Model 205 Tube Welding Power Supply

Part No. 740108

Revision J

Operator’s Manual

M O D E L 2 0 5

T

O P E R A T O R ’ S M A N U A L

INTRODUCTION

he Model 205 is a power source and controller for automatic orbital tube welding. It is

intended to be used only in conjunction with AMI or EXEL orbital tube weldheads.

The Model 205 power supply provides GTAW (Gas Tungsten Arc Welding) current

with pulsation controls, high frequency arc starting, purge gas controls, weldhead arc

rotation and automatic timing functions. Users need only to supply input AC power, a

regulated gas source with flow meter and the appropriate weldhead.

NOTICE

This document and the information contained herein is the property of Arc Machines, Inc. It

is proprietary and submitted and received in confidence. It shall be used only for the

purpose for which it is submitted and shall not be copied in whole or in part without the prior

express written permission of Arc Machines, Inc. The information in this document has

been carefully reviewed and is believed to be accurate. However, no responsibility is

assumed for inaccuracies.

Information and instructions in this document are subject to change and Arc Machines, Inc.

reserves the right to change specifications and data without notice.

i

M O D E L 2 0 5

O P E R A T O R ’ S M A N U A L

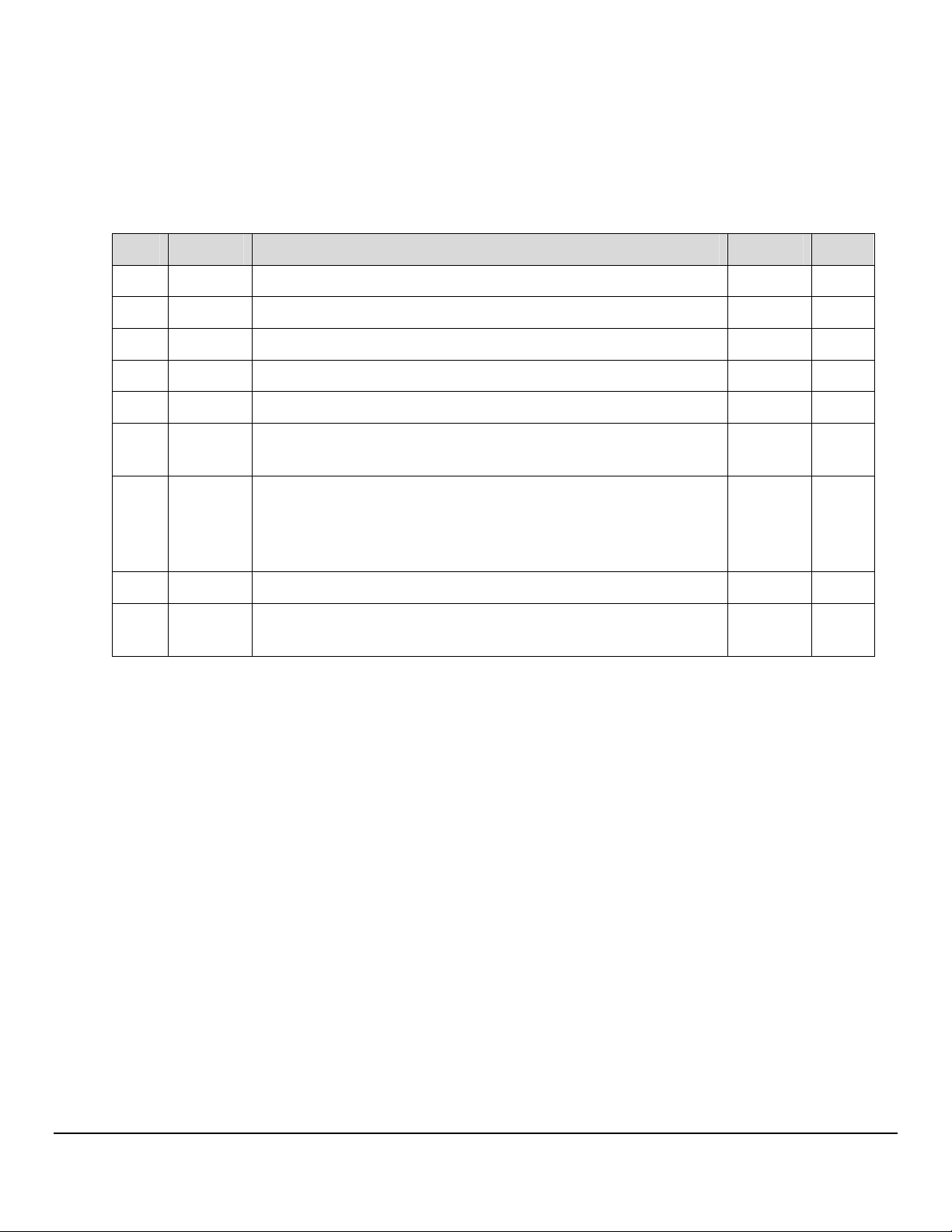

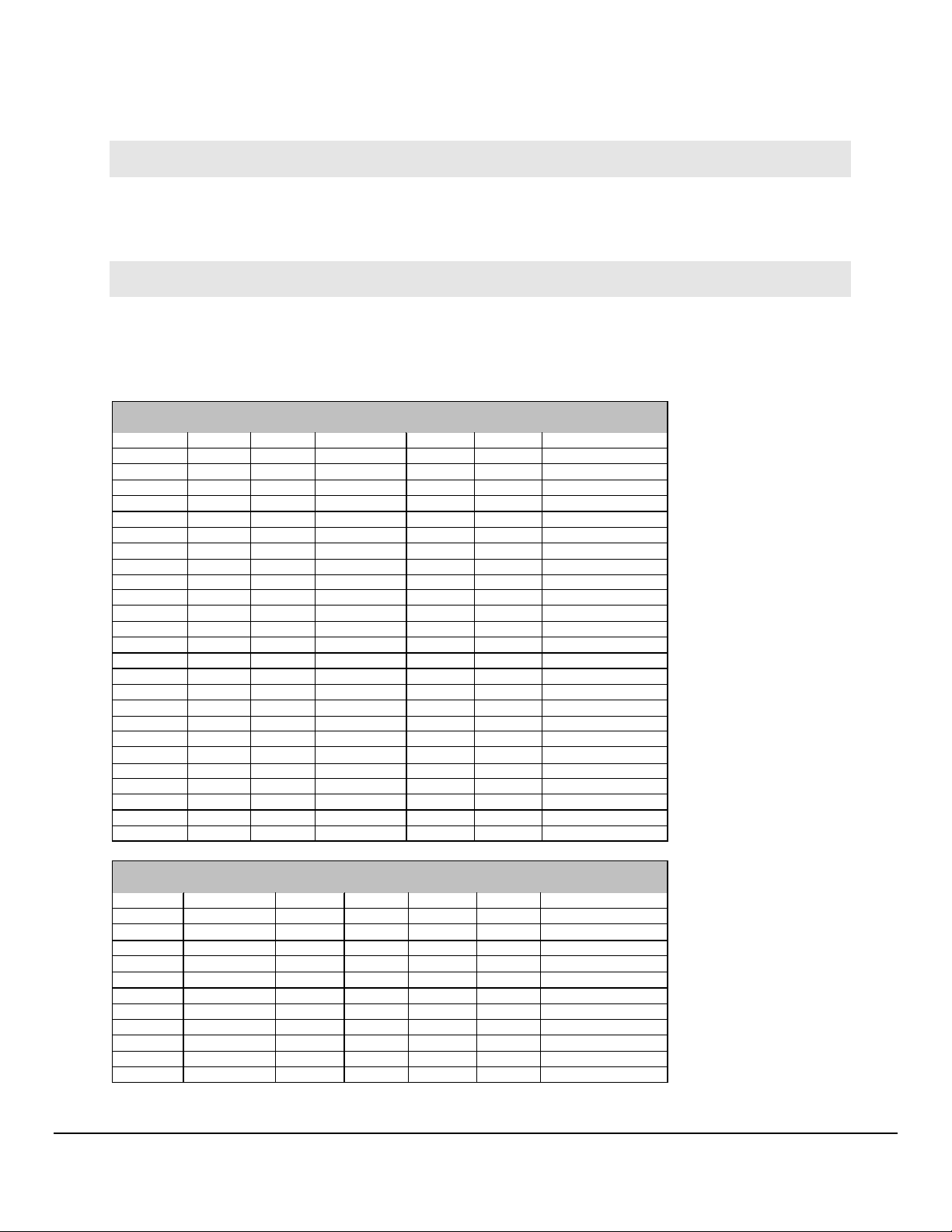

Revision History

Rev ECO No.

Change Description Date Appr.

A N/A Initial release 3/10/09 B.F.

B 5355 Update sections 2.0, 3.0, 4.0, 5.0 & 6.0; delete Glossary 5/14/09 B.F.

C 5411 Update section 4.10.9 Performing a Weld 07/06/09 B.F.

D 5447 CE changes 12/30/09 D.C.

E 5713 Correct table in Section 6.1.2 with correct weight 06/16/10 D.C.

F 5817 Incorporate S/W v1.5, corrections for CE changes, add

12/08/10 D.C.

power grounded to section 2.0, update obsolete data

G 6346 Incorporate M21 W/H information, add changes to Run

06/15/12 D.C.

screen, add Associated Data look-up tables, add

information on system initiate 0.5 second delay, add

information on +1%/-1% buttons, update UK address.

H 6518 Section 6.2, changed picture of Remote Pendant (pg51) 3/20/13 BL

J 6646 Add Weld Data Recording functionality and update

2/25/14 W.O.

applicable screens

ii

ii

iiii

M O D E L 2 0 5

O P E R A T O R ’ S M A N U A L

Table of Contents

Table of Contents

Table of ContentsTable of Contents

INTRODUCTION.................................................................................................... i

NOTICE..............................................................................................................i

Revision History ............................................................................................ii

Table of Contents .........................................................................................iii

1.0 SAFETY PRECAUTIONS...................................................................... 1

1.1 SHOCK HAZARD WARNING................................................................ 1

1.2 WARNING LABEL DEFINITIONS ......................................................... 3

2.0 SPECIFICATIONS .................................................................................5

2.1 ELECTRICAL ........................................................................................ 5

2.2 ELECTICAL SERVICE GUIDE .............................................................. 6

2.3 PHYSICAL DIMENSIONS .....................................................................6

2.4 PROGRAMMABLE AND OPERATIONAL FUNCTIONS ...................... 7

3.0 INITIAL SETUP......................................................................................8

3.1 SYSTEM SYMBOLS..............................................................................8

3.2 INSPECTION .......................................................................................10

3.3 POWER CONNECTION....................................................................... 11

3.4 WELDING GAS CONNECTIONS ........................................................ 11

3.5 MODEL 205 TO M8 / M9 WELDHEAD HOOK UP ..............................12

3.6 MODEL 205 TO EXEL ROTOR DRIVER HOOK UP........................... 16

3.7 MODEL 205 TO M21 WELDHEAD HOOK UP ....................................17

4.0 OPERATION........................................................................................ 18

4.1 SYSTEM FUNCTIONS......................................................................... 18

4.2 INITIAL POWER ON............................................................................20

4.3 SET-UP FUNCTIONS ..........................................................................21

4.4 OPENING THE LAST WELD SCHEDULE ..........................................25

4.5 SELECTING A WELD SCHEDULE FROM THE LIBRARY ................25

4.6 MODIFY A WELD SCHEDULE ...........................................................26

4.7 COPY A WELD SCHEDULE ...............................................................30

4.8 CREATE A WELD SCHEDULE........................................................... 33

4.9 WELDHEAD CALIBRATION...............................................................35

4.10 PERFORMING A WELD.....................................................................36

4.11 WELD DATA RECORDING................................................................40

5.0 MAINTENANCE AND TROUBLE-SHOOTING ................................... 43

6.0 OPTIONS.............................................................................................52

iii

iii

iiiiii

M O D E L 2 0 5

Hazard

Chapter

1

O P E R A T O R ’ S M A N U A L

1.0 SAFETY PRECAUTIONS

The Model 205 is intended to be used only with AMI or EXEL weldheads for the purpose of

GTAW welding of metal tube. The system is not to be used for any other purpose, specifically

heating or cutting.

WARNING

I C O N K E Y

Warning

Electrical

THAT HE HAS READ AND/OR BEEN MADE AWARE OF ALL OF THE SAFETY-RELATED

ITEMS CONTAINED IN THIS MANUAL.

The nature of the GTAW process creates some POTENTIAL

HAZARDS. In accordance with international safety regulations the

EXCLAMATION SYMBOL indicates that this equipment is considered

HAZARDOUS. The LIGHTNING FLASH SYMBOL indicates that

there are potential electrical hazards. The use and display of these

symbols make it the OPERATOR’S RESPONSIBILITY TO ENSURE

1.1 SHOCK HAZARD WARNING

HIGH VOLTAGE is present on exposed internal terminals. The ELECTRODE (tungsten /

weldhead rotor) is also an EXPOSED TERMINAL and by its nature the GTAW process requires

electrical potential to be present on the electrode during arc starting and during welding.

1

M O D E L 2 0 5

O P E R A T O R ’ S M A N U A L

All AMI Power Supplies contain a “bleeder” circuit to ground any residual potential

after welding or after an aborted or bad arc start attempt. These circuits take a few seconds

to operate or could fail.

The electrode should always be considered a possible shock hazard. This is

especially true when the system is in “weld sequence”, ready to weld, is welding or has just

finished welding. Equipment/component failure, system abuse or improper maintenance

could result in electrical potential at the weldhead even when not in “weld sequence”.

