10500 Orbital Way

Pacoima, California 91331 U.S.A.

MODEL 227 POWER SUPPLY

OPERATION MANUAL

Document No. 740063

DATE

A

2367

B

3053

C

3583

MODEL 227

OPERATION MANUAL

NOTICE

This document and the information contained herein is the property of Arc Machines, Inc.. It

is proprietary and submitted and received in confidence. It shall be used only for the purpose

for which it is submitted and shall not be copied in whole or in part without the prior express

written permission of Arc Machines, Inc.

The information in this document has been carefully reviewed and is believed to be accurate.

However, no responsibility is assumed for inaccuracies.

Information and instructions in this document are subject to change and Arc Machines, Inc.

reserves the right to change specifications and data without notice.

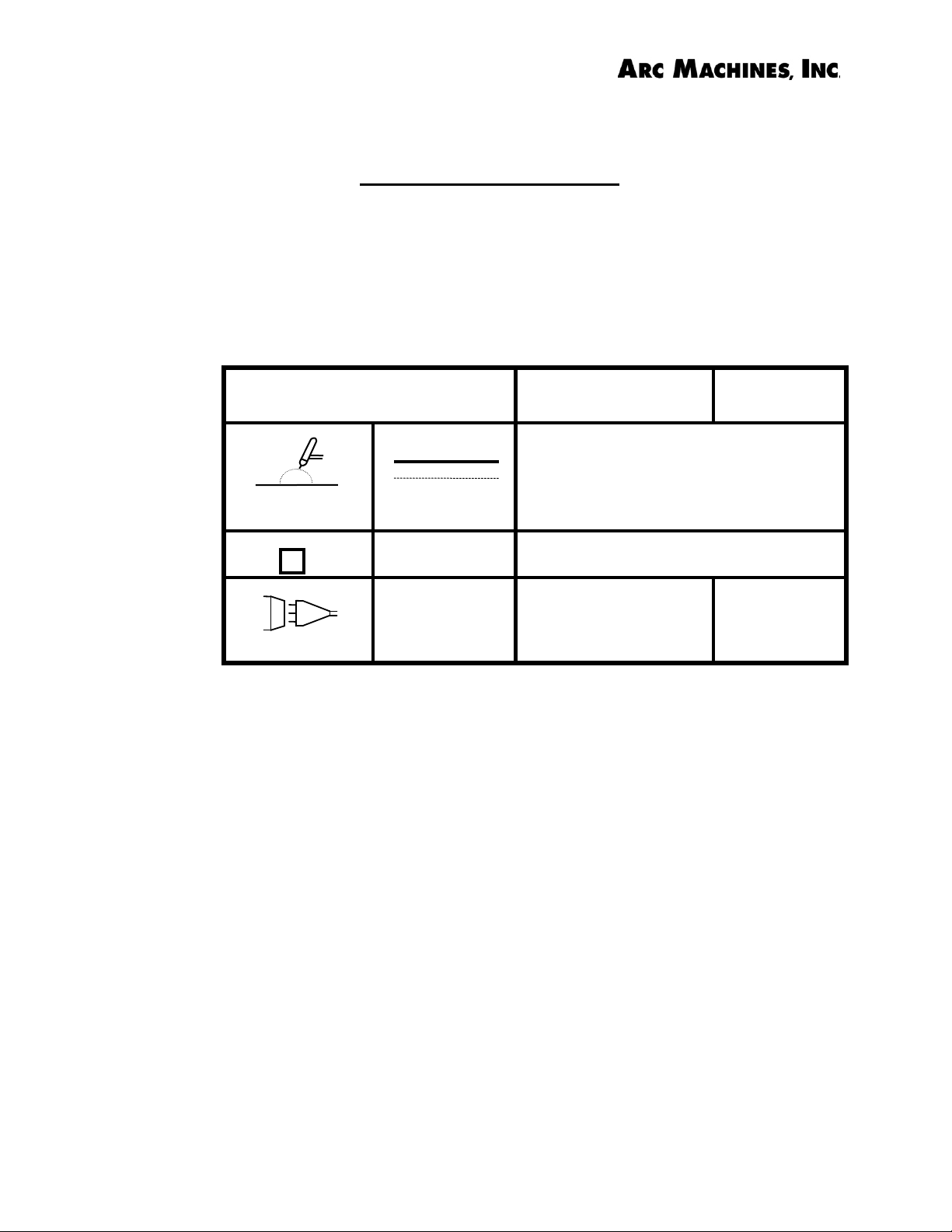

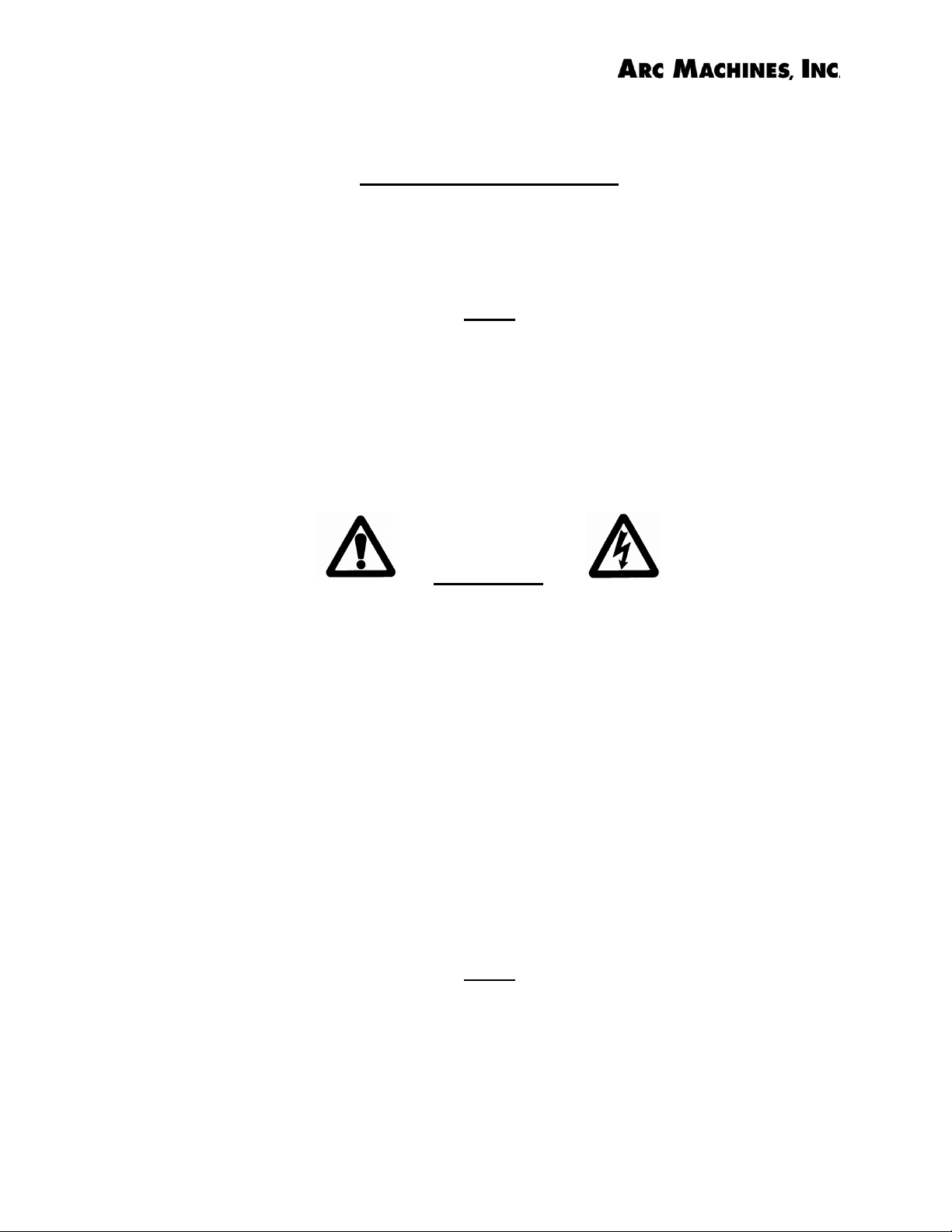

WARNING

The nature of the GTAW process creates some POTENTIAL HAZARDS. In accordance

with international safety regulations the EXCLAMATION SYMBOL indicates that this

equipment is considered HAZARDOUS until an operator has been made aware of these

POTENTIAL HAZARDS by READING THIS MANUAL. The LIGHTNING FLASH

SYMBOL indicates that there are potential electrical hazards. The use and display of these

symbols make it the OPERATOR’S RESPONSIBILITY TO INSURE THAT HE HAS

READ AND/OR BEEN MADE AWARE OF ALL OF THE SAFETY-RELATED ITEMS

CONTAINED IN THIS MANUAL.

Publication date : First Edition - February 12, 1992

Copyright 1992 by Arc Machines, Inc.

All rights reserved

REV DCO # CHANGE DESCRIPTION

Revised to include required IEC-974 information 10/03/96 GPE

Add M227/207-CW Spec-info pgs: iv, v, 1.1, 2.4, 4.14,

4.16, 5.7, 7.6, 7.8, 8.1, 8.2.

Added Offset adj. Information to sect. 7. Replaced Sect. 7,

Pg. i & iv.

04/08/98 GPE

03/23/00 GPE

D 3682 Removed ref to miller coolant pages 8.1,8.2 7/19/00 GPE

E 4633 Correct typo in section 7.2.14 2/25/08 LEC

i

APR

Doc # 740063 Rev E

MODEL 227

OPERATION MANUAL

EFFECTIVITY

Features and operation of the Model 227 are derived mostly from SOFTWARE. This

document is based on the latest STANDARD version of SOFTWARE at the time of last

revision (see revision page).

Some deviations in actual operation, from this document, are possible depending on the

software version of a particular machine. Please feel free to contact Arc Machines

Service Department for documentation or information on how software updates effect

this document.

