Page 1

Service Manual

ARCAM

A65/75

Issue 1.0

DiVA A65, A75 & P75 Plus

Amplifi ers

ARCAM

Page 2

Contents List

!

Contents list

!

Circuit description

!

Service guide

!

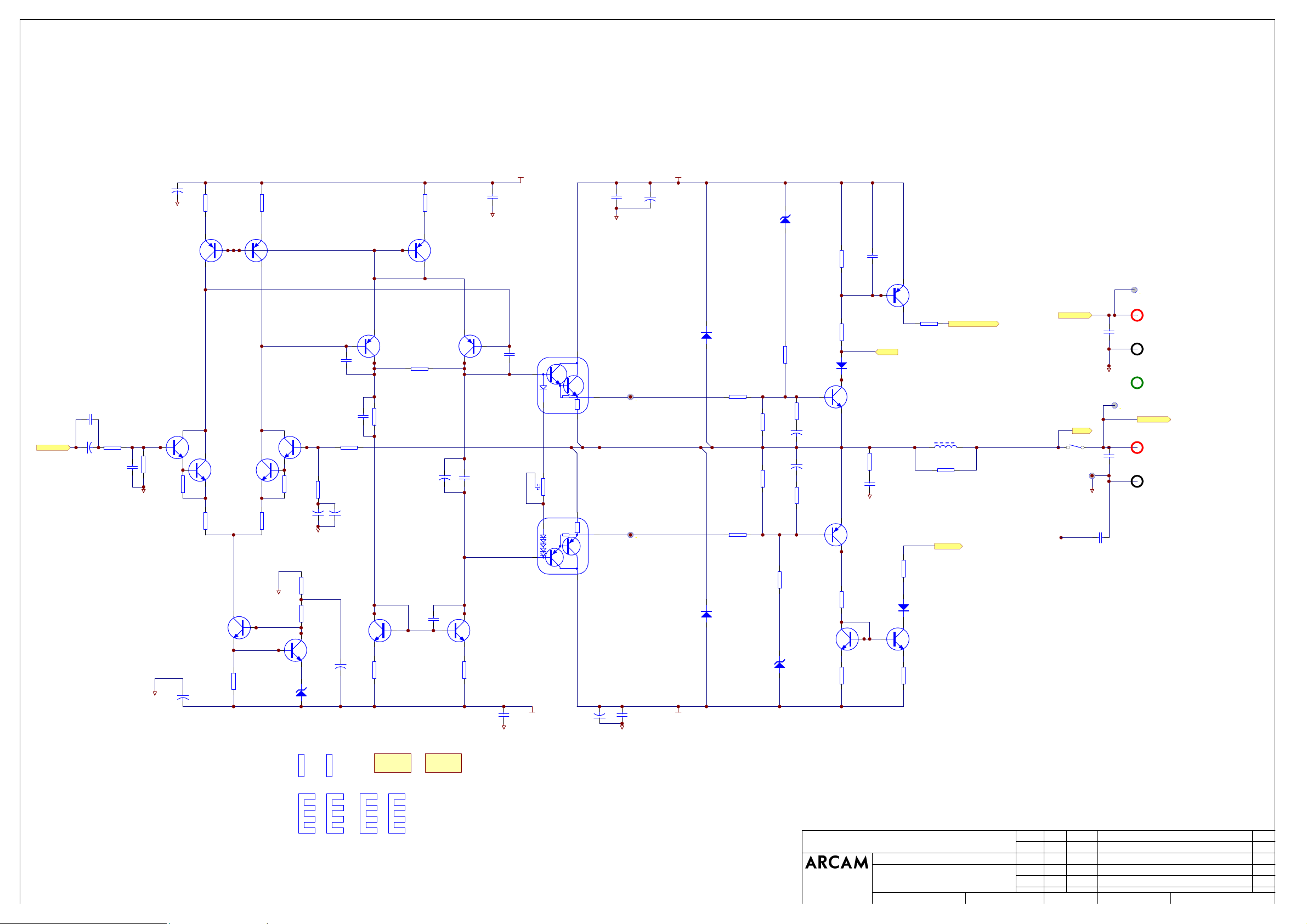

Circuit diagrams

!

Component overlays

!

Circuit board parts list

!

General assembly parts list

Page 3

A65/75/75P Plus Circuit Description

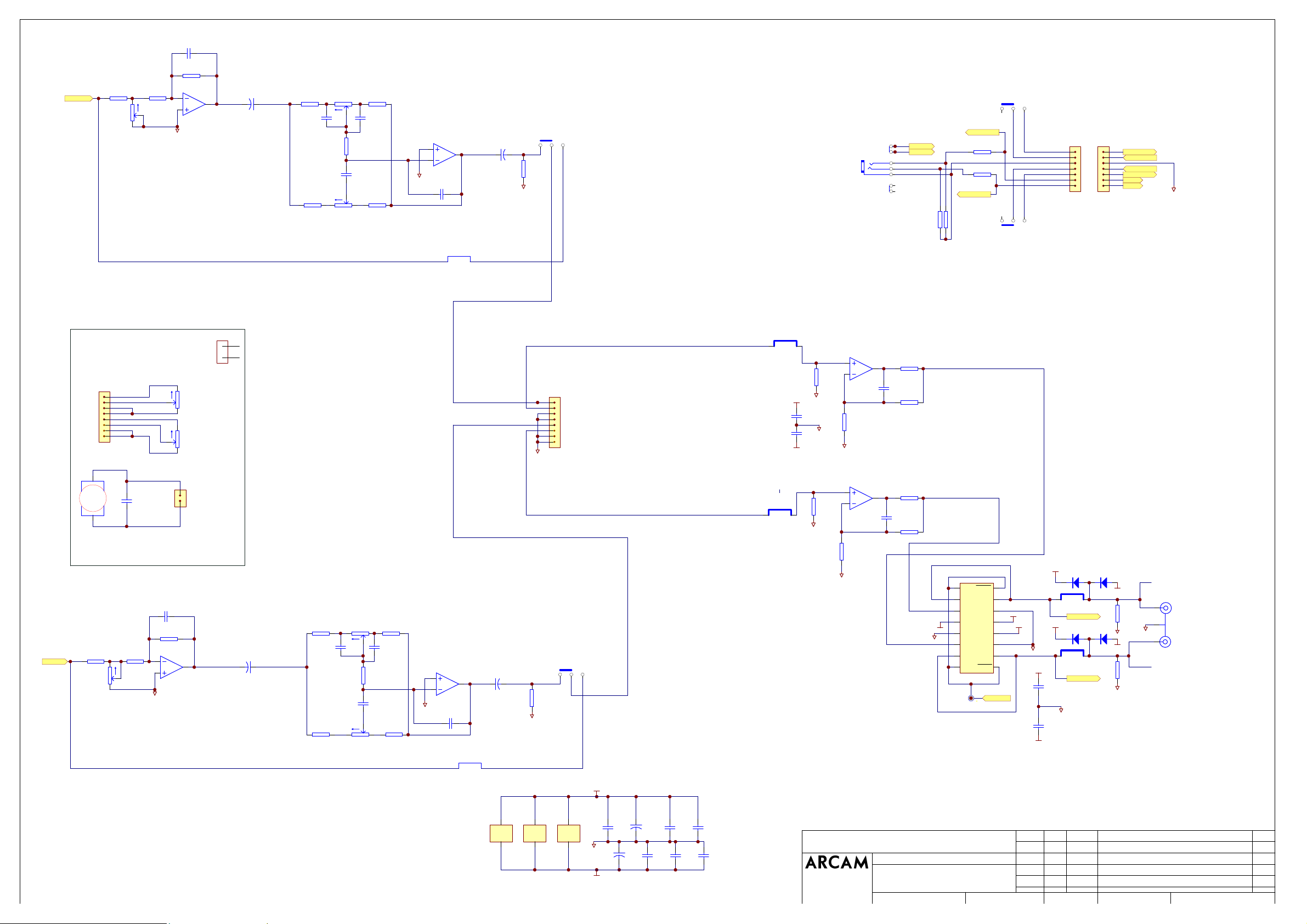

PSU

In order get the output devices to tu rn fully on and achieve the

greatest efficiency, an auxiliary rail is formed from a charge pump

driven by the main AC outputs from the transformer. C304,305 &

D301,302 charge on alternate cycles. In th e other cycle the charge

on C304,305 is pu mped into C310,311 respectively. Thi s creates a

voltage much greater than the standard rails, but wi th low regulation

and high ripple. This is then regulated to 38V via emitter followers

Q300,302,303,305 from a zener stabilized voltage (D304,305)

The Pre-amp ±15V supply comes from linear regulators Z300,301.

The transformer is a dual voltage unit, the required voltage being

selected b y which fuse holder is fitted with the appropriat e fuse. If an

alternative to 115V or 230V is requ ired then a different transformer

is fitted. Th e secondary is centre tapped for the main rails, but a

separate winding is added for the uC supply.

The star ground p oint SP300 is not a component on the PCB and is

on the schematic only for layout purposes.

Pre-amp

The direct signal path (line in, tone controls defeated) consists of a

single op-amp gain stage, buffering the j-fet input multiplexers and

Tape Monitor and AV switches . The selected input is AC coupled to

the op-amp, the output is DC to the Pre-out, via a j- f et "pre-mute"

switch. This switch is controlled by the uC in such a way that when

ever the output relay changes state signal is removed from the power

amplifier (A65/75).

The MM phono stage (by passable A75 only, SW100) is opamp

based. The circuit is AC coupled to give RIAA/IEC low frequency

response. The c artridge is loaded by R100,101,C119,120. The 1kHz

gain is 56dB, and RIAA eq set by

R110,112,111,113,C127,129,128,130.

Each line input has static protection a ffor ded by the ba ck to back

diodes (e.g. D101,103), and RF filtering is set by R118,C134 etc.

The selected input is buffered for Tap e output by Z104 set as a

follower. The output resistor is inside the feedback loop so to keep

the output impedance low and short protection is catered for.

C121,122 maintain stabilit y i nto capacitive loads.

From the tape monitor switch (Z105) onwards the signal is AC

coupled (C151,152). From there the signal is fed to the tone controls.

These consist of two stages: Balance and buffer (Z160), and

Bass/Treble Z161. The output of this stage is again AC coupled.

Switch SW162 selects whether the tone adjusted signal or a direct

signal reaches the gain section. In the A75 Z164 can be used to

bypass the volu me control when AV input is selected. This fixes th e

gain to allow an external AV processor to control the volume setting.

The gain stage (Z163) has a gain of 2.2, and the same low impedance

output arrangement as the Tape output. The signal from this stage to

the Pre- amp outputs and the Power amp input is controlled by a

pre-mute (Z171). This removes thumps and clicks, and in the case of

the Power amp r elay changing state, removes signal so ar cing will

not take place.

