Page 1

FLEX

User’s Manual

Page 2

1

Table of Contents

Page

1. Introduction 2

2. Radio Controlled Safety 3

3. General System Information

A. Transmitter Handset

1. External Illustration 4

2. Internal Illustration 5

B. Receiver Unit

1. External Illustration 6

2. Internal Illustration 7

4. Function Settings

A. Transmitter Handset

1. System Channel Settings 8

2. Pushbutton Functions with LED Display Settings 9~13

B. Receiver Unit

1. System Channel Settings 13

2. Output Relay Configurations 14~15

3. Dip-switch Settings 16~17

4. Jumpers Settings 18

5. System Channels Table 19

6. Receiver Installation

A. Output Relay Contact Diagrams 20

B. Receiver Mounting

1. Pre-installation Precautions 21

2. Step-by-Step Installation 21~22

3. System Testing 22

7. Operating Procedure

A. Transmitter Operation 23

B. Status Light Indicators & Warnings

1. Transmitter STATUS Light Indication 24

2. Receiver STATUS Light Indication 25

3. Receiver SQ Light Indication 25

4. Receiver Power Light Indication 25

5. Receiver COM Light Indication 25

C. Trouble Shooting Tips 26

8. System Specification 27

9. Spare Parts 28

Page 3

2

1. Introduction

The ARC FLEX radio remote control systems are designed for control of industrial equipment and

machinery such as overhead traveling cranes, jib cranes, gantry cranes, tower cranes, electric hoists, winches,

monorails, conveyor belts, mining equipment and other material handling equipment where wireless control is

preferred.

Each FLEX system consists of a transmitter handset and receiver unit. Other standa rd-equipped

accessories include transmitter waist belt, “AA” batteries, compass direction decal sheet and user’s manual.

List of notable features include:

* 62 user-adjustable channels – no more fixed channels and fragile quartz crystals to break.

* Over one million sets of unique ID codes (20-bit) – unlike many other radio control systems on the

market, the FLEX system never repeats ID codes.

* Advanced microprocessor controls with 32-bit CRC and Hamming Codes programming – ultra fast,

safe, precise and error-free encoding and decoding.

* Ultra-durable transmitter push button – good for up to one million press cycles.

* Ultra power-saving transmitter – requires only two “AA” Alkaline or rechargeable batteries

(2000mA or above) for more than 100 hours of continuous operating time between replacements or

recharging.

* Ultra durable nylon and fiberglass composite enclosures – resist breakage from high impacts and

frequent drops ; no more fragile casings to replace.

* 100% water and shock resistant

* Adjustable waist belt for easy carry and operation.

Page 4

3

2. Radio Controlled Safety

Flex radio remote control system should be operated by persons with sufficient amount of knowledge and

skill in crane operation and safety. Persons being trained to operate a radio remote controlled crane should

possess the knowledge of all hazards peculiar to radio remote controlled crane operation, ability to judge

distance and moving objects, equipment capacity and radio remote controlled safety rules. Radio remote

controlled cranes should not be operated by any person with insufficient eyesight, hearing, illness, and under

influence of drugs and medications that may cause loss of crane control.

Below are some general operating safety tips that should be strictly followed when operating a radio

remote controlled crane.

1. Prior to crane operation always check the transmitter handset for any damage that might inhibit

proper crane operation.

2. Always check if the red emergency stop button is working properly prior to crane operation.

3. Check the battery status LED on the transmitter for any signs of low battery power.

4. Check the Status LED on the transmitter for any signs of irregularities. Please refer to the

“Transmitter Status Light Indicators & Warnings ” on page 24.

5. The crane limit switches should be checked prior to crane operation or at the beginning of each shift.

When checking limit switches the hoist should be centered over an area free of personnel and

equipment.

6. If power to the crane is removed, the ope rator should turn off the transmitter power immediately

until the power to the crane is restored.

7. If the crane fails to respond properly to operator’s command the operator should stop operation, turn

the transmitter power off, and then report the condition to their supervisor.

8. The transmitter power should be turned off after each use. If the transmitter handset is not in use

always turn the power off and stored it in a safe or designated location. Never leave the transmitter

handset unattended in the working area.

9. Even though Flex system is capable of allowing up to four systems with same channel in use

without interfering with one another, it is always a good practice not to use the same RF channel as

any other Flex systems in use within a distance of 200 feet.

10. Never operate a crane or equipment with two identical channel and ID transmitter handsets at the

same time within the same facility.

