Page 1

P1 AmpliÞer

ARCAM

Bringing music & movies to life

Service

Manual

Issue 1.0

ARCAM

Bringing music & movies to life

Page 2

!

Circuit description

!

Circuit diagrams

o

L929AY switch PCB

o L962AY amplifier main PCB

!

Transformers

o L929TX – 115/230VAC toroidal

o L927TX – 100VAC toroidal

o

L907TX – 100VAC frame

!

Exploded view diagram

Contents List

!

Mechanical & packing parts list

!

Circuit board silk screen & parts list

o L929AY switch PCB

o L962AY amplifier main PCB

Page 3

Fmj P1 Amplifier circuit description

roduct description

P

The

P1 has been has been designed to

by A.Moore

provide unsurpassed sound quality, the main

design features are as follows.

Gain switchable between Arcam gain

o

and THX gain (29dB closed loop) a 0dB

signal equates to 100 watts into 8

ohms.

P

ower supply/Control description

The

mains input is applied via SKT1. Y

capacitors C1 and C2 and X capacitor, C5

provide filtering and EMC suppression R2

provides a discharge path for the capacitors.

SW1 allows the selection of the mains voltage

that the unit will operate from, the main standby

transformer TX1 and the main transformer TX2

have duel primary windings, these windings are

connected in parallel for 115v operation and in

series for 230v operation.

o Input switchable between unbalance

phono and balance XLR.

o The amp is capable of producing >180

watts of sinusoidal output into an 8

ohm load and greater than 300 watts

into a 3.2 ohm load (subject to thermal

dissipation limits).

o Relay coupled for silent on/off

operation.

o Opto-isolated fault and control lines to

the control PCB.

o DC coupled signal path with

integrating servo to remove residual

DC errors.

o Instantaneous safe operating area

protection.

o Exceptionally low harmonic and

intermodulatiion distortion.

o Flat frequency response.

o Fast and asymmetric slew rate.

High damping factor

o

o Unconditionally stable into loads of

upto +/- 90-degree phase.

TX1 is powered at all times when a mains

voltage is applied to the mains input socket the

secondary of this transformer is fused by via FS3

and rectified by diode bridge DBR1 and

regulated to 5V by low dropout regulator at

location REG2 to provide a constant +5v(D)

supply for the micro.

Please note

: the digital supply ground is

connected to the chassis ground via a 100-ohm

resistor.

Relay RLY1 provides a means of powering the

main transformer for normal operation (as

apposed to standby operation where only TX1 is

powered) this relay is under the control of the

Micro IC1 and SW3 on the control board the

relay contacts of RLY1 are suppressed by C3

and C4 these prevent sparking and increase the

relay life span.

The circuitry around TR10 functions as a mains

present detection circuit A.C is feed into this

circuit before the Bridge network at location

DBR1 when mains is present the circuit drives HI

via opto-coupler TR11.

Relay 2 is the speaker output control relay this is

used to prevent clicks and pops at power/power

down and to disconnect the speaker output

under a fault condition, this relay is controlled by

the Micro at location IC1 as the P1 has no

manual speaker switching capabilities the micro

will automatically initialise the speaker relay 3

seconds after power up, the control line SPKR1

on pin 5 of CON 4 switches high to switch the

relay ON via TR9.

Page 4

The P1 has two trigger inputs these are

applied by SKT2 and are wire OR-ed by D5

and D6. The single trigger signal is clamped

to 4v7 by DZ1 and fed to the control card by

CON4. Applying a 12v trigger signal to

either (or both) trigger inputs on the SKT2

instructs the microcontroller to enable or

disable the power amplifier. The trigger will

be seen as a HI line on Pin 11 of CON 4.

The P1 also provides two 2 triggered

outputs. These are current limited 12v D.C

levels, which are used to provide trigger

signals to other units within the customer’s

installation. The 12v output is present when

transformer TX2 is live i.e. when the unit is

not in standby.

TX2 has a Low voltage secondary winding

that supplies the trigger outputs only via

bridge rectifier DBR4 this is fed into REG1

(7812) regulator, TR1 and TR2 offer a

60mA current limit for both trigger outputs

and the entire circuit stage is fused by FS6

(T315mA) in case of overload.

The P1 utilizes a fairly unique

amp

power supply configuration these

main power

include.

The VAS stage is supplied by higher voltage

rails than the following output driver stage, this

allows the driver stage to fully saturate the

output driver stage without the use of a boot

strap circuit. This supply is exceptionally quite

and is critical to the sound quality of the P1.

Amplifier Stage

The

XLR connector at CON100 allows

balanced inputs to be applied to the amplifier

and CON101 allows for the balanced signal to

be daisy chained to a second P1.

The signal from CON100 is driven into IC100

this is a Balanced to single ended converter it

supplies a signal-ended output from a single

XLR input. The IC derives it power supply rails

from the +/- 67v rails these are dropped to

+/- 15v by the TR100 and TR114.

The unbalanced inputs signal arrives at

SKT100; the selection between the two input

options is accomplished by SW100. The

selected signal is clamped +/- 5v3 by the series

Zeners at location DZ103 and DZ104 this is to

prevent damage to the input of op-amp IC200,

due to leaky source signal or electrostatic

discharges.

Fig 1. Power amp power supplies.

Power supply Powers

+/- 67v D.C VAS stage.

+/- 58v D.C Output driver stage.

The t

wo sets of supplies are driven from

their own secondary windings and bridge

rectifier circuits DBR5 and DBR6 Rectify

the +/- 58v rails these are smoothed by

20,000uf of capacitance per phase. DBR2

and DBR3 are supplying the +/- 70v rails

these are dropped to +/- 67 by the Network

of R5, R6, R7, R8 and TR3, TR4, TR5, TR6

this is not a regulated supply as the rails

need to track the +/- 58v rails under mains

power fluctuations.

Please note: The +/- 70v rails are

individually fused by 315mA(T) fuses at

locations FS4 and FS5.

SW101 allows for the selection of two gain

settings these are 28.3 for “THX” and 37.5 for

the Arcam setting. The roll off setting is

340Khz.

The main power amplifier circuit is a classic

current feed-back design and can be thought of

as a large current feed-back op-amp the

topology is a refined high power output variant

of the A90/P7 design.

Op-amp IC101 is configured as a non-inverting

amplifier with a gain of 2. It’s purpose is to

provide current outputs (via it’s own power

supply pins) and a current input via it’s output

pin, the Op-amp performs the voltage to

current conversion (I-V) and phase splitting

necessary to drive the voltage gain stage. The

current feed-back occurs because the output of

IC101 drives into a 44 ohm load formed by the

two 22 ohm resistors R142 and R143 down to

ground, the power

Cont///

Page 5

supply pin currents are half wave-rectified

versions of the drive current of the amplifier.

This causes the voltage gain, which is buffered

and passed on to the outputs. The feedback

from pin 1 of IC101 acts to reduce the gain of the

amplifier; when this current is roughly equal to

the current required to drive the input signal into

44-ohm’s equilibrium is reached and the closed

loop gain is defined. The output stage provides

the vast majority of the current required to drive

the 44-ohm load. The op-amp only needs to

provide a very small error current to give the

required voltage magnification.

Transistors TR101 and TR116 are common base

amplifiers their purpose is to provide the +/- 15v

rails necessary to drive the op-amp whilst

allowing the power supply currents that are

drawn to pass through into the Wilson current

mirror stage, this is formed by PNP transistors

TR102, TR104 and TR122 the NPN mirror is

formed by TR115, TR117 and TR122.

TR103 combines the two current mirrors to

provide a very high-gain current to voltage

(transresistance) gain stage roughly 80dB at low

frequency C114 and C132 with R149, R150

combine to give a open-loop pole at roughly

10Khz and a corresponding open-loop zero

around 500Khz. This allows for good time

domain performance and clean square wave

reproduction with no sign of ringing or overshoot.

Diodes D100 and D101 act to limit the current

through TR115 and TR112, if the input current

exceeds 14mA the diodes conduct and the

transresistance stage becomes a constant

current source killing the open loop gain and

preventing damage to the transistors.

TR103 provides a 4.7v bias voltage to allow

the following pre-driver stage to operate in

Class A.

TR123 and TR125 form a Class A pre-driver

emitter follower stage to boost the current gain

and isolate the transresistance stage from the

output transistors. TR105 and TR118 act as a

30mA current limit and prevent the destruction

of TR123 and TR125 under a fault condition.

R109, R164, R110 and R165 loosely decouple

the emitters of TR123 and TR125 from the

output stage.

TR128, TR129 and TR126, TR127 are Sanken

SAP 15N and SAP 15P Bi-polar output drivers

RV100 is the Bias adjust preset D104 protect

the Output drivers from destruction if RV100

goes open circuit.

C144 to C147 provide local R.F stability and

prevent oscillation. D111 and D112 are catch

diodes to reduce the effects of back-EMF from

the loudspeaker coils/load.

R164, R183, C150 and L100 form the Zobel

network, these components ensure that the

amplifier sees a constant load of 4.7 ohms at

high at very high frequencies and improve

stability – reduce H.F noise. L100 and R183

decouple the load at high frequencies to

ensure amplifier stability into capacitive loads.

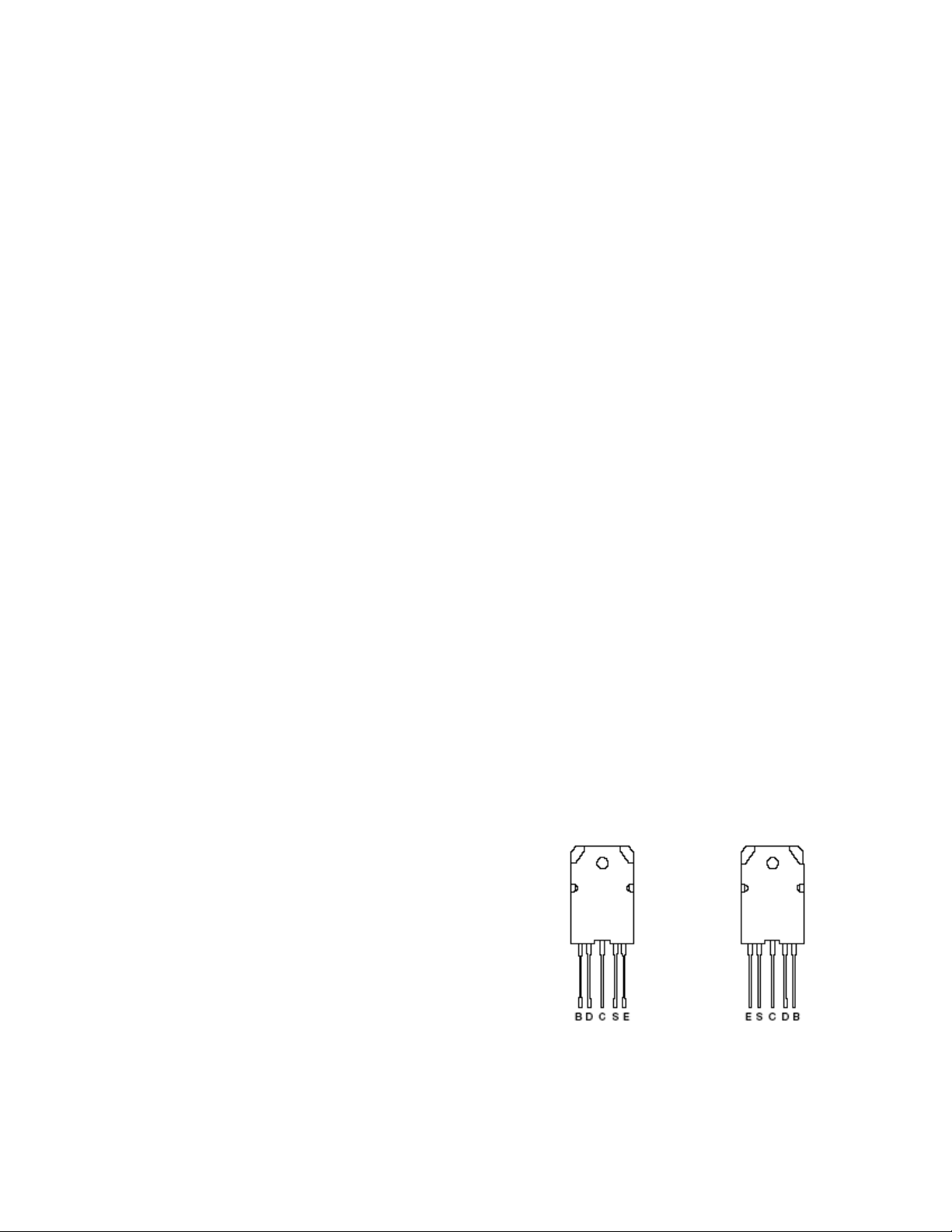

SAP 15NY SAP 15PY

IC101 forms a D.C intergrating servo. Its

purpose is to remove residual D.C errors due to

slight device mismatch and component

tolerances. It is configured as an inverting

intergrator with a time constant of <0.5 seconds.