The users/operators of this equipment must take all precautions necessary to avoid

contact with the ELECTRODE at “ALL TIMES”. The only exception is when actually

replacing or adjusting the electrode and this should be done WITH THE POWER TURNED

OFF.

If performed with the power “ON” the system must be in “TEST” mode out of weld

sequence and the USER MUST OBSERVE COMMON SAFETY PRACTICES such as

grounding the electrode to ensure discharge before actually touching it.

Most AMI Power Supplies feature High Frequency (HF) Arc Starting. This is a High

Voltage/High Frequency electrical transmission process. To eliminate any HF shock

possibility “AVOID ALL CONTACT” with the Welding WORK (ground), the ELECTRODE or

the WELDHEAD during arc start.

Remember, there is a possible shock hazard in all welding power supplies at

ALL times.

2222

M O D E L 2 0 5

O P E R A T O R ’ S M A N U A L

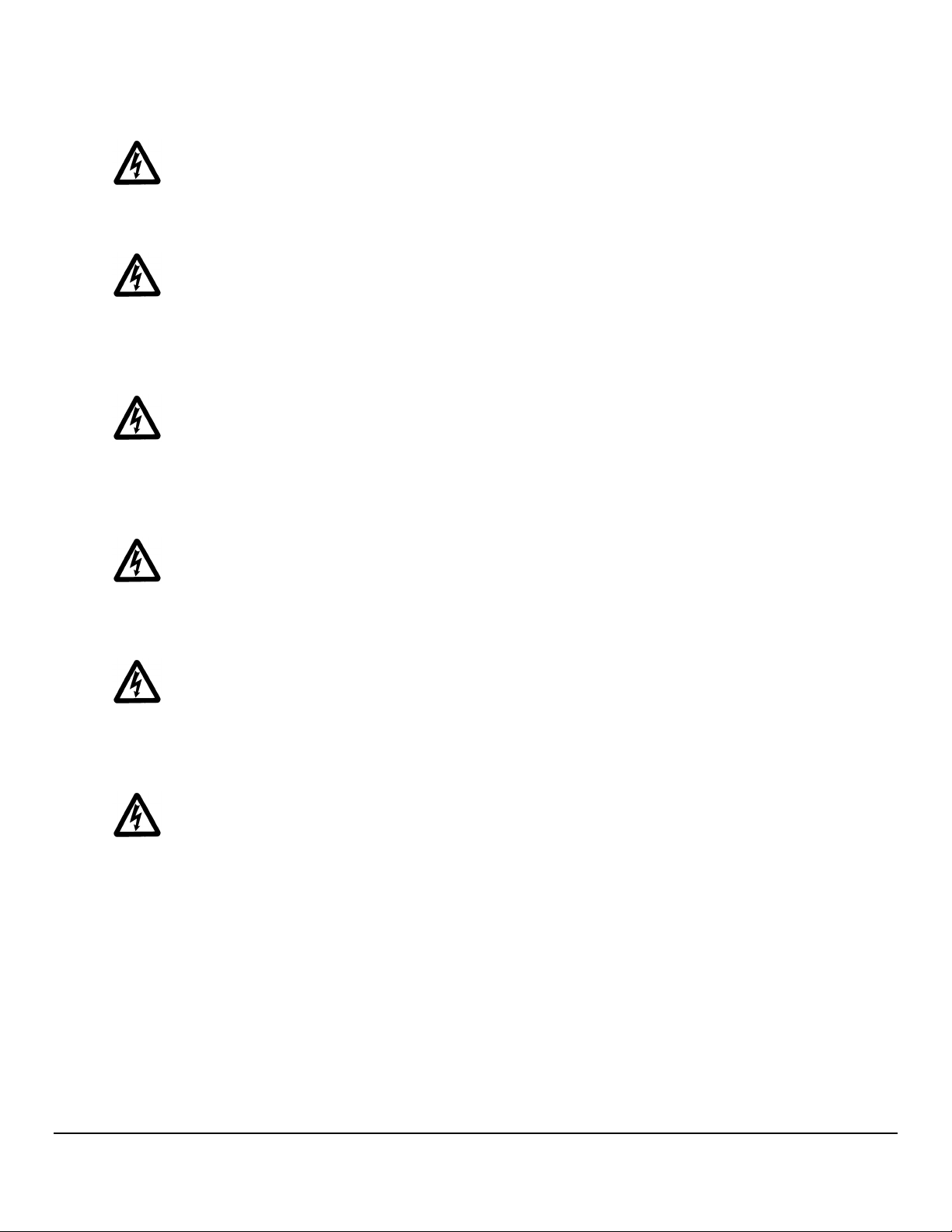

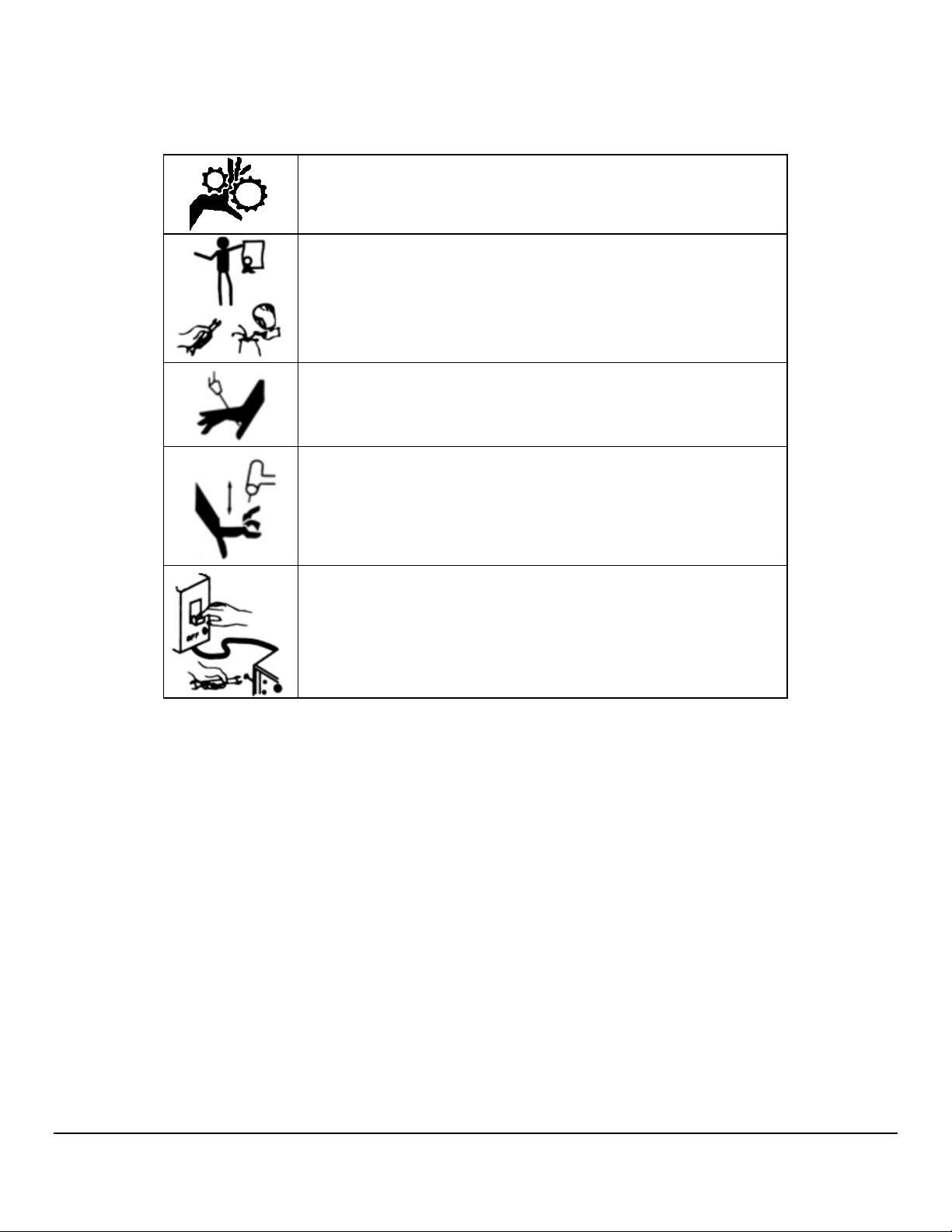

1.2 WARNING LABEL DEFINITIONS

The table below contains caution and warning labels for the operation of this equipment. Before

operating this or any welding equipment users should be familiar with ANSI-49.1 Safety in

Welding and Cutting.

ELECTRIC SHOCK from welding electrode or wiring can kill.

HIGH FREQUENCY RADIO WAVES can cause interference and

sometimes even damage to nearby electronic equipment (such

as computers) that are un-protected.

MAGNETIC FIELDS can affect implanted medical devices.

Wearers of pacemakers should keep away until consulting their

doctor.

Welding can cause FIRE OR EXPLOSIONS. Do not weld near

FLAMMABLE or EXPLOSIVE MATERIALS. Have the proper

type of extinguisher in the work area.

WEAR NON-FLAMMABLE protective clothing, footwear and

head gear at all times.

HOT PARTS can cause severe burns. Do not touch recently

welded components. Avoid touching torch components and

welding fixtures soon after welding.

ARC RAYS can burn the eyes and skin. The welding arc emits

ultra-violet (UV) radiation and the molten weld gives off infra-red.

Both can burn eyes and skin if unprotected. Suitable eye and skin

protection must be worn.

BUILD UP OF GAS can injure or kill. Weld materials can emit

toxic fumes during welding. WELD ONLY IN AREAS WITH

ADEQUATE VENTILATION.

FUMES AND GASES can be hazardous. Welding produces

fumes and gases. Breathing these fumes and gases can be

hazardous to your health. DO NOT weld in enclosed areas

without proper ventilation or respirators.

3333

M O D E L 2 0 5

O P E R A T O R ’ S M A N U A L

MOVING PARTS - Keep hands and fingers clear of fans,

gears, rotors, wire feed, rotation and AVC mechanisms

WARNING: AMI factory training is essential for all Welding

Operators and Maintenance Technicians who operate AMI

equipment.

WELDING WIRE and ELECTRODES are sharp and can cause

injury.

MOVING PARTS may cause crush or pinch points.

WARNING: Disconnect the input power to the machine before

opening or servicing. Discharge all circuits that store high

voltage such as capacitor packs. Only AUTHORIZED and

QUALIFIED service personnel should open this equipment.

4444

M O D E L 2 0 5

90V

90V

90V

90V

Chapter

2

O P E R A T O R ’ S M A N U A L

2.0 SPECIFICATIONS

These specifications pertain the to Model 205 power supply only. For weldheads, refer to the

specification sheet of each particular model. For non-AMI supplied equipment such as gas

tanks and regulators, refer to the original manufacturer’s documentation.

The Model 205 is a mobile system that is intended be hand carried. The supporting equipment

such as weldheads, water coolers, gas regulators, remote controls and extension cables can

also be hand carried. Items such as gas tanks and welding fixtures should be moved with

appropriate equipment and safety precautions. Gas tanks should be securely anchored to

prevent toppling over.

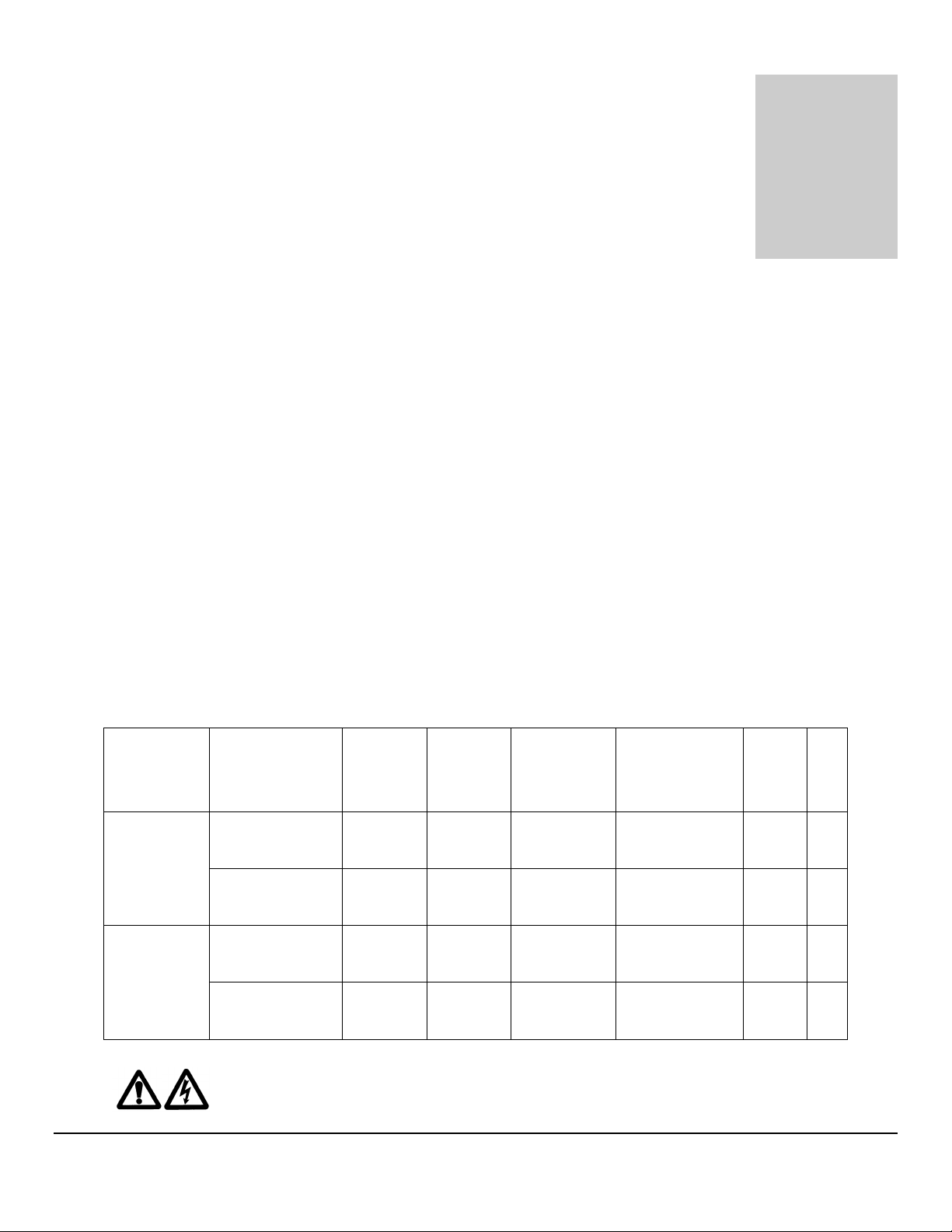

2.1 ELECTRICAL

INPUT POWER DETAIL

The Model 205 can operate on the following Auto Adjusting for Single Phase AC input:

Input Power

Single-Phase

AC

115 Volts TIG

20A

230 Volts TIG

20A

Rated Welding

Output

100A @ 14.0

Volts DC, 100%

Duty Cycle

150A @ 16.0

Volts DC, 30%

Duty Cycle

100A @ 14.0

Volts DC, 100%

Duty Cycle

150A @ 16.0

Volts DC, 30%

Duty Cycle

Welding

Amperage

Range

5 - 150A

5 - 150A

5 - 150A

5 - 150A

Max OCV

DC (Up)

12-16

12-16

12-16

12-16

Rated Peak

Starting

Voltage (Up)

15 KV 18.4 2.1 2.1

15 KV 28 3.4 3.1

15 KV 8.3 2 1.9

15 KV 14.2 3.2 3.1

Amperes Input

At Rated Load

Output, 50/60Hz,

Single-Phase

KVA

@

Duty

Cycle

KW

Input power must be grounded.

5555

M O D E L 2 0 5

O P E R A T O R ’ S M A N U A L

OUTPUT POWER

Straight polarity, constant current DC regulation intended for GTAW welding only. Static

characteristic of all power supplies is flat.

5 to 150 amperes DC using 100 to 120 VAC input.

5 to 150 amperes DC using 200 to 240 VAC input.

CIRCUIT BREAKER – ON/OFF, two pole, 20 Ampere at 250 VAC.

DUTY CYCLE – determined by the AC input voltage and the required output current. The

Model 205 system has an internal thermal sensor that will limit operation should the

temperature exceed the safe operating parameters.

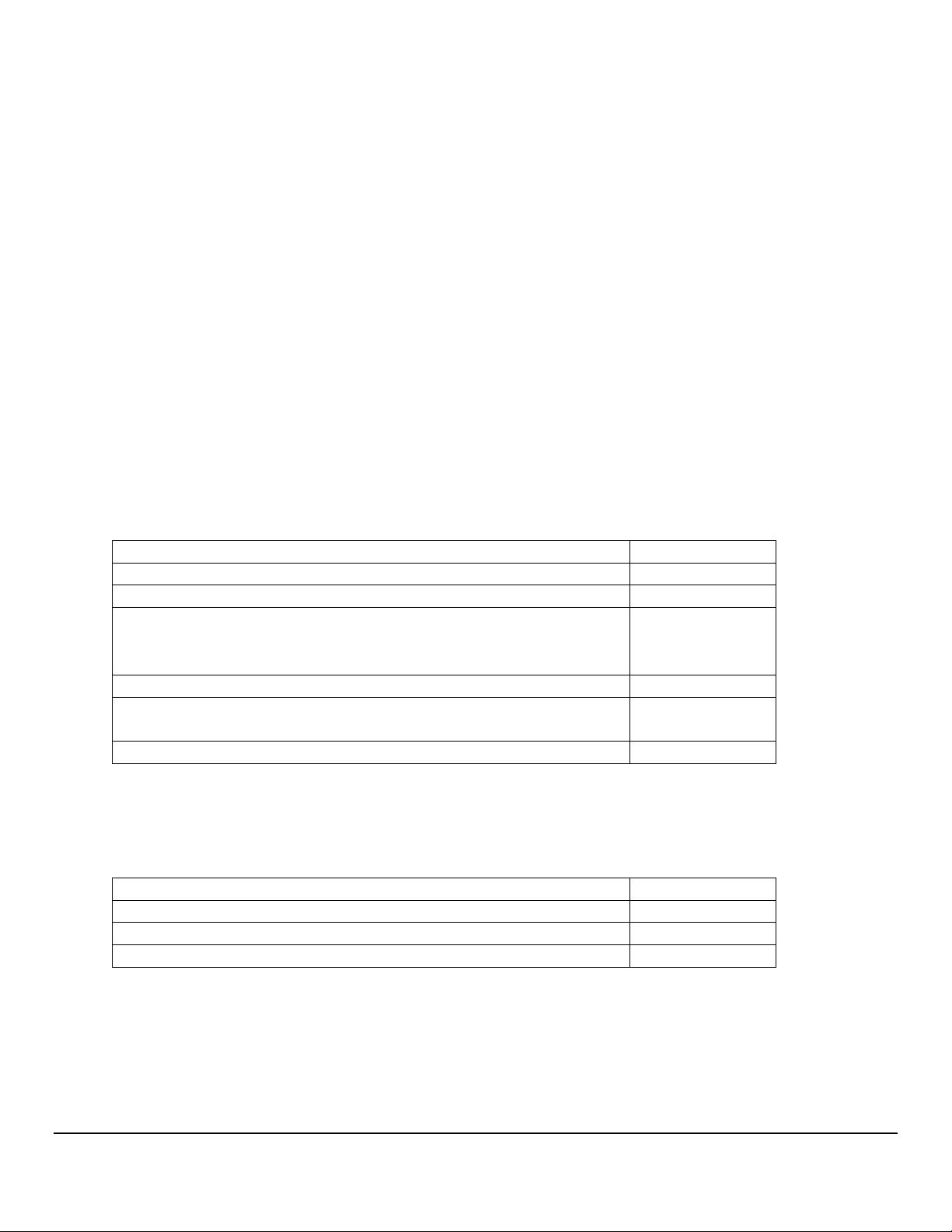

2.2 ELECTICAL SERVICE GUIDE

FUNCTION RANGE

INPUT VOLTAGE 115/230

INPUT AMPERES AT RATED OUTPUT 13.1

MAX RECOMMENDED STD FUSE RATING IN AMPERES

• CIRCUIT BREAKER, TIME DELAY

• NORMAL OPERATING

15

20

MIN INPUT CONDUCTOR SIZE IN AWG 14

MAX RECOMMENDED INPUT CONDUCTOR

LENGTH IN FEET (METERS)

91 (28)

MIN GROUNDING CONDUCTOR SIZE IN AWG 14

2.3 PHYSICAL DIMENSIONS

POWER SUPPLY HEIGHT 18” (457mm)

POWER SUPPLY WIDTH 19” (483mm)

POWER SUPPLY DEPTH 14” (356mm)

POWER SUPPLY WEIGHT 51 lbs (22 kg)

6666

M O D E L 2 0 5

O P E R A T O R ’ S M A N U A L

2.4 PROGRAMMABLE AND OPERATIONAL FUNCTIONS

SINGLE ENTRY FUNCTIONS

FUNCTION RANGE

PREPURGE 5.0 – 999.0 seconds

POSTPURGE 5.0 – 999.0 seconds

UPSLOPE 0.0 – 99.9 seconds

START LEVEL 5.0 – 150.0 amps

DOWNSLOPE 00.0 – 99.9 seconds

LEVEL ADVANCE TIME / POSITION

TRAVEL START DELAY 00.0 – 99.9 seconds

TRAVEL DIRECTION CW / CCW

MULTI-LEVEL FUNCTIONS

The following functions can be programmed at each level to change value during a

given weld sequence.

FUNCTION RANGE

LEVEL POSITION 0 – 9999 degrees

LEVEL DEGREES 0 – 9999 degrees

SLOPE DEGREES 0 – 9999 degrees

TIME 0.1 – 999.9 seconds

SLOPE TIME 0.0 – 999.9 seconds

PRIMARY AMPS * 5.0 – 150.0 amps

BACKGROUND AMPS 5.0 – 150.0 amps

PRIMARY TRAVEL As defined by Weldhead **

BACKGROUND TRAVEL As defined by Weldhead **

PRIMARY PULSE 0.01 – 9.99 seconds

BACKGROUND PULSE 0.01 – 9.99 seconds

PULSE MODE ON / OFF

TRAVEL MODE ON / STEP / CONT

* For single level schedules the PRIMARY AMPS function is replaced by START AMPS and

END AMPS functions

** TRAVEL functions are in 0.01 RPM increments

7777

M O D E L 2 0 5

Chapter

3

O P E R A T O R ’ S M A N U A L

3.0 INITIAL SETUP

This manual is intended to assist users of this equipment in set up and basic

operation. It is NOT INTENDED AS A SUBSTITUTE FOR FACTORY TRAINING.

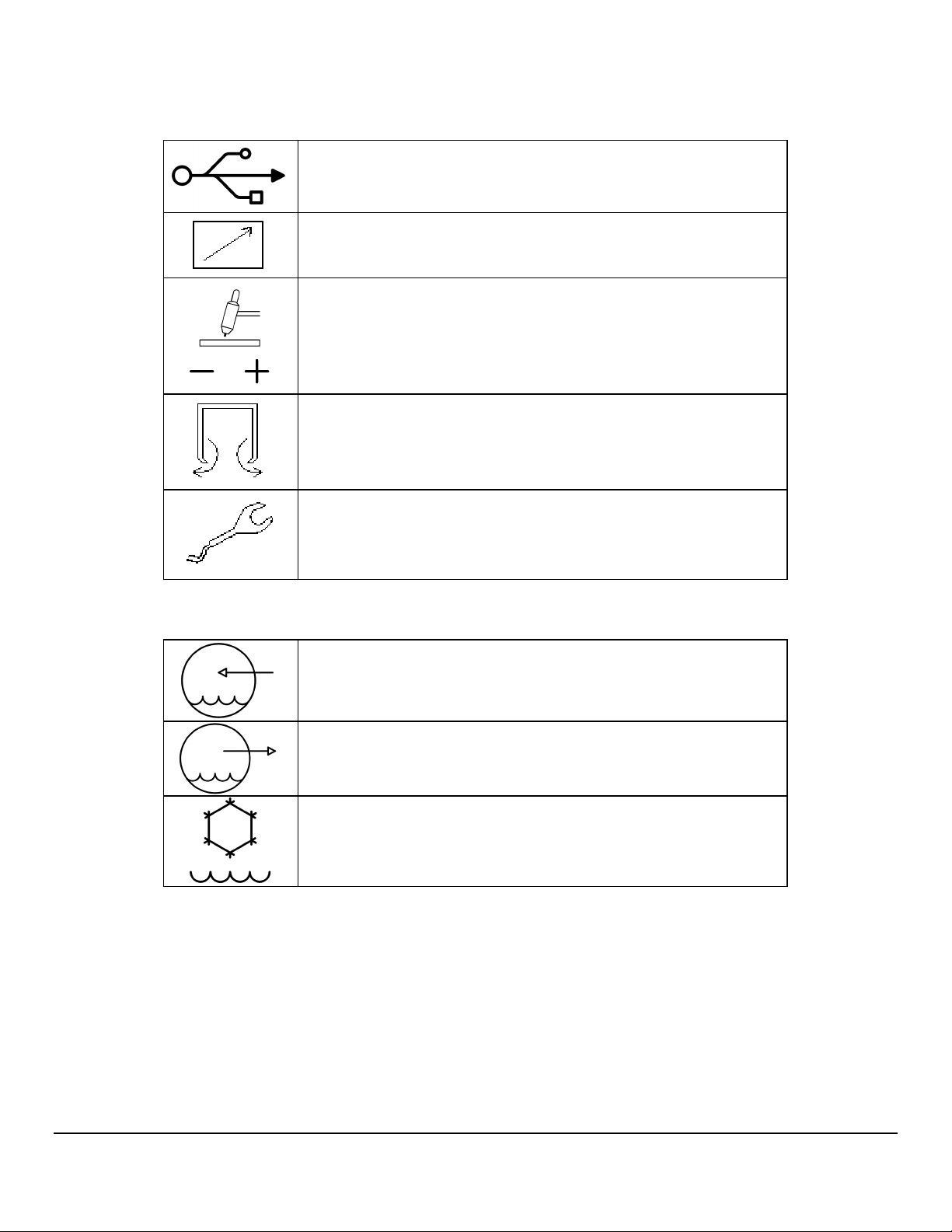

3.1 SYSTEM SYMBOLS

The following symbols are present on the Model 205 version 13B050100-02

Revision NC and up:

WARNING: Read this manual! This document contains

information that could help prevent injury or damage to the

equipment.

115/230 VAC INPUT - AC mains input, 100-240 volts AC,

50/60 Hz.

ON OFF - On/Off switch (circuit breaker).

ARC GAS INPUT - input for the arc shielding gas. An external

regulator and flow indicator must be used.

8888

M O D E L 2 0 5

O P E R A T O R ’ S M A N U A L

USB - USB port. Devices should not be left plugged in while

welding.