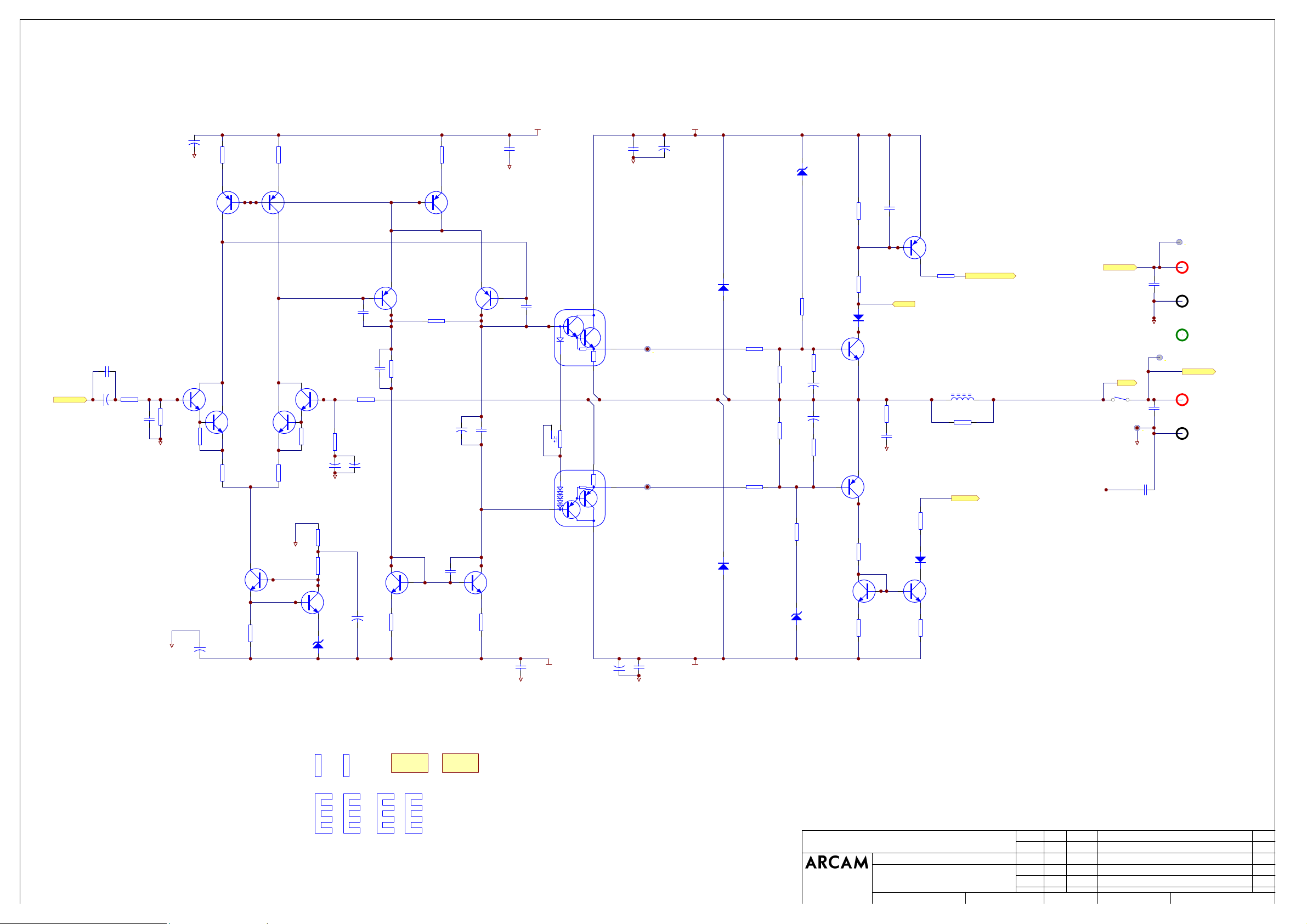

Power Amplifier

The new topology is a high gain voltage feedback design, with a

bipolar output stage. Its signal path is designed to be fully

symmetrical, despite not having a symmetrical circuit (symmetrical

rail to rail). This is achieved with a new dual differential input gain

block, where the input differential sees a symmetrical active load

(Q600,601,700,701) before driving the second voltage amplification

stage (VAS) differential (Q603,604,703,704). This could be

described as two Wilson mirrors with their bases clamped together.

The second differential also has an active load of a more traditional

mirror (Q610,611,710,711), and this gives a push pull signal to the

input of the output stage, improving on the traditional single ended

current source of the often called "blameless" topology.

The input pair (Q60 6,607,618,619, 706,707,718,719 ) are in a

Darlington confi guration to lower input current offset which in turn

will lower DC offset at the output, as the impeda nces seen on the

input nodes are necessarily high for the wide bandwidth required.

The output stage is a simple bipola r darlington (Q614,615,714,715).

However, the devices used are Darlingt on devices with integral

diodes. This means the bias temperature compensation i s part of the

output device enabling smaller number of devices, no extra devices

on the heatsink (vital for this mechanical layout) and more consistent

temperature compensation of bias. Also the resi st ors are also

integral, saving a large amount of PCB real estate and hand insertion

cost, while also able to be used as bias set test points and protection

sensing.

Due to the dec reased efficiency of this type of output stage over the

previous bootstrapped Mosfet output, a separate set of rails is

required for the VAS stage in order to satu rate the output transistors.

The operation of this is outlined in the Power supply section.

However, these rails are individually regulated for each channel to

decrease power supply crosstalk.

The protecti on of the output stage is taken care of by a proprietary IC

(Z101). This takes care of the switch on delay (R150,C149), DC

offset (R102,103,C147), Thermal trip (TH100), and safe operating

area.

The safe op erating area is monitored by a network which

compensates for the voltage across the output devices , current

through them, and duration of power (R627,606,625,605,C617 &

symmetrical associated components) and this is sent to the protection

IC via (Q605,612,613,616,617,712,713,716,717).

The output of the protection IC is sent to the micro controller (uC) to

signal the output relay (RLY1) status. Also, for output muti ng

purposes, the uC can switch the relay via Q100.

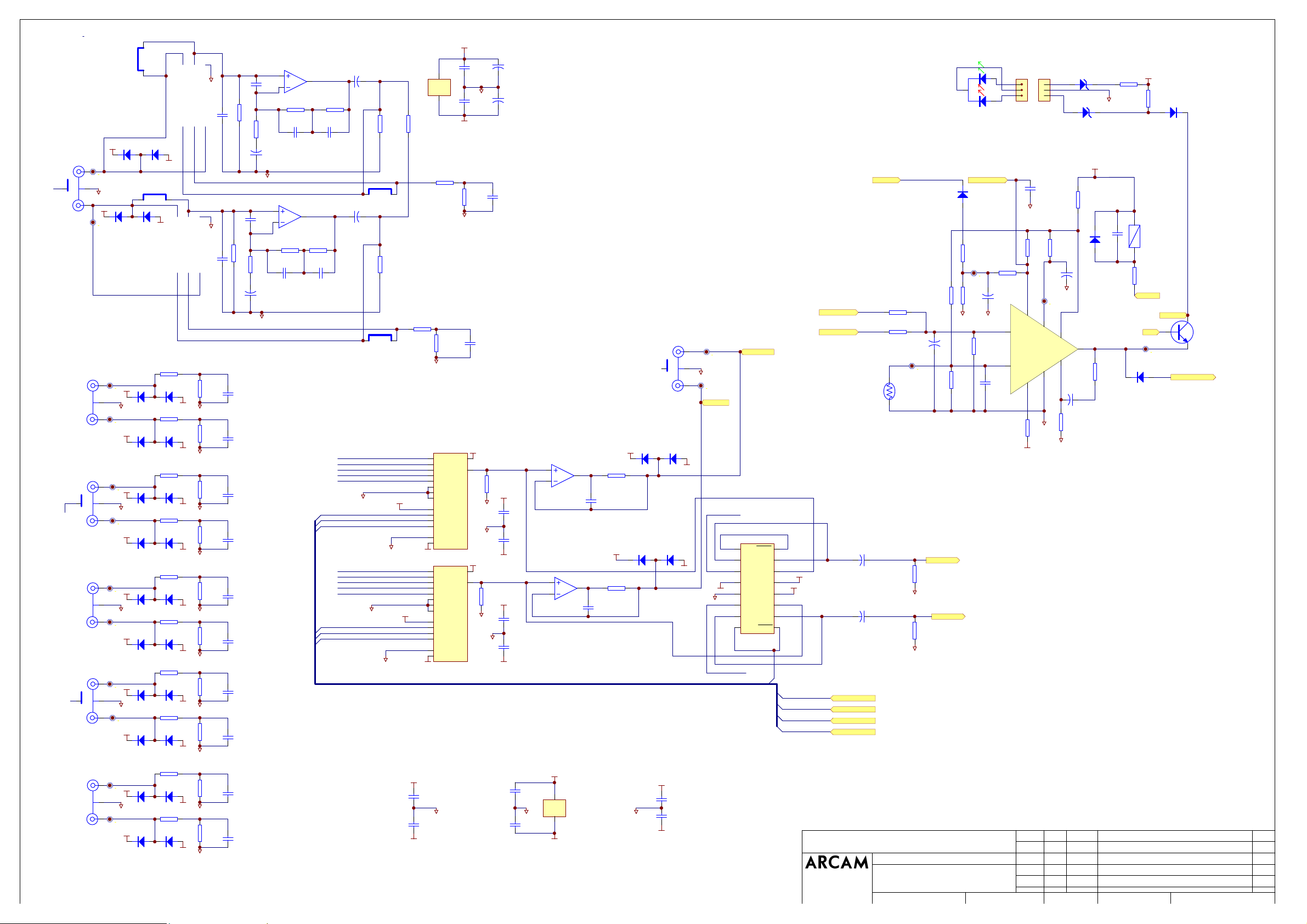

Input Selection

The uC cont r o ls the operation of the unit. IR commands are received

from RX900 on a break-off PCB found on the front panel and fed via

LK900/LK903 3-way ribbon. On power on/off the current state of

the pre-amp switching stored in an EEPR O M Z906. The inp ut

switching is 5V logic level and is direct from the uC to the DPDT

analogue switches in the case of Tape Monito r ( Z105), AV

(Z164,A75 on ly), Pre-mute (Z171) and Mute Q100. The source

selector is achieved by 8 way analogue multiplexors (Z102,103) and

the control signals are decoded from the uC from MUX1,2,3 by

Z907 which also drives the appropriate front panel LED. The input

selection is set by the remote control or the rotary encoder on the

front panel display PCB. Tape monitor and AV mode(A75 only) is

set by SW900.

Volume Control

The volume control is a motorized manual type, where the signals

are routed through the 8-way ribbon LK189. The motor drive comes

from Z905, which is a logic level controllable motor driver. It has its

own unregulated PSU (D907,C920),an d the speed of the volume

knob is dictated by the REF pin. The circuit (Q900,R905,901,C901)

allows the speed to vary from just ab ove stall to full as the volume

control button is depressed on the remote.

SIM Module

The connector PL161 (P75 only) allows the fitting of the ARCAM

SIM module. In order to allow this to operate LK172 & LK173 must

be removed. This will allow 12V trigger signals to operate the P75.

Headphones

The Speaker outputs (SK600,700) are connected to the headphone

socket (SK162) via an 8-way ribbon LK170,171. The output is

attenuated by a resistor network R161,162,236,237. The Relay drive

is fed through the headphone socket's switch (HPSW1,2) so that

when headphones are inserted the speakers are disconnected. Switch

SW163 allows the separate switching of the second speaker

terminals on SK600,700.

Page 4

A65, A75 & P75 Service Guide

Fault diagnostics

Fault Action

No power Check mains fuse

Stuck in protection Check power supply rails

Intermittent audio on one channel Check for dry joints around o/p

Fails to respond to commands Check supply to remote circuit

Volume control rubs on front panel Pull knob out from fascia

Audio crackles on o/p Check for component break down

Power supply test points

Position Voltage

LK125 +37 volts DC

LK126 -37 volts DC

LK271 or black speaker terminal 0 volts

LK303 +15 volts DC

LK301 - 15 volts DC

Q300 emitter +38 volts DC

Q304 emitter +38 volts DC

Q302 emitter -38 volts DC

Q305 emitter -38 volts DC

D910 emitter +5 volts DC remote supply

IQ settings

Model IQ setting Comments - (22/01/02)

A65 37mV

A75 37mV

P75 37mV

A85 12mV Set for 8.5mV cold, reset for 12mV when warm

P85 12mV Set for 8.5mV cold, reset for 12mV when warm

A65 plus 12 to 15mV

A75 plus 12 to 15mV

P75 plus 12 to 15mV

!

