Page 1

600mm

Intergrated Canopy

Manual

MODEL

IRI6WE3

Installation and Operation

Page 2

IRI6WE3 and IRI9WE3 Installation and Operation Manual

Dear Customer,

We thank you for choosing this quality appliance and hope you enjoy many years of

reliable service.

Please ensure this manual is read carefully before installation and use. Keep t his

manual in a safe and accessible location should futu re r ef eren ce be requir ed.

Regards

Home Appliances

CONTENTS

Contents 1

Safety Warnings 2

Dimensions 3

Installation 4-8

Operation 9

Maintenance and Clean ing 10-11

Service 11

- 1 -

Page 3

IRI6WE3 and IRI9WE3 Installation and Operation Manual

SAFETY WARNINGS

• Installation of this Integrated Canopy Rangehood must be carried by a

qualified and competen t installer.

• The manufacturer disc l aim s and liability for any dam age o r i n jury caused as a

result of not following instruction of installation contained in this instruction

manual.

• This Integrated Canopy Rangehood is not intended for use by young children

or infirm persons w it hout supervison.

• Young children should be supervised to ensure they do not play with this

Integrated Canopy Rangehood.

• To avoid possible electric shock this Int eg rated Canopy Rangehood should

be unplugged before any m aint enance or cleaning is carried out.

• This Integrated Canop y Ran geh o o d cannot be installed in an external

environment.

• The Grease Filters should be cleaned at least once a mo n t h t o avoid the risk

of fire.

• Flambe cooking cann o t be carried out under the Integrated Canopy

Rangehood and is not re com m en ded for use over Barbeques.

• Ducting must be independent from any other form of ducting of other

household heating sources.

• Ducting into wall cavities is prohibited unless the cavity has been designed for

this purpose

• Lit gas burner should never remain uncovered or on when there is no pan

present due to the risk of fire.

• Adequate ventilation o f t h e ro o m is re quired when the cooker hood is used

at the same time as appliances burning gas or other fuels.