REMOTE - Remote control connection

GROUND(+) ELECTRODE(-) - weldhead ground and electrode

connections.

ARC GAS OUTPUT - output for the arc shielding gas connection.

WELDHEAD CONTROL - weldhead motor control. Intended for

AMI and EXEL weldheads only.

The optional water cooler M205-CW is marked with the following symbols:

WATER RETURN - cooling water input.

WATER OUT - cooling water output.

Cooling liquid tank fill opening.

9999

M O D E L 2 0 5

O P E R A T O R ’ S M A N U A L

3.2 INSPECTION

The Model 205 is shipped with a variety of peripheral equipment such as gas hoses, fittings and

cables. An exact list of these items is included with each power supply shipment and should be

located prior to setup.

• After unpacking, inspect all items for obvious physical damage and loose parts. If

damage is evident, contact a factory representative before using. If water

condensation is apparent, dry the unit before using.

• Check all fittings and connectors for proper seating and ensure that all protective

boots are in place. If the unit is not properly seated or protected short circuits, poor

connections or inert gas leaks could occur.

• Ensure that all cables are routed and protected in such a way that they will not be

subject to heat or equipment / personnel traffic. Ensure that the cables DO NOT

come in contact with HOT PIPE.

• For operation the Model 205 must be placed on a flat level surface capable of

supporting the weight of the unit, cables, and any other options. The Model 205

can be mounted on top of the optional water cooler provided the installation will

not cause the unit to topple over.

• Check the gas and coolant hoses (if used) to ensure that they are not pinched or

bent as this will restrict flow.

• Ensure that the Model 205 has adequate air flow and the intakes and exhaust vents

are not restricted.

• Ensure that there is bare metal contact between the weldhead components which

connect to GROUND (clamp inserts, etc.) and the tube to be welded.

10

10

1010

M O D E L 2 0 5

O P E R A T O R ’ S M A N U A L

3.3 POWER CONNECTION

To avoid severe equipment damage ensure that the Model 205 power supply is

connected to the correct input AC power as listed in Section 2.0 Specifications.

The Model 205 can operate on any single phase voltage from 100V AC to 240V AC.

Provided the input voltage is within this range, the unit will automatically adjust for the input

voltage.

1. The Model 205 is supplied with a 15 foot power cord. A suitable AC line connector

matching the input power must be supplied and installed by the user. Color coding of

the power cord is as follows:

Green/Yellow: Equipment grounding conductor

White/Gray: Grounded circuit conductor, Neutral

Black: Ungrounded circuit conductor, Line

2. Ensure that the circuit breaker is in the down or OFF position.

3. Connect the AC line connector to the power cord.

Do not connect the Model 205 to the AC power source until all installation

steps are complete

3.4 WELDING GAS CONNECTIONS

The Model 205 is intended for typical GTAW gases ONLY. NEVER CONNECT

OXYGEN OR ACETYLENE TO THE MODEL 205.

1. The Arc Gas hose is supplied with the Model 205. This hose is made of material

selected specifically for automatic welding. HOSES MADE FROM OTHER

MATERIAL ARE NOT RECOMMENDED (especially rubber, nylon, or tygon).

2. This 10 foot (3 meter) hose should be installed from the gas regulator/flow meter

(user supplied) to the ARC GAS INPUT fitting on the Model 205. The hose is

supplied with the fittings required to mate with the Model 205 and most domestic

(USA) inert gas flow meters.

11

11

1111

M O D E L 2 0 5

O P E R A T O R ’ S M A N U A L

3. The arc gas is controlled by a solenoid and flow sensor in the Model 205. Attach the

input gas line to ARC GAS INPUT fitting on the Model 205, NOT DIRECTLY TO

THE WELDHEAD.

4. Attach the other end of the input gas hose to the gas regulator/flow meter. Fitting it

loosely by hand, tighten the nut slightly with a wrench to ensure there are no leaks.

DO NOT OVER TIGHTEN. The use of plumbers tape or grease is NOT

RECOMMENDED.

The Model 205 arc gas solenoid valve is rated at 50 PSI (345 kPa) maximum

pressure, DO NOT EXCEED THIS RATING.

3.5 MODEL 205 TO M8 / M9 WELDHEAD HOOK UP

Always turn the power supply off before making any cable or connection

changes to the power supply.

Non-liquid-cooled weldheads (Models 9-250 and 9-500) connect directly to the Model

205. Liquid-cooled weldheads connect to the Model 205 via a short pig-tail or via an

adapter cable. If needed an extension cable can be used. The extension cable

connects to the Model 205, then to the weldhead for non liquid-cooled weldheads or to

the adapter cable for liquid-cooled weldheads.

Pig-tail Connections

1. Connect the ground and electrode brass quick-disconnect fittings on the pig-tail to

the mating fittings on the weldhead. Pull the knurled ring on the female fitting back

and fully insert the male fitting. These connectors are fully seated when the ring will

spring back to its original position. Slide the rubber boots together and secure them

in place, being careful not to dislodge the connectors. Male boots should cover the

connection first. The boots protect the connectors and prevent shorting to ground.

2. Attach the ground and electrode connectors on the pig-tail to their respective

GROUND(+) and ELECTRODE(-) terminals on the Model 205. Align the

keyways, push in and turn clockwise until fully locked.

12

12

1212

M O D E L 2 0 5

O P E R A T O R ’ S M A N U A L

3. Insert the two coolant line quick-disconnect fittings on the pig-tail into the mating

WATER OUT and WATER RETURN connectors on the Model 205-CW.

These connectors are interchangeable so either connector may be connected to

either mating fitting. To prevent accidental disconnection after making the

connection, finger-tighten the lock screw on the male connectors.

4. Attach the weldhead control male connector on the weldhead to the WELDHEAD

CONTROL connector on the Model 205. Note the positioning keyway and

NEVER FORCE or use tools on the cable connectors. Hand-tighten the connecting

ring being careful not to cross-thread the ring.

5. Insert the male gas quick-disconnect fitting on the weldhead to the mating ARC GAS

OUTPUT connector on the Model 205 and hand-tighten the lock screw to

prevent accidental disconnection. Slide the rubber boot over the connection.

Adapter Cable Connections

1. Connect the ground and electrode brass quick-disconnect fittings on the adapter

cable to the mating fittings on the weldhead. Pull the knurled ring on the female

fitting back and fully insert the male fitting. These connectors are fully seated when

the ring will spring back to its original position. Slide the rubber boots together and

secure them in place, being careful not to dislodge the connectors. Male boots

should cover the connection first. The boots protect the connectors and prevent

shorting to ground.

2. Attach the weldhead control male connector on the weldhead to the mating

weldhead control female connector on the adapter cable. Align the keyways and

carefully screw the retaining ring in place. DO NOT use tools and be careful not to

cross-thread the fitting. To help prevent damage screw the connector dust caps to

each other.

3. Insert the male gas quick-disconnect fitting on the weldhead to the mating female

fitting on the adapter cable. Hand-tighten the lock screw to prevent accidental

disconnection. Slide the rubber boots over the connection and secure them

together.

4. Attach the ground and electrode connectors on the adapter cable to their respective

GROUND(+) and ELECTRODE(-) terminals on the Model 205. Align the

keyways, push in and turn clockwise until fully locked.

13

13

1313

M O D E L 2 0 5

O P E R A T O R ’ S M A N U A L

5. Insert the two coolant line quick-disconnect fittings on the adapter cable into the

mating WATER OUT and WATER RETURN connectors on the Model 205-

CW. These connectors are interchangeable so either connector may be connected

to either mating fitting. To prevent accidental disconnection after making the

connection, finger-tighten the lock screw on the male connectors.

6. Attach the weldhead control male connector on the adapter cable to the

WELDHEAD CONTROL connector on the Model 205. Note the positioning

keyway and NEVER FORCE or use tools on the cable connectors. Hand-tighten the

connecting ring being careful not to cross-thread the ring.

7. Insert the male gas quick-disconnect fitting on the adapter cable to the mating ARC

GAS OUTPUT connector on the Model 205 and hand-tighten the lock screw to

prevent accidental disconnection. Slide the rubber boot over the connection.

