Arc Machines 205 WDR User Manual

Model 205 Tube Welding Power Supply

Part No. 740108

Revision J

Operator’s Manual

M O D E L 2 0 5

T

O P E R A T O R ’ S M A N U A L

INTRODUCTION

he Model 205 is a power source and controller for automatic orbital tube welding. It is

intended to be used only in conjunction with AMI or EXEL orbital tube weldheads.

The Model 205 power supply provides GTAW (Gas Tungsten Arc Welding) current

with pulsation controls, high frequency arc starting, purge gas controls, weldhead arc

rotation and automatic timing functions. Users need only to supply input AC power, a

regulated gas source with flow meter and the appropriate weldhead.

NOTICE

This document and the information contained herein is the property of Arc Machines, Inc. It

is proprietary and submitted and received in confidence. It shall be used only for the

purpose for which it is submitted and shall not be copied in whole or in part without the prior

express written permission of Arc Machines, Inc. The information in this document has

been carefully reviewed and is believed to be accurate. However, no responsibility is

assumed for inaccuracies.

Information and instructions in this document are subject to change and Arc Machines, Inc.

reserves the right to change specifications and data without notice.

i

M O D E L 2 0 5

O P E R A T O R ’ S M A N U A L

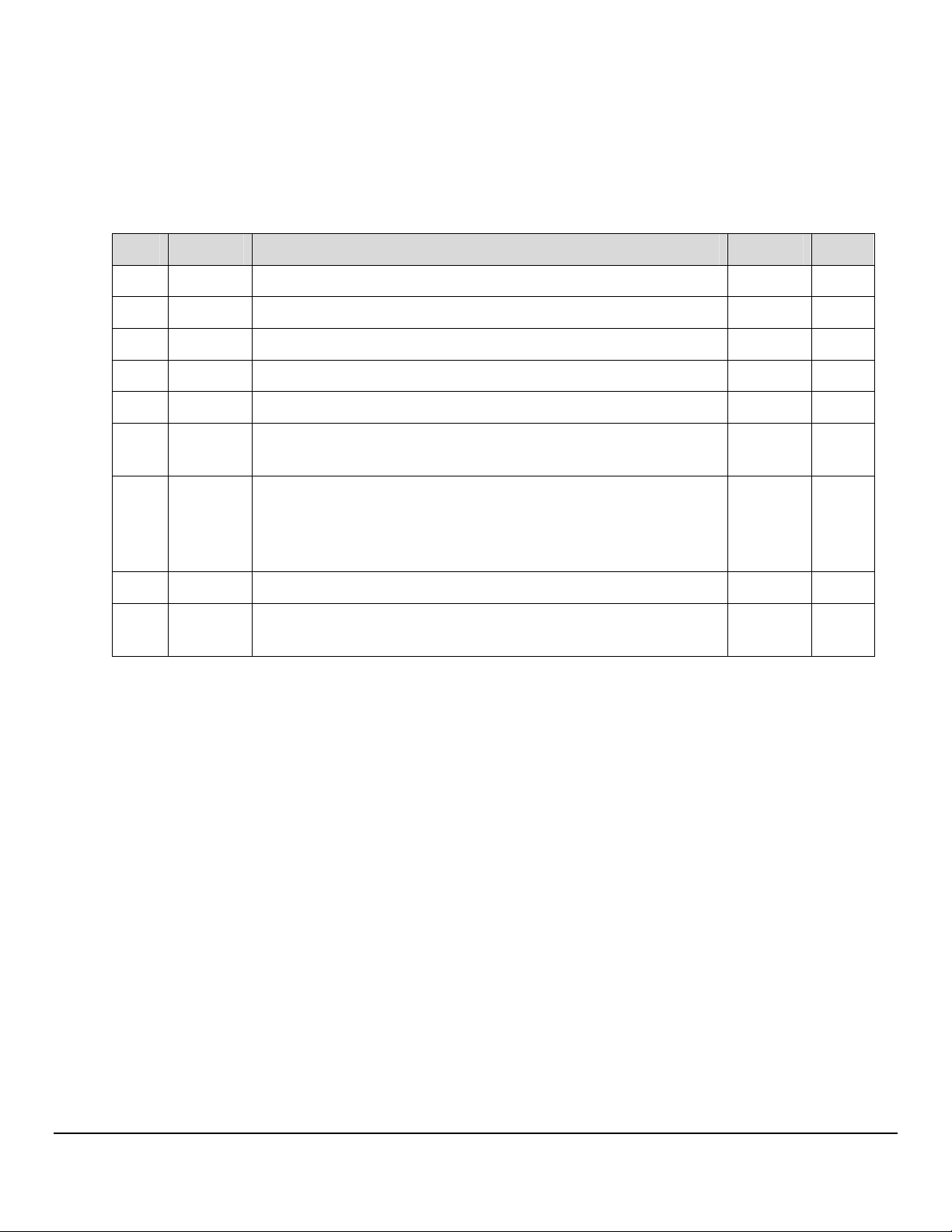

Revision History

Rev ECO No.

Change Description Date Appr.

A N/A Initial release 3/10/09 B.F.

B 5355 Update sections 2.0, 3.0, 4.0, 5.0 & 6.0; delete Glossary 5/14/09 B.F.

C 5411 Update section 4.10.9 Performing a Weld 07/06/09 B.F.

D 5447 CE changes 12/30/09 D.C.

E 5713 Correct table in Section 6.1.2 with correct weight 06/16/10 D.C.

F 5817 Incorporate S/W v1.5, corrections for CE changes, add

12/08/10 D.C.

power grounded to section 2.0, update obsolete data

G 6346 Incorporate M21 W/H information, add changes to Run

06/15/12 D.C.

screen, add Associated Data look-up tables, add

information on system initiate 0.5 second delay, add

information on +1%/-1% buttons, update UK address.

H 6518 Section 6.2, changed picture of Remote Pendant (pg51) 3/20/13 BL

J 6646 Add Weld Data Recording functionality and update

2/25/14 W.O.

applicable screens

ii

ii

iiii

M O D E L 2 0 5

O P E R A T O R ’ S M A N U A L

Table of Contents

Table of Contents

Table of ContentsTable of Contents

INTRODUCTION.................................................................................................... i

NOTICE..............................................................................................................i

Revision History ............................................................................................ii

Table of Contents .........................................................................................iii