- 2 -

Page 4

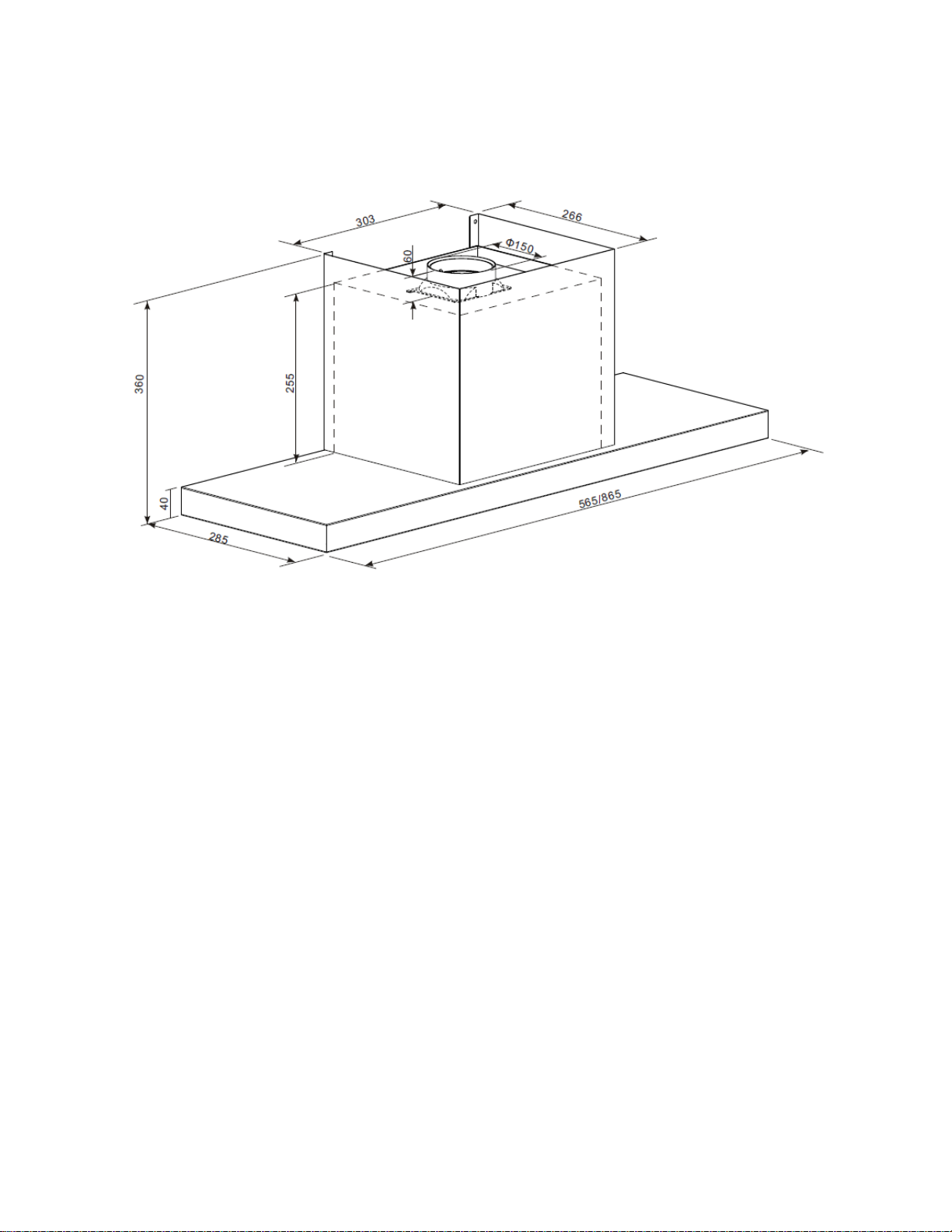

DIMENSIONS

Dimensions of IRI6WE3 and IRI9WE3

IRI6WE3 and IRI9WE3 Installation and Operation Manual

- 3 -

Page 5

IRI6WE3 and IRI9WE3 Installation and Operation Manual

INSTALLATION

The IRI6WE3 and IRI9WE3 are designed to be installed fully integrated into an overhead

cupboard as pictured below. The IRI6WE3 is suited for a 600mm cupboard and the IRI9WE3

suited for a 900mm cupboard.

Installation of the IRI9WE3 Integrated rangehood in an overhead cupboard

Height Requirement

The minimum installation height requirement above the

highest point of the cooktop to the rangehood filter should

be no less than 65cm. For the best performance, the

maximum height should not exceed 75cm. (Fig. 1)

Fig . 1

- 4 -

Page 6

IRI6WE3 and IRI9WE3 Installation and Operation Manual

INSTALLATION - Position of Mounting Bracket

The Integrated Rangehood is mounted to the rear of the overhead cupboard. Supplied with

the rangehood is a mounting bracket (Fig. 2)

Fig . 2

Prior to installation, check the measurement from the screw holes in the mounting bracket to

the base of the rangehood. Achieve this by placing the mounting bracket onto the rear of

the Integrated rangehood and measure from base of rangehood to the mid point of the

centre screw hole on the mounting bracket. This may vary slightly to the dimensions

mentioned in Fig. 3. and should be the one you use to ensure the base of the rangehood is

level with the base of the overhead cupboards.

Centre the mounting bracket on the rear panel of the overhead cupboard. Ensure the

mounting bracket is level and mark the 3 screw holes positions. Drill pilot holes into the rear

panel at the positions you have marked. Relocate mounting bracket and fasten it with

appropriate screws to the rear cupboard panel. Before tightening completely check the

level is correct. (Fig. 3)

- 5 -

Page 7

IRI6WE3 and IRI9WE3 Installation and Operation Manual

Mounting bracket

Integrated Rangehood

Removable shelf

(Cannot be permanently

fixed if the need for

servicing is required)

Fig. 4

Slots to mount to

tabs of mounting

bracket

Mounting bracket

Integrated Rangehood

Removable shelf

(Cannot be permanently

fixed if the need for

servicing is required)

Fig. 4

Slots to mount to

tabs of mounting

bracket

150mm duct spigot 150mm flexible ducting

INSTALLATION – Fitting of Integrated Rangehood

Fit 150mm duct spigot (pictured below) with the four 8mm screws provided over the

rectangular hole located at the top rear of the integrated rangehood. Fit 150mm flexible

ducting (pictured below), supplied, to the ducting spigot, Using one of the nylon ties,

supplied, secure the ducting to the duct spigot.