ii

Doc # 740063 Rev E

MODEL 227

OPERATION MANUAL

TABLE OF CONTENTS

SECTION DESCRIPTION PAGE

SECTION I INTRODUCTION

1.0 Introduction 1.1

1.1 Safety Precautions 1.2

1.2 Operational Precautions 1.4

1.3 RF and EMI emissions 1.5

1.4 Shock Hazard Warning 1.8

SECTION II SPECIFICATIONS

2.0 Electrical 2.1

2.1 Physical Construction 2.3

2.2 Programmable Functions 2.3

2.3 Multi-level Functions 2.4

2.4 Non-Programmable Functions 2.4

2.5 Ambient Temperature Ranges 2.4

2.6 Cable Operating Distance Limits 2.4

SECTION III INSTALLATION

3.0 Inspection 3.1

3.1 Power Connection 3.1

3.2 Welding Gas Connections 3.2

3.3 Adapter Cable to M-227 Installation 3.3

3.4 Weld Head Installation 3.7

3.5 Ground (Work) Cable Installation 3.7

3.6 Remote Pendant Installation 3.8

SECTION IV SYSTEM FUNCTIONS

4.0 Introduction 4.1

4.1 Functional Description, General 4.1

4.2 Weld Library and Description 4.3

4.3 Weld Sequence 4.3

4.4 Panel Keys 4.11

4.5 Operate Mode Switch 4.14

4.6 Faults 4.14

4.7 Sensor 1,2,3 Faults 4.16

4.8 Set-Up Functions 4.16

4.9 Glossary of Abbreviations 4.17

4.10 Glossary of Terms 4.18

iii

Doc # 740063 Rev E

MODEL 227

OPERATION MANUAL

TABLE OF CONTENTS

SECTION DESCRIPTION PAGE

SECTION V OPERATION

5.0 Introduction 5.1

5.1 Initial Power-On 5.1

5.2 Use of Next/Prev 5.2

5.3 Weld Schedule Selection 5.3

5.4 Pass Advance 5.4

5.5 Viewing Function Values 5.6

5.6 Overriding Function Values 5.6

5.7 Set Up Functions 5.7

5.8 Remote Pendant Operation 5.11

5.9 Rotation Calibration 5.14

5.10 Wire Feed Calibration 5.15

5.11 Manual Advance Function 5.16

5.12 Welding Operation 5.17

5.13 Printer Operation 5.18

SECTION VI PROGRAMMING

6.0 Introduction 6.1

6.1 Create a Weld Schedule 6.1

6.2 Modify a Weld Schedule 6.4

6.3 Copy a Weld Schedule 6.5

6.4 Transfer/Receive a Weld Schedule 6.5

6.5 Delete a Weld Schedule 6.6

6.6 Program Select Function 6.6

SECTION VII CALIBRATION

7.0 Introduction 7.1

7.1 Equipment Required 7.1

7.2 Current Servo 7.2

7.3 AVC Servo 7.4

7.4 Oscillator Servo 7.5

7.5 General Maintenance 7.7

7.6 System Fault Corrections 7.8

7.7 Error Messages 7.11

7.8 Miscellaneous Maintenance 7.12

SECTION VIII OPTIONS

8.0 Introduction 8.1

8.1 M227/207-CW & M207-CW Cooling Units 8.1

8.2 M-227-EMM External Memory Module 8.3

iv

Doc # 740063 Rev E

MODEL 227

OPERATION MANUAL

LIST OF ILLUSTRATIONS

NUMBER DESCRIPTION PAGE

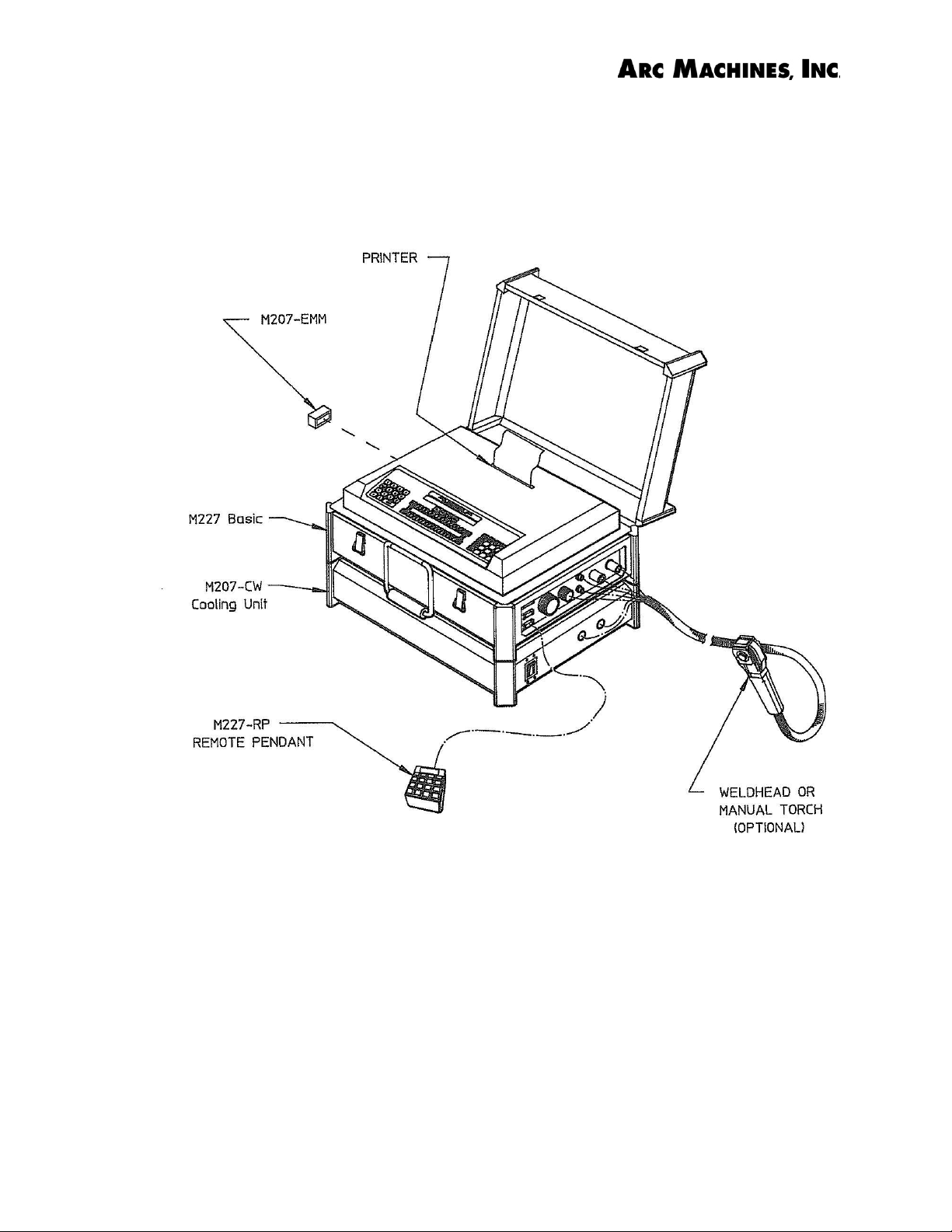

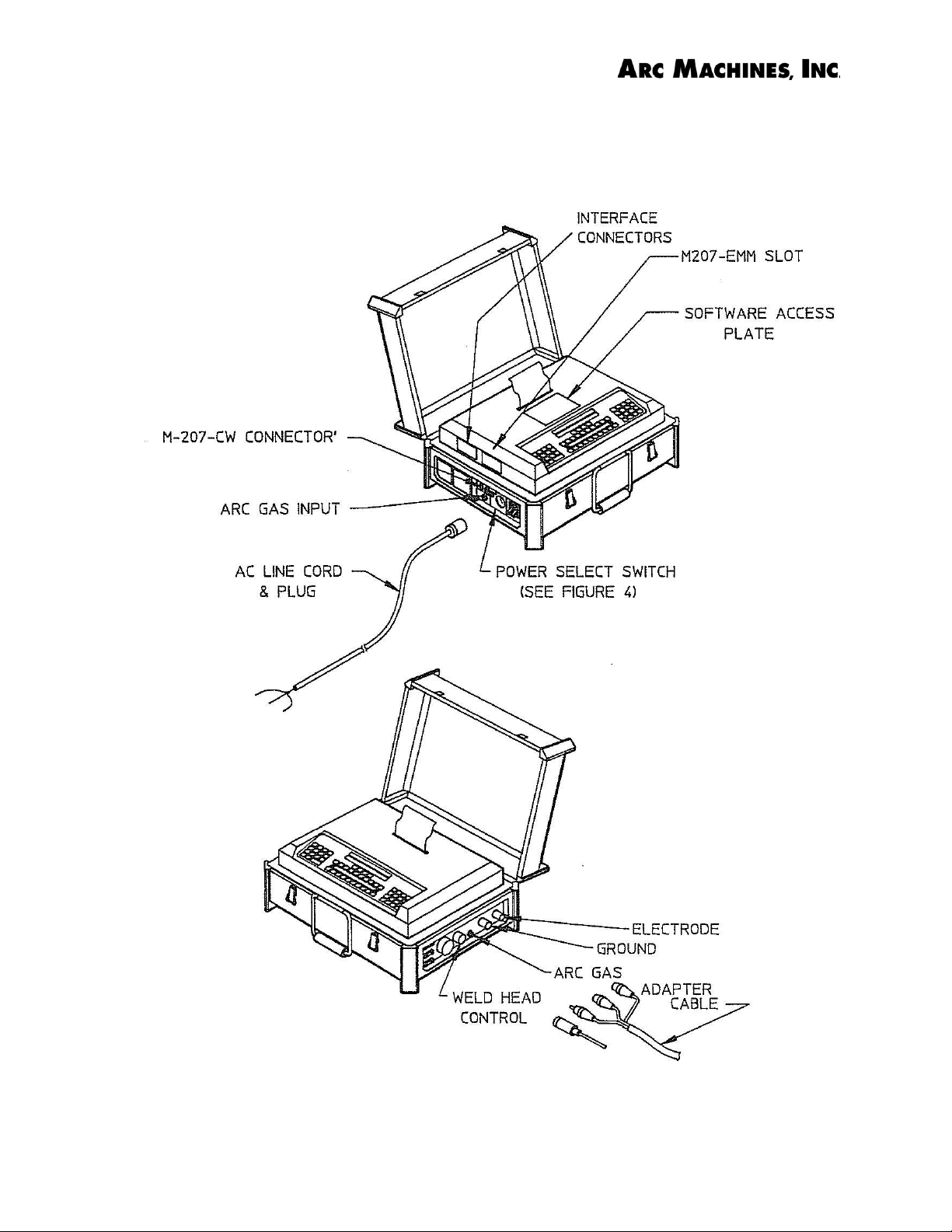

FIGURE 1 SYSTEM CONFIGURATION 1.7

FIGURE 2 INSTALLATION LOCATIONS 3.4

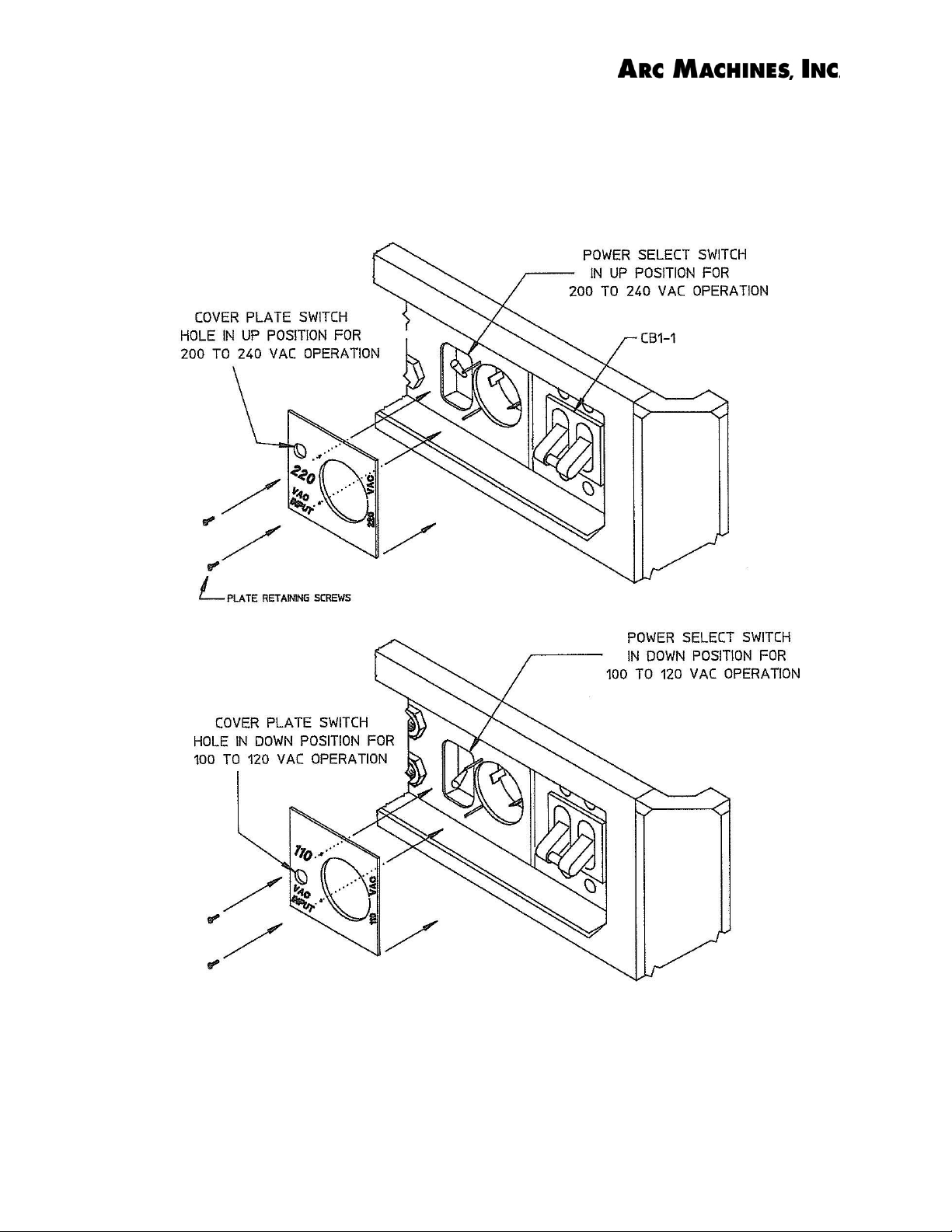

FIGURE 3 AC POWER SET-UP 3.5

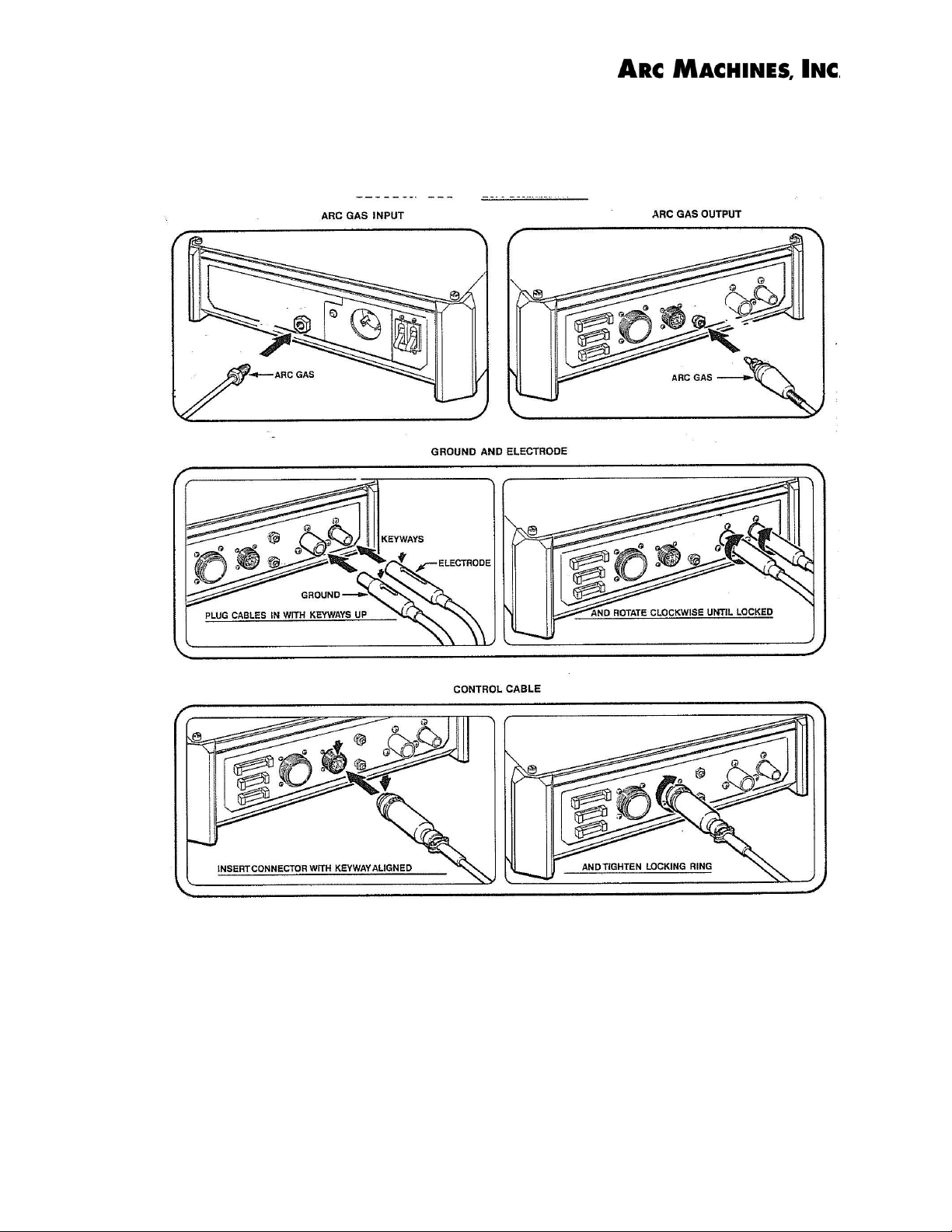

FIGURE 4 CABLE CONNECTIONS 3.6

FIGURE 5 SEQUENCE TIMING CHART 4.7

FIGURE 6 PANEL KEY LOCATIONS 4.8

FIGURE 7 USE OF NEXT/PREV KEYS 5.5

FIGURE 8 STANDARD REMOTE PENDANT 5.10

FIGURE 9 M227/207-CW or M207-CW INSTALLATION 8.4

v

Doc # 740063 Rev E

MODEL 227

OPERATION MANUAL

SECTION I - INTRODUCTION

1.0 INTRODUCTION

This manual is intended to assist users of this equipment in set-up and basic

operation. Automated welding requires a good deal of operator expertise which

also requires AMI supplied, hands-on training. THIS MANUAL IS NOT

INTENDED AS A SUBSTITUTE FOR THAT TRAINING.

The Model 227 (M-227) welding power supply is part of a complete welding

system intended for the welding of tubes, pipes and fittings (see figure 1). The

complete system consists of the M-227 power supply, adapter cable, gas lines and a

variety of different AMI Welding Heads or Torch Fixture devices (Heads and

Fixtures are sold separately).

The standard version of the M-227 power supply provides GTAW current with

pulsation controls, high frequency arc starting, purge gas controls, weld head arc

rotation, cold wire feed, Arc Voltage Control, Torch Weave/Steering (Oscillation)

and automatic timing functions. Another version is available without the

AVC and

Oscillator functions. The M-227 includes a Remote Operators Pendant and comes

ready to weld. Users need only to supply input AC power, regulated gas source

with flow meter and the appropriate weld head or manual torch.

Some operation conditions may require optional components such as the M227/207 CW Cooling Unit (for liquid cooled weld heads and torches). The M-227 family

of options also includes memory back up devices, off-line programming and quality

assurance options such as chart recorders.

The system can also be used as a manual welding power source using an optional

manual torch with a variety of manual welding options such as a variable current

foot controller with remote start/stop switch.

In-depth weld development instructions, weld head set-up, maintenance and

troubleshooting are contained in other manuals, documents and training classes

and are not included in this manual. Contact your AMI representative for more

information about these items.

NOTE

1.1

Doc # 740063 Rev E

MODEL 227

OPERATION MANUAL

SECTION I - INTRODUCTION

1.1 SAFETY PRECAUTIONS

This section contains cautions and warnings concerning the operation of this

equipment and welding equipment in general. However, in addition to reading

this manual and before operating this or any welding equipment, users should

reference and be familiar with “ANSI-49.1 Safety in Welding and Cutting”.

This standard is published by the American National Standards Institute and the

American Welding Society.

WARNING: Touching energized electrical parts can cause

fatal shocks and burns. When in weld sequence the electrode

and work are electrically energized. Incorrectly installed or

improperly grounded equipment is a hazard.

WARNING: This equipment is authorized to use a type of

arc starter that produces a High Frequency Radio Wave

(sometimes called HF and/or RF Starting). It can cause

interference and sometimes even damage to nearby electronic

equipment (such as computers) that are un-protected or poorly

protected against such interference.

WARNING: Magnetic Fields from High Currents can affect