Page 5

4

3. General System Information

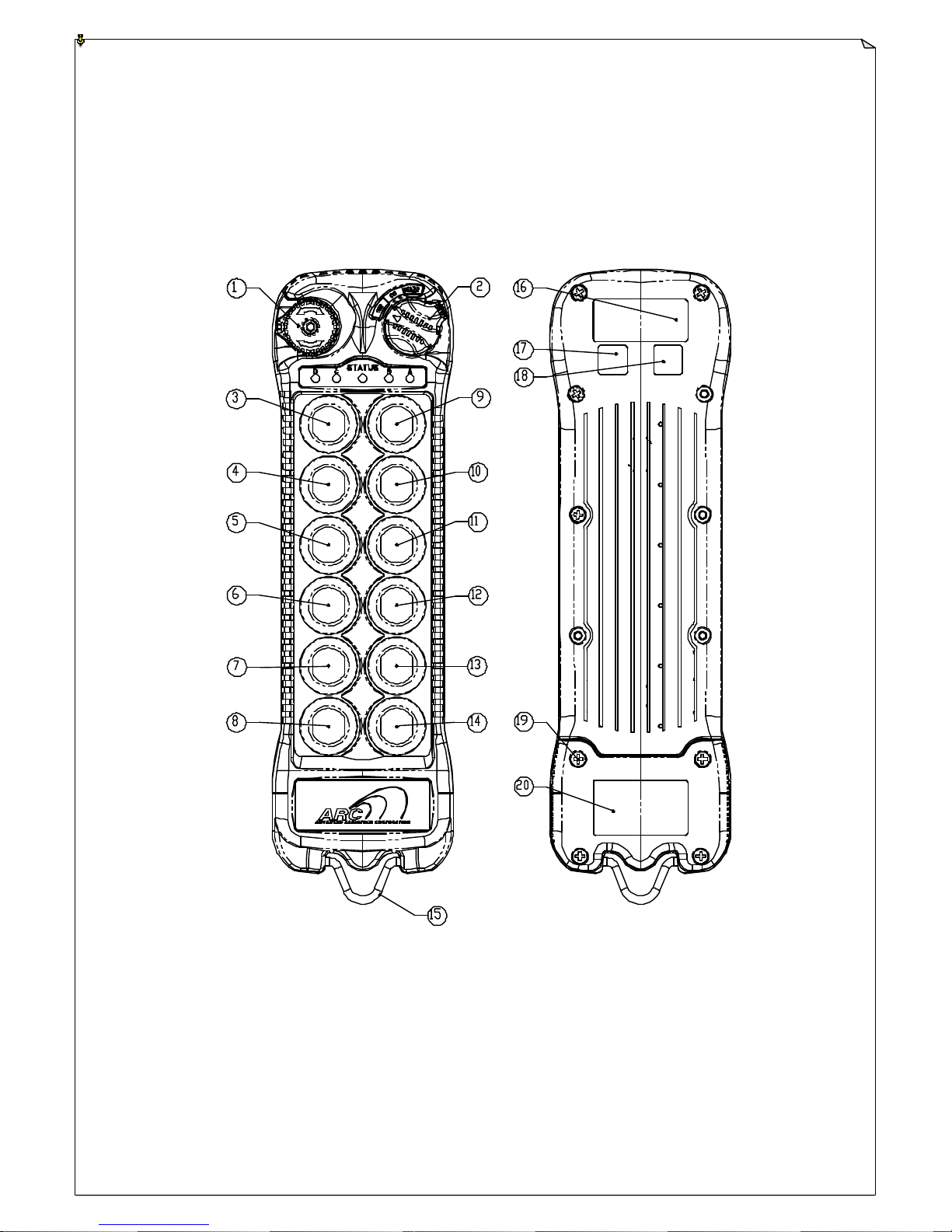

A. TRANSMITTER HANDSET

1. External Illustration

Fig. 01 Fig. 02

1. Emergency Stop Button 8. Push button #12 15. Strap Holder

2. Power Key Switch 9. Push button #1 16. System Information

3. Push button #2 10. Push button #3 17. System Channel

4. Push button #4 11. Push button #5 18. Crane Number

5. Push button #6 12. Push button #7 19. Battery Cover

6. Push button #8 13. Push button #9 20. FCC/CE Information

7. Push button #10 14. Push button #11

Page 6

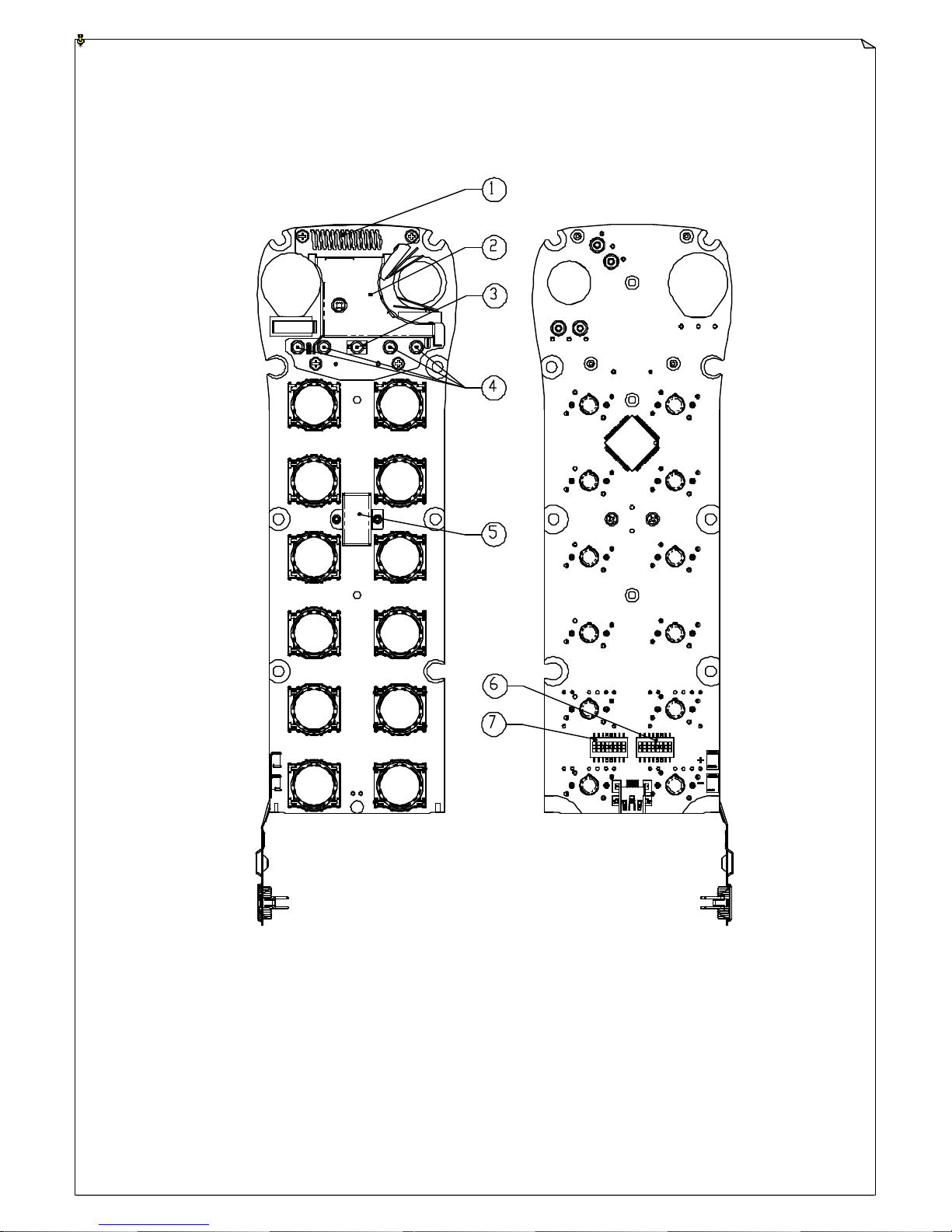

5

2. Internal Illustration

Fig. 03 Fig. 04

1. Arial Antenna 5 I-CHIP

2. Transmitting Board 6 Function Dip-Switch

3. Status LED Display 7 Channel Dip-Switch

4. Function LED Display

Page 7

6

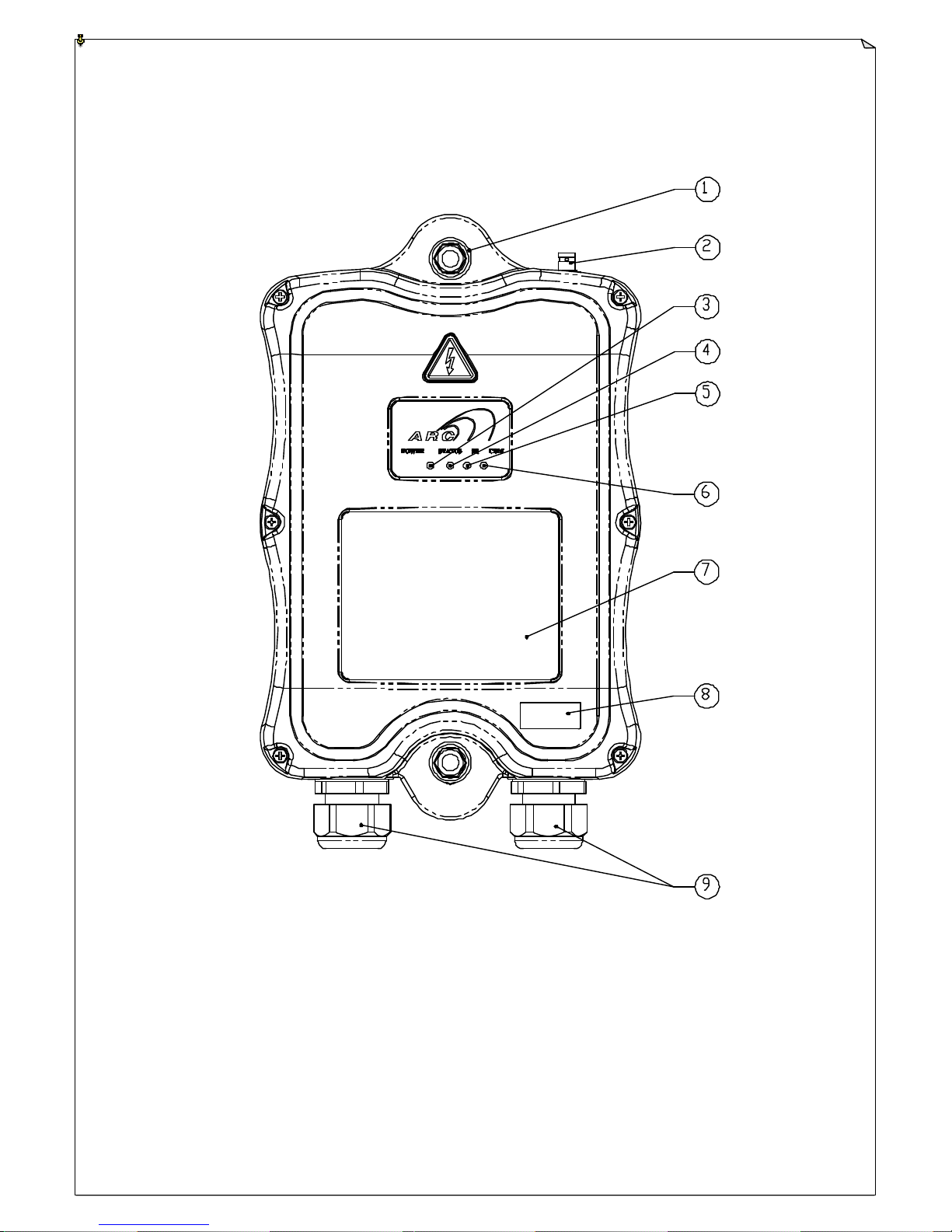