A hole or cutout needs to be made in the centre rear of the removable shelf positioned

above the integrated rangehood for the ducting to go through.

Mount the Integrated Rangehood onto the two tabs on the mounting bracket into the two

matching slots located at the rear of the rangehood. (Fig. 4)

- 6 -

Page 8

IRI6WE3 and IRI9WE3 Installation and Operation Manual

Motor housing cover

Duct spigot

150mm Ducting required

and ducted to outside of

the home

U-shaped box

to cover

ducting

(Needs to be

removable)

Removable shelf

(Cannot be permanently

fixed if the need for

servicing is required)

Shelf support

brackets x 4

Fig. 5

Motor housing cover

Duct spigot

150mm Ducting required

and ducted to outside of

the home

U-shaped box

to cover

ducting

(Needs to be

removable)

Removable shelf

(Cannot be permanently

fixed if the need for

servicing is required)

Shelf support

brackets x 4

Fig. 5

INSTALLATION – Ducted or Re-circulating

The integrated rangehood can be installed in either ducted or re-circulating method. The

integrated rangehood is supplied with a small length of flexible duct, although may not be

sufficient in all installations. The installer needs to determine the method in which the

rangehood will be installed and may need to supply the appropriate components to duct

the rangehood correctly.

Ducted installation

Ducting components will need to be supplied by the installer as every installation can be

different. The size of the duct pipe needs to be no less than 150mm in diameter. Use of

smaller diameter duct pipe will effect performance and create air noise from the

rangehood.

The shelf above the top of the rangehood needs to removable, should the need for servicing

be required at a later date. The shelf needs to be located no less than 400mm above the

top of the rangehood as the metal motor housing supplied needs to be put in place after

the rangehood has been installed. Above the shelf a U-shaped box can be made to cover

the duct so it cannot be seen when the overhead cupboard is open. (Fig.5)

- 7 -

Page 9

IRI6WE3 and IRI9WE3 Installation and Operation Manual

Motor housing cover

Duct spigot

150mm

Ducting

(supplied)

150mm diameter hole in top of cupboard

U-shaped box

to cover

ducting

(Needs to be

removable)

Removable shelf

(Cannot be permanently

fixed if the need for

servicing is required)

Shelf support

brackets x 4

Mesh Cover

recommended to

keep out insect or

vermin.

Fig. 6

Motor housing cover

Duct spigot

150mm

Ducting

(supplied)

150mm diameter hole in top of cupboard

U-shaped box

to cover

ducting

(Needs to be

removable)

Removable shelf

(Cannot be permanently

fixed if the need for

servicing is required)

Shelf support

brackets x 4

Mesh Cover

recommended to

keep out insect or

vermin.

Motor housing cover

Duct spigot

150mm

Ducting

(supplied)

150mm diameter hole in top of cupboard

U-shaped box

to cover

ducting

(Needs to be

removable)

Removable shelf

(Cannot be permanently

fixed if the need for

servicing is required)

Shelf support

brackets x 4

Mesh Cover

recommended to

keep out insect or

vermin.

Fig. 6

INSTALLATION – Ducted or Re-circulating

Re-circulation installation

150mm flexible duct is provided with the integrated rangehood for re-circulatiing installation.

This type of installation can be executed to the top of a cupboard or through a bulkhead

above the cupboard. In both cases a mesh cover will need to be supplied by the installer to

keep out insects and vermin. The size of the duct pipe needs to be no less than 150mm in

diameter. Use of smaller diameter duct pipe will effect performance and create air noise

from the rangehood.

The shelf above the top of the rangehood needs to removable, should the need for servicing

be required at a later date. The shelf needs to be located no less than 400mm above the

top of the rangehood as the metal motor housing supplied needs to be put in place after

the rangehood has been installed. Above the shelf a U-shaped box can be made to cover

the duct so it cannot be seen when the overhead cupboard is open. (Fig.6)

Carbon filters may be required to reduce any fumes or smells being re-directed back into

the kitchen environment. Call 1800 805 300 to order carbon filters if required.