To isolate a fault between pre and power stage remove C602 (left channel) or C702 (right

channel).

!

Always check and re-solder o/p device SAP15N and SAP15P pin connections.

!

Replace Z900 IC if software version is below version 3 ( note version 82 is also ok ).

!

Make sure R127 is not touching LK130.

!

When replacing the top cover with a new top it may be necessary to re-drill the fixing holes.

Check transformer connections

Check power supply rails

Check protection circuit voltages

Check for dry joints on o/p devices

devices

Check IC Z900

Check remote flex foil cable

Check for dry joints on selector pcb

using hot air gun & freezer spray

Check transformer connections

Hints & tips

Page 5

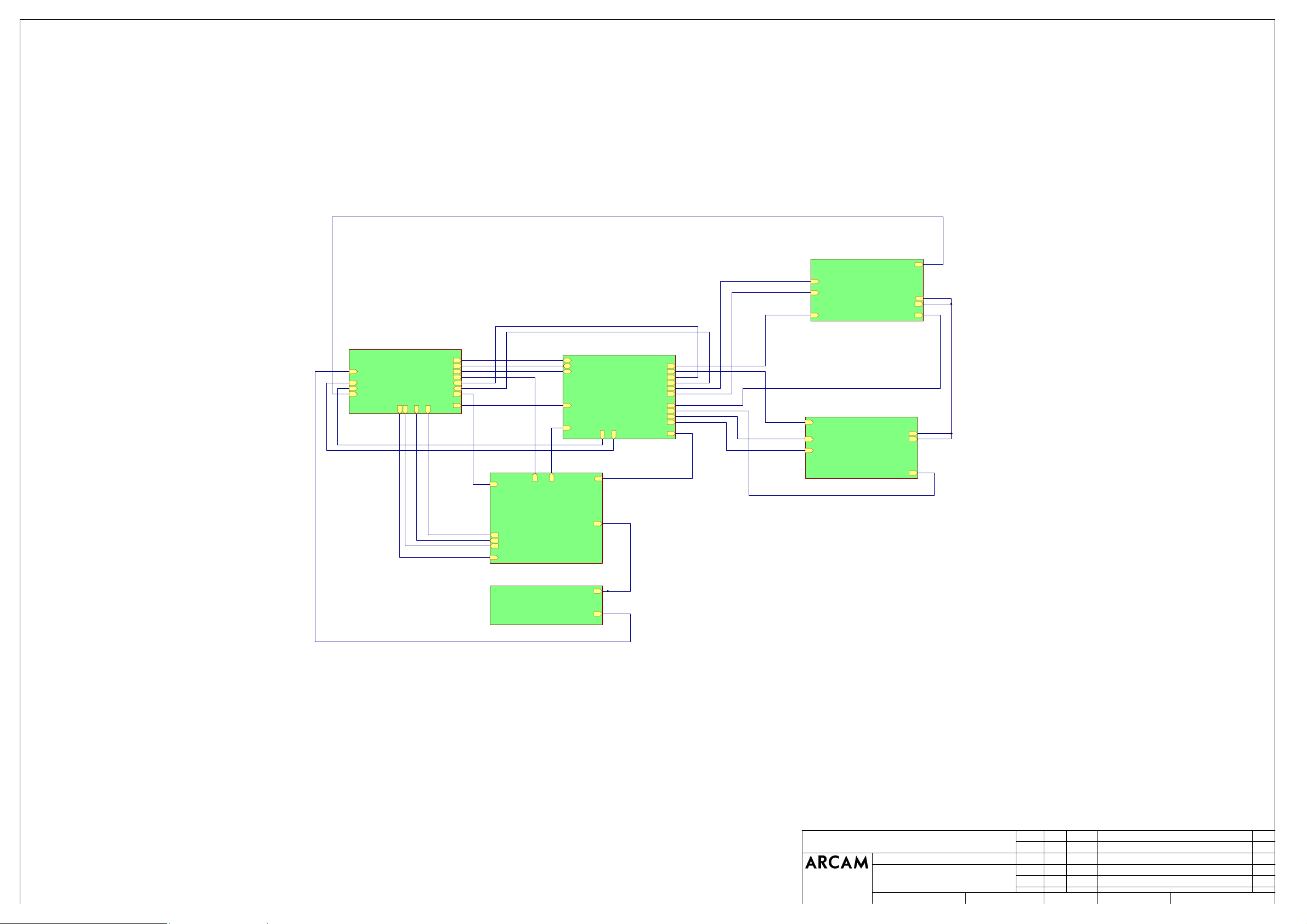

PHONO & INPUTS

L942C3_1.0.SCH

ACSENSE

PROT_OP_L

PROT_OP_R

PROTECTION MUTE

TAPECONTROL

MUX2

MUX3

PROT SENSE

SELOPL

SELOPR

HPSW2

TAPOL

TAPOR

MUX1

HPSW1

REMOTE CONTROL

L942C7_1.0.SCH

MUTE

MUX1

MUX2

MUX3

PROT SENSE

TONE CONTROL

L942C4_1.0.SCH

AVCONTROL

PREMUTE

TAPECONTROL

SELOPL

SELOPR

HPSW2

HPSW1

PREMUTE

ACLT1

PROT_OP_R

PROT_OP_L

PWRLEFT

PWRRIGHT

TAPOL

TAPOR

SP2_SEND_L

SP2_RETN_L

OP_L

OP_R

SP2_SEND_R

SP2_RETN_R

AVCONTROL

LEFT CHANNEL

L942C5_1.0.SCH

SP2_SEND_L

SP2_RETN_L

PWRLEFT

RIGHT CHANNEL

L942C6_1.0.SCH

PWRRIGHT

SP2_SEND_R

SP2_RETN_R

PROTECTION

OP_L

A1

A1

OP_R

A1

A1

POWER SUPPLY

L942C2_1.0.SCH

ACLT1

ACSENSE

USE 'exlude A65' FILTER FOR BOM

DRAWING TITLE

A & R Cambridge Ltd.

Pembroke Avenue

Waterbeach

Cambridge CB5 9PB

A65 PLUS AMP

Filename:

L942C1_1.0.PRJ

Notes:

TOP SHEET FOR A65 L942AY

Contact Engineer:

01_E020

Contact Tel: (01223) 203 200Travis Pierce

ECO No. DESCRIPTION OF CHANGE

TGP 12/12/01 PRODUCTION RELEASE 1.0

DATE

INITIALS

11-Dec-2001

Printed:

1 7Sheet of

DRAWING NO.

L942C1

ISSUE

Page 6

C600

100U EL 100V

0V_HF

+38V_L

+

R601

100R MF

R602

100R MF

R615

47R MF

0V_HF

C613

100N PE 100V

C614

100N PE 100V

0V_HF

+37V

+

C603

100U 50V YXF LOW Z

D601

ZENER 400MW 27V

PWRLEFT

C623

100N PE 100V

C602

+

22U SILMIC 2

R600

1K0 MF

C603

100P PPW

0V_SIG

R612

100K MF

0V_HF

R632

12K MF

Q600

BC556B

Q619

BC546B

+

C601

100U EL 100V

Q606

BC546B

R613

47R MF

Q607

BC546B

R617

680R MF

Q608

BC546B

Q601

BC556B

R614

47R MF

0V_HF

Q618

BC546B

R633

12K MF

C605

100U SILMIC 2

0V_SIG

R618

10K MF

R619

10K MF

Q609

BC546B

D600

4V7 400MW

C604

100P PPW

C610

100N PE 100V

R616

2K7 MF

+

R611

100K MF

+

C624

100U 25V ZA EL

Q611

2SC2240GR

+

C616

10U EL

Q604

2SA970GR

R620

10K MF

R603

100R MF

R634

470K MF

C625

10U EL

C607 100P PPW

Q602

BC556B

Q603

2SA970GR

+

C611

100N PE 100V

Q610

2SC2240GR

R604

100R MF

C612

100N PE 100V

RV600

220R PSET

0V_HF

C608

100P PPW

-38V_L

Q614

SAP15N

Q615

SAP15P

C626

100U 50V YXF LOW Z

Bias-L +

SET BIAS TO 12mV

Bias-L -

C615

+

100N PE 100V

0V_HF

-37V

D603

1N4003F

D604

1N4003F

R627

430R MF

R628

430R MF

R606

100R MF

R607

100R MF

R625

6K8 MF

R605

100R MF

C617

+

10U EL

+

C618

10U EL

R608

100R MF

R626

6K8 MF

D602

ZENER 400MW 27V

Q613

BC546B

R621

680R MF

R622

10K MF

D605

1N4148

Q612

2SC2240GR

0V_LS_L

Q616

2SA970GR

R624

10K MF

R609

100R MF

C609

22N CD

A1

R630

4R7 W2 CF

C619

100N PE 100V

Q605

BC556B

R623

10K MF

D606

1N4148

Q617

ZTX653

R610

100R MF

R629

47K MF

PROTECTION

L600

2U2H LAC SMALL

R631

2R2 CF

A1

SP2_RETN_L

470P CD

OP_L

RLY1A

RLY G5Z-2A-E

SPLE600

PD6

C620

0V_LS_L

0V_LS_L

C622

1N0 CD

SPLD600

C621

470P CD

SPLS600

Bot+

SK600B

SPKSKT_G

Bot-

SK600C

CHASS

SPKSKT_G

SP2_SEND_L

Top+

SK600A

SPKSKT_G

Top-

CL600

E856MC

HS600

E81801-75

CL601

E856MC

HS601

E81801-75

SP600

Q2-PAD-SAP

HS602

E81801-75

21mm x 32mm

SELF ADHESIVE

Q2 PAD

E852MC

HS603

E81801-75

SP601

21mm x 32mm

SELF ADHESIVE

Q2 PAD

E852MC

Q2-PAD-SAP

USE 'exlude A65' FILTER FOR BOM

DRAWING TITLE

A & R Cambridge Ltd.

Pembroke Avenue

Waterbeach

Cambridge CB5 9PB

A65 PLUS AMP

Filename:

L942C5_1.0.SCH

Notes:

Left Channel Power Amplifier

Contact Engineer:

01_E020

Contact Tel: (01223) 203 200Travis Pierce

ECO No. DESCRIPTION OF CHANGE

TGP 12/12/01 PRODUCTION RELEASE 1.0

DATE

INITIALS

11-Dec-2001

Printed:

5 7Sheet of

DRAWING NO.