pacemakers. PACEMAKER WEARERS KEEP AWAY

UNTIL CONSULTING YOUR DOCTOR.

Doc # 740063 Rev E

WARNING: Disconnect the input power to the machine

before opening or servicing. Discharge all circuits that store

high voltage such as capacitor packs. Only QUALIFIED

service personnel should open this equipment.

WARNING: Welding can cause fires or explosions. Do not

weld near FLAMMABLE or EXPLOSIVE MATERIALS.

Watch for fire. Have proper type of extinguisher in work area.

WARNING: Welding Operators should wear non-flammable

protective clothing, footwear and head gear.

1.2

cause severe burns. Do not touch recently welded components.

OPERATION MANUAL

SECTION I - INTRODUCTION

1.1 SAFETY PRECAUTIONS

WARNING: Never weld on sealed containers or pipes. This

may result in an EXPLOSION.

WARNING: Welding produces high temperatures in both the

welded components and the welding equipment. Both can

MODEL 227

Doc # 740063 Rev E

soon after use. Avoid touching torch components and welding

fixtures soon after welding.

WARNING: The welding arc emits ultra-violet (UV) radiation

and the molten weld gives off infra-red (IR). Both can burn

eyes and skin if unprotected. Suitable eye and skin protection

Avoid touching internal components of the welding system

must be worn.

WARNING: Weld materials can emit toxic fumes during

welding. WELD ONLY IN AREAS WITH ADEQUATE

VENTILATION.

WARNING: Most GTAW gases like Argon are non-toxic,

however, Argon is heavier than air and will displace the

normal atmosphere in enclosed areas. DO NOT WELD IN

ENCLOSED AREAS WITH OUT PROPER VENTILATION

OR RESPIRATORS.

WARNING: AMI factory training is essential for all Welding

Operators and Maintenance Technicians who operate AMI

equipment.

WARNING: Before operating, storing or handling, always

make sure that the M-227, M-227-RP Pendant, weld heads and

cables are not exposed to rain or standing water. SYSTEM

COMPONENTS ARE NOT WEATHER-PROOF.

1.3

MODEL 227

OPERATION MANUAL

SECTION I - INTRODUCTION

1.1 SAFETY PRECAUTIONS

WARNING: Keep hands and fingers clear from moving parts

such as fans, gears rotors, Wire Feed, Rotation and AVC

Mechanisms.

1.2 OPERATIONAL PRECAUTIONS

The following is a check list for operating personnel to follow to insure minimum

system down-time due to improper operation and handling:

1. TOO AVOID severe equipment damage VERIFY that the M-227 is

connected to the correct Input AC power (see section 3.1).

2. Before operating, check all fittings and connectors for proper seating and that

all protective boots are in place. If not properly seated or protected, short

circuits, poor connections or inert gas leaks could occur.

3. The M-227 is intended for typical GTAW gases ONLY. NEVER CONNECT

OXYGEN OR ACETYLENE TO THE M-227.

4. Before operating, insure that all cables are routed or protected in such a way

that they will not be subject to heat, equipment and/or personnel traffic. Insure

that the cables DO NOT come in contact with HOT PIPE.

5. When storing or handling cables, always keep the protective boots and dust

caps on all connectors and fittings until ready to install. A major cause of

downtime in any automatic welding system is improper care and use of cables.

WARNING: The M-227 Power Supply is not intended for

pipe thawing or heating in any form.

WARNING: The M-227 Power Supply weighs in excess of

91 lbs (41.3 kg). It has no handles and is not intended to be

carried by a single person. Be sure to follow your local, OSHA,

international or employer guidelines for proper methods of

lifting and re-locating this equipment.

1.4

Doc # 740063 Rev E

MODEL 227

OPERATION MANUAL

SECTION I - INTRODUCTION

1.2 OPERATIONAL PRECAUTIONS

6. Before operating, insure that the M-227 has adequate air flow. Do not restrict

the intakes or exhaust vents of the power supply.

7. Before operating, always insure that there is bare metal contact between the

weld head components which connect to GROUND (clamp inserts, etc.) and

the tube or pipe to be welded.

8. When storing or handling weld heads, always keep them in the protective

containers they are shipped in, or optional carrying case, until ready to install.

9. When operating, storing or handling, insure that the system is protected against

dirt, dust, etc. NEVER GRIND NEAR AN EXPOSED WELD HEAD OR

THE M-227.

10. Do not use acid, corrosives, liquid “Easy Out” or any liquid substance on the

M- 227 or any AMI weld head. When cleaning, use only a light solution of

Isopropyl alcohol on a soft cloth .

11. When handling, take extreme care to avoid dropping the M-227, weld heads,

cables or any accessories.

12. Do not attempt to move tube end into position using the weld head as a lever.

13. Do not add any lubrication like graphite, oil or grease to the weld heads or

power supply unless it is specified in the operation or maintenance manual

for that equipment.

1.3 RF AND EMI EMISSIONS

1. WHY RF?

“It has long been recognized that in the practice of welding and cutting,

there are circumstances where it is required to assist the process using

radio frequency voltage. In order to arc weld an electric arc must be created,

because of safety and economic concerns, the no load voltage of arc power

sources is kept as low as practical. Thus, a source of high voltage with a

high safety factor must be utilized. Radio Frequency voltage is the best

method of meeting these criteria for many reasons.” (quoted from

CISPR/B/63).

1.5

Doc # 740063 Rev E

MODEL 227

OPERATION MANUAL

SECTION I - INTRODUCTION

1.3 RF AND EMI TRANSMISSIONS

2. RF REGULATION

The FCC regulates the RF emission limitations for welding equipment by the

use of an IEC (international) regulation created by the Special Committee on

Radio Interference (known as CISPR) subcommittee B. The regulation of

record is:

CISPR/B/63

“CODE OF PRACTICE FOR THE USE OF WELDING AND CUTTING

POWER SOURCES UTILIZING RADIO FREQUENCY VOLTAGE FOR

STARTING OR STABILIZING THE ARC.”