Any D.C offset at the output of the amplifier will

cause the output if the op-amp to go negative

increasing the current in the negative supply pin

and thus pulling the output down to ground (and

SAP

vica versa). D108 protects the inverting input of

the op-amp under fault condition.

S-E 0.22 Ohm

Under output driver failure conditions the 0.22 internal

emitter resistor will usually go open, the resistor should be

measured between pins S and E.

Page 6

Protection circuit block

The P

1 Power amplifier incorporates 4 modes of

protection these are as follows.

o Instantaneous VI current limiting.

D.C offset protection.

o

o Over-Temperature.

o Insulation failure.

VI current

The

limit circuit is built around TR106

and TR119 they sense the voltage across the

0.22-emitter resistors (hence emitter current) and

the collector emitter current or device power

dissipation exceeds a preset limit.

The circuit is designed to allow large unrestricted

currents into loads of 3 ohms and above but limit

the current into a short circuit or very low

impedance loads.

C141, C142 and R162, R163 form a 2.2ms time

constant, which will allow larger transients of

current delivery for a few milliseconds, to ensure

that the amplifier has a sufficiently large transient

capability to drive “difficult” loudspeaker loads.

TR106 senses positive current surges and

TR119 senses negative surges these intern

activate TR107 and switch the optocoupler

OPTO100A this fault notification is sent to the

microcontroller and the output relay is switched

off to protect the amplifier/loudspeaker coils.

D.C offset

The

protection is built around TR108

and TR109 a positive D.C offset will switch

TR108, a negative D.C offset will switch TR120

this will intern switch TR110 and TR109 on in

either case this causes the optocoupler at

location OPTO100B to transmit a fault line signal

to the micro.

RTH100 is low when the amplifier is cool

typically a few hundred ohms, in the event of a

thermal overload situation (Above 110 c)

RTH100 will go into a high impedance state

this will switch TR121 on and intern this will

switch TR111 on and cause OPTO 100C to

send a fault line flag to the micro.

The remaining protection stage is an

insulation breakdown detect circuit this is

essentially looking for a breakdown of the

insulating pad between the output devices and

the heatsinks thus +60v path to ground.

The protection is formed around bridge rectifier

package DBR100, this will route current

through the LED in optocoupler OPTO 100D in

the event that the DGND and AGND ground

planes move apart by more than 10v. When

the transistor in the Opto conducts the thyristor

formed by TR112 and TR132 is turned On.

Once the Thyristor conducts it pulls the

SHUTDOWN* signal low and turns TR8 (Sheet

2) off thus opening both Speaker relays and

the Power relay.

Please note

: The unit can only be reset once

the mains power supply to the unit has been

removed and the Amplifiers own power

supplies have been given sufficient time to

discharge +30 secs. The standby transformer

of course remains active.

TR130 asserts the microprocessor fault line

DCPROT so that the micro can indicate the

fault via the front panel mounted LED.

Fig 2 Fault line location and operational status.

Pl

ease note:

Con 4 is the connector between

the main board and the display board, use Pin

2 of Con 4 as a reference (DGND).

The Thermistor RTH100 provides

protection

and is connected to the positive

Thermal

supply rails adjacent to the collector leg of the

output driver at location TR125 this allow the

thermistor to sense the temperature of the output

device. The output impedance of

Fault line Location Status

D.C offset Con 4 Pin 9 LOW (0v)

V/I Prot Con 4 Pin 8 LOW (0v)

Thermal Con 4 Pin 7 LOW (0v)

Page 7

Test Specification

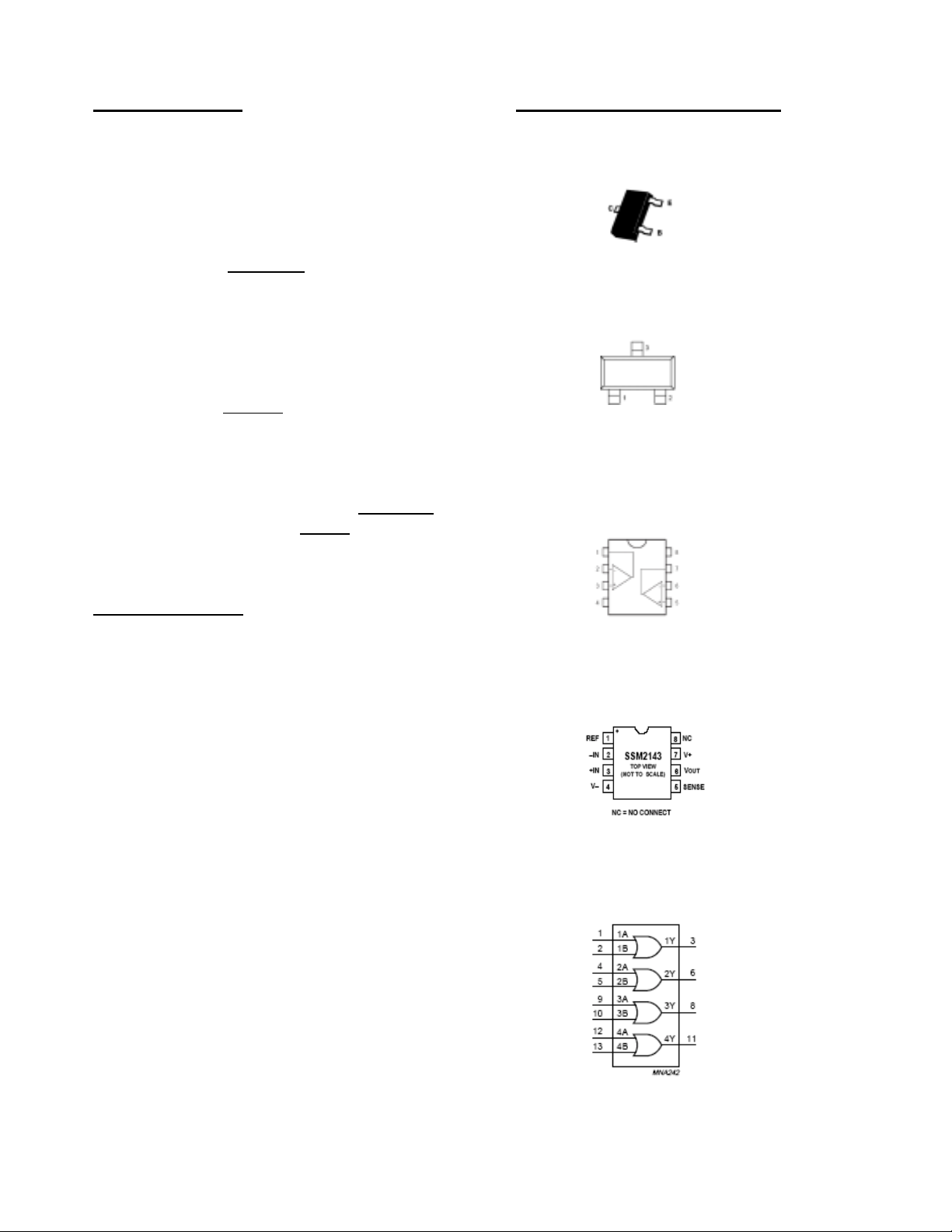

Major component identification.

Fr

equency response

. 8-ohm load

Input set to 1v rms

20Hz – 20kHz = +/- 0.5 dB

Distortion

. THD+N 0dBR 4-ohm load.

.

Input set to 1v rms.

20Hz – 20Khz = <0.02%

aximum output

M

into an 8-ohm load.

Input level set to 1.34 rms 1Khz = 180 watts

di

stortion should be below 0.05%

THD+N

Bias setting notes

FMMT 497/597

BC849/BC859

1=Base

2=Emitter

3=Collector

TLO 72

The bias

of the P1 is set using an Audio

precision audio analysis package and we

calibrate the power stage for minimum THD the

bench set up procedure follows.

o

Set the input signal to 150mv rms,

frequency to 10kHz. Induce a 4-ohm load

at the speaker output.

o

Rotate preset RV100 clockwise and

observe that the THD falls. Continue to

rotate the preset until the THD falls to a

minimum level and just starts to clime

again.

o

Switch input signal off and allow the

amplifier the Quiesce +30secs

o

Measure the bias level at test point Con

103 (Bias read) and confirm the reading is

below the absolute max of 35mV.

