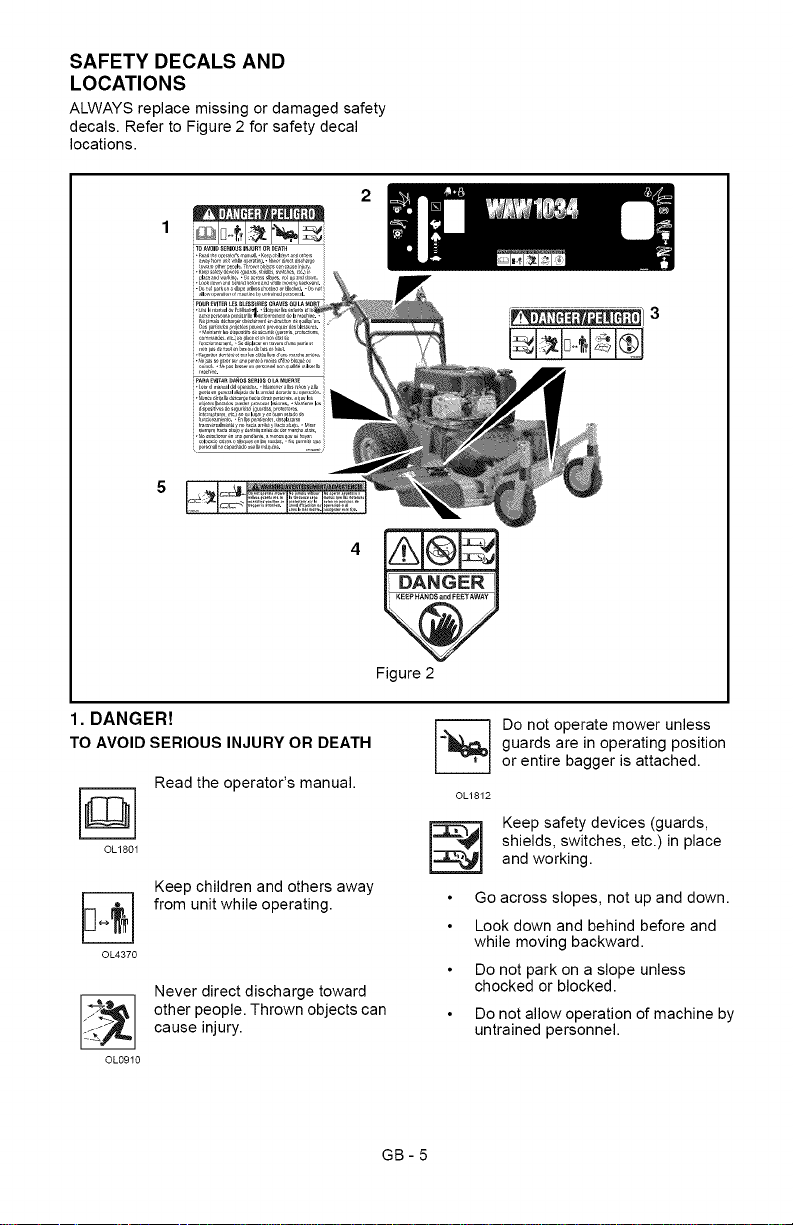

SAFETY DECALS AND

LOCATIONS

ALWAYS replace missing or damaged safety

decals. Refer to Figure 2 for safety decal

locations.

1

1. DANGER!

TO AVOIDSERIOUS INJURYOR DEATH

Read the operator's manual.

OL180I

Keep children and others away

from unit while operating.

©L4370

Never direct discharge toward

other people. Thrown objects can

cause injury.

OL0910

Figure 2

GB-5

guards are in operating position

=] o not operate mower unless

or entire bagger is attached.

©L1812

shields, switches, etc.) in place

Keep safety devices (guards,

and working.

Go across slopes, not up and down.

Look down and behind before and

while moving backward.

Do not park on a slope unless

chocked or blocked.

Do not allow operation of machine by

untrained personnel.

2. WARNING!

Read the operator's manual.

OL180I

4. DANGER!

KEEP HANDS AND FEET AWAY

Do not operate mower unless guards are in

operating position or bagger is attached.

5. WARNING!

Keep children and others away

from unit while operating.

©L4370

Never direct discharge toward

other people. Thrown objects can

cause injury.

OL0910

Shut off engine, remove key, and

read manual before you adjust or

repair unit.

©L1812

Wear appropriate hearing

protection.

3. DANGER! ROTATING PARTS

Always keep feet and hands

away from rotating parts.

OL1809

Always stand clear of discharge

area. Do not direct discharge

toward other people.

Keep people away from unit

while operating.

Shut off engine, remove key,

and read manual before you

adjust or repair unit.

©L1812

¢_ AIwaySarea.stand clearofdischarge

©L1814

÷ Do not operate mower unless

bagger is attached or guards

are in operating position.

OLI815

SAFETY RULES

If unit is to be used by someone other than

original purchaser; loaned, rented or sold,

ALWAYS provide this manual and any

needed safety training before operation.

Learn applicable rules and laws in your area,

including those that may restrict the age of

the operator.

Read, understand and follow all safety

practices in Owner/Operator Manual before

beginning assembly. Failure to follow

instructions could result in personal injury

and/or damage to unit.

If the operator or the mechanic cannot read

the manual, it is the owner's responsibility to

explain it to them. Only the user can prevent

and is responsible for accidents or injuries

occurring to themselves, other people or

property.

ALWAYS remove key (if equipped) and

disconnect wire from spark plug before

assembly. Unintentional engine start up can

cause death or serious injury.

Complete a walk around inspection of unit

and work area to understand:

work area

your unit

all safety decals.

Clear work area of stones, sticks, wire and

foreign objects which might be picked up and

thrown. Tall grass can hide obstacles.

Know the work area. Stay alert for holes,

rocks, rough terrain and hidden hazards.

®

OL1813

NO STEP! Always keep feet

away from rotating parts.

Keep away from drop-offs, ditches, or

embankments that could cause operator to

lose footing or control of unit.

ALWAYS be aware of traffic when operating

along streets or curbs.

GB-6

Keepworkareaclearofallpersons,children

andpets.

Keepchildrenoutoftheworkareaandunder

thewatchfulcareofaresponsibleadult.

ALWAYSoperateunitwhenthereisgood

visibilityandlight.

DONOTmowwetgrass.

ALWAYSbesureofyourfooting.Keepafirm

holdonhandlebar.Walk,NEVERrun.

Engine/bladecontrolfeatureonmowerstops

engineandbladewithin5secondswhenever

operatorreleasesPTOlever.Checkthis

featurefrequently.Iffeaturefailstooperate,

disconnectsparkplugwireandadjustorhave

itrepairedbeforeusingunit.

Onlytrainedadultsmayoperateorservice

unit.Trainingincludesactualoperation.The

ownerisresponsiblefortrainingusers.

NEVERoperateafterorduringtheuseof

medication,drugsoralcohol.Unitrequires

completeandunimpairedattention.

NEVERallowchildrentouseorservice

mower.

ALWAYSkeephandsandfeetawayfrom

rotatingparts.Rotatingpartscancutoffbody

parts.

ALWAYSkeephandsawayfrompinchpoints.

Fumesfromengineexhaustcancausedeath

orseriousinjury.DONOTrunengineinan

enclosedarea.

ALWAYSprotecteyes,face,andbodywith

adequatesafetygearandprotectiveclothes.

Wearsturdyfootwear,gloves,ahardhatand

safetygogglesorsafetyglasseswithside

shieldswhileoperatingmower.

Wearappropriatehearingprotection.

NEVERoperatemowerbarefootorwhen

wearingopensandalsorcanvasshoes.

NEVERwearlooseclothes,longhairor

jewelrythatmaygetcaughtinrotatingparts.

ALWAYSstandclearofdischargewhen

operatingunit.

NEVERdirectdischargetowardbystanders.

Operatorisresponsibleforbystandersafety.

DONOTtouchhotparts.Allowpartstocool.

Keepsafetydevicesorguardsinplaceand

functioningproperly.NEVERmodifyor

removesafetydevices.

Read,understand,andfollowallinstructions

inthemanualandonthemachinebefore

starting.Understand:

Howtooperateallcontrols

Thefunctionsofallcontrols

HowtoSTOPinanemergency.

DONOTattempttostartyourengineuntil

youknowwhatthecontrolsdoandhowthey

work.

DONOTtiltmowerwhenstartingit.

Keepfeetawaywhenstartingengine.

DONOTstarttheengineoroperatemower

withoutsidedischargecoverorside

dischargedeflectorinstalled.

Neverleavearunningunitunattended.

Takeallpossibleprecautionswhenleaving

unitunattended.

ALWAYSshutoffengine,removekey

(electricstartmodels)anddisconnectspark

plugwiretopreventaccidentalstartingor

unauthorizeduse.

Stopengineifanyoneenterstheworkarea.

