Page 1

The SA150/SA200

Stereo Power

Amplifiers

A&e

■ A

.8 J

HH |M[[B

H BSm

A & R Cambridge Ltd.

Owners Handbook

Page 2

Contents

Introduction

Installing and using your SA150/SA200

Back Panel connections

Front Panel controls 4

Fitting or changing side cheeks

Technical Details

Spares Kit

Input Connector Wiring

Fuses

Removal of Top Cover

SA150 Technical Specification

SA200 Technical Specification

Guarantee for UK sales

Inside back cover

1

2

2

5

6

6

6

7

9

10

11

Important Notice

1. If your SA150 or SA200 is not delivered fitted with solid wood side cheeks it will

instead be supplied with thin, black, metal transit panels. These must be removed

and the appropriate wood side cheeks fitted before the amplifier is first used. See

page 5 for full details.

2. Please retain the carton and all packing materials provided with this equipment so

that it may be repacked correctly if it ever becomes necessary to transport the unit or

to return it for service. ,

3. If servicing is required then the equipment should be properly packed and returned

to the dealer from whom it was purchased. It is essential to include a covering letter

giving your name and address and a brief but thorough description of the fault.

Page 3

Introduction

The A&R Cambridge SA150 and SA200 are robust high performance stereo power amplifiers.

Their continuous power ratings (into 8 ohm loads) are 75 Watts and 100 Watts per channel

respectively. Used with a suitable pre-amplifier or control unit (e.g. the A&R C200) either model

will form the basis of a top quality sound system.

These units are built to the highest standards and are designed to blend well with domestic

surroundings. Solid Afromosia side cheeks of the same height as the amplifiers are normally

supplied as standard; a set of tall side cheeks for stacking either amplifier with the matching

A&R C200 control unit is available as an optional extra.

For very high power operation both the SA150 and SA200 are convertible to “bridged mono”

operation. Please consult your dealer for further information and availability.

Please study this manual carefully to ensure that you get the best results from your amplifier.

Remember your dealer is there to help you. He has full technical and service information for all

A&R Cambridge products and considerable experience of their use in a variety of systems. If,

however, he is unable to answer your query then do not hesitate to contact us directly.

Page 4

Installing and using your

SA150/SA200

Back Panel Connections

G,

G

loudspeaker

terminals (right)

Figure ]

loudspeaker

terminals (left)

Mains Supply

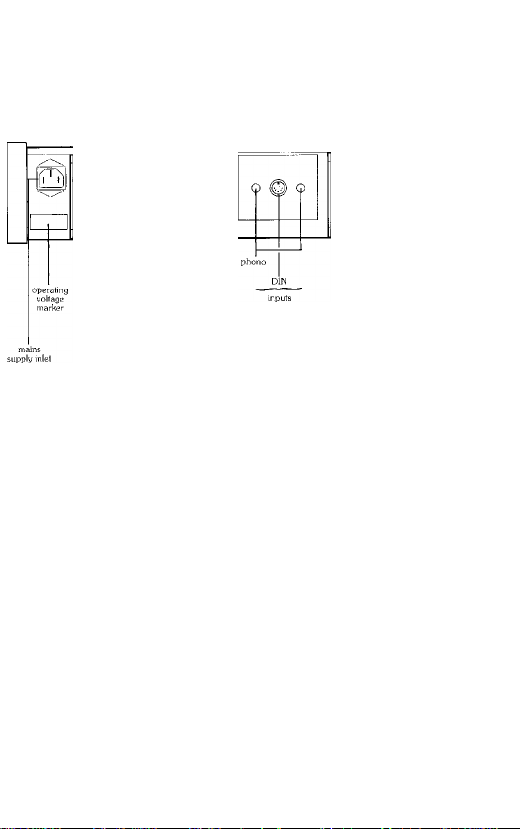

The SA150 and SA200 are normally set up for use with a nominal 240V 50/60 Hz supply.

They can be modified for 220V or 120V operation by your dealer or the manufacturer. CSA

(North American} models are suitable for 120V supplies only. The correct supply voltage is

marked on the rear panel underneath the AC power supply inlet.