SSM2143

74HC32N

Page 8

ITEM1 1 Blank PCB P35/P1 FMJ Amp Microcontroller BoardL929PB

+5V_D

CON1

MOLEX

5229-NAPB

CON2

MOLEX

5229-NAPB

D2

1N4148

DO-35

C8

100UF

25V

YK

R1

10K

0W25

MF

R2

10K

0W25

MF

SP2 LED

SW1

SKHVPB000A

2

SP2 SW

IC2E

74HC32N

DIP-14

14

VCC

7

GND

TR1

BC556B

TO-92

R12

560R

0W25

MF

1

0V_D

LED1

5mm

GRN

LED 5mm

+5V_D

14

13

12

11

10

9

8

7

6

5

4

3

2

1

R22

R23

R24

10K

10K

0W25

MF

R10

10K

0W25

MF

10K

0W25

MF

R11

10K

0W25

MF

0V_D

0V_D

0V_D

0W25

MF

0V_D

+5V_D

14

13

12

11

10

9

8

7

6

5

4

3

2

1

R9

10K

0W25

MF

0V_D

+5V_D

C14

100UF

R19

25V

YK

470R

0W25

MF

R20

470R

0W25

MF

R21

470R

0W25

MF

0V_D

R17

10K

0W25

MF

R18

10K

0W25

MF

R25

10K

0W25

MF

R26

10K

0W25

MF

TR5

BC546B

TO-92

TR6

BC546B

TO-92

TR7

BC546B

TO-92

SPARE1

STANDBY

SPKR1 ON

SPKR2 ON

THERMPROT 1

VIPROT 1

DCPROT 1

AC PRESENT

TRIGGER

REMOTE

SPARE2

STANDBY

SPKR1 ON

SPKR2 ON

THERMPROT 2

VIPROT 2

DCPROT 2

AC PRESENT

TRIGGER

REMOTE

SPKR1 ON

SPKR2 ON

STANDBY

SP2 SW

SP1 SW

SP1 LED

SPKR2 ON

SPKR1 ON

STANDBY

PWR SW

REMOTE

TRIGGER

AC PRESENT

THERMPROT

LK1

0R0

0W25

MF

0V_D

LINK LK1 IS USED

TO CONFIGURE PCB

FOR USE IN P35 OR P1

FOR P35 - LEAVE LK1 INTACT

FOR P1 - CUT LINK

THERMPROT 1

THERMPROT 2

VIPROT 1

VIPROT 2

DCPROT 1

DCPROT 2

SPARE1

SPARE2

0V_D

IC2A

1

2

74HC32N

DIP-14

IC2B

4

5

74HC32N

DIP-14

IC2C

9

10

74HC32N

DIP-14

IC2D

12

13

74HC32N

DIP-14

LK2

0R0

0W25

MF

0V_D

3

6

8

11

IC1

HT48R30A-1

L019SW

DIP-28

1

PB5

2

PB4

3

PA3

4

PA2

5

PA1

6

PA0

7

PB3

8

PB2

9

PB1

10

PB0

11

VSS

12

(TMR)/INT

13

PC0

14

PC1

THERMPROT

VIPROT

DCPROT

SPARE

PB6

PB7

PA4

PA5

PA6

PA7

OSC2

OSC1

VDD

RES

PC5

PC4

PC3

PC2

28

27

26

25

24

23

22

21

20

19

18

17

16

15

DCPROT

VIPROT

SP2 LED

PWR GRN

PWR RED

SPARE

+5V_D

C2

100N

50V

X7R

0V_D

DRAWING TITLE

C1

100N

50V

X7R

D1

1N4148

DO-35

C3

100N

50V

X7R

+5V_D

R16

100K

0W25

MF

C5

10UF

50V

YK

C4

100N

50V

X7R

X1

4 00MHz

SIL-3

3

C6

100UF

25V

YK

1

2

C7

100UF

25V

YK

R3

10K

0W25

MF

R4

10K

0W25

MF

SP1 LED

SW2

SKHVPB000A

1

2

SP1 SW

FIX1

Dia 3.5mm

1

0V_D

TR2

BC556B

TO-92

R13

560R

0W25

MF

LED2

5mm

GRN

LED 5mm

FIX2

Dia 3.5mm

C9

100N

50V

X7R

R5

10K

0W25

MF

R6

10K

0W25

MF

PWR RED

SW3

SKHVPB000A

1

2

PWR SW

FIX3

1

Dia 3.5mm

C10

100N

50V

X7R

TR4

BC556B

TO-92

3mm

BICOL

LED 3mm

RED GRN

FIX4

1

Dia 3 5mm

C11

100N

50V

X7R

R14

330R

0W25

MF

0V_D

1

R15

180R

0W25

MF

TR3

BC556B

TO-92

LED3

FIX5

Dia 3.5mm

C12

100N

50V

X7R

R7

10K

0W25

MF

R8

10K

0W25

MF

PWR GRN

1

C13

100N

50V

X7R

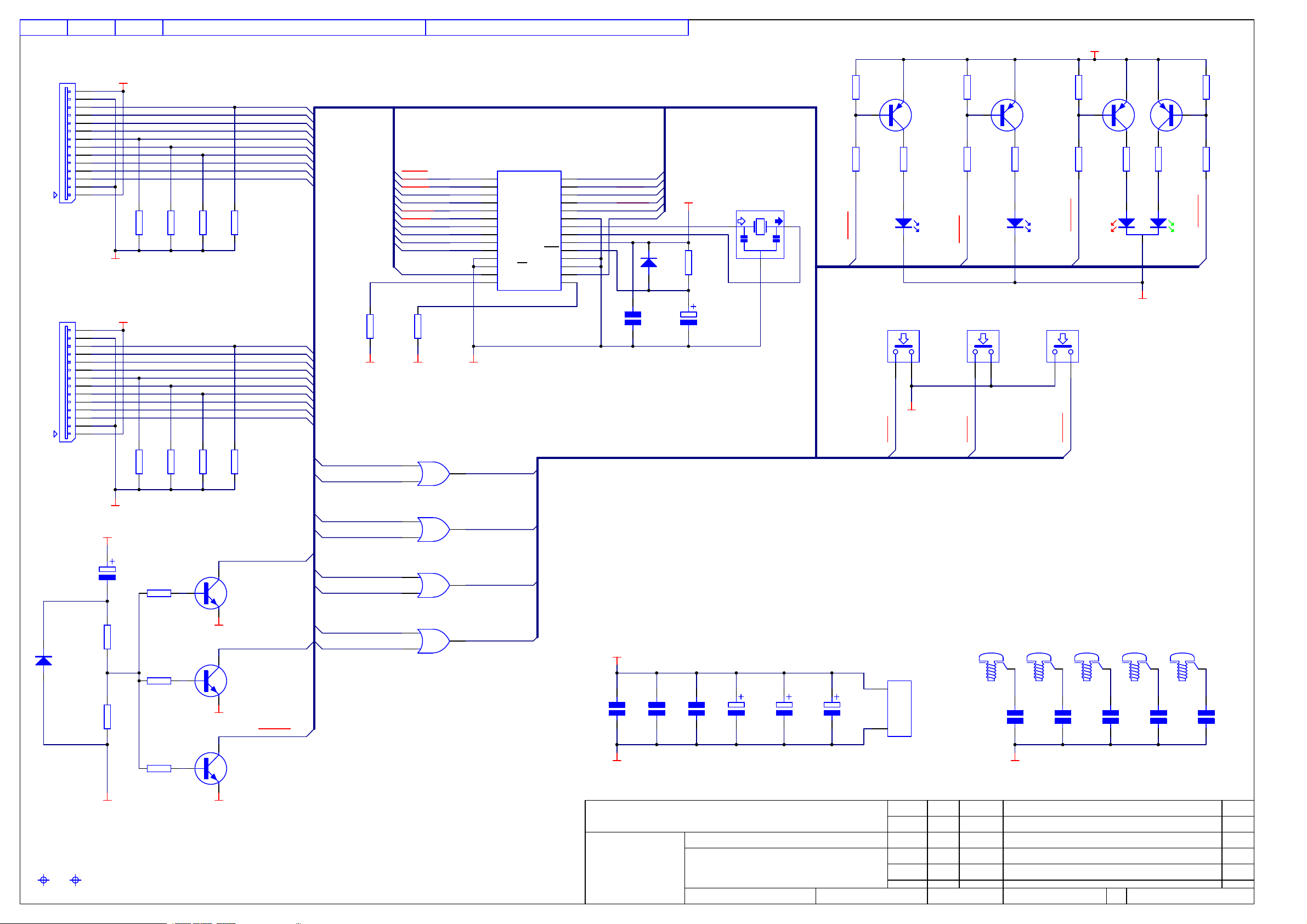

P35 / P1 Switch PCB

TOOL1 TOOL2

ARCAM

A & R Cambridge Ltd.

Pembroke Avenue

Waterbeach

Cambridge CB5 9PB

Filename:

Notes:

Contact Engineer:

L929CT_1.0.sch

KAL 8/05/03 Redrawn, LED1, 2 swapped, Connectors rewired, LK1, 2 added 1.003_E125

WAF 2/01/02 HOLTEK, Z1 UPDATED B.103_E001

JR 1/11/01 LEDS TO 5MM AND MAINS SWITCH B.0

ECO No. DESCRIPTION OF CHANGE

Contact Tel: (01223) 203243Kevin Lamb

INITIALS

Printed:

DATE

13-May-2003

1 1Sheet of

A3

DRAWING NO.

L929CT

ISSUE

Page 9

QTY DESCRIPTIONPART No. NOTESITEM

ITEM1 1 Clip For SW Profile HeatsinkF006

ITEM2 1 Fuseholder Cover For 20mm FuseholderF022

ITEM3 1 Fuseholder Cover For 20mm FuseholderF022

ITEM4 1 Fuseholder Cover For 20mm FuseholderF022

ITEM5 1 Fuseholder Cover For 20mm FuseholderF022

ITEM6 1 Fuseholder Cover For 20mm FuseholderF022

ITEM7 1 Fuseholder Cover For 20mm FuseholderF022 Cover For FHLDR6

ITEM8 1 Blank PCB P1 Amplifier Main BoardL962PB

ITEM9 2 Pad Damping 15x6x3MM Sorbo haneE802AP See Assy Drawing for location

ITEM11 1 Earth Lead Assy 75MM8M101

Clip for REG1

Cover For FHLDR1

Cover For FHLDR2

Cover For FHLDR3

Cover For FHLDR4

Cover For FHLDR5

See Assy Drawing for locationITEM10 3 Pad Damping 7 5x6x3 Sorbo haneE826AP

FD1

FD2

FD3

FD4

L962CT3_2

L962CT3_2 0_Power Amplifier.sch

VIPROT

DC

THERM

SHUTDOWN*

FIX1

CHASSIS1

Dia 3.2mm

FIX3

Dia 3.5mm

1

FIX2

Dia 3.2mm

FIX4

Dia 3.5mm

1

CHASSIS1

L962CT2_2

L962CT2_2.0_PSU and Control.Sch

VIPROT

DC

THERM

SHUTDOWN*

FIX5

Dia 3.5mm

FIX7

Dia 3.5mm

1

1

CHASSIS2

FIX6

Dia 3.5mm

FIX8

Dia 3.5mm

FIX9

Dia 3.5mm

FIX11

Dia 3.5mm

FIX10

Dia 3.5mm

FIX12

Dia 3.5mm

FIX13

Dia 3.5mm

FIX14

Dia 3.5mm

TOOL1

TOOL2

TOOL3

TOOL4

DRAWING TITLE

P1 Amplifier Main PCB

23425

A & R Cambridge Ltd.

Pembroke Avenue

Waterbeach

Cambridge CB5 9PB

Filename:

Notes:

Contact Engineer:

L962CT1_2.0.Sch

03_E249 KAL 2 022/08/03 Stability mods

03_E203 KAL 1 016/07/03 Production Release, VI Limi ing changes

03_E184 KAL B.123/06/03 Changed sorbothane part numbers, corrected R179-182, R185-187

03_E111 KAL B.011/04/03 Corrected CON4, Redesigned protection cct and voicing mods

03_E055 KAL Minor Change to re-label gain switch posi ions A.118/02/03

ECO No. DESCRIPTION OF CHANGE

Contact Tel: (01223) 203243Kevin Lamb

INITIALS

Printed:

DATE

22-Aug-2003

1 1Sheet of

DRAWING NO.