1.0 SAFETY PRECAUTIONS...................................................................... 1

1.1 SHOCK HAZARD WARNING................................................................ 1

1.2 WARNING LABEL DEFINITIONS ......................................................... 3

2.0 SPECIFICATIONS .................................................................................5

2.1 ELECTRICAL ........................................................................................ 5

2.2 ELECTICAL SERVICE GUIDE .............................................................. 6

2.3 PHYSICAL DIMENSIONS .....................................................................6

2.4 PROGRAMMABLE AND OPERATIONAL FUNCTIONS ...................... 7

3.0 INITIAL SETUP......................................................................................8

3.1 SYSTEM SYMBOLS..............................................................................8

3.2 INSPECTION .......................................................................................10

3.3 POWER CONNECTION....................................................................... 11

3.4 WELDING GAS CONNECTIONS ........................................................ 11

3.5 MODEL 205 TO M8 / M9 WELDHEAD HOOK UP ..............................12

3.6 MODEL 205 TO EXEL ROTOR DRIVER HOOK UP........................... 16

3.7 MODEL 205 TO M21 WELDHEAD HOOK UP ....................................17

4.0 OPERATION........................................................................................ 18

4.1 SYSTEM FUNCTIONS......................................................................... 18

4.2 INITIAL POWER ON............................................................................20

4.3 SET-UP FUNCTIONS ..........................................................................21

4.4 OPENING THE LAST WELD SCHEDULE ..........................................25

4.5 SELECTING A WELD SCHEDULE FROM THE LIBRARY ................25

4.6 MODIFY A WELD SCHEDULE ...........................................................26

4.7 COPY A WELD SCHEDULE ...............................................................30

4.8 CREATE A WELD SCHEDULE........................................................... 33

4.9 WELDHEAD CALIBRATION...............................................................35

4.10 PERFORMING A WELD.....................................................................36

4.11 WELD DATA RECORDING................................................................40

5.0 MAINTENANCE AND TROUBLE-SHOOTING ................................... 43

6.0 OPTIONS.............................................................................................52

iii

iii

iiiiii

M O D E L 2 0 5

Hazard

Chapter

1

O P E R A T O R ’ S M A N U A L

1.0 SAFETY PRECAUTIONS

The Model 205 is intended to be used only with AMI or EXEL weldheads for the purpose of

GTAW welding of metal tube. The system is not to be used for any other purpose, specifically

heating or cutting.

WARNING

I C O N K E Y

Warning

Electrical

THAT HE HAS READ AND/OR BEEN MADE AWARE OF ALL OF THE SAFETY-RELATED

ITEMS CONTAINED IN THIS MANUAL.

The nature of the GTAW process creates some POTENTIAL

HAZARDS. In accordance with international safety regulations the

EXCLAMATION SYMBOL indicates that this equipment is considered

HAZARDOUS. The LIGHTNING FLASH SYMBOL indicates that

there are potential electrical hazards. The use and display of these

symbols make it the OPERATOR’S RESPONSIBILITY TO ENSURE

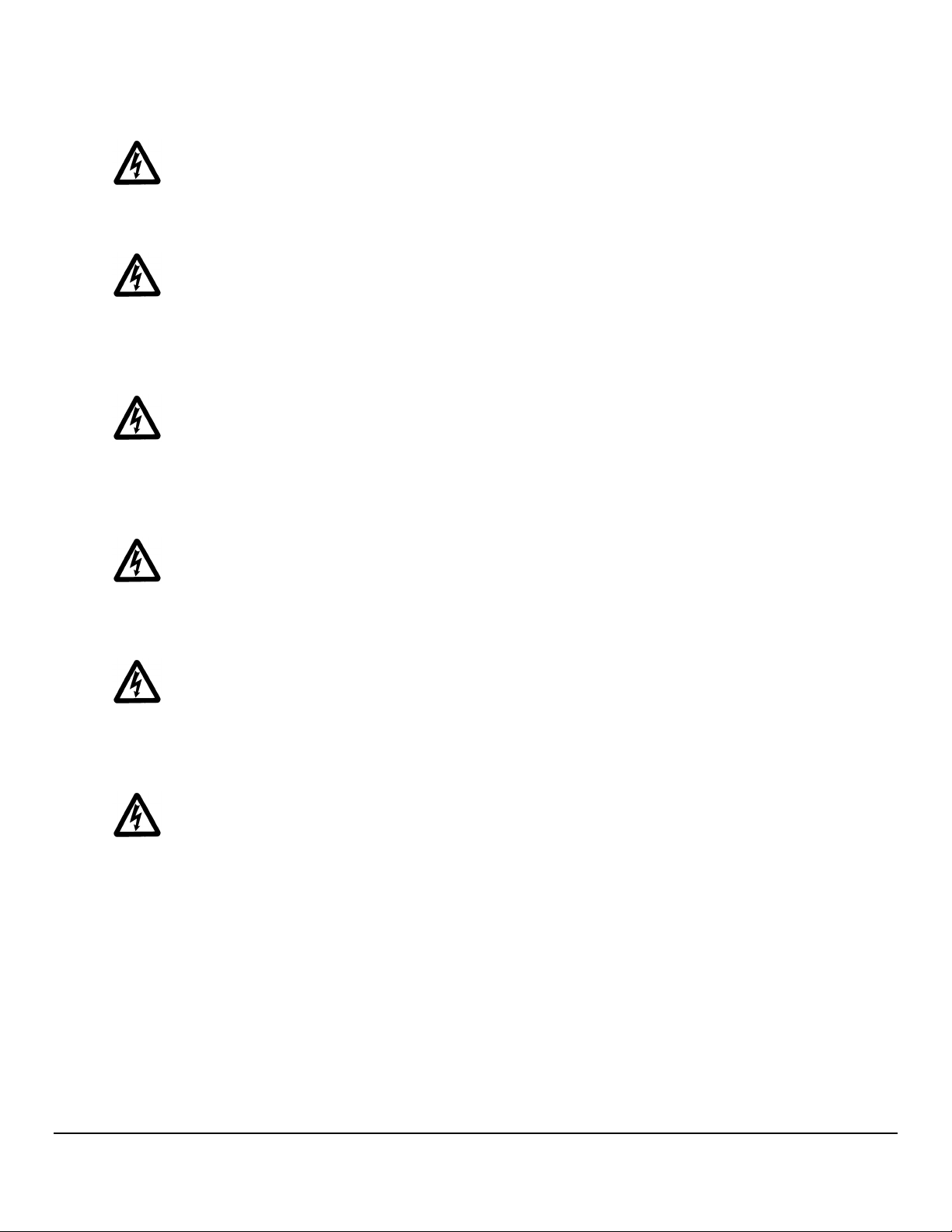

1.1 SHOCK HAZARD WARNING

HIGH VOLTAGE is present on exposed internal terminals. The ELECTRODE (tungsten /

weldhead rotor) is also an EXPOSED TERMINAL and by its nature the GTAW process requires

electrical potential to be present on the electrode during arc starting and during welding.

1

M O D E L 2 0 5

O P E R A T O R ’ S M A N U A L

All AMI Power Supplies contain a “bleeder” circuit to ground any residual potential

after welding or after an aborted or bad arc start attempt. These circuits take a few seconds

to operate or could fail.

The electrode should always be considered a possible shock hazard. This is

especially true when the system is in “weld sequence”, ready to weld, is welding or has just

finished welding. Equipment/component failure, system abuse or improper maintenance

could result in electrical potential at the weldhead even when not in “weld sequence”.

The users/operators of this equipment must take all precautions necessary to avoid

contact with the ELECTRODE at “ALL TIMES”. The only exception is when actually

replacing or adjusting the electrode and this should be done WITH THE POWER TURNED

OFF.

If performed with the power “ON” the system must be in “TEST” mode out of weld

sequence and the USER MUST OBSERVE COMMON SAFETY PRACTICES such as

grounding the electrode to ensure discharge before actually touching it.

