Page 1

NAVWEPS 16-30ARC5-501

Handbook

BENCH TEST

And

ALIGNMENT PROCEDURE

RADIO EQUIPMENT

AN/ARC-5

PUBLISHED BY DIRECTION OF THE CHIEF OF THE BUREAU OF NAVAL WEAPONS

1 October 1949

Page 2

TABLE OF CONTENTS

SECTION I INTRODUCTION

1--1. PURPOSE OF BENCH MAINTENANCE PROCEDURE.

1--4. DESCRIPTION OF PROCEDURE.

1--6. USE OF THE PROCEDURE.

1--11. GENERAL DESCRIPTION OF AN/ARC-5 EQUIPMENT.

1--14. TEST EQUIPMENT.

SECTION II PERFORMANCE CHECKS

2--1. GENERAL.

2--4. RECEIVER CHECKS.

2--9. BAND NOISE.

2--12. SENSITIVITY.

2--15. SELECTIVITY.

2--17. AVC CHARACTERISTICS.

2--21. TRANSMITTER CHECKS.

2--26. TRANSMITTER TRACKING AND LOADING.

2--29. MODULATION CHECK.

SECTION III ALIGNMENT PROCEDURE

3--1. RECEIVER ALIGNMENT.

3--6. TRANSMITTER ALIGNMENT.

SECTION IV TROUBLE ISOLATION

4--1. RADIO RECEIVER.

4--4. AUDIO-FREQUENCY CIRCUIT.

4--6. INTERMEDIATE-FREQUENCY CIRCUIT.

4--8. CONVERTER CIRCUIT. (Follow chart below).

4--10. RADIO-FREQUENCY CIRCUIT.

4--11. ANTENNA CIRCUIT.

4--12. TRANSMITTER AND MODULATOR.

4--15. OSCILLATOR.

4--16. FINAL AMPLIFIER.

4--17. MODULATOR.