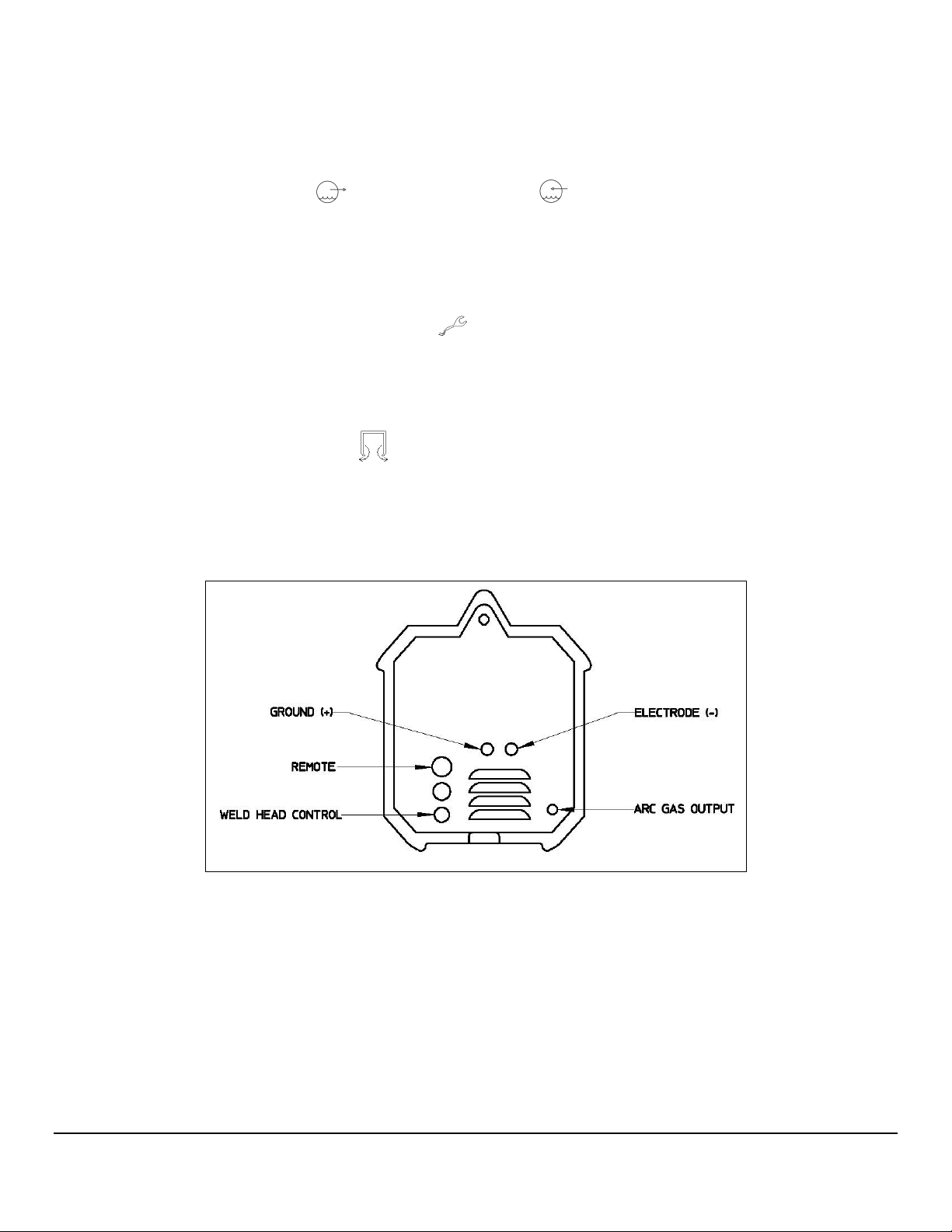

Fig. 1

Hookups for Non-Liquid Cooled Weldheads

14

14

1414

M O D E L 2 0 5

O P E R A T O R ’ S M A N U A L

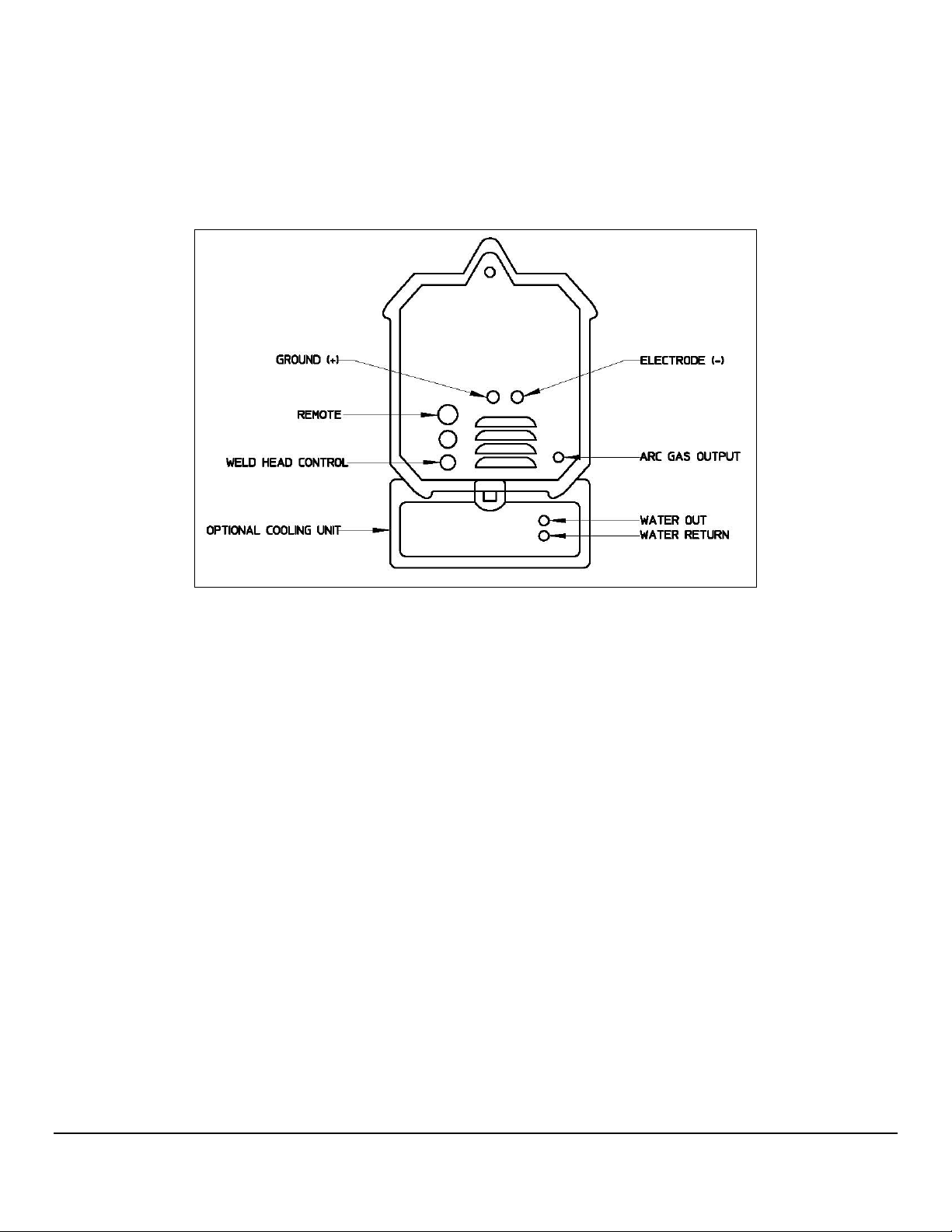

Hookups for Liquid Cooled Weldheads

Fig. 2

15

15

1515

M O D E L 2 0 5

O P E R A T O R ’ S M A N U A L

3.6 MODEL 205 TO EXEL ROTOR DRIVER HOOK UP

Always turn the power supply off before making any cable or connection

changes to the power supply.

The EXEL rotor driver (Model RDR-005) connects directly to the Model 205. The rotor

driver has NO connections to the M205-CW Cooling Unit.

1. Attach the ground and electrode connectors on the rotor driver to their respective

GROUND(+) and ELECTRODE(-) terminals on the Model 205. Align the

keyways, push in and turn clockwise until fully locked.

2. Attach the weldhead control male connector on the rotor driver to the WELDHEAD

CONTROL connector on the Model 205. Note the positioning keyway and

NEVER FORCE or use tools on the cable connectors. Hand-tighten the connecting

ring being careful not to cross-thread the ring.

3. Insert the male gas quick-disconnect fitting on the rotor driver to the mating ARC

GAS OUTPUT connector on the Model 205 and hand-tighten the lock screw to

prevent accidental disconnection. Slide the rubber boot over the connection.

Note

Note: for installation of the other components of the EXEL weldhead assembly

(rotor unit and fixture) see the Exel Welding System Rotor Units and Rotor Driver

Operation Manual, P/N 740111.

16

16

1616

M O D E L 2 0 5

O P E R A T O R ’ S M A N U A L

3.7 MODEL 205 TO M21 WELDHEAD HOOK UP

Always turn the power supply off before making any cable or connection

changes to the power supply.

Note

Note: for hook up of the M21 weldhead see the Model 21 Weldhead Operation

Manual, P/N 740122.

17

17

1717

M O D E L 2 0 5

Chapter

4

O P E R A T O R ’ S M A N U A L

4.0 OPERATION

Operation covers those steps that must be taken to enter a weld schedule and perform

a weld.

Ensure that the operator has installed the Model 205 per Section 3.0 and has a good

understanding of system functions (Section 4.1).

Ensure that the system is protected against dirt, dust, etc. NEVER GRIND NEAR AN

EXPOSED WELDHEAD OR THE MODEL 205.

Protect the system from water and liquid spray. Do not use the system if excessive

moisture is present.

4.1 SYSTEM FUNCTIONS

The Model 205 is intended for use with AMI or EXEL orbital welding heads and has

functions designed for these weldheads. This section describes what these functions are

and may, where needed for clarification, indicate how they are commonly, but not always,

used.

• LIBRARY - The heart of the Model 205 is its MEMORY. The values of each parameter for a

given weld are only programmed one time. After that the Model 205 will store the parameter

values by schedule NAME, DIAMETER, WALL thickness, and MATERIAL.

The operator may find a particular weld schedule by scrolling through the library listings or

by using the SEARCH feature which can search by DIAMETER, WALL thickness or

MATERIAL.

18

18

1818

M O D E L 2 0 5

O P E R A T O R ’ S M A N U A L

• WELD SEQUENCE AND LEVELS – A weld schedule is started by manually initiating

Sequence Start. Once the sequence is started, the system operation of functions is fully

automatic.

A weld schedule has the ability to change values for most functions as the electrode

traverses around the tube. The weld schedule is broken down into LEVELS and each level

can contain a change to one or more functions. A weld schedule can contain up to 100

levels. The advance from level to level is automatic and can be programmed by time or

degrees.

• TRAVEL FUNCTION – The system is equipped with a motor servo controller that

provides the power and regulation for rotating the electrode around weld seam. The

rotation is programmed in revolutions per minute (RPM) and can be programmed to

rotate continuously or stepped (synchronized with current pulsation).

• PULSATION – The system can rapidly change or pulse back and forth between two

different values of current and two different values of rotation travel. The HIGH value is

designated as the PRIMARY value and the LOW value is designated as the

BACKGROUND value. The pulsation rate is programmed by setting both the PRIMARY

and BACKGROUND PULSE timers.

• FAULT STATUS – The system monitors arc gas flow, arc volts and power supply

temperature. If any of these functions fall outside certain limits the system will alert the

operator and weld schedule will be halted (See Section 5.3).

• GAS FUNCTIONS – As stated, the Model 205 is intended for the GTAW process. This

process requires a welding gas (usually inert) for operation. The Model 205 is equipped

with a gas solenoid and input/output connectors for the control of the welding gas. Flow

rates are not controlled by the power supply and must be set via an external flow meter.

• PRINT FUNCTIONS – A thermal printer is built into the Model 205. It will print the library

of weld schedules as well as the programmed values and associated data of a specific

weld schedule.

• WELD DATA RECORDING – The system has the capability of recording data from the

weld. This data is feedback data from both the Travel and Current servos and is

recorded every 0.1 second. This data is saved to the hard drive of the Model 205 as a

Weld Data Record. The name of the Weld Data Record is a concatenation of the Power

Supply & Power Supply Serial Number & Weld Schedule Name & Weld ID. This record

can be exported to a USB memory stick to be loaded to a PC then viewed / printed.

Note

A Weld Data Record can ONLY be created in Weld Mode and ONLY when Weld Data

Recording is enabled.

19

19

1919

M O D E L 2 0 5

O P E R A T O R ’ S M A N U A L

4.2 INITIAL POWER ON

Before proceeding with POWER ON it is EXTREMELY important to have a basic

understanding of SYSTEM FUNCTIONS. Read Section 4.1 - System Functions before

proceeding.

1. Before connecting or energizing the AC power verify that all input power set up

requirements of Section 3.0 have been complied with.

2. Connect the AC power cable to the AC source and to the 115/230 VAC INPUT

connector on the Model 205. Move the circuit breaker to the ON position.

3. If the Model 205-CW is installed connect the AC cord to 110 or 220 VAC, single phase

power. Set the ON/OFF switch to the ON position.

Note

The Model 205-CW contains a flow sensor. The green lamp indicates that there is

sufficient flow. If this lamp goes out either the water level is too low or there is a

blockage in the line. Add coolant or clear the blockage before continuing to weld.

4. Boot-up and display the HOME screen takes approximately one minute.

20

20

2020

M O D E L 2 0 5

O P E R A T O R ’ S M A N U A L

4.3 SET-UP FUNCTIONS

The SET UP screen is used for the initial configuration of the power supply. Use this

screen to set up the following functions:

Date/Time setting

Password setting

Language selection

Language Update

DATE/TIME SETTING

1. From the HOME screen press SETUP.

2. From the SETUP screen select each Date and Time field to be changed.

Enter the new date and time data on the 10-key pad, then press ENTER.

When all data has been entered press the SET DATE/TIME button to set the

new date and time.

PASSWORD SETTING

The Model 205 can be set up to require a password entry to use the machine.

Your unit is shipped to you with no password requirement.

1. OPERATOR: An Operator may load and run any weld schedule but may

not create, change, delete, or copy a weld schedule.

21

21

2121

M O D E L 2 0 5

O P E R A T O R ’ S M A N U A L

2. SUPERVISOR: A Supervisor may load and run any weld schedule. In

addition, a Supervisor may create, change, delete, or copy a weld schedule.

3. PROGRAMMER: A Programmer has the same level of access as a

Supervisor and in addition can delete or change the Operator, Supervisor

and Programmer passwords, perform all Setup functions, calibrate the

Model 205 and create, change or delete languages.

1. From the Home screen press SETUP.

2. From the ENTER PASSWORD screen enter the Programmer password.

3. Press CHANGE OPERATOR, SUPERVISOR, or PROGRAMMER

PASSWORD.

4. Enter the old password into the OLD PASSWORD field (or leave blank if

no password is assigned).

5. Enter the password into the NEW PASSWORD field.

6. Re-enter the password into the CONFIRM PASSWORD field.

7. Press ENTER.

8. Re-boot the system – from the Home screen press SHUTDOWN then

press YES on the Shut Windows screen. Wait for the screen to go blank

before turning off the circuit breaker.

TO DELETE OR CHANGE A PASSWORD:

1. From the HOME screen press SETUP.

2. From the ENTER PASSWORD screen enter the Programmer password.

3. You may now select which password to delete or change by pressing

CHANGE OPERATOR PASSWORD, CHANGE SUPERVISOR

PASSWORD or CHANGE PROGRAMMER PASSWORD and follow the

steps above. Setting blank fields in the NEW PASSWORD and CONFIRM

NEW PASSWORD fields will delete the password.

TO SETUP A PASSWORD:

TO RESTORE A PASSWORD:

1. If you have lost or forgotten your password contact AMI Service

Department to obtain a one-day password. This will restore access to the

unit and allow you to set up new passwords.

LANGUAGE SELECTION

The Model 205 contains multiple pre-programmed languages. In addition, you may

customize a language or create a new language by replacing existing button names or

data entry titles with your own description.

Selecting one of the pre-programmed languages:

1. From the HOME screen press SETUP.

2. From the SETUP screen press LANGUAGE.

3. Select any of the languages displayed.

22

22

2222

M O D E L 2 0 5

O P E R A T O R ’ S M A N U A L

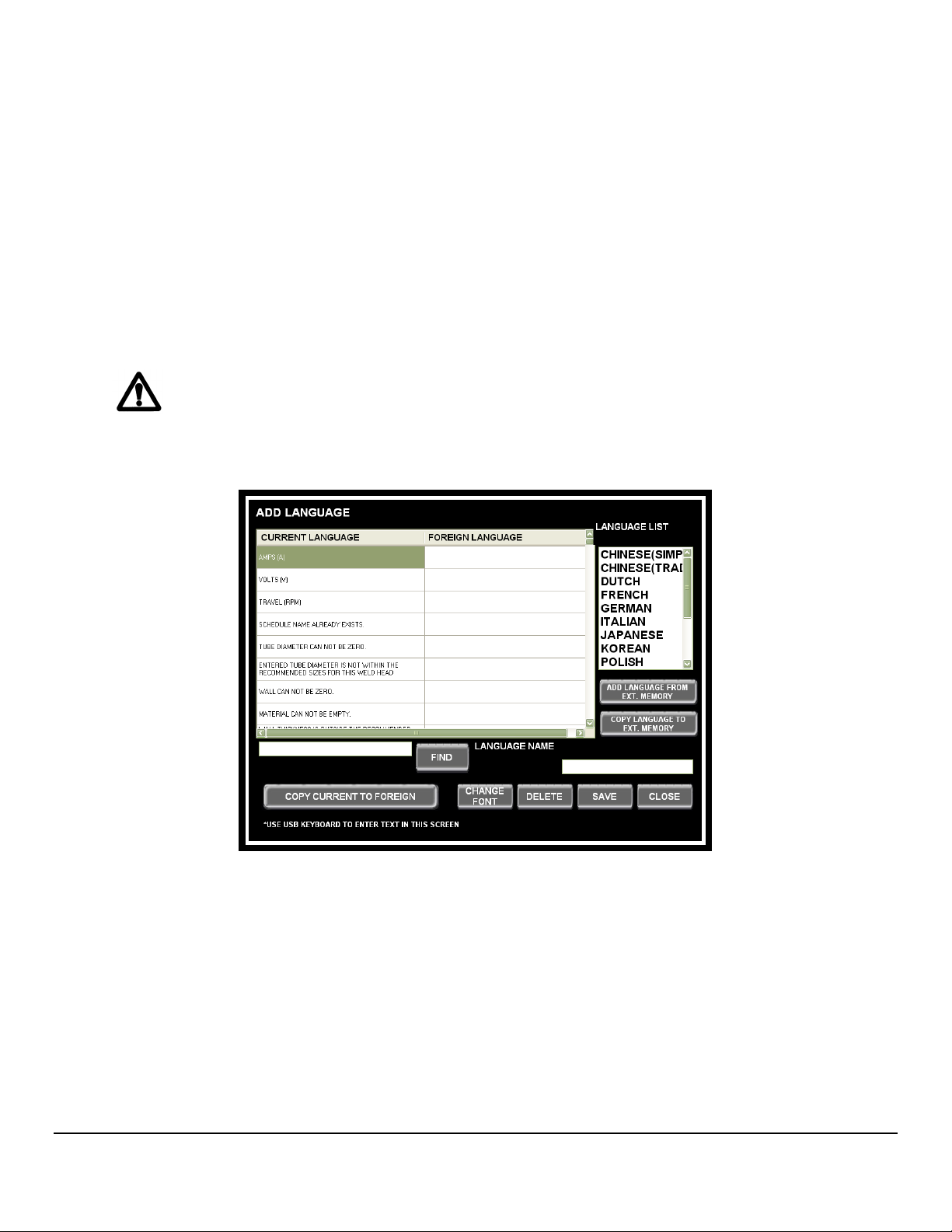

LANGUAGE UPDATE

Customizing a pre-programmed language or creating a language from a

pre-programmed language:

1. Insert a USB memory stick in the Model 205 USB port.

2. From the HOME screen press SETUP.

3. From the SETUP screen press ADD LANGUAGE.

4. Select a language from the list that the new language will be based on.

5. Enter the word to be changed in the textbox and press FIND (note: the

search is case sensitive)

6. Type the new word in the FOREIGN LANGUAGE column.

7. When you are finished making your changes you may overwrite the

existing language and keep the original name or enter a new name in the

LANGUAGE NAME field.