Most AMI Power Supplies feature High Frequency (HF) Arc Starting. This is a High

Voltage/High Frequency electrical transmission process. To eliminate any HF shock

possibility “AVOID ALL CONTACT” with the Welding WORK (ground), the ELECTRODE or

the WELDHEAD during arc start.

Remember, there is a possible shock hazard in all welding power supplies at

ALL times.

2222

M O D E L 2 0 5

O P E R A T O R ’ S M A N U A L

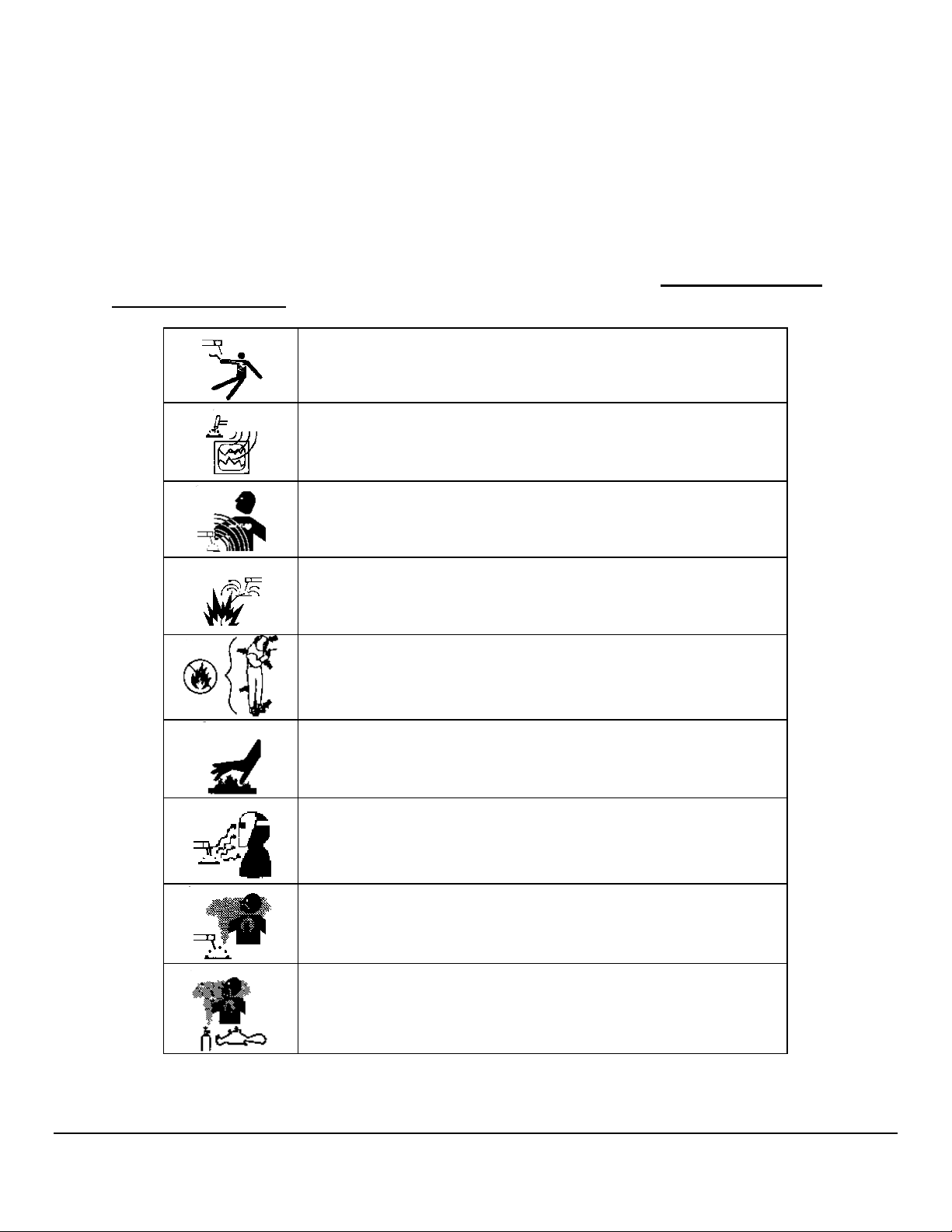

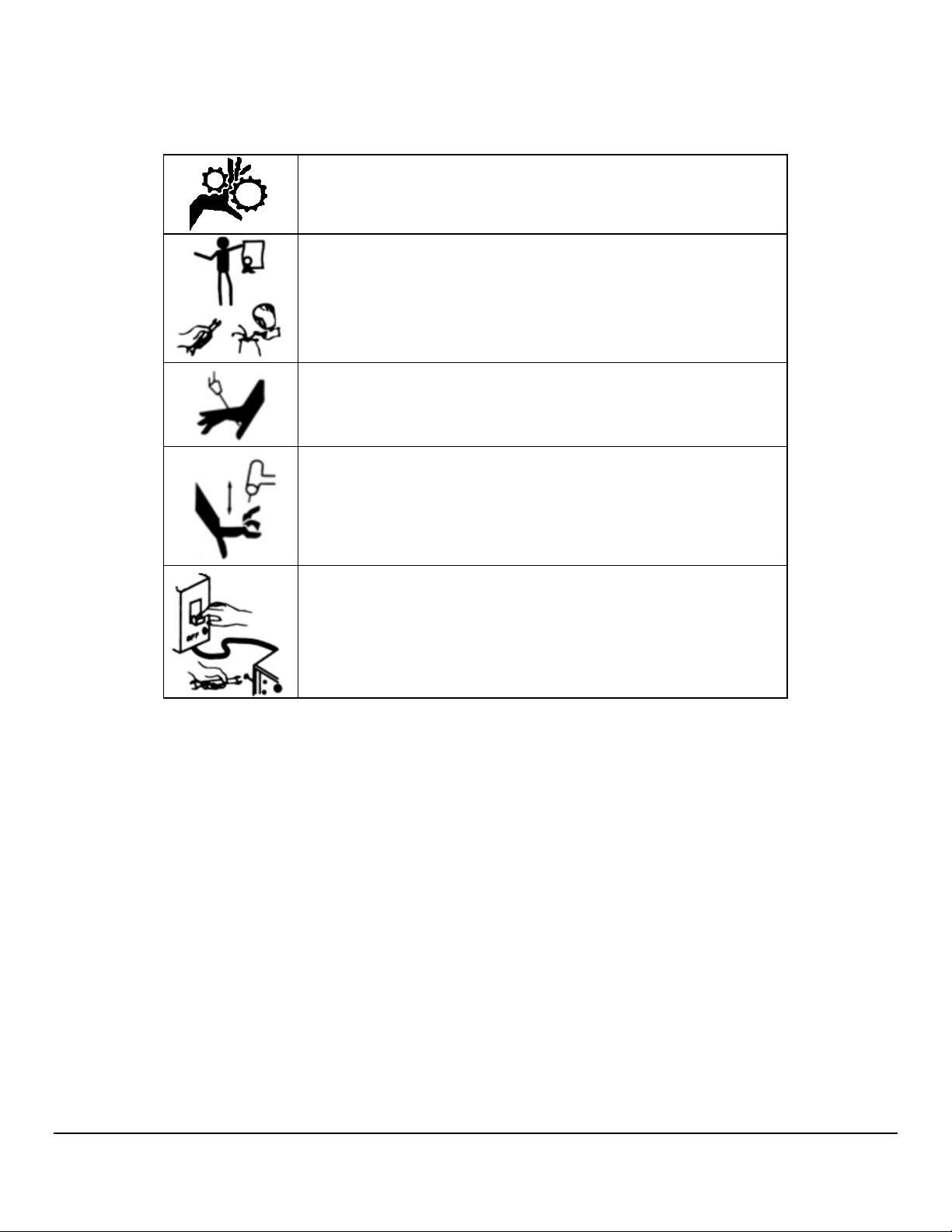

1.2 WARNING LABEL DEFINITIONS

The table below contains caution and warning labels for the operation of this equipment. Before

operating this or any welding equipment users should be familiar with ANSI-49.1 Safety in

Welding and Cutting.