The AC power supply inlet of the SA150 and SA200 is via a standard lEC chassis mounting

plug. A moulded lEC socket, fitted with 2 metres (6.5 ft) of cable, is supplied to fit the lEC plug

(Note that the lEC plug and socket are a tight fit; before first using the amplifier it is therefore

important to ensure that the socket is pushed home firmly into the amplifier’s chassis plug}

The wire end of the cable should be terminated with a 3 pin (earthed) plug, wired according to

the international colour code and fitted with a 10 Amp or 13 Amp fuse. The inrernational colour

code is;

Some models may already have a suitable plug fitted as standard.

The SA150 and SA200 also have an anti-surge mains fuse fitted internally. It is recommended

that the supply to each model should be disconnected when the amplifier is not in use.

UNDER NO CIRCUMSTANCES SHOULD THE AMPLIFIER COVER BE REMOVED

Earth — green/yellow

Live — brown

Neutral — blue

UNLESS THE SUPPLY IS DISCONNECTED.

Input Connections

A combination of 5 pin DIN socket and phono connectors is fitted as standard. Certain models

may however only have either DIN or phono sockets fitted. In all cases the panel carrying these

sockets is removable to enable special versions to be supplied, e.g. for “bridged mono"

operation or professional applications. Contact your dealer or the factory for further details.

Page 5

Loudspeciker Connections

The outputs of the SA150 and SA200 are suitable for driving loudspeakers of 4 ohms nominal

impedance or higher. Both models will drive 4 ohm loads whose impedance dips to as low as

2 ohms, but care should be taken not to operate continuously at high levels into impedances of

less than 4 ohms.

The loudspeaker terminals will accept either bare wires or 4mm plugs. The left hand speaker has

its pair of terminals near the left hand of the rear panel (when viewing from the front of the

amplifier); the right hand speaker terminals are near the centre of the rear panel. The spacing of

the terminals is 19mm (0.75 inch) to accept standard twin speaker plugs.

One side of your speaker (normally the -side) should be connected to the black terminal; the

other (the +side) should be connected to the red terminal. For stereo applications it is important

to ensure that the two speakers are connected in phase (i.e. both wired the same way round to

the amplifier). Do not make any connections between the left and right loudspeaker leads

(except in “bridged mono” applications—see separate instruction sheet).

The SA150 and SA200 are unconditionally stable and suitable for use with all types of

loudspeaker leads, including the 'high definition’ types. For good practical results we recommend

the use of heavy duty cables having at least 2 sq mm cross sectional area for each conductor. It is

also good practice for the two speaker leads to be of equal length and you should ensure that all

connections at both the amplifier and speaker are tight.

It is possible to use several pairs of loudspeakers in parallel with the SA150 or SA200 provided

the overall impedance does not fall below the limits described above. No speaker switching is

provided on the amplifiers as this invariably will cause some degradation of the signal, however

slight. If it is necessary to switch speakers we recommend that the main pair be wired directly to

the amplifier wherever possible and that only the ‘extension’ speakers be switched.

With both models it is possible to reduce the value of output fuse fitted in the amplifier in order to

provide the best protection for both the speaker and amplifier. See page 7 for full details.

Heat Sink

The heat produced by the SA150 and SA200 is dissipated into the air by the large ceist heat sinks

whose fins form most of the rear panel. When the amplifier is in use these will run warm and may

become quite hot when the unit is run near full power, particularly into low impedance loads.

This is perfectly normal. However, if the fins become too hot to touch switch off the amplifier

at once and consult your dealer.

N.B. To ensure that the amplifier does not overheat it is important that the natural flow of air over

the heat sinks is not obstructed. It is also unwise to place heat sensitive items (such as L.P.

records) on top of or immediately above the amplifier.

Page 6

Front Panel Controls

Mains Power

To switch on the amplifier, depress the power on/off switch located on the extreme right of the

front panel until it latches home. The small rectangular LED (light emitting diode) adjacent to the

switch should glow green.

To turn off the power amplifier depress the power on/off switch again so that it unlatches.