L942C5

ISSUE

Page 7

REPLACE WITH IDENTICAL PART

ACLT1

R900

1R0 FU

MOTE900

C900

10N CD

0V_DIG

D906

1N4003F

R903

100R MF

R902

+

C914

100R MF

220U EL

0V_DIG

RX900

PIC-26043TM2

3

2

O/P

+5V

O/P

GND1Case

Case

GND +5V

REMOTE SENSOR SNAP OFF BOARD

IR RX

SUPPORT PAD

SP1

IR RX SUPPORT PAD

R901

12K MF

R904

10R MF

D908

ZENER 5V1 400MW

LK900

1

2

3

L856CA

+5v

R905

33K MF

+

C901

100U EL

0V_DIG

+5v

+

C915

100U EL

3WAY CABLE HOLDER

D907

1N4003F

LK903

+5V

Q900

BC556B

1

2

3

P900

REMO900

0V_DIG

C912

10N CD

3

5

4

6

9

0V_DIG

+5V

C916

100N CD

0V_DIG

PROT SENSE

CC1

MC1

REF

MC2

CC2

Z900

1

2

3

4

5

6

7

8

9

10

11

12

13

14

PB5

PB4

PA3

PA2

PA1

PA0

PB3

PB2

PB1

PB0

VSS

(TMR)/INT

PC0

PC1

+5V

Z905

8

BA6109

VCC17VCC2

VOLUME DRIVEMOTOR DRIVER

28

PB6

27

PB7

26

PA4

25

PA5

24

PA6

23

PA7

22

OSC2

21

OSC1

20

VDD

19

RES

HT48R30 28-DIP-B-0

18

PC5

17

PC4

16

PC3

15

PC2

R913

10K MF

5

6WP7

SCL

SDA

4

VSS

3

0V_DIG

+

C920

1M0 25V

0V_DIG 0V_DIG

2

MD1

1

GND

0V_DIG

10

MD2

8

VDD

A01A12A2

Z906

24C01

C917

100N CD

C913

10N CD

D910

1N4148

R912

100K MF

+5v

MOTSUP900

+5v

+ C921

10U EL

0V_DIG

R914

4K7 MF

C918

100N CD

VOLM901

VOLMOT900

1Y271

1 2

VOLM900

X900

0V_DIG

CST4.00

0V_DIG

D911

1N4148

SK900

FFC10V

10

Disp H

Disp G

Disp I

SW900A

2PCO_NON_LAT

123

456

SW900B

2PCO_NON_LAT

MUTE

PREMUTE

Disp D

Disp F

Disp E

TAPECONTROL

AVCONTROL

MUX1

MUX2

MUX3

Disp C

Disp B

Disp A

123456789

0V_DIG

0V_DIG

13

14

15

12

1

5

2

4

6

11

10

9

7

Z907A

74HC4051

X0

X1

X2

X3

X4

X5

X6

X7

INH

A

B

C

VEE

3

X

R915

220R MF

+5v

0V_DIG

+5v

C919

100N CD

16

Z907B

VDD

GND

74HC4051

8

WARNING SAFETY CRITICAL COMPONENT

USE 'exlude A65' FILTER FOR BOM

DRAWING TITLE

A & R Cambridge Ltd.

Pembroke Avenue

Waterbeach

Cambridge CB5 9PB

A65 PLUS AMP

Filename:

L942C7_1.0.SCH

Notes:

uC, Volume Drive & Remote Control

Contact Engineer:

Contact Tel: (01223) 203 200Travis Pierce

ECO No. DESCRIPTION OF CHANGE

TGP 12/12/01 PRODUCTION RELEASE 1.001_E020

INITIALS

Printed:

DATE

11-Dec-2001

7 7Sheet of

DRAWING NO.

L942C7

ISSUE

Page 8

PHONO4G

TUNER

VCR

PHONO4G

TAPE IN

SK100A

EMC

PHONO4G

PHINR

SK100B

CD

SK103A

PHONO4G

SK103B

AV/DVD

SK102A

PHONO4G

SK102B

PHONO4G

F

N

+15v

D101

1N4148

1

PHINL

0V_SIG

+15v

D100

1N4148

CDL

4

TOP

BOT

EMC

EMC

+15v

F

6

N

5

1

F

N

F

N

1

F

N

F

N

1N4148

0V_SIG

CDR

+15v

1N4148

TUNL

+15v

1N4148

0V_SIG

TUNR

+15v

1N4148

VCRL

+15v

D110

1N4148

0V_SIG 0V_SIG

VCRR

+15v

1N4148

DVDL

+15v

1N4148

0V_SIG 0V_SIG

DVDR

+15v

1N4148

TAPL

+15v

1N4148

0V_SIG 0V_SIG

TAPR

+15v

1N4148

LK101

10MM LINK

1 2

D103

1N4148

LK102

1 2

10MM LINK

D102

1N4148

-15v

R118

1K0 MF

D104

1N4148

R119

1K0 MF

D105

1N4148

R121

1K0 MF

D108

1N4148

R122

1K0 MF

D109

1N4148

R123

1K0 MF

1N4148

R124

1K0 MF

D111

1N4148

R125

1K0 MF

D120

1N4148

R126

1K0 MF

D121

1N4148

R127

D122

1N4148

R128

1K0 MF

D123

1N4148

-15v

D106

D107

D112

D113

D114

D115

D124

D125

1K0 MF

D126

D127

-15v

-15v

-15v

-15v

-15v

-15v

-15v

-15v

-15v

-15v

0V_SIG

0V_SIG

0V_SIG

0V_SIG

0V_SIG

0V_SIG

0V_SIG

0V_SIG

0V_SIG

R130

100K MF

VCROR

R131

100K MF

TUNOL

R133

100K MF

TUNOR

R134

100K MF

CDOL

R135

100K MF

CDOR

R136

100K MF

DVDOL

R137

100K MF

DVDOR

R142

100K MF

TAPEOL

R143

100K MF

TAPEOR

R144

100K MF

C120

VCROL

C119

100P PP

R101

100P PP

C134

470P PPW

C135

470P PPW

C137

470P PPW

C138

470P PPW

C139

470P PPW

C140

470P PPW

C141

470P PPW

C142

470P PPW

C143

470P PPW

C144

470P PPW

R100

47K MF

+

C123

47P CD

47K MF

+

0V_SIG

C124

47P CD

R108

470R MF

C125

22U EL

0V_SIG

R109

470R MF

C126

22U EL

5

6

4N7 PP

3

2

R111

680K MF

C128

Z100A

NE5532

R110

680K MF

C127

4N7 PP

Z100B

NE5532

7

1

R113

56K MF

C130

1N3 PP

R112

56K MF

C129

1N3 PP

MUX1

MUX2

MUX3

AUXOL

VCROL

TUNOL

CDOL

DVDOL

AUXOR

VCROR

TUNOR

CDOR

DVDOR

MUX1

MUX2

MUX3

C131

+

22U EL

1 2

C132

+

22U EL

1 2

0V_SIG

0V_SIG

R114

8K2 MF

LK103

10MM LINK

R115

8K2 MF

LK104

10MM LINK

0V_SIG

0V_SIG

+15V

+

0V_SIG

AUXOL

C136

470P PPW

0V_SIG

0V_SIG

0V_SIG

0V_SIG

R139

100K MF

R138

100K MF

C145

10U EL

+

C146

10U EL

C133

470P PPW

+15v

C107

100N CD

C108

100N CD

-15v

+15v

C109

100N CD

C114

100N CD

-15v

C115

100N CD

C116

100N CD

3

2

5

6

+15v

Z104C

TL072

-15v

Z104A

TL072

Z104B

TL072

84

ACSENSE

PROT_OP_L

SK101A

TAPE OUT

EMC

PHONO4G

+15v

D117

D119

1N4148

D116

1N4148

+15v

-15v

1N4148

D118

1N4148

C110

100N CD

C118

100N CD

R154

1

47R MF

C122

100P PP

+15v

R155

7

47R MF

C121

100P PP

0V_SIG0V_SIG0V_SIG

TAPOL

1

F

N

0V_SIG

TAPOR

TAPOR

-15v

-15v

-15v

0V_SIG

TAPEOL

TAPECONTROL

Z105

1

SEL1

2

D1

3

S1

4

VGND5VL

6

S4

7

D4

8

SEL4

DG413DJ

TAPECONTROL

TAPEOR

TAPOL

SEL2

SEL3

D2

S2

V+

S3

D3

16

15

14

13

+5v

12

11

10

9

TAPECONTROL

MUX1

MUX2

MUX3

+15v

TAPECONTROL

MUX1

MUX2

MUX3

USE 'exlude A65' FILTER FOR BOM

DRAWING TITLE

A & R Cambridge Ltd.

Pembroke Avenue

Waterbeach

Cambridge CB5 9PB

A65 PLUS AMP

R102

47K MF

R103

47K MF

C147

100U NP

Therm

TH100

PTH90DEG

C151

+

100U SILMIC 2

C152

+

100U SILMIC 2

Filename:

Notes:

R140

100K MF

0V_SIG

R141

100K MF

0V_SIG

L942C3_1.0.SCH

Phono Stage & Input Selection

Contact Engineer:

C101

100N CD

84

Z100C

NE5532

C102

100N CD

R116

18K MF

R120

1K0 MF

12

11

10

+5v

16

15

14

-15v

12

11

10

+5v

16

15

14

-15v

+15V

C112

100N CD

C113

100N CD

-15V

R117

1K0 MF

0V_SIG

Z102

4

X0

5

X1

6

X2

7

X3

X4

X5

X6

9

X7

2

EN

1

A0

A1

A2

GND

3

V-

DG408DJ

Z103

4

X0

5

X1

6

X2

7

X3

X4

X5

X6

9

X7

2

EN

1

A0

A1

A2

GND

3

V-

DG408DJ

R132

100K MF

-15V

0V_SIG

AUXOR

V+

V+

D

D

R129

100K MF

+15v

13

8

+15v

13

8

R156

1K5 MF

SELOPL

SELOPR

LED100

G

R

LED RED/GRN 3MM

PROTECTION

D128

1N4003F

R148

470R FU

AC Det

R104

47K MF

0V_HF 0V_HF

R105

47K MF

R157

100K MF

Contact Tel: (01223) 203 200Travis Pierce

LK100

L856CA

LK100A

1

2

3

3WAY CABLE HOLDER

0V_HF

R149

100K MF

C148

+

1U0 EL

2

IN1

3

IN2

C153

10N CD

1

5

R106

47K MF

PWR

V-

C117

470P CD

RC

1

2

3

C149

100U EL

8

RC

0V

4

R150

100K MF

0V_HF

9

V+

FB

7

D134

5V6 400MW

+

O

C150

+

1U0 EL

R152

0V_HF

0V_HF

TGP 12/12/01 PRODUCTION RELEASE 1.001_E020

INITIALS

Printed:

33K MF

11-Dec-2001

R151

18K MF

-37V

ECO No. DESCRIPTION OF CHANGE

D131

5V6 400MW

+37V

R145

10K MF

Z101

TA7317P

6

DATE

0V_HF

D130

1N4003F

R107

47K MF

R146

2K7 1W CF

C154

100N PE 100V

R153

1K0 1W CF

HPSW1

D132

1N4148

3 7Sheet of

+37V

R147

2K7 1W CF

D129

1N4003F

RLY1C

RLY G5Z-2A-E

HPSW2

MUTEPROT_OP_R

Prot

Q100

2SC2240GR

PROT SENSE

DRAWING NO.

L942C3

ISSUE

Page 9

LK1

LINK10NP

LK2

LINK10NP

LK3

LINK10NP

LK4

LINK10NP

LK5

LINK10NP

LK201

LINK10NP

LK212

LINK15NP

LK220

LINK20NP

LK267

LINK17.5NP

LK268

LINK17.5NP

LK269

LINK15NP

LK6

LINK10NP

LK7

LINK10NP

LK8

LINK10NP

LK9

LINK10NP

LK10

LINK10NP

LK202

LINK10NP

LK213

LINK15NP

LK11

LINK10NP

LK12

LINK10NP

LK13

LINK10NP

LK14

LINK10NP

LK15

LINK10NP

LK203

LINK10NP

LK221

LINK20NP

LK270

LINK17.5NP

LK271

LINK15NP

LK272

LINK17.5NP

LK16

LINK10NP

LK17

LINK10NP

LK18

LINK10NP

LK19

LINK10NP

LK20

LINK10NP

LK204

LINK10NP

LK214

LINK15NP

LK21

LINK10NP

LK22

LINK10NP

LK23

LINK10NP

LK24

LINK10NP

LK25

LINK10NP

LK205

LINK10NP

LK215

LINK15NP

LK222

LINK20NP

LK26

LINK10NP

LK27

LINK10NP

LK28

LK08NP

LK29

LINK10NP

LK30

LINK10NP

LK206

LINK10NP

MAINS_N300

MAINS_E300

MAINS_L300

LK31

LINK10NP

LK32

LINK10NP

LK33

LINK10NP

LK34

LINK10NP

LK35

LINK10NP

LK207

LINK10NP

LK216

LINK15NP

LK223

LINK20NP

C300

3N3 MAINS

LK36

LINK10NP

LK37

LINK10NP

LK38

LINK10NP

LK39

LINK10NP

LK40

LINK10NP

LK208

LINK10NP

MAINS INPUT

SK300

IEC3

N E L

E

N

A1007

PD300

TOOLING

0V_HF

LK41

LINK10NP

LK42

LINK10NP

LK43

LINK10NP

LK44

LINK10NP

LK45

LINK10NP

LK209

LINK10NP

LK217

LINK15NP

LK224

LINK20NP

PD301

TOOLING

L

C301

3N3 MAINS

MAINS SWITCH

SW300B

SW300A

A1007

CS1

220N X2 CLASS

Chassis Earth Point,

Use correct screw and washer.