NEVERattempttomakeanyadjustmentsto

unitwhileengineisrunning(exceptwhere

specificallyrecommended).Stopengine,

removekey(electricstartmodels)andwait

forallmovingpartstostopbeforeservicing.

DONOTmakecuttingheightwheel

adjustmentswhiletheengineisrunning.

Ifyoustrikeanobject,orifequipment

vibratesabnormally,stopengineatonce,wait

formovingpartstostopanddisconnectwire

fromsparkplug.Repairanydamagebefore

restartingunit.

Stopenginebeforeremovingandemptying

grassbag.

Whenmulchingorbagging,ALWAYSinstall

dischargecover.

Whensidedischarging,ALWAYSinstallside

dischargedeflector.

ALWAYSshutoffengine,allowbladetostop

anddisconnectsparkplugwirebefore

clearingclogsorcleaningunit.

Checkgrassbagforwear,damage,and/or

deterioration.ReplaceonlywithAriens

originalequipmentreplacementpartsfor

safety.

Toreducefirehazardandoverheating,keep

equipmentfreeofgrass,leaves,debrisor

excessivelubricants.

Useextracarewhenapproachingblind

corners,shrubs,trees,orotherobjectswhich

mayobscurevision.

DONOTmowattoofastarate.DONOT

changeenginegovernorsettingorover-

speedtheengine.

Donotoperatemowerongravelorloose

materialsuchassand.Stopmowerwhen

crossingdrives,walks,orroadstoprevent

damageorinjuryfromthrownobjects.

GB-7

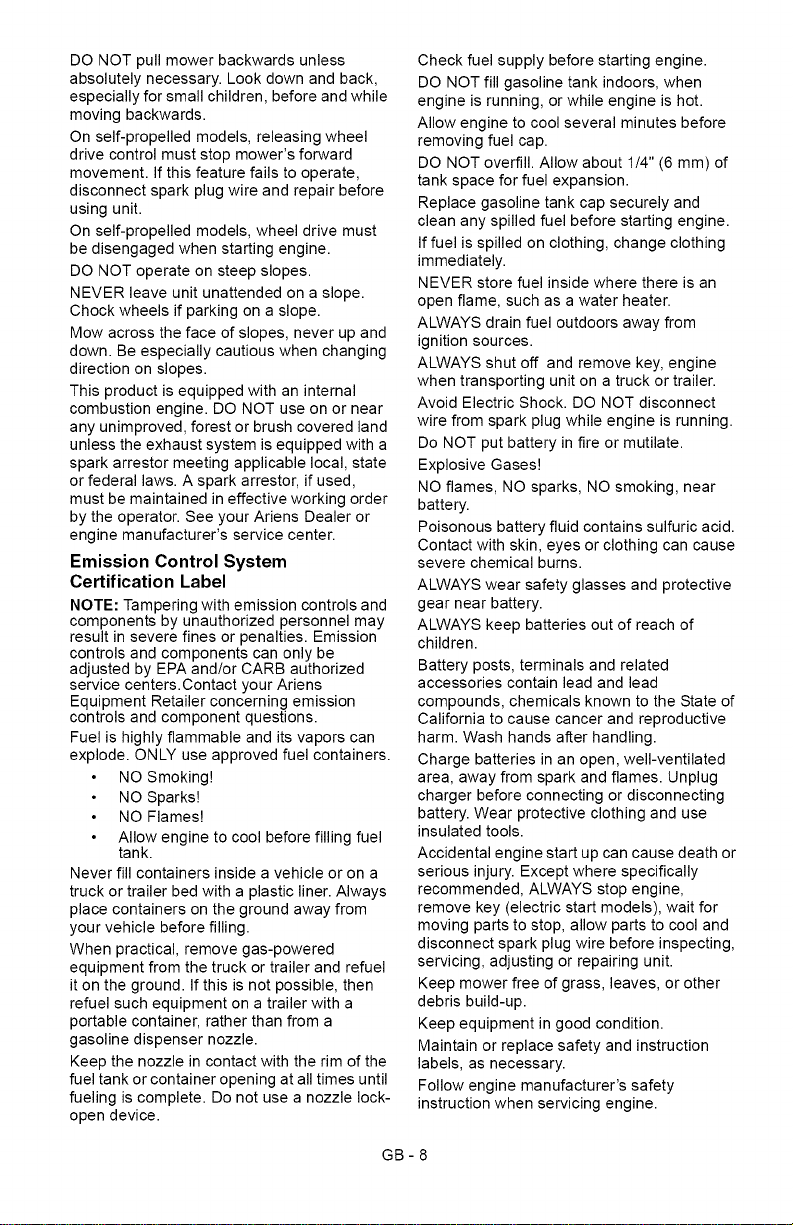

DONOTpullmowerbackwardsunless

absolutelynecessary.Lookdownandback,

especiallyforsmallchildren,beforeandwhile

movingbackwards.

Onself-propelledmodels,releasingwheel

drivecontrolmuststopmower'sforward

movement.Ifthisfeaturefailstooperate,

disconnectsparkplugwireandrepairbefore

usingunit.

Onself-propelledmodels,wheeldrivemust

bedisengagedwhenstartingengine.

DONOToperateonsteepslopes.

NEVERleaveunitunattendedonaslope.

Chockwheelsifparkingonaslope.

Mowacrossthefaceofslopes,neverupand

down.Beespeciallycautiouswhenchanging

directiononslopes.

Thisproductisequippedwithaninternal

combustionengine.DONOTuseonornear

anyunimproved,forestorbrushcoveredland

unlesstheexhaustsystemisequippedwitha

sparkarrestormeetingapplicablelocal,state

orfederallaws.Asparkarrestor,ifused,

mustbemaintainedineffectiveworkingorder

bytheoperator.SeeyourAriensDealeror

enginemanufacturer'sservicecenter.

EmissionControlSystem

CertificationLabel

NOTE:Tamperingwithemissioncontrolsand

componentsbyunauthorizedpersonnelmay

resultinseverefinesorpenalties.Emission

controlsandcomponentscanonlybe

adjustedbyEPAand/orCARBauthorized

servicecenters.ContactyourAriens

EquipmentRetailerconcerningemission

controlsandcomponentquestions.

Fuelishighlyflammableanditsvaporscan

explode.ONLYuseapprovedfuelcontainers.

NOSmoking!

NOSparks!

NOFlames!

Allowenginetocoolbeforefillingfuel

tank.

Neverfillcontainersinsideavehicleorona

truckortrailerbedwithaplasticliner.Always

placecontainersonthegroundawayfrom

yourvehiclebeforefilling.

Whenpractical,removegas-powered

equipmentfromthetruckortrailerandrefuel

itontheground.Ifthisisnotpossible,then

refuelsuchequipmentonatrailerwitha

portablecontainer,ratherthanfroma

gasolinedispensernozzle.

Keepthenozzleincontactwiththerimofthe

fueltankorcontaineropeningatalltimesuntil

fuelingiscomplete.Donotuseanozzlelock-

opendevice.

Checkfuelsupplybeforestartingengine.

DONOTfillgasolinetankindoors,when

engineisrunning,orwhileengineishot.

Allowenginetocoolseveralminutesbefore

removingfuelcap.

DONOToverfill.Allowabout1!4"(6mm)of

tankspaceforfuelexpansion.

Replacegasolinetankcapsecurelyand

cleananyspilledfuelbeforestartingengine.

Iffuelisspilledonclothing,changeclothing

immediately.

NEVERstorefuelinsidewherethereisan

openflame,suchasawaterheater.

ALWAYSdrainfueloutdoorsawayfrom

ignitionsources.

ALWAYSshutoffandremovekey,engine

whentransportingunitonatruckortrailer.

AvoidElectricShock.DONOTdisconnect

wirefromsparkplugwhileengineisrunning.

DoNOTputbatteryinfireormutilate.

ExplosiveGases!

NOflames,NOsparks,NOsmoking,near

battery.

Poisonousbatteryfluidcontainssulfuricacid.

Contactwithskin,eyesorclothingcancause

severechemicalburns.

ALWAYSwearsafetyglassesandprotective

gearnearbattery.

ALWAYSkeepbatteriesoutofreachof

children.

Batteryposts,terminalsandrelated

accessoriescontainleadandlead

compounds,chemicalsknowntotheStateof

Californiatocausecancerandreproductive

harm.Washhandsafterhandling.

Chargebatteriesinanopen,well-ventilated

area,awayfromsparkandflames.Unplug

chargerbeforeconnectingordisconnecting

battery.Wearprotectiveclothinganduse

insulatedtools.

Accidentalenginestartupcancausedeathor

seriousinjury.Exceptwherespecifically

recommended,ALWAYSstopengine,

removekey(electricstartmodels),waitfor

movingpartstostop,allowpartstocooland

disconnectsparkplugwirebeforeinspecting,

servicing,adjustingorrepairingunit.

Keepmowerfreeofgrass,leaves,orother

debrisbuild-up.