B. RECEIVER UNIT

1. External Illustration

Fig. 05

1. Shock Absorber 6. COM LED Display

2. External Antenna BNC Jack 7. Output Contact Diagram

3. Power LED Display 8. System Information

4. Status LED Display 9. Cable Gland/ Cord Grip

5. SQ LED Display

Page 8

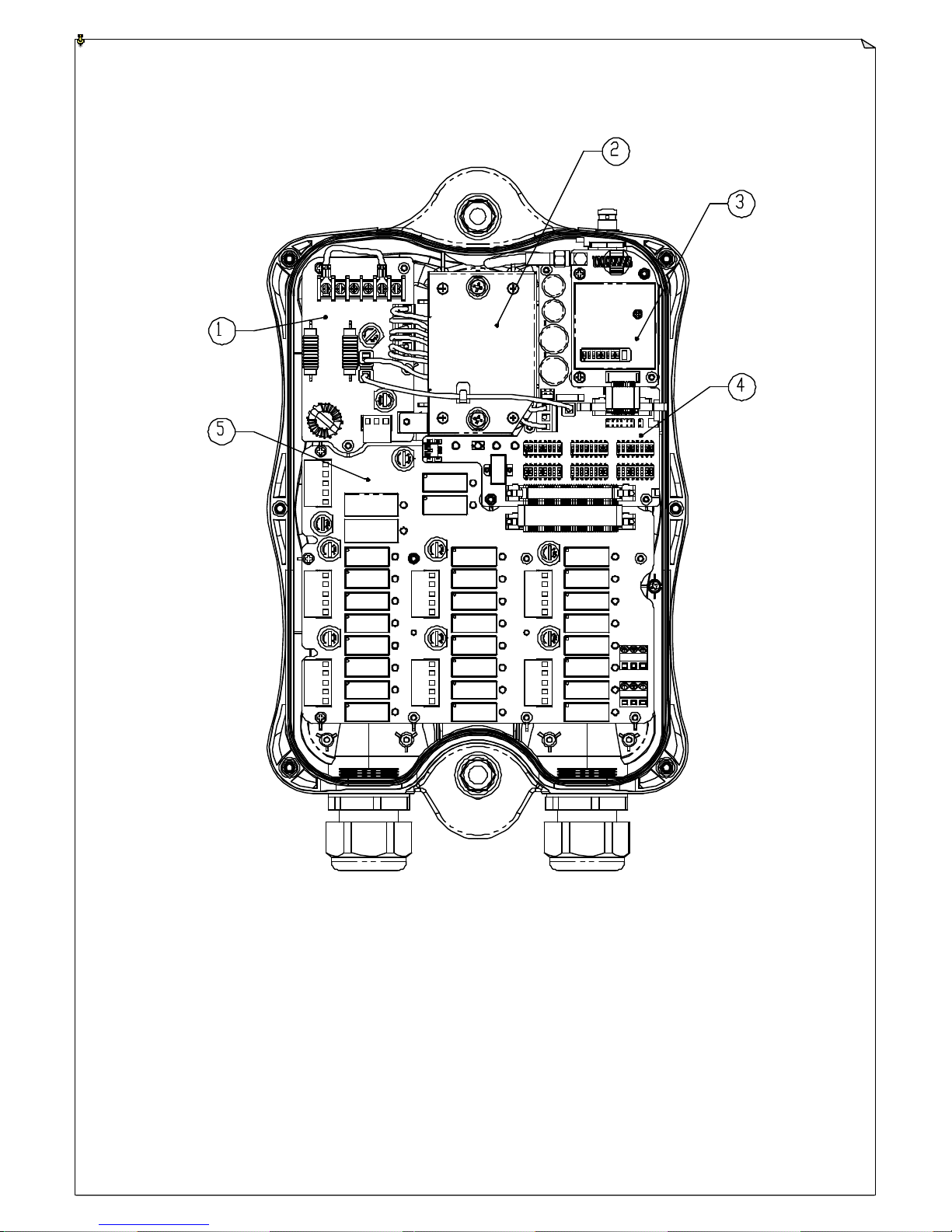

7

2. Internal Illustration

Fig. 06

1. AC Line Filter 4. Decoder Board

2. Power Transformer 5. Relay Board

3. Receiving Board

Page 9

8

71 42 3 5 6 8

4. Function Settings

A. TRANSMITTER HANDSET

1. System Channel Settings

Fig. 07

Set the transmitter channel simply by adjusting the channel dip-switch located on the backside of the

transmitter encoder board. The system channel table located on page 19 will tell you which dip setting

correspond to which channel. Do make sure that when you change the channel of the transmitter you

must also cha nge the channel of the receiver as well. The channel on both transmitter and receiver must

be identical in order for the system to work.

Example:

Top slot ? “1”

(Fig. 08 ) Bottom slot ? “0”

The above dip setting would be “100100”, which corresponds to “channel 36” in the system

channels table on page 19.

1 2 3 4 5 6 7 8 1 2 3 4 5 6 7 8

CHANNEL FUNCTION

Page 10

9

1 2 3 4 5 6 7 8 1 2 3 4 5 6 7 8

CHANNEL FUNCTION

2. Push Button Functions with LED Display Settings

A. 1-Stage Toggle Switch with LED Display

Below are settings for toggle or latching functions. You can set each and every push button

on the transmitter with toggle d (latching) relay contact. The number (1 to 4) below the

push button tells you which LED on the transmitter will light up when the push button is

pressed.