R300

100R MF

LK46

LK51

LINK10NP

LINK10NP

LK47

LK52

LINK10NP

LINK10NP

LK48

LK53

LINK10NP

LINK10NP

LK49

LK54

LINK10NP

LINK10NP

LK50

LK55

LINK10NP

LINK10NP

LK210

LK211

LINK10NP

LINK10NP

LK218

LINK15NP

LK225

LINK20NP

PD302

TOOLING

PD304

TOOLING

C302

3N3 MAINS

LK56

LINK10NP

LK57

LINK10NP

LK58

LINK10NP

LK59

LINK10NP

LK60

LINK10NP

LK277

LINK10NP

LK219

LINK15NP

C303

1N0 CD

0V_DIG

FS300

AS1A25

PD305

TOOLING

R311

D304

D305

0V_SIG

10R FU

R312

10R FU

+ C312

220U EL 50V

+ C313

220U EL 50V

C317

100N CD

C318

100N CD

Q300

BC546B

0V_HF0V_PSU

Q302

BC556B

+

C106

1U0 EL

+

C105

1U0 EL

+38V_R

+38V_R

C319

100N CD

C320

-37V_R -37V_L

100N CD

-38V_R

Z300

7805

I

Vin

Vout

GND

G

D306

10V 400MW

D307

10V 400MW

G

GND

I

Vin

Vout

Z301

7905

Q304

BC546B

+38V_L

Q305

BC556B

O

O

+37V_L

-38V_L

+15V

+

C315

100U EL

+

C316

100U EL

-15V

+300

-300

SELECT VOLTAGE

BY FITTING FS201

OR FS202

T300

FS301

AS2A5_115V

GREEN300

FIT ONLY ONE FUSE

T301

BLUE300

SK302

1

CAGECLAMP1

3

Orange

2

Dark Grey

1

Blue

SK301

CAGECLAMP3

Green

230V

115V

SCREEN

TX300

L836TX

EL

EARTH LEAD

8M101

EARTH LEAD

9Vac

SK303

Grey

Grey

CAGECLAMP2

BLUE301

SK304

Orange

Blue

Orange

CAGECLAMP3A

ACSENSE

C304

+

47U EL 100V

ACLT1

AC

1

2

0V_DIG

1

BR300

+

3

~

OR300

1

2

3

OR301

2

~

-

BRGBU8D

4

C305

47U EL 100V

+

C308

10M EL 50V

C309

10M EL 50V

+

+

+37V

-37V

C306

100N PE 100V

0V_SIG

0V_DIG

C307

100N PE 100V

0V_HF

D301

1N4003F

D302

1N4003F

0V_PSU

D300

1N4003F

D303

1N4003F

PSUP300

0V_LS_L

SP300

STAR_10

NSUP300

0V_HF

C310

+

100U EL 100V

ZENER 500MW 39V

C311

+

100U EL 100V

ZENER 500MW 39V

0V_LS_R

R301

4K7 MF

R302

4K7 MF

DO NOT USE THE FOLLOWING NUMBERS AS LINKS - THE DESIGNATORS ARE ALREADY USED ON OTHER PARTS OF THIS CCT!

LK100, LK101, LK102, LK103, LK104, LK168, LK170, LK171, LK172, LK173, LK174, LK175, LK176, LK177

LK126

LK61

LINK10NP

LK62

LINK10NP

LK63

LINK10NP

LK64

LINK10NP

LK65

LINK10NP

LK278

LINK10NP

LK230

LINK15NP

LK226

LINK20NP

PD303

TOOLING

LK66

LINK10NP

LK67

LINK10NP

LK68

LINK10NP

LK69

LINK10NP

LK70

LINK10NP

LK279

LINK10NP

LK231

LINK15NP

PD311

TARGET1

LK71

LK76

LK81

LK86

LINK10NP

LINK10NP

LINK10NP

LINK10NP

LK72

LK77

LK82

LK87

LINK10NP

LINK10NP

LINK10NP

LINK15NP

LK73

LK78

LK83

LK88

LINK10NP

LINK10NP

LINK10NP

LINK10NP

LK74

LK79

LK84

LK89

LINK10NP

LINK10NP

LINK10NP

LINK10NP

LK75

LK80

LK85

LK90

LINK10NP

LINK10NP

LINK10NP

LINK10NP

LK280

LK281

LK252

LK253

LINK10NP

LINK10NP

LINK10NP

LINK10NP

LK232

LINK15NP

LK227

LINK20NP

PD312

TARGET1 Y301

LK228

LINK20NP

PD306

TOOLING

LK233

LINK15NP

PD307

TOOLING

LK91

LINK10NP

LK92

LINK10NP

LK93

LINK10NP

LK94

LINK10NP

LK95

LINK10NP

LK255

LINK10NP

LK234

LINK15NP

LK229

LINK20NP

PD308

TOOLING

LK96

LINK10NP

LK97

LINK10NP

LK98

LINK10NP

LK99

LINK10NP

LK300

LINK10NP

LK235

LINK15NP

PD309

TOOLING

LK105

LINK10NP

LK301

LINK10NP

LK246

LINK20NP

LK106

LINK10NP

LK107

LINK10NP

LK108

LINK10NP

LK109

LINK10NP

LK110

LINK10NP

LK236

LINK15NP

PD310

TOOLING

LK111

LINK10NP

LK112

LINK10NP

LK113

LINK10NP

LK114

LINK10NP

LK115

LINK10NP

LK303

LINK10NP

LK247

LINK20NP

Y300

TX WIRE CLIP

LK116

LINK10NP

LK117

LINK10NP

LK118

LINK10NP

LK119

LINK10NP

LK120

LINK10NP

LK304

LINK10NP

LK237

LINK15NP

TX WIRE CLIP

LK121

LINK10NP

LK122

LINK10NP

LK123

LINK10NP

LK124

LINK10NP

LK125

LINK20NP

LK238

LINK15NP

LK248

LINK20NP

LINK17.5NP

LK127

LINK10NP

LK128

LINK10NP

LK129

LINK10NP

LK130

LINK10NP

EL300

Spare Fuse Clip

FUSE CLIP

LK131

LINK10NP

LK132

LINK10NP

LK133

LINK10NP

LK134

LINK10NP

LK135

LINK10NP

LK249

LINK20NP

LK136

LINK10NP

LK137

LINK10NP

LK138

LINK10NP

LK139

LINK10NP

LK140

LINK10NP

LK240

LINK15NP

LK141

LINK10NP

LK142

LINK10NP

LK143

LINK10NP

LK145

LINK10NP

LK241

LINK15NP

LK250

LINK20NP

LK148

LINK10NP

LK149

LINK10NP

LK150

LINK10NP

LK151

LINK10NP

LK152

LINK10NP

LK153

LINK10NP

LK154

LINK10NP

LK155

LINK10NP

LK242

LINK15NP

LK251

LINK20NP

LK156

LINK10NP

LK157

LINK10NP

LK158

LINK10NP

LK159

LINK10NP

LK160

LINK10NP

LK243

LINK15NP

LK161

LINK10NP

LK162

LINK10NP

LK163

LINK10NP

LK164

LINK10NP

LK165

LINK10NP

LK254

LINK20NP

LK166

LINK10NP

LK167

LINK10NP

LK244

LINK15NP

LK178

LINK10NP

LK179

LINK10NP

LK180

LINK10NP

LK245

LINK15NP

LK181

LINK10NP

LK182

LINK10NP

LK183

LINK10NP

LK185

LINK10NP

LK256

LINK15NP

LK186

LINK10NP

LK187

LINK10NP

LK188

LINK10NP

LK189

LINK10NP

LK190

LINK10NP

LK257

LINK15NP

LK191

LINK10NP

LK192

LINK10NP

LK193

LINK10NP

LK194

LINK10NP

LK195

LINK10NP

LK196

LINK10NP

LK197

LINK10NP

LK198

LINK10NP

LK199

LINK10NP

LK258

LINK10NP

LK265

LINK15NP

PCB1

L940PB_A

PCB

DD300

PCB MATERIAL

CEM1, 2 OZ Cu

CEM1_20Z

PS300

Photo Strip

PHOTO_STRIP

DD302

A1 Horizontal

Paper Marker

DD_A1H

WARNING SAFETY CRITICAL COMPONENT

REPLACE WITH IDENTICAL PART

USE 'exlude A65' FILTER FOR BOM

DRAWING TITLE

A & R Cambridge Ltd.

Pembroke Avenue

Waterbeach

Cambridge CB5 9PB

A65 PLUS AMP

Filename:

L942C2_1.0.SCH

Notes:

POWER SUPPLY

Contact Engineer:

Contact Tel: (01223) 203 200Travis Pierce

ECO No. DESCRIPTION OF CHANGE

TGP 12/12/01 PRODUCTION RELEASE 1.001_E020

INITIALS

Printed:

DATE

11-Dec-2001

2 7Sheet of

DRAWING NO.

L942C2

ISSUE

Page 10

C700

100U EL 100V

0V_HF

+

Q700

BC556B

R701

100R MF

R702

100R MF

Q701

BC556B

R715

47R MF

Q702

BC556B

0V_HF

+38V_R

C713

100N PE 100V

C714

100N PE 100V

0V_HF

+37V

+

C706

100U 50V YXF LOW Z

D701

ZENER 400MW 27V

SPLS700

PWRRIGHT

C723

100N PE 100V

+

C702

22U SILMIC 2

R700

1K0 MF

C703

100P PPW

0V_SIG

R712

100K MF

0V_HF

Q719

BC546B

R732

12K MF

+

C701

100U EL 100V

Q706

BC546B

R713

47R MF

Q708

BC546B

Q707

BC546B

R717

680R MF

R714

47R MF

0V_HF

Q718

BC546B

R733

12K MF

C705

100U SILMIC 2

0V_SIG

R718

10K MF

R719

10K MF

Q709

BC546B

D700

4V7 400MW

C704

100P PPW

C710

100N PE 100V

R716

2K7 MF

+

R711

100K MF

+

C724

100U 25V ZA EL

+

C716

10U EL

Q704

2SA970GR

R720

10K MF

R703

100R MF

Q711

2SC2240GR

R721

470K MF

C725

10U EL

C707 100P PPW

+

Q703

2SA970GR

C711

100N PE 100V

Q710

2SC2240GR

R704

100R MF

C712

100N PE 100V

RV700

220R PSET

0V_HF

C708

100P PPW

-38V_R

Q714

SAP15N

Q715

SAP15P

+

C709

100U 50V YXF LOW Z

Bias-R +

SET BIAS TO 12mV

Bias-R -

C715

100N PE 100V

0V_HF

-37V

D703

1N4003F

D704

1N4003F

R727

430R MF

R728

430R MF

R706

100R MF

R707

100R MF

R725

6K8 MF

R705

100R MF

+

C717

10U EL

+

C718

10U EL

R708

100R MF

R726

6K8 MF

Q713

BC546B

D702

ZENER 400MW 27V

D705

1N4148

Q712

2SC2240GR

0V_LS_R

Q716

2SA970GR

R724

10K MF

R709

100R MF

A1

R730

4R7 W2 CF

C719

100N PE 100V

R723

10K MF

D706

1N4148

Q717

ZTX653

R710

100R MF

L700

2U2H LAC SMALL

R731

2R2 CF

A1

SP2_RETN_R

470P CD

OP_R

RLY1B

RLY G5Z-2A-E

SPLE700

0V_LS_R

PD6

C720

0V_LS_R

C722

1N0 CD

SPLD700

C721

470P CD

Bot+

SK700B

SPKSKT_G

Bot-

SK700C

CHASS

SPKSKT_G

SP2_SEND_R

Top+

SK700A

SPKSKT_G

Top-

SP700

21mm x 32mm

SELF ADHESIVE

Q2 PAD

E852MC

Q2-PAD-SAP

SP701

21mm x 32mm

SELF ADHESIVE

Q2 PAD

E852MC

Q2-PAD-SAP

USE 'exlude A65' FILTER FOR BOM

DRAWING TITLE

A & R Cambridge Ltd.