L962CT1

ISSUE

Page 10

SH1

EARTH

EMC Shield

SKT1

BULGIN

PX0580

NEUTRAL

115V 230V

R2

1M5

0W5

VR37

LIVE

2A22B

1A11B

SW1

18-000-0019

FHLDR1

20mm HLDR

FS1 T6.3AS506

FS2 T6.3AS506

FHLDR2

20mm HLDR

RLY1B

Takamisawa

F1CA005V

C1

GREEN

3N3

250V

CER

1

C2

3N3

250V

CER

EARTH

C5

220N

275V

PP X2

N

E

L

CON1

WAGO

256

MAINS WIRING AND AUXILIARY SUPPLY

RLY1A

F1CA005V

Takamisawa

TX1

Open Frame

1 5

C3

3N3

250V

CER

C4

3N3

250V

CER

9V

9V

115V

2

3 7

115V

4

D3

BAS16

SOT-323

HS1A

SW50-2

FS3

6

T315mA

S504

FHLDR3

20mm HLDR

8

CON3

4

5

6

MOLEX

44472

1

2

3

C11

100N

50V

0805

TX WIRE COLOURS

1 BLUE

3 BROWN

4 BLACK

6 WHITE

DBR1

W02G

C21

3300UF

25V

YK

8.8C/W

+5

REG2

L4940V5

TO-220

C12

100N

50V

0805

VP70V VP67V

C13

100N

50V

0805

+5V(D)

DGND

C33

1000UF

10V

YK

D4

BAS16

SOT-323

P3

MAINS PRESENT DETECT

R15

10K

0W25

1206

D6

BAS16

SOT-323

TR10

BC849B

SOT-23

R16

2K2

0W25

1206

C36

100UF

25V

YK

P4

+5V(D)

DGND

R17

4K7

0W25

1206

TR11

MMUN2211LT1

SOT-23

SKT2

HOSIDEN

HSJ

GND1

GND2

SKT3

HOSIDEN

HSJ

GND1

GND2

NC1

NC2

EMCGND

NC1

NC2

D1 BAS16

SOT-323

D2 BAS16

SOT-323

TR1

BD179

TO-126

TR2

FMMT497

SOT-23

R1

10R

0W25

1206

C9

100N

50V

0805

CHASSIS1

C6

100P

100V

0805

R3

3K3

0W25

1206

C10

100N

50V

0805

+12V(D)

CON2

VN70VAC2 VN70VAC1

VP58VAC1

VP58VAC2

VN58VAC1

VN58VAC2

P1

REG1

L7812CV

TO-220

C7

100N

50V

0805

5

4

3

2

1

MOLEX

44472

+12

+18V(D)

DGND

10

9

8

7

6

C8

100N

50V

0805

VP70VAC2

VP70VAC1

VP18VAC2

VP18VAC1

TX WIRE COLOURS

1 GREEN

2 YELLOW

3 ORANGE

4 RED

5 WHITE

6 GREY

7 VIOLET

8 BLACK

9 BROWN

10 BLUE

L1

70R@100MHz

R4

2K2

0W25

1206

DZ1

BZX84C

4V7

SOT-23

DGND

R18

10K

0W25

1206

VP70VAC1

VP70VAC2

VP58VAC1

VP58VAC2

VN58VAC1

VN58VAC2

VN70VAC1

VN70VAC2

VP18VAC2

VP18VAC1

FS4

T315mA

S504

FHLDR4

20mm HLDR

FS5

T315mA

S504

FHLDR5

20mm HLDR

FS6

T315mA

S504

FHLDR6

20mm HLDR

AGND_SIG

AGND_PSU1

AGND_PSU3

C15

100N

100V

MKS2

C16

100N

100V

MKS2

C14

100N

100V

MKS2

DBR5

GBU8D

DBR6

GBU8D

C17

100N

100V

MKS2

DBR4

W02G

C18

100N

100V

MKS2

AGND_PSU2

AGND_RC

SP1

DBR2

W02G

DBR3

W02G

AGND_C1

AGND_LS

AGND_C2

C24

10,000UF

71V

AM

C26

10,000UF

71V

AM

+18V(D)

DGND

AGND_C1

AGND_C2

C32

1000UF

35V

YK

P2

CHASSIS2

C25

10,000UF

71V

AM

C27

10,000UF

71V

AM

100R 0W25

VP58V

VN58V

R12

1206

R19

10K

1W

CF

AGND_PSU3

R20

10K

1W

CF

DGND

C22

1000UF

100V

YK

AGND_PSU2

C23

1000UF

100V

YK

C28

47UF

100V

YK

C29

47UF

100V

YK

DRAWING TITLE

23425

A & R Cambridge Ltd.

Pembroke Avenue

Waterbeach

Cambridge CB5 9PB

TR3

TR4

FMMT497

SOT-23

TR5

FMMT597

SOT-23

TR6

2SC5171

TO-220

C19

100N

100V

MKS2

C20

100N

100V

MKS2

D5

BAS16

SOT-323

2SA1930

TO-220

R13

68K

0W25

1206

R14

68K

0W25

1206

R5

2K2

0W25

1206

R6

2K2

0W25

1206

C30

47UF

100V

YK

C31

47UF

100V

YK

R7

2K2

0W25

1206

R8

2K2

0W25

1206

P1 Amplifier Main PCB

Filename:

L962CT2 2.0 PSU and Control.Sch

Notes:

Contact Engineer:

AGND_PSU1

VN67VVN70V

C34

100UF

100V

YXF

C35

100UF

100V

YXF

+5V(D)

RLY1C

Takamisawa

F1CA005V

DGND

P5

TR7

FMMT497

SOT-23

TR8

FMMT497

SOT-23

SHUTDOWN*

DC

VIPROT

THERM

INITIALS

Printed:

+5V(D)

R10

2K2

0W25

1206

P7

03_E249 KAL 2.022/08/03 Stability mods

03_E203 KAL 1.016/07/03 Production Release, VI Limiting changes

03_E184 KAL B.123/06/03 Changed sorbothane part numbers, corrected R179-182, R185-187

03_E111 KAL B.011/04/03 Corrected CON4, Redesigned protection cct and voicing mods

03_E055 KAL Minor Change to re-label gain switch positions A.118/02/03

Contact Tel: (01223) 203243Kevin Lamb

ECO No. DESCRIPTION OF CHANGE

R9

2K2

0W25

1206

DCPROT

VIPROT

THERMPROT

DATE

22 Aug 2003

D7

BAS16

SOT-323

P6

2 3Sheet of

+12V(D)

AMPLIFIER

MUTING

RELAY

RLY2B

Omron

G2R-1-E-12VDC

TR9

P8

FMMT497

SOT-23

TRIGGER

AC PRESENT

SPKR2 ON

SPKR1 ON

STANDBY*

R11

2K2

0W25

1206

DGND

DRAWING NO.

D8

BAS16

SOT-323

+5V(D)

