10500 Orbital Way

Pacoima, California 91331 U.S.A.

MODEL 307 POWER SUPPLY

OPERATOR TRAINING GUIDELINES

Document No. 740096

Doc. Rev. A

HEADQUARTERS

Arc Machines, Inc.

10500 Orbital Way

Pacoima, CA 91331 U.S.A.

Tel.: 1- 818 896-9556

Fax: 1-818 890-3724

sales@arcmachines.com

GERMAN OFFICE

Arc Machines GmbH

Markelsbach 2

D-53804 Much, Germany

Tel.: 02245 / 91680

Fax: 02245 / 916868

sales@arcmachines.de

EUROPEAN OFFICE

Arc Machines, Inc.

Chemin du Lavasson 2

CH-1196 Gland

Switzerland

Tel.: +41 / 22 / 995.00.51

Fax: +41 / 22/ 995.00.59

sales@arcmachines.ch

www.arcmachines.com

Document No. 740096

Rev. A

UK OFFICE

Arc Machines UK Limited

Unit 4, Raynesway Park Drive

Derby, DE21 7BH England

Tel.: 01332 / 574000

Fax: 01332 / 757757

sales@arcmachines.co.uk

MODEL 307

Operator Training Guidelines

Arc Machines, Inc.

General Guidelines for Orbital Tube and Pipe Welding

The Arc Machines Model 307 is designed to be a versatile orbital

welding control and power supply system. The Windows™-basedModel 307 features the absolute latest state-of

-the art technology,

from its 200 ampere second-generat

its color VGA display with touch screen. The Windows™ environment makes the Model 307 uniquely suited for weld logging and

weld documentation. The basic Model 307 features a complete complement of controls including gas flow and available water cooling

necessary to oper

ing tasks ranging from small diameter fusion tube welds to welding

thin-

Effective Date: September 1, 2004

Copyright 2005, Arc Machines, Inc.

wall piping with filler wire addition.

ate AMI orbital weld heads for in-place field weld-

ion solid state power supply to

Arc Machines, Inc. Model 307 Orbital Welder Training

A 5917 Correct output tolerance on pg 36 3/24/11 D.C.

Model 307 Operator Training Guidelines

Notice

This document and the information contained herein is the property of Arc

Machines, Inc. It is proprietary and submitted and received in confidence. It

shall be used only for the purpose for which it is submitted and shall not be

copied in whole or in part without the prior express written permission of Arc

Machines, Inc.

The information in this document has been carefully reviewed and is believed

to be accurate. However, no responsibility is assumed for inaccuracies.

Information and instructions in this document are subject to change and Arc

Machines, Inc. reserves the right to change specifications and data without

notice.

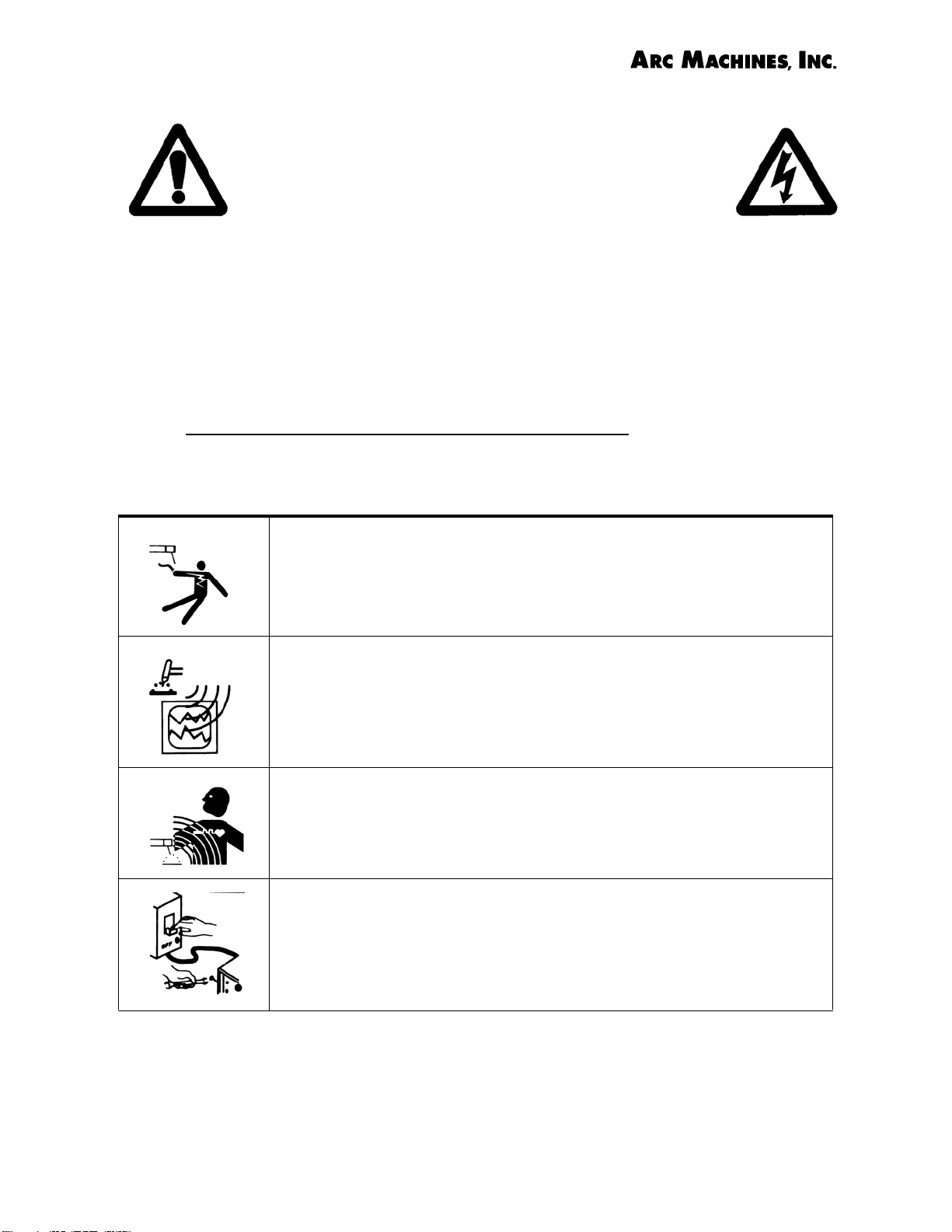

WARNING!

The nature of the GTAW process creates some POTENTIAL HAZARDS. In

accordance with international safety regulations the EXCLAMATION SYMBOL

indicates that this equipment is considered HAZARDOUS until an operator has

been made aware of these POTENTIAL HAZARDS by READING THIS MAN-

UAL. The LIGHTNING FLASH SYMBOL indicates that there are potential electrical hazards. The use and display of these symbols make it the OPERATOR’S

RESPONSIBILITY TO INSURE THAT HE HAS READ AND/OR BEEN MADE

AWARE OF ALL SAFETY-RELATED ITEMS CONTAINED IN THIS MANUAL.

Publication date: First Edition - September 2004

Copyright 2005 by Arc Machines, Inc.

All rights reserved.

REV DCO# CHANGE DESCRIPTION DATE APR

Document No. 740096 i.

Rev. A

Arc Machines, Inc. Model 307 Orbital Welder Training

MODEL 307 OPERATOR TRAINING GUIDELINES

EFFECTIVITY

Features and operation of the Model 307 are derived mostly from SOFTWARE.

This document is based on the latest STANDARD version of SOFTWARE at the

time of last revision (see revision page).

Some deviations in actual operation, from this document, are possible

depending on the software version of a particular machine. Please feel free to

contact Arc Machines Service Department for documentataion or information

on how software updates effect this document.

Document No. 740096 ii.

Rev. A

Table of Contents

1

INTRODUCTION

MODEL 307

OPERATOR TRAINING

GUIDELINES

2

3

4

5

6

7

8

9

10

11

SAFE OPERATION

ICONS, BUTTONS, SYMBOLS

MODEL 307 INSTALLATION

SEQUENCE OF EVENTS/

WELD PARAMETERS

POWER SUPPLY OPERATION

& FUNCTIONS

MODEL 307 LIBRARY

AUTOGENERATION OF WELD

SCHEDULES

MANUAL CREATION OF

WELD SCHEDULES

ASSOCIATED DATA

WELDING WITH THE 307

General Guidelines for

Orbital Welding of Tube

& Thin-Wall Pipe

Document No. 740096

Effective Date: September 1, 2004

Draft May 2005

12

13

14

15

16

17

18

19

20

WELD PROCEDURE

OPTIMIZATION

WELD HEAD CALIBRATION

& OPERATION

END-PREPARATION FOR

ORBITAL WELDING

TUNGSTEN

SPECIFICATIONS

PURGE GASES AND PURGE

PARAMETERS

WELD CRITERIA/WELD

QUALIFICATION

DATA ACQUISITION/

ADVANCED FUNCTIONS

APPENDICES

INDEX

Arc Machines, Inc. Model 307 Orbital Tube Welder Training

Chapter 1. Introduction to Orbital Welding with

the Model 307 Power Supply

rc Machines’

A

based Model 307 Power

Supply is designed for

autogenous orbital GTA

welding. In addition to

the standard tube-welding functions it also has

wire feed capabilities.

The Model 307 was

developed for economy

and ease of use and will

automatically generate a

weld schedule or program when the Arc

Machines weld head and

weld component dimensions are entered. To

meet the Industry’s demands for quality assurance (QA) and weld data

collection, the Model 307 has extensive capabilities to store and transmit

detailed weld documentation and historical data.

new Windows™-

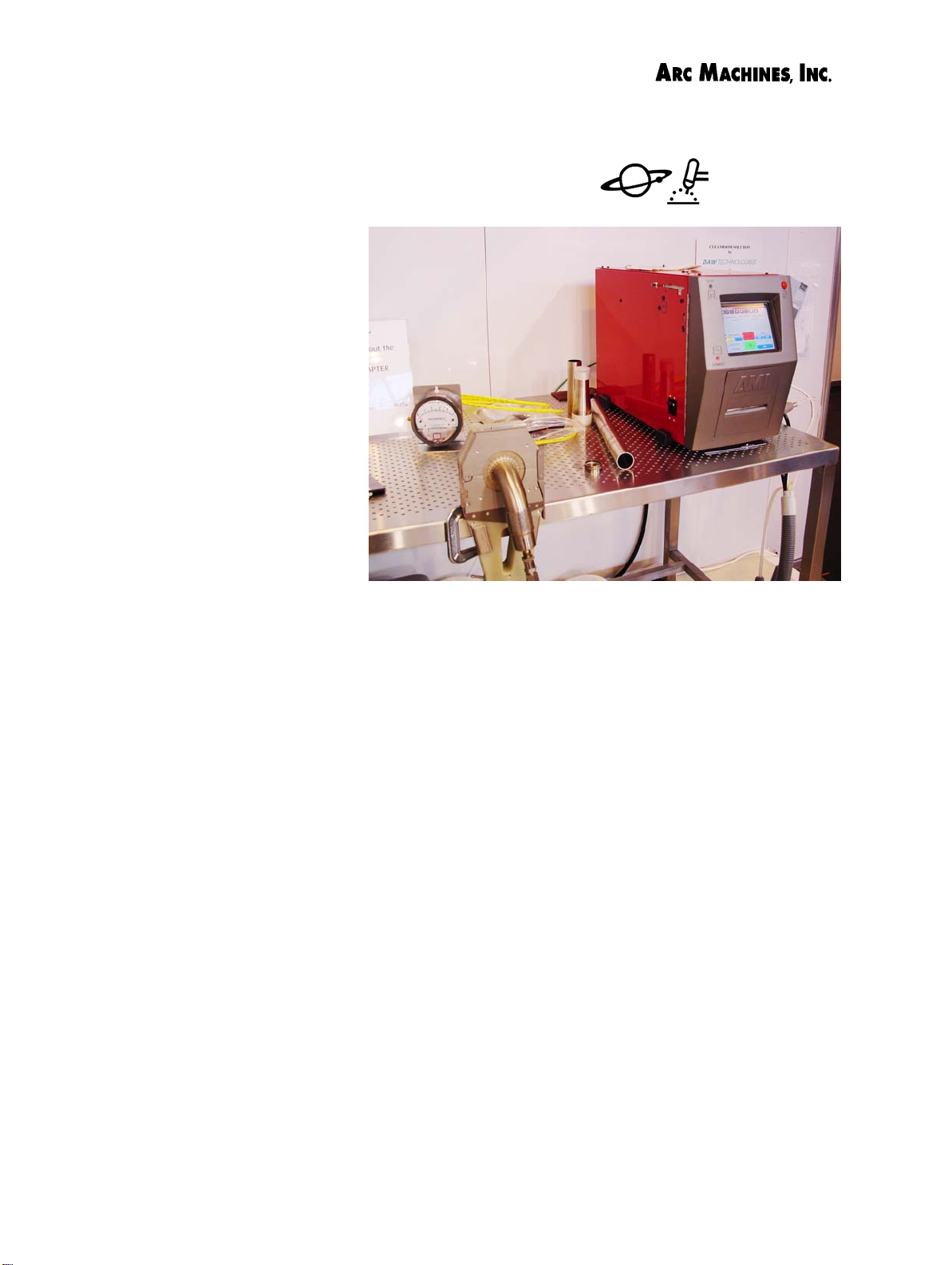

Arc Machines’ Model 307 Power Supply and Model 8-2000 weld

head on a cleanroom bench at the WELDEX show in the UK.