Keepequipmentingoodcondition.

Maintainorreplacesafetyandinstruction

labels,asnecessary.

Followenginemanufacturer'ssafety

instructionwhenservicingengine.

GB-8

Checkallhardwareatregularintervals,

especiallybladeattachmentbolts.Keepall

hardwareproperlytightened.

Anextensionspring,whenextended,stores

energyandcanbedangerous.Alwaysuse

toolsspecificallydesignedforinstallingor

removinganextensionspring.Always

compressorextendspringsslowly.

Beforetippingunit,removefuelandbattery(if

equipped).

Useextracarewhenloadingorunloading

unitontotrailerortruck.

Ensureallwheelblocks,jackstandsandtie

downswillsupportunitduringmaintenance.

Replaceworn-outmufflersimmediately.

Continuedusecouldresultinfireor

explosion.

Sharpedgescancutoramputatefingersora

hand.Wrapbladeorwearsturdyglovesto

service.

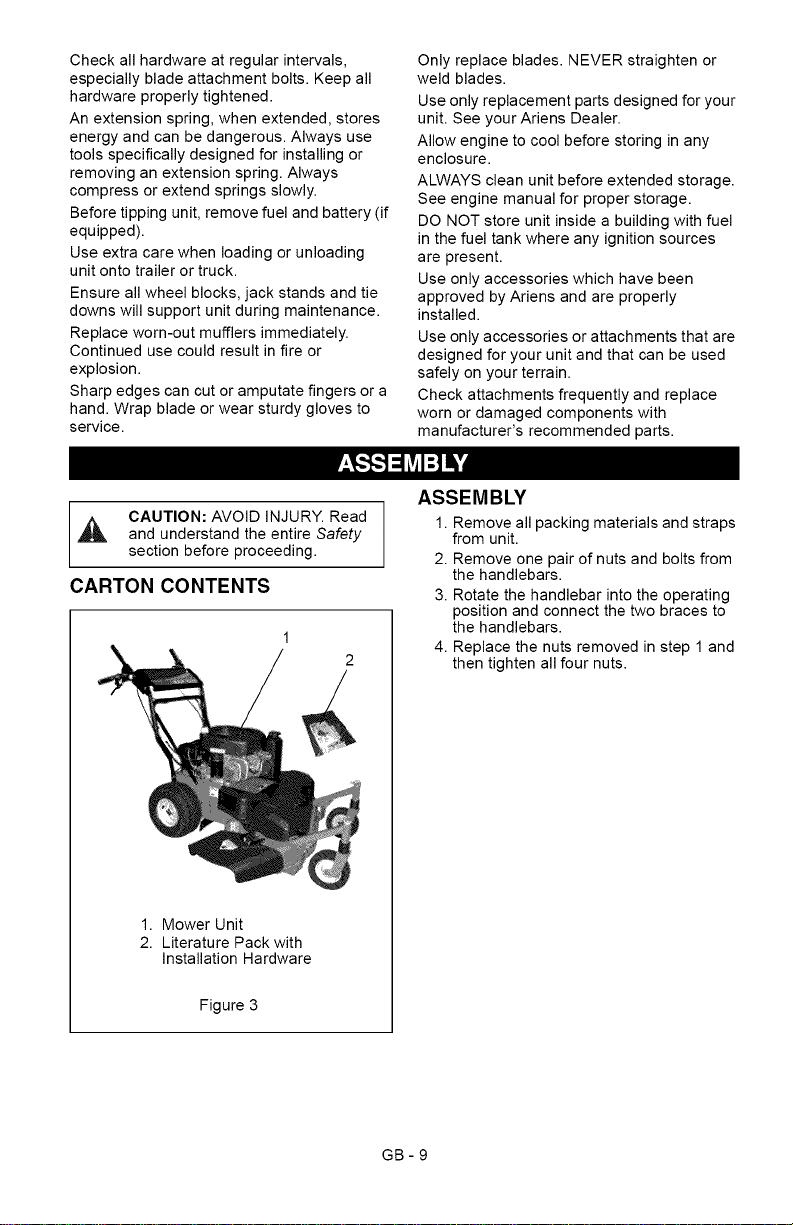

=1 i:] 4,d

CAUTION: AVOID INJURY. Read

and understand the entire Safety

section before proceeding.

CARTON CONTENTS

1

2

Onlyreplaceblades.NEVERstraightenor

weldblades.

Useonlyreplacementpartsdesignedforyour

unit.SeeyourAriensDealer.

Allowenginetocoolbeforestoringinany

enclosure.

ALWAYScleanunitbeforeextendedstorage.

Seeenginemanualforproperstorage.

DONOTstoreunitinsideabuildingwithfuel

inthefueltankwhereanyignitionsources

arepresent.

Useonlyaccessorieswhichhavebeen

approvedbyAriensandareproperly

installed.

Useonlyaccessoriesorattachmentsthatare

designedforyourunitandthatcanbeused

safelyonyourterrain.

Checkattachmentsfrequentlyandreplace

wornordamagedcomponentswith

manufacturer'srecommendedparts.

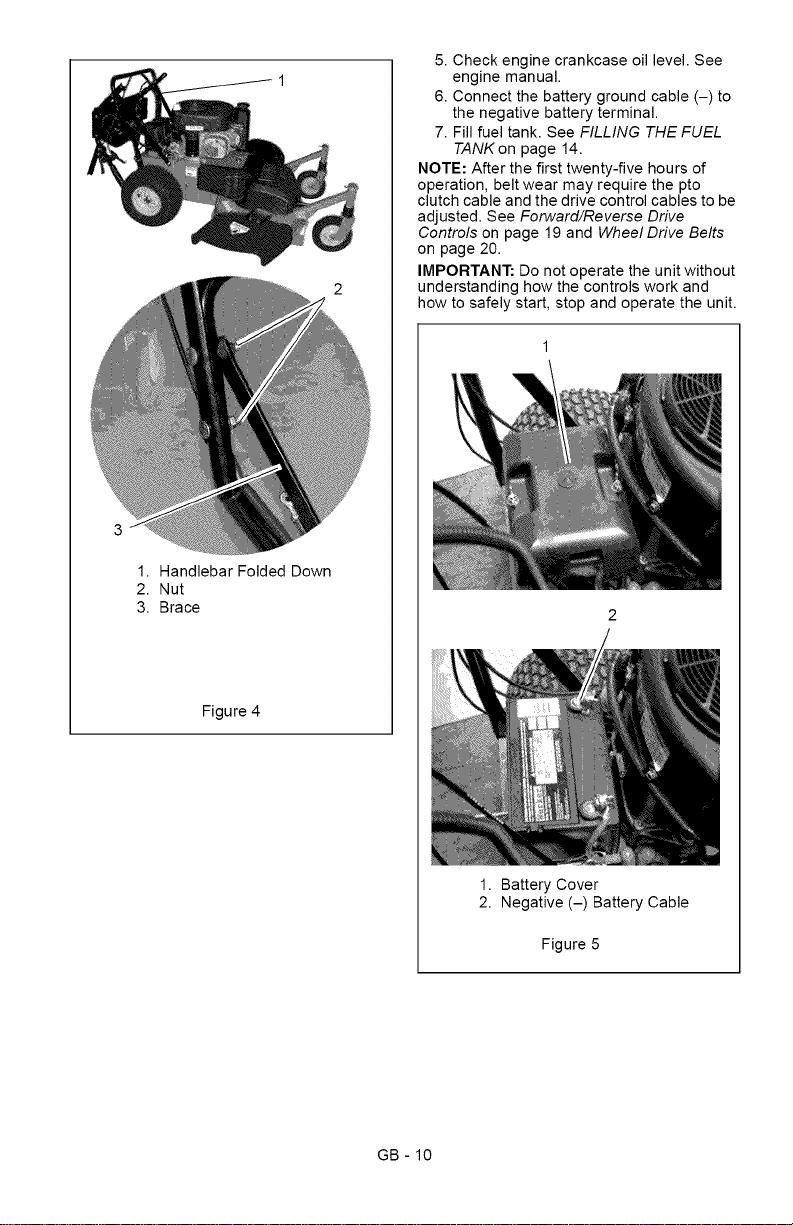

ASSEMBLY

1. Remove all packing materials and straps

from unit.

2. Remove one pair of nuts and bolts from

the handlebars.

3. Rotate the handlebar into the operating

position and connect the two braces to

the handlebars.

4. Replace the nuts removed in step 1 and

then tighten all four nuts.