CON4

14

13

12

11

10

9

8

7

6

5

4

3

2

1

MOLEX

5229-NCPB

L962CT1

TO DISPLAY CARD

ISSUE

Page 11

AGND_S G

CON100

Neutrik

NC3MBH-B

1 2

3

3

G

SELECT XLR

SELECT PHONO

SKT100

KUNMING

GOLD

SCRN

CHASSIS1

15VD

-15VD

21

SW100A

SPUN191 00

CON101

Neutrik

NC3FBH2-B

2 1

D106

BAV99

SOT 23

NC1

C1

NO1

R192

R106

100R 0W25

1206

C126

1N0

100V

FKP2

3

3

SW100B

SPUN191 00

12CON102

NF

VP67V

R125

6K8

0W25

MF

C120

R126

7UF

6K8

TR100

15VD

12

G

NC2

C2

NO2

D107

BAV99

SOT-23

IC100

SSM21 3S

SO-8

7

VCC

SNS

2

N-

VO

3

N

REF

VEE

-15VD

GA N

GA NP7ARCAM

DZ100

BZX8 C

V7

SOT-23

P100

DZ101

BZX8 C

V7

NF

SOT-23

5

6

1

AGND_S G

AGND_SIG

AGND_SIG

SW101A

SPUN191 00

R123

820R

0W25

MF

C100

100N

50V

0805

AGND_PSU1

AGND PSU1

C101

100N

50V

0805

SW101B

SPUN191 00

NC1

C1

NO1

R12

6K8

0W25

MF

C129

70P

100V

FKP2

C127

100UF

25V

CFNE

C128

100UF

25V

CFNE

NC2

GAIN=28.3

C2

GAIN=37.0

NO2

R129

100R

0W25

MF

AGND PSU1

AGND_S G

C102

NF

R100

10R

0W25

1206

R101

10R 0W25

1206

P101

VN67V

FMMT 97

SOT-23

AGND_PSU1

P102

TR11

FMMT597

SOT 23

AGND_PSU1

0W25

MF

R127

6K8

0W25

MF

R128

6K8

0W25

MF

C130

22UF

20V

OSCON

C131

22UF

20V

OSCON

AGND_PSU1

DZ102

DZ103

AGND PSU1

100V

YK

NF

NF

C121

7UF

100V

YK

C109

NF

AGND_S G

C103

REF100

LM 31AIM3

SOT-23

REF101

LM 31AIM3

SOT-23

C112

NF

AGND_SIG

AGND_SIG

C110

100N

100V

MKS2

AGND_S G

C111

100N

100V

MKS2

AGND_SIG

R132

22K

0W25

MF

AGND_SIG

100N

50V

0805

C10

100N

50V

0805

R130

12K

0W25

1206

P103

R10

2K2

0W25

1206

R131

12K

0W25

1206

P10

R105

2K2

0W25

1206

AGND_S G AGND PSU1

R133

D100

7R

BAS16

0W25

SOT-323

1206

P105 P112

TR115

FMMT597

SOT-23

C135

6U8 63V

MKS

R1 2

22R

0W25

MF

R1 3

22R

0W25

MF

AGND_SIG

D101

BAS16

SOT-323

7

R118

K7

0W25

1206

R138

1K5 0W25

MF

R1

1K8 0W25

MF

R1 0

1K5 0W25

MF

R1 6

1K8 0W25

MF

C136

NF

C101B

TL072CD

SO-8

TR101

FMMT 97

SOT-23

C137

10N

50V

0603

AGND_S G

P108

IC101A

TL072CD

8

3

SO-8

1

2

P109

TR116

FMMT597

SOT-23

C138

10N

50V

0603

AGND_S G

TR102

FMMT 97

SOT-23

P111 P116

R13

7R

0W25

1206

6

5

R139

1K5 0W25

MF

R1 5

1K8 0W25

MF

R1 1

1K5 0W25

MF

R1 7

1K8 0W25

MF

AGND_PSU1

P106

P107

R137

0R0

0W25

1206

P110

C113

100N

100V

MKS2

C115

100N

100V

MKS2

C11

100N

100V

MKS2

AGND_PSU1

R1 8

1M0 0W25

D108

BAV99

SOT 23

AGND PSU1

C122

100V

YK

1206

C123

100V

YK

7UF

7UF

R102

6K8 0W25

1206

C132

22UF

20V

OSCON

R103

6K8 0W25

1206

R135

7R

0W25

1206

P113

33P 250V

TR117

FMMT597

SOT-23

TR105

FMMT 97

R168

150K

0W25

MF

SOT-23

TR122

B17 0

SOT-89

C139

PP

TR125

2SC 5 8

SOT-89

P121

R109

P122

100R

R16

0W25

1206

22R

0W25

P131

1206

R175

150R

0W25

1206

C1

7P

200V

0805

Trim output stage Iq

C133

22UF

20V

OSCON

R176

150R

0W25

1206

D10

BAS16

SOT-323

RV100

100R

LIN

C1 5

7P

200V

0805

R165

22R

0W25

1206

P126

TR123

2SA17 0

SOT-89

C116

100N

100V

MKS2

P12

AGND_SIG

R169

150K

0W25

TR103

FMMT 97

SOT-23

R161

22R

0W25

1206

TR12

B 5 8

SOT-89

TR10

FMMT 97

SOT-23

R136

7R

0W25

1206

MF

P123

TR118

FMMT597

SOT-23

R110

100R

P125

0W25

1206

R1 9

6K8

0W25

1206

P11

R150

1K0

0W25

1206

C1 0

33P 250V

PP

P115

D109

SBYV27-200

DO-15

TR126

SAP15NY

SAP

TR128

SAP15PY

SAP

D110

SBYV27-200

DO-15

C117

100N

100V

MKS2

R177

150R

0W25

1206

C13

22UF

20V

OSCON

R178

150R

0W25

1206

VP58V

C12

7UF

100V

YK

Measure Iq

CON103

1

2

HARWIN

M20-973

C125

7UF

100V

YK

VN58V

D111

1N 003

DO- 1

D112

1N 003

DO- 1

BASE1

EMITTER1

OUTPUT

EMITTER2

BASE2

AGND_RC

LS100

G P PRECISION

L100

2U2

R183

10R 2W

CF

R18

R7

2W

CF

C150

7N

100V

MKS2

RLY2A

Omron

G2R-1-E-12VDC

CHASSIS1

AGND_LS

C118

100N

100V

MKS2

AGND_PSU3

C1 6

7P

200V

0805

C1 7

7P

200V

0805

TR127

SAP15NY

SAP

TR129

SAP15PY

SAP

R153

1K0

0W25

1206

R15

1K0

0W25

1206

C119

100N

100V

MKS2

R152

1K0

0W25

1206

R155

1K0

0W25

1206

AGND PSU3

BASE2

BASE1

EMITTER1

OUTPUT

EMITTER2

R167

1K2

0W25

1206

R166

1K2

0W25

1206

P118

R108

330R

0W25

1206

P119

R107

330R

0W25

1206

VP58V

R116

18K

0W25

1206

P117

R189

2K2 0W25

R188

1206

18K

0W25

1206

C1 1

P157

10UF

50V

YK

R162

1K0

0W25

1206

R163

1K0

0W25

1206

C1 2

10UF

50V

YK

R190

18K

0W25

1206

2K2 0W25

P120

R117

18K

0W25

1206

VN58V

DZ105

BZX8 C

33V

SOT-23

DZ106

BZX8 C

33V

SOT-23

P156

R191

1206

D102

BAS16

SOT-323

R111

100R

0W25

1206

R112

100R 0W25

1206

R113

100R 0W25

1206

Instant SOA limiting

D103

BAS16 SOT-323

P127

R179

OPTO100A

PC3Q66Q

MINI FLAT

1

C107

2

100N

R171

50V

0805

22K

0W25

TR106

P128

FMMT 97

C105

SOT-23

100N

50V

0805

C106

100N

50V

0805

TR119

P129

FMMT597

SOT-23

P130

R170

22K

0W25

1206

P135

AGND_PSU3

C1 8

100UF

16V

NONP

1206

P133

R151

1K0

0W25

1206

P13

TR107

FMMT 97

SOT-23

C1 9

100UF

16V

NONP

DC offset detection

5V(D) 5V(D) 5V(D)

16

15

R119

K7

0W25

1206

DGND

R120

K7

0W25

1206

OPTO100B

PC3Q66Q

VIPROT

MINI-FLAT

3 1

P136P132 P137

R172

22K

0W25

1206

P138

D105

BAS16

SOT-323

P139

TR108

FMMT 97

SOT 23

TR120

FMMT597

SOT 23

P1 0

R173

22K

0W25

1206

P1 3 P1

R11

100R

0W25

1206

AGND_PSU3

P1 1

TR110

FMMT 97

SOT-23

13

R121

K7

0W25

1206

DGND

R17

22K

0W25

1206

P1 2

TR109

FMMT 97

SOT-23

R115

100R

0W25

1206

DCPROT

P1 6

DRAWING I LE

23425

A & R Cambridge Ltd

Pembroke Avenue

Waterbeach

Cambridge CB5 9PB

OPTO100C

PC3Q66Q

M NI-FLAT

R180

22K

0W25

1206

5

6

TR111

FMMT 97

SOT 23

12

11

R122

K7

0W25

1206

DGND

Over temperature sensing

DBR100

W02G

C151

AGND_PSU3DGND

100N

50V

0805

DZ107

BZX8 C 6V8

SOT-23

P1 8

P1 Amplifier Main PCB

Fi ename:

L962C 3_2 0_Power Amplifier sch

Notes:

Contact Engineer:

270R

0W25

THERMPROT

1206

P1 5

R181

10K

0W25

P1 7

1206

R182

10K

0W25

1206

OPTO100D

7

8

PC3Q66Q

MINI-FLAT

R156

1K0

0W25

1206

P158

60V DC Output Fault Detect

Contact el: 01223) 203243Kevn Lamb

RTH100

PTC 110DEG

PTC

P1 9

R185

P150

100K

TR121

0W25

1206

FMMT597

SOT-23

R186

120K

0W25

1206

R187

39K

0W25

1206

AGND_PSU3

R159

P151 P152

10

9

1K0 0W25

1206

03_E2 9 KAL 2.022/08/03 Stab lity mods

03_E203 KAL 1.016/07/03 Production Re ease, VI Limiting changes

03_E18 KAL B.123/06/03 Changed sorbothane part numbers, corrected R179-182, R185-187

03_E111 KAL B 011/0 /03

03_E055 KAL Minor Change to re-abel gain switch pos tions A.118/02/03

ECO No DESCRP ION OF CHANGE

NI IALS

Prn ed:

C1 3

DZ10

BZX8 C

100UF

15V

25V

SOT-23

YK

5V(D)

R157

1K0

0W25

1206

P153

R158

C108

1K0

0W25

100N

50V

0805

TR112

BC8 9B

SOT 23

22 Aug 2003

DA E

TR132

1206

BC859B

SOT-23

P155

R160

1K0

0W25

1206

Corrected CON , Redesigned protect on cct and voicing mods

3 3Sheet of

VIPROT

DCPROT

THERMPROT

5V(D)

5V(D)

TR131

MMUN2111LT1

SOT-23

P15

DRAWING NO

TR130

MMUN2111LT1

SOT-23

SHUTDOWN*

TR113

MMUN2211LT1

SOT-23

DGND

VIPROT

DC

THERM

L962CT

ISSUE

Page 12

120mm dia max

windings connect to 10 way molex connector 39-01-2105. Use MOLEX pin

This load current is not typical of normal operation which is considered to be

Transformer Specifica ion For 115/230V P1 transformer

Arcam Part Number L926TX

Material Safety Specification

1. Winding Wire to be Grade 2 (130C ra ing) to BS 60317-4 1995

2. Mylar Polyester Insulator 130C Rated

3. Potting Compound PC3502 E135297(M) or equivalent.

Mechanical Specification

1. Centre of transformer to be potted (as shown).

2. Primary windings connect to 6 way MOLEX connector 39-01-2065.

Secondary

44476-3112.

MOLEX connectors have pin numbers indicated on them. Connectors to be

UL94V0 rated.

Note Molex UL94V0 receptacles may be long lead time items.

Equivalent Conexcon 6740 Series UL94V0 parts may be used.

6 Way receptacle 6740-1060

10 Way receptacle 6740-1100

3. Primary wires are enclosed in a common sleeve. Secondary wires are

enclosed in a common sleeve.

Use UL rated sleeving.

4. All wire lengths in mm. Lengths are +5.0, -0

5. Please adhere rubber insulating pad to bottom of transformer as shown.

Electrical Specification

1. Transformer to have dual 115V primaries to allow parallel opera ion for

115V input and series operation with 230V input.

2. Transformer input voltage range

115V -18% +14% (97.5V to 132 5V)

230V -18% +14% (195V to 265V)

3. Transformer to have 5 secondary windings as show in the adjacent

drawing.

4. Loaded DC voltages specified at 230V AC in (wi h transformer primaries

in series)

5. Each secondary winding to have a full wave (4diode) bridge to produce a

single DC rail.

(AS shown in diagram)

6. Output Capacitance to be as specified per rail.

7. Output voltages to be as specified in table and as shown in diagram.

8. Note. Transformer to be used in a power amplifer. The specified load

currents on the high power rails (VP58V, VN58V) represent the effective

current drawn when the amplifier is loaded to full rated power (200W) into

an 8ohm load and operated continuously.

1/8th of full rated power. SECONDARIES

WHITE

6

3

BROWN

Secondary Winding Voltage and Current Specs

Bridge Rectifier Vf diode = 1.1V per leg = 2.2V Total

(ideal TX assumed)

AC Winding

Connector Latch

46

1253

Pin outs of Molex connectors

As viewed looking down at the end

the wires enter the connector

BLACK

4

5

1

2

BLUE

Label

VP70V

VP58V

VN58V

VN70V

VP18V

10

5

Capacitor

Cout

(uF)

1000

20,000

20,000

1000

1000

10 9

BLUE

WHITE

10 way6 way

BROWN

9

4

RED

12736845

VIOLET

BLACK

7

8

2

3

ORANGE

YELLOW

Effec ive DC

Load Current

(mA)

50

2250

2250

50

175

1mm

GREY

Wires to exit from near top of TX

Such that wires do not obstruct lid

6

Note Lid is only 1mm above top

face of max height transformer

1

GREEN

Secondary

Voltage

(V r m.s.) (Ohm)(Volt) (Volt)

50 8

43 0

43 0

50 8

14.35

Capacitor

Peak Voltage

18.75

COUNTERBORE DIA 25mm

Lid

Rubber insulating pad

Capacitor

Vpk Vmin

(Volt)

70.2

58.8

58.8

70.2

Min Voltage

17.25

69.8

57.8

57.8

69.8

Capacitor

Average

Voltage

70.0

58.3

58.3

70.0

18.0

3

6

50mm

78mm max

SCREEN WIRE GREEN/YELLOW

6 way MOLEX MFIT JNR

4

6 Way Molex

1

40mm

POTTING COMPOUND

7mm DIA HOLE

Rubber insula ing pad to have

7mm minimum diameter hole through centre 6

Load Resistor

to simulate

Load RL

25.6

25.6

1400

102.8

Secondary

Winding r.m.s.

Current

(A r m.s.)

0.251400

8.0

8.0

0.25

0.52

PRIMARIES

BROWN

115Vac

WHITE

BLACK

115Vac

BLUE

200mm

160mm

SCREEN WIRE

PR MARIES

SECONDARIES

50.8Vac

43.0Vac

43.0Vac

50.8Vac

14.35Vac

90 degree

VP70V

VP58V

VN58V

VN70V

VP18V

BLACK

BROWN

RED

ORANGE

YELLOW

GREEN

BLUE

WHITE

GREY

VIOLET

8

9

4

3

2

1

10 Way Molex

10

5

7

Voltage on Reservoir Capacitor

10mS

TEST CIRCUIT

AC IN

Vf = 1.1V

per diode

10 way MOLEX MFIT JNR

Vpk

Vaverage

Vmin

130mm

+VOUT

DRAWING TITLE

+

Cout

RL see above table.

ARCAM

GND

A & R Cambridge Ltd.

Pembroke Avenue

Waterbeach

Cambridge CB5 9PB

POWER TX FOR P1 115/230V

Filename:

Notes:

Contact Engineer:

L926TX_1.0.sch

Contact Tel: (01223) 203243Kevin Lamb

ECO No. DESCRIPTION OF CHANGE

INITIALS

Printed:

DATE

7-Aug-2003

1 1Sheet of

A3

DRAWING NO.

L926TX

1 0Reduced VP58V, VN58V to 43.0VacKAL03_E240

B.3'UL rated sleeving' was 'UL94-V0'SLS03_E193

B.2Added note about UL94-V0 sleevingKAL03_E192

B.1Corrected Schema ic Symbol pin numbersKAL03_E158

B.0Changed Pri wire colours, VP58 and VN58 +1V, lead out formsKAL03_E141

ISSUE

Page 13

Transformer Specifica ion For 100V P1 transformer

windings connect to 10 way molex connector 39-01-2105. Use MOLEX pin

This load current is not typical of normal operation which is considered to be

Arcam Part Number L927TX

Material Safety Specification

1. Winding Wire to be Grade 2 (130C ra ing) to BS 60317-4 1995

2. Mylar Polyester Insulator 130C Rated

3. Potting Compound PC3502 E135297(M) or equivalent.

Mechanical Specification

1. Centre of transformer to be potted (as shown).

2. Primary windings connect to 6 way MOLEX connector 39-01-2065.

Secondary

44476-3112.

MOLEX connectors have pin numbers indicated on them. Connectors to be

UL94V0 rated.