Welding personnel can program the Model 307 in time per level or simply

enter the desired weld head position in rotational degrees for the end of

each level, and time required to complete the level will be entered automatically. Weld parameters are clearly visible on the 307’s touch screen

and can easily be modified by the operator if changes should be necessary.

Input Power. The Model 307 Power Supply operates on 110 to 240 VAC,

50/60 Hz, single phase only, without reconnection.

Weld Current. The Model 307 has a programma

amperes of primary welding current, while av

ited to 150 amps or less. The Model 307 will warn users if programmed

current v

Weld Heads. The Model 307 operates all standard AMI fusion weld heads

includin

It can also operate the Model 95 series of wire-feed weld heads. The motor

controls can accept DC tachometer velocity feedback, or quadrature-encoder position and velocity information.

alues exceed recommendations for particular weld heads.

g the Model 8 and Model 9 series, Model 4, Model 85, and Model 96.

ble range of 5 to 200

erage current is software-lim-

Document No. 740096 Chapter 1. Page 1.

Rev. A

Arc Machines, Inc. Model 307 Orbital Tube Welder Training

Left and above: Welding in a dairy plant with a Model 8-4000 weld head.

Right: A Model 4-500 bench mount weld head.

Real-time digital data acquisition. The Model 307 captures and displays

real-time streaming data for welding current, pulsation, arc voltage and

travel speed during the weld and displays the data in graphical form on the

Model 307 screen at the end of the weld. The power supply can compare

the actual data gathered during the weld and report whether the weld

parameters were performed within pre-set acceptance limits.

Weld Logging. The Model 307’s Intel® Pentium® processor makes this

power supply uniquely suited for weld logging and weld documentation.

Weld records are created by the Model 307 when a weld identification (ID)

number is assigned to the weld. Users can select from a variety of fields of

Associated Data which include weld head and power supply serial numbers; material type and heat numbers of tubing, fittings or other weld components; gas type, flow rates to weld head and weld I.D., dewar serial

number; and electrode type and geometry.

Project management. Rapid retrieval of weld records is import

ant for

users who may be subject to audits from the FDA or other regulatory

agency. Weld records stored in the Model 307 memory can be retrieved by

project, wel

d identification number, date, welding operator, or other field.

Weld records can be downloaded onto electronic media or to a computer for compilation

of records for a particular job thus avoiding

the necessity of re-entering this data manually. Weld I.D. numbers as well as other identifying data may also be printed onto an

adhesive-backed plastic label that can be

used for weld identification purposes.

It should be understood that no welding

machine can unequivocally detect and indicate the quality of a particular weld. The

Model 307 can, however, provide a detailed

Document No. 740096 Chapter 1. Page 2.

Rev. A

Model 95-6625 Weld Head with wireFeed capabilities welding a flange to a

pipe in Guatemala. Photo courtesy of

Alimentos Maravilla S.A.

Arc Machines, Inc. Model 307 Orbital Tube Welder Training

record of each weld, so that if quality questions arise, the process of tracing the root cause of a problem is greatly simplified.

Statement of purpose: This manual is intended for use in an Arc

Machines, Inc. Model 307 Tube Welder Training class taught by a factoryapproved Arc Machines, Inc. Instructor. IT IS NOT A SUBSTITUTE FOR

THAT TRAINING. The purpose of such a class is to enable welding personnel to quickly and easily understand the basic functions and safe operation

of the Model 307 Power Supply and appropriate weld head(s) and to use this

equipment successfully in their application.

Students must be able to correctly set up the power supply and be able to

calibrate and install the weld head with correct tube-clamp inserts and the

correct tungsten type, diameter an

d length. They must understand the

basics of purging and know how to set the correct flow rates for the weld

head they are using.

Hands-On. Students are given sufficient hands-on tr

aining to enable them

to generate weld programs, to make welds, and to evaluate the welds.

Trainees should also be familiar with the end-preparation requirements for

orbital welding. They are expected to recognize an acceptable weld for

their industry or application and be able to make adjustments in the weld

program or procedures in order to produce welds that comply with the

standards of their industry.

Upon successful completion of this course, which is typically comprised of

two 8-hour days and, at the discretion of the instructor, students will

be awarded an Arc Machines, Inc. Certificate of Completion.

Document No. 740096 Chapter 1. Page 3.

Rev. A

Arc Machines, Inc. Model 307 Orbital Tube Welder Training

Chapter 2. Safe Operating Procedure -

S

afety Precautions for Model 307 Operation

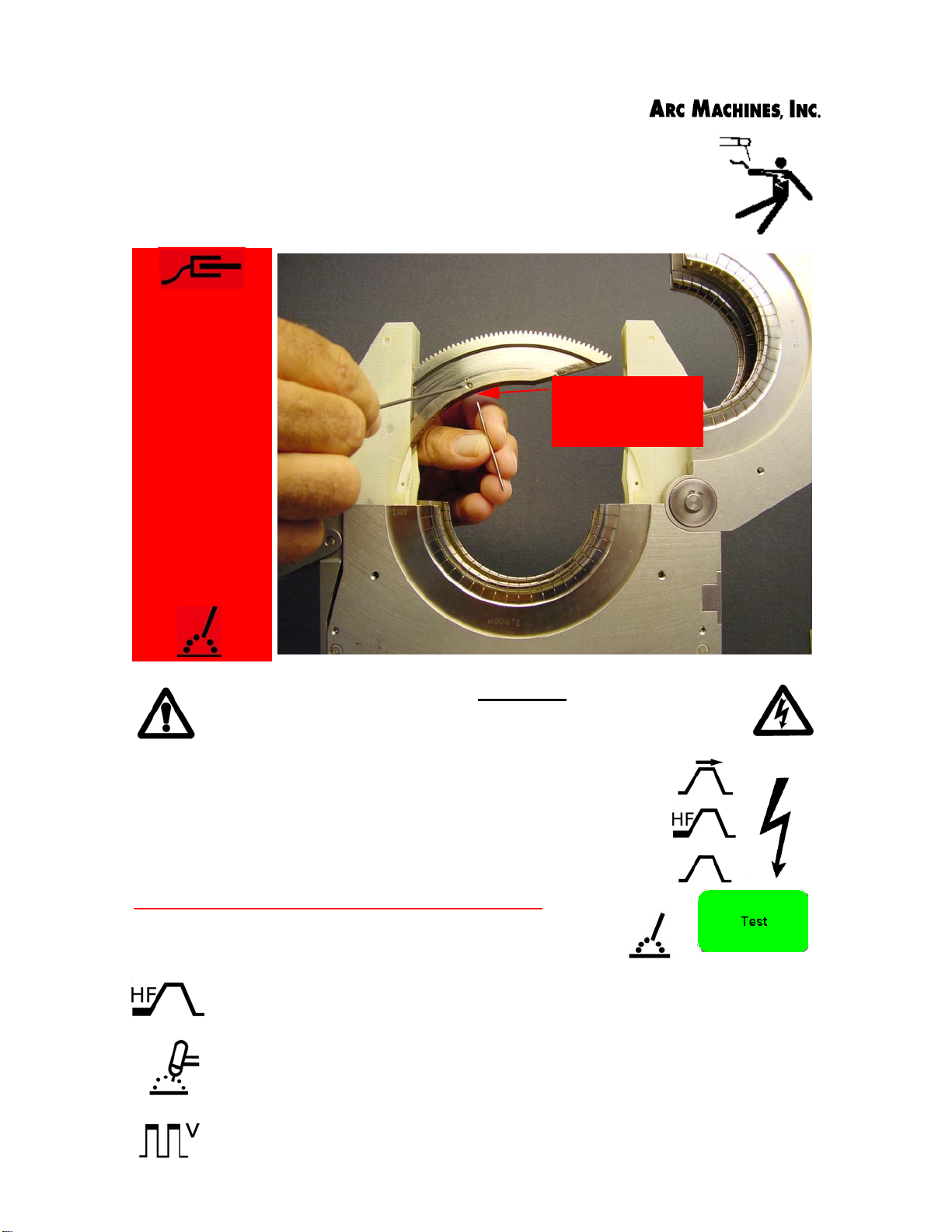

AVOID ALL

CONTACT

WITH THE

WELDING

WORK

(GROUND) OR

ELECTRODE

DURING ARC

START

Electrode installation in a Model 8

weld head.

THE ELECTRODE SHOULD ALWAYS BE

CONSIDERED A POSSIBLE SHOCK HAZARD.

This is especially true whenever the system is:

• IN SEQUENCE

• READY TO WELD,

• IS WELDING,

• OR HAS JUST FINISHED WELDING.

When replacing or adjusting the electrode:

• Set power supply to “TEST” mode

Most AMI Power Supplies feature RF (radio frequency) Arc

Starting. This is a High Voltage/High Frequency electrical transmission process. The GTAW process requires electrical potential

(high voltage) to be present on the electrode and on exposed

internal terminals during arc starting and during welding. ALL

AMI Power Supplies contain a “bleeder” circuit to ground any

residuals or potential after welding or after an aborted or bad

“arc start” attempt. However, these circuits take a few seconds

to operate or could fail.

Document No. 740096 Chapter 2. Page 1.

Rev. A

Arc Machines, Inc. Model 307 Orbital Tube Welder Training

Model 307 Do’s and Don’ts

Safe Use of Orbital Welding Equipment

DO’s

1. Do VERIFY correct AC Power Source (100 or 240 VAC

single phase) before plugging in the Model 307.

2. Do Autocal weld head (or select Manual Option)

each time the Model 307 is connected to a different

weld head. The weld head must be calibrated to the

power supply it is connected to.

3. Do CHECK ALL CABLE AND QUICK-DISCONNECT

FITTINGS

boots are in place.

to insure proper seating and that protective

4. Do check for GAS LEAKS on all external Gas fittings.

5. Do PROTECT WELD HEADS by storing in shipping

container (or otherwise suitably protected) when not in

use.

6. Do

NECTORS when not in use.

7. Do insure that the PROPER ELECTRODE is installed in

the weld head.

8. Do use a REGULATOR AND FLOWMETER designed for the

gas that is being used and suitable for the purity

requirements of the application.

KEEP PROTECTIVE COVERS ON THE MOTOR CABLE CON-

Document No. 740096 Chapter 2. Page 2.

Rev. A

Arc Machines, Inc. Model 307 Orbital Tube Welder Training

DON’TS

1. Don’t GRIND near the Weld Head or Power Supply

without protecting them.

2. Don’t use acid or other corrosives on or near the

Weld Head. A

(IPA) is the only approved liquid for cleaning of weld

heads or the Model 307.

LIGHT APPLICATION OF ISOPROPYL ALCOHOL

3. Don’t attempt to weld without a secure

WORK (GROUND) CONNECTION when using the Manual TIG

BARE METAL

Tor ch .

4. Don’t attempt to weld without PROPER FACING AND

CLEANING OF THE MATERIAL to be welded. Use only

approved cleaning products.

5. Don’t drop the Weld Head, Remote Pendant,

Cables, or Power Supply. Precautions should be taken

to secure this equipment in production situations.

6. Don’t route the cables where they will be

DAMAGE from traffic or equipment.

SUBJECT TO

7. Don’t expose the Weld Head, Remote Pendant,

Cables, or Power Supply to

ING OPERATION. Do not operate equipment when wet.

RAIN OR STANDING WATER DUR-

8. Don’t pull on cables. This will result in

DAMAGE TO THE EQUIPMENT.

Document No. 740096 Chapter 2. Page 3.

Rev. A

Arc Machines, Inc. Model 307 Orbital Tube Welder Training

Don’ts

9. Don’t attempt to move tube end into position using

the Weld Head as an alignment tool. USE PIPE STANDS,

CLAMPS, ALIGNMENT TOOLS, etc. to hold the tube or

pipe in position for welding. Tack welding of components with a weld head or a manual torch prior to

orbital welding may be necessary in some applications.

10. Don’t add oil or grease to the weld head.

11. Don’t increase GAS FLOW RATE (CFH) beyond levels

specified for each particular weld head.

12. Don’t allow TUNGSTEN OR OTHER METAL PARTICLES to

enter the gear train of the weld heads. This will cause

serious (and expensive) damage.

13. Don’t switch the Model 307 Power Supply ON and

OFF rapidly with circuit breaker (CB-1). To do so may

result in loss of stored information or resetting of system functions.

RF and EMI Emissions

Arc Machines’ policy is to comply with the IEC and FCC regulation. Every

t has been made to reduce RF emissions from our power supplies to

effor

the absolute minimum.

Document No. 740096 Chapter 2. Page 4

Rev. A

Arc Machines, Inc. Model 307 Orbital Welder Training

Model 307 Warnings

WARNINGS!

Safety Precautions

This section, concerning safe operating procedures for the

Model 307, should be read and understood before proceeding to

other sections of the training manual. It also contains precautions and warnings for the operation of welding equipment in

general. In addition, users should reference and become familiar

with “ANSI-49.1 Safety in Welding and Cutting

American National Standards Institute.

” published by the

WARNING: Touching energized electrical parts can cause fatal

shocks and burns. When in weld sequence the electrode and work

are electrically energized. Incorrectly installed or improperly

grounded equipment is a hazard.