Fig. 08

DIP PB1 PB2 PB3 PB4 PB5 PB6 PB7 PB8 PB9 PB10 PB11 PB12

1 00000001

4

2 00000010 3 4

3 00000011 2 3 4

4 00000100 1 2 3 4

5 00000101 4

6 00000110 3 4

7 00000111 2 3 4

8 00001000 1 2 3 4

9 00001001 4

10 00001010 3 4

11 00001011 2 3 4

12 00001100 1 2 3 4

13 00001101 4

14 00001110 3 4

15 00001111 2 3 4

16 00010000 1 2 3 4

1 ? LED #1 will light up when the push button is pressed

2 ? LED #2 will light up when the push button is pressed

3 ? LED #3 will light up when the push button is pressed

4 ? LED #4 will light up when the push button is pressed

Page 11

10

B. 3-Stage Selector Swi tch

DIP PB1 PB2 PB3 PB4 PB5 PB6 PB7 PB8 PB9 PB10 PB11 PB12

17

00010001

A/1&2

18 00010010 B/1&2

19 00010011 C/1&2

20 00010100 D/1&2

21 00010101 A/3&4

22 00010110 B/3&4

23 00010111 C/3&4

24 00011000 D/3&4

25 00011001 A/1&2

A/3&4

26 00011010 A/1&2

B/3&4

27 00011011 A/1&2

C/3&4

28 00011100 A/1&2

D/3&4

29 00011101 B/1&2

B/3&4

30 00011110 B/1&2

C/3&4

31 00011111 B/1&2

D/3&4

32 00100000 C/1&2

C/3&4

33 00100001 C/1&2

D/3&4

34 00100010

D/1&2 D/3&4

35 00100011

36 00100100 B/1&2

37 00100101 C/1&2

38 00100110

/1&2

39 00100111 A/3&4

40 00101000 B/3&4

41 00101001 C/3&4

42 00101010 D/3&4

A ? Select A/B

B ? Select 0/A/B

C ? Select A/B/A+B

D ? Select 0/A/B/A+B

Page 12

11

3-Stage Selector Switch - Continued

43 00101011

A/3&4

44 00101100 A/1&2

B/3&4

45 00101101

A/1&2

C/3&4

46 00101110

/1&2 D/3&4

47 00101111

/1&2 B/3&4

48 00110000 B/1&2

C/3&4

49 00110001 B/1&2

D/3&4

50 00110010

/1&2 C/3&4

51 00110011 C/1&2

D/3&4

52 00110100

D/3&4

53 00110101 A/1&2

54 00110110 B/1&2

55 00110111 C/1&2

56 00111000 D/1&2

57 00111001 A/3&4

58 00111010 B/3&4

59 00111011 C/3&4

60 00111100 D/3&4

61 00111101 A/1&2

A/3&4

62 00111110 A/1&2

B/3&4

63 00111111 A/1&2

C/3&4

64 01000000 A/1&2

D/3&4

65 01000001 B/1&2

B/3&4

66 01000010 B/1&2

C/3&4

67 01000011

B/1&2 D/3&4

68 01000100 C/1&2

C/3&4

69 01000101 C/1&2

D/3&4

70 01000110 D/1&2

D/3&4

71 01000111

72 01001000 B/1&2

73 01001001

C/1&2

74 01001010

/1&2

75 01001011 A/3&4

76 01001100 B/3&4

77 01001101 C/3&4

Page 13

12

3-Stage Selector Switch - Continued

78 01001110 D/3&4

79 01001111

A/3&4

80 01010000 A/1&2

B/3&4

81 01010001 A/1&2

C/3&4

82 01010010

/1&2 D/3&4

83 01010011

/1&2 B/3&4

84 01010100 B/1&2

C/3&4

85 01010101 B/1&2

D/3&4

86 01010110

/1&2 C/3&4

87 01010111 C/1&2

D/3&4

88 01011000

D/3&4

C. 1-Stage Toggle + 3-Stage Selector Switch Combination

89 01011001 1 A/3&4

90 01011010 1 B/3&4

91 01011011 1 C/3&4

92 01011100 1 D/3&4

93 01011101 1 2 A/3&4

94 01011110 1 2 B/3&4

95 01011111 1 2 C/3&4

96 01100000 1 2 D/3&4

97 01100001 1 A/3&4

98 01100010 1 B/3&4

99 01100011 1 C/3&4

100 01100100 1 D/3&4

101 01100101 1 2 A/3&4

102 01100110 1 2 B/3&4

103 01100111 1 2

C/3&4

104 01101000 1 2 D/3&4

105 01101001 1 A/3&4

106 01101010 1 B/3&4

Page 14

13

1 2 3 4 5 6 7 8

1-Stage Toggle + 3-Stage Selector Switch Combination - Continued

107 01101011 1 C/3&4

108 01101100 1 D/3&4

109 01101101 1 2 A/3&4

110 01101110 1 2 B/3&4

111 01101111 1 2 C/3&4

112 01110000 1 2 D/3&4

113 01110001 1 A/3&4

114 01110010 1 B/3&4

115 01110011 1 C/3&4

116 01110100 1 D/3&4

117 01110101 1 2 A/3&4

118 01110110 1 2 B/3&4

119 01110111 1 2 C/3&4

120 01111000 1 2

D/3&4

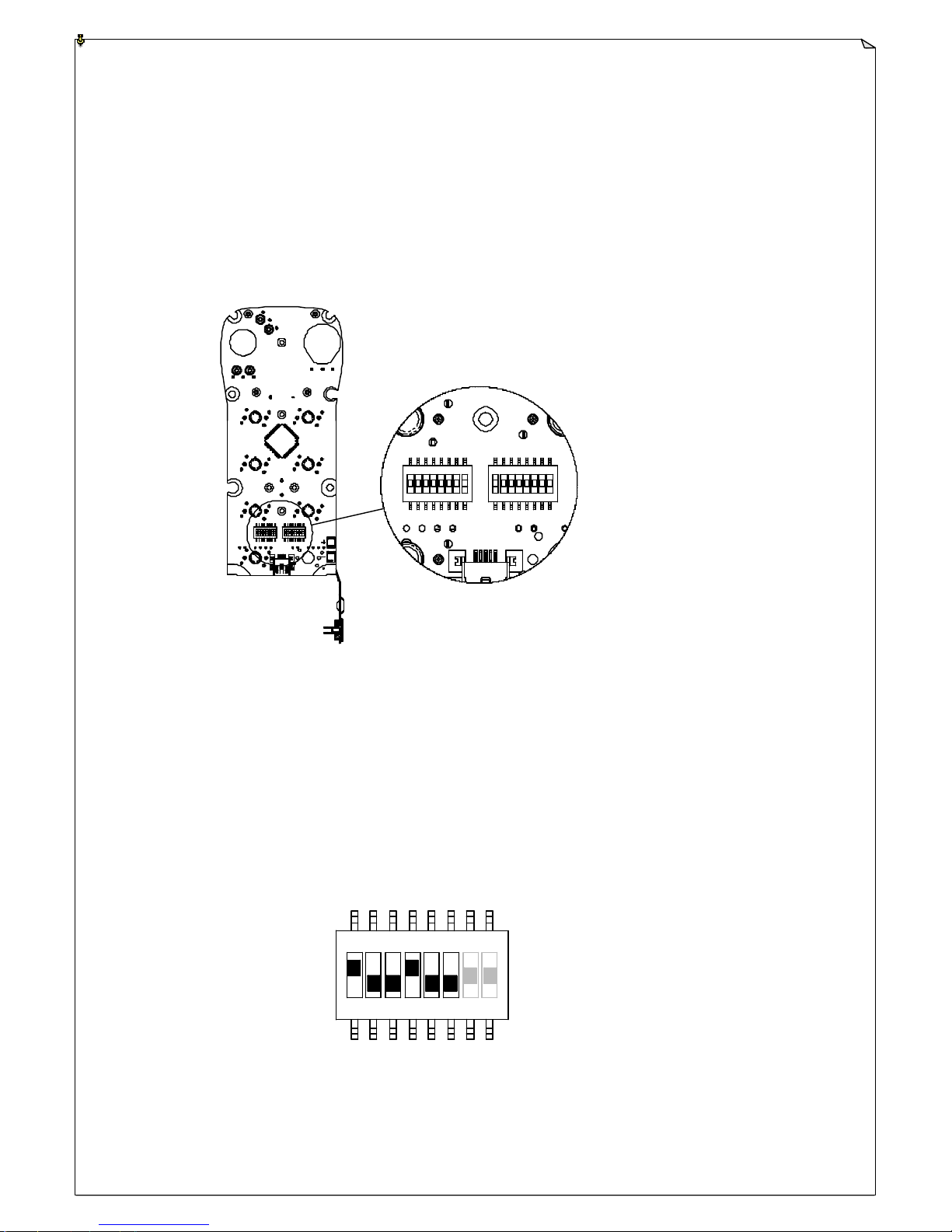

B. RECEIVER UNIT

1. System Channel Setting

Fig. 09

Set the receiver channel simply by adjusting the channel dip-switch located on the receiving board located

inside the receiver unit. The system channel table located on page 19 will tell you which dip setting

correspond to which channel. Do make sure that when you change the channel of the receiver you must

also change the channel of the transmitter as well. The channel on both transmitter and receiver mus t be