The regulation states that due to the variety of work requirements and

conditions it is virtually impossible to establish fixed, normalized and

predictable tests and test setups for RF limits that would actually mean

something. Instead of limits they state the following:

“The manufacturer must design and produce equipment that is functional but

at the same time, design this equipment to keep electromagnetic radiation at

a minimum.”

“The user has the responsibility to install and use the power source per the

instructions of the manufacturer. Through this practice, it is reasonable to

assume that the probability of electromagnetic disturbances will be

significantly reduced. However, if some electromagnetic disturbances are

felt, then it is the responsibility of the USER of the equipment to resolve the

situation.”

3. RF PROTECTION

AMI policy is to comply with the IEC (and thus FCC) regulations. Our

design rules and procedures include testing and observing this area. We can

assure our customers that every effort has been made to reduce RF

emissions to the absolute minimum from our power sources.

However, this does not mean that a user will not have occasional problems

with RF interference with other equipment due to the use of our equipment.

This is the nature of RF starting.

1.6

Doc # 740063 Rev E

MODEL 227

OPERATION MANUAL

Doc # 740063 Rev E

SYSTEM CONFIGURATON

1.7

MODEL 227

OPERATION MANUAL

SECTION I - INTRODUCTION

1.3 RF AND EMI TRANSMISSIONS

3. RF PROTECTION (continued)

Most RF noise interference problems are going to be either set-up related or

caused by poor or no filtering on the behalf of the equipment that is being

interfered with. Most problems are easily correctable but each one must be

looked at on a “case by case basis.”

4. EMI SUPPRESSION

The M-227 is equipped with a heavy-duty Pi-Network filter, connected to

the input power line, to prevent propagation of EMI either into or out of the

M-227. The all-metal enclosures and internal shields prevent radiated EMI.

1.4 SHOCK HAZARD WARNING

As already stated in this manual “High Voltage” is present on exposed internal

terminals. The ELECTRODE (tungsten and M-9 rotors) is also an “exposed

terminal” and by its nature the GTAW process requires electrical potential to be

present on the electrode during arc starting and of course during the welding.

All AMI Power Supplies contain a “bleeder” circuit to ground any residual

potential after welding or after an aborted or bad “arc start” attempt. However,

these circuits take a few seconds to operate or COULD FAIL.

“THE ELECTRODE SHOULD ALWAYS BE CONSIDERED A POSSIBLE

SHOCK HAZARD”. This is especially true when ever the system is in “weld

sequence” ready to weld, is welding, or has just finished welding. However,

equipment/component failure, system abuse, or improper maintenance could result

in electrical potential at the weld head “even when not in weld sequence”.

The users/operators of this equipment must take all precautions necessary to avoid

contact with the ELECTRODE at “ALL TIMES”. The only exception is when

actually replacing or adjusting the electrode and this should be done “WITH THE

POWER TURNED OFF”.

If performed with the power “ON” the system must be in test mode out of weld

sequence and the USER MUST OBSERVE COMMON SAFETY PRACTICES

such as grounding the electrode to insure discharge before actually touching it.

REMEMBER, there is a “POSSIBLE” shock hazard in all welding power supplies

at “ALL” times.

Most AMI Power Supplies feature High Frequency (HF) Arc Starting. This is a

High Voltage/High Frequency electrical transmission process. To eliminate any

HF shock possibility “AVOID ALL CONTACT” with the Welding WORK

(ground), the ELECTRODE or the WELD HEAD during arc start.

Doc # 740063 Rev E

1.8

S

MODEL 227

OPERATION MANUAL

SECTION II - SPECIFICATION

The following contains only general specifications about the M-227 Power

Supply. More detailed information is available in AMI Specification No. 227.

2.0 ELECTRICAL

1. RATING PLATE DEFINITIONS

1) Company: Country:

Arc Machines, Inc. USA

8) Process:

G.T.A.W.

23) Shock Rating:

15) Input:

1~ 50/60 HZ

1) - Manufacturer and Country of Origin.

3) - Model Number Rating Plate applies to.

4) - Serial Number (located on M-227 Center Plate, not on rating plate).

6) - International and USA Standards that the equipment meets.

8) - Weld Process symbol for GTAW welding.

9) - Rated MIN and MAX Outputs at Continuous Current with no pulsation.

Rated MIN and MAX Outputs when current is pulsing.

MAX current output using 110 VAC input is 100 Amperes.

10) - Symbol that output is Direct Current (DC) only.

11) - Rated No Load Output Voltage (open circuit voltage) is 59 volts.

12) - The M-227 is a 100 % Duty Cycle for the rated outputs (9).

15) - Input Voltage type contains symbol for single (1) phase Alternating

Current (AC) input at 50 or 60 Hz frequency.

18) - Nominal Input Voltage value is 110 VAC or 220 VAC.

19) - Rated maximum current required from the AC supply. Given for both

I1 maximum (I1max) and I1 effective (I1eff). 30 Ampere service is required

for both 110 VAC and 220 VAC operation.

10) Type:

DC

11) No-load Voltage:

U

= 59V

0

18) Voltage:

U1 = 110V

220V

3) Model:

Model 227

9) Output Continuous Current:

Minimum Maximum

6) Standards:

NEMA EW1

IEC 974-1

3A / 5V 200A / 20V

Output Pulsed Current

Minimum Maximum

3A / 5V 225A / 20V

12) Duty Cycle:

X = 100% ALL RATED OUTPUTS

19) Input Current:

I

= 30A I

1max

30A 30A

2.1

= 30A

1eff

21/22) Rating/Class:

IP21

Doc # 740063 Rev E

MODEL 227

OPERATION MANUAL

SECTION II - SPECIFICATION

2.0 ELECTRICAL

1. RATING PLATE DEFINITIONS

21) - International Protection (IP) rating. The M-227 is rated IP21 which

includes protection against a limited amount of exposure to rain (does

not make it weather proof or intended for all weather usage).

22) - The M-227 is rated as class I. No symbol is used for class I equipment.

23) - “S” Symbol indicates a welding power source which is suitable for an

environment with an increased electric shock hazard.

2. INPUT POWER, DETAIL - The M-227, as shipped standard, can operate on

the following Single Phase input AC:

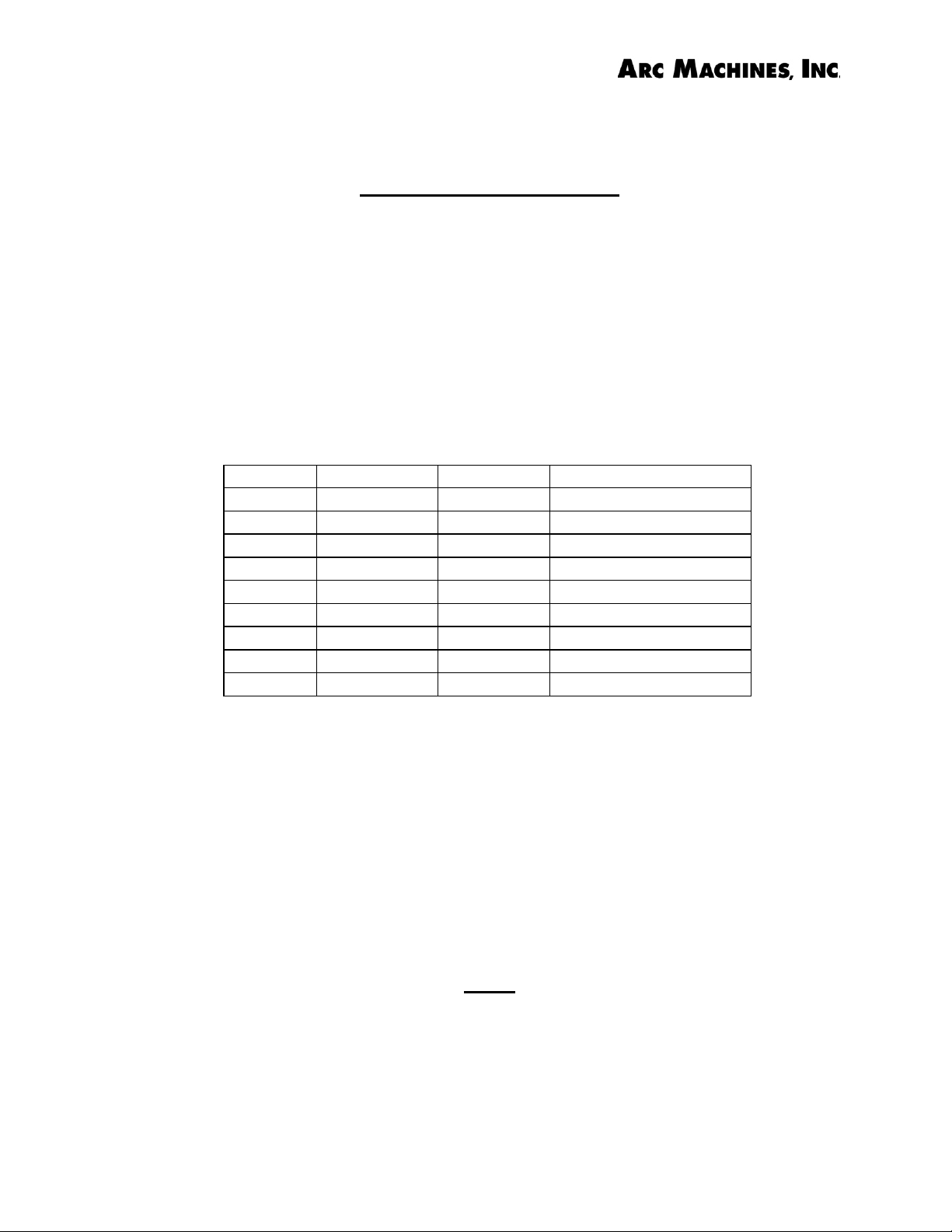

Voltage Tolerance Freq. Max Input Current

100 VAC + 32%, -10% 50/60 Hz 30 amperes

110 VAC + 20%, -18% 50/60 Hz 30 amperes

115 VAC + 15%, -22% 50/60 Hz 30 amperes

120 VAC + 10%, -25% 50/60 Hz 30 amperes

200 VAC + 32%, -10% 50/60 Hz 30 amperes

208 VAC + 27%, -13% 50/60 Hz 30 amperes

220 VAC + 20%, -18% 50/60 Hz 30 amperes

230 VAC +15%, -22% 50/60 Hz 30 amperes

240 VAC + 10%, -25% 50/60 Hz 30 amperes

+/- % indicates the allowable input voltage change to maintain performance as

specified. Maximum input current is based on maximum output current at

maximum arc voltage. See section 3.1 for installation.

3. OUTPUT POWER - Straight polarity, constant current DC regulation

intended for GTAW welding only. Static characteristic of the M-227 is flat.

Minimum current Output all cases .................... = 3 Amperes DC

Maximum current Output:

Set up for 110 VAC input ............. = 100 Amperes DC continuous or peak pulse.

Set up for 220 VAC input ............. = 200 Amperes DC continuous current

225 Amperes DC peak pulse

The M-227 is limited, by software, not to be able to be programmed for an

average current (between primary and background) of greater than 200 Amperes.

However, a peak pulse can be up to 225 amperes as long as the average does

not exceed 200 amperes.