8. Press SAVE.

Changing a language Font, Style and Size:

The words in some languages require more letters than others. To fit additional

characters into all fields the font, style and/or size may need to be changed.

1. From the HOME screen press SETUP.

2. From the SETUP screen press ADD LANGUAGE.

3. Select the language to be changed.

4. Press CHANGE FONT.

5. Select a different Font, Style and/or Size and press OK.

6. Press SAVE to overwrite this language or enter a new name in the LANGUAGE

NAME textbox and press SAVE.

Deleting a language:

1. From the HOME screen press SETUP.

2. From the SETUP screen press ADD LANGUAGE.

3. Select the language to be deleted from the list and press DELETE.

Copy a language to External Memory:

1. Insert a USB memory stick in the Model 205 USB port.

2. From the HOME screen press SETUP.

3. From the SETUP screen press ADD LANGUAGE.

4. Select a language from the LANGUAGE LIST

5. From the ADD LANGUAGE screen press COPY LANGUAGE TO EXT

MEMORY.

6. When the Windows® Browse for Folder screen displays, select the external

memory location: D.

7. Press OK.

23

23

2323

M O D E L 2 0 5

O P E R A T O R ’ S M A N U A L

Add a language from External Memory:

1. Insert a USB memory stick in the Model 205 USB port.

2. From the HOME screen press SETUP.

3. From the SETUP screen press ADD LANGUAGE.

4. From the ADD LANGUAGE screen press ADD LANGUAGE FROM EXT

MEMORY.

5. When the Windows® Open screen displays, select the language file in the

external memory to be added (*.lgv file).

6. Press OK.

When adding a language from external memory the language MUST be formatted for

the Model 205 software otherwise the screens will be corrupted when this language is

selected.

24

24

2424

M O D E L 2 0 5

O P E R A T O R ’ S M A N U A L

4.4

4.4 OPENING THE LAST WELD SCHEDULE

4.44.4

Skip to Step 4.8 if no weld schedules are stored in the library.

1. From the HOME screen, press OPEN LAST.

OPENING THE LAST WELD SCHEDULE

OPENING THE LAST WELD SCHEDULEOPENING THE LAST WELD SCHEDULE

4.5

4.5 SELECTING A WELD SCHEDULE FROM THE LIBRARY

4.54.5

Skip to Step 4.8 if no weld schedules are stored in the library.

1. From the HOME screen, press LIBRARY.

2. Weld schedules will be listed from newest to oldest. Select a weld schedule then

SELECTING A WELD SCHEDULE FROM THE LIBRARY

SELECTING A WELD SCHEDULE FROM THE LIBRARYSELECTING A WELD SCHEDULE FROM THE LIBRARY

press LOAD.

25

25

2525

M O D E L 2 0 5

O P E R A T O R ’ S M A N U A L

Note

Use the UP or DOWN arrows to find additional weld schedules.

Note

You may search for and segregate weld schedules by DIAMETER, WALL or MATERIAL.

Select one or more of these categories from the 3 drop-down lists, select the weld schedule,

then press LOAD.

4.6 MODIFY A WELD SCHEDULE

Skip to Step 4.8 if no weld schedules are stored in the library.

1. From the HOME screen press OPEN LAST (to modify the last weld schedule

loaded) or LIBRARY to select and load a weld schedule from the Library.

26

26

2626

M O D E L 2 0 5

O P E R A T O R ’ S M A N U A L

2. From the RUN screen press SCHEDULE.

3. The first parameters displayed are the SINGLE ENTRY parameters. The MULTI-

LEVEL parameters and ASSOCIATED DATA parameters are accessed by using the

NEXT button on each screen.

Single Entry Parameters:

27

27

2727

M O D E L 2 0 5

O P E R A T O R ’ S M A N U A L

Multi-Level Parameters:

Associated Data Parameters:

4. Select each field to be modified and enter the text or value via the on-screen alpha-

numeric keyboard or 10-key pad, then press the RETURN or ENTER key. The

changes will automatically be saved.

28

28

2828

M O D E L 2 0 5

Length

Diameter

O P E R A T O R ’ S M A N U A L

Note

If the +1% or -1% button is pressed on the Multi Level screen the Primary Amps will

be incremented or decremented by this percentage. This is for the purpose of

‘tweaking’ the current to improve the quality of the weld.

Note

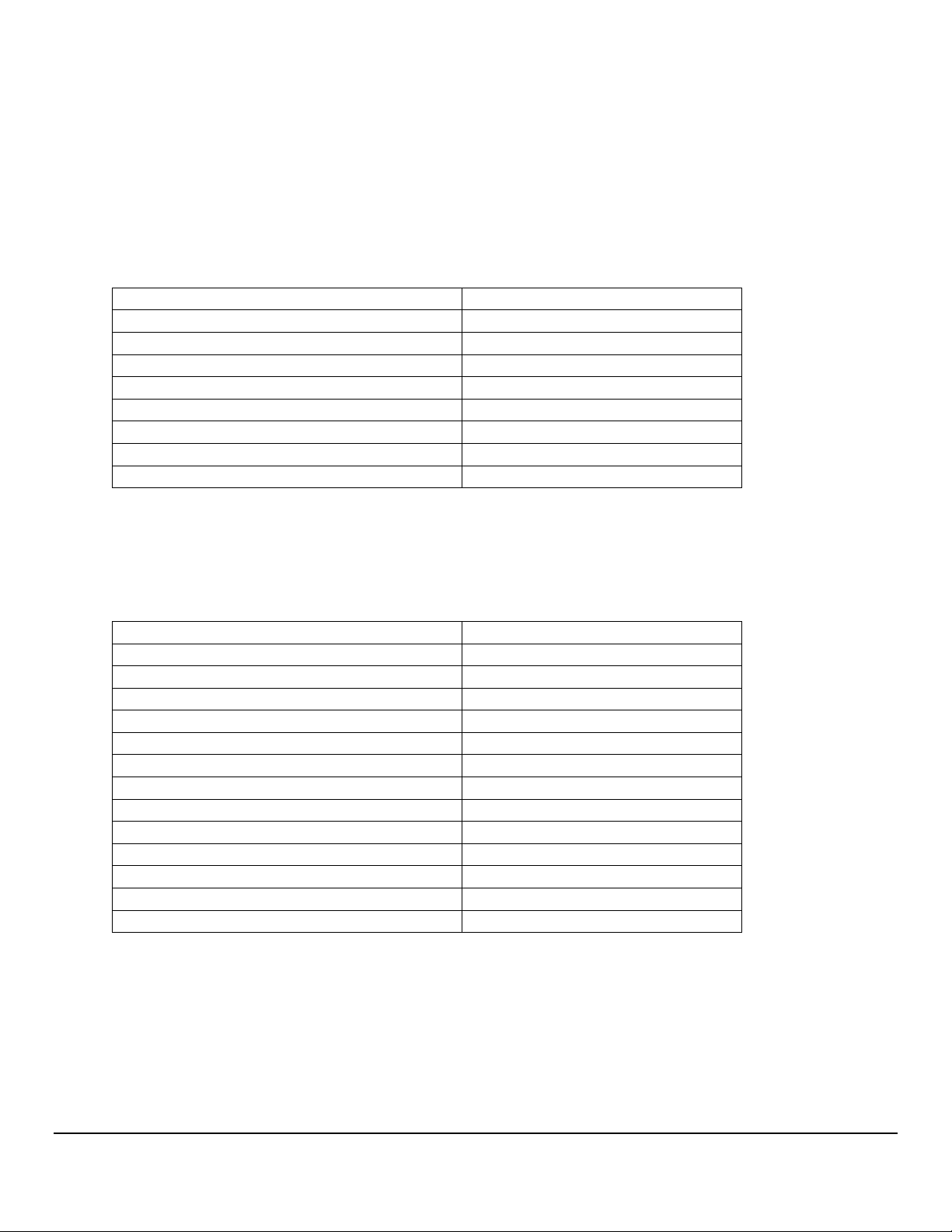

Associated Data parameters are information only. Electrode Diameter, Arc Gap,

Electrode Length and Part Number are calculated for M8 and M9 weldheads. For

EXEL and M21 weldheads these fields are populated from the following look-up

tables:

Rotor Unit Rotor OD Arc Gap Tube OD Electrode

RTU-004 0.796 0.035 0.125 0.301 0.040 TC04-0301-02

0.250 0.238 0.040 TC04-0238-02

RTU-008SL 1.696 0.035 0.125 0.750 0.040 TC04-0750-02

0.250 0.688 0.040 TC04-0688-02

0.375 0.626 0.040 TC04-0626-02

0.500 0.563 0.040 TC04-0563-02

RTU-008 1.814 0.035 0.125 0.809 0.040 TC04-0809-02

0.250 0.746 0.040 TC04-0746-02

0.375 0.685 0.040 TC04-0685-02

0.500 0.622 0.040 TC04-0622-02

0.625 0.560 0.040 TC04-0560-02

RTU-016SL 2.628 0.040 0.500 1.024 0.062 TC06-1024-02

0.750 0.899 0.062 TC06-0899-02

1.000 0.772 0.062 TC06-0772-02

RTU-032 3.75 0.045 0.500 1.580 0.062 TC06-1580-02

0.750 1.456 0.062 TC06-1456-02

1.000 1.331 0.062 TC06-1331-02

1.500 1.081 0.062 TC06-1081-02

2.000 0.830 0.062 TC06-0830-02

Electrode

P/N

Weld Head Tube OD Electrode

Length

M21-500 1/8" 0.395 0.020 0.040 0.005 TC04-0395-005

1/4 " 0.325 0.035 0.040 0.005 TC04-0325-005

3/8" 0.260 0.035 0.040 0.005 TC04-0260-005

1/2" 0.195 0.049 0.040 0.005 TC04-0195-005

M21-1000 1/4" 0.706 0.035 0.062 0.005 TC06-0706-005

3/8" 0.643 0.035 0.062 0.005 TC06-0643-005

1/2" 0.573 0.049 0.062 0.005 TC06-0573-005

3/4" 0.440 0.065 0.062 0.01 TC06-0440-01

1" 0.315 0.065 0.062 0.01 TC06-0315-01

Wall Electrode

Diameter

Diameter

29

29

2929

Tip

P/N

M O D E L 2 0 5

O P E R A T O R ’ S M A N U A L

4.7 COPY A WELD SCHEDULE

The Model 205 has the ability to make a copy of a weld schedule and save it under a

new name in the Model 205 Library.

You may also copy one or all weld schedules stored in the Model 205 Library and save

them to a USB Memory stick, or copy one or all weld schedules on a USB memory stick

and save them to the Model 205 Library.

• Copy a weld schedule in the Model 205 Library

1. From the HOME screen press LIBRARY then select the weld schedule to be

copied.

2. Press COPY. Enter a new schedule name and press either SAVE or

RETURN. The new schedule will be saved to the Library.

30

30

3030

M O D E L 2 0 5

O P E R A T O R ’ S M A N U A L

• View Weld Schedules Stored On a USB Stick

1. Insert a USB memory stick into the USB port on the Model 205.

2. From the HOME screen press LIBRARY.

3. From LIBRARY press VIEW USB.

• Copy one or all weld schedules in the Model205 Library and save to a USB

memory stick.

1. Insert a USB memory stick into the USB port on the Model 205.

2. From the HOME screen press LIBRARY.

3. Select a weld schedule to be copied and press COPY.

4. For copying one weld schedule to a USB stick press COPY TO USB. For

copying ALL weld schedules to a USB stick, press COPY ALL TO USB.

31

31

3131

M O D E L 2 0 5

O P E R A T O R ’ S M A N U A L

• Copy one or all weld schedules from a USB memory stick to the Model 205

Library

1. Insert a USB memory stick into the USB port on the Model 205.

2. From the HOME screen press LIBRARY, then press VIEW USB.

3. Select the weld schedule to be copied and press COPY TO M205. If copying

all weld schedules press COPY ALL TO M205.