WARNING: This equipment is authorized to use a type of arc starter

that produces a High Frequency Radio Wave (sometimes called

HF or RF Starting). It can cause interference and sometimes even

damage to nearby electronic equipment (such as computers) that

are unprotected or poorly protected against such interference.

WARNING: Magnetic fields from High Currents can affect pacemakers. Pacemaker wearers should avoid being in close proximity

to welding systems.

WARNING: Disconnect the input power to the machine before

opening or servicing. Discharge all circuits that store high voltage

such as capacitor packs. Only

open this equipment.

QUALIFIED service personnel should

Document No. 740096 Chapter 2. Page 1.

Rev. A

Arc Machines, Inc. Model 307 Orbital Welder Training

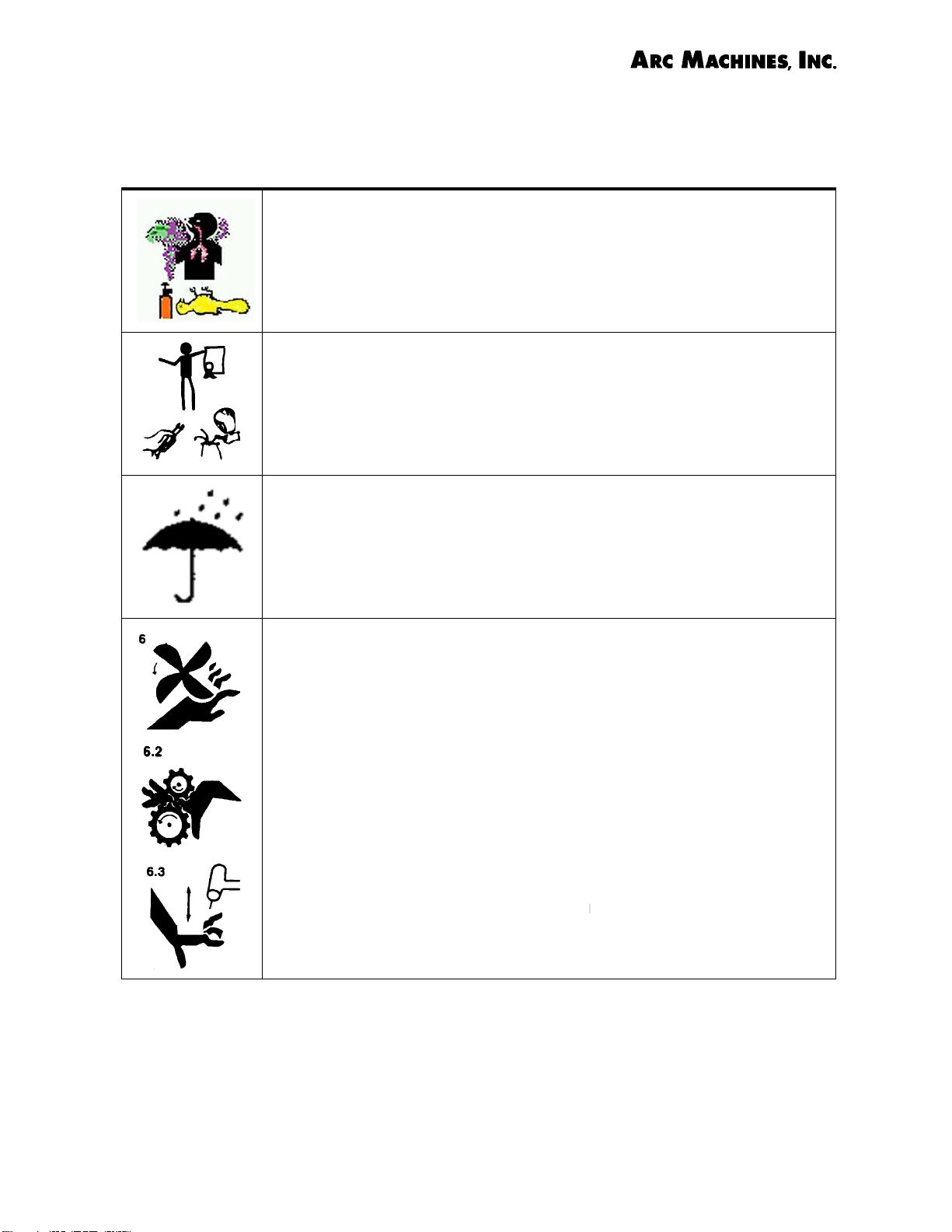

MODEL 307 WARNINGS Continued:

WARNING: Welding can cause fires or explosions. Do not weld near

flammable or explosive materials. Watch for fire. Have proper type

of extinguisher in work area.

WARNING: Welding Operators should wear non-flammable protective clothing, footwear and head gear.

WARNING: Never weld on sealed containers or pipes. This may

result in an EXPLOSION.

WARNING: Welding produces high temperatures in both the

welded components and the welding equipment. Both can cause

severe burns. Do not touch recently welded components. Avoid

touching internal components of the welding system soon after use.

Avoid touching torch components and welding fixtures soon after

welding.

WARNING: The welding arc emits ultra-violet (UV) radiation and the

molten weld gives off infra-red. Both can burn eyes and skin if

unprotected. Suitable eye and skin protection must be worn.

WARNING: Weld materials can emit toxic fumes during welding.

HEXAVALENT CHROMIUM, which is given off when stainless steel is

welded, causes lung cancer in humans. See Semi F79-0703

Appendix- HEXAVALENT CHROMIUM ALERT. WELD ONLY IN

AREAS WITH ADEQUATE VENTILATION.

Document No. 740096 Chapter 2. Page 2.

Rev. A

Arc Machines, Inc. Model 307 Orbital Welder Training

MODEL 307 WARNINGS Continued:

WARNING: Most GTAW gases like argon are non-toxic, however,

argon is heavier than air and will displace the normal atmosphere in

enclosed areas. DO NOT WELD IN ENCLOSED AREAS WITHOUT PROPER VENTILATION OR RESPIRATORS.

WARNING: AMI factory training is essential for all Welding Operators and Maintenance Technicians who operate AMI equipment.

Consult factory for dates of training classes and other training

information.

WARNING: Some systems, such as the M-307 Power Supply are

intended solely for indoor use and must be kept dry. Before operating, storing, or handling, always make sure that the M-307, M-307RP Pendant, weld heads and cables are not exposed to rain or

standing water. SYSTEM COMPONENTS ARE NOT WATER

PROOF.

WARNING: Keep hands and fingers clear from moving parts such

as fans, gears, rotors, and Rotation Mechanisms.

Document No. 740096 Chapter 2. Page 3.

Rev. A

Arc Machines, Inc. Model 307 Orbital Tube Welder Training

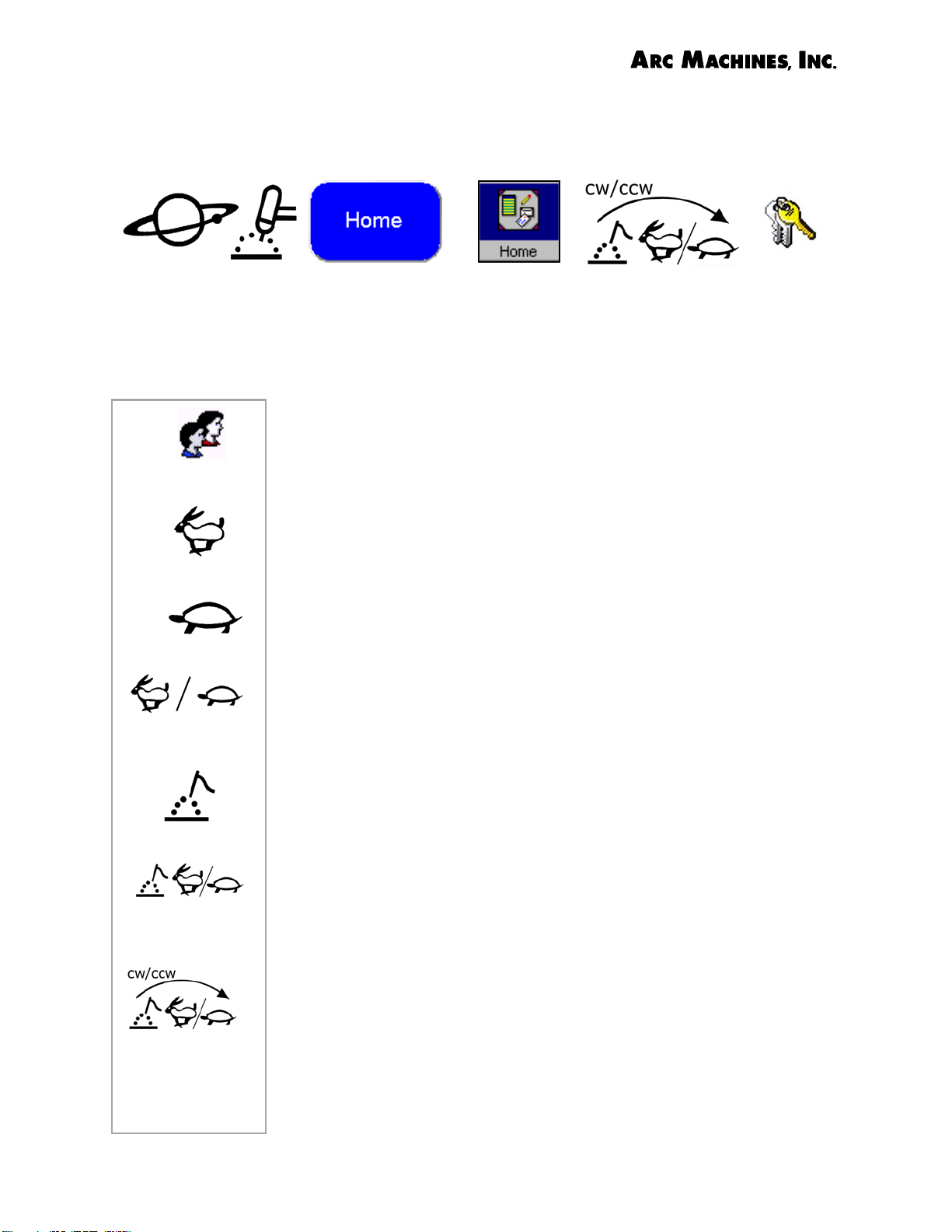

Chapter 3. Model 307 Icons, Buttons, and Symbols

Symbols and Icons have been used throughout this manual to illustrate key

points. It is hoped that this will make the manual easier to understand and to

translate for non-English-speaking people. The Windows™ operating system

uses icons as buttons that must be touched or clicked on with a mouse to

perform certain functions.