4. CIRCUIT BREAKER - ON/OFF, two pole, 30 Ampere at 250 VAC.

Doc # 740063 Rev E

NOTE

2.2

MODEL 227

OPERATION MANUAL

2.1 PHYSICAL CONSTRUCTION

Cabinet material - aluminum

Height = 13.9 inch (353.1mm) cover closed

12.3 inch (312.4 mm) cover removed

Width = 22.75 inch (577.9 mm)

Depth = 19.25 inch (489.0 mm)

Weight = 91 lbs (41.3 kg)

2.2 PROGRAMMABLE FUNCTIONS

PREPURGE TIME = 010 - 999 seconds

POSTPURGE TIME = 000 - 999 seconds

UPSLOPE TIME = 00.0 - 99.9 seconds

DOWNSLOPE TIME = 00.0 - 99.9 seconds

ROTATION START DELAY = 00.0 - 99.9 seconds

ROTATION MODE SETTINGS = CONT - STEP - OFF

ROTATION DIRECTION = CW - CCW

PRIMARY ROTATION SPEED = 0.00 - 20.0 RPM

BACKGROUND ROTATION SPEED = 0.00 - 20.0 RPM

WIRE FEED START DELAY = 00.0 - 99.9 seconds

PRIMARY WIRE FEED SPEED = 000 - 200 IPM

BACKGROUND WIRE FEED SPEED = 000 - 200 IPM

WIRE FEED STOP DELAY = 00.0 - 99.9 seconds

WIRE FEED RETRACT TIME = 0.0 - 1.0 seconds

PRIMARY AVC = 5.0 - 20.0 volts

BACKGROUND AVC = 5.0 - 20.0 volts

AVC START DELAY TIME = 00.0 - 99.9 seconds

AVC STOP DELAY TIME = 00.0 - 99.9 seconds

AVC MODE SETTINGS = CONT - SAMPLE - OFF

OSCILLATION MODE = ON - OFF

TORCH OSCILLATION AMPLITUDE = Determined by Head Type

OSCILLATION IN and OUT DWELL TIMES = 0.00 - 9.99 seconds

OSCILLATION EXCURSION TIME = 0.00 - 9.99 seconds

PULSE MODE SETTINGS = ON - OFF - SYNC (to osc)

PRIMARY PULSE TIME = 0.00 - 9.99 seconds

BACKGROUND PULSE TIME = 0.00 - 9.99 seconds

LEVELS = 1 - 99

LEVEL TIME (each level) = 000 - 999 seconds*

PRIMARY CURRENT = 3 - 225 amperes*

BACKGROUND CURRENT = 3 - 225 amperes*

* = Can be in increments of 0.1

Doc # 740063 Rev E

SECTION II - SPECIFICATION

2.3

MODEL 227

OPERATION MANUAL

SECTION II - SPECIFICATION

2.3 MULTI-LEVEL FUNCTIONS - The following functions can be programmed to

change value during a given weld sequence.

FUNCTION POSSIBLE CHANGES

LEVEL TIME = 1 to 99 levels

PRIMARY CURRENT = 1 to 99 levels

BACKGROUND CURRENT = 1 to 99 levels

PRIMARY PULSE TIME = 1 to 99 levels

BACKGROUND PULSE TIME = 1 to 99 levels

PULSE MODE (ON/OFF/SYNC) = 1 to 99 levels

PRIMARY ROTATION RPM = 1 to 99 levels

BACKGROUND ROTATION RPM = 1 to 99 levels

ROTATION MODE (CONT/STEP/OFF) = 1 to 99 levels

PRIMARY WIRE FEED SPEED = 1 to 99 levels

BACKGROUND WIRE FEED SPEED = 1 to 99 levels

AVC MODE = 1 to 99 levels

PRIMARY AVC = 1 to 99 levels

BACKGROUND AVC = 1 to 99 levels

OSC AMPLITUDE = 1 to 99 levels

OSC DWELL and EXCURSION TIMES = 1 to 99 levels

2.4 NON-PROGRAMMABLE FUNCTIONS

WIRE FEED MODE SWITCH = ON/OFF

SYSTEM MODE KEY SWITCH = PROGRAM/OPERATE/LOCK

MANUAL PURGE = ON/OFF

2.5 AMBIENT TEMPERATURE RANGE - 32 F (0 C) to 110 F (45 C).

2.6 CABLE OPERATING DISTANCE LIMITS - Standard = 50 ft (15.2 m)

Maximum = 100 ft (30.5 m)

The standard distance consists of a 40 ft Pipe Weld Head Adapter cable and a 10 ft

Weld Head cable combined together. The maximum distance is achieved by

adding extension cables to the standard cables.

The above are considered normal limits and using a standard M227/207-CW or

M207-CW Cooling Unit Option. With special options, greater distances can be

achieved.Consult with an AMI technical representative for more information.

2.4

Doc # 740063 Rev E

MODEL 227

OPERATION MANUAL

SECTION III - INSTALLATION

3.0 INSPECTION

1. After unpacking, inspect all items for obvious physical damage and loose

parts. If damage is evident, contact a factory representative before using.

NOTE

If water condensation is apparent, dry the unit before using.

2. All M-227’s are shipped with a variety of peripheral equipment such as gas

hoses, fittings, manuals (including this one) and electrical drawings. An

exact list of these items is included with each power supply shipment. This

manual will reference some of those items, so before beginning installation, these

items should be located and be available.

3.1 POWER CONNECTION

WARNING

Do not connect the M-227 power supply to any AC power other than the ones

listed in section 2.0.2.

The M-227 can operate on 9 different input line voltages and must be set up for the

one you are using. Use the following procedure to insure that the M-227 is set-up for

the correct AC power.

1. The M-227 is supplied with a 25 ft power cord. One end has a connector on it

that plugs into the side of the M-227. The wires on the other end are pig-

tailed (no connector). A suitable AC line connector, matching the input

power, must be supplied and installed by the user. Color coding of the

power cord is as follows:

Black ................. = Hot (high line side)

White ................. = Neutral (low line side)

Green/Yellow .... = Ground (protective earth ground)

NOTE

For additional ground reference there is a ground symbol silk-screened next to

the ground pin on the M-227 Input AC connector on the Input Panel.

3.1

Doc # 740063 Rev E

MODEL 227

OPERATION MANUAL

SECTION III - INSTALLATION

3.1 POWER CONNECTION

2. Install the AC line connector onto the power cord.

NOTE

DO NOT PLUG THE M-227 INTO THE AC POWER SOURCE UNTIL

ALL INSTALLATION STEPS OF THIS MANUAL ARE COMPLETE.

3. Insure that the circuit breaker (CB-1) is in the OFF (down) position (see

figure 3).

4. Using figure 2 and 3 as a reference, locate the power SELECT SWITCH

(next to the input power connector). The switch is concealed by a cover

plate and only the top of the switch handle can be seen through a hole in the

plate. The plate is labeled as to what voltage it is currently set for.

5. If the M-227 is to be run on 100, 110, 115 or 120 VAC, this switch must be

in the 110 VAC position. If it is to be run on 200, 208, 220, 230 or 240

VAC, it must be in the 220 VAC position.

6. To change the power select switch position, remove the cover retaining

screws (see figure 3) and remove the cover. Set the switch to the alternate

position and install the cover plate. It must be flipped over so the hole in the

plate will fit over the switch handle in the new position. This will

automatically expose the alternate voltage label on the other side.

3.2 WELDING GAS CONNECTIONS

1. An Arc Input Gas Hose is supplied with the M-227. This hose is made of

material selected specifically for automatic welding. HOSES MADE

FROM OTHER MATERIAL ARE NOT RECOMMENDED (especially

rubber, nylon or tygon).

2. The 10 foot (3m) hose should be installed from the gas regulator/flowmeter

(user supplied) to the ARC GAS INPUT fittings required to mate with the

M-227 and most domestic (USA) inert gas flow meters.

The arc gas line is controlled by a solenoid and flow sensor in the M-227

and MUST BE connected to the M-227 (not directly to the weld head or

torch). After installing the hose and fittings loosely by hand, tighten the

retaining nuts slightly with a wrench to insure there are no leaks, but do not

over-tighten. The use of plumbers tape or grease is not recommended.

3.2

Doc # 740063 Rev E

MODEL 227

OPERATION MANUAL

SECTION III - INSTALLATION

3.2 WELDING GAS CONNECTIONS

CAUTION

The M-227 arc gas solenoid valve is rated at 50 PSI (345KPa) maximum

pressure, DO NOT EXCEED THIS RATING.

3. No I.D. Purge line is provided, but most GTAW welds will require the inside

be purged with Argon. Most piping situations will require I.D. purging from

sources and entry points a long distance from the M-227, so no outlet or

monitoring is provided. However, be sure to provide an I.D. purge if the

weld procedure requires it.

3.3 ADAPTER CABLE TO M-227 INSTALLATION

The M-227 comes standard with a 40 ft Pipe Weld Head Adapter Cable. This will be

used for most Weld Heads. However, some Weld Heads will use a different Adapter

Cable or additional cables. The correct cables required should be resolved at the time

of order. The following section refers mainly to the connection of the Pipe Weld

Adapter Cable.

NOTE

The Pipe Weld Head Adapter Cable consists of a 40 ft Control Adapter Cable and a

40 ft Service Adapter Cable. The two cables are not tied together as a unit.

WARNING

Always turn the power supply off before making any cable or connection changes to

the M-227 power supply.

1. One end of an adapter cable ALWAYS connects to the weld head. The

other end connects to the M-227 or to a weld head extension cable. The

connector types and keyways are different for each item (except gas).

Use the following steps for connection to the M-227 (see figure 2 and 4).

2. Connect the Service Adapter ELECTRODE connector to its respective

terminal on the M-227. Align the keyway, push in and twist clockwise until

fully locked.

3. Weld head CONTROL connector - Just before installing, unscrew the dust

caps on the electrical connectors on the cable and M-227. Insert the multi pin electrical connector into the M-227. Insert the multi-pin electrical

connector into the M-227 connector labeled PIPE WELD HEAD

CONTROL. Note the positioning keyway and NEVER FORCE or use tools

on the cable connections. Hand tighten the connecting ring after the pins are

firmly seated.

3.3

Doc # 740063 Rev E

MODEL 227

OPERATION MANUAL

Doc # 740063 Rev E

INSTALLATON LOCATONS

3.4

MODEL 227

OPERATION MANUAL

Doc # 740063 Rev E

AC POWER SET-UP

3.5

MODEL 227

OPERATION MANUAL

Doc # 740063 Rev E

CABLE CONNECTIONS

3.6

MODEL 227

OPERATION MANUAL

SECTION III - INSTALLATION

3.3 ADAPTER CABLE INSTALLATION (continued)

4. Insert the Service cable male gas quick-disconnect into the M-227 ARC

GAS OUTPUT connector.

5. Insert the two coolant quick-disconnects into the COOLANT IN and

COOLANT OUT connectors on the CW (if being used). The cable

coolant connectors are interchangeable and it does not matter which one

goes to in or out.

3.4 WELD HEAD INSTALLATION - The weld head cable connects to the adapter

cable. Refer to the Weld Head Operation manual as you perform this installation.

1. The male brass quick dis-connect on the adapter cable provides the electrode

power and one leg of the coolant path. Connect it to the mating female

quick dis-connect on the Weld Head.

2. Connect the other coolant quick dis-connect and gas quick dis-connect (they

are different types and sizes) to their mates on the Weld Head Cable.

3. After the Electrode, Coolant and Gas connectors are secure and checked,

slide the rubber boots on each line together and secure them in place. These

boots provide both a safety factor to prevent shorting to ground and also act

as a retainer to prevent the connectors from coming apart.

4. Unscrew the CONTROL connector dust caps on both cables just before

installing. Insert the adapter connector into the head connector. Note the

positioning keyway and NEVER FORCE or use tools on the cable

connections. Using just your hand, tighten the connecting ring until the pins

are firmly seated. Screw the two dust caps together to prevent them from

swinging around.

3.5 GROUND (WELDING WORK) CABLE INSTALLATION

1. A 50 ft Ground Cable with a “C” type clamp on one end and a Cam-lok quick

dis-connect is provided.

2. Connect the quick dis-connect to the GROUND connector on the M-227 or

the Ground Extension Cable if one is provided.

3. Connect the Ground Clamp to a “bare” metal surface on the Pipe to be

welded. It should be placed as close to the weld as possible.

3.7

Doc # 740063 Rev E

MODEL 227

OPERATION MANUAL

SECTION III - INSTALLATION

3.6 REMOTE PENDANT INSTALLATION

Always turn the power supply OFF before making any cable or connection

changes to

the M-227 power supply.

1. Insert the M-227-RP cable connector into the M-227 Panel connector

labeled REMOTE.

2. If a M-227-RP extension is used, it is installed between the M-227 and the

RP.

3. If required the M-227 can be operated without the RP Unit.

CAUTION

Installation is now complete but before proceeding with POWER ON it is

EXTREMELY important to have a basic understanding of SYSTEM

FUNCTIONS. Read section IV (system functions) before proceeding with

OPERATION (section V) or PROGRAMMING (section VI).

3.8

Doc # 740063 Rev E

MODEL 227

OPERATION MANUAL

SECTION IV - SYSTEM FUNCTIONS

4.0 INTRODUCTION

The M-227 is intended for use with AMI orbital welding heads and has functions

designed for these weld heads. This section describes what these functions are and

may, where needed for clarification, indicate how they are commonly (but not

always) used.

Step 4.1 is a general description; the remaining steps describe, in more detail, the

items of step 4.1. Only FUNCTION is discussed here. Details of function ranges and

tolerances can be found in section II of this manual and the AMI Specification No.