The SA150 and SA200 generate very little in the way of undesirable switching surges into the

loudspeakers when they are turned on and off but they will faithfully amplify any surges generated

by preceding equipment. As the amplifiers are very powerful, these surges may cause damage to

certain loudspeakers through no fault of the power amplifier. Note that any A&R equipment likely

to be used with the SA150 or SA200 (e.g. C200 control unit or A60AP amplifier) is fully

suppressed, so that no switch on surge will occur. However, if your pre-amplifier is in any way

suspect it is wise to turn on the power amplifier some moments after switching on the

pre-amplifier, in order to allow the pre-amplifier’s circuits to settle down. Similarly, the power

amplifier should be turned off well before the preamplifier in order to allow its power supply to

discharge fully.

LED Overload Indicator

On both the SA150 and SA200 the front panel LED to the left of the power on/off switch

normally glows green to show that the DC power supplies in the amplifier are operating. It will

continue to glow green for a short time after the amplifier is switched off as the DC voltages decay.

On the SA200 only the LED also functions as an overload indicator. If either channel of the

SA2CK) clips or distorts significantly then the LED will change colour momentarily from green to

red. If the overload is maintained then the LED will glow red continuously and to avoid possible

speaker damage the preamplifier volume control should be turned down immediately.

Page 7

Fitting or Changing Side Cheeks

If your SA150 or SA200 is not already supplied fitted with Afromosia wood side cheeks it will be

fitted with thin metal transit panels. These must be removed and the appropriate wood side

cheeks fitted before the amplifier is first used. The wood cheeks are available in two

heights—standard (95mm) and tall (145mm). The latter leaves sufficient clearance underneath

the SA200 to accept the C200 control unit. To fit the cheeks, proceed as follows (see figures 3

and 4);-

1. Ensure the SA200 is disconnected from the mains supply.

2. Using a N® 2 "Posidriv’ screwdriver remove the four bright metal screws from each side of the

amplifier- This will free the transit cheeks. Do not attempt to remove the black screws as these

hold together parts of the main chassis.

3. Fit the wooden end cheeks using the M4 hex socket cap screws and washers provided. The

screws must be tightened firmly with the Allen Key provided. Ensure that the wooden cheeks

are fitted the right way round; they are counter-bored where necessary to clear protrusions on

the amplifier chassis. Note that the two side cheeks are identical.

To exchange side cheeks (e.g. from standard height to tall) simply unscrew the M4 hex socket

cap screws holding in each old cheek. The new pair may then be fitted following the procedure

of paragraph 3 above.

Never operate the amplifier without the proper side cheeks fitted as this could constitute a safety

hazard.

Page 8

Technical Details

Spares Kit

You are provided with a spares and accessory kit containing the following;-

SA150

1 lEC line socket with 2m (6.5ft) mains lead.

1 3mm AF Allen key.

2 Spare speaker fuses (2.5 Amp fast blow. 20mm x 5mm).

2 Spare speaker fuses (1.6 Amp fast blow. 20mm x 5mm).

SA200

1 lEC line socket with 2m (6.5ft) mains lead.

1 3mm AF Allen key.

2 Spare speaker fuses (3.15 Amp fast blow. 20mm x 5mm).

2 Spare speaker fuses (2 Amp fast blow, 20mm x 5mm).

In addition, if either amplifier is not already provided with factory fitted wooden side cheeks the

spares kit will also contain 8 M4 x 16mm hex socket cap screws and M4 washers, plus one pair of

side cheeks (either short or tall).

Input Connector Wiring

Viewed from rear of amplifier, or plug as wired (see Figure 5).

Figure 5

For connecting either model to the A&R C2(X) control unit (standard DIN output version) or the

A&R A60 AP amplifier, a crossover DIN to DIN lead is required. A&R leads type L—05

(0.6m, 2ft) or L—05/2 (2 metres, 6.5ft) are recommended. Either lead may also be used to

connect the SA150 and SA200 to most other manufacturers’ pre-amplifiers which use a 5 pin

180° DIN socket with the output signals on pins 1 & 4.