32

32

3232

M O D E L 2 0 5

O P E R A T O R ’ S M A N U A L

4.8 CREATE A WELD SCHEDULE

The Model 205 provides two versions of manual weld schedule creation: Manual Multi level

and Manual S3 (Single Level Sloped) and four versions of Automatic weld schedule

generation: Auto Continuous Travel, Auto Stepped Travel, Auto Tack, and Auto S3.

1. From the HOME screen press CREATE NEW.

2. Enter the Weld Schedule NAME.

3. Enter the DIAMETER, WALL and, MATERIAL.

4. Press the WELDHEAD MODEL field and select the weldhead that you will be using.

Note

Use the ENTER key (on the displayed 10-key pad) or the RETURN key (on the

displayed keyboard) to SAVE each entry before making an entry into the next field.

Note

The Name, Diameter, Wall and Material will be displayed in the Library. The Diameter,

Wall, and Weldhead Model will be used for establishing welding parameters for

Automatic Weld Schedule generation.

5. Toggle the INCH key to select inches or millimeters to represent the size of the tube to

be welded.

33

33

3333

M O D E L 2 0 5

O P E R A T O R ’ S M A N U A L

6. The welding parameters may now be entered manually by selecting either MANUAL

MULTI or MANUAL S3, or a weld schedule may be automatically generated by

selecting AUTO CONTINUOUS TRAVEL, AUTO STEPPED TRAVEL, AUTO TACK,

or AUTO S3.

• Manual Multi – this option allows the entry of a multi-level weld schedule. You may

program up to (and not including) 100 levels. Electrode rotation can be either

continuous or stepped (synchronized with current pulsation).

• Manual S3 – this program allows the entry of an S3 weld schedule. An S3 schedule

is a single-level program that ramps the current down over the course of the weld

rather than stepping it down via multiple levels. This ramping is programmed by

selecting a starting amps (START AMPS), a background amps, and an ending amps

(END AMPS). Over the course of the weld the amps will ramp down to the value

programmed into END AMPS while pulsing between the ramping down starting

amps value and the background amps value.

• Auto Continuous Travel – this version of automatic programming will create a 4-

level weld schedule with electrode rotation in the continuous mode.

• Auto Stepped Travel – this version of programming will create a 4-level weld

schedule with electrode rotation in the stepped mode. In this case the electrode

rotation will be synchronized with the current pulsation. The most common method

used rotates the electrode during the background amps and stops the electrode

rotation during the primary amps.

34

34

3434

M O D E L 2 0 5

O P E R A T O R ’ S M A N U A L

• Auto S3 – this version of automatic programming will generate a single-level

program that continually ramps the current down over the course of the weld. This

ramping is established by programming a starting amps (START AMPS) and an

ending amps (END AMPS).

• Auto-Tack – this type of auto programming creates a weld schedule for tacking. You

may specify the approximate depth of tack penetration, the number of tacks, and a

tacking sequence – sequential or balanced.

4.9

4.9 WELDHEAD

4.94.9

Any time a different weldhead or weld schedule is selected the weldhead must be calibrated

to that weldhead and schedule.

1. Load the weld schedule from the Library. When the RUN screen opens press

WELDHEAD CALIBRATION

WELDHEADWELDHEAD

CALIBRATE.

CALIBRATION

CALIBRATION CALIBRATION

2. Check to be sure that it is safe to run the weldhead rotation and press START.

3. The calibration process rotates the electrode twice around at two different speeds.

At the completion of calibration the screen will display CALIBRATION COMPLETED.

If the calibration fails, an adjustment to the weldhead calibration potentiometer is

required.

35

35

3535

M O D E L 2 0 5

O P E R A T O R ’ S M A N U A L

If an adjustment to the weldhead’s calibration potentiometer is required the

screen will display

CALIBRATION FAILED – TURN TRIM POT CCW – TRY AGAIN

or

CALIBRATION FAILED – TURN TRIM POT CW – TRY AGAIN

4. Using the screw driver supplied with the weldhead turn the weldhead’s

potentiometer a few turns in the recommended direction and re-run the calibration

procedure (Steps 1 & 2). Continue these steps until the screen displays

CALIBRATION COMPLETED.

Note

M21 weldheads do NOT have a calibration potentiometer.

To prevent possible injury do not open the weldhead until the calibration process is

complete.

4444.10

.10 PERFORMING A W

.10.10

1. Install the weldhead per Section 3.5 and the specification sheet for the weldhead.

2. From the HOME screen press the LIBRARY key, select a weld schedule and press LOAD,

or use the OPEN LAST key to access the last schedule used.

3. Before performing the weld calibrate the weldhead to the schedule being used per Section 4.9.

This is required when a different schedule and/or weldhead is used.

4. Install the correct tungsten and the material to be welded into the weldhead as described in

the weldhead manual.

5. Turn on the gas source at the regulator/flow meter. Press the PURGE button and set the

required flow rate for the weldhead being used. Continue manual purge until all lines are

filled with the gas and all moisture and impurities have been removed. Turn the purge OFF

by pressing the PURGE button again.

Note

The font on the PURGE button turns red when it is activated.

PERFORMING A WELD

PERFORMING A WPERFORMING A W

ELD

ELDELD

Note

If for any reason the Operator leaves the Weld screen the manual purge will stop.

36

36

3636

M O D E L 2 0 5

O P E R A T O R ’ S M A N U A L

6. The Model 205 features a WELD/TEST button. In the TEST mode the unit will allow for

electrode rotation but will not strike an arc. The WELD or TEST font on the button turns yellow

to indicate which mode the system is set to.

7. When you are ready to start welding press the WELD/TEST button to put the power supply

in WELD mode.

8. Press START to initiate the weld. The center of the RUN screen displays a count-down of

each weld sequence.

Note

For M21 weldheads refer to the Model 21 Weldhead Operation Manual on how to initiate and

stop a weld sequence.

37

37

3737

M O D E L 2 0 5

O P E R A T O R ’ S M A N U A L

9. Once the operator manually presses the START button the following events will

occur automatically:

• EVENT 1: PREPURGE - welding gas will start to flow and continue to flow for the entire

weld sequence from the gas source through the power supply to the weldhead.

Complete gas coverage should be obtained before the arc is struck. How long it flows

before the arc is struck is called the PREPURGE time. Minimum programmable time is

5 seconds. Refer to the on line HELP for minimum recommended PREPURGE time for

each weldhead.

• EVENT 2: ARC START - when PREPURGE time is complete the gas will continue to

flow and a high frequency pulse will be generated to establish an arc between the

electrode and the weld joint.

Note

When the system initiates it waits for 0.5 second for either an arc start or arc fault response.

• EVENT 3: UPSLOPE - when an UPSLOPE is programmed the arc will be initiated at the

programmed START LEVEL amps. As soon as the arc is established the amps will

ramp up to the programmed Level 1 PRIMARY AMPS value. When an UPSLOPE is not

programmed, the arc will be initiated at the Level 1 PRIMARY AMPS value.

Once the arc is established and PULSE MODE programmed to ON the weld current will

pulse between the PRIMARY and BACKGROUND amp values. The amount of time it

remains at these values is determined by the PRIMARY and BACKGROUND PULSE

times.

In most cases, rotation of the arc should not begin until full penetration of the weld has

been achieved. Once the arc is established the TRAVEL START DELAY time will begin

to count. When this time has counted down, the weld schedule will advance to Level 1

and begin rotating the electrode at the Level 1 programmed travel speed for the Level 1

programmed number of seconds or degrees of rotation.

After the TRAVEL START DELAY time is complete, the electrode will begin to travel in

one of the 3 programmable PULSE MODES:

OFF - Prevent rotation from occurring.

CONTINUOUS - Rotates the electrode continuously at the PRIMARY TRAVEL

speed, regardless of PULSE MODE.

STEP - Rotates the electrode, alternating between the PRIMARY TRAVEL speed

and the BACKGROUND TRAVEL speed. This function is synchronized to the

PRIMARY PULSE time and the BACKGROUND PULSE time.

38

38

3838

M O D E L 2 0 5

O P E R A T O R ’ S M A N U A L

Note

The electrode rotation direction is a Single Entry function and cannot be programmed to

change direction during a weld.

• EVENT 4: LEVEL 1 and FOLLOW-ON LEVELS - at the end of TRAVEL START

DELAY the program will automatically advance to Level 1 and then to follow-on

levels.

If programmed by DEGREES the electrode will rotate to position programmed in each

level before advancing to the next level. If programmed by TIME the electrode will rotate

for the amount of time programmed in each level.

• EVENT 5: DOWNSLOPE – at the end of the last level over the course of the

programmed DOWNSLOPE time both primary and background amps will ramp

down while continuing to pulse until the arc is extinguished.

• EVENT 6: POSTPURGE – once the arc is extinguished the POSTPURGE time

begins counting down. During this time the arc gas continues to flow into the

weldhead.

• EVENT 7: RETURN TO HOME – at the end of the POSTPURGE the gas will

shut off, the weldhead rotor will return to its HOME position, and the Weld

Number will update.

• COMPLETE: after the rotor has returned to its HOME position the welded tube

can be removed from the weldhead.

• Press the PRINT button to print the Weld Schedule if desired.

DO NOT attempt to open the weldhead to remove the weld until the rotor has

returned to its home position.

39

39

3939

M O D E L 2 0 5

O P E R A T O R ’ S M A N U A L

4.11

4.11 WELD DATA RECORDING

4.114.11

• Setup and Enable Weld Data Recording

1. Press WDR to open the Weld Data Recording screen.

WELD DATA RECORDING

WELD DATA RECORDINGWELD DATA RECORDING

2. Enter data in each of the fields

Note

Power Supply Model Number, Power Supply Serial Number and Weldhead Model Number

are already stored in the system so these fields are automatically filled.

Note

The ONLY required field is Weld ID and it must be unique. If a non-unique value is entered

(Weld Camino de las Estrellas ID that has already been used) an error message will be

displayed.

3. Press WDR ENABLED to turn on Weld Data Recording.

40

40

4040

M O D E L 2 0 5

O P E R A T O R ’ S M A N U A L

• Record Weld Data

1. Press RUN to return to the Weld screen.

2. Toggle WELD/TEST to WELD.

Note

The font on the WDR button turns yellow if Weld Data Recording is enabled AND Weld/Test

is set to Weld.

3. Press START to start the weld sequence and the Weld Data Recording

Note

The font on the WDR button turns red while the weld data is being recorded.

• Export Weld Data Record

1. Insert a USB memory stick into the USB port on the Model 205.

2. Press WDR to return to the Weld Data Recording screen.

41

41

4141

M O D E L 2 0 5

O P E R A T O R ’ S M A N U A L

3. Press EXPORT WDR FILE to select a WDR file and an export destination.

4. Press OK

Note

The OK button will ONLY be enabled when BOTH the Source and Destination fields are

filled. The Destination will normally be the D:\ drive which is the USB memory stick.

5. Repeat steps 3 and 4 to export additional WDR files.

6. Remove the USB memory stick and load on a PC to view / print the weld data

record(s).

Note

The exported weld data record(s) will be in *.csv format and can be opened in Microsoft

Excelor Notepad.

42

42

4242

M O D E L 2 0 5

Chapter

5

O P E R A T O R ’ S M A N U A L

5.0 MAINTENANCE AND TROUBLE-SHOOTING

Always disconnect the AC power cable from the line voltage before

attempting to work with this welding power supply.

5.1 GENERAL MAINTENANCE

• COOLANT - the water tank in the optional Model 205-CW cooling unit holds

approximately 0.75 gallons (2.8 liters) of fluid. Check the fluid level periodically. The

use of different weldheads will remove fluid from the tank over a period of time. Fill

the tank per instructions in Section 6.1 COOLING UNIT.

• Cleaning exterior and interior surfaces. Prolonged use in dusty shop or outside

environments may cause the outside surfaces to accumulate a coating of dirt and

dust. Do not use shop air to blow dust particles away from the panels since it is

usually too wet. Use a vacuum cleaner with a soft brush. Where a vacuum brush

cannot reach use a clean soft paint brush and then vacuum.

• INPUT/OUTPUT PANEL CONNECTIONS - periodic inspection of the Model 205

panel as well as electrode/gas/water return quick-disconnects on all cables should

be performed. Damaged, dented or deformed connectors may cause poor or unsafe

operation and water or gas leakage. The O-ring inside the weldhead electrode and

gas quick-disconnects should be periodically cleaned and re-greased.

• Precautions to follow for storing or handling:

Always keep weldheads in the protective containers they are shipped in or in an optional

carrying case until ready for use. Residual coolant should be drained from the weldhead

cables to prevent corrosion.

43

43

4343

M O D E L 2 0 5

O P E R A T O R ’ S M A N U A L

Always keep the protective boots and dust caps on all connectors and fittings until cables

are ready to be installed. A major cause of downtime in any automatic welding system is

improper care and use of cables.

Take extreme care to avoid dropping the power supply or the weldheads.

Always disconnect the power input cable from the junction box or wall-plug

before cleaning.

DO NOT USE acid, corrosives or any liquid substance on the Model 205 or any AMI

weldhead. When cleaning use only a light solution of isopropyl alcohol on a soft cloth.

DO NOT ADD lubrication such as graphite, oil, or grease to the weldhead or power

supply unless it is specified in the operation manual for that equipment.