Note Molex UL94V0 receptacles may be long lead time items.

Equivalent Conexcon 6740 Series UL94V0 parts may be used.

6 Way receptacle 6740-1060

10 Way receptacle 6740-1100

3. Primary wires are enclosed in a common sleeve. Secondary wires are

enclosed in a common sleeve.

Use UL rated sleeving.

4. All wire lengths in mm. Lengths are +5.0, -0

5. Please adhere rubber insulating pad to bottom of transformer as shown.

Electrical Specification

1. Transformer to have dual 100V primaries to allow parallel opera ion for

100V input.

2. Transformer input voltage range

100V -15% +15% (85V to 115V)

3. Transformer to have 5 secondary windings as show in the adjacent

drawing.

4. Loaded DC voltages specified at 100V AC in (wi h transformer primaries

in parrallel)

5. Each secondary winding to have a full wave (4diode) bridge to produce a

single DC rail.

(AS shown in diagram)

6. Output Capacitance to be as specified per rail.

7. Output voltages to be as specified in table and as shown in diagram.

8. Note. Transformer to be used in a power amplifer. The specified load

currents on the high power rails (VP58V, VN58V) represent the effective

current drawn when the amplifier is loaded to full rated power (200W) into

an 8ohm load and operated continuously.

1/8th of full rated power.

Connector Latch

46

1253

Pin outs of Molex connectors

As viewed looking down at the end

the wires enter the connector

BLACK

WHITE

4

5

6

1

2

3

BLUE

BROWN

10 9

BLUE

10

5

WHITE

10 way6 way

BROWN

9

4

RED

BLACK

7

8

2

3

ORANGE

12736845

VIOLET

GREY

6

1

GREEN

YELLOW

Wires to exit from near top of TX

Such that wires do not obstruct lid

1mm

Note Lid is only 1mm above top

face of max height transformer

Secondary Winding Voltage and Current Specs

Bridge Rectifier Vf diode = 1.1V per leg = 2.2V Total

(ideal TX assumed)

AC Winding

Label

VP70V

VP58V

VN58V

VN70V

VP18V

Capacitor

Cout

(uF)

1000

20,000

20,000

1000

1000

Effec ive DC

Load Current

(mA)

50

2250

2250

50

175

Secondary

Voltage

(V r m.s.) (Ohm)(Volt) (Volt)

50 8

43 0

43 0

50 8

14.35

Capacitor

Peak Voltage

Vpk Vmin

(Volt)

70.2

58.8

58.8

70.2

18.75

120mm dia max

COUNTERBORE DIA 25mm

Lid

Rubber insulating pad

Capacitor

Min Voltage

69.8

57.8

57.8

69.8

17.25

Capacitor

Average

Voltage

70.0

58.3

58.3

70.0

18.0

SECONDARIES

BLACK

PRIMARIES

50.8Vac

3

6

50mm

78mm max

4

6 Way Molex

1

SCREEN WIRE GREEN/YELLOW

40mm

POTTING COMPOUND

7mm DIA HOLE

Rubber insula ing pad to have

7mm minimum diameter hole through centre 6

BROWN

WHITE

BLACK

BLUE

100Vac

100Vac

43.3Vac

43.3Vac

50.8Vac

14.35Vac

200mm

160mm

SCREEN WIRE

Load Resistor

to simulate

Load RL

25.6

25.6

1400

102.8

Secondary

Winding r.m.s.

Current

(A r m.s.)

0.251400

8.0

8.0

0.25

0.52

PR MARIES

6 way MOLEX MFIT JNR

90 degree

SECONDARIES

VP70V

BROWN

RED

VP58V

ORANGE

YELLOW

VN58V

GREEN

BLUE

VN70V

WHITE

GREY

VP18V

VIOLET

8

9

4

3

2

1

10 Way Molex

10

5

7

Voltage on Reservoir Capacitor

10mS

TEST CIRCUIT

AC IN

Vf = 1.1V

per diode

10 way MOLEX MFIT JNR

Vpk

Vaverage

Vmin

130mm

+VOUT

DRAWING TITLE

+

Cout

RL see above table.

ARCAM

GND

A & R Cambridge Ltd.

Pembroke Avenue

Waterbeach

Cambridge CB5 9PB

POWER TX FOR P1 100V

Filename:

Notes:

Contact Engineer:

L927TX_1.0.sch

1 0Reduced VP58V, VN58V to 43.0VacKAL03_E240

B.1'100V' text was '115/230V', 'UL rated sleeving' was 'UL94-V0'SLS03_E193

B.0Changed voltages as per L926TX, sleeving to be UL94-V0KAL03_E192

A.0Prototype ReleaseKAL03_E006

ECO No. DESCRIPTION OF CHANGE

Contact Tel: (01223) 203243Kevin Lamb

INITIALS

Printed:

DATE

7-Aug-2003

1 1Sheet of

A3

DRAWING NO.

L927TX

ISSUE

Page 14

Page 15

Page 16

P1 Mechanical and packing parts list

Part No Item no Description

GENERAL MECHANICAL PARTS

E200AY 4 Rear Panel Assembly FMJ P1

E212AY 6 FMJ A32 Chassis Assembly

E822PM1 7 Foot Black Alpha

E907MC 9 Koolpad O/P Device Diva A85

E912MC 10 Clamp 85 Amp Transistor

E918HK 11 Heatsink FMJ P1

E921MC 12 Clamp Heatsink Diva P85 3RD Channel

HA3V06A 15 M Screw Torx P/H M3x6MM ST ZP

HA4A12B 16 M Screw Pan Supa M4x12MM ST BLK

HA5K70A 17 Bolt Hex HD M5x70MM ST ZP

HA5L20B 18 M/C Hex HD. Bolt M5-0.8X20MM Steel - Zinc Black Passivate

HA6K50A 19 Bolt Hex HD M6x50MM Mczp

HB25V12B 20 Screw Taptite M2.5X12MM Pan Torx(T8) Steel Zinc Plate Black

HE6V06B 21 Screw Sftp Torx No.6x6MM BLK

HF4V09B 22 Screw Self-Tapping-Sems NO.4 X 9MM Pan Torx-Slot Steel Zinc-Plate BLK

HJ4A00A 23 Nut M4 Full ST ZP

HL4SB 24 Washer M4 Int Shakeproof BLK

HL5CA 25 Bright Washer M5 (Form C) to BS 4320

HL6MA 26 Bright Washer M6 (Mudguard O.D. 20mm)

L915CA 27 Cable FFC 0.1" 14WAY A85 Disp - Pwr

L929AY 28 P35/P1 FMJ Amp Microcontroller Board Assembly

L926TX 29 115/230 VAC Toroid transformer

L927TX 29 100 VAC only Toroid transformer

BLACK CASE PARTS

E210AYB 2 FMJ P1/P35-3 Black Cover Assembly

HA4V06B 3 M Screw Torx M4x6MM Stainless Steel Black

E189AYB 1 FMJ Black P1 Fascia Complete Assembly

Made up of the following parts :-

8Q006 8Q006 FMJ Tact Button Spring

E083AY FMJ A32 Sub-Panel Assy

E199AYB Front Panel Assembly Black FMJ P1

E830MC Badge Metal Arcam FMJ

E847PM Lightpipe FMJ

E894PMB Button Power FMJ A32 Black

HL25AB HL25AB FMJ Tact Button Fastener

E933AY FMJ I/R Window Assy (STD. SCREENED)

HA3A04A M/C Pan Supa M3X4 Stzp

SILVER CASE PARTS

E210AY 2 FMJ P1/P35-3 Silver Cover Assembly

HA4V06S 3 M Screw Torx M4x6MM Stainless Steel Silver

E189AY 1 FMJ Silver P1 Fascia Complete Assembly

Made up of the following parts :-

8Q006 8Q006 FMJ Tact Button Spring

E083AY FMJ A32 Sub-Panel Assy

E199AY Front Panel Assembly Silver FMJ P1

E830MC Badge Metal Arcam FMJ

E847PM Lightpipe FMJ

E894PM Button Power FMJ A32 Silver

HL25AB HL25AB FMJ Tact Button Fastener

E933AY FMJ I/R Window Assy (STD. SCREENED)