1. Mower Unit

2. Literature Pack with

Installation Hardware

Figure 3

GB-9

1.HandlebarFoldedDown

2.Nut

3.Brace

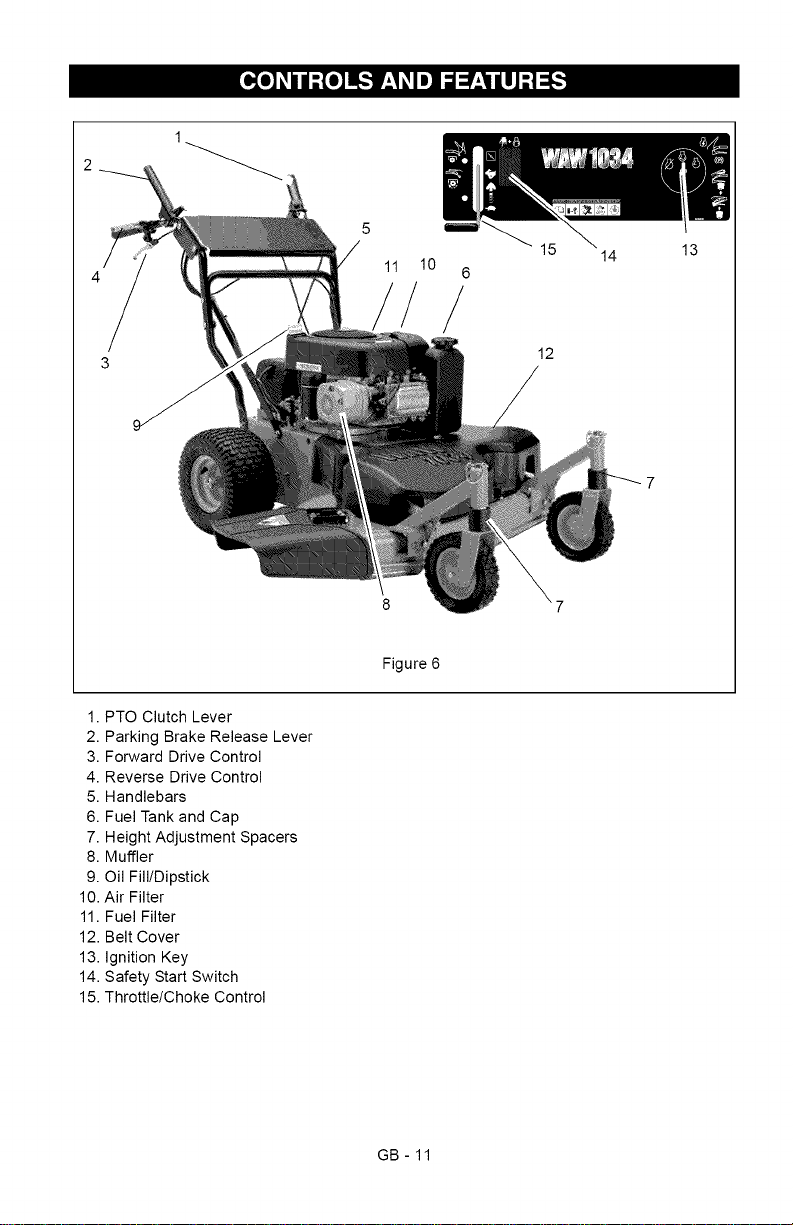

5.Checkenginecrankcaseoillevel.See

enginemanual.

6.Connectthebatterygroundcable(-)to

thenegativebatteryterminal.

7.Fillfueltank.SeeFILLING THE FUEL

TANKon page 14.

NOTE: After the first twenty-five hours of

operation, belt wear may require the pro

clutch cable and the drive control cables to be

adjusted. See Forward/Reverse Drive

Controls on page 19 and Wheel Drive Belts

on page 20.

IMPORTANT: Do not operate the unit without

understanding how the controls work and

how to safely start, stop and operate the unit.

Figure4

1. Battery Cover

2. Negative (-) Battery Cable

Figure 5

GB - 10

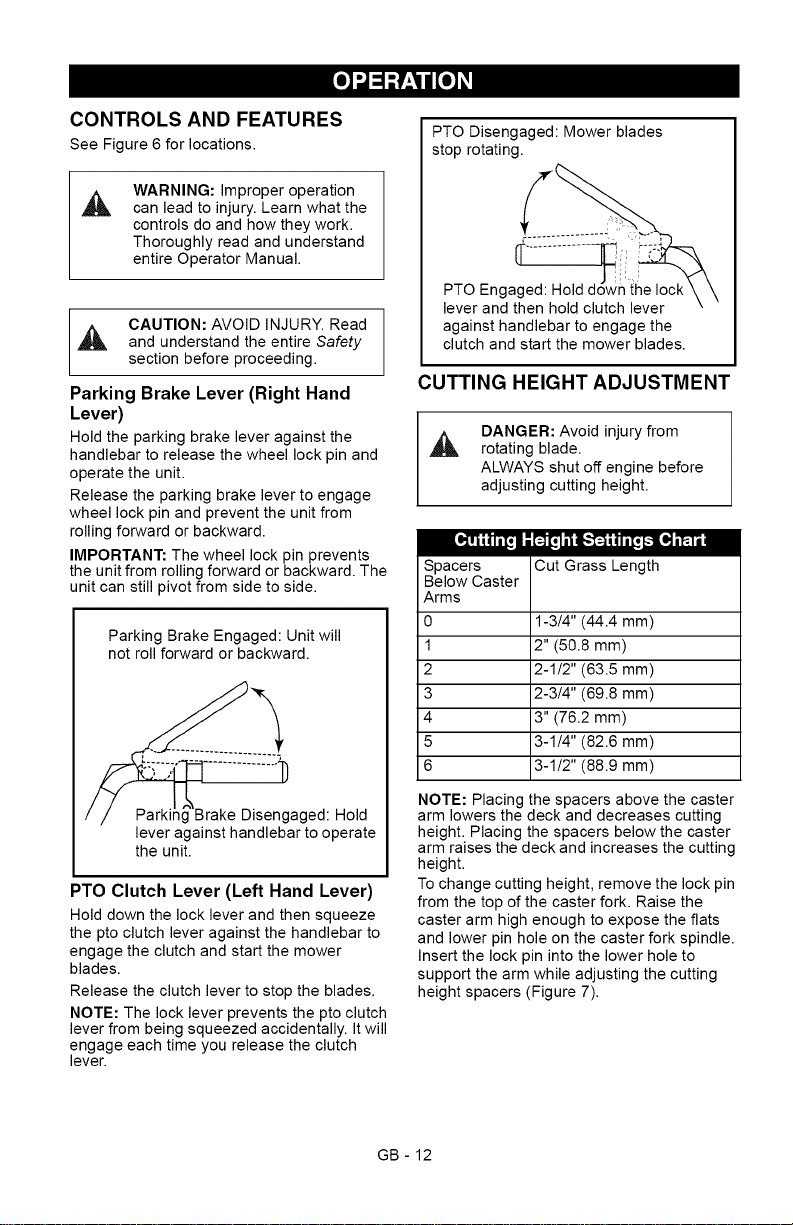

[o_o_o_,,._ r±__ln]l_::W±_uttl_t_

1

2

5

10

4 /

11

6

14

13

/

12

1. PTO Clutch Lever

2. Parking Brake Release Lever

3. Forward Drive Control

4. Reverse Drive Control

5. Handlebars

6. Fuel Tank and Cap

7. Height Adjustment Spacers

8. Muffler

9. Oil Fill/Dipstick

10. Air Filter

11. Fuel Filter

12. Belt Cover

13. Ignition Key

14. Safety Start Switch

15. Throttle/Choke Control

Figure 6

GB- 11

CONTROLS AND FEATURES

See Figure 6 for locations.

WARNING: Improper operation

,_ can lead to injury. Learn what the

controls do and how they work.

Thoroughly read and understand

entire Operator Manual.

CAUTION: AVOID INJURY. Read

and understand the entire Safety

section before proceeding.

Parking Brake Lever (Right Hand

Lever)

Hold the parking brake lever against the

handlebar to release the wheel lock pin and

operate the unit.

Release the parking brake lever to engage

wheel lock pin and prevent the unit from

rolling forward or backward.

IMPORTANT: The wheel lock pin prevents

the unit from rolling forward or backward. The

unit can still pivot from side to side.

Parking Brake Engaged: Unit will

not roll forward or backward.

lever against handlebar to operate

the unit.

PTO Clutch Lever (Left Hand Lever)

Hold down the lock lever and then squeeze

the pto clutch lever against the handlebar to

engage the clutch and start the mower

blades.

Release the clutch lever to stop the blades.

NOTE: The lock lever prevents the pto clutch

lever from being squeezed accidentally. It will

engage each time you release the clutch

lever.

gaged: Hold

PTO Disengaged: Mower blades

stop rotating.

PTO Engaged:

lever and then hold clutch lever

against handlebar to engage the

clutch and start the mower blades.