ELECTRIC SHOCK from welding electrode or wiring can kill.

HIGH FREQUENCY RADIO WAVES can cause interference and

sometimes even damage to nearby electronic equipment (such

as computers) that are un-protected.

MAGNETIC FIELDS can affect implanted medical devices.

Wearers of pacemakers should keep away until consulting their

doctor.

Welding can cause FIRE OR EXPLOSIONS. Do not weld near

FLAMMABLE or EXPLOSIVE MATERIALS. Have the proper

type of extinguisher in the work area.

WEAR NON-FLAMMABLE protective clothing, footwear and

head gear at all times.

HOT PARTS can cause severe burns. Do not touch recently

welded components. Avoid touching torch components and

welding fixtures soon after welding.

ARC RAYS can burn the eyes and skin. The welding arc emits

ultra-violet (UV) radiation and the molten weld gives off infra-red.

Both can burn eyes and skin if unprotected. Suitable eye and skin

protection must be worn.

BUILD UP OF GAS can injure or kill. Weld materials can emit

toxic fumes during welding. WELD ONLY IN AREAS WITH

ADEQUATE VENTILATION.

FUMES AND GASES can be hazardous. Welding produces

fumes and gases. Breathing these fumes and gases can be

hazardous to your health. DO NOT weld in enclosed areas

without proper ventilation or respirators.

3333

M O D E L 2 0 5

O P E R A T O R ’ S M A N U A L

MOVING PARTS - Keep hands and fingers clear of fans,

gears, rotors, wire feed, rotation and AVC mechanisms

WARNING: AMI factory training is essential for all Welding

Operators and Maintenance Technicians who operate AMI

equipment.

WELDING WIRE and ELECTRODES are sharp and can cause

injury.

MOVING PARTS may cause crush or pinch points.

WARNING: Disconnect the input power to the machine before

opening or servicing. Discharge all circuits that store high

voltage such as capacitor packs. Only AUTHORIZED and

QUALIFIED service personnel should open this equipment.

4444

M O D E L 2 0 5

90V

90V

90V

90V

Chapter

2

O P E R A T O R ’ S M A N U A L

2.0 SPECIFICATIONS

These specifications pertain the to Model 205 power supply only. For weldheads, refer to the

specification sheet of each particular model. For non-AMI supplied equipment such as gas

tanks and regulators, refer to the original manufacturer’s documentation.

The Model 205 is a mobile system that is intended be hand carried. The supporting equipment

such as weldheads, water coolers, gas regulators, remote controls and extension cables can

also be hand carried. Items such as gas tanks and welding fixtures should be moved with

appropriate equipment and safety precautions. Gas tanks should be securely anchored to

prevent toppling over.

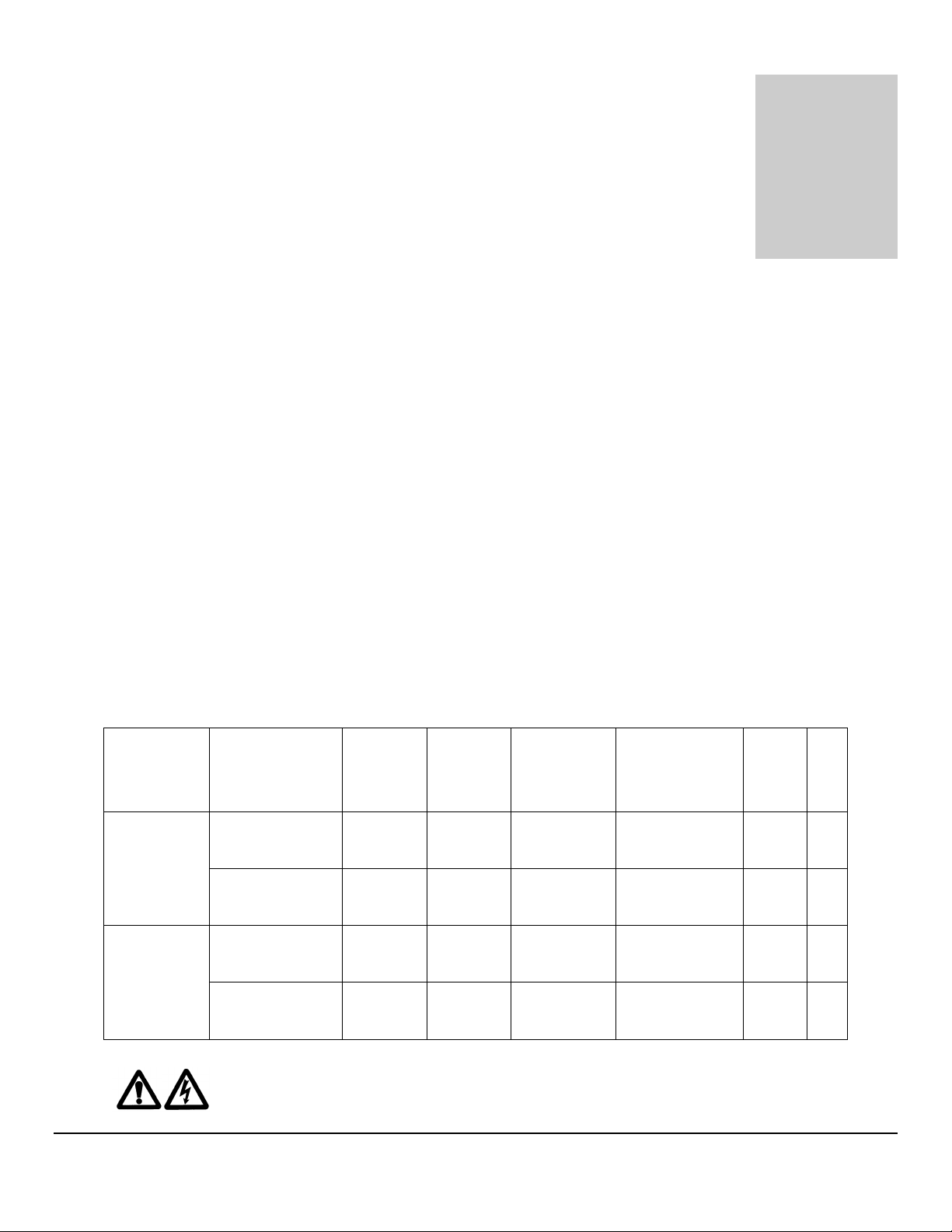

2.1 ELECTRICAL

INPUT POWER DETAIL

The Model 205 can operate on the following Auto Adjusting for Single Phase AC input:

Input Power

Single-Phase

AC

115 Volts TIG

20A

230 Volts TIG

20A

Rated Welding

Output

100A @ 14.0

Volts DC, 100%

Duty Cycle

150A @ 16.0

Volts DC, 30%

Duty Cycle

100A @ 14.0

Volts DC, 100%

Duty Cycle

150A @ 16.0

Volts DC, 30%

Duty Cycle

Welding

Amperage

Range

5 - 150A

5 - 150A

5 - 150A

5 - 150A

Max OCV

DC (Up)

12-16

12-16

12-16

12-16

Rated Peak

Starting

Voltage (Up)

15 KV 18.4 2.1 2.1

15 KV 28 3.4 3.1

15 KV 8.3 2 1.9

15 KV 14.2 3.2 3.1

Amperes Input

At Rated Load

Output, 50/60Hz,

Single-Phase

KVA

@

Duty

Cycle

KW

Input power must be grounded.

5555

M O D E L 2 0 5

O P E R A T O R ’ S M A N U A L

OUTPUT POWER

Straight polarity, constant current DC regulation intended for GTAW welding only. Static

characteristic of all power supplies is flat.

5 to 150 amperes DC using 100 to 120 VAC input.

5 to 150 amperes DC using 200 to 240 VAC input.

CIRCUIT BREAKER – ON/OFF, two pole, 20 Ampere at 250 VAC.

DUTY CYCLE – determined by the AC input voltage and the required output current. The

Model 205 system has an internal thermal sensor that will limit operation should the

temperature exceed the safe operating parameters.

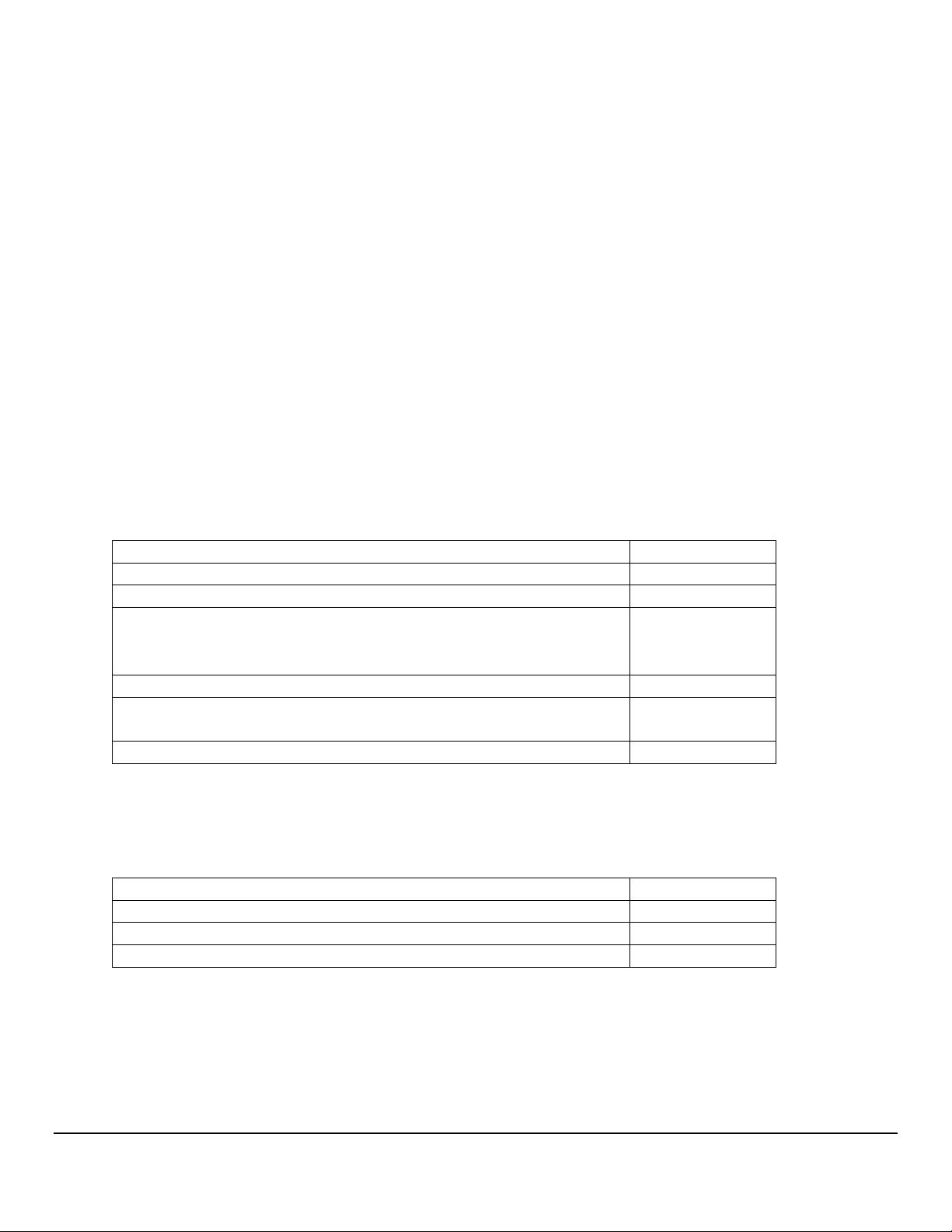

2.2 ELECTICAL SERVICE GUIDE

FUNCTION RANGE

INPUT VOLTAGE 115/230

INPUT AMPERES AT RATED OUTPUT 13.1

MAX RECOMMENDED STD FUSE RATING IN AMPERES

• CIRCUIT BREAKER, TIME DELAY

• NORMAL OPERATING

15

20

MIN INPUT CONDUCTOR SIZE IN AWG 14

MAX RECOMMENDED INPUT CONDUCTOR

LENGTH IN FEET (METERS)

91 (28)

MIN GROUNDING CONDUCTOR SIZE IN AWG 14

2.3 PHYSICAL DIMENSIONS

POWER SUPPLY HEIGHT 18” (457mm)

POWER SUPPLY WIDTH 19” (483mm)

POWER SUPPLY DEPTH 14” (356mm)

POWER SUPPLY WEIGHT 51 lbs (22 kg)