HA3A04A M/C Pan Supa M3X4 Stzp

PACKAGING MATERIAL

E827PK Carton Printed FMJ

E828PK End Caps Pair FMJ A22 / P25 / DT26

E826PK Carton Plain FMJ

E967SL FMJ P1 Carton Label

SH139 Handbook FMJ C30/P35/P1 Multi

E888PM Blanking Plug For 4MM Binding Post

Page 17

Page 18

P1 Amplifier display cct board L929AY issue 2.0

Designator Part Description

C1 2A410 Capacitor Ceramic 5mm Pitch 50V 10% 100nF

C2 2A410 Capacitor Ceramic 5mm Pitch 50V 10% 100nF

C3 2A410 Capacitor Ceramic 5mm Pitch 50V 10% 100nF

C4 2A410 Capacitor Ceramic 5mm Pitch 50V 10% 100nF

C5 2N610 Capacitor Radial Electrolytic Dia 5mm Pitch 5mm 10UF 50V

C6 2N710 Capacitor Radial Electrolytic Dia 5mm Pitch 5mm 100UF 25V

C7 2N710 Capacitor Radial Electrolytic Dia 5mm Pitch 5mm 100UF 25V

C8 2N710 Capacitor Radial Electrolytic Dia 5mm Pitch 5mm 100UF 25V

C9 2A410 Capacitor Ceramic 5mm Pitch 50V 10% 100nF

C10 2A410 Capacitor Ceramic 5mm Pitch 50V 10% 100nF

C11 2A410 Capacitor Ceramic 5mm Pitch 50V 10% 100nF

C12 2A410 Capacitor Ceramic 5mm Pitch 50V 10% 100nF

C13 2A410 Capacitor Ceramic 5mm Pitch 50V 10% 100nF

C14 2N710 Capacitor Radial Electrolytic Dia 5mm Pitch 5mm 100UF 25V

CON1 8K7014A Con Series 2.54MM Horiz FFC 14WAY

CON2 8K7014A Con Series 2.54MM Horiz FFC 14WAY

D1 3A4148 Diode Small Signal 1N4148 DO-35 Package

D2 3A4148 Diode Small Signal 1N4148 DO-35 Package

IC1 L019AY Programmed HT48R30A-1 With Software For P35

IC2 5J7432 IC Quad 2 Input OR Gate 74HC32N

ITEM1-1 L929PB Blank PCB P35/P1 FMJ Amp Microcontroller Board

ITEM2-1 8S028N IC Skt 28PIN 0.3IN

LED1 3D001 LED 5mm Green SLR-56MGT32

LED2 3D001 LED 5mm Green SLR-56MGT32

LED3 3D006 LED 3mm Red/Green Tri-Colour L-93WEGW

LK1 1H000 Resistor Metal Film 0.25W 0R0

LK2 1H000 Resistor Metal Film 0.25W 0R0

R1 1H310 Resistor Metal Film 0.25W 1% 10K

R2 1H310 Resistor Metal Film 0.25W 1% 10K

R3 1H310 Resistor Metal Film 0.25W 1% 10K

R4 1H310 Resistor Metal Film 0.25W 1% 10K

R5 1H310 Resistor Metal Film 0.25W 1% 10K

R6 1H310 Resistor Metal Film 0.25W 1% 10K

R7 1H310 Resistor Metal Film 0.25W 1% 10K

R8 1H310 Resistor Metal Film 0.25W 1% 10K

R9 1H310 Resistor Metal Film 0.25W 1% 10K

R10 1H310 Resistor Metal Film 0.25W 1% 10K

R11 1H310 Resistor Metal Film 0.25W 1% 10K

R12 1H156 Resistor Metal Film 0.25W 1% 560R

R13 1H156 Resistor Metal Film 0.25W 1% 560R

R14 1H133 Resistor Metal Film 0.25W 1% 330R

R15 1H118 Resistor Metal Film 0.25W 1% 180R

R16 1H410 Resistor Metal Film 0.25W 1% 100K

R17 1H310 Resistor Metal Film 0.25W 1% 10K

R18 1H310 Resistor Metal Film 0.25W 1% 10K

R19 1H147 Resistor Metal Film 0.25W 1% 470R

R20 1H147 Resistor Metal Film 0.25W 1% 470R

R21 1H147 Resistor Metal Film 0.25W 1% 470R

R22 1H310 Resistor Metal Film 0.25W 1% 10K

R23 1H310 Resistor Metal Film 0.25W 1% 10K

R24 1H310 Resistor Metal Film 0.25W 1% 10K

R25 1H310 Resistor Metal Film 0.25W 1% 10K

R26 1H310 Resistor Metal Film 0.25W 1% 10K

SW1 A1504 Switch Tact 2-PIN Low Prof With Gnd Pin

SW2 A1504 Switch Tact 2-PIN Low Prof With Gnd Pin

SW3 A1504 Switch Tact 2-PIN Low Prof With Gnd Pin

TR1 4A556 Transistor BC556B TO92 Package

TR2 4A556 Transistor BC556B TO92 Package

TR3 4A556 Transistor BC556B TO92 Package

TR4 4A556 Transistor BC556B TO92 Package

TR5 4A546 Transistor BC546B TO92 Package

TR6 4A546 Transistor BC546B TO92 Package

TR7 4A546 Transistor BC546B TO92 Package

X1 7W005 Ceramic Resonator 4.00MHz

Page 19

Page 20

P1 Amplifier main cct board L962AY issue 2.1

Designator Part Description

C1 2K233 Capacitor X1 Y2 Rated Ceramic 7.5mm Pitch 3N3 250V

C2 2K233 Capacitor X1 Y2 Rated Ceramic 7.5mm Pitch 3N3 250V

C3 2K233 Capacitor X1 Y2 Rated Ceramic 7.5mm Pitch 3N3 250V

C4 2K233 Capacitor X1 Y2 Rated Ceramic 7.5mm Pitch 3N3 250V

C5 2D422 Capacitor X2 Boxed Polypropylene 22.5mm Pitch 275V 220NF

C6 2L110 Capacitor SM 0805 NPO Ceramic 5% 100V 100P

C7 2J410 Capacitor SM 0805 X7R Ceramic 10% 50V 100N

C8 2J410 Capacitor SM 0805 X7R Ceramic 10% 50V 100N

C9 2J410 Capacitor SM 0805 X7R Ceramic 10% 50V 100N

C10 2J410 Capacitor SM 0805 X7R Ceramic 10% 50V 100N

C11 2J410 Capacitor SM 0805 X7R Ceramic 10% 50V 100N

C12 2J410 Capacitor SM 0805 X7R Ceramic 10% 50V 100N

C13 2J410 Capacitor SM 0805 X7R Ceramic 10% 50V 100N

C14 2KA410 Capacitor Boxed Polyester 5mm Pitch 5% 100VDC 100N

C15 2KA410 Capacitor Boxed Polyester 5mm Pitch 5% 100VDC 100N

C16 2KA410 Capacitor Boxed Polyester 5mm Pitch 5% 100VDC 100N

C17 2KA410 Capacitor Boxed Polyester 5mm Pitch 5% 100VDC 100N

C18 2KA410 Capacitor Boxed Polyester 5mm Pitch 5% 100VDC 100N

C19 2KA410 Capacitor Boxed Polyester 5mm Pitch 5% 100VDC 100N

C20 2KA410 Capacitor Boxed Polyester 5mm Pitch 5% 100VDC 100N

C21 2N833 Capacitor Radial Electrolytic Dia 16mm Pitch 7.5mm 3300UF 25V

C22 2N810D Capacitor Radial Electrolytic Dia 18mm Pitch 7.5mm 1000UF 100V

C23 2N810D Capacitor Radial Electrolytic Dia 18mm Pitch 7.5mm 1000UF 100V

C24 2P910AM Capacitor Radial Electrolytic Dia 40mm PCB Mount 10,000uF 71V

C25 2P910AM Capacitor Radial Electrolytic Dia 40mm PCB Mount 10,000uF 71V

C26 2P910AM Capacitor Radial Electrolytic Dia 40mm PCB Mount 10,000uF 71V

C27 2P910AM Capacitor Radial Electrolytic Dia 40mm PCB Mount 10,000uF 71V

C28 2N647B Capacitor Radial Electrolytic Dia 10mm Pitch 5mm 47UF 100V

C29 2N647B Capacitor Radial Electrolytic Dia 10mm Pitch 5mm 47UF 100V

C30 2N647B Capacitor Radial Electrolytic Dia 10mm Pitch 5mm 47UF 100V

C31 2N647B Capacitor Radial Electrolytic Dia 10mm Pitch 5mm 47UF 100V

C32 2N810C Capacitor Radial Electrolytic Dia 12.5mm Pitch 5mm 1000UF 35V

C33 2N810A Capacitor Radial Electrolytic Dia 10mm Pitch 5mm 1000UF 10V

C34 2Z710F Capacitor Low Impedance Radial Electrolytic Dia 12.5mm Pitch 5mm 100UF 100V

C35 2Z710F Capacitor Low Impedance Radial Electrolytic Dia 12.5mm Pitch 5mm 100UF 100V