The phono sockets may also be used to connect the SA150 or SA2(X) to a suitable pre-amplifier.

For best results only interconnecting leads of the highest quality should be used.

The input impedance of both the SA150 and SA200 is 20 kii and the voltage gain of each

channel of both models is 29dB (28.3 times). This is equivalent to an input sensitivity of l.OOV

r.m.s. for 100 Watts r.m.s. into 8 ohms for the SA200 and 0.87V r.m.s. for 75 Watts r.m.s. into

8 ohms for the SA150. These figures ensure that both power amplifiers should work with almost

all pre-amplifiers and signal sources which provide nominal outputs of between 500mV and 2V

r.m.s. If in doubt consult your dealer.

L R

Page 9

Fuses

Output Fuses

Both the SA150 and SA200 are fitted with fuses (one per channel) in their output circuits to

provide extra protection for both amplifier and loudspeakers in the event of medium to long term

overloads. Each fuse is placed within the feedback loop of its power amplifier channel to eliminate

the audible effects of having a speaker fuse in series with the loudspeaker.

In addition, in the SA200 only, the circuit is so designed that, if an output fuse blows, not only

will the sound from the loudspeaker cease but the overload LED on the front panel will glow red

almost continuously if any attempt is made to play music through the system at normal volume

settings. This is a certain indication that one or both speaker fuses have failed and need replacing

(see over).

Choosing Output Fuse Ratings

The output fuses fitted to the SA150 and SA200 are of a sufficient value to ensure that the

amplifier will drive 4 ohm loudspeakers satisfactorily, with little risk of the fuses failing on normal

programrhe material. However many loudspeakers have a much higher average impedance than

4 ohms and in order to provide them with the optimum protection against overdriving, it may be

desirable to fit output fuses of a somewhat lower rating. Suitable spares for nominal 8 ohm

loudspeakers are provided with the SA150 and SA200, as shown in the table below. Some

suitable values for fuses (not supplied) which may be used with 16 ohm loudspeakers are also

shown. In all cases it is wise to use the lowest fuse value possible which does not fail on normal

programme material and some experimentation may be worthwhile here. Similarly, if

loudspeakers are used which will not accept the full power output of the amplifier, then the fuses

should also be down rated in order to provide the loudspeakers with best possible protection

against overload. If in doubt consult your dealer or the loudspeaker manufacturer.

Nominal impedance

of loudspeaker

4 ohms

8 ohms

16 ohms

In all cases the fuses used should be 20mm x 5mm “fast blow” types.

IN NO CIRCUMSTANCES SHOULD “SLOW BLOW" OR “ANTI SURGE” FUSES BE USED,

OR VALUES GREATER THAN THE HIGHEST LISTED IN THE TABLE ABOVE. THIS

WOULD RESULT IN INADEQUATE PROTECTION OF THE AMPLIFIER AGAINST

OVERLOAD AND WILL INVALIDATE THE GUARANTEE.

Suggested fuse value

SA150 SA200

2.5 Amp

1.6 Amp

1.0 Amp

3.15 Amp

2.0 Amp

1.25 Amp

Power Supply Fuses

These are—2.5 Amp fast blow 20mm x 5mm diameter fuses (model SA150).

These are—3,15 Amp fast blow 20mm x 5mm diameter fuses (model SA200).

THEY ARE NOT USER REPLACEABLE.

If any of these fuses fail there is probably a fault in the amplifier—do not change the fuses but

consult your dealer.

Page 10

Mains Fuses

All models are fitted with an anti surge (slow blow) 20mm x 5mm diameter fuse, designed to

protect against faults in the amplifier, transformer and mains switch. The values are shown below:

SA200 (all voltages) 5A

SA150 (220/240V) 1.6A

SA150(120V) 3.15A

THESE FUSES ARE NOT USER REPLACEABLE

Should the SA150 or SA200 fail to function at switch-on the fault is probably external to the

amplifier. In particular, check the fuse in the mains plug (and distribution board, if used) before

suspecting the power amplifier. The switch-on surge currents of the SA150 and SA200 are very

great which is why a 10 or 13 Amp fuse is recommended for the mains plug. You should also

ensure that the lEC mains socket is pushed seuaely home into the lEC plug on the back panel of

the amplifier.