6666

M O D E L 2 0 5

O P E R A T O R ’ S M A N U A L

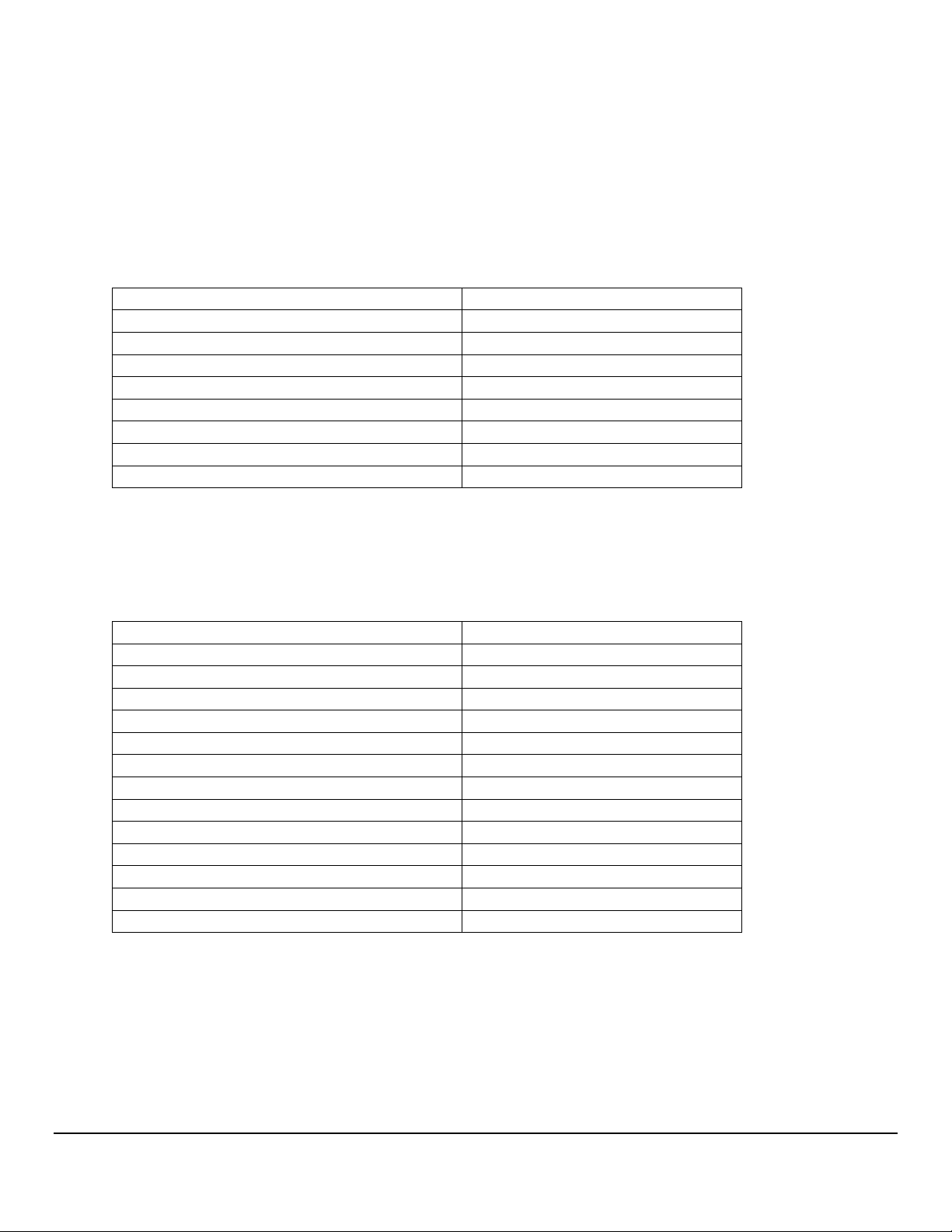

2.4 PROGRAMMABLE AND OPERATIONAL FUNCTIONS

SINGLE ENTRY FUNCTIONS

FUNCTION RANGE

PREPURGE 5.0 – 999.0 seconds

POSTPURGE 5.0 – 999.0 seconds

UPSLOPE 0.0 – 99.9 seconds

START LEVEL 5.0 – 150.0 amps

DOWNSLOPE 00.0 – 99.9 seconds

LEVEL ADVANCE TIME / POSITION

TRAVEL START DELAY 00.0 – 99.9 seconds

TRAVEL DIRECTION CW / CCW

MULTI-LEVEL FUNCTIONS

The following functions can be programmed at each level to change value during a

given weld sequence.

FUNCTION RANGE

LEVEL POSITION 0 – 9999 degrees

LEVEL DEGREES 0 – 9999 degrees

SLOPE DEGREES 0 – 9999 degrees

TIME 0.1 – 999.9 seconds

SLOPE TIME 0.0 – 999.9 seconds

PRIMARY AMPS * 5.0 – 150.0 amps

BACKGROUND AMPS 5.0 – 150.0 amps

PRIMARY TRAVEL As defined by Weldhead **

BACKGROUND TRAVEL As defined by Weldhead **

PRIMARY PULSE 0.01 – 9.99 seconds

BACKGROUND PULSE 0.01 – 9.99 seconds

PULSE MODE ON / OFF

TRAVEL MODE ON / STEP / CONT

* For single level schedules the PRIMARY AMPS function is replaced by START AMPS and

END AMPS functions

** TRAVEL functions are in 0.01 RPM increments

7777

M O D E L 2 0 5

Chapter

3

O P E R A T O R ’ S M A N U A L

3.0 INITIAL SETUP

This manual is intended to assist users of this equipment in set up and basic

operation. It is NOT INTENDED AS A SUBSTITUTE FOR FACTORY TRAINING.