Pembroke Avenue

Waterbeach

Cambridge CB5 9PB

A65 PLUS AMP

Filename:

L942C6_1.0.SCH

Notes:

Right Channel Power Amplifier

Contact Engineer:

Contact Tel: (01223) 203 200Travis Pierce

ECO No. DESCRIPTION OF CHANGE

TGP 12/12/01 PRODUCTION RELEASE 1.001_E020

INITIALS

Printed:

DATE

11-Dec-2001

6 7Sheet of

DRAWING NO.

L942C6

ISSUE

Page 11

SELOPL

R200

24K MF

RV167A

10K LIN POT

R210

10K MF

0V_SIG

C197

10P CD

Z160A

2

3

4560D

R212

68K MF

1

C200

+

47U EL 35V

R202

4K7 MF

Tone controls :

8dB cut and boost

BASS

RV166A

10K LIN POT

C204

220N PE

R214

3K3 MF

RV165A

10K LIN POT

TREBLE

Pot arrow shows max boost

R205

4K7 MF

C208

4N7 PP

R204

4K7 MF

C206

220N PE

R216

3K3 MF

0V_SIG

3

2

Z161A

4560D

C210

100P PP

1

LK200

LINK10NP

C202

+

10U EL

0V_SIG

123

R232

100K MF

SW162A

2PCO

SK162

HPSKT

LHC

RHC

SW163A

2PCO

123

PROT_OP_L

4

HPSW1

5

L

HPSW2 SP2_SEND_L

2

3

1

6

7

R

R236

100R W2 CF

330R 1W CF

PROT_OP_R

R237

100R W2 CF

R161

330R 1W CF

R162

456

SW163B

2PCO

LK170

1

2

3

4

5

6

7

L825CA

LK171

1

2

3

4

5

6

7

L825CA

SP2_RETN_L

SP2_RETN_R

SP2_SEND_R

OP_L

OP_R

0V_LS_R

SELOPR

LK168

L809CA

1

2

3

4

5

6

7

8

RV164C

6A360M

+

+ -

VOLUME POT SNAP OFF BOARD

R201

24K MF

RV167B

10K LIN POT

C195

10N CD

R213

10K MF

0V_SIG

10P CD

68K MF

Z160B

6

5

4560D

C196

R211

RV164A

6A360M

RV164B

6A360M

VOLMOTA161

2W CABLE HOLDER

1 2

7

RV164D

9

Case

7

6A360M

C201

+

47U EL 35V

R203

4K7 MF

C205

220N PE

Tone controls :

8dB cut and boost

R215

3K3 MF

BASS

R206

RV166B

4K7 MF

10K LIN POT

C207

220N PE

R207

4K7 MF

C209

4N7 PP

R217

RV165B

10K LIN POT

TREBLE

Pot arrow shows max boost

3K3 MF

0V_SIG

5

6

Z161B

4560D

C211

100P PP

7

LK239

LINK10NP

C203

+

10U EL

0V_SIG

0V_SIG

R233

100K MF

LK169

1

2

3

4

5

6

7

8

L809CA

SW162B

2PCO

456

+15V

LK176

1 2

10MM LINK

Fit on A65 only

C216

100N CD

C217

100N CD

LK177

1 2

10MM LINK

Fit on A65 only

+15v

-15v

0V_SIG

0V_SIG

0V_SIG

R234

100K MF

R235

100K MF

0V_SIG

0V_SIG

Z163A

3

2

OPA2134PA

R240

1K0 MF

Z163B

5

6

OPA2134PA

R160

1K0 MF

1

7

R230

47R MF

C227

100P PPW

R238

1K2 MF

R231

47R MF

C228

100P PPW

R239

1K2 MF

0V_SIG

-15v

PREMUTE161

PREMUTE

Z171

1

SEL1

2

D1

3

S1

4

VGND5VL

6

S4

7

D4

8

SEL4

DG413DJ

PREMUTE

SEL2

SEL3

16

15

D2

CUT LINK IF CIM FITTED (8P ONLY)

14

S2

+15v

13

V+

+5v

12

11

S3

D3

PREMUTE

0V_SIG

10

CUT LINK IF CIM FITTED (8P ONLY)

9

+15v

-15v

+15v

1 2

+15v

1 2

C223

100N CD

0V_SIG

C224

100N CD

D164

1N4148

LK173

10MM LINK

PWRRIGHT

D166

1N4148

LK172

10MM LINK

PWRLEFT

D165

1N4148

D167

1N4148

-15v

0V_SIG

-15v

0V_SIG

R208

100K MF

R209

100K MF

FIT LINKS FOR 8P

FIT LINK FOR 8P ONLY

SK101B

5

BOT

6

0V_SIG

4

TOP

PHONO4G

FIT LINK FOR 8P ONLY

N

F

PREAMP OUT

84

Z163C

OPA2134PA

Z160C

4560D

84

Z161C

4560D

84

0V_SIG

-15V

C213

100N CD

+

C215

22U EL

+

C214.

22U EL

C220

100N CD

C218

100N CD

C221

100N CD

C219

100N CD

C222

100N CD

USE 'exlude A65' FILTER FOR BOM

DRAWING TITLE

A & R Cambridge Ltd.

Pembroke Avenue

Waterbeach

Cambridge CB5 9PB

A65 PLUS AMP

Filename:

L942C4_1.0.SCH

Notes:

Pre-amp Out, Tone & Headphone

Contact Engineer:

01_E020

Contact Tel: (01223) 203 200Travis Pierce

ECO No. DESCRIPTION OF CHANGE

TGP 12/12/01 PRODUCTION RELEASE 1.0

DATE

INITIALS

11-Dec-2001

Printed:

4 7Sheet of

DRAWING NO.

L942C4

ISSUE

Page 12

PHONO & INPUTS

L940C3_1.0.SCH

ACSENSE

PROT_OP_L

PROT_OP_R

PROTECTION MUTE

TAPECONTROL

MUX2

MUX3

PROT SENSE

SELOPL

SELOPR

HPSW2

TAPOL

TAPOR

MUX1

HPSW1

REMOTE CONTROL

L940C7_1.0.SCH

MUTE

MUX1

MUX2

MUX3

PROT SENSE

TONE CONTROL

L940C4_1.0.SCH

AVCONTROL

PREMUTE

TAPECONTROL

SELOPL

SELOPR

HPSW2

HPSW1

PREMUTE

ACLT1

PROT_OP_R

PROT_OP_L

PWRLEFT

PWRRIGHT

TAPOL

TAPOR

SP2_SEND_L

SP2_RETN_L

OP_L

OP_R

SP2_SEND_R

SP2_RETN_R

AVCONTROL

LEFT CHANNEL

L940C5_1.0.SCH

SP2_SEND_L

SP2_RETN_L

PWRLEFT

RIGHT CHANNEL

L940C6_1.0.SCH

PWRRIGHT

SP2_SEND_R

SP2_RETN_R

PROTECTION

OP_L

A1

A1

OP_R

A1

A1

POWER SUPPLY

L940C2_1.0.SCH

ACLT1

ACSENSE

USE EXCLUDE NF TO CREATE RUN OUT SHEET FOR A75

USE EXCLUDE A65 TO CREATE RUN OUT SHEET FOR A65

DRAWING TITLE

A & R Cambridge Ltd.

Pembroke Avenue

Waterbeach

Cambridge CB5 9PB

A75 PLUS AMP

Filename:

L940C1_1.0.prj

Notes:

TOP SHEET FOR A75 L940AY

Contact Engineer:

TGP

01_E020 12/12/01 PRODUCTION RELEASE 1.0

ECO No. DESCRIPTION OF CHANGE

INITIALS

11-Dec-2001

Contact Tel: (01223) 203 200Travis Pierce

Printed:

DATE

1 7Sheet of

DRAWING NO.

L940C1

ISSUE

Page 13

C600

100U EL 100V

0V_HF

+

Q600

BC556B

R601

100R MF

R602

100R MF

Q601

BC556B

R615

47R MF

Q602

BC556B

C613

100N PE 100V

0V_HF

+38V_L

C614

100N PE 100V

0V_HF

+37V

+

C606

100U 50V YXF LOW Z

D601

ZENER 400MW 27V

R621

680R MF

C609

22N CD

PWRLEFT

C623

100N PE 100V

C602

+

22U SILMIC 2

R600

1K0 MF

C603

100P PPW

0V_SIG

R612

100K MF

0V_HF

R632

12K MF

Q619

BC546B

+

C601

100U EL 100V

Q606

BC546B

R613

47R MF

Q607

BC546B

47R MF

R617

680R MF

R614

Q608

BC546B

R633

12K MF

100U SILMIC 2

0V_HF

Q618

BC546B

C605

R618

10K MF

R619

10K MF

CL600

E856MC

HS600

E81801-75

C604

100P PPW

R616

2K7 MF

+

0V_SIG

Q609

BC546B

D600

4V7 400MW

CL601

E856MC

HS601

E81801-75

C610

100N PE 100V

R611

100K MF

C624

+

100U 25V ZA EL

2SC2240GR

+

C616

10U EL

Q611

HS602

E81801-75

Q604

2SA970GR

R620

10K MF

R603

100R MF

SP600

21mm x 32mm

SELF ADHESIVE

Q2 PAD

E852MC

Q2-PAD-SAP

HS603

E81801-75

2SA970GR

R634

470K MF

C625

10U EL

C607 100P PPW

SP601

21mm x 32mm

SELF ADHESIVE

Q2-PAD-SAP

Q2 PAD

E852MC

Q603

+

C611

100N PE 100V

Q610

2SC2240GR

R604

100R MF

C612

100N PE 100V

RV600

220R PSET

0V_HF

C608

100P PPW

-38V_L

Q614

SAP15N

Q615

SAP15P

C626

100U 50V YXF LOW Z

+

Bias-L +

SET BIAS TO 12mV

Bias-L -

C615

100N PE 100V

0V_HF

-37V

D603

1N4003F

D604

1N4003F

R627

430R MF

R628

430R MF

R606

100R MF

R607

100R MF

R626

6K8 MF

Q605

BC556B

R625

6K8 MF

R605

100R MF

C617

+

10U EL

+

C618

10U EL

R608

100R MF

Q613

BC546B

D602

ZENER 400MW 27V

R622

10K MF

D605

1N4148

Q612

2SC2240GR

0V_LS_L

Q616

2SA970GR

R624

10K MF

R609

100R MF

A1

R630

4R7 W2 CF

C619

100N PE 100V

R623

10K MF

D606

1N4148

Q617

ZTX653

R610

100R MF

R629

47K MF

PROTECTION

L600

2U2H LAC SMALL

R631

2R2 CF

A1

USE EXCLUDE NF TO CREATE RUN OUT SHEET FOR A75

USE EXCLUDE A65 TO CREATE RUN OUT SHEET FOR A65

DRAWING TITLE

A & R Cambridge Ltd.