Inspecting and Changing Fuses

In order to inspect or change the fuses you will need to remove the top cover (see Figures 6

and 7).

BEFORE REMOVING THE COVER ALWAYS SWITCH OFF THE AMPLIFIER AND

DISCONNECT THE MAINS SUPPLY. NOTE THAT THE MAINS FUSE REMAINS LIVE

WHENEVER THE AMPLIFIER IS PLUGGED INTO THE MAINS, EVEN WHEN THE

AMPUFIER SWITCH IS IN THE OFF POSITION.

To remove the top cover use a No 1 ‘Posidriv’ screwdriver to take out the three black screws

located along the top rear edge of the amplifier, above the heat-sinks. The cover may then be

lifted gently upwards and backwards in order to free it from its locating slot in the front panel. 1 he

positions of the fuses arc shown in Figure 4. Replacement of the cover is a straight reversal of the

above procedure.

nllMlJI nllMlII

left hand _

output fuse

max. 2 5 Amp

quick blow

(SA150)

Tiax. 3.15 Amp

quick blow

(S.A200I

Figure 6. Location of Fuses

right hand

output fuse

lax. 2.5 Amp

quick blow

¡SA150)

ax. 3.15 Amp

quick blow

)

no

ISA200)

\

NofuSER

REPLACEABl.E

Page 11

i'e®

Yso

Page 12

SA150 Technical Specification

Inputs

Fixed level inputs are connected to pin 3 (LEFT) and pin 5 (RIGHT) of a 5 pin 180° DIN socket

and/or two phono sockets located in the rear sub panel. This sub panel is removable to allow

other types of connector to be substituted, if required.

Sensitivity

Gain to loudspeaker terminals

Signal/noise ratio

Input impedance

Outputs

Loudspeaker outputs are via red and black heavy duty screw terminals. These will accept bare

wires or 4mm (‘Banana’) plugs. Suitable for 4-16 ohm loudspeakers.

The continuous power output, both channels driven (at 0.08% t.h.d., 20 Hz-20 kHz), exceeds

The typical maximum power output at 1 kHz, at clipping (0.1% t.h.d.), both channels driven is

Total Harmonic Distortion

At any level up to 75W/8 ohms, 1 kHz > 0.03% (typ. 0.01%)

At any level up to llOW/4 ohms, 1 kHz > 0.05% (typ. 0.02%)

Frequency Response

-I- 0. - 0.5 dB 10 Hz-20 kHz, It is recommended that the pre-amplifier’s high frequency response

should be curtailed to at least — 3 dB at 50 kHz.

Power Requirements

240VAC, 48-63 Hz, 500VA maximum. The unit may be dealer adjusted to work at 220V or

120V if required.

0.87V (ref. 75W/8ohms. 1 kHz)

29.0 dB at 1 kHz, non-inverting

> 100 dB, unweighted or CCIR/ARM

weighted, (ref. 75W/8 ohms)

20 kQ

75W/channel into 8 ohms

1 low/channel into 4 ohms

90W/channel into 8 ohms

125W/channel into 4 ohms

Dimensions (overall)

Weight

Width 464mm (I8V4")

Height 95mm (3^/4")

Depth 350mm (13^4”)

Net 9 kg (20 lb)

Packed 13 kg (29 lb)

Page 13

SA200 Technical Specification

Inputs

Fixed level inputs are connected to pin 3 (LEFT) and pin 5 (RIGHT) of a 5 pin 180° DIN socket

and/or two phono sockets located in the rear sub panel. This sub panel is removable to allow

other types of connector to be substituted, if required.

Sensitivity

Gain to loudspeaker terminals

Signal/noise ratio

Input impedance

Outputs

Loudspeaker outputs are via red and black heavy duty screw terminals. These will accept bare

wires or 4mm (‘Banana’) plugs. Suitable for 4-16 ohm loudspeakers.