Page 3

Page 4

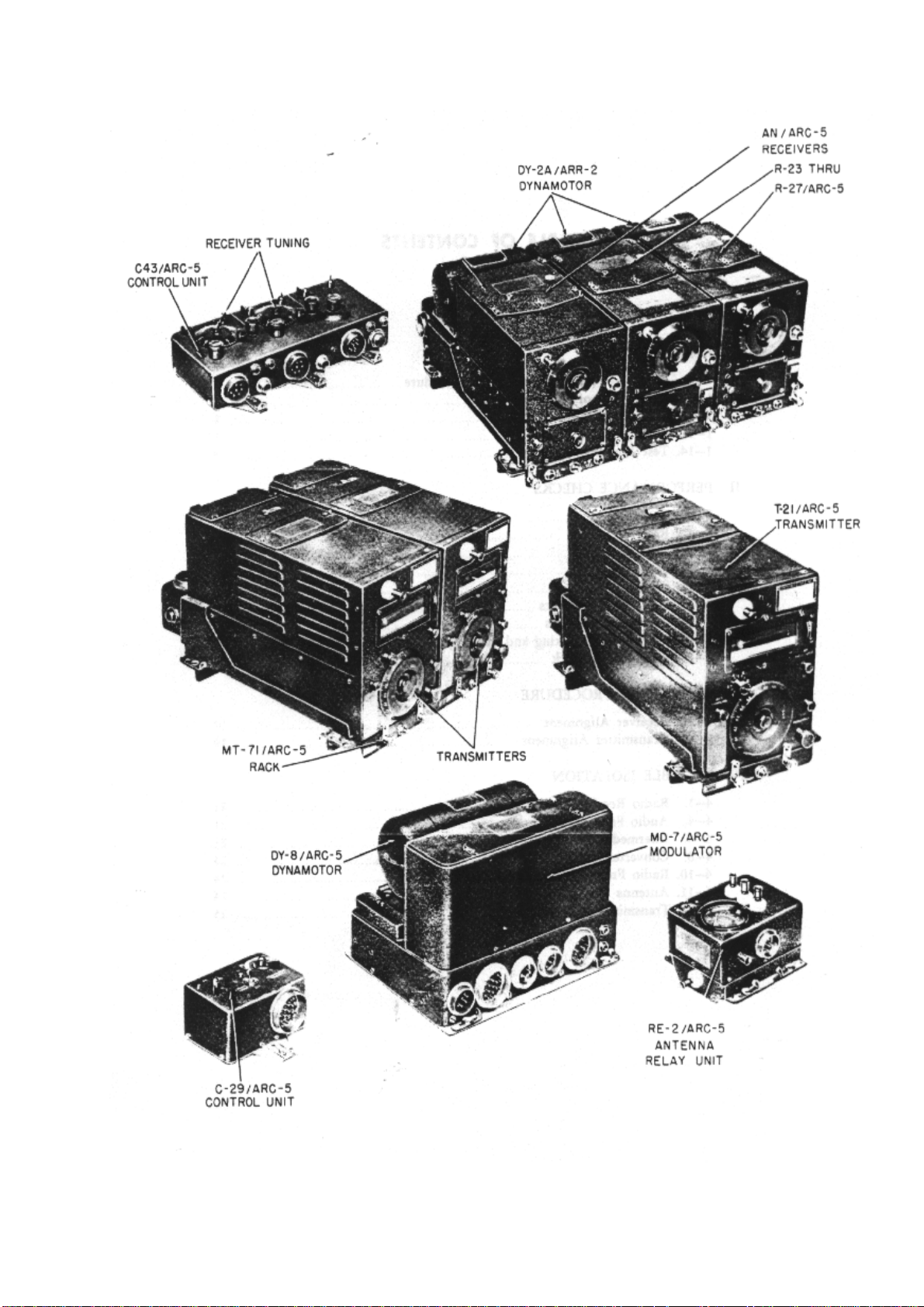

Figure 1-1. AN/ARC-5 Equipment

SECTION I INTRODUCTION

1--1. PURPOSE OF BENCH MAINTENANCE PROCEDURE.

1--2. The basic approach used in the development of this manual has been that of dividing all

equipments into two categories:

a. Components operating at or above a minimum standard of satisfactory performance.

b. Defective or poorly performing components.

1--3. Bench maintenance is reduced, first, to determining whether or not an equipment is operating

satisfactorily, and, second, repairing the equipment if it is found to be defective. This division results in

a procedure having four sections:

a. INTRODUCTION -- This section presents a brief description of the basic function of the subject

equipment, its primary power requirements, inter-unit connecting cables, a suggested bench mock-up,

and other information necessary for quick reference with respect to proper maintenance techniques.

b. PERFORMANCE CHECKS -- These are of primary importance and are to be performed in

sequence upon the subject equipment. An equipment that meets all the requirements of this series of

checks is thereby determined to be satisfactory. An equipment that fails in any one of several of the

check requirements is assigned, by means of proper references, to the appropriate steps in one or

both of the two sections described below.

c. ALIGNMENT -- This section details the steps necessary to return the equipment to a properly

aligned condition. Practical methods requiring a minimum of maintenance time are employed.

d. TROUBLE ISOLATION -- This section of the procedure is divided into sections, each of which deals

with a specific component, stage or stages according to the function of the equipment. When the

maintenance technician is referred to a section of TROUBLE ISOLATION by the failure of the

equipment to meet the standards set up in PERFORMANCE, he will find detailed instructions and data

pertinent to the function. Additional aids in the form of sectional schematics and suggested testing

techniques are at his fingertips. This eliminates time-consuming manual searching, thus increasing the

work output and efficiency of the technician.

1--4. DESCRIPTION OF PROCEDURE.