227. Details about operating these functions can be found in section V.

4.1 FUNCTIONAL DESCRIPTION, GENERAL

1. LIBRARY - The heart of the M-227 is its MEMORY. The values of each

function, for a given weld, are only programmed one time. After that the M 227 will store the function values (for that weld) by WELD SCHEDULE

NUMBER (#) and description.

When a particular weld type is needed to be made the Operator can locate it

in the WELD SCHEDULE LIBRARY by description or by weld schedule

number (#).

2. WELD SEQUENCE AND LEVELS - Selected weld schedules are started

by manually initiating the SEQUENCE START. Once the sequence is

started the system operation can be totally automatic.

In addition to functions to start and stop the weld, the weld sequence

includes the ability to preset changes in function values and modes. These

changes are called LEVELS and as many as 100 levels can be used for each

weld sequence. All weld schedules start with (and must have) Level 1.

If preset changes are desired they will be set in LEVELS 2, 3, ETC. The

LEVELS advance from 1 to 2, 2 to 3, etc. automatically as a function of

time, or they can be advanced by the Operator manually.

3. CURRENT SOURCE AND CONTROL - The M-227 is a pulsed, 225

ampere peak, constant current, straight polarity, GTAW power source. The

current value(s) can be set between 3 and 225 Amps.

NOTE

The M-227 is limited, by software, not to be able to be programmed for an

average current (between primary and background) greater than 200 Amperes.

However, a peak pulse can be up to 225 amperes as long as the average does

not exceed 200 amperes.

4.1

Doc # 740063 Rev E

MODEL 227

OPERATION MANUAL

SECTION IV - SYSTEM FUNCTIONS

4.1 FUNCTIONAL DESCRIPTION, GENERAL

4. TRAVEL FUNCTION - The system is equipped with a motor servo

controller that provides the power and regulation for rotating the arc around

the weld seam. The system controls the movement in revolutions per

minute (RPM) or inches per minute (IPM) depending on weld head type.

NOTE

The motor servo can only work properly if the weld head being used is

equipped with a motor assembly designed for operation on the M-227.

5. WIRE FEED FUNCTION - The system is equipped with a motor servo

controller that provides the power and regulation for feeding Wire into the

weld puddle. The system controls the feed in Inches per Minute (IPM).

6. AVC FUNCTION - The standard M-227 comes with an Arc Voltage

Control (AVC) Motor Servo. A version of the M-227 is also available

without AVC. The AVC in conjunction with a weld head with an AVC

motor is used to maintain the desired Arc Gap between the Electrode and

the weld puddle.

7. TORCH OSCILLATION - The standard M-227 comes with an OSC Motor

Servo. A version of the M-227 is also available without OSC. The OSC

in conjunction with a weld head with an OSC motor is used to perform both

cross-seam steering during a weld and to provide welding weave across the

weld during rotation.

8. PULSATION - The system can rapidly change or PULSE back and forth

between two (2) different values of CURRENT, TRAVEL, WIRE FEED

and AVC. The normal or HIGH value is designated the PRIMARY value.

The other or LOW value is designated the BACKGROUND value. This

pulsation is done as a function of time by using the PRIMARY and

BACKGROUND PULSE TIMES to set an exact amount of time for each

PRIMARY and BACKGROUND function to occur or the pulsation can be

synchronized to the movement of the Torch Oscillator function.

9. OVERRIDES - The weld schedule programmer can set the M-227 to allow

the operator to change the value of some weld schedule functions. The

programmer can also set limits to the amount of changes the operator can

make to each function.

4.2

Doc # 740063 Rev E

MODEL 227

OPERATION MANUAL

SECTION IV - SYSTEM FUNCTIONS

4.1 FUNCTIONAL DESCRIPTION, GENERAL

10. FAULT STATUS - The system continuously monitors certain function such

as gas flow, coolant flow, ground fault, system temperature and input AC.

If there are any problems the system will alert the operator and in some

cases, where weld quality might be affected, the system will stop the

welding process.

11. GAS FUNCTIONS - As stated, the M-227 is intended for the GTAW

process. This process requires a welding gas (usually inert) for operation

and the M-227 is equipped with a gas solenoid and input/output connectors

for the control of the welding (arc) gas.

12. PRINT FUNCTIONS - Built into the M-227 is a Thermal Printer. The

printer allows copies of the Library and complete weld schedule to be made.

4.2 WELD LIBRARY AND WELD DESCRIPTION

Each weld schedule programmed into the system memory is identified and

displayed (when selected) with the following information:

1. # = Individual WELD SCHEDULE NUMBER from 001 to 100.

2. OD = Outside diameter in inches or mm of the weld.

3. WALL = Wall thickness in inches or mm of the weld.

4. MAT = Uses abbreviations to identify the base material the schedule is

programmed to run.

5. HEAD = Uses Weld Head Model number to identify what AMI Head the

schedule is programmed to run.

6. PASS = Indicates total number of weld passes programmed to complete the

weld.

4.3 WELD SEQUENCE - Although the M-227 can be used as a manual welding

power source, it is primarily intended to follow an automatic SEQUENCE.

After a weld schedule is selected and the weld head is setup, the SEQUENCE will

be manually started by the operator and the following events will occur

automatically (see figure 5 for the timing chart):

1. EVENT 1: PREPURGE - Welding gas will start to flow (for the entire

weld) from the gas source (user supplied) through the power supply to the

weld head. Complete gas coverage should be obtained before the arc is

struck. How long it flows before the arc is struck is called the PREPURGE

TIME.

4.3

Doc # 740063 Rev E

MODEL 227

OPERATION MANUAL

SECTION IV - SYSTEM FUNCTIONS

4.3 WELD SEQUENCE

2. EVENT 2: ARC START - When PREPURGE time is complete the M-227

will initiate an arc. The Arc Start MODE can be set to either RF or TOUCH.

In RF mode a high frequency pulse will be generated to establish an arc

between the electrode and the weld joint. In TOUCH mode the AVC will

perform a TOUCH START and initiate the arc (can only be used with

Weld Heads with an AVC function).

3. EVENT 3: LEVEL 1 TIME, START LEVEL, UPSLOPE, TRAVEL and

WIRE START DELAY, AVC START DELAY and OSC UPSLOPE When the arc is established the following functions all start at the same time:

1. LEVEL 1 TIME - When the arc is established all weld functions are

considered to be in LEVEL 1. If the TIMER MODE is in AUTO the

LEVEL 1 Timer will start to count and the M-227 will stay in LEVEL 1

until this time is complete. If the TIMER MODE is set to MANUAL the

system will still be in LEVEL 1 but the timer will not be counting and

the system will stay in LEVEL 1 until the operator manually advances or

ends the sequence.

2. WELD CURRENT START LEVEL - As the arc is established the weld

current will jump to a small value. This current is used to stabilize the

arc and is called the START LEVEL. Its value is programmable and

may need to be changed depending on certain conditions. However, it

is not a multi-level function and it is only used to help initiate the arc.

3. WELD CURRENT UPSLOPE - Sometimes it may be necessary to raise

the weld current to full value slowly. This is called UPSLOPE. When

the arc is established the weld current will start to rise to the PRIMARY

and BACKGROUND (if pulsed) value programmed in LEVEL 1. The

time it takes to rise to full value is the UPSLOPE TIME.

4. PRIMARY and BACKGROUND PULSE TIMES - When the arc is

established and the LEVEL 1 PULSE MODE is programmed to the ON

position, the weld current will be pulsing between the PRIMARY and

BACKGROUND functions at the rate set by the Level 1 PULSE

TIMES.

5. TRAVEL START DELAY - Rotation of the arc should not occur in

most cases, until full penetration of the weld has been achieved. When

the arc is established the TRAVEL START DELAY time will begin to

count. When this programmable period of time is complete the weld

head will start to rotate the arc.

Doc # 740063 Rev E

4.4

MODEL 227

OPERATION MANUAL

SECTION IV - SYSTEM FUNCTIONS

4.3 WELD SEQUENCE

3. EVENT 3:

6. WIRE FEED START DELAY - Feeding of the Wire should not occur,

in most cases, until travel has started. When the arc is established the

WIRE FEED START DELAY time will begin to count. When this time

is complete the wire will be able to feed if the Wire Mode is set to ON.

7. AVC START DELAY - The AVC should not be turned on until the

current is near full value and the puddle has stabilized. When the arc is

established the AVC START DELAY time will begin to count. When

this time is complete the AVC will be able to operate.

8. OSCILLATOR UPSLOPE - The Torch Oscillator Upslope is linked to

the current Upslope time. During the Current Upslope time the

Oscillator Amplitude (movement) will start at 0 amplitude and slowly

increase to the full program value of OSC Amplitude by the end of

current Upslope.

9. OSCILLATOR DWELL and EXCURSION TIMERS - The Oscillator

movement is based on time. The Level 1 Dwell and Excursion Timers

start counting at the beginning of Event #3 (if OSC MODE is set to ON).

4. EVENT 4: FULL LEVEL FUNCTIONS - Sometime after the arc is

established, depending on the weld schedule, the current UPSLOPE, OSC

UPSLOPE and all START DELAYS (Travel, Wire, AVC) will be completed

and all of the following functions will be in effect:

1. LEVEL 1 TIME - Will be counting towards 0. During its count all of

the below functions will be occurring:

2. LEVEL 1 PULSE MODE - The PULSE MODE can be set in each

LEVEL to work several different ways:

ON = In the ON mode system will pulse between PRIMARY and

BACKGROUND function values using the PULSE TIMERS for

timing control.

OFF = In the OFF mode all system functions will be in

PRIMARY only. No BACKGROUND functions will be done.

SYNC = In the SYNC Mode the system will pulse between

PRIMARY and BACKGROUND function values using the

Oscillator Dwell and Excursion Timers for pulse control.

4.5

Doc # 740063 Rev E

MODEL 227

OPERATION MANUAL

SECTION IV - SYSTEM FUNCTIONS

4.3 WELD SEQUENCE

4. EVENT 4: FULL LEVEL FUNCTIONS -

3. LEVEL 1 PRIMARY PULSE TIME - If the LEVEL 1 PULSE MODE

is ON this function will now be timing the Primary pulses (see Event 3).

4. LEVEL 1 BACKGROUND PULSE TIME - If the LEVEL 1 PULSE

MODE is ON this function will now be timing the Background pulses.

5. LEVEL 1 PRIMARY AMPS - After UPSLOPE the system will be

regulating this programmed value of current each time the system goes to

Primary Pulse either using the Level 1 Primary Pulse Time or the Level 1

Osc Dwell Time if the Level 1 Pulse Mode is in SYNC.

6. LEVEL 1 BACKGROUND AMPS - If the LEVEL 1 PULSE MODE

was programmed to ON or SYNC, the system will be regulate the

Level 1 Background current value after each Level 1 Primary pulse.

7. LEVEL 1 TRAVEL MODE - After the TRAVEL START DELAY time

is complete the Travel will function in one of these programmable modes.

OFF = Will prevent rotation from occurring.

CONT = Runs the travel at the PRIMARY-RPM speed only,

regardless of PULSE MODE.

STEP = Will pulse the travel between the PRIMARY-RPM and

BACKGROUND-RPM speed. If the TRAVEL MODE is in

STEP but the PULSE MODE is in OFF then only PRIMARY will

occur (without pulsing there are no background functions).

8. LEVEL 1 PRIMARY-RPM - After the Travel Start Delay time is

complete the travel function will begin. If the Level 1 Travel Mode is

programmed to CONT the travel will be rotating the arc at the Primary RPM rate continuously regardless of any pulsing. If the Travel Mode is

STEP it will rotate the arc at the Primary-RPM speed each time the

system goes to PRIMARY.

9. LEVEL 1 BACKGROUND RPM - If the LEVEL 1 PULSE MODE is in

ON or SYNC and the TRAVEL MODE is in STEP the system will

rotate the arc at the BACKGROUND-RPM each time the system goes to

a BACKGROUND pulse.

NOTE

Travel direction is programmable CLOCKWISE or COUNTER CLOCKWISE. After the Travel Start Delay the Head will rotate in the

programmed direction. The direction is not programmable by LEVELS.

4.6

Doc # 740063 Rev E

MODEL 227

OPERATION MANUAL

Doc # 740063 Rev E

SEQUENCE TIMING CHART

4.7

MODEL 227

OPERATION MANUAL

Doc # 740063 Rev E

PANEL KEY LOCATIONS

4.8

MODEL 227

OPERATION MANUAL

SECTION IV - SYSTEM FUNCTIONS

4.3 WELD SEQUENCE

4. EVENT 4: FULL LEVEL FUNCTIONS -

10. LEVEL 1 PRIMARY WIRE - After the Wire Start Delay time is

complete the Wire Feeder will feed at the Primary Wire Feed value

whenever the system is in Primary and the Wire Mode is set to ON.