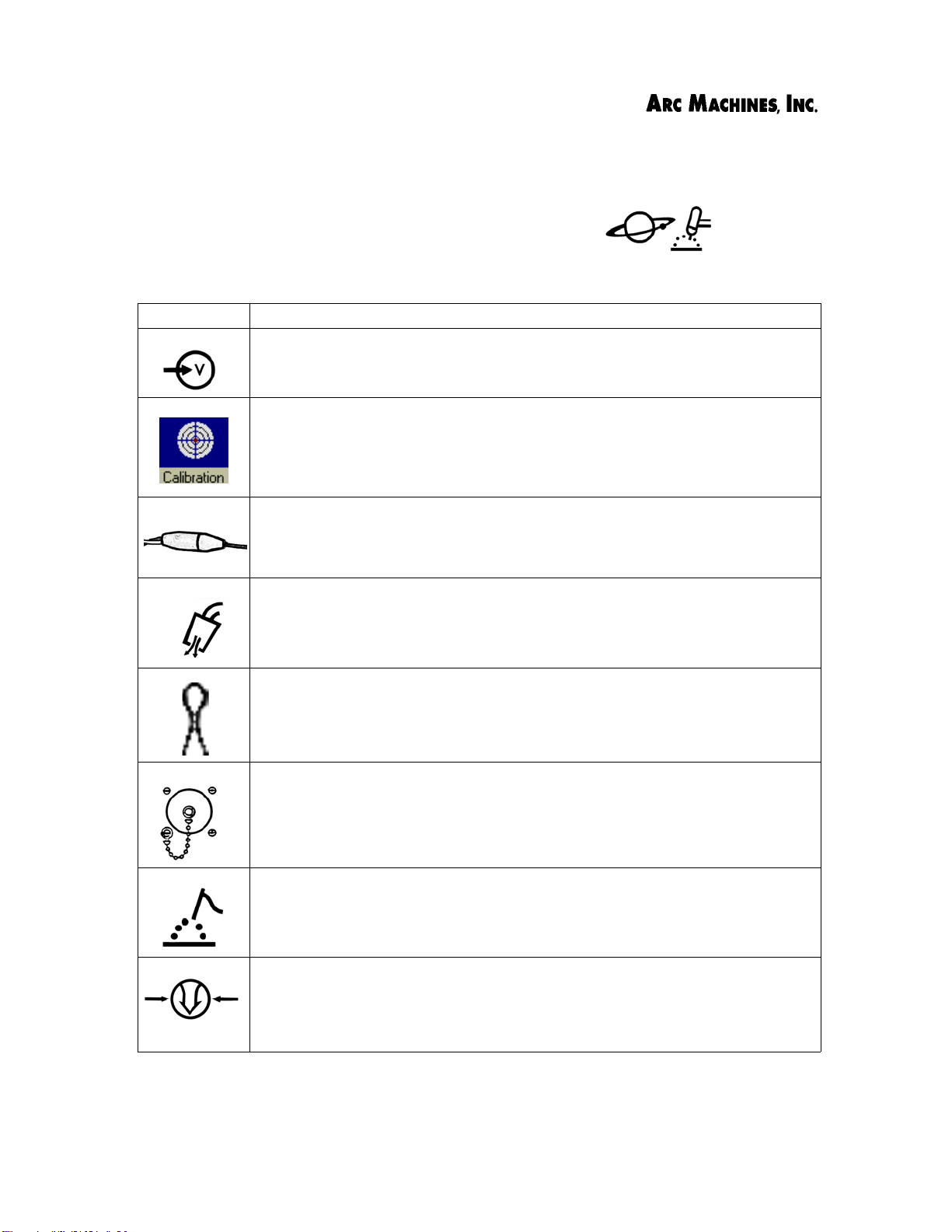

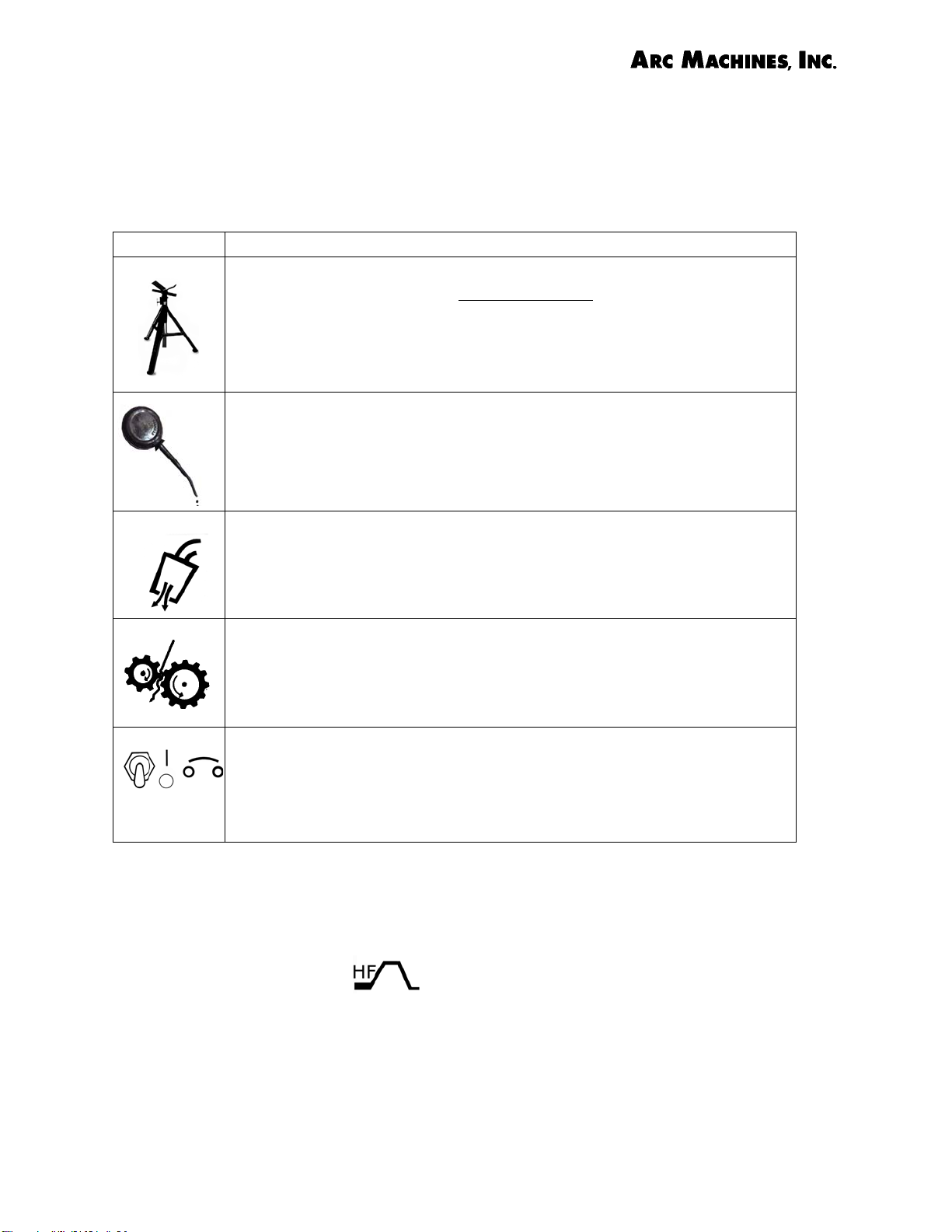

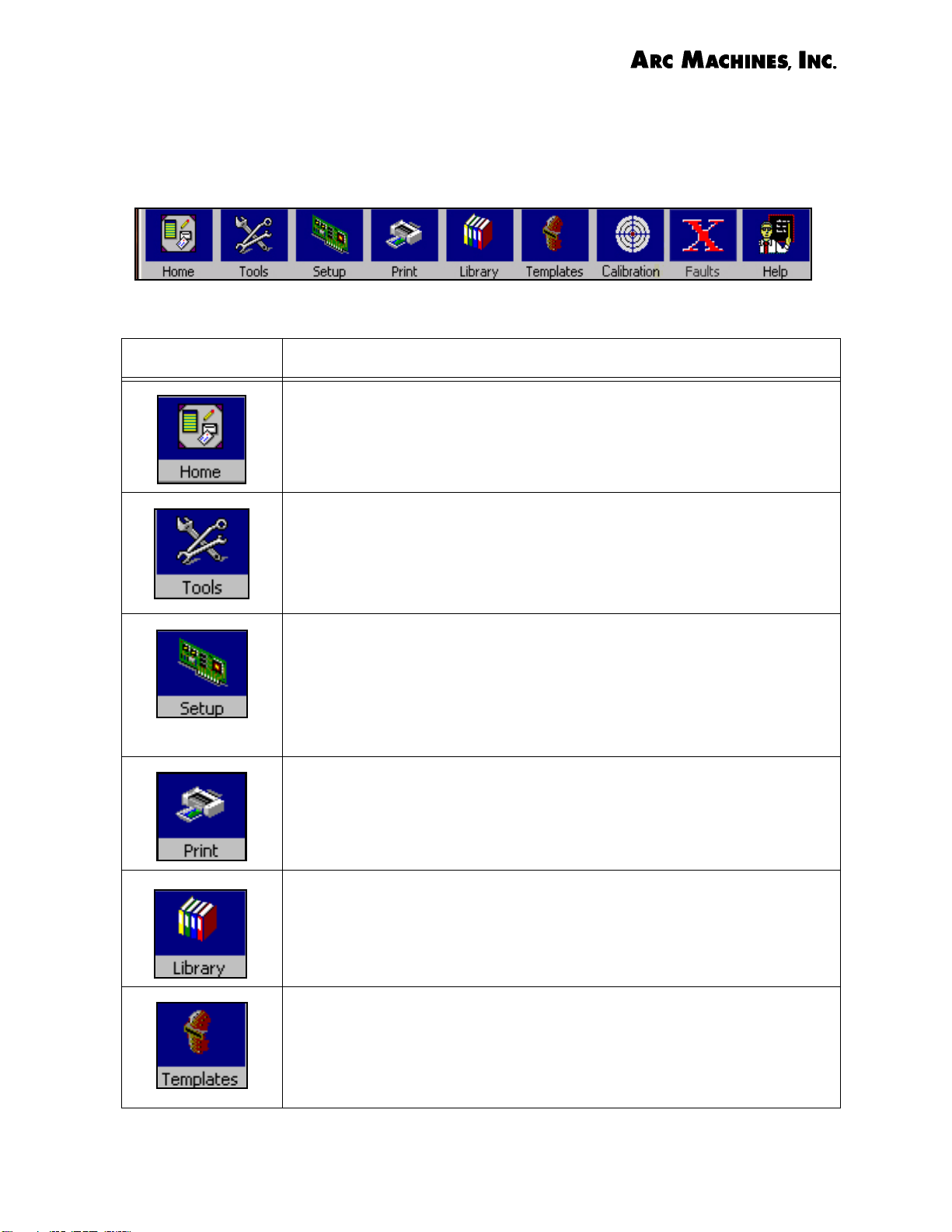

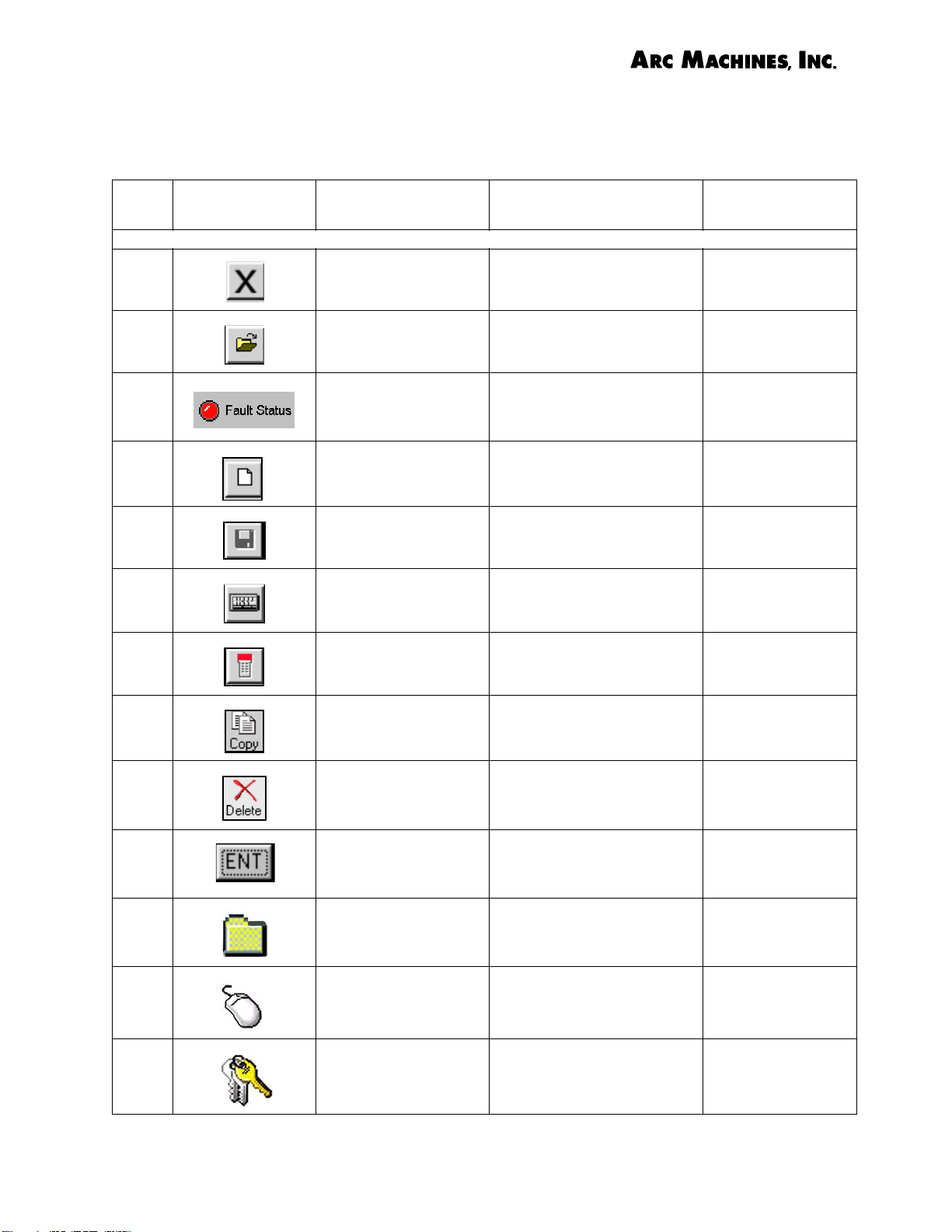

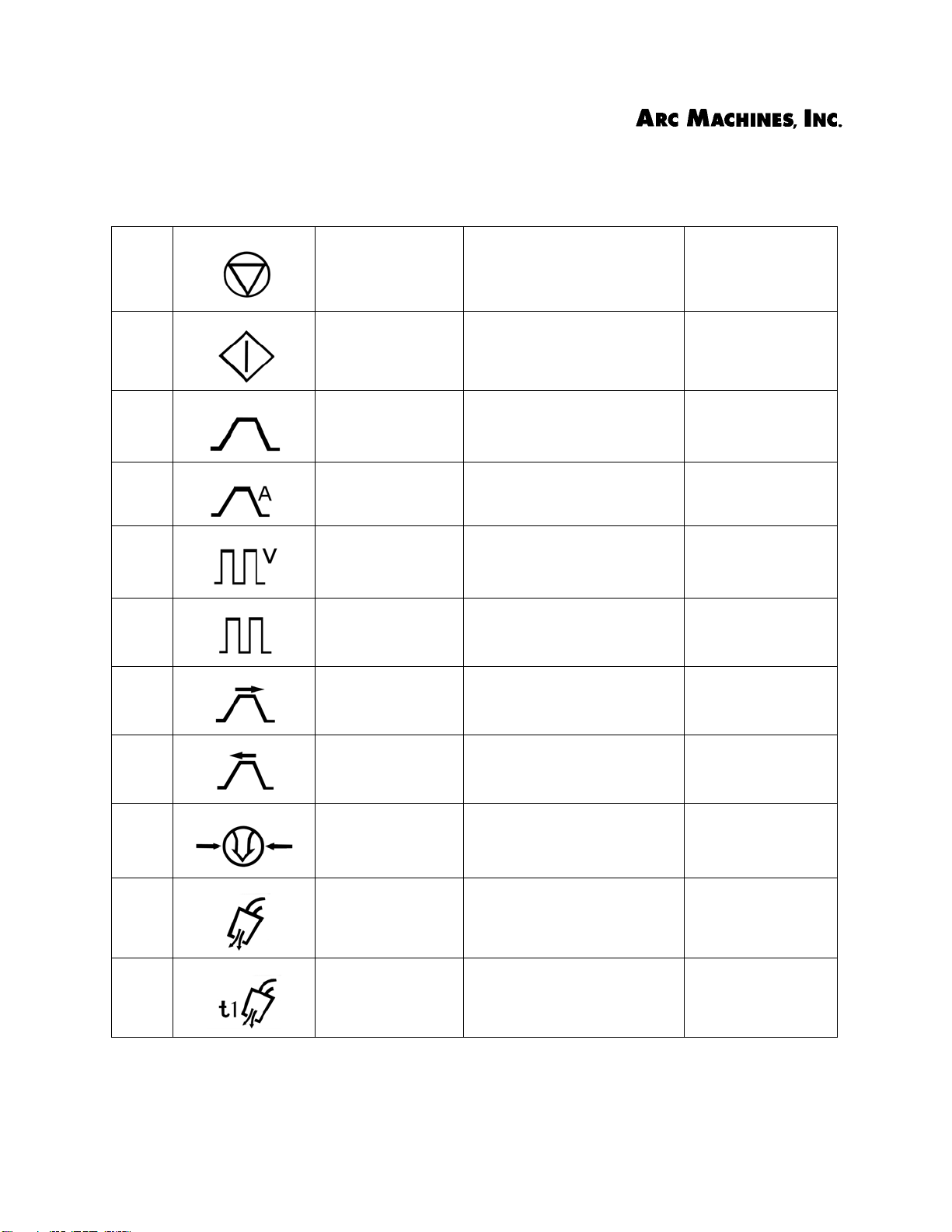

Table 1. Toolbar Icons.

Table 2. Computer buttons which appear on the touch

USER

screen and open screens or perform fu

307 are shown in Table 2.

nctions on the Model

FAST

SLOW

RUN/IDLE

OR SPEED

ELECTRODE

ELECTRODE

TRAVEL SPEED

ELECTRODE

TRAVEL

DIRECTION

Table 3. Windows™- based Computer Icons used on

the Model 307 Power Supply.

Table 4. Graphic symbols used in this manual. (Symbols

related to Safety are shown in Chapter 2.) The source of the

original symbols are listed when known. When symbols

have been used in previously unpublished combinations, the

source of the original symbols are given as well as the

designation AMI to show that they have been modified in

some way by Arc Machines, Inc.

Graphic Symbols. Graphic symbols designed for use on

arc welding and cutting apparatu

(1999 revision) by the National Electric Manufacturers

Association (NEMA). While many of these symbols were

shown alone, suggestions for using them in combination to

describe combined functions were presented. In this manual

sever

ways. For example, the rabbit is the symbol for fast, while

the tortoise is the symbol for slow or idle. Together they can

mean run/ idle or speed. When combined with the symbol

for electrode, the combined symbols can be used to signify

electrode travel speed. The addition of the curved arrow,

which is the symbol for direction of rotation, creates a

symbol for the direction of electrode travel.

al of the Graphic symbols have been combined in new

s have been published

Document No. 740096 Chapter 3. Page 1.

Rev. A

Arc Machines, Inc. Model 307 Orbital Tube Welder Training

The TOOL BAR at the top of the Model 307 Touch Screen displays icons

which have a variety of functions which are listed below. When an icon is

greyed out, this means that the icon’s function is not available from that

screen.

Table I. Model 307 TOOLBAR ICONS

ICON FUNCTION

Touching the Home icon will return the user to the Model