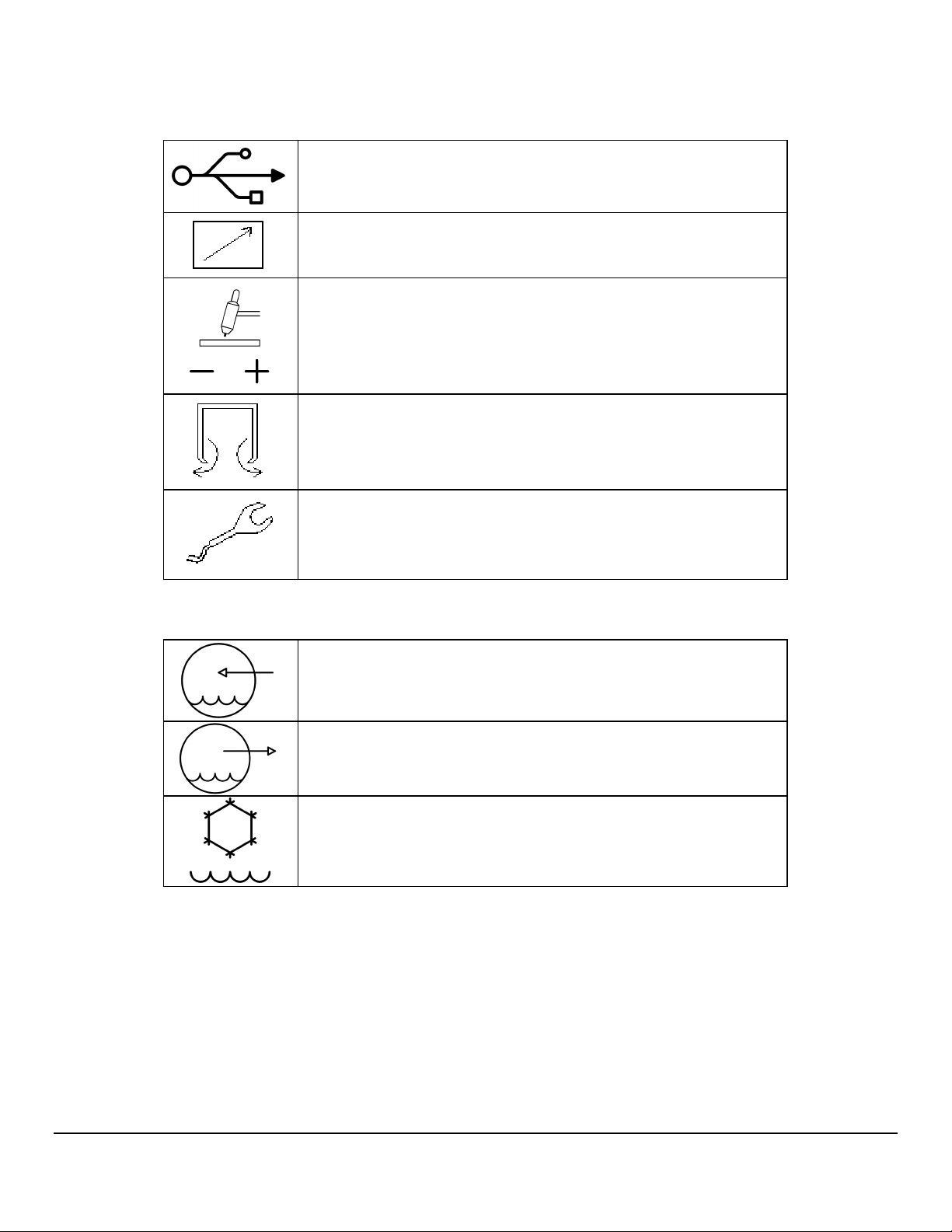

3.1 SYSTEM SYMBOLS

The following symbols are present on the Model 205 version 13B050100-02

Revision NC and up:

WARNING: Read this manual! This document contains

information that could help prevent injury or damage to the

equipment.

115/230 VAC INPUT - AC mains input, 100-240 volts AC,

50/60 Hz.

ON OFF - On/Off switch (circuit breaker).

ARC GAS INPUT - input for the arc shielding gas. An external

regulator and flow indicator must be used.

8888

M O D E L 2 0 5

O P E R A T O R ’ S M A N U A L

USB - USB port. Devices should not be left plugged in while

welding.

REMOTE - Remote control connection

GROUND(+) ELECTRODE(-) - weldhead ground and electrode

connections.

ARC GAS OUTPUT - output for the arc shielding gas connection.

WELDHEAD CONTROL - weldhead motor control. Intended for

AMI and EXEL weldheads only.

The optional water cooler M205-CW is marked with the following symbols:

WATER RETURN - cooling water input.

WATER OUT - cooling water output.

Cooling liquid tank fill opening.

9999

M O D E L 2 0 5

O P E R A T O R ’ S M A N U A L

3.2 INSPECTION

The Model 205 is shipped with a variety of peripheral equipment such as gas hoses, fittings and

cables. An exact list of these items is included with each power supply shipment and should be

located prior to setup.

• After unpacking, inspect all items for obvious physical damage and loose parts. If

damage is evident, contact a factory representative before using. If water

condensation is apparent, dry the unit before using.

• Check all fittings and connectors for proper seating and ensure that all protective

boots are in place. If the unit is not properly seated or protected short circuits, poor

connections or inert gas leaks could occur.

• Ensure that all cables are routed and protected in such a way that they will not be

subject to heat or equipment / personnel traffic. Ensure that the cables DO NOT

come in contact with HOT PIPE.

• For operation the Model 205 must be placed on a flat level surface capable of

supporting the weight of the unit, cables, and any other options. The Model 205

can be mounted on top of the optional water cooler provided the installation will

not cause the unit to topple over.

• Check the gas and coolant hoses (if used) to ensure that they are not pinched or

bent as this will restrict flow.

• Ensure that the Model 205 has adequate air flow and the intakes and exhaust vents

are not restricted.

• Ensure that there is bare metal contact between the weldhead components which

connect to GROUND (clamp inserts, etc.) and the tube to be welded.

10

10

1010

M O D E L 2 0 5

O P E R A T O R ’ S M A N U A L

3.3 POWER CONNECTION

To avoid severe equipment damage ensure that the Model 205 power supply is

connected to the correct input AC power as listed in Section 2.0 Specifications.

The Model 205 can operate on any single phase voltage from 100V AC to 240V AC.

Provided the input voltage is within this range, the unit will automatically adjust for the input

voltage.

1. The Model 205 is supplied with a 15 foot power cord. A suitable AC line connector

matching the input power must be supplied and installed by the user. Color coding of

the power cord is as follows:

Green/Yellow: Equipment grounding conductor

White/Gray: Grounded circuit conductor, Neutral

Black: Ungrounded circuit conductor, Line

2. Ensure that the circuit breaker is in the down or OFF position.

3. Connect the AC line connector to the power cord.

Do not connect the Model 205 to the AC power source until all installation

steps are complete

3.4 WELDING GAS CONNECTIONS

The Model 205 is intended for typical GTAW gases ONLY. NEVER CONNECT

OXYGEN OR ACETYLENE TO THE MODEL 205.

1. The Arc Gas hose is supplied with the Model 205. This hose is made of material

selected specifically for automatic welding. HOSES MADE FROM OTHER

MATERIAL ARE NOT RECOMMENDED (especially rubber, nylon, or tygon).

2. This 10 foot (3 meter) hose should be installed from the gas regulator/flow meter

(user supplied) to the ARC GAS INPUT fitting on the Model 205. The hose is

supplied with the fittings required to mate with the Model 205 and most domestic

(USA) inert gas flow meters.

11

11

1111

M O D E L 2 0 5

O P E R A T O R ’ S M A N U A L

3. The arc gas is controlled by a solenoid and flow sensor in the Model 205. Attach the

input gas line to ARC GAS INPUT fitting on the Model 205, NOT DIRECTLY TO

THE WELDHEAD.

4. Attach the other end of the input gas hose to the gas regulator/flow meter. Fitting it

loosely by hand, tighten the nut slightly with a wrench to ensure there are no leaks.

DO NOT OVER TIGHTEN. The use of plumbers tape or grease is NOT

RECOMMENDED.

The Model 205 arc gas solenoid valve is rated at 50 PSI (345 kPa) maximum

pressure, DO NOT EXCEED THIS RATING.

3.5 MODEL 205 TO M8 / M9 WELDHEAD HOOK UP

Always turn the power supply off before making any cable or connection

changes to the power supply.

Non-liquid-cooled weldheads (Models 9-250 and 9-500) connect directly to the Model

205. Liquid-cooled weldheads connect to the Model 205 via a short pig-tail or via an

adapter cable. If needed an extension cable can be used. The extension cable

connects to the Model 205, then to the weldhead for non liquid-cooled weldheads or to

the adapter cable for liquid-cooled weldheads.

Pig-tail Connections

1. Connect the ground and electrode brass quick-disconnect fittings on the pig-tail to

the mating fittings on the weldhead. Pull the knurled ring on the female fitting back

and fully insert the male fitting. These connectors are fully seated when the ring will

spring back to its original position. Slide the rubber boots together and secure them

in place, being careful not to dislodge the connectors. Male boots should cover the

connection first. The boots protect the connectors and prevent shorting to ground.