Pembroke Avenue

Waterbeach

Cambridge CB5 9PB

A75 PLUS AMP

Filename:

L940C5_1.0.SCH

Notes:

Left Channel Power Amplifier

Contact Engineer:

Contact Tel: (01223) 203 200Travis Pierce

ECO No. DESCRIPTION OF CHANGE

SPLS600

SP2_RETN_L

C620

470P CD

0V_LS_L

OP_L

RLY1A

RLY G5Z-2A-E

SPLE600

0V_LS_L

C622

PD6

1N0 CD

TGP01_E020 12/12/01 PRODUCTION RELEASE 1.0

DATE

INITIALS

11-Dec-2001

Printed:

SPLD600

C621

470P CD

5 7Sheet of

Bot+

SK600B

SPKSKT_G

Bot-

SK600C

CHASS

SPKSKT_G

SP2_SEND_L

Top+

SK600A

SPKSKT_G

Top-

DRAWING NO.

L940C5

ISSUE

Page 14

ACLT1

R900

1R0 FU

MOTE900

C900

10N CD

0V_DIG

D906

1N4003F

R903

100R MF

R902

+

C914

100R MF

220U EL

0V_DIG

GND1Case

REMOTE SENSOR SNAP OFF BOARD

R904

10R MF

D908

ZENER 5V1 400MW

RX900

PIC-26043TM2

3

2

O/P

+5V

O/P

Case

GND +5V

IR RX

SUPPORT PAD

SP1

IR RX SUPPORT PAD

+5v

R901

12K MF

+

C901

100U EL

0V_DIG

+5v

+

3WAY CABLE HOLDER

LK900

1

2

3

L856CA

D907

1N4003F

R905

33K MF

C915

100U EL

LK903

Q900

BC556B

1 2

1

2

3

+5V

P900

LK901

10MM LINK

REMO900

0V_DIG

C912

10N CD

3

5

4

6

9

0V_DIG

+5V

C916

100N CD

0V_DIG

PROT SENSE

CC1

MC1

REF

MC2

CC2

1

2

3

4

5

6

7

8

9

10

11

12

13

14

Z900

PB5

PB4

PA3

PA2

PA1

PA0

PB3

PB2

PB1

PB0

VSS

(TMR)/INT

PC0

PC1

+5V

Z905

8

BA6109

VCC17VCC2

VOLUME DRIVEMOTOR DRIVER

28

PB6

27

PB7

26

PA4

25

PA5

24

PA6

23

PA7

22

OSC2

21

OSC1

20

VDD

19

RES

HT48R30 28-DIP-B-0

18

PC5

17

PC4

16

PC3

15

PC2

R913

10K MF

5

6WP7

SCL

SDA

4

VSS

3

0V_DIG

+

C920

1M0 25V

0V_DIG 0V_DIG

2

MD1

1

GND

0V_DIG

10

MD2

8

VDD

A01A12A2

Z906

24C01

C917

100N CD

C913

10N CD

D910

1N4148

R912

100K MF

+5v

MOTSUP900

+5v

+ C921

10U EL

0V_DIG

R914

4K7 MF

C918

100N CD

VOLM901

VOLMOT900

1Y271

1 2

VOLM900

X900

0V_DIG

CST4.00

D911

1N4148

0V_DIG

SK900

FFC10V

10

Disp H

Disp G

Disp I

SW900A

2PCO_NON_LAT

123

456

SW900B

2PCO_NON_LAT

MUTE

PREMUTE

Disp D

Disp F

Disp E

TAPECONTROL

AVCONTROL

MUX1

MUX2

MUX3

Disp C

Disp B

Disp A

123456789

0V_DIG

0V_DIG

13

14

15

12

1

5

2

4

6

11

10

9

7

Z907A

74HC4051

X0

X1

X2

X3

X4

X5

X6

X7

INH

A

B

C

VEE

3

X

R915

220R MF

+5v

0V_DIG

+5v

C919

100N CD

16

Z907B

VDD

GND

74HC4051

8

WARNING SAFETY CRITICAL COMPONENT

REPLACE WITH IDENTICAL PART

USE EXCLUDE NF TO CREATE RUN OUT SHEET FOR A75

USE EXCLUDE A65 TO CREATE RUN OUT SHEET FOR A65

DRAWING TITLE

A & R Cambridge Ltd.

Pembroke Avenue

Waterbeach

Cambridge CB5 9PB

A75 PLUS AMP

Filename:

L940C7_1.0.SCH

Notes:

uC, Volume Drive & Remote Control

Contact Engineer:

TGP01_E020 12/12/01 PRODUCTION RELEASE 1.0

ECO No. DESCRIPTION OF CHANGE

INITIALS

11-Dec-2001

Contact Tel: (01223) 203 200Travis Pierce

Printed:

DATE

7 7Sheet of

DRAWING NO.

L940C7

ISSUE

Page 15

PHONO4G

TUNER

VCR

PHONO4G

TAPE IN

SK100A

EMC

PHONO4G

PHINR

SK100B

CD

SK103A

PHONO4G

SK103B

AV/DVD

SK102A

PHONO4G

SK102B

PHONO4G

F

N

+15v

D101

1N4148

1

PHINL

0V_SIG

+15v

D100

1N4148

CDL

4

TOP

BOT

EMC

EMC

+15v

F

6

N

F

N

F

N

F

N

F

N

1N4148

0V_SIG

5

CDR

+15v

1N4148

TUNL

1

+15v

1N4148

0V_SIG

TUNR

+15v

1N4148

VCRL

+15v

1N4148

0V_SIG 0V_SIG

VCRR

+15v

1N4148

DVDL

1

+15v

1N4148

0V_SIG 0V_SIG

DVDR

+15v

1N4148

TAPL

+15v

1N4148

0V_SIG 0V_SIG

TAPR

+15v

1N4148

LK101

10MM LINK

1 2

D103

1N4148

LK102

1 2

10MM LINK

D102

1N4148

-15v

R118

1K0 MF

D104

1N4148

R119

1K0 MF

D105

1N4148

R121

1K0 MF

D108

1N4148

R122

1K0 MF

D109

1N4148

R123

1K0 MF

D110

1N4148

R124

1K0 MF

D111

1N4148

R125

1K0 MF

D120

1N4148

R126

1K0 MF

D121

1N4148

R127

D122

1N4148

R128

1K0 MF

D123

1N4148

-15v

D106

D107

D112

D113

D114

D115

D124

D125

1K0 MF

D126

D127

101112

SW100D

4PCO

SW100B

4PCO

456

789

SW100C

4PCO

SW100A

4PCO

123

-15v

-15v

-15v

-15v

-15v

-15v

-15v

-15v

-15v

-15v

0V_SIG

0V_SIG

0V_SIG

0V_SIG

0V_SIG

0V_SIG

0V_SIG

0V_SIG

0V_SIG

R130

100K MF

VCROR

R131

100K MF

TUNOL

R133

100K MF

TUNOR

R134

100K MF

CDOL

R135

100K MF

CDOR

R136

100K MF

DVDOL

R137

100K MF

DVDOR

R142

100K MF

TAPEOL

R143

100K MF

TAPEOR

R144

100K MF

C120

VCROL

C119

100P PP

R101

100P PP

C134

470P PPW

C135

470P PPW

C137

470P PPW

C138

470P PPW

C139

470P PPW

C140

470P PPW

C141

470P PPW

C142

470P PPW

C143

470P PPW

C144

470P PPW

R100

47K MF

+

C123

47P CD

47K MF

+

0V_SIG

C124

47P CD

R108

470R MF

C125

22U EL

0V_SIG

R109

470R MF

C126

22U EL

5

6

4N7 PP

3

2

R111

680K MF

C128

Z100A

NE5532

R110

680K MF

C127

4N7 PP

Z100B

NE5532

7

1

R113

56K MF

C130

1N3 PP

R112

56K MF

C129

1N3 PP

C131

+

22U EL

1 2

C132

+

22U EL

1 2

MUX1

MUX2

MUX3

LK103

10MM LINK

LK104

10MM LINK

AUXOL

VCROL

TUNOL

CDOL

DVDOL

AUXOR

VCROR

TUNOR

CDOR

DVDOR

MUX1

MUX2

MUX3

R114

8K2 MF

R115

8K2 MF

0V_SIG

0V_SIG

R116

18K MF

R120

1K0 MF

0V_SIG

0V_SIG

+5v

Z100C

NE5532

R117

1K0 MF

0V_SIG

+5v

84

R132

100K MF

+15V

-15V

+15V

-15V

0V_SIG

AUXOR

4

5

6

7

12

11

10

9

2

1

16

15

14

3

-15v

4

5

6

7

12

11

10

9

2

1

16

15

14

3

-15v

C112

100N CD

C113

100N CD

C101

100N CD

0V_SIG

C102

100N CD

R129

100K MF

Z102

X0

X1

X2

X3

X4

X5

X6

X7

EN

A0

A1

A2

GND

V-

DG408DJ

Z103

X0

X1

X2

X3

X4

X5

X6

X7

EN

A0

A1

A2

GND

V-

DG408DJ

AUXOL

C136

470P PPW

V+

D

V+

D

+

C145

10U EL

+

C146

10U EL

C133

470P PPW

+15v

13

8

0V_SIG

0V_SIG

+15v

13

8

0V_SIG

R139

100K MF

R138

100K MF

0V_SIG

+15v

100N CD

100N CD

-15v

+15v

-15v

C107

C108

C109

100N CD

C114

100N CD

C115

100N CD

C116

100N CD

+15v

Z104C

TL072

-15v

LED100

G

3WAY CABLE HOLDER

R

LED RED/GRN 3MM

ACSENSE

R156

C147

100U NP

Therm

1K5 MF

0V_SIG

0V_SIG

PROT_OP_L

SK101A

TAPE OUT

EMC

PHONO4G

+15v

D117

Z104A

3

2

TL072

Z104B

5

6

TL072

84

R154

1

47R MF

C122

100P PP

+15v

R155

7

47R MF

C121

100P PP

+15v

C110

100N CD

-15v

C118

100N CD

0V_SIG0V_SIG0V_SIG

1N4148

D116

1N4148

D119

1N4148

D118

1N4148

TAPOL

1

F

N

0V_SIG

TAPOR

TAPOR

-15v

-15v

-15v

0V_SIG

TAPEOL

TAPECONTROL

Z105

1

SEL1

2

D1

3

S1

4

VGND5VL

6

S4

7

D4

8

SEL4

DG413DJ

TAPECONTROL

TAPEOR

TAPOL

SEL2

SEL3

D2

S2

V+

S3

D3

16

15

14

13

+5v

12

11

10

9

TAPECONTROL

MUX1

MUX2

MUX3

+15v

TAPECONTROL

USE EXCLUDE NF TO CREATE RUN OUT SHEET FOR A75

USE EXCLUDE A65 TO CREATE RUN OUT SHEET FOR A65

DRAWING TITLE

A & R Cambridge Ltd.