11. LEVEL 1 BACKGROUND WIRE - After the Wire Start Delay is

complete the Wire Feeder will feed at the Background Wire Feed value

whenever the system is in Background and the Wire Mode is ON.

12. LEVEL 1 AVC MODE - The AVC can be set in each Level to work

several different ways:

OFF = Will prevent the AVC servo from operating.

CONT = Allows the AVC to work continuously both in the

PRIMARY and BACKGROUND functions, using the Level 1

AVC value when in Primary and using the Level 1 Background

AVC value when in Background.

SAMP/PRI = Allows the AVC to work only during the

PRIMARY current, using only the Primary AVC value. The

AVC position will not move during Background.

SAMP/BCK = Allows the AVC to work only during the

BACKGROUND current. using only the Background AVC

value. The AVC position will not move during Primary.

13. LEVEL 1 PRIMARY AVC - After the AVC START DELAY time is

complete and the AVC MODE is in CONT or SAMP/PRI. the AVC

will maintain this value during the Primary current.

14. LEVEL 1 BACKGROUND AVC - After the AVC START DELAY

time is complete and the AVC MODE is in CONT or SAMP/BCK the

AVC will maintain this value during the Background current.

15. LEVEL 1 OSCILLATOR AMPLITUDE - Is the distance the Torch

Oscillator will move from full IN to full OUT during the EXCURSION

TIME programmed in LEVEL 1.

16. LEVEL 1 OSCILLATOR EXCURSION TIME - The time in LEVEL

1 that the oscillator will travel from full IN to full OUT position.

17. LEVEL 1 IN DWELL TIME - The amount of time the oscillator will

stay at the IN position before EXCURSION to the OUT position.

18. LEVEL 1 OUT DWELL TIME - The amount of time the oscillator

will stay at the OUT position before EXCURSION to the IN position.

Doc # 740063 Rev E

4.9

MODEL 227

OPERATION MANUAL

SECTION IV - SYSTEM FUNCTIONS

4.3 WELD SEQUENCE

5. EVENT 5: LEVEL 2 TO LAST PROGRAMMED LEVEL - As the arc is

rotated around the weld it is usually necessary to program changes in the

current, pulse times, modes and rotation speed. These changes are called

LEVELS and up to 100 can be programmed for each sequence. Each

LEVEL contains the same functions and options as EVENT 4. In TIMER

MODE AUTO each LEVEL TIME sets the duration of that level. TIMER

MODE MANUAL the system will stay in a programmed level until

MANUAL ADVANCED by the Operator (from the Remote Pendant).

6. EVENT 6: DOWNSLOPE - When the last programmed LEVEL is

complete the WELD SEQUENCE will begin the process of stopping

as follows:

1. Current and Oscillator DOWNSLOPE - To avoid cratering and cracking

of the weld the current and oscillator need to be reduced slowly. The last

LEVEL PRIMARY-AMP value and BACKGROUND-AMP value (if

pulsed) and OSC AMPLITUDE will start to decrease towards 0. The

time it takes to reach arc cutoff (about 3 amps) is called the

DOWNSLOPE time and it is programmable.

2. WIRE STOP DELAY TIMER - At the end of the last Level the WIRE

STOP DELAY time will start counting. The WIRE will continue to feed

until this time is complete. When the wire quits feeding the wire will

automatically retract (go in reverse) for the programmed RETRACT

TIME.

3. AVC STOP DELAY - At the end of the last Level the AVC STOP

DELAY time will start counting. The AVC will continue to operate until

this time is complete.

NOTE

The ROTATION function does not have a STOP DELAY. The Weld Head

will continue to TRAVEL for the DOWNSLOPE time and then turn off.

7. EVENT 7: POSTPURGE - At the end of DOWNSLOPE, when the current

is less than 3 amperes, the arc will go out. All functions except gas flow will

stop. The gas should not be stopped until the weld and electrode are cooled

enough to prevent oxidation. How long the gas continues to flow is called

the POSTPURGE TIME.

4.10

Doc # 740063 Rev E

MODEL 227

OPERATION MANUAL

SECTION IV - SYSTEM FUNCTIONS

4.3 WELD SEQUENCE

8. EVENT 8: RETURN TO HOME AND RESET - When POSTPURGE is

complete the gas will shut off. When the gas shuts off, Weld Heads with

“Return to Home” functions (M-9, M-95, M-79) will then have the rotor

automatically return to the open position for removal. The System will then

reset and be ready to make another weld.

4.4 PANEL KEYS - The following are descriptions of all active operating keys

contained on the system Main Panel (see figure 6):

1. ALL STOP KEY - Active only during weld sequence in test or weld mode.

When pressed it will stop the sequence, turn off the arc with no downslope

and start the postpurge process (see 4.3 event 7).

2. C KEY - Used for screen clear or cancel, it will end (without storing) the

screen being displayed and return to the beginning of any step. The screen

will prompt the operator to indicate what will happen if the C key is pressed.

3. CE KEY - The Clear Entry key is used to clear numbers entered with the

numeric keys before the ENTER key is pressed. Use this key when a mistake

is make using the numeric keys.

4. ENTER KEY - Used at the end of each step to indicate completion and to

move to the next step or screen.

5. F KEYS - These are function keys numbered 1 to 16. Each key is aligned

with a portion of the display and are used to activate, cycle or alter the item

displayed above or below it. Each key will alter different functions

depending on whet screen is being displayed. Use of the F keys is always

prompted by the screens.

6. L KEY - The M-227 is multi-lingual. Pressing this key will change the

display from English to French to German, etc.. The L key is always active.

7. LIB KEY - Used to access the LIBRARY (weld schedule memory/storage).

8. MANUAL PURGE KEY - Active at all times. Used for manually turning

on the gas solenoid. When ON, the gas solenoid will be energized and it

will stay ON until this key is manually pressed again.

9. METER KEY - Only one of the displays is used as a BAR GRAPH METER

during Welding. Limited functions are shown. Use this key to access the

desired meter function. Remember that meter readouts are provided for

functional troubleshooting only. They are not intended for verification of

system performance.

4.11

Doc # 740063 Rev E

MODEL 227

OPERATION MANUAL

SECTION IV - SYSTEM FUNCTIONS

4.4 PANEL KEYS

10. NEXT LEVEL KEY - Active when weld schedules with more than one

level are being displayed. An * will appear on the displays to indicate that

more levels are programmed for that weld schedule.

11. NEXT PASS KEY - Used to retrieve from memory the next weld pass

parameters for the weld schedule being used.

12. NEXT SCREEN KEY - Active when another screen (more data) is available

for a weld schedule or function. An * will appear on the display to indicate

that more data is available on the next screen.

13. NUMERIC KEYS - Used to select weld schedule number (3) or to enter

numbers during programming, overriding and set-up functions.

14. PREV LEVEL KEY - Same as NEXT LEVEL but levels appear in reverse

order.

15. PREV PASS KEY - Used to retrieve from memory the previous parameters

used for the previous pass.

16. PREV SCREEN KEY - Same as NEXT SCREEN but screens appear in

reverse order.

17. PRINT KEY - If pressed when the status screen is displayed a copy of

system hours and software revision will be printed. If pressed during the

library screen a copy of the entire library will be printed. If pressed while

displaying a weld schedule the entire weld schedule will be printed. This key

will not be activate any other time. It cannot be used during an actual weld

sequence. The date will be printed on every copy.

18. PRO KEY - Active only if the OPERATE MODE SWITCH is in the

PROGRAM position. Pressing the PRO key from the Status screen will

access the programming modes. During programming the PRO key is also

used to store information.

19. SEQ START KEY - Active with the schedule screen. When pressed this

key will start the weld sequence (see 4.3).

20. SEQ STOP KEY - Active only during weld sequence. When pressed this key

will stop the weld sequence and start the downslope function (4.3 event 6).

4.12

Doc # 740063 Rev E

MODEL 227

OPERATION MANUAL

SECTION IV – SYSTEM FUNCTIONS

4.4 PANEL KEYS

21. SET UP KEY - Active at all times except during a weld sequence. When

pressed this key will allow access to various set-up options (see 4.8).

22. TVL CW JOG KEY - Active at all times. When pressed the weld head will

rotate the electrode in the counterclockwise direction

23. TVL CCW JOG KEY - Active at all times. When pressed the weld head

will rotate the electrode in the counterclockwise direction.

24. WELD/TEST KEY - At power on the M-227 will always be in the TEST

mode. In TEST mode a weld sequence can be run but NO ARC will be

struck. The user must press this key to initiate WELD mode. Once this is

done the M-227 will stay in WELD mode as long as the same weld schedule

is displayed. Changing schedules will cause the system to return to the

TEST mode.

25. WIRE JOG FWD KEY - Used to feed the wire out manually before

sequence for installation and set-up purposes.

26. WIRE JOG REV KEY - Used to pull the wire back manually before

sequence for installation and set-up purposes. This key should be used

sparingly because most weld heads do not have a reel take up function and

the wire can back-lash if too much wire is retracted.

27. WIRE MODE ON/OFF KEY - After Wire Start Delay the Wire can only

turn on if the wire mode is set to ON.

28. AVC UP JOG KEY - Used to move, prior to and after welding, the AVC

(and torch) in the up direction.

29. AVC DOWN JOG KEY - Used to move, prior to and after welding, the

AVC (and torch) in the down direction.

30. OSC IN JOG KEY - Used to STEER the Oscillator and torch toward (IN) the

Weld Head.

31. OSC OUT JOG KEY - Used to STEER the Oscillator and torch away (OUT)

from the Weld Head.

32. STOP PRINT KEY - This key will allow the user to stop the printing

process for any reason.

33. PAPER FEED KEY - This key allows the user to advance the paper in the

printer.

4.13

Doc # 740063 Rev E

MODEL 227

OPERATION MANUAL

SECTION IV - SYSTEM FUNCTIONS

4.5 OPERATE MODE SWITCH

This is a three position switch with a locking key. When set to the desired position

(mode) the key can be removed, to prevent any non-key holder from changing the

mode.

1. OPERATE/WELD SELECT POSITION - The OPERATE mode is for

standard welding operations. It allows access to all weld schedules and set up screens. All normal system operations, such as weld sequence, etc. are

performed in this mode. In this mode the operator CANNOT perform any

PROGRAMMING functions or changes to the memory such as creating,

modifying, transferring or deleting.

2. MODE LOCK - After weld schedule has been selected it may be locked-in

to prevent selection of any other weld schedule. This feature is intended

primarily for when the operator is welding out-of-sight of the M-227 or if a

supervisor wishes to insure that ONLY a particular weld schedule is used.

3. PROGRAM/OPERATE - In order to CREATE, MODIFY, TRANSFER,

COPY or DELETE a weld schedule in the system memory, the mode switch

must be set to this position. All system operations, such as weld sequence,

can also be performed in this mode.

CAUTION

Authorization and access to the OPERATE MODE KEY should be controlled.

When the switch is set to the PROGRAM mode the operator may permanently

MODIFY (change) or DELETE weld schedule information contained in the

system memory.

4.6 FAULTS

The M-227 has the ability to monitor certain functions. If they are not working

correctly a system fault (FLT) will alert the operator to the problem. The following is

a description of each type of fault (FLT):

1. TEMP FLT - Power supply internal TEMPERATURE IS TOO HIGH

Fault creates an ALL STOP condition if it occurs during weld sequence.

2. COOL FLT - Insufficient TORCH COOLANT FLOW. Active only with

the M227/207-CW or M207-CW option and the fault can be disabled from the

SETUP Screen.

When active the fault creates an ALL STOP condition if it occurs during

weld sequence.

3. LVPS FLT - Problem with the Low Voltage DC Power Supplies. Fault

creates SEQ STOP if it occurs during weld sequence.

4.14

Doc # 740063 Rev E

MODEL 227

OPERATION MANUAL

SECTION IV - SYSTEM FUNCTIONS

4.6 FAULTS

4. GAS FLT - TORCH GAS FLOW is not detected. Fault creates an ALL

STOP if it occurs during a weld.

5. INPUT FLT - If the M-227 cannot achieve desired outputs because of

inadequate AC input. Fault creates a SEQ STOP of it occurs during a weld.