identical in order for the system to work.

Page 15

14

2. Output Relay Configurations

1. 3 Relays per Motion – Shared 2nd Speed Rely

For connections with output relay configuration as Forward 1st speed (F1), Reverse

1st speed (R1) and Forward/Rever se 2nd speed (F/R2) . Forward and Reverse 2nd

speed (F/R2) shared the same output.

2. 4 Relays per Motion (Type A) – Separate 1st and 2nd Speed Relay

For connections with output relay configuration as Forward 1st speed (F1), Reverse

1st spee d (R1), Forward 2nd speed (F2) and Reverse 2nd speed (R2). Forward and

Reverse 2nd speed its own output.

3. 4 Relays per Motion (Type B) – Shared 1st and 2nd Speed Relay

For connections with output relay configuration as Forward motion (F), Reverse

motion (R), Forward/Reverse 1st speed (F/R1) and Forward/Reverse 2nd speed

(F/R2).

4. 3-Relay Configuration with Close/Close Contact at 2nd Speed

At 2nd speed , both 1st and 2nd speed output relays are activated or closed (F+FR2 or

R+FR2 relays activated).

5. 4-Relay (Type-A) Configuration with Open/Close Contact at 2nd Speed

At 2nd speed, only 2nd speed output relay is activated or closed (F2 or R2 relay

activated)

6. 4-Relay (Type-A) Configuration with Close/Close Contact at 2nd Speed

At 2nd speed, both 1st and 2nd speed relays are activated or closed (F+F2 or R+R2

relays activated)

7. 4-relay (Type-B) Configuration with F/FR2 Contact at 2nd Speed

At 2nd speed, both forward/reverse motion and 2nd speed relays are closed (F+FR2 or

R+FR2 relays activated)

8. 4-Relay Configuration with F/FR1/FR2 Contact at 2nd Speed

At 2nd speed, forward motion, forward/reverse 1st speed and forward/reverse 2nd

speed relays are close ( F+FR1+FR2 relays activated)

9. ON/OFF Function

The user can set the two adjacent push buttons to act as an ON & OFF power switch.

Pressing the OFF button will activates the OFF output relay and deactivates the ON output

relay.

Page 16

15

10. Magnet ON/OFF Function

The user can set the two adjacent push buttons to control a magnet. To activate the magnet

just press the button with the Magnet symbol. To deactivate the magnet, for safety purpose,

you must press and hold the button with the Magnet symbol and press the OFF button.

Pressing the OFF button alone can and will not deactivate the magnet.

11. Brake Function

When the transmitter push button is released from 2nd speed down to 1st speed, electronically,

both 1st and 2nd speed output relays will be deactivated for up to 1.0 second and then with 1st

speed output relay reactivated thereafter.

12. External Warning Function

The user can install an external warning device (rotating lights, horn, etc … ) to a special

“function relay” located inside the receiver. The user can choose which push button pairs or

crane motion he wants to have external warnings when push button is pressed. If the

programmed push button is pressed it will activate the function relay thus activating the

external warning device.

13. Momentary Contact

When push button is released the output relay corresponds to that push button will be

deactivated.

14. Toggled (Latching) Contact

When push button is released the output relay corresponds to that push button will remained

activated until next time the user presses the same push button again.

15. 3rd Speed Function

This function allows the crane to travel additional step beyond 2nd speed. At second speed,

pressing the 3rd speed push button will toggle between 2nd and 3rd speed.

16. Auxiliary Stop Function

The special stop function acts as a 2nd emergency stop button. The receiver MAIN will also

be deactivated when this Stop push button is pressed.

Page 17

16

3. Dip-Switch Settings

There are six dip-switches located on the decoder board, whi ch is one dip-switch per motion or

push button pair (1 dip-switch per left and right push button) .