2. Attach the ground and electrode connectors on the pig-tail to their respective

GROUND(+) and ELECTRODE(-) terminals on the Model 205. Align the

keyways, push in and turn clockwise until fully locked.

12

12

1212

M O D E L 2 0 5

O P E R A T O R ’ S M A N U A L

3. Insert the two coolant line quick-disconnect fittings on the pig-tail into the mating

WATER OUT and WATER RETURN connectors on the Model 205-CW.

These connectors are interchangeable so either connector may be connected to

either mating fitting. To prevent accidental disconnection after making the

connection, finger-tighten the lock screw on the male connectors.

4. Attach the weldhead control male connector on the weldhead to the WELDHEAD

CONTROL connector on the Model 205. Note the positioning keyway and

NEVER FORCE or use tools on the cable connectors. Hand-tighten the connecting

ring being careful not to cross-thread the ring.

5. Insert the male gas quick-disconnect fitting on the weldhead to the mating ARC GAS

OUTPUT connector on the Model 205 and hand-tighten the lock screw to

prevent accidental disconnection. Slide the rubber boot over the connection.

Adapter Cable Connections

1. Connect the ground and electrode brass quick-disconnect fittings on the adapter

cable to the mating fittings on the weldhead. Pull the knurled ring on the female

fitting back and fully insert the male fitting. These connectors are fully seated when

the ring will spring back to its original position. Slide the rubber boots together and

secure them in place, being careful not to dislodge the connectors. Male boots

should cover the connection first. The boots protect the connectors and prevent

shorting to ground.

2. Attach the weldhead control male connector on the weldhead to the mating

weldhead control female connector on the adapter cable. Align the keyways and

carefully screw the retaining ring in place. DO NOT use tools and be careful not to

cross-thread the fitting. To help prevent damage screw the connector dust caps to

each other.

3. Insert the male gas quick-disconnect fitting on the weldhead to the mating female

fitting on the adapter cable. Hand-tighten the lock screw to prevent accidental

disconnection. Slide the rubber boots over the connection and secure them

together.

4. Attach the ground and electrode connectors on the adapter cable to their respective

GROUND(+) and ELECTRODE(-) terminals on the Model 205. Align the

keyways, push in and turn clockwise until fully locked.

13

13

1313

M O D E L 2 0 5

O P E R A T O R ’ S M A N U A L

5. Insert the two coolant line quick-disconnect fittings on the adapter cable into the

mating WATER OUT and WATER RETURN connectors on the Model 205-

CW. These connectors are interchangeable so either connector may be connected

to either mating fitting. To prevent accidental disconnection after making the

connection, finger-tighten the lock screw on the male connectors.

6. Attach the weldhead control male connector on the adapter cable to the

WELDHEAD CONTROL connector on the Model 205. Note the positioning

keyway and NEVER FORCE or use tools on the cable connectors. Hand-tighten the

connecting ring being careful not to cross-thread the ring.

7. Insert the male gas quick-disconnect fitting on the adapter cable to the mating ARC

GAS OUTPUT connector on the Model 205 and hand-tighten the lock screw to

prevent accidental disconnection. Slide the rubber boot over the connection.

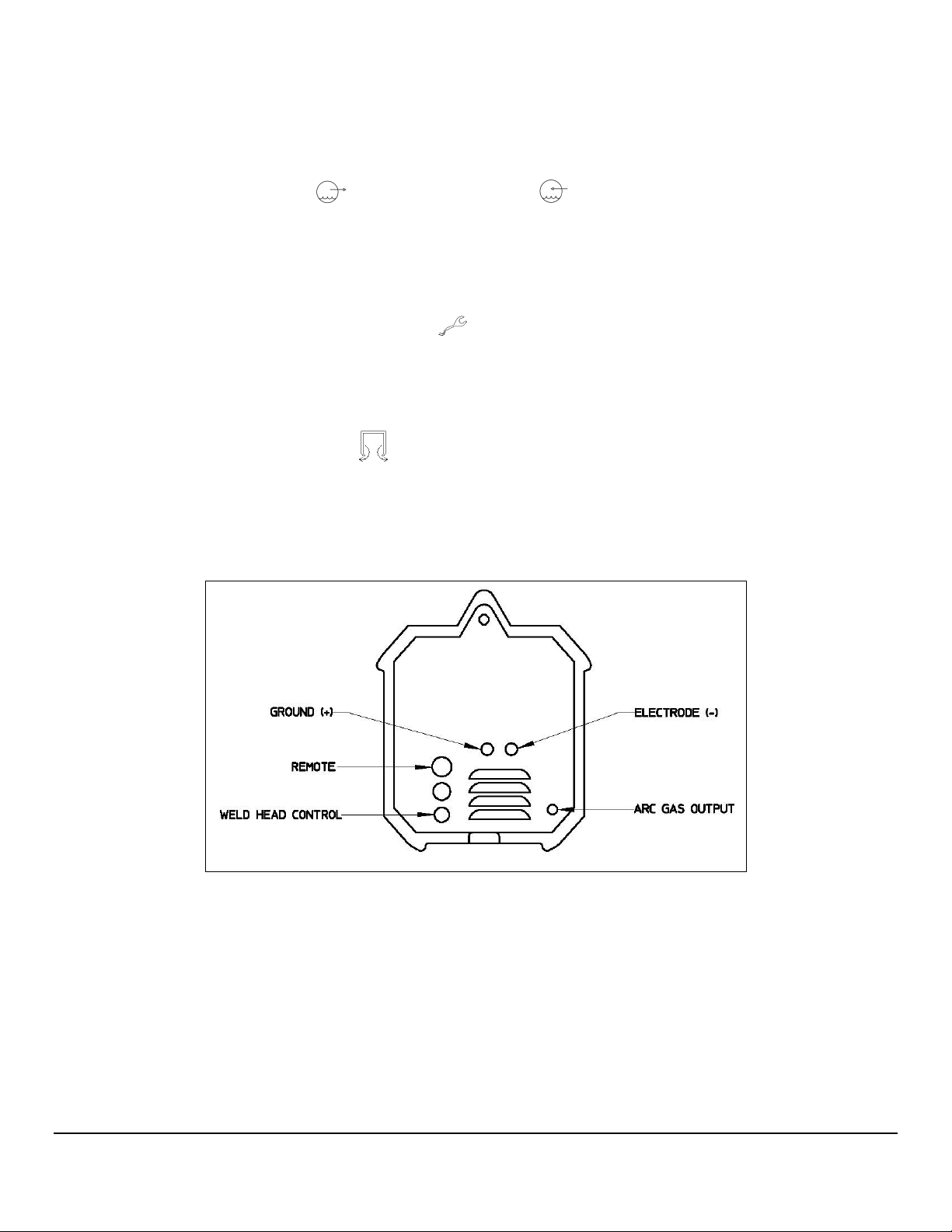

Fig. 1

Hookups for Non-Liquid Cooled Weldheads

14

14

1414

Loading...

Loading...