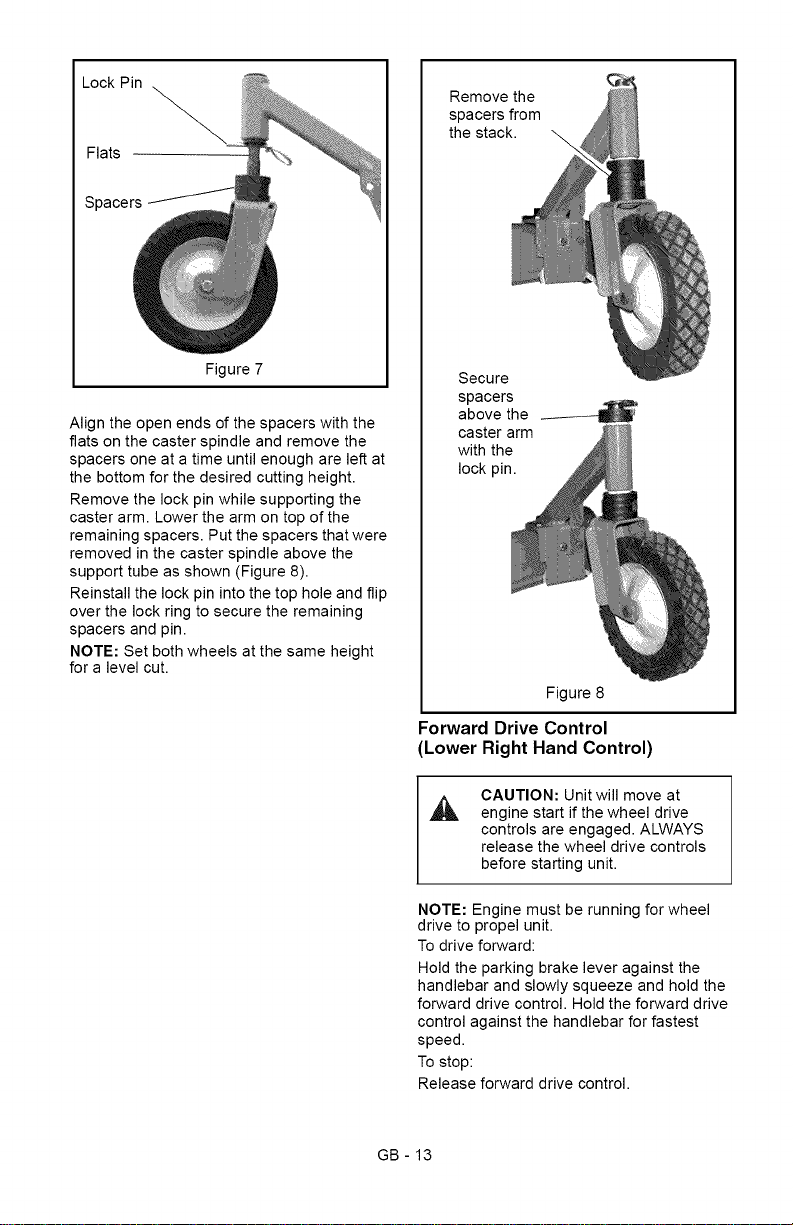

CUTTING HEIGHT ADJUSTMENT

DANGER: Avoid injury from

rotating blade.

ALWAYS shut off engine before

adjusting cutting height.

[ ., ,. "- . - . [..]_

Spacers Cut Grass Length

Below Caster

Arms

0 1-3/4" (44.4 mm)

1 2" (50.8 mm)

2 2-1/2" (63.5 mm)

3 2-3/4" (69.8 mm)

4 3" (76.2 mm)

5 3-1/4" (82.6 mm)

6 3-1/2" (88.9 mm)

NOTE: Placing the spacers above the caster

arm lowers the deck and decreases cutting

height. Placing the spacers below the caster

arm raises the deck and increases the cutting

height.

To change cutting height, remove the lock pin

from the top of the caster fork. Raise the

caster arm high enough to expose the flats

and lower pin hole on the caster fork spindle.

Insert the lock pin into the lower hole to

support the arm while adjusting the cutting

height spacers (Figure 7).

GB - 12

LockPin

Flats

Spacers

Removethe

spacersfrom

thestack.

Figure7

Aligntheopenendsofthespacerswiththe

flatsonthecasterspindleandremovethe

spacersoneatatimeuntilenoughareleftat

thebottomforthedesiredcuttingheight.

Removethelockpinwhilesupportingthe

casterarm.Lowerthearmontopofthe

remainingspacers.Putthespacersthatwere

removedinthecasterspindleabovethe

supporttubeasshown(Figure8).

Reinstallthelockpinintothetopholeandflip

overthelockringtosecuretheremaining

spacersandpin.

NOTE:Setbothwheelsatthesameheight

foralevelcut.

Secure

spacers

abovethe

casterarm

withthe

lockpin.

Figure8

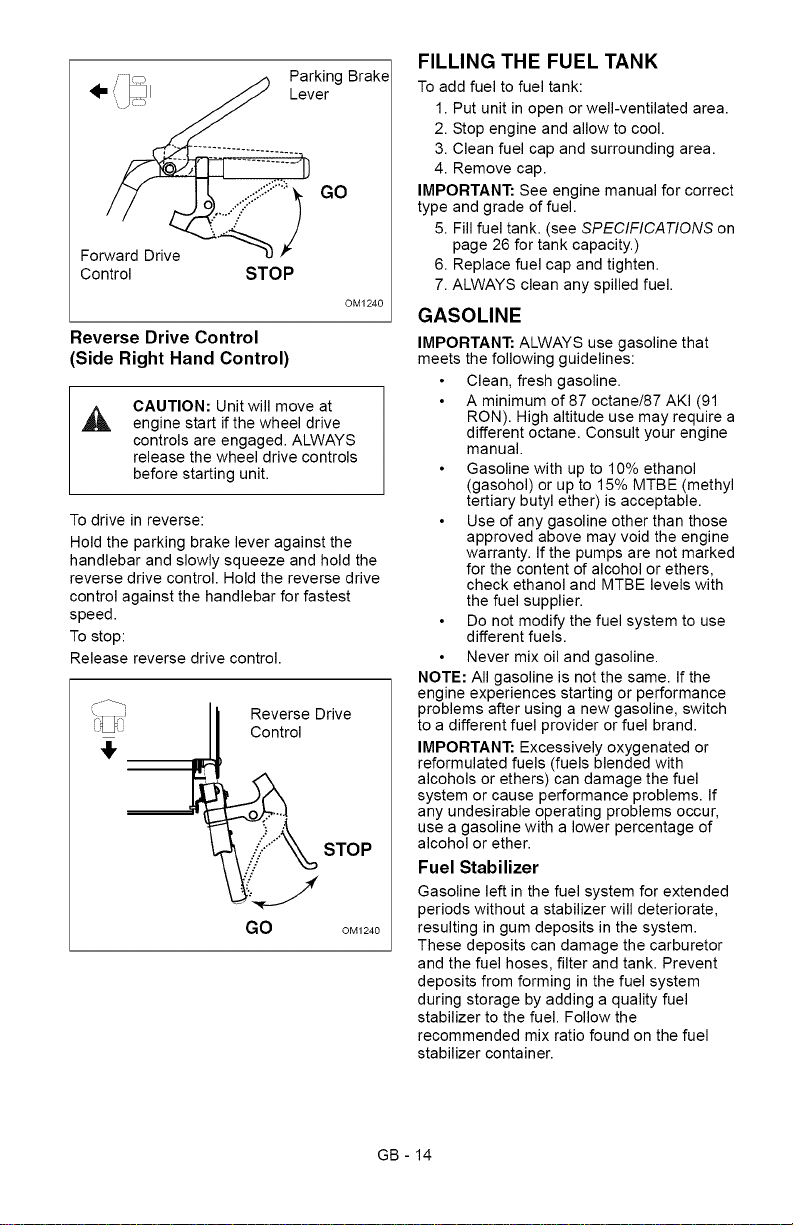

Forward Drive Control

(Lower Right Hand Control)

CAUTION: Unit will move at

engine start if the wheel drive

controls are engaged. ALWAYS

release the wheel drive controls

before starting unit.

NOTE: Engine must be running for wheel

drive to propel unit.

To drive forward:

Hold the parking brake lever against the

handlebar and slowly squeeze and hold the

forward drive control. Hold the forward drive

control against the handlebar for fastest

speed.

To stop:

Release forward drive control.