Pembroke Avenue

Waterbeach

Cambridge CB5 9PB

A75 AMPLIFIER PLUS

R102

47K MF

R103

47K MF

TH100

PTH90DEG

C151

+

100U SILMIC 2

C152

+

100U SILMIC 2

MUX1

MUX2

MUX3

Filename:

L940C3_1.0.SCH

Notes:

Phono Stage & Input Selection

Contact Engineer:

R140

100K MF

R141

100K MF

SELOPL

PROTECTION

D128

1N4003F

R148

470R FU

AC Det

R104

47K MF

0V_HF 0V_HF

R105

47K MF

R157

100K MF

SELOPR

Contact Tel: (01223) 203 200Travis Pierce

C148

+

1U0 EL

C153

10N CD

R149

100K MF

2

3

LK100

L856CA

LK100A

1

2

3

IN1

IN2

0V_HF

1

PWR

V-

5

C117

470P CD

R106

47K MF

RC

1

2

3

C149

100U EL

8

RC

0V

4

R150

100K MF

0V_HF

9

V+

FB

7

D134

5V6 400MW

+

O

C150

D131

5V6 400MW

+37V

R145

10K MF

Z101

TA7317P

6

0V_HF

D130

1N4003F

R107

47K MF

R146

2K7 1W CF

C154

100N PE 100V

+

1U0 EL

R151

18K MF

-37V

ECO No. DESCRIPTION OF CHANGE

R152

33K MF

0V_HF

0V_HF

TGP01_E020 12/12/01 PRODUCTION RELEASE 1.0

DATE

INITIALS

11-Dec-2001

Printed:

3 7Sheet of

+37V

RLY1C

RLY G5Z-2A-E

R153

1K0 1W CF

HPSW1

MUTEPROT_OP_R

Prot

D132

1N4148

R147

2K7 1W CF

D129

1N4003F

R158

47K MF

HPSW2

DRAWING NO.

Q100

2SC2240GR

PROT SENSE

L940C3

ISSUE

Page 16

C300

3N3 MAINS

MAINS_N300

MAINS_E300

MAINS_L300

MAINS INPUT

SK300

IEC3

N E L

E

N

A1007

PD300

TOOLING

0V_HF

L

C301

3N3 MAINS

MAINS SWITCH

SW300B

SW300A

A1007

CS1

220N X2 CLASS

Chassis Earth Point,

Use correct screw and washer.

R300

100R MF

R311

D304

D305

0V_SIG

R312

10R FU

10R FU

+ C312

220U EL 50V

0V_HF0V_PSU

+ C313

220U EL 50V

C317

100N CD

100N CD

Q300

BC546B

Q302

BC556B

+

C106

1U0 EL

+

C105

1U0 EL

+38V_R

+38V_R

C319

100N CD

C320

-37V_R -37V_L

100N CDC318

-38V_R

Z300

7805

I

Vin

Vout

GND

G

D306

10V 400MW

D307

10V 400MW

G

GND

I

Vin

Vout

Z301

7905

Q304

BC546B

+38V_L

Q305

BC556B

O

O

+37V_L

-38V_L

+15V

+

C315

100U EL

+

C316

100U EL

-15V

+300

-300

FS300

AS1A25

C302

3N3 MAINS

SELECT VOLTAGE

BY FITTING FS201

OR FS202

T300

FS301

AS2A5_115V

GREEN300

FIT ONLY ONE FUSE

T301

BLUE300

SK302

1

CAGECLAMP1

3

Orange

2

Dark Grey

1

Blue

SK301

CAGECLAMP3

Green

230V

115V

SCREEN

TX300

L816TX

9Vac

SK303

1

Grey

2

Grey

CAGECLAMP2

BLUE301

SK304

1

Orange

2

Blue

3

Orange

CAGECLAMP3A

ACSENSE

EL

EARTH LEAD

8M101

EARTH LEAD

AC

OR301

ACLT1

0V_DIG

OR300

3

C314

100P CD

C304

+

47U EL 100V

C305

47U EL 100V

+

+37V

1

BR300

+

~

-

4

2

~

BRGBU8D

+

C308

10M EL 50V

10M EL 50V

+

C309

-37V

C306

100N PE 100V

0V_SIG

0V_DIG

C307

100N PE 100V

0V_HF

D301

1N4003F

D302

1N4003F

0V_PSU

D300

1N4003F

D303

1N4003F

PSUP300

0V_LS_L

SP300

STAR_10

NSUP300

0V_HF

C310

+

100U EL 100V

ZENER 500MW 39V

C311

+

100U EL 100V

ZENER 500MW 39V

0V_LS_R

R301

4K7 MF

R302

4K7 MF

DO NOT USE THE FOLLOWING NUMBERS AS LINKS - THE DESIGNATORS ARE ALREADY USED ON OTHER PARTS OF THIS CCT!

LK100, LK101, LK102, LK103, LK104, LK168, LK170, LK171, LK172, LK173, LK174, LK175, LK176, LK177,LK200, LK239

LK1

LINK10NP

LK2

LINK10NP

LK3

LINK10NP

LK4

LINK10NP

LK5

LINK10NP

LK201

LINK10NP

LK212

LINK15NP

LK220

LINK20NP

LK267

LINK17.5NP

LK268

LINK17.5NP

LK269

LINK15NP

LK6

LINK10NP

LK7

LINK10NP

LK8

LINK10NP

LK9

LINK10NP

LK10

LINK10NP

LK202

LINK10NP

LK213

LINK15NP

LK11

LINK10NP

LK12

LINK10NP

LK13

LINK10NP

LK14

LINK10NP

LK15

LINK10NP

LK203

LINK10NP

LK221

LINK20NP

LK270

LINK17.5NP

LK271

LINK15NP

LK272

LINK17.5NP

LK16

LINK10NP

LK17

LINK10NP

LK18

LINK10NP

LK19

LINK10NP

LK20

LINK10NP

LK204

LINK10NP

LK214

LINK15NP

LK21

LINK10NP

LK22

LINK10NP

LK23

LINK10NP

LK24

LINK10NP

LK25

LINK10NP

LK205

LINK10NP

LK215

LINK15NP

LK222

LINK20NP

LK26

LINK10NP

LK27

LINK10NP

LK28

LK08NP

LK29

LINK10NP

LK30

LINK10NP

LK206

LINK10NP

LK31

LINK10NP

LK32

LINK10NP

LK33

LINK10NP

LK34

LINK10NP

LK35

LINK10NP

LK207

LINK10NP

LK216

LINK15NP

LK223

LINK20NP

LK36

LINK10NP

LK37

LINK10NP

LK38

LINK10NP

LK39

LINK10NP

LK40

LINK10NP

LK208

LINK10NP

LK217

LINK15NP

PD301

TOOLING

LK41

LINK10NP

LK42

LINK10NP

LK43

LINK10NP

LK44

LINK10NP

LK45

LINK10NP

LK209

LINK10NP

LK224

LINK20NP

PCB1

L940PB_1

PD302

TOOLING

PCB

LK46

LINK10NP

LK47

LINK10NP

LK48

LINK10NP

LK49

LINK10NP

LK50

LINK10NP

LK210

LINK10NP

LK218

LINK15NP

LK51

LINK10NP

LK52

LINK10NP

LK53

LINK10NP

LK54

LINK10NP

LK55

LINK10NP

LK211

LINK10NP

LK225

LINK20NP

PD304

TOOLING

LK56

LINK10NP

LK57

LINK10NP

LK58

LINK10NP

LK59

LINK10NP

LK60

LINK10NP

LK277

LINK10NP

LK219

LINK15NP

C303

1N0 CD

0V_DIG

PD305

TOOLING

LK61

LINK10NP

LK62

LINK10NP

LK63

LINK10NP

LK64

LINK10NP

LK65

LINK10NP

LK278

LINK10NP

LK230

LINK15NP

LK226

LINK20NP

PD303

TOOLING

LK66

LINK10NP

LK67

LINK10NP

LK68

LINK10NP

LK69

LINK10NP

LK70

LINK10NP

LK279

LINK10NP

LK231

LINK15NP

PD311

TARGET1

PS300

Photo Strip

PHOTO_STRIP

LK71

LK76

LK81

LK86

LINK10NP

LINK10NP

LINK10NP

LINK10NP

LK72

LK77

LK82

LK87

LINK10NP

LINK10NP

LINK10NP

LINK15NP

LK73

LK78

LK83

LK88

LINK10NP

LINK10NP

LINK10NP

LINK10NP

LK74

LK79

LK84

LK89

LINK10NP

LINK10NP

LINK10NP

LINK10NP

LK75

LK80

LK85

LK90

LINK10NP

LINK10NP

LINK10NP

LINK10NP

LK280

LK281

LK252

LK253

LINK10NP

LINK10NP

LINK10NP

LINK10NP

LK232

LINK15NP

LK227

LINK20NP

PD312

TARGET1 Y301

UD1

Update Box

UPDATE_BOX

LK228

LINK20NP

PD306

TOOLING

LK233

LINK15NP

PD307

TOOLING

LK91

LINK10NP

LK92

LINK10NP

LK93

LINK10NP

LK94

LINK10NP

LK95

LINK10NP

LK255

LINK10NP

LK234

LINK15NP

LK229

LINK20NP

PD308

TOOLING

LK96

LINK10NP

LK97

LINK10NP

LK98

LINK10NP

LK99

LINK10NP

LK300

LINK10NP

LK235

LINK15NP

PD309

TOOLING

WARNING SAFETY CRITICAL COMPONENT

REPLACE WITH IDENTICAL PART

LK105

LINK10NP

LK301

LINK10NP

LK246

LINK20NP

LK106

LINK10NP

LK107

LINK10NP

LK108

LINK10NP

LK109

LINK10NP

LK110

LINK10NP

LK236

LINK15NP

PD310

TOOLING

TX WIRE CLIP

LK111

LINK10NP

LK112

LINK10NP

LK113

LINK10NP

LK114

LINK10NP

LK115

LINK10NP

LK303

LINK10NP

LK247

LINK20NP

Y300

LK116

LINK10NP

LK117

LINK10NP

LK118

LINK10NP

LK119

LINK10NP

LK120

LINK10NP

LK304

LINK10NP

LK237

LINK15NP

TX WIRE CLIP

LK121

LINK10NP

LK122

LINK10NP

LK123

LINK10NP

LK124

LINK10NP

LK125

LINK20NP

LK238

LINK15NP

LK248

LINK20NP

LK126

LK131

LK136

LINK17.5NP

LK127

LINK10NP

LK128

LINK10NP

LK129

LINK10NP

LK130

LINK10NP

EL300

Spare Fuse Clip

FUSE CLIP

LINK10NP

LK132

LINK10NP

LK133

LINK10NP

LK134

LINK10NP

LK135

LINK10NP

LK249

LINK20NP

LINK10NP

LK137

LINK10NP

LK138

LINK10NP

LK139

LINK10NP

LK140

LINK10NP

LK240

LINK15NP

LK141

LINK10NP

LK142

LINK10NP

LK143

LINK10NP

LK145

LINK10NP

LK241

LINK15NP

LK250

LINK20NP

LK148

LINK10NP

LK149

LINK10NP

LK150

LINK10NP

LK151

LINK10NP

LK152

LINK10NP

LK153

LINK10NP

LK154

LINK10NP

LK155

LINK10NP

LK242

LINK15NP

LK251

LINK20NP

LK156

LINK10NP

LK157

LINK10NP

LK158

LINK10NP

LK159

LINK10NP

LK160

LINK10NP

LK243

LINK15NP

LK161

LINK10NP

LK162

LINK10NP

LK163

LINK10NP

LK164

LINK10NP

LK165

LINK10NP

LK254

LINK20NP

LK166

LINK10NP

LK167

LINK10NP

LK244

LINK15NP

USE EXCLUDE NF TO CREATE RUN OUT SHEET FOR A75

USE EXCLUDE A65 TO CREATE RUN OUT SHEET FOR A65

DRAWING TITLE

A & R Cambridge Ltd.

Pembroke Avenue

Waterbeach