44

44

4444

M O D E L 2 0 5

O P E R A T O R ’ S M A N U A L

5.2 CURRENT OUTPUT CALIBRATION

This procedure is intended for calibration/verification of output current by the user. True

verification of current output for Quality Control purposes must be performed with a calibrated

External Calibration Shunt. This shunt may be obtained from Arc Machines, Inc. (Part Number

13B072511-01).

All personnel attempting to calibrate, trouble-shoot, or repair the Model 205 must be

familiar with its operation. They must understand the circuits and have a complete

understanding of the controls and their relationships.

All personnel must be aware of the location of hazardous voltage-carrying

conductors, terminals, heat sinks, etc. and must employ safety precautions when working

with the Model 205.

EQUIPMENT REQUIRED

• Digital Multimeter (DMM), minimum 4-digit readout. The meter must have

floating inputs (not connected to line or chassis ground) with a minimum of

1 mega ohm input impedance. Battery operated devices are recommend.

Suggested: Fluke Model 8060A or equivalent.

• AMI Fusion Weldhead rated for 150 amperes and a pipe or tube that will

not melt away with 150 amps applied. As an alternative a manual torch

can be set up on a flat plate (refer to Section 5.2.2).

• AMI External Shunt, 1 mV/amp, Part Number 13B072511-01 (optional).

• Argon or other acceptable GTAW gas source.

45

45

4545

M O D E L 2 0 5

O P E R A T O R ’ S M A N U A L

PROCESS

A weld schedule is required for calibration and will need to be created the first time a

calibration is done.

1. Set up a Weldhead rated for 150 amps continuous duty and insert a tube, pipe, or copper

rod that can withstand 150 amps of continuous current with no rotation. If these items are

not available then use a Hand Torch on a large plate with the torch fixed so it cannot

change the gap during calibration.

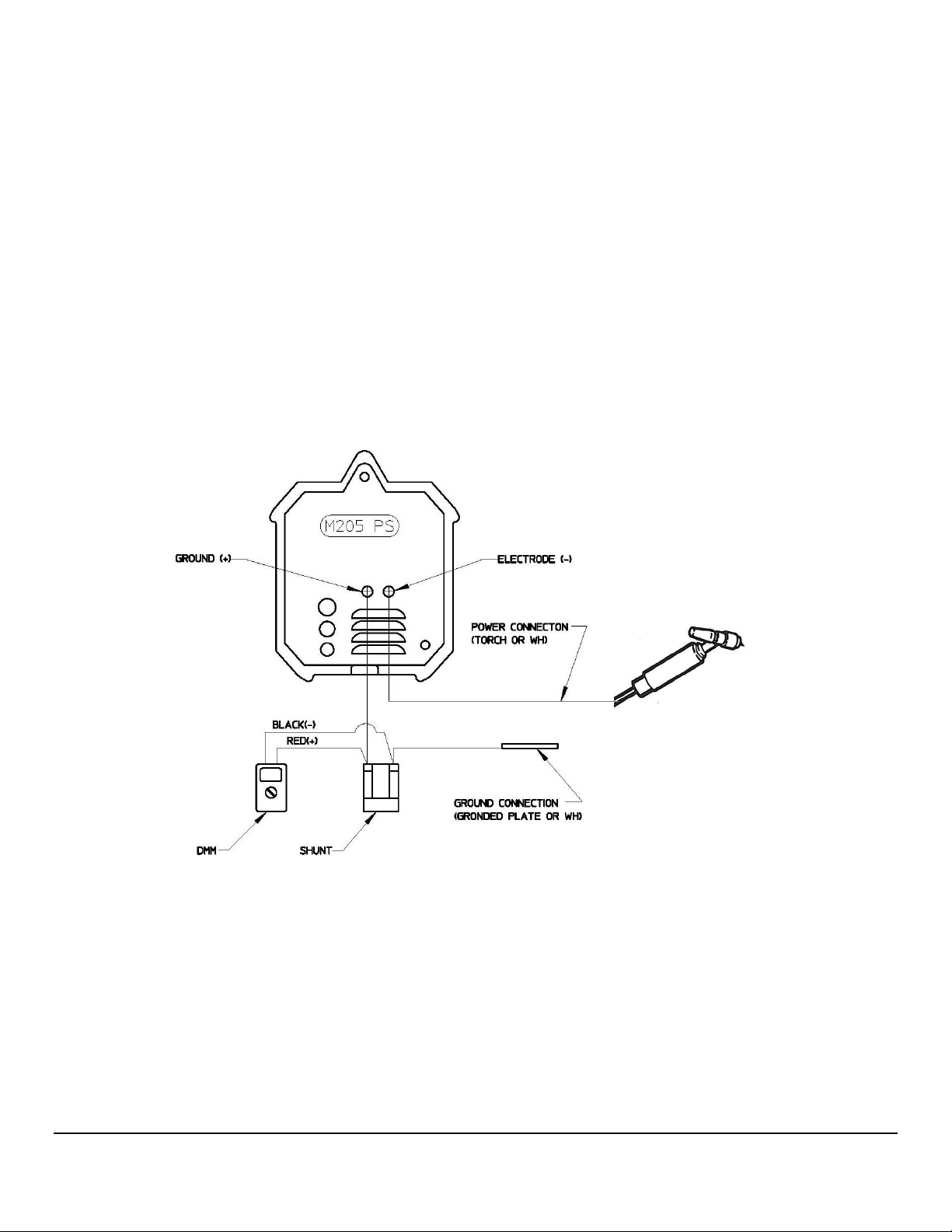

2. Connect the shunt between the ground connection on the power supply and the ground

connection on the weldhead or manual torch. Current is always measured along the return

path (Fig. 3).

Fig. 3

46

46

4646

M O D E L 2 0 5

O P E R A T O R ’ S M A N U A L

3. From the HOME screen press SETUP

4. From the SETUP screen press ADVANCED.

47

47

4747

M O D E L 2 0 5

O P E R A T O R ’ S M A N U A L

Note

To prevent unauthorized personnel from accessing the calibration feature a temporary

one-day password is required. Contact the AMI Service department for this password.

You will need the Power Supply serial number displayed on the HOME screen to obtain

this password.

5. Input the one-day password and press ENTER.

6. Setup the Digital Multimeter to read the 200 mVDC scale.

7. Prepare to insert the test probes into the red and black terminals on the shunt.

Any testing or recording instruments connected to any points in the machine or to the

welding head may be exposed to extremely high transient voltage at the time the arc starter

operates. ENSURE THAT ALL TEST EQUIPMENT IS DISCONNECTED DURING ARC START.

Make sure that when an arc is struck nothing will be overheated or melted.

Note

If an orbital weldhead is used instead of a manual torch you will need to hook up the

weldhead arc gas line to the power supply

48

48

4848

M O D E L 2 0 5

O P E R A T O R ’ S M A N U A L

8. The START button is located in the upper right corner of the screen. Once you have

determined it is safe to initiate an arc press START. After the arc is established connect

the black and red test probes from the DMM to the shunt (Fig. 3).

9. The weld schedule will remain at each Command level for 15 seconds and advance

through all 10 Commands. During this process make note of the DMM mV reading at each

Command.

10. At the conclusion of the weld sequence enter each of the DMM readings into the SHUNT

column.

11. Press HOME to return to the HOME screen

49

49

4949

M O D E L 2 0 5

O P E R A T O R ’ S M A N U A L

5.3 TROUBLESHOOTING

The Model 205 has the ability to monitor certain functions. If they are not working

correctly a system fault will alert the operator to the problem.

SYSTEM FAULT CORRECTIONS

When a System Fault occurs prior to or during welding it is required for the operator to

clear the fault condition before continuing.

Some faults are only temporary and the fault is corrected when the arc goes out. But all

faults will cause the FAULT SCREEN to appear and let the operator know why the

sequence was stopped.

The following is a general description of the cause of each type of fault and some

recommendation for correction. In all cases, when the fault is corrected the operator

must press the OK button to close the FAULT SCREEN.

• TEMPERATURE - the Model 205 has an internal temperature sensor (thermal switch).

If the Power Supply internal temperature rises above the safe limit, a TEMPERATURE

fault occurs. This can only occur if there is some type of blockage of air circulation, fan

failure, component failure within the Power Supply, or that the system is being operated

in ambient air temperatures above or below its rating of 0° C (32° F) and 45° C (104° F)

/ 95% humidity (non-condensing).

This Fault should only occur during an actual weld sequence. If it occurs when the

machine is not welding then a serious internal problem exists. In this case turn the

Power Supply OFF and call an AMI Service representative.

• GAS - this fault will occur at the beginning of a weld sequence or during a weld

sequence. If arc gas flow through the system should stop or fall below 7 CFH, a fault

will occur.

Check that the Gas Source is turned on and that adequate gas is available. Check all

gas hoses and connections for free flow. This is usually the problem.

50

50

5050

M O D E L 2 0 5

O P E R A T O R ’ S M A N U A L

If there is no problem with the source or with the hoses and their connections then an

internal failure of the flow switch, solenoid or internal hosing is possible. Contact an

AMI Service representative.

• ARC VOLTS LOW or STUB OUT - this fault will only occur when an arc is present and

will no longer exist when the arc goes out. If the arc voltage gets too low (below 5 volts)

or the electrode should touch the weld puddle an ARC VOLT fault will occur. This

creates an ALL STOP condition and does not actuate the RETURN TO HOME function

after Postpurge.

• ARC VOLTS HIGH - if the arc voltage is too high (above 20 volts) during a weld

sequence this fault will occur. It usually occurs if a hole is made in the weld, causing

the arc to wander over to the far side of the hole. The most common cause of this is

either poor tube fit-up or excessive gas pressure inside the tube causing the weld to

blow out and create a hole.

• BAD START - if for any reason the Model 205 cannot establish a stable arc at the end

of Prepurge the system will display a BAD START fault. There can be several reasons

for this to occur. The most common are poor ground or electrode connections,

contaminated gas or a contaminated electrode. Another common cause of a BAD

START is too short of a Prepurge time. This is especially true when a system or

weldhead is being used for the first time in a shift. While it sits unused atmosphere can

propagate into the cables. Before performing the first weld of a shift, use the Manual

Purge for a minute or two to initially clear the gas lines.

Note

AMI recommends 2% Ceriated welding electrodes. They have proven to be much

more effective than 2% Thoriated electrodes for RF transmission and are reported to

have longer life than 2% Thoriated Electrodes.

Note

There are no user serviceable components located inside the Model 205. Do not open

the unit in an attempt to repair it. Contact Arc Machines if the unit is malfunctioning or

suspected of being broken. As such no wiring diagram or internal circuit drawing is

provided.

51

51

5151

M O D E L 2 0 5

Chapter

6

O P E R A T O R ’ S M A N U A L

6.0 OPTIONS

The following are installation and operation instructions for Model 205 options. Some

options have their own manuals and these are not discussed in this section.

Always turn the power supply OFF before making any cable or connection

changes to the Model 205 power supply.

6.1 COOLING UNIT (Model 205-CW)

SPECIFICATIONS

AC INPUT POWER 90–260 VAC 1 Phase, 4 amps max.

COOLANT CAPACITY 0.75 gallons (2.8 liters)

CIRCULATION 0.5 GPM (2.8 LPM)

52

52

5252

M O D E L 2 0 5

O P E R A T O R ’ S M A N U A L

PHYSICAL CONSTRUCTION

MATERIAL Aluminum cabinet/Polyethylene tank

HEIGHT 6.25 inches (159 mm)

WIDTH 19.0 inches (483 mm)

DEPTH 14.0 inches (356 mm)

WEIGHT (with water) 27 lbs (12.3 kg)

WEIGHT (without water) 21.5 lbs (9.8 kg)

PUMP 60 PSI (413 kPa)

INSTALLATION

1. The cooling unit is shipped dry and requires 0.75 gallons (2.8 liters) of either:

• CLEAN DISTILLED or DE-IONIZED water

• CLEAN DISTILLED or DE-IONIZED water and OPTISHIELD® 'Plus' (mix per

manufacturer’s instructions)

• A 50/50 mixture of ethylene glycol and CLEAN DISTILLED or DE-IONIZED water

DO NOT USE automotive antifreeze or STOP-LEAK type antifreeze

2. Before mounting the Model 205-CW Cooling Unit to the Model 205 remove the fill cap

and add the coolant mixture. Replace the fill cap.

3. Place the Model 205 onto the Model 205-CW Cooling Unit and close the latches on each

end.

4. For connections to the weldhead see Section 3.5.

5. The Model 205-CW contains a flow sensor. The green lamp indicates that there is

sufficient flow. If this lamp goes out either the water level is too low or there is a

blockage in the line. Add coolant or clear the blockage before continuing to weld.

DO NOT OPERATE the water cooling unit WITHOUT coolant in the tank OR

WITHOUT a water flow path (water OUT to IN through a weldhead).

53

53

5353

M O D E L 2 0 5

O P E R A T O R ’ S M A N U A L

6.2 OPTIONAL REMOTE PENDANT

• Allows for the remote START/STOP of a weld sequence, JOG of the weldhead rotor,

manual gas PURGE, and return to HOME of the weldhead rotor.

• Attach the remote pendant connector to the REMOTE connector on the Model

205. Note the positioning keyway and NEVER FORCE or use tools on the cable

connectors. Hand-tighten the connecting ring being careful not to cross-thread the

ring.

Note

The EXEL RDR-005 rotor driver contains a built-in remote pendant which is fully

functional with the Model 205.

Note

The remote pendant cannot be connected if an M21 weldhead is being used.

Note

For additional available options, such as extension cables contact Arc Machines, Inc.

54

54

5454

M O D E L 2 0 5

O P E R A T O R ’ S M A N U A L

55

55

5555

Loading...

Loading...