Carbon Filter code – CF160 (2 supplied)

- 8 -

Page 10

IRI6WE3 and IRI9WE3 Installation and Operation Manual

Light

High

Mid

Low

Fig. 7

Light

High

Mid

Low

Light

High

Mid

Low

Fig. 7

OPERATION

The integrated rangehood is fitted with push button Back-lit electronic controls.

There is 1 light push button and 3 speed push buttons, Low, Mid and High to control the air

flow speeds. (Fig. 7)

Light Control

To turn ON the halogen lights, depress the Light electronic push button once. When ON, the

back lit push button will glow blue. To turn lights OFF, depress the Light electronic push button

again.

Speed Control

To turn ON the rangehood, depress either the Low, Mid or High electronic push buttons.

When ON, the back lit push button will glow blue to indicate your selection. You may wish to

start on Low prior to cooking commencing and at any time switch to Mid or High without

having to turn off the Low speed first. You can depress any speed at any time and it will

cancel the previous speed chosen. To turn of OFF the rangehood depress the indicated

electronic push button again.

At the end of cooking it is recommended to run the rangehood on low for up to 10 minutes

to help remove any residual fumes and smoke produced during cooking.

- 9 -

Page 11

IRI6WE3 and IRI9WE3 Installation and Operation Manual

Step 1. Remove lamp cover using

points to assist in easy removal

Step 2. Place cover in safe place

as it is made from glass

Step 3. Grip the halogen bulb and

pull from holder

Step 4. Remove lamp and discard

in a safe and proper manner.

Step 5. Using a tissue or gloves to

halogen bulbs)

Step 6. Re-fit lamp cover carefully.

Ensure it is securely positioned.

Glass

MAINTENANCE and CLEANING

WARNING

ALWAYS un-plug the rangehood PRIOR to any maintenance or c leaning being

carried out, to avoid p ossible ele ct ric shock.

To ensure long lasting performance and efficiency, regular maintenance and cleaning of

your integrated rangehood should be performed.

Replacing Halogen Bulbs

After many hours of operation halogen bulbs may require replacement. This can be done by

the owner. Please follow the following steps to conduct this procedure.

Halogen bulb type – 20W 12V G4

NOTE: Replacement of halogen light bulbs are not covered under the 2 years parts and

labour warranty.

a small screwdriver, there are 4

protect bulb, fit new halogen bulb.

(Oil from the skin can affect

- 10 -

Page 12

IRI6WE3 and IRI9WE3 Installation and Operation Manual

MAINTENANCE and CLEANING

WARNING

ALWAYS un-plug the rangehood P RIOR to any maintenance or c leaning being

carried out, to avoid p ossible ele ct ric shock.

Cleaning of Grease Filter

We recommend cleaning of the grease filter to be done at least every 4 weeks. Cleaning of

the grease filter ensures continued performance of the rangehood.

Remove the grease filter and soak in warm to hot water containing liquid detergent. Soak for

at least 5 minutes to break down the grease build-up. Without applying too much pressure

use a soft brush to remove stubborn grease residue. Rinse under clean water. Ensure that the

filter is completely dry before re-fitting to rangehood.

The grease filter can be cleaned in the dishwasher on a normal wash program at a

temperature around 60 Degrees Celsius. NOTE: Some dis-colouration of the grease filter may

occur when cleaned in the dishwasher.

Cleaning of the Rangehood

As cooking can create a great deal of grease, we recommend that the rangehood body

and motor housing area be cleaned every 3 months. Ensure that non caustic, abrasive

detergents or harsh chemicals are not used to clean the rangehood as this could cause

damage.

Regularly cleaning the rangehood will ensure you get the best performance of your

appliance. Use hot water, detergent and a soft cloth to carry out the cleaning of your

rangehood. DO NOT excess water during cleaning and keep water away from the motor

and other electronic components.

Avoid cleaning immediately after using the rangehood as components and lights could still

be hot. Clean the rangehood when it has not been in operation.

Carbon Filters

Carbon Filters CANNOT be washed and re-used. Carbon filters, if used, require replacement

every 4 to 6 months depending on usage.

SERVICE

Should you experience any problems with your rangehood, please un-plug immediately and

as soon as possible, contact Service on

Toll Free 1800 805 300

Alternatively you can book a service call on our website

www.customersupport.integratedappliancegroup.com.au

- 11 -

Loading...

Loading...