Fig. 10

Dip Settings

Relay Functions

# of Relays

Used

0000001 Closed/Closed Relay Action at 2nd Speed 4

0000010 Closed/Closed Relay Action at 2nd Speed 3

0000011 Opened/Closed Relay Action at 2nd Speed 4

0000100 F/FR2 Relay Action at 2nd Speed 4

0000101 F/FR1/FR2 Relay Action at 2nd Speed 4

0000110 On/Off 2

0000111 Magnet On/Off 2

0010001 Closed/Closed Relay Action + External Warning 4

0010010 Closed / Close d Relay Action + External Warning 3

0010011 Opened/Closed Relay Action + External Warning 4

0010100 F/FR2 Relay Action + External Warning 4

0010101 F/FR1/FR2 Relay Action + External Warning 4

0100001 Closed/Closed + Brake 4

0100010 Closed/Closed Relay Action + Brake 3

0100011 Opened/Closed Relay Action + Brake 4

0100100 F/FR2 Relay Action + Brake 4

0100101 F/FR1/FR2 Relay Action + Brake 4

0110001 Closed/Closed Relay Action + Brake + External Warning 4

0110010 Closed/Closed Relay Action + Brake + External Warning 3

0110011 Opened/Closed Relay Action + Brake + External Warning 4

0110100 F/FR2 Relay Action + Brake + External Warning 4

0110101 F/FR1/FR2 Relay Action + Brake + External Warning 4

Page 18

17

Dip-Switch Settings - Continued

Dip Settings

Relay Function for the

Left Push Button

Relay Function for the

Right Push Button

# of Relays

Used

1000000 Momentary Contact Momentary Contact 2

1001000 Toggled Contact Momentary Contact 2

1000001 Momentary Contact Toggled Contact 2

1001001 Toggled Contact Toggled Contact 2

1000010 Momentary Contact 3rd Speed 2

1001010 Toggled 3rd Speed 2

1010000 3rd Speed Momentary Contact 2

1010001 3rd Speed Toggle Contact 2

1000111 Momentary Contact Auxiliary Stop 2

1001111 Toggled Contact Auxiliary Stop 2

1010111 3rd Speed Auxiliary Stop 2

1111000 Auxiliary Stop Momentary Contact 2

1111001 Auxiliary Stop Toggled Contact 2

1111010 Auxiliary Stop 3rd Speed 2

Page 19

18

4. Jumper Settings

Jumper settin gs are applied to functions such as MAIN cutoff time, system startup and

transmitter push button layout. The jumpers are located on top of the dip -switches.

Fig. 11

Jumper Settings

Function

JP1

(Blank)

JP2

(Blank)

Receiver MAIN never deactivates unless transmitter power is turned off or

emergency stop command is initiated

JP1

(Inserted)

JP2

(Blank)

Receiver MAIN deactivates automatically after 5 minutes of inactivity.

JP1

(Blank)

JP2

(Inserted)

Receiver MAIN deactivates automatically after 30 minutes of inactivity.

JP1

(Inserted)

JP2

(Inserted)

Receiver MAIN deactivates automatically after 60 minutes of inactivity.

JP4

(Blank)

JP5

(Blank)

Normal right-to-left push button configuration

JP4

(Blank)

JP5

(Inserted)

In-line push button configuration (top to bottom)

Page 20

19

5. System Channel Table

Channel Dip Setting Channel Dip Setting

I-CHIP 000000 note A 32 100000

01 000001 33 100001

02 000010 34 100010

03 000011 35 100011

04 000100 36 100100

05 000101 37 100101

06 000110 38 100110

07 000111 39 100111

08 001000 40 101000

09 001001 41 101001

10 001010 42 101010

11 001011 43 101011

12 001100 44 101100

13 001101 45 101101

14 001110 46 101110

15 001111 47 101111

16 010000 48 110000

17 010001 49 110001

18 010010 50 110010

19 010011 51 110011

20 010100 52 110100

21 010101 53 110101

22 010110 54 110110

23 010111 55 110111

24 011000 56 111000

25 011001 57 111001

26 011010 58 111010

27 011011 59 111011

28 011100 60 111100

29 011101 61 111101

30 011110 62 111110

31 011111 Reserved 111111

Note A: When set to all “0” the priority goes to the channel assigned inside the I-CHIP

Note B: Use only dip position #1 through position #6 for system channel setting.

Page 21

20

6. Receiver Installation

A. OUTPUT RELAY CONTACT DIAGRAM

Fig. 12

Page 22

21

B. RECEIVER MOUNTING

1. Pre-installation Precautions

1. Make sure that the transmitter and receiver are with identical serial number, channel and ID

code.

2. Make sure the receiver is not set to the same channel as any other systems in use in the

surrounding area.

3. Prior to installation, make sure that the crane or equipment is working properly prior to

installation.

4. Make sure the power source to the receiver is set correctly.

5. Prior to installation, switch off the main power source to the crane or equipment.

Fig. 13

Page 23

22

2. Step-By-Step Installation

1. For better reception, the location of the receiver should be visible to the operator at all time.

2. The location selected should not be exposed to high levels of electric noise. Mounting the

receiver next to an unshielded variable frequency drive may cause minor interference.

Always locate the receiver as far away from variable frequency drive as possible.

3. Ensure the selected location has adequate space to accommodate the receiver.

4. Make sure the receiver is in upright position.

5. Drill two holes (10mm in diameter) on the control panel or location where the receiver is to be

install ed (Refer to Fig. 13 on page 21).

6. Make sure the bolts are tightened after installation.

7. For system wiring please refer to Fig.12 on page 20.

3. System Testing

1. Turn on the power source to the receiver and test the MAIN relay output by pressin g the red

emergency stop button and observe that it properly opens and closes the main line

disconnect contactor.

2. Test the operation of each function to ensure it corresponds to the transmitter direction labels

or the pendent it is replacing.

3. Test the limit switches to see if they are working properly.

4. If your new remote control is replacing an existing pendant, make sure it is completely

disconnected and placed in a safe location to prevent unwanted control command.

Page 24

23

7. Operation Procedure

A. TRANSMITTER OPERATION

a. Reset the emergency stop button located on the top left hand side of the transmitter handset by

rotating it either clockwise or counter clockwise, the red button will pop up.

b. Turn on the transmitter power by inserting the black-colored key onto the power key slot located on

the top right hand side of the transmitter handset and rotate it clockwise to “On” position.

c. After turning on the transmitter power, the green light on the transmitter status LED will light up for

up to 2 seconds, which means that the system is ok. If the green light did not appear on the Status

LED, then please refer to “Status Light Indicators & Warnings” on page 24.

d. If there are no signs of any system irregularities, then rotate the power key further clockwise to

“Start” position for up to 1 second, this will activate the receiver MAIN. The power key will

retract back to “On” position automatically after release.

e. Now press any push button on the transmitter handset to operate the crane or equipment.

f. In case of an emergency press down the red emergency stop button will immediately disconnect the

receiver mainline. The transmitter status LED will blink red (refer to page 24). To reset the

emergency stop button just rotate the red button either direction, it will pop up. Then rotate the

power key to “start” to resume operation (MAIN activated) .

g. To turn off the transmitter handset, just rotate the power key to “Off” position, it will disconnect the

transmitter power and the receiver MAIN altogether .

h. Change batteries simply by unscrew the battery cover located on the back side of the transmitter

handset.