C36 2N710 Capacitor Radial Electrolytic Dia 5mm Pitch 5mm 100UF 25V

C100 2J410 Capacitor SM 0805 X7R Ceramic 10% 50V 100N

C101 2J410 Capacitor SM 0805 X7R Ceramic 10% 50V 100N

C102 2J410 Capacitor SM 0805 X7R Ceramic 10% 50V 100N

C103 2J410 Capacitor SM 0805 X7R Ceramic 10% 50V 100N

C104 2J410 Capacitor SM 0805 X7R Ceramic 10% 50V 100N

C105 2J410 Capacitor SM 0805 X7R Ceramic 10% 50V 100N

C106 2J410 Capacitor SM 0805 X7R Ceramic 10% 50V 100N

C107 2J410 Capacitor SM 0805 X7R Ceramic 10% 50V 100N

C108 2J410 Capacitor SM 0805 X7R Ceramic 10% 50V 100N

C109 2KA410 Capacitor Boxed Polyester 5mm Pitch 5% 100VDC 100N

C110 2KA410 Capacitor Boxed Polyester 5mm Pitch 5% 100VDC 100N

C111 2KA410 Capacitor Boxed Polyester 5mm Pitch 5% 100VDC 100N

C112 2KA410 Capacitor Boxed Polyester 5mm Pitch 5% 100VDC 100N

C113 2KA410 Capacitor Boxed Polyester 5mm Pitch 5% 100VDC 100N

C114 2KA410 Capacitor Boxed Polyester 5mm Pitch 5% 100VDC 100N

C115 2KA410 Capacitor Boxed Polyester 5mm Pitch 5% 100VDC 100N

C116 2KA410 Capacitor Boxed Polyester 5mm Pitch 5% 100VDC 100N

C117 2KA410 Capacitor Boxed Polyester 5mm Pitch 5% 100VDC 100N

C118 2KA410 Capacitor Boxed Polyester 5mm Pitch 5% 100VDC 100N

C119 2KA410 Capacitor Boxed Polyester 5mm Pitch 5% 100VDC 100N

C120 2N647B Capacitor Radial Electrolytic Dia 10mm Pitch 5mm 47UF 100V

C121 2N647B Capacitor Radial Electrolytic Dia 10mm Pitch 5mm 47UF 100V

C122 2N647B Capacitor Radial Electrolytic Dia 10mm Pitch 5mm 47UF 100V

C123 2N647B Capacitor Radial Electrolytic Dia 10mm Pitch 5mm 47UF 100V

C124 2N647B Capacitor Radial Electrolytic Dia 10mm Pitch 5mm 47UF 100V

Page 21

P1 Amplifier main cct board L962AY issue 2.1

Designator Part Description

C125 2N647B Capacitor Radial Electrolytic Dia 10mm Pitch 5mm 47UF 100V

C126 2DA210 Capacitor Boxed Polypropylene 5mm Pitch 100V 5% 1N0

C127 2P710AC Capacitor Radial Electrolytic Elna ROA Series 100UF 25V

C128 2P710AC Capacitor Radial Electrolytic Elna ROA Series 100UF 25V

C129 2DA147 Capacitor Boxed Polypropylene 5mm Pitch 100V 5% 470P

C130 2P622P Capacitor Radial Electrolytic Oscon SP 22UF 20V

C131 2P622P Capacitor Radial Electrolytic Oscon SP 22UF 20V

C132 2P622P Capacitor Radial Electrolytic Oscon SP 22UF 20V

C133 2P622P Capacitor Radial Electrolytic Oscon SP 22UF 20V

C134 2P622P Capacitor Radial Electrolytic Oscon SP 22UF 20V

C135 2KB568 Capacitor Boxed Polyester 22.5mm Pitch 10% 63V 6U8

C136 2KA447 Capacitor Boxed Polyester 5mm Pitch 5% 100VDC 470N

C137 2JC310 Capacitor SM 0603 X7R Ceramic 10% 50V 10N

C138 2JC310 Capacitor SM 0603 X7R Ceramic 10% 50V 10N

C139 2D033W2 Capacitor Boxed Polyprop 5mm Pitch 250V 5% 33P

C140 2D033W2 Capacitor Boxed Polyprop 5mm Pitch 250V 5% 33P

C141 2N610 Capacitor Radial Electrolytic Dia 5mm Pitch 5mm 10UF 50V

C142 2N610 Capacitor Radial Electrolytic Dia 5mm Pitch 5mm 10UF 50V

C143 2N710 Capacitor Radial Electrolytic Dia 5mm Pitch 5mm 100UF 25V

C144 2C047B Capacitor SM 0805 NPO Ceramic 200V 5% 47PF

C145 2C047B Capacitor SM 0805 NPO Ceramic 200V 5% 47PF

C146 2C047B Capacitor SM 0805 NPO Ceramic 200V 5% 47PF

C147 2C047B Capacitor SM 0805 NPO Ceramic 200V 5% 47PF

C148 2V710 Capacitor Non-Polar Radial Electrolytic 100UF 16V

C149 2V710 Capacitor Non-Polar Radial Electrolytic 100UF 16V

C150 2KA347 Capacitor Boxed Polyester 5mm Pitch 5% 100VDC 47N

C151 2J410 Capacitor SM 0805 X7R Ceramic 10% 50V 100N

CON1 8Q003 Con Cage Clamp 1WAY

CON2 8K2310 Con Minifit HCS 10WAY

CON3 8K2306 Con Minifit HCS 6WAY

CON4 8K7014 Con 2.54MM Vertical FFC 14WAY

CON100 8K3101 XLR PCB Male Neutr k NC3MBH-B

CON101 8K3001 XLR PCB Female Neutrik NC3FBH2-B

CON102 8K2402 Con CT Series Vertical 2WAY

CON103 8K6201 Con Single ROW Hdr 0.1IN Vertical 2WAY

D1 3AS16W Diode Surface Mount Small Signal BAS16W SOT-23 Package

D2 3AS16W Diode Surface Mount Small Signal BAS16W SOT-23 Package

D3 3AS16W Diode Surface Mount Small Signal BAS16W SOT-23 Package

D4 3AS16W Diode Surface Mount Small Signal BAS16W SOT-23 Package

D5 3AS16W Diode Surface Mount Small Signal BAS16W SOT-23 Package

D6 3AS16W Diode Surface Mount Small Signal BAS16W SOT-23 Package

D7 3AS16W Diode Surface Mount Small Signal BAS16W SOT-23 Package

D8 3AS16W Diode Surface Mount Small Signal BAS16W SOT-23 Package

D100 3AS16W Diode Surface Mount Small Signal BAS16W SOT-23 Package

D101 3AS16W Diode Surface Mount Small Signal BAS16W SOT-23 Package

D102 3AS16W Diode Surface Mount Small Signal BAS16W SOT-23 Package

D103 3AS16W Diode Surface Mount Small Signal BAS16W SOT-23 Package

D104 3AS16W Diode Surface Mount Small Signal BAS16W SOT-23 Package

D105 3AS16W Diode Surface Mount Small Signal BAS16W SOT-23 Package

D106 3AV99W Diode Dual Surface Mount Small Signal BAV99 SOT-23 Package

D107 3AV99W Diode Dual Surface Mount Small Signal BAV99 SOT-23 Package

D108 3AV99W Diode Dual Surface Mount Small Signal BAV99 SOT-23 Package

D109 3BYV27 Diode SBYV27-200 DO-15 Package

D110 3BYV27 Diode SBYV27-200 DO-15 Package

D111 3B4003 Diode 1N4003 DO-41 Package

D112 3B4003 Diode 1N4003 DO-41 Package

DBR1 3BW02 Diode Bridge Rectifier W02G Plastic Package

DBR2 3BW02 Diode Bridge Rectifier W02G Plastic Package

DBR3 3BW02 Diode Bridge Rectifier W02G Plastic Package

DBR4 3BW02 Diode Bridge Rectifier W02G Plastic Package

DBR5 3BGBU8D Diode Bridge Rectifier GBU8D Plastic Package 8A 200V

Page 22

P1 Amplifier main cct board L962AY issue 2.1

Designator Part Description

DBR6 3BGBU8D Diode Bridge Rectifier GBU8D Plastic Package 8A 200V

DBR100 3BW02 Diode Bridge Rectifier W02G Plastic Package

DZ1 3CW34V7 Zener Diode 0.25W Surface Mount BZX84C4V7 SOT-23 Package

DZ100 3CW34V7 Zener Diode 0.25W Surface Mount BZX84C4V7 SOT-23 Package

DZ101 3CW34V7 Zener Diode 0.25W Surface Mount BZX84C4V7 SOT-23 Package

DZ102 3CW315V Zener Diode 0.25W Surface Mount BZX84C15V SOT-23 Package

DZ103 3CW315V Zener Diode 0.25W Surface Mount BZX84C15V SOT-23 Package

DZ104 3CW315V Zener Diode 0.25W Surface Mount BZX84C15V SOT-23 Package

DZ105 3CW333V Zener Diode 0.25W Surface Mount BZX84C33V SOT-23 Package

DZ106 3CW333V Zener Diode 0.25W Surface Mount BZX84C33V SOT-23 Package

DZ107 3CW310V Zener Diode 0.25W Surface Mount BZX84C10V SOT-23 Package

FHLDR1 8S004 Fuseholder 20MM PCB

FHLDR2 8S004 Fuseholder 20MM PCB

FHLDR3 8S004 Fuseholder 20MM PCB

FHLDR4 8S004 Fuseholder 20MM PCB

FHLDR5 8S004 Fuseholder 20MM PCB

FHLDR6 8S004 Fuseholder 20MM PCB

FS1 C56263 Fuse Bussmann S506 T6.3A

FS2 C56263 Fuse Bussmann S506 T6.3A

FS3 C54132 Fuse Bussmann S504 T315mA

FS4 C54132 Fuse Bussmann S504 T315mA

FS5 C54132 Fuse Bussmann S504 T315mA

FS6 C54132 Fuse Bussmann S504 T315mA

HS1 F008 Heatsink TO-220 SW50-2 8.8 Deg C/W

IC100 5A2143 IC Balanced Line Receiver AD SSM2143S SO-8 Package

IC101 5B072D Opamp TL072CD SO-8 Package

ITEM1-1 F006 Clip For SW Profile Heatsink

ITEM2-1 F022 Fuseholder Cover For 20mm Fuseholder

ITEM3-1 F022 Fuseholder Cover For 20mm Fuseholder

ITEM4-1 F022 Fuseholder Cover For 20mm Fuseholder

ITEM5-1 F022 Fuseholder Cover For 20mm Fuseholder

ITEM6-1 F022 Fuseholder Cover For 20mm Fuseholder

ITEM7-1 F022 Fuseholder Cover For 20mm Fuseholder

ITEM8-1 L962PB Blank PCB P1 Amplifier Main Board

ITEM9-1 E802AP Pad Damping 15x6x3MM Sorbothane

ITEM9-2 E802AP Pad Damping 15x6x3MM Sorbothane

ITEM10-1 E826AP Pad Damping 7.5x6x3 Sorbothane

ITEM10-2 E826AP Pad Damping 7.5x6x3 Sorbothane

ITEM10-3 E826AP Pad Damping 7.5x6x3 Sorbothane

ITEM11-1 8M101 Earth Lead Assy 75MM

L1 7F004 Ferrite Bead SM1206 70R@100MHz

L100 7D002C Inductor AC 2u2 Self Bonded

LS100 8D420G Connector 4mm 4 Way Vertical

OPTO100 5T3Q66 Opto Isolator Quad PC3Q66Q

R1 1A010 Resistor 1206 Surface Mount 0.25W 1% 10R

R2 1KA515 Resistor Metal Glazed 0.5W 5% 1M5

R3 1A233 Resistor 1206 Surface Mount 0.25W 1% 3K3

R4 1A222 Resistor 1206 Surface Mount 0.25W 1% 2K2

R5 1A222 Resistor 1206 Surface Mount 0.25W 1% 2K2

R6 1A222 Resistor 1206 Surface Mount 0.25W 1% 2K2

R7 1A222 Resistor 1206 Surface Mount 0.25W 1% 2K2

R8 1A222 Resistor 1206 Surface Mount 0.25W 1% 2K2

R9 1A222 Resistor 1206 Surface Mount 0.25W 1% 2K2

R10 1A222 Resistor 1206 Surface Mount 0.25W 1% 2K2

R11 1A222 Resistor 1206 Surface Mount 0.25W 1% 2K2

R12 1A110 Resistor 1206 Surface Mount 0.25W 1% 100R

R13 1A368 Resistor 1206 Surface Mount 0.25W 1% 68K

R14 1A368 Resistor 1206 Surface Mount 0.25W 1% 68K

R15 1A310 Resistor 1206 Surface Mount 0.25W 1% 10K

R16 1A222 Resistor 1206 Surface Mount 0.25W 1% 2K2

R17 1A247 Resistor 1206 Surface Mount 0.25W 1% 4K7

Page 23

P1 Amplifier main cct board L962AY issue 2.1

Designator Part Description

R18 1A310 Resistor 1206 Surface Mount 0.25W 1% 10K

R19 1E310 Resistor Carbon Film 1W 5% 10K

R20 1E310 Resistor Carbon Film 1W 5% 10K

R100 1A010 Resistor 1206 Surface Mount 0.25W 1% 10R

R101 1A010 Resistor 1206 Surface Mount 0.25W 1% 10R

R102 1A268 Resistor 1206 Surface Mount 0.25W 1% 6K8

R103 1A268 Resistor 1206 Surface Mount 0.25W 1% 6K8

R104 1A222 Resistor 1206 Surface Mount 0.25W 1% 2K2

R105 1A222 Resistor 1206 Surface Mount 0.25W 1% 2K2

R106 1A110 Resistor 1206 Surface Mount 0.25W 1% 100R

R107 1A133 Resistor 1206 Surface Mount 0.25W 1% 330R

R108 1A133 Resistor 1206 Surface Mount 0.25W 1% 330R

R109 1A110 Resistor 1206 Surface Mount 0.25W 1% 100R

R110 1A110 Resistor 1206 Surface Mount 0.25W 1% 100R

R111 1A110 Resistor 1206 Surface Mount 0.25W 1% 100R

R112 1A110 Resistor 1206 Surface Mount 0.25W 1% 100R

R113 1A110 Resistor 1206 Surface Mount 0.25W 1% 100R

R114 1A110 Resistor 1206 Surface Mount 0.25W 1% 100R

R115 1A110 Resistor 1206 Surface Mount 0.25W 1% 100R

R116 1A318 Resistor 1206 Surface Mount 0.25W 1% 18K

R117 1A318 Resistor 1206 Surface Mount 0.25W 1% 18K

R118 1A247 Resistor 1206 Surface Mount 0.25W 1% 4K7

R119 1A247 Resistor 1206 Surface Mount 0.25W 1% 4K7

R120 1A247 Resistor 1206 Surface Mount 0.25W 1% 4K7

R121 1A247 Resistor 1206 Surface Mount 0.25W 1% 4K7

R122 1A247 Resistor 1206 Surface Mount 0.25W 1% 4K7

R123 1H182 Resistor Metal Film 0.25W 1% 820R

R124 1H268 Resistor Metal Film 0.25W 1% 6K8

R125 1H268 Resistor Metal Film 0.25W 1% 6K8

R126 1H268 Resistor Metal Film 0.25W 1% 6K8

R127 1H268 Resistor Metal Film 0.25W 1% 6K8

R128 1H268 Resistor Metal Film 0.25W 1% 6K8

R129 1H110 Resistor Metal Film 0.25W 1% 100R

R130 1A312 Resistor 1206 Surface Mount 0.25W 1% 12K

R131 1A312 Resistor 1206 Surface Mount 0.25W 1% 12K

R132 1H322 Resistor Metal Film 0.25W 1% 22K

R133 1A047 Resistor 1206 Surface Mount 0.25W 1% 47R

R134 1A047 Resistor 1206 Surface Mount 0.25W 1% 47R

R135 1A047 Resistor 1206 Surface Mount 0.25W 1% 47R

R136 1A047 Resistor 1206 Surface Mount 0.25W 1% 47R

R137 1A000 Resistor 1206 Surface Mount 0.25W 1% 0R0

R138 1H215 Resistor Metal Film 0.25W 1% 1K5

R139 1H215 Resistor Metal Film 0.25W 1% 1K5

R140 1H215 Resistor Metal Film 0.25W 1% 1K5

R141 1H215 Resistor Metal Film 0.25W 1% 1K5

R142 1H022 Resistor Metal Film 0.25W 1% 22R

R143 1H022 Resistor Metal Film 0.25W 1% 22R

R144 1H218 Resistor Metal Film 0.25W 1% 1K8

R145 1H218 Resistor Metal Film 0.25W 1% 1K8

R146 1H218 Resistor Metal Film 0.25W 1% 1K8

R147 1H218 Resistor Metal Film 0.25W 1% 1K8

R148 1A510 Resistor 1206 Surface Mount 0.25W 1% 1M0

R149 1A268 Resistor 1206 Surface Mount 0.25W 1% 6K8

R150 1A210 Resistor 1206 Surface Mount 0.25W 1% 1K0

R151 1A210 Resistor 1206 Surface Mount 0.25W 1% 1K0

R152 1A210 Resistor 1206 Surface Mount 0.25W 1% 1K0

R153 1A210 Resistor 1206 Surface Mount 0.25W 1% 1K0

R154 1A210 Resistor 1206 Surface Mount 0.25W 1% 1K0

R155 1A210 Resistor 1206 Surface Mount 0.25W 1% 1K0

R156 1A210 Resistor 1206 Surface Mount 0.25W 1% 1K0

R157 1A210 Resistor 1206 Surface Mount 0.25W 1% 1K0