307 Home (Opening) Screen.

Touching the Tools icon displays a menu for 307 functions for English/Metric conversions, Electrode rotation

IPM/RPM conversions, Backup Gas Pressure conversions,

a Weld Time calculator, an Electrode Calculator and a

regular Calculator.

The Setup icon displays the System Setup screen which

has functions for Backup or Transfer of weld schedules,

Security, Fault Setup, In-Sequence Display, Printer

Setup, Language, Keyboard, Weld Head Data, reset Total

Weld counter, a list of 307 screens, setting of Date or

Time, and Power Supply information.

Touching the Print icon prints a weld schedule or report

if the user is connected to a printer.

Touching the Library icon displays the list of weld programs (schedules) stored in the 307 Memory, external

data storage device, or remote M307 power supply.

Touching the Templates icon from a Weld Schedule

Screen brings up a screen with important data regarding

the weld head specified for the schedule being used.

Document No. 740096 Chapter 3. Page 2.

Rev. A

Arc Machines, Inc. Model 307 Orbital Tube Welder Training

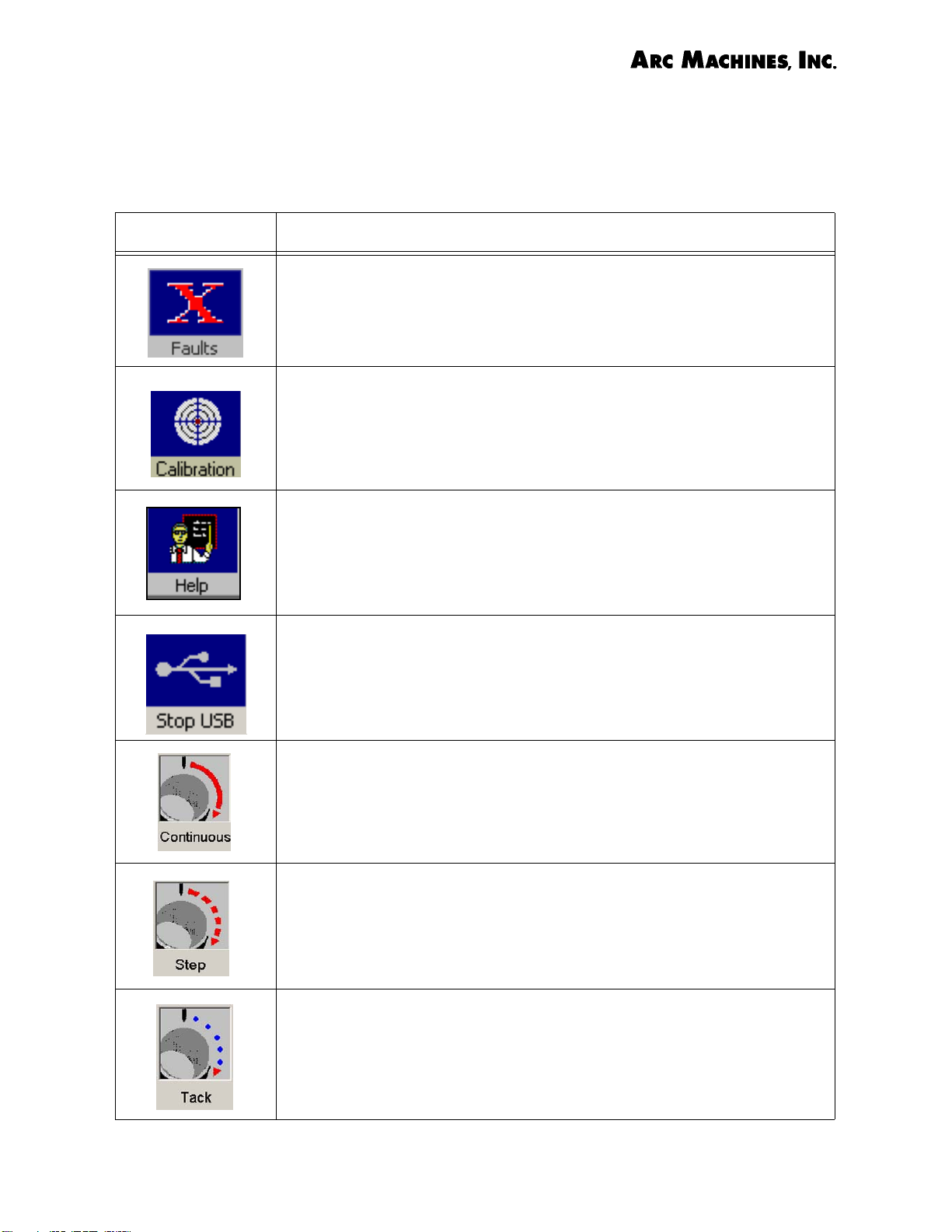

Table I. Model 307 TOOLBAR ICONS

ICON FUNCTION

Touching the Faults icon on the toolbar displays fault

settings.

Touching the Calibration icon brings up a screen with

directions for calibrating the weld head to the Model 307

Power Supply. The Icon will be greyed out if there is no

weld head connected to the power supply.

Touching the Help icon brings up the 307 Help information.

The Stop USB icon is visible from the Weld Schedule

Library screen. Press the Stop USB icon prior to removing

a USB memory stick from the Model 307 or saved files

may be lost.

Touching the Continuous Icon initiates the autogeneration of a weld schedule in which the rotation is continuous

(Primary RPM only).

Touching the Step icon initiates the autogeneration of a

weld schedule with STEP rotation mode in which the electrode moves only during the background current pulse.

Touching the Tack icon initiates the autogeneration of a

weld schedule for making orbital tack welds.

Document No. 740096 Chapter 3. Page 3.