The continuous power output, both channels driven (at 0.08% t.h.d., 20 Hz-20 kHz), exceeds

The typical maximum power output at 1 kHz. at clipping (0.1% t.h.d.), both channels driven is

Total Harmonic Distortion

At any level up to lOOW/8 ohms. 1 kHz < 0.03% (typ. 0.01%)

At any level up to 160W/4 ohms, 1 kHz < 0.05% (typ. 0.02%)

Frequency Response

-I- 0, - 0.5 dB 10 Hz-20 kHz. It is recommended that the pre-amplifier’s high frequency response

should be curtailed to at least - 3 dB at 50 kHz.

Power Requirements

240 VAC. 48-63 Hz, 600 VA maximum. The unit may be dealer adjusted to work at 220V or

120V if required.

l.OOV (ref. lOOW/8 ohms, 1 kHz)

29.0 dB at 1 kHz, non-inverting

> 100 dB. unweighted or CCIR/ARM

weighted, (ref. 100W/8ohms)

20ki>

lOOW/channel into 8 ohms

160W,/channel into 4 ohms

125W/channel into 8 ohms

195W/channcl into 4 ohms

Dimensions (overall)

Weight

Width 464mm (I8V4")

Height 95mm (3^4")

Depth 350rnm (13%")

Net 10.0 kg (22 lb)

Packed 14.0 kg (31 lb)

Page 14

Guarantee for U.K. Sales

This equipment has been fully tested and a full record of these tests made before despatch from

the factory. Both the workmanship and the performance of this equipment are (except as set out

below) guaranteed against defects for a period of one year from the date of purchase provided

that it was originally purchased from an authorised U.K. dealer under a consumer sale agreement.

(The words “consumer sale” shall be construed in accordance with Section 15 of the Supply of

Goods (Implied Terms) Act 1973).

The Manufacturers can accept no responsibility for defects arising from accident, misuse, wear and

tear, neglect or through unauthorised adjustment and or repair, neither can they accept

responsibility for damage or loss occurring during transit to or from the person claiming under this

guarantee.

This guarantee covers both labour and parts and is transferable to subsequent purchasers but the

liability of the Manufacturers is limited to the cost of repair or replacement (at the discretion of the

Manufacturers) of the defective parts and under no circumstances extends to consequential loss or

damage.

Claims under this guarantee

This equipment should be packed in the original packing and returned to the dealer from whom it

was purchased or, failing this, any other authorised A&R Cambridge dealer. If it is not possible to

return the equipment by hand, then it should be sent carriage prepaid by a reputable carrier.

Should the original packing not be available, replacement packing can be purchased from the

Manufacturers. The equipment should not be sent by post.

DO NOT CONSIGN THE EQUIPMENT TO A&R CAMBRIDGE UNLESS YOU HAVE FIRST

BEEN SPECIFICALLY REQUESTED TO DO SO BY THE MANUFACTURER’S TECHNICAL

SERVICE DEPARTMENT. DO NOT UNDER ANY CIRCUMSTANCES ATTEMPT TO

DISASSEMBLE THE EQUIPMENT BEFORE DESPATCH.

If you have any difficulty complying with these requirements, please contact the Manufacturers at

the following address:-

A&R Cambridge Limited,

Denny End Industrial Centre,

Waterbeach,

Cambridge CB5 9PB.

Tel: (0223) 861550

Telex: 817345 (ARCAM G)

In either case you should state clearly your name and address, the date and place of purchase,

together with a brief description of the fault experienced.

In the event of equipment being returned which on test is found to comply with the published

specification the Manufacturers reserve the right to charge a reasonable fee for testing the

equipment and for return carriage.

Enquiries

The Manufacturers are happy to answer any queries you may have regarding the use of this

equipment on the condition that this enquiry is by letter and a stamped addressed envelope is

provided. You should state clearly the serial number of the unit, the dealer from whom it was

purchased and the date of purchase.

THIS GUARANTEE IN NO WAY VARIES OR REMOVES A PURCHASER’S STATUTORY

RIGHTS.

Printed by Clanpress (King’s Lynn) Ltd., King’s Lynn, Norfolk,

Issue 1 March 1983

Loading...

Loading...