GB - 13

_, / __ ./_ Parking Brake

Forward Drive

Control STOP

OM1240

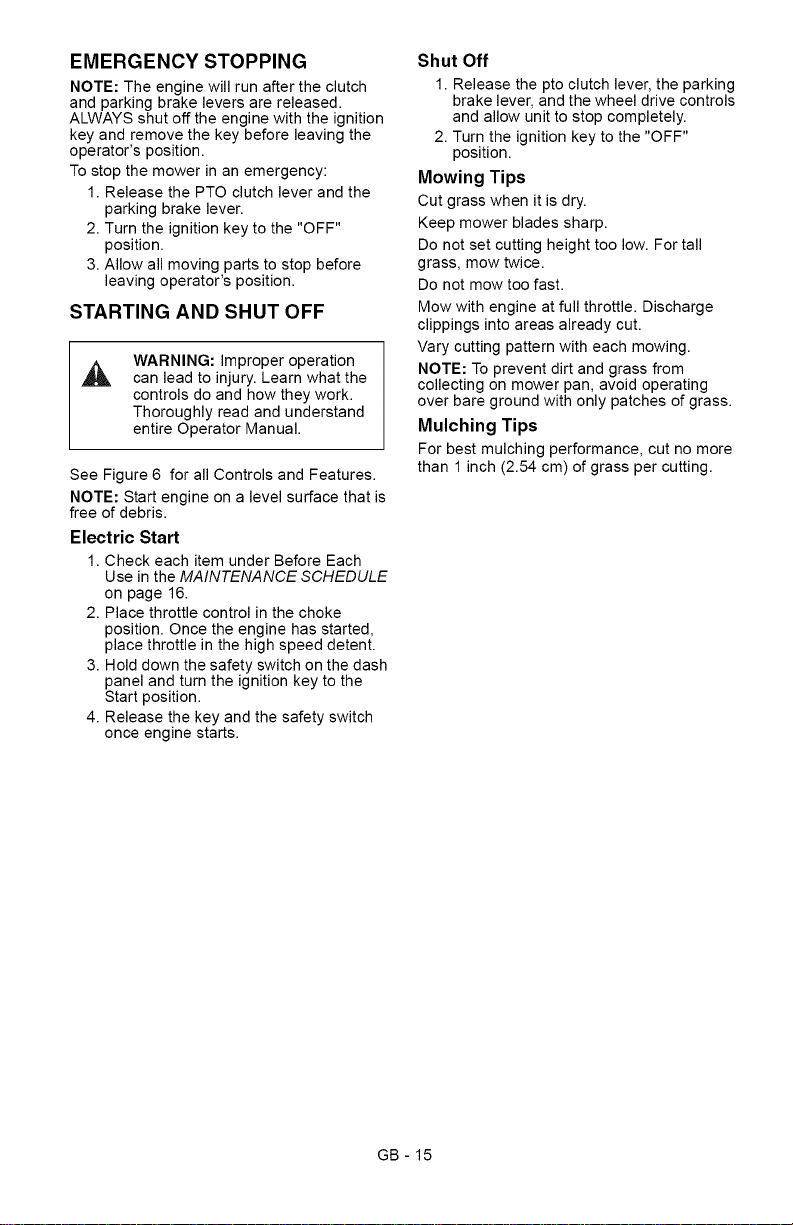

Reverse Drive Control

(Side Right Hand Control)

CAUTION: Unit will move at

A

engine start if the wheel drive

controls are engaged. ALWAYS

release the wheel drive controls

before starting unit.

To drive in reverse:

Hold the parking brake lever against the

handlebar and slowly squeeze and hold the

reverse drive control. Hold the reverse drive

control against the handlebar for fastest

speed.

To stop:

Release reverse drive control.

__olReverse Drive

__i._ STOP

"_O'_ OM1240

FILLING THE FUEL TANK

To add fuel to fuel tank:

1. Put unit in open or well-ventilated area.

2. Stop engine and allow to cool.

3. Clean fuel cap and surrounding area.

4. Remove cap.

IMPORTANT: See engine manual for correct

type and grade of fuel.

5. Fill fuel tank. (see SPECIFICATIONS on

page 26 for tank capacity.)

6. Replace fuel cap and tighten.

7. ALWAYS clean any spilled fuel.

GASOLINE

IMPORTANT: ALWAYS use gasoline that

meets the following guidelines:

Clean, fresh gasoline.

A minimum of 87 octane/87 AKI (91

RON). High altitude use may require a

different octane. Consult your engine

manual.

Gasoline with up to 10% ethanol

(gasohol) or up to 15% MTBE (methyl

tertiary butyl ether) is acceptable.

Use of any gasoline other than those

approved above may void the engine

warranty. If the pumps are not marked

for the content of alcohol or ethers,

check ethanol and MTBE levels with

the fuel supplier.

Do not modify the fuel system to use

different fuels.

Never mix oil and gasoline.

NOTE: All gasoline is not the same. If the

engine experiences starting or performance

problems after using a new gasoline, switch

to a different fuel provider or fuel brand.

IMPORTANT: Excessively oxygenated or

reformulated fuels (fuels blended with

alcohols or ethers) can damage the fuel

system or cause performance problems. If

any undesirable operating problems occur,

use a gasoline with a lower percentage of

alcohol or ether.

Fuel Stabilizer

Gasoline left in the fuel system for extended

periods without a stabilizer will deteriorate,

resulting in gum deposits in the system.

These deposits can damage the carburetor

and the fuel hoses, filter and tank. Prevent

deposits from forming in the fuel system

during storage by adding a quality fuel

stabilizer to the fuel. Follow the

recommended mix ratio found on the fuel

stabilizer container.

GB - 14

EMERGENCY STOPPING

NOTE: The engine will run after the clutch

and parking brake levers are released.

ALWAYS shut off the engine with the ignition

key and remove the key before leaving the

operator's position.

To stop the mower in an emergency:

1. Release the PTO clutch lever and the

parking brake lever.

2. Turn the ignition key to the "OFF"

position.

3. Allow all moving parts to stop before

leaving operator's position.

STARTING AND SHUT OFF

WARNING: Improper operation

A

can lead to injury. Learn what the

controls do and how they work.

Thoroughly read and understand

entire Operator Manual.

See Figure 6 for all Controls and Features.

NOTE: Start engine on a level surface that is

free of debris.

Electric Start

1. Check each item under Before Each

Use in the MAINTENANCE SCHEDULE

on page 16.

2. Place throttle control in the choke

position. Once the engine has started,

place throttle in the high speed detent.

3. Hold down the safety switch on the dash

panel and turn the ignition key to the

Start position.

4. Release the key and the safety switch

once engine starts.

Shut Off

1. Release the pto clutch lever, the parking

brake lever, and the wheel drive controls

and allow unit to stop completely.

2. Turn the ignition key to the "OFF"

position.

Mowing Tips

Cut grass when it is dry.

Keep mower blades sharp.

Do not set cutting height too low. For tall

grass, mow twice.

Do not mow too fast.

Mow with engine at full throttle. Discharge

clippings into areas already cut.

Vary cutting pattern with each mowing.

NOTE: To prevent dirt and grass from

collecting on mower pan, avoid operating

over bare ground with only patches of grass.

Mulching Tips

For best mulching performance, cut no more

than 1 inch (2.54 cm) of grass per cutting.

GB- 15

,_ CAUTION: AVOID INJURY. Read

and understand the entire Safety

section before proceeding.

Ariens Dealers will provide any service, parts

or adjustments which may be required to

keep your unit operating at peak efficiency.

Should engine require service, contact an

Ariens Dealer or an authorized engine

manufacturer's service center.

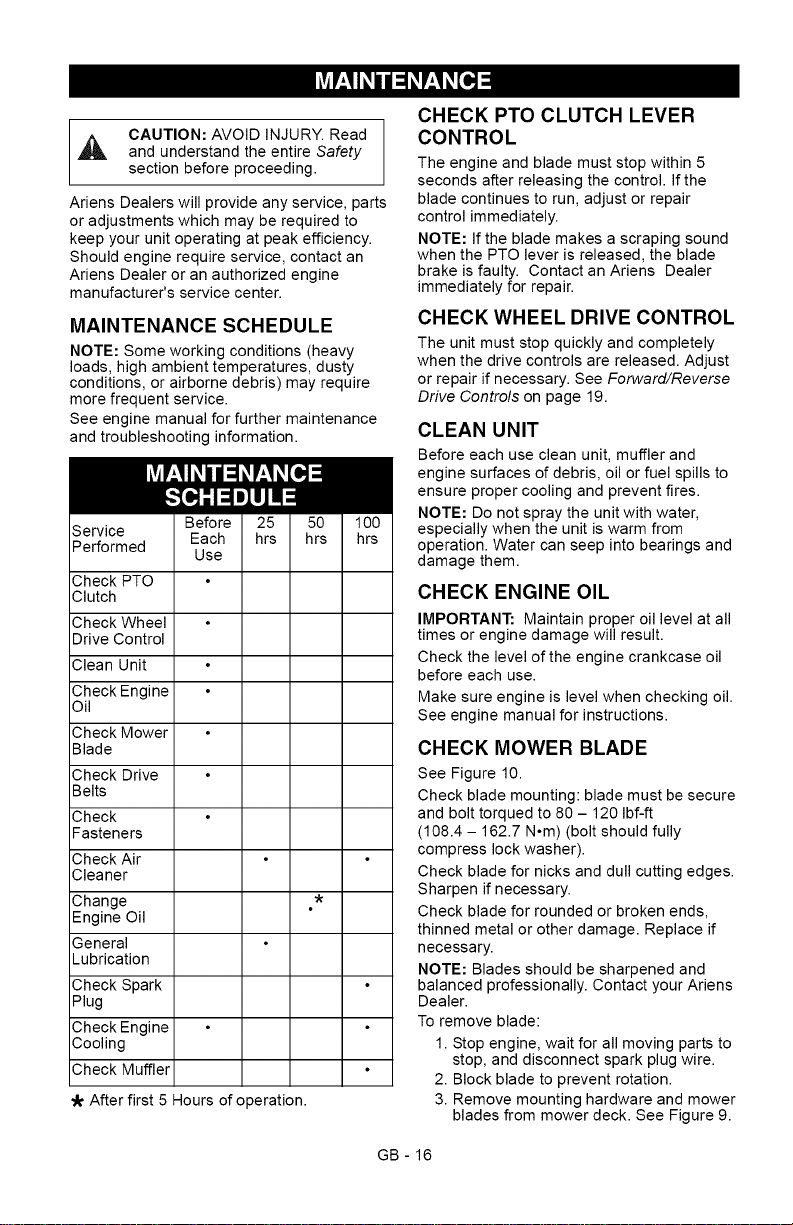

MAINTENANCE SCHEDULE

NOTE: Some working conditions (heavy

loads, high ambient temperatures, dusty

conditions, or airborne debris) may require

more frequent service.