Rev. A

Arc Machines, Inc. Model 307 Orbital Tube Welder Training

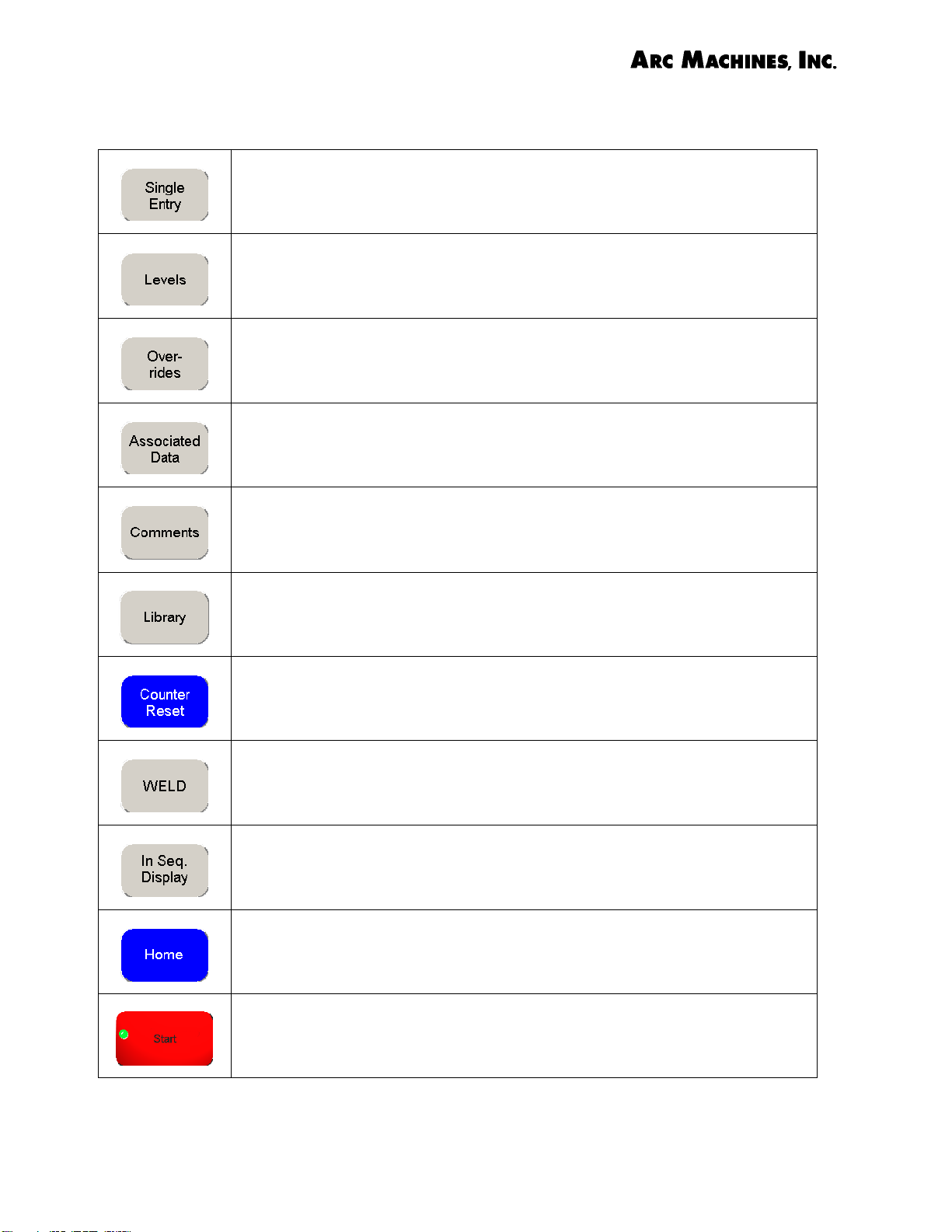

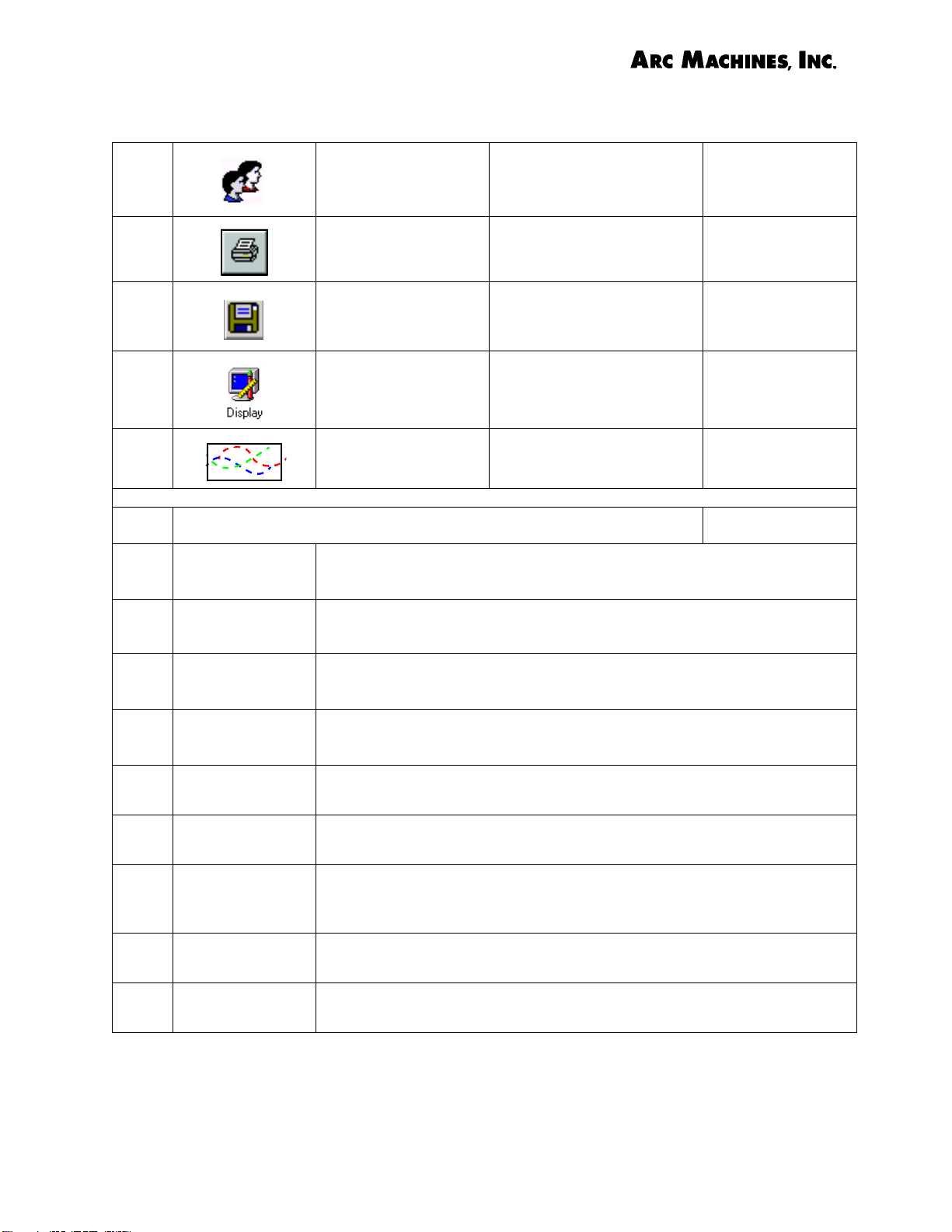

Table 2. Buttons used on the Model 307 Power Supply

Pressing Single Entry displays the Weld Schedule - Single Entry

screen on which weld parameters which apply to all levels of a weld

program are entered.

Pressing the Levels button displays the Weld Schedule - Weld Levels

screen on which weld parameters that can be changed for each level,

such as amperages and pulse times, are entered.

Pressing Overrides opens the Weld Schedule - Overrides screen on

which upper and lower limits for weld schedule parameters may be set.

Pressing Associated Data opens the Associated Data Main Screen

from which other screens are accessible for entering data on Tube,

Equipment, Gas, Electrodes and Comments.

Pressing Comments opens the Associated Data Comments screen

which is a blank screen for writing comments about a particular weld

schedule.

Pressing Library opens the Model 307 Weld Schedule Library in

which weld schedules stored in the Model 307 Library are listed and may

be opened for welding.

Pressing Counter Reset opens the Counter/Alert Indicator screen.

From this screen you may enable, disable, or reset the alert indicator

and weld counter.

Pressing Weld opens the Weld Schedule Weld Screen from which the

weld sequence (welding) can be initiated when in Weld Mode.

Pressing In Seq. Display opens the In-Sequence Display Selection

Screen which allows the user to select data for display during the weld

sequence.

Pressing Home returns the user to the Model 307 Opening Screen (1).

Pressing the Start button in Weld Mode initiates the Weld Sequence.

Pressing Start from Test Mode initiates a weld sequence in which an arc

is not struck.

Document No. 740096 Chapter 3. Page 4

Rev. A

Arc Machines, Inc. Model 307 Orbital Tube Welder Training

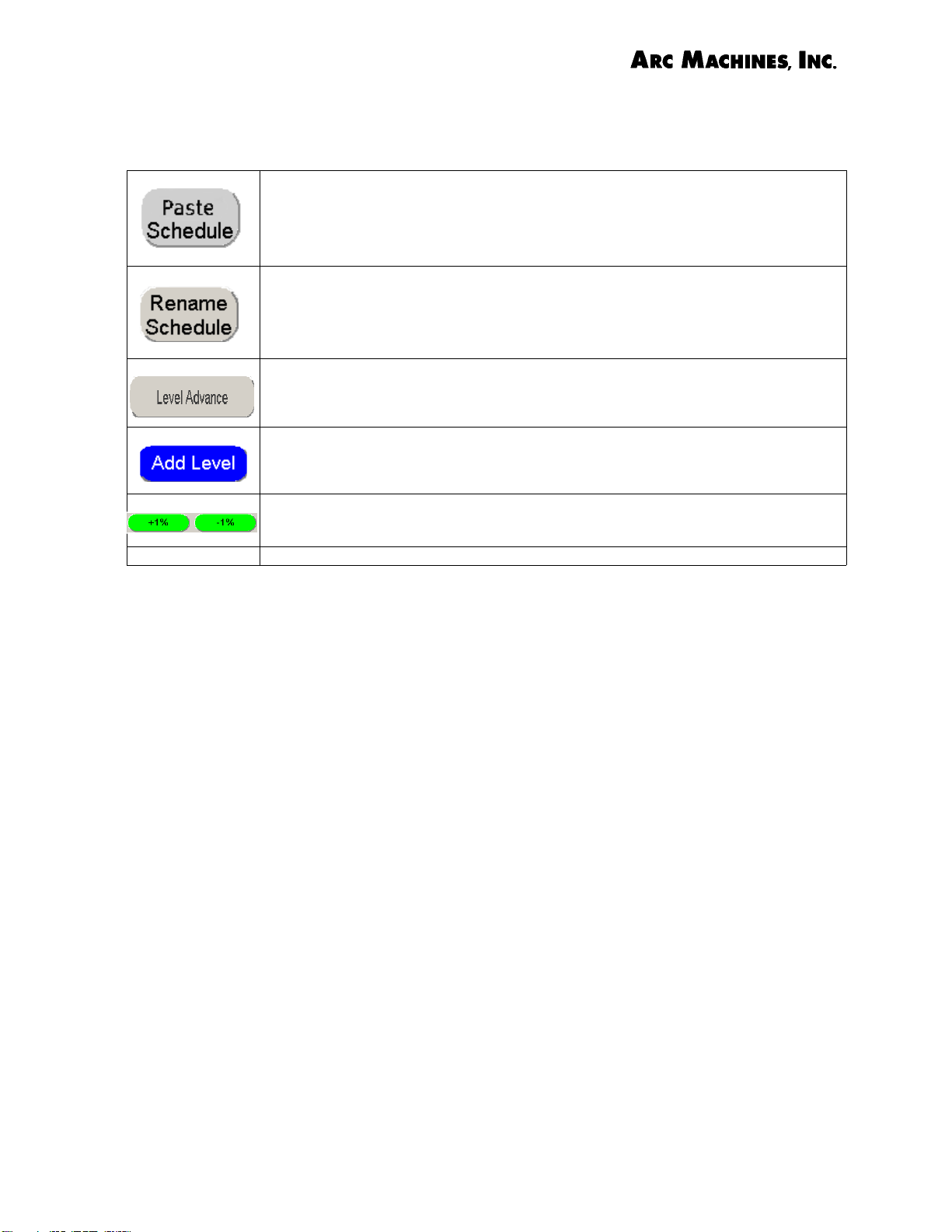

Table 2. Buttons used on the Model 307 Power Supply

Pressing the Test button on the Weld Schedule Weld Screen puts the

Model 307 into Weld Mode.

Pressing the red WELD button on the Weld Schedule Weld screen puts

the Model 307 into Test Mode.

Touching the Data Acquistion button opens the Weld Identification

Information screen. Weld Data Recording may be enabled or disabled

from this screen.

Touching the Weld Main button opens the Weld Schedule Main screen

of the open weld schedule.

Library Buttons

Create Folder opens a screen on which the name of the new folder is

entered. This folder may be used for storing a user-defined group of

weld schedules.

Rename Folder opens a screen on which the name of a specified folder

appears. A new name may be assigned to the folder.

Delete Folder opens a screen asking whether the user truly wants to

delete the selected folder. To delete the folder touch YES. To cancel

choose NO.

Paste Folder will paste a folder that has been copied into the selected

Library.

Copy Folder copies the selected folder which may then be pasted into a

remote machine.

Open Schedule. When a weld schedule is selected in the Library, this

button will open the schedule to the Main Weld Schedule Screen.

Copy Schedule copies the selected schedule so that it may be pasted

into another folder or to the Library of a remote machine.

Delete Schedule will ask the user if he truly wishes to delete a selected

schedule. When the user touches YES, the schedule will be deleted.

Document No. 740096 Chapter 3. Page 5

Rev. A

Arc Machines, Inc. Model 307 Orbital Tube Welder Training

Table 2. Buttons used on the Model 307 Power Supply

Paste Schedule inserts a copied schedule into another folder of the

same power supply or into a folder in a Library in remote power supply.

Rename Schedule allows the user to change the name of a selected

schedule by typing in the new name from the keyboard.

Level Advance. Touching the Level Advance button on the touch screen

or on the remote pendant during the weld sequence advances the

program to the next level.

Add Level. When the Levels screen of a weld schedule is visible additional Levels may be added to the schedule by touching this button.

Plus or Minus 1%. Both Primary and Background Amps of a weld

schedule are changed 1% up or down by touching one of these buttons.

Document No. 740096 Chapter 3. Page 6

Rev. A

Arc Machines, Inc. Model 307 Orbital Tube Welder Training

Table 3. Computer Icons used on Model 307

NO. Symbol

1

2

3

4

5

6

Function, Keyword or Phrase

Close - At upper

right of screen

Open To S i gn i fy O pen i ng o f a

Fault Status

Indicator - Red or

Green

New To S ign i fy C rea tin g a

Save To Signify Saving a File Microsoft

Keyboard To Signify a Computer

Application Source

To S i gn i fy C los i ng o f a

Computer file

Computer File

Red Si

Condition - Green is OK

New File

Keyboard

gnifies a 307 Fault

Microsoft

Microsoft

AMI

Microsoft

Microsoft

7

8

9

10

11

12

13

307 RP Symbol To Signify the 307

Remote Pendant

Copy To Signify Copying or

Duplicating a File

Delete To Signify Deleting a File Microsoft

ENT Button used to Signify

the Enter Key on a Keyboard

Folder To Signify File Folder for

Weld Schedules

Mouse To S ign ify u se o f a

Mouse, Mouse Click, or

Software

Password To S ign i fy u se o f a

Password to Access a

Program or Syste

m

AMI

Microsoft

Microsoft

Microsoft

AMI

Microsoft

Microsoft

Document No. 740096 Chapter 3. Page 7

Rev. A

Arc Machines, Inc. Model 307 Orbital Tube Welder Training

Table 3. Computer Icons used on Model 307

14

15

16

17

18

1 Touch

Screen

Users To S i gn i fy U ser s (o r

Classification of User

such as Supervisor, etc.)

Printer To Signify a Printer or to

Print a File

Floppy disk To Signify a File or Data

such as a Weld

Record(s)

Display To Signify a Computer

Monitor Screen

Streaming Data To S i gn i fy Re al T ime

Digital Data Output

Windows® Functions and Definitions

A Computer Screen that Accepts Commands by Touch

Microsoft

Microsoft

Microsoft/AMI

Microsoft

AMI

2 Too lb ar

3 Pull-Down

Menu

4 Left or Right

Click

5 Double Click

6 Check Boxes

Scroll Bar

Drag

Drop

Windows® places toolbars across the tops of programs with buttons for various tasks such as copy, cut, paste, etc.