Page 25

24

B. STATUS LIGHT INDICATORS & WARNINGS

1. Transmitter STATUS Light Indication

Type Display Type Indication

Voltage below 2.3V at initial power on,

transmitter shuts off, change batteries

1

Constant red

Voltage below 1.8V during operation,

transmitter shuts off, change batteries

2

Blinking red

“on” → 0.15 second

“off” → 1.85 seconds

Voltage below 2.2V during operation, warning,

change batteries suggested

3

2 red blinks followed by a

1.85-second pause (off)

The pushbutton

jammed or defective

4

3 red blinks followed by a

1.85-second pause (off)

EEPROM error

5

4 red blinks followed by a

1.85-second pause (off)

Transmitting error, system can not locked on

to the designated channel

6

Constant green for 2 seconds

Transmitter power on prior to initiating the

START function

7

Blinking green at every 2-second

interval

When pushbutton is pressed, signal transmitted

8

Blinking red

“on” → 1.0 second

“off” → 1.0 second

Stop command initiated with MAIN

disconnected

Page 26

25

2. Receiver STATUS Light Indication

Type Display Type Indication

1

Blinking red

Stop command initiated with MAIN

disconnected

2

Blinking green (fast) Decoding in process

3

Blinking green (slow) Decoding on standby

3. Receiver SQ Light Indication

Type Display Type (Red) Indication

1

On Transmission received

2

Off No transmission

3

Blinks intermittently (fast) Other radio interference

4. Receiver POWER Light Indication

Type Display Type (Red) Indication

1

On Power to receiver

2

Off No power to receiver

5. Receiver COM Light Indication

Type Display Type (Red) Indication

1

On Power to relay board

2

Off No power to relay board

Page 27

26

C. TROUBLE SHOOTING TIPS

Problems Possible Causes Recommendation

Transmitter low battery power

Check the transmitter battery level

Emergency stop button

activated prior to st artup

Prior to turning on the transmitter power

switch make sure that the red emergency

stop button is elevated.

Improper startup procedure

Redo the startup procedure by holding

the power key at “START” position for

up to 1.0 second and then release

Incorrect system RF channel

Check and make sure that the transmitter

handset and receiver unit both have the

same system RF channel

Incorrect system ID code

Check and make sure that the transmitter

handset and receiver unit both have the

same system ID code

No responds when

transmitter push

button is pressed

(Improper startup & settings)

System out of range

Make sure that the startup procedure

must be done within 150 feet from the

receiver location

Defective transmitter and

receiver RF board

Check the SQ display on the face of the

receiver unit. If it does not light up

when push button is pressed then either

the transmitter or receiver RF board is

defective. First replace the transmitter

RF board. If SQ display still not lid

when push button is pressed then the go

ahead and replace the receiver RF

board.

No responds when

transmitter push

button is pressed

(Damaged hardware)

Defective transmitter encoder

board

If still no responds, then replace the

transmitter encoder board.

Incorrect input voltage

Make sure the source voltage is set

correctly

Blown fuse Check for any blown fuse

No AC power to

the receiver

Incorrect wiring Check input voltage connection

Outputs do not

correspond to

transmitter

Incorrect output connection

Check the entire system wiring again.

Please refer to the output diagram on the

face of the receiver unit

Page 28

27

8. System Specifications

Frequency Range : 433~43 4 MHz

Number of Channels : 62 channels adjustable

Channel Spacing : 25 KHz

Modulation : Digital Frequency Modulation based on Manchester

Code, 20bit address, 32bit CRC Parity Check and

Hamming Code.

Decoder : Microprocessor-controlled

Hamming Distance : 4

Frequency Control : Synthesized PLL (Phase Lock Loop)

Receiver Sensitivity : -112dBm

Spurious Emission : -50dB

Antenna Impedance : 50 ohms

Tran smitting Power : 0.25mW

Enclosure Rating : IP-66

Output Contact Rating : 250V @ 10 Amps

Transmitter Operating Voltage : 3.0V

Receiver Power Consumption : 11.0 VA

Operating Temperature : -13℉ ~ 167℉

Transmitter Dimension : 23.cm (L) x 6.9cm (W) x 3.5cm (H)

Receiver Dimension (All Models) : 36.3cm (L) x 22.8cm (W) x 7.0cm (H)

Transmitter Weight : 12.5 ounce (include batteries)

Receiver Weight (All Models) : 5.5 pound

Number of Motions : Up to 6 Motions (12 pushbuttons)

Page 29

28

9. Spare Parts

1. Transmitting Board (433/434MHz) TRB 01

2. Encoder Board (complete with push buttons) ENB 06

3. I-CHIP (complete) ICP 01

4. Receiver Board RVB 01

5. Decoder Board DEB 01

6. Receiver Relay Board RLB 06

7. AC Line Filter Board LFB 01

8. Power Transformer PTF 01

9. Transmitter Top Casing TTC 03

10. Transmitter Bottom Casing TBC 03

11. Transmitter Battery Cover TBC 04

12. Receiver Top Casing RTC 01

13. Receiver Bottom Casing RBC 01

14. Cord Grip / Cable Gland CGR 01

15. Shock Absorber SAB 01

16. 2-Speed Push Button PBN 02

17. 3-Stage Selector Switch SWT 01

18. Push Button Rubber Boot PRB 01

19. Emergency Stop Button EMS 01

20. Transmitter Power Keys Switch PWK 01

21. Waist Belt WBT 01

22. Waist Belt Ring WBR 01

23. Safety MAIN relay SMR 01

24. Regular Output Relay RLY 01

25. Dust Cover CVR 03

Loading...

Loading...