See engine manual for further maintenance

and troubleshooting information.

Service

Performed

Check PTO

Clutch

Check Wheel

Drive Control

Clean Unit

Check Engine

Oil

Check Mower

Blade

Check Drive

Belts

Check

Fasteners

Check Air

Cleaner

Change

Engine Oil

General

Lubrication

Check Spark

Plug

Check Engine

Cooling

Check Muffler

After first 5 Hours of operation.

CHECK PTO CLUTCH LEVER

CONTROL

The engine and blade must stop within 5

seconds after releasing the control. If the

blade continues to run, adjust or repair

control immediately.

NOTE: If the blade makes a scraping sound

when the PTO lever is released, the blade

brake isfaulty. Contact an Ariens Dealer

immediately for repair.

CHECK WHEEL DRIVE CONTROL

The unit must stop quickly and completely

when the drive controls are released. Adjust

or repair if necessary. See Forward/Reverse

Drive Controls on page 19.

CLEAN UNIT

Before each use clean unit, muffler and

engine surfaces of debris, oil or fuel spills to

ensure proper cooling and prevent fires.

NOTE: Do not spray the unit with water,

especially when the unit is warm from

operation. Water can seep into bearings and

damage them.

CHECK ENGINE OIL

IMPORTANT: Maintain proper oil level at all

times or engine damage will result.

Check the level of the engine crankcase oil

before each use.

Make sure engine is level when checking oil.

See engine manual for instructions.

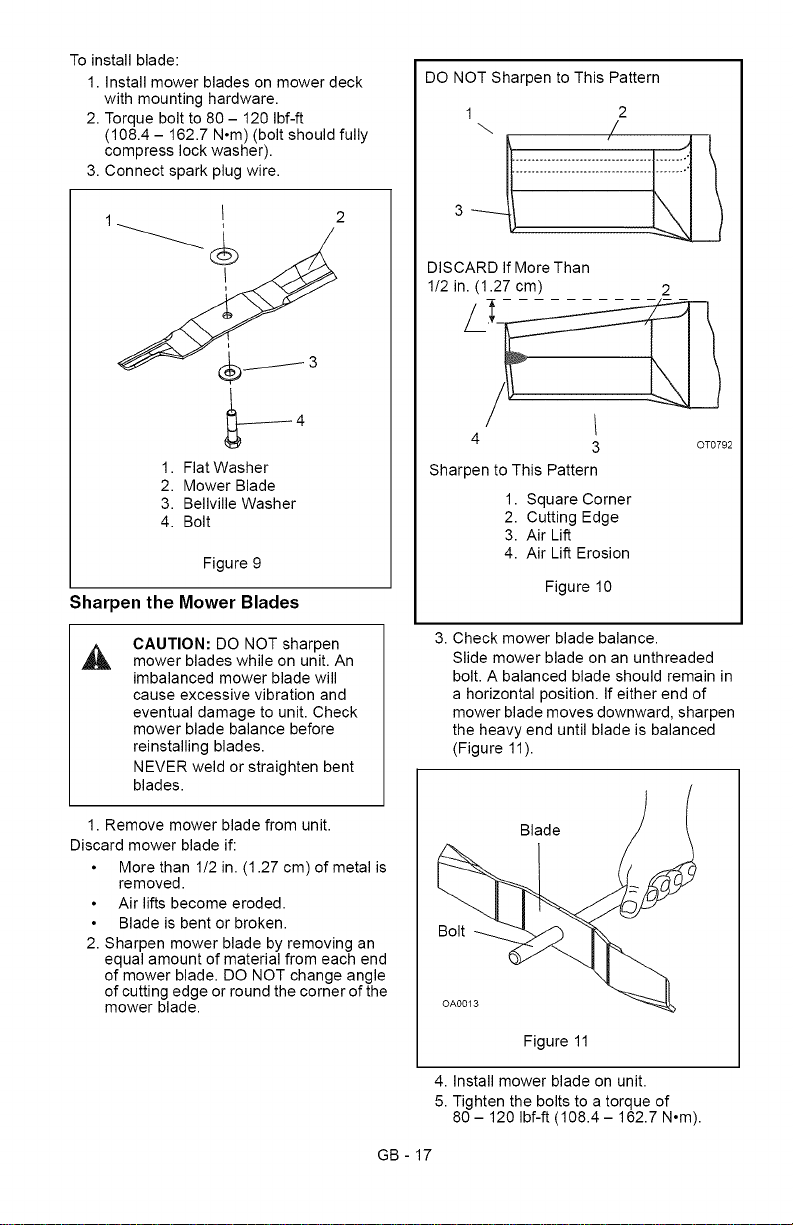

CHECK MOWER BLADE

See Figure 10.

Check blade mounting: blade must be secure

and bolt torqued to 80 - 120 Ibf-ft

(108.4 - 162.7 Nom) (bolt should fully

compress lock washer).

Check blade for nicks and dull cutting edges.

Sharpen if necessary.

Check blade for rounded or broken ends,

thinned metal or other damage. Replace if

necessary.

NOTE: Blades should be sharpened and

balanced professionally. Contact your Ariens

Dealer.

To remove blade:

1. Stop engine, wait for all moving parts to

stop, and disconnect spark plug wire.

2. Block blade to prevent rotation.

3. Remove mounting hardware and mower

blades from mower deck. See Figure 9.

GB - 16

Toinstallblade:

1.Installmowerbladesonmowerdeck

withmountinghardware.

2.Torqueboltto80- 120Ibf-ft

(108.4- 162.7N°m)(boltshouldfully

compresslockwasher).

3.Connectsparkplugwire.

I 2

DO NOT Sharpen to This Pattern

1 2

DISCARD If More Than

1/2 in. (1.27 cm) 2

--

1.FlatWasher

2.MowerBlade

3.BellvilleWasher

4.Bolt

Figure9

Sharpen the Mower Blades

CAUTION: DO NOT sharpen

mower blades while on unit. An

imbalanced mower blade will

cause excessive vibration and

eventual damage to unit. Check

mower blade balance before

reinstalling blades.

NEVER weld or straighten bent

blades.

1. Remove mower blade from unit.

Discard mower blade if:

More than 1/2 in. (1.27 cm) of metal is

removed.

Air lifts become eroded.

Blade is bent or broken.

2. Sharpen mower blade by removing an

equal amount of material from each end

of mower blade. DO NOT change angle

of cutting edge or round the corner of the

mower blade.

4

Sharpen to This Pattern

1. Square Corner

2. Cutting Edge

3. Air Lift

4. Air Lift Erosion

3. Check mower blade balance.

Slide mower blade on an unthreaded

bolt. A balanced blade should remain in

a horizontal position. If either end of

mower blade moves downward, sharpen

the heavy end until blade is balanced

(Figure 11).

Blade

Bolt

3 OT0792

Figure 10

Figure 11

4. Install mower blade on unit.

5. Tighten the bolts to a torque of

80- 120 Ibf-ft (108.4- 162.7 N°m).

GB - 17

CHECK DRIVE BELTS

Check drive belts and replace if worn or

damaged. See Wheel Drive Belts on page 20.

CHECK FASTENERS

Check all fasteners for proper tightness. Pay

special attention to blade hardware and all

guards, shields and safety devices.

CHECK AIR CLEANER

See engine manual for specific information.

CHANGE ENGINE OIL

IMPORTANT: Change engine crankcase oil

after first five (5) hours of operation. Then

change oil after every 25 hours of operation.

Refer to engine manual for instructions and

proper oil type.

IMPORTANT: Proper oil level must be

maintained at all times or engine damage will

result. DO NOT overfill. Be sure engine is

level when adding oil.