A list of options that appears when choosing a selection from the

Menu Bar or other feature.

To push and release the right or left button on the mouse. These

have separate functions.

To push and release the left mouse button twice in rapid succession.

Clicking in a box next to an option places a check in the box and

changes its setting.

Box at right hand side of screen that when moved vertically up or

down moves the viewing window up or down. A similar scroll bar at

the bottom of the screen moves the view from side to side.

A four-step process that moves an object across your desktop.

First touch the object and drag the object to the new location.

(Used after Drag) Letting go of the mouse (or releasing your finger) allows the object to remain at the new location.

Document No. 740096 Chapter 3. Page 8

Rev. A

Arc Machines, Inc. Model 307 Orbital Tube Welder Training

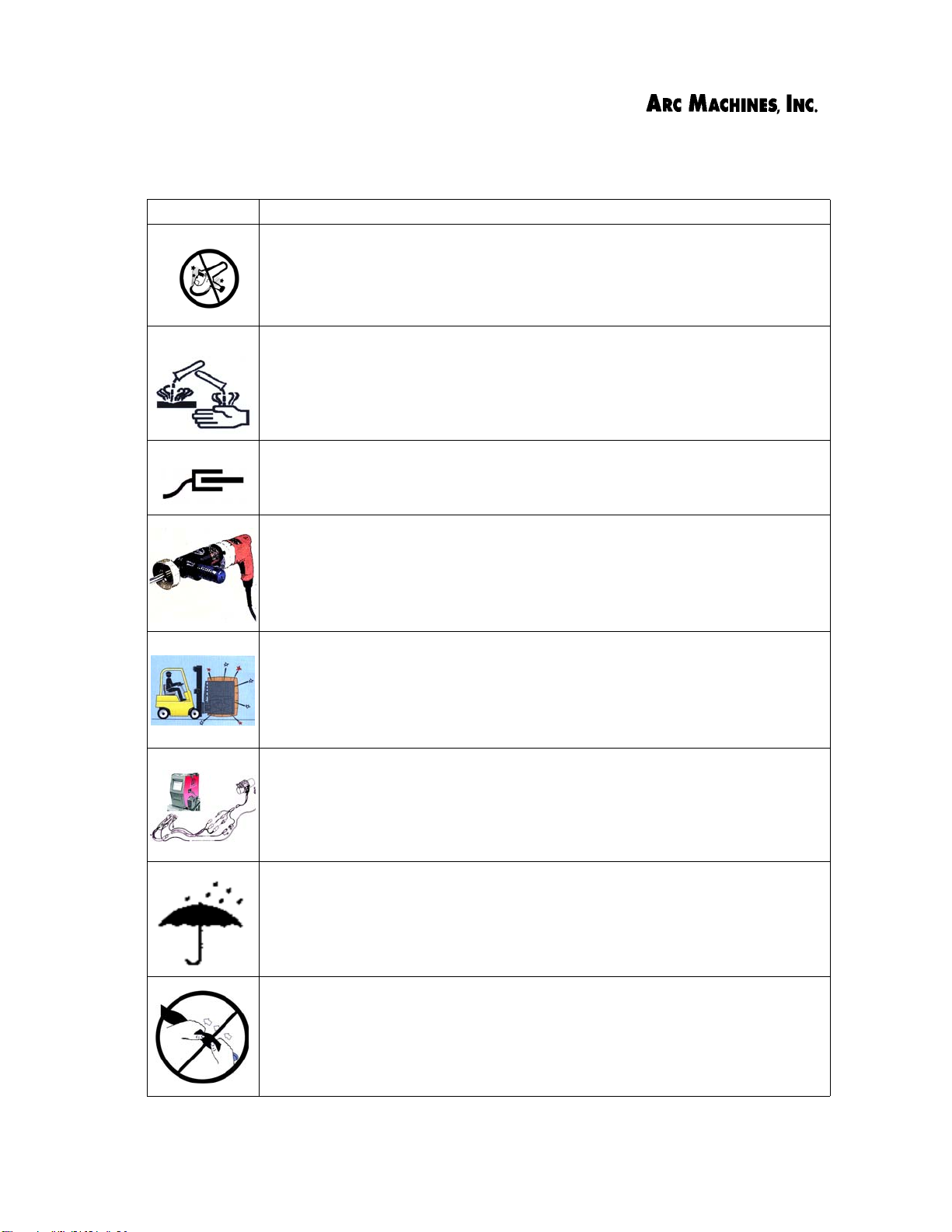

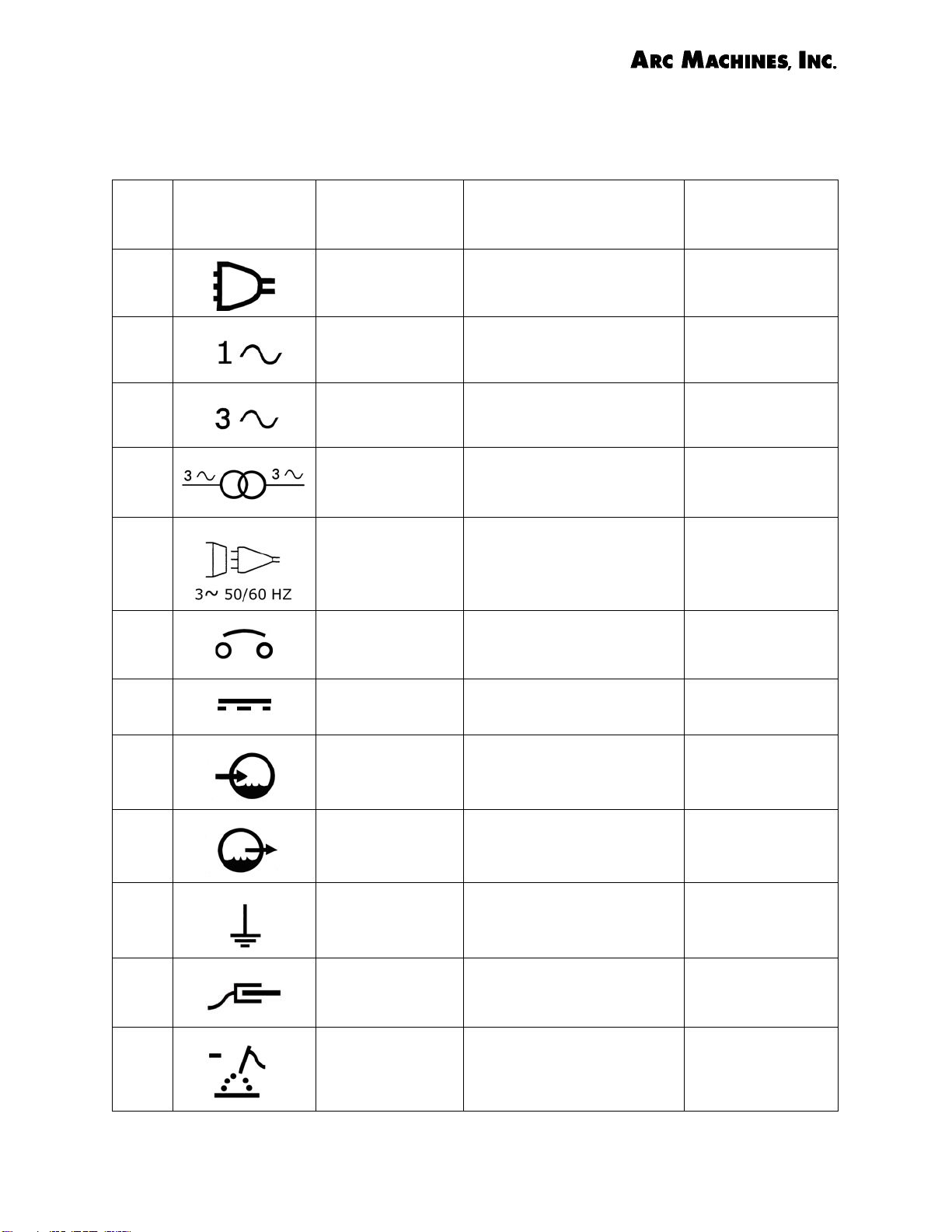

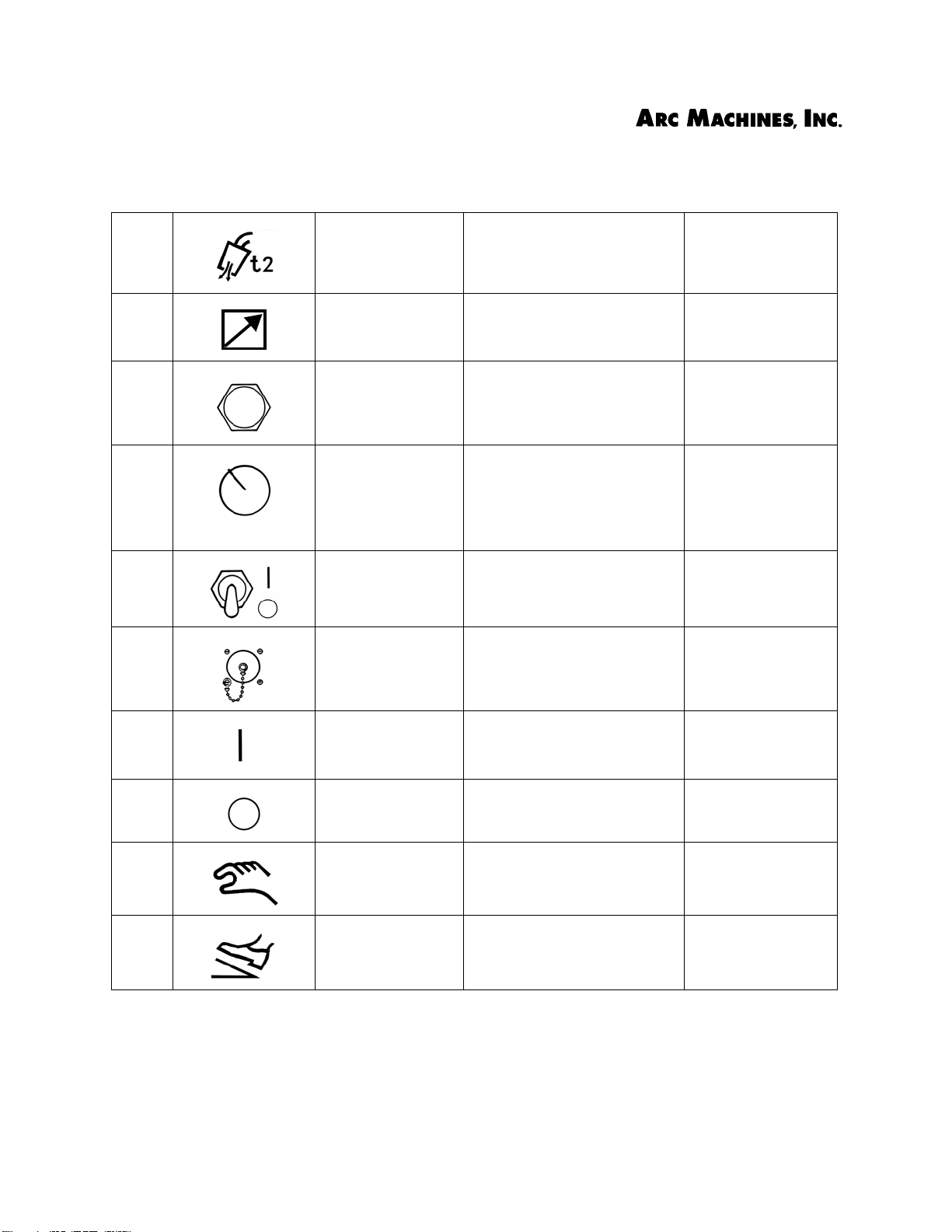

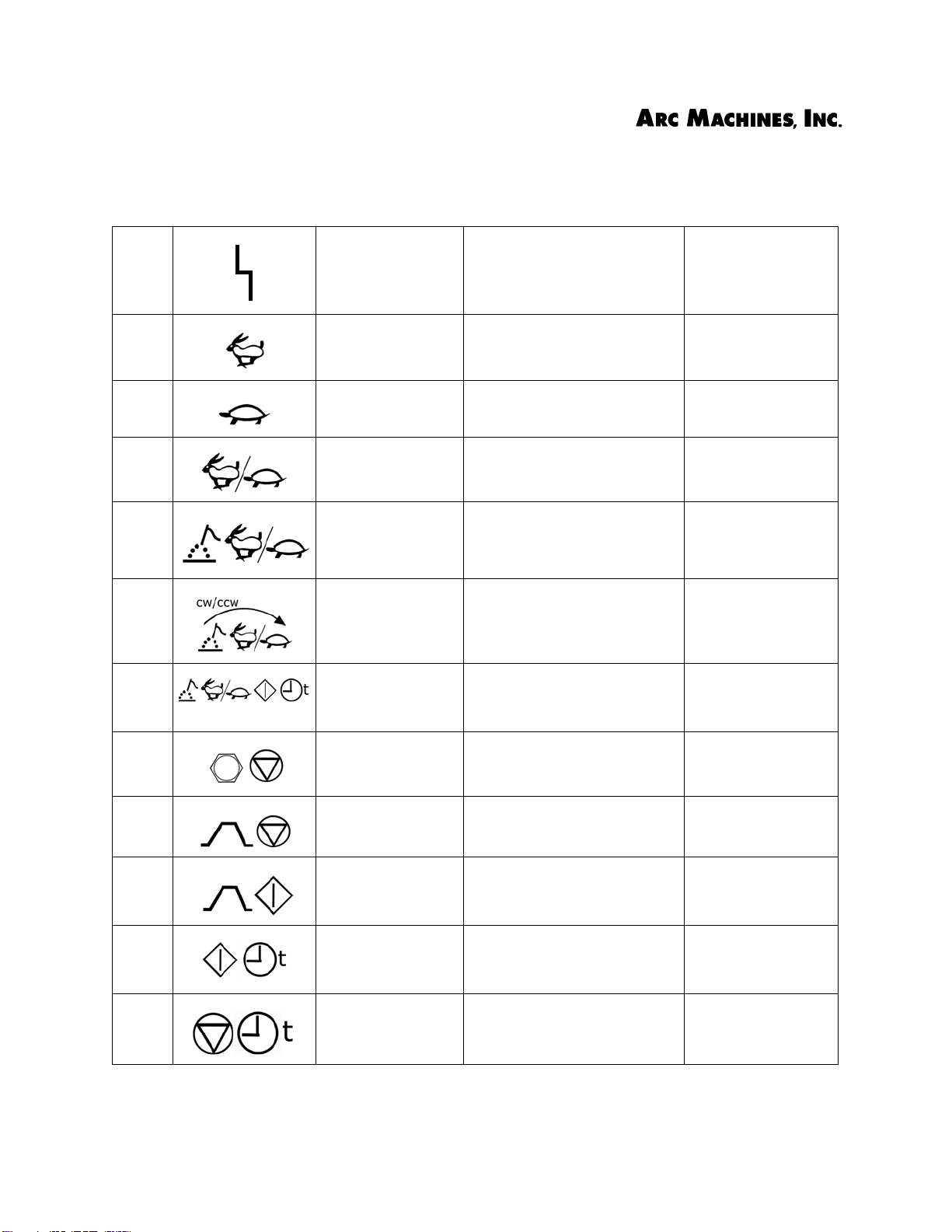

Table 4. Graphical Symbols used in this Manual

NO. Symbol

1

2

3

4

5

6

Function, Keyword or

Phrase

Line To Signify a Power Line or

Single Phase To Signify Single Phase IEC 974

Three Phase To Signify Three Phase IEC 974

Three Phase

Trans f orme r

Line Connection

(Three Phase at

50 to 60 Hertz)

Circuit Breaker To S ign i fy a Ci r cui t

Application Source

ANSI/NEMA

Cord

Signifies Three Phase

Trans f orme r

gn i fy a Li n e Co nne c-

To S i

tion

Breaker in an Electrical

Circuit

IEC

974

IEC 974

ANSI/NEMA

7

8

9

10

11

12

Direct Current

(DC)

Water

Coolant Input

Water Coolant

Output

Earth (Ground) To S ign i fy t he E art h

Work Connection

Electrode Negative

Signifies Direct Current IEC 417

To S i gn i fy Wa t er

(Coolant) Input

To S i gn i fy Wa t er

(Coolant) Output

(Ground) Connection

To Signify a Work Piece

Connection

To S i gn i fy E lec t ro d e N e gative Connection or

Switch P

osition

5031

ANSI/NEMA

ANSI/NEMA

IEC 417

5017

ISO 7000-0453

ANSI/NEMA

Document No. 740096 Chapter 3. Page 9

Rev. A

Arc Machines, Inc. Model 307 Orbital Tube Welder Training

Table 4. Graphical Symbols used in this Manual

13

14

15

16

17

18

Electrode To S ign ify a n E l ect rod e ANSI/NEMA

Electrode

generic

Gas Type To Signify the Type of

Gas Supply To Signify a Gas Supply ANSI/NEMA

Gas Input To Signify Gas Input ANSI/NEMA

Ventilating and

Air Circulating

Fan

Signifies a generic electrode

Gas Such As Argon, CO

To Signify a Ventilating

Fan or Air Circulating

ANSI/NEMA

ANSI/NEMA

2

ISO 7000-0089

19

20

21

Document No. 740096 Chapter 3. Page 10

Rev. A

Grinder To Signify not to grind in

certain areas - contamination caused by grinding

Protective Boots

over Cable

Connector

Exclamation

Point

To Signify Secure Connection with Protective

Boots

To Signify Warning, Danger, Caution

AMI

AMI

IEC 417

5036A

Arc Machines, Inc. Model 307 Orbital Tube Welder Training

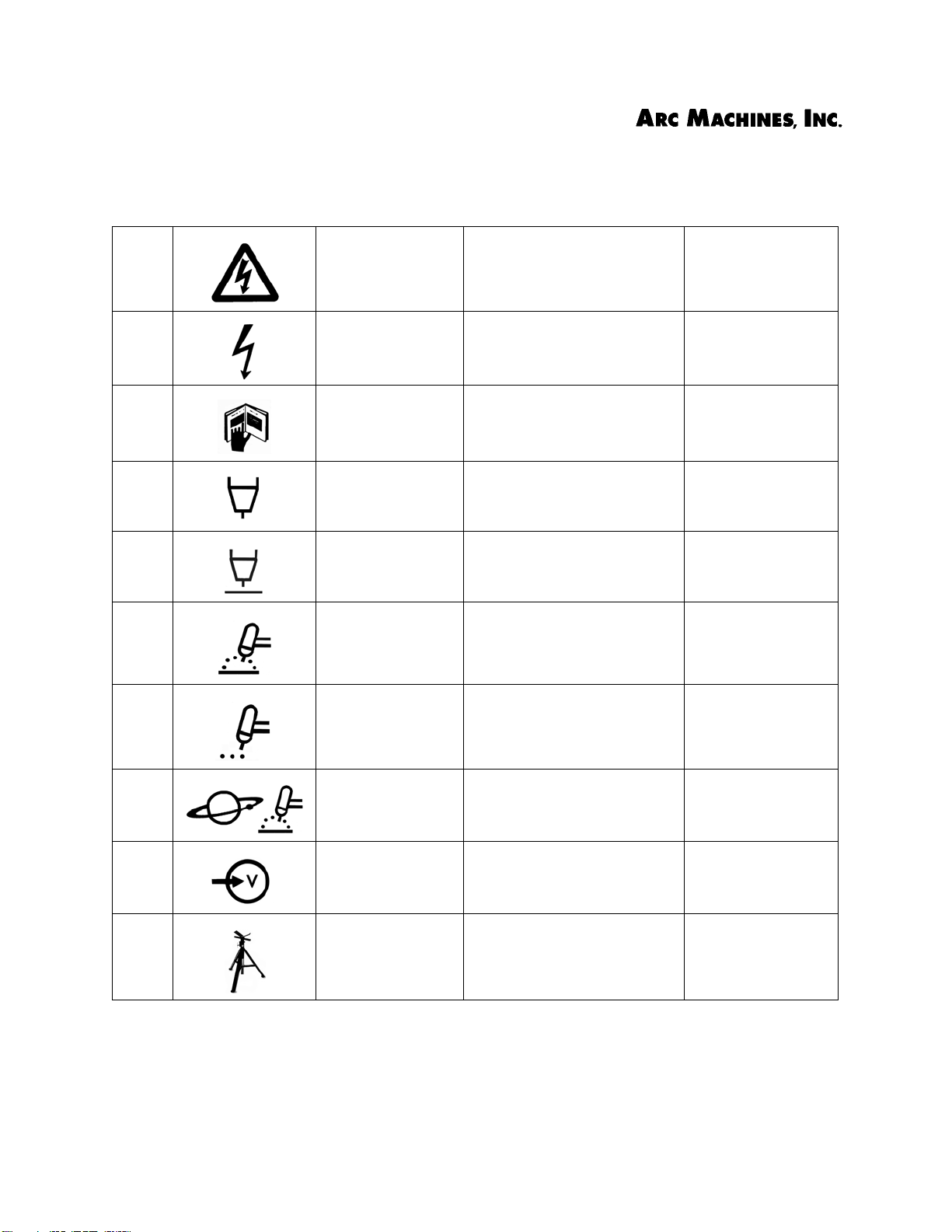

Table 4. Graphical Symbols used in this Manual

22

23

24

25

26

27

Lightning Symbol for Severe Elec-

trical Shock Hazard

Dangerous Voltage

Read Operator’s Manual

Tor c h Signifies a Welding or

Arc Gap or Arc

Voltage Control

(AVC)

Gas Tungsten

Arc Welding

(GTAW) Torch

To S i gn i fy D ang e ro u s

Voltage

To Signify that the Operator’s Manual Should be

Read

Cutting Torch

Signifies Arc Gap or Arc

Voltage Control (AVC)

To S ign i fy a GTA W Tor c h ISO 7000-0465

IEC 417

5036A

IEC 417

5036A

SAE

ANSI/NEMA

ANSI/NEMA

AMI