6. SENSOR 1,2,3 - User defined (see 4.7, 4.8 and 5.8).

7. BAD START - Indicates that the system was unable to sustain an arc.

8. STUB OUT - If the Arc Voltage gets too low or the electrode should touch

the puddle then a stub out will occur.

9. HIGH VOLTS - If the Arc Voltage gets too high a fault will occur.

10. GROUND FAULT - On Heads with Ground Fault Sense, if the Work

Ground is not connected to the Work piece the system will detect this and

prevent arc start.

11. OSC LIMIT - On Heads with OSC limit switches, if they are engaged the

system will create an ALL STOP.

12. AVC LIMIT - On Heads with AVC limit switches, if they are engaged the

system will create an ALL STOP.

The method of alerting the operator depends on what the fault is and when it

occurs. A problem with TEMP, LVPS or INPUTAC when the M-227 is first

turned on will create a FAULT SCREEN and the fault must be corrected before

the M-227 will proceed with any other functions.

A problem with COOL, GAS or SENSOR is common at power on or when

preparing for welding. These items will only create the FAULT SCREEN if they

occur during weld sequence. BAD START appears only during weld sequence

(after pre-purge) and does not create a fault screen.

STUB OUT and HIGH VOLTS will only occur during a weld and will cause an

ALL STOP condition. After postpurge the normal “return to home” sequence will

also be disabled.

4.15

Doc # 740063 Rev E

MODEL 227

OPERATION MANUAL

4.7 SENSOR 1, 2, 3 FAULTS

The M-227 has 3 separate inputs that the user can define for creating a fault

condition based on some external problem. The most common is connecting a gas

analyzer(s) to the M-227 to detect excessive Oxygen in the I.D. purge of a weld.

The user must make these connections and uses the SET-UP screen (see 5.8) to

define what a fault is for this external input.

4.8 SET-UP FUNCTIONS

The following SET-UP functions provide some customizing and calculating

features to enhance system performance:

1. CALCULATE - Calculates TUNGSTEN LENGTH, IPM to RPM

conversions and WELD TIME.

2. WELD-SELECT - The M227-RP may select up to 4 pre-determined weld

schedules from memory. This function defines the schedules that are picked.

3. COOLANT FAULT - Used to enable or disable Coolant Fault whether or

not a M227/207-CW or M207-CW is connected.

4. REV - Used to display the SOFTWARE REVISION of a particular M-227.

Depending on intended use, M-227’s may have different software revisions.

5. PRINT EMM - Used to print a copy of the EMM memory.

6. AMP - TIME - Used to change the last significant digit of Level Current or

Level Time from whole numbers to tenths (000 to 000.0).

7. ARC V FLT - Used to de-activate STUB OUT and HIGH VOLT faults

These faults are usually needed to be turned off for manual welding.

8. SENSORS - Activates and defines EXTERNAL Fault inputs (see 5.8).

9. PRINTER - Used to select AUTO or MANUAL print mode.

10. OSC SPEED - Used to set the speed that the OSC IN Key and OSC OUT

key move the Oscillator Steering.

11. DATE RESET - Used to reset the DATE.

12. AVC JOG SPEED - Used to set the speed of the AVC JOG UP and AVC

JOG DOWN. Primarily used to refine Touch Start Operation.

13. OPERATOR I.D. - Allows the Operator to enter his name or ID number.

Once entered it will be printed on all copies of weld schedules.

14. POWER SUPPLY SERIAL NUMBER - Allows entry of Power Supply

Serial #. Once entered it will be printed on all copies of weld schedules.

Doc # 740063 Rev E

SECTION IV - SYSTEM FUNCTIONS

4.16

MODEL 227

OPERATION MANUAL

SECTION IV - SYSTEM FUNCTIONS

4.9 GLOSSARY OF DISPLAY SYMBOLS AND ABBREVIATIONS - The M-227

displays contain many abbreviations. The following is an alphabetical listing:

AL = Aluminum

AMP = Amperes

BCK = Background (low value of a function that pulses)

CAL = Calibrate or calibration

CCW = Counterclockwise

CONT = Continuous operation

COOL = Coolant flow

CS = Carbon steel

CW = Clockwise

DLY = Delay time

EXT = External input or function

FLT = Fault

HAS = Hastaloy

INC = Inconel

INPUTAC = Input power AC voltage check

IPM = Inches per minute

LIB = Library, listing of programmed weld schedules

LVL = Level or levels

LVPS = Low voltage DC power supply check

MAT = Material

MNL = Monel

OD = Outside diameter

OK = Mean monitored function is operating properly.

PRE-PURGE-POST = PREPURGE, postpurge columns.

PRI = Primary function value

PRI-AMP-BCK = Primary amp, background amp columns

PRI-PULSE-BCK = Primary time, background time columns

PRI-RPM-BCK = Primary speed, background speed columns

PRO = Program mode

REV = Software revision or sometimes Reverse

ROT = Rotation or travel function

ROT DLY = Rotation or travel start delay time

RPM = Revolutions per minute

SP = Special material

SS = Stainless steel

SYS HOURS = System hours indicate total power-on time.

TEMP = Power supply internal temperature

TI = Titanium

# = Weld schedule number

* = Indicates that more information is available

Doc # 740063 Rev E

4.17

MODEL 227

OPERATION MANUAL

SECTION IV - SYSTEM FUNCTIONS

4.10 GLOSSARY OF DISPLAY TERMS - The M-227 displays contain many terms that

do not relate directly to a function or sequence. The following is a listing of

those terms:

AMIWELD = Name, type and revision of software

ARC GAP = Distance needed between electrode and weld.

ARC HOURS = Total hours system has been welding.

BAD START = Problem has occurred with RF start.

CALCULATE = Function calculates RPM or tungsten length.

CANCEL = Ends step without storing or completing.

COPY = Allows a schedule to be copied with a new #.

CREATE = For creating a new weld schedule.

DATE RESET = Resets date function.

DELETE = Used to delete a weld schedule from memory.

INVALID NUMBER = Can appear by attempting to CREATE a weld

schedule that already exists or by Selecting a weld

schedule that does not exist.

MODE LOCK = Screen cannot be changed. Weld schedule (if

selected) will be locked in.

MODIFY = Used to permanently change a weld schedule.

OPERATE = Operate mode only, cannot program.

OVERRIDES = Ability to change a value temporarily.

PROGRAM/OPERATE = Ability to program or operate.

RING = Insert ring is used for filler material.

ROTOR OD = Outside diameter of M-9 rotor.

SENSOR 1,2,3 = User defined faults.

STORE = Puts weld information into memory.

TRANSFER = Allows copying of memory to another M-227 or

to the M-227-EMM.

TYPE = Describes the basic type of weld.

WALL = Wall thickness of the weld.

WARNING = Used to indicate that if step is continued a

permanent loss of information will result.

4.18

Doc # 740063 Rev E

MODEL 227

OPERATION MANUAL

SECTION V - OPERATION

5.0 INTRODUCTION

Operation covers those steps that must be taken to actually perform a weld.

Programming and development of schedules are not covered in this section.

It is very important to insure, before operating, that the operator has INSTALLED

the M-227 per section III and has a good understanding of functions from section IV.

Function explanations are not covered in this section.

The M-227 uses two displays to provide information and instructions for use. For

the most part, the information and instructions presented on these displays are

adequate explanation of operation. This section is only intended as a guideline to get

started with for first time users AFTER HAVING ATTENDED AN AMI

M-227 TRAINING CLASS.

5.1 INITIAL POWER ON/STATUS SCREEN

1. Before connecting or energizing the AC power; verify that all input power

set up requirements of Section III have been complied with.

WARNING

Applying 200 VAC or greater input power to a M-227 set up for 110 VAC

operation WILL CAUSE THE INPUT VARISTERS TO FAIL. MAKE

SURE THE INPUT POWER SET UP IS CORRECT FOR THE POWER

BEING USED.

2. The M-227 can be turned on without the adapter cable, gas hoses or weld

head connected. However, to verify proper operation they must be

connected. Insure that all of these connections are per Section III.

3. Plug in the AC power cable to the AC source. Move the circuit breaker

(CB1) to the ON position.

4. After a few seconds the STATUS SCREEN will appear as shown on the

next page:

NOTE

If the input power is too low it is possible for the screens not to turn on,

be scrambled or get a fault screen indicating a LVPS fault. If these

conditions occur recycle CB1. If they continue to occur check the input

power and the power setup of the M-227.

5.1

Doc # 740063 Rev E

MODEL 227

OPERATION MANUAL

SECTION V - OPERATION

5.1 INITIAL POWER ON/STATUS SCREEN

4. (continued)

UPPER SCREEN

TO WELD PRESS LIB TO PROGRAM PRESS PRO

SYS HOURS - 00000.0 ARC HOURS - 00000.0

LOWER SCREEN

TEMP-OK INPUTAC-OK GAS-OK LVPS-OK

COOL-OK SENSOR1-OK 2-OK 3-OK

Actual hours will appear where the above show 0. COOL, GAS or

SENSOR 1,2,3 may indicate FLT where OK appears. This is considered

normal at power-up.

5.2 USE OF NEXT/PREV SCREENS/LEVELS

Weld schedules contain more data than can be shown at one time. To display this

data the NEXT/PREV SCREEN keys and NEXT/PREV LEVEL keys must be

used. These keys are located at the corners of the lower display. When there is

more data on another screen or level, a flashing * will appear in the appropriate

corner (s) to indicate that more information is available.

Screen/Level keys are used in selection of a weld schedule and all weld schedules

use 8 basic Lower Screen Displays that appear in the following order:

1. PROMPT SCREEN = Appears when a weld schedule is called up from

memory. Gives instructions in lower display and shows Library Description,

Weld Mode and Fault Status in upper display.

2. LEVEL 01 AMPS - TIME - PULSE = Displays the value of Amps, Level

Time and Pulse Times for Level 1.

3. LEVEL 01 RPM/IPM - MODES = Displays the value of Travel Speeds,

Travel Mode and Pulse Mode for Level 1.

4. LEVEL 01 WIRE -AVC-AVC MODE = Displays the value of Wire Feed

Speeds, AVC settings and AVC MODE for Level 1.

5. LEVEL 01 OSC = Displays the value of Osc Amplitude, IN Dwell, Out

Dwell and Excursion times for Level 1.

5.2

Doc # 740063 Rev E

MODEL 227

OPERATION MANUAL

5.2 USE OF NEXT/PREV SCREENS/LEVELS

6. PURGE - SLOPE - ROT DELAY = Displays the time for Prepurge,

Postpurge, Upslope, Downslope Rotation Direction and Rotation Start

7. WF DELAY - RETRACT - T/MODE - OSC MODE = Displays settings

for Wire Feed Start Delay, Stop Delay, Wire Retract Time, Timer Mode and

Osc Mode

8. AVC DELAY - START MODE - RESPONSE - START LEVEL =

Displays settings for AVC Start Delay, Stop Delay, Response and Start Level.

Pressing the NEXT SCREEN key will advance the display in the above order.

When viewing screen 2 to 8 (above) pressing the PREV SCREEN key will

reverse the order.

The weld schedule can be programmed to have up to a 100 levels of screen 2, 3, 4

and 5. When viewing screen 2, 3, 4 or 5 the operator can press the NEXT LEVEL

key to view the values for the next level for those same functions (if programmed).

When displaying level 2 or greater, pressing the PREV LEVEL key will then

display the previous level.

Pressing the NEXT SCREEN or PREV SCREEN key after using the NEXT

LEVEL or PREV LEVEL key will display the NEXT SCREEN for that LEVEL,

except if the next screen is 1, 6, 7 or 8, these screens are the same for all levels.

Reference figure 7 for a flow chart on the use of NEXT/PREV SCREEN and

LEVEL keys.

5.3 WELD SCHEDULE SELECTION

The following describes how to select a weld schedule from the LIBRARY. The

Operate Mode switch must be in the OPERATE or PROGRAM position. Be sure

to have read section 5.2 (use the Next/Prev keys) before proceeding.

1. The STATUS Screen of 5.1 should be displayed. If not press the C key until

until the STATUS screen appears.

2. Press the LIB key and the following display will appear:

Doc # 740063 Rev E

SECTION V - OPERATION

5.3

MODEL 227

OPERATION MANUAL

SECTION V - OPERATION

5.3 WELD SCHEDULE SELECTION

2. (continued)

USE SCREEN KEYS TO FIND # PRESS ENTER