GENERAL LUBRICATION

The unit has sealed maintenance-free

spindles and transmission. The unit should

not require lubrication except for light oil or

grease at pivot points.

CHECK SPARK PLUG

Spark plug should be replaced every 100

hours of operation or each year.

NOTE: Loose spark plug wire terminals can

cause sparking. Replace terminal if

damaged.

CHECK ENGINE COOLING

WARNING: HOT SURFACES can

,&

cause death or serious injury. DO

NOT TOUCH parts which are hot

from operation. ALWAYS allow

parts to cool.

To prevent overheating, air must circulate

freely around the cooling fins, cylinder head

and block.

Every 100 hours of operation or yearly (more

often if conditions require) remove blower

housing and clean cooling fins. See engine

manual for instructions.

CHECK MUFFLER

Check muffler for debris, cracks, wear, or

other damage.

CAUTION: Replace worn-out

,_ mufflers immediately. Continued

use could result in fire or

explosion.

GB - 18

,_ CAUTION: AVOID INJURY. Read

and understand the entire Safety

section before proceeding.

PTO CLUTCH

WARNING: If you cannot adjust

the controls so the unit drives

properly, immediately take the unit

to your local authorized dealer for

repairs.

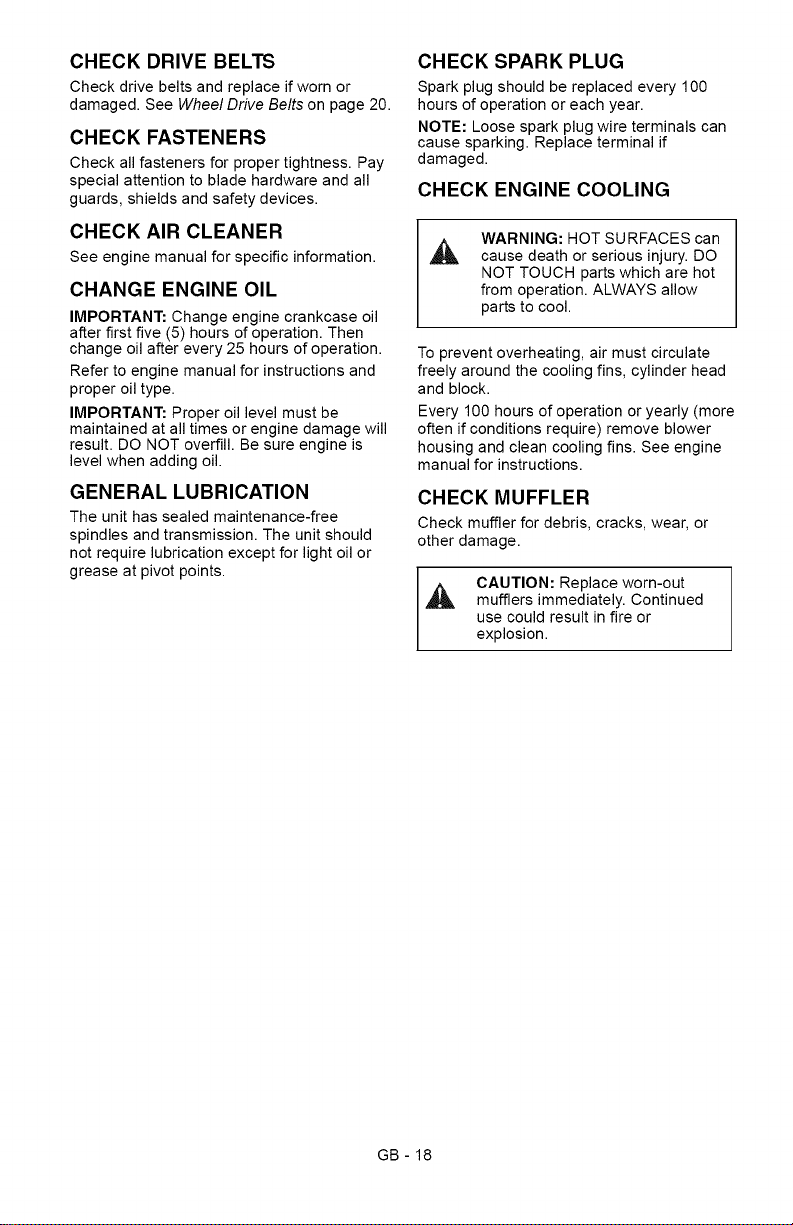

1. Test the pto clutch adjustment.

With the clutch disengaged, the blade

brake should touch the brake drum.

With the clutch engaged, the blade

brake should not touch the brake drum

and the deck belt should be under

tension.

2. Loosen the lock nut on the cable

adjuster under the dash panel.

3. Turn the adjuster body to tighten or

loosen the clutch cable.

NOTE: There must be some slack in the

clutch cable with the clutch disengaged.

4. Tighten the lock nut to hold the

adjustment.

IMPORTANT: If you cannot adjust the pto

clutch or if it fails to operate properly,

immediately take the unit to your Ariens

dealer for repair.

Forward/Reverse Drive Controls

WARNING: If you cannot adjust

the controls so the unit drives

properly, immediately take the unit

to your local authorized dealer for

repairs.

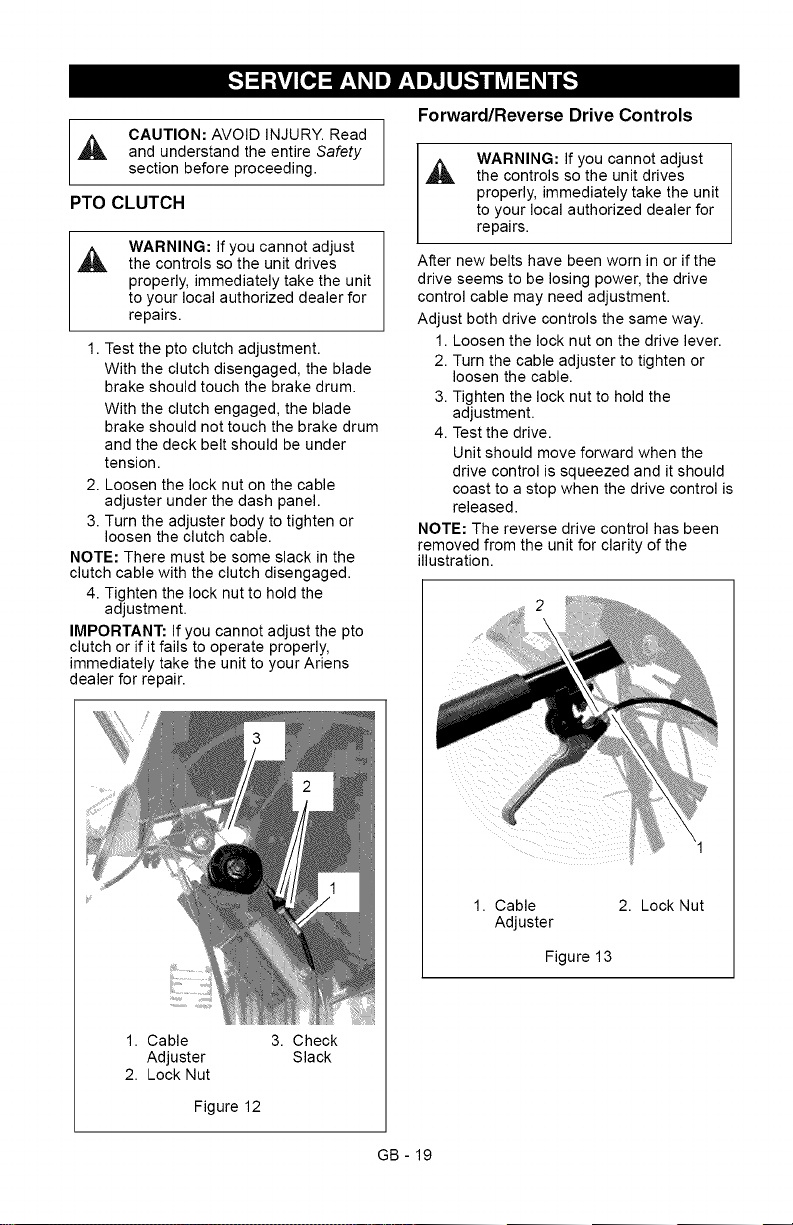

After new belts have been worn in or if the

drive seems to be losing power, the drive

control cable may need adjustment.

Adjust both drive controls the same way.

1. Loosen the lock nut on the drive lever.

2. Turn the cable adjuster to tighten or

loosen the cable.

3. Tighten the lock nut to hold the

adjustment.

4. Test the drive.

Unit should move forward when the

drive control is squeezed and it should

coast to a stop when the drive control is

released.

NOTE: The reverse drive control has been

removed from the unit for clarity of the

illustration.

1. Cable 3. Check

Adjuster Slack

2. Lock Nut

Figure 12

1. Cable 2. Lock Nut

Adjuster

Figure 13

GB - 19

Loading...

Loading...