28

29

30

V

31

Document No. 740096 Chapter 3. Page 11

Rev.A

Ta c k We ld i ng

(GTAW)

Orbital GTAW To Signify the Orbital

Input Voltage/

Power

Pipestand To S ig n ify use o f a

To Signify Tack Welds

with a GTAW Torch

GTAW Process

To Signify Input Voltage

(Power)

Pipestand

ISO 7000-0465

ISO 7000-0465

AMI

IEC 417

5034

ANSI/NEMA

AMI

Arc Machines, Inc. Model 307 Orbital Tube Welder Training

Table 4. Graphical Symbols used in this Manual

32

33

34

35

36

37

38

Stop of Action To Signify the Stop (of

Action) Function or Control

Start To Signify the Start (of

Action) Function or Control

Process Cycle To Signify One Complete

Process Cycle

(Weld Sequence)

Weld Current To Signify Welding Amps

During Process Cycle

Arc Volts To Signify Arc Volts Dur-

ing Process Cycle

Pulse Signifies Pulse Function

or Control

Sequence

Advance

To Signify Advancing to

the Next Sequence Event

(Level)

ANSI/NEMA

ANSI/NEMA

ANSI/NEMA

ANSI/NEMA

ANSI/NEMA

ANSI/NEMA

ANSI/NEMA

39

40

41

42

Document No. 740096 Chapter 3. Page 12

Rev. A

Sequence

Deadvance

Air (Gas) Pressure

Purge by Gas To Signify Purging of Air

Gas Preflow To Signify Gas Preflow

To Signify Returning to

the Previous Sequence

Event (Level)

To Signify Air (or Gas)

Pressure Function or Control

(by Gas)

Time (PREPURGE)

ANSI/NEMA

ANSI/NEMA

ISO

7000-0474

ISO 7000-0474

ANSI/NEMA

Arc Machines, Inc. Model 307 Orbital Tube Welder Training

Table 4. Graphical Symbols used in this Manual

43

44

45

46

47

48

Gas Postflow To Signify Gas Postflow

(POSTPURGE) Flow

Remote Signifies Remote Opera-

tion or Control

Pushbutton To Signify a Pushbutton

Switch used to Start or

Stop a Function

Panel/LOCAL To Signify Panel/Local

Function or Switch such

as a Switch to Change

Between a Local Control

and a Remote Control

ON-OFF Switch To S ign i fy a n ON -OF F

Switch

Receptacle To Signify a Receptacle

Type Connector

ISO 7000-0474

ANSI/NEMA

ANSI/NEMA

ANSI/NEMA

ANSI/NEMA

ANSI/NEMA

ANSI/NEMA

49

50

51

52

Document No. 740096 Chapter 3. Page 13

Rev. A

ON

(Enable)

OFF

(Disable)

Hand To S i gn i fy M anu al

Foot Control To Signify a Foot Control

To Signify the ON or

Enabled State of a

Function

To Signify the OFF or Disabled State of a Function

Control of a Function or

Tool

Device, Function, Connection or Control

ANSI/NEMA

ANSI/NEMA

ANSI/NEMA

ANSI/NEMA

Arc Machines, Inc. Model 307 Orbital Tube Welder Training

Table 4. Graphical Symbols used in this Manual

53

54

55

56

57

58

59

Disturbance (or

change)

Fast To Signify Fast Action or

Slow To Signify Slow Action or

Travel Speed To S ign ify Trav e l or Run

Electrode Travel

Speed

Direction of

electrode travel

Electrode Travel

Start Delay

To S ign i fy a Di s tur ban ce

in the Proper Run of a

Procedure, or Fault Condition

Operation

Operation

Speed

To Signify Travel Speed

of the Electrode or Torch

To S ign i fy D ire cti o n o f

Electrode Travel

To Signify the Time after

Arc Start that the Electrode Begins to Move

ISO 7000-0228

SAE

SAE

SAE

SAE

ANSI/NEMA

AMI

ANSI/NEMA

/AMI

ANSI/NEMA

/AMI

60

61

62

63

64

Document No. 740096 Chapter 3. Page 14

Rev.A

ALL STOP To S ign i fy s hut dow n of

Power Supply

Sequence STOP To Signify stopping of the

weld sequence

START

Sequence

Start Delay

Time

Stop Delay Time To Signify a Timed Delay

To Signify initiation of

weld sequence

To Signify a Timed Delay

in Starting a Function

in Stopping a Function

ANSI/NEMA

AMI

ANSI/NEMA

AMI

ANSI/NEMA

AMI

ANSI/NEMA

AMI

ANSI/NEMA

AMI

Loading...

Loading...