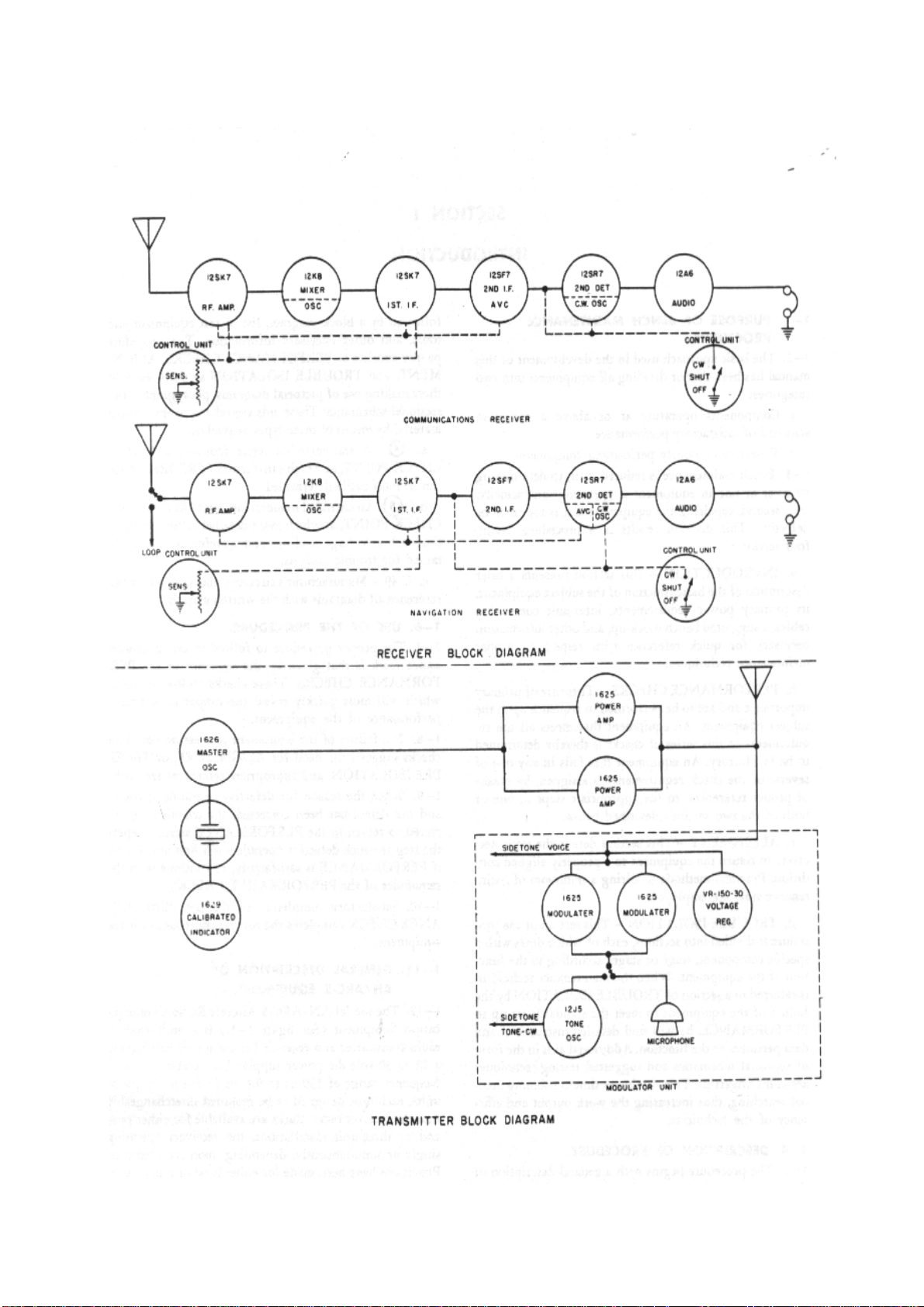

1--5. The procedure begins with a general description of the appearance, function, and operational

characteristics of the AN/ARC-5 Communications Equipment. It is followed by a block diagram, list of

test equipment and tools, and other necessary information. The procedure proper consists of

PERFORMANCE CHECKS, ALIGNMENT, and TROUBLE ISOLATION sections, each of these

making use of pictorial diagrams, photographs, and sectional schematics. These aids are related to

the written material by means of three types of symbols:

a. A star-encircled letter indicates a MAJOR CHECK POINT, at which satisfactory PERFORMANCE

can be most easily determined.

b. An encircled numeral indicates SECONDARY CHECK POINT, at which more detailed circuit

information such as voltage readings and waveforms, can be obtained for trouble analysis.

c. C-49 -- Manufacturer's circuit symbols, used to cross-reference all diagrams with the written

material.

1--6. USE OF THE PROCEDURE.

1--7. The proper procedure to follow in bench maintenance work is that given by the sequence of the

PERFORMANCE CHECKS. These checks follow an order which will most quickly reveal the proper or

improper performance of the equipment.

1--8. The failure of the equipment to meet one of these checks suggests the need for ALIGNMENT, or

TROUBLE ISOLATION, and appropriate references are made.

1--9. When the reason for defective operation is found and the defect has been corrected, the

technician is directed to return to the PERFORMANCE section, repeat the step at which defective

operation was first noted, and, if PERFORMANCE is satisfactory, to continue with the remainder of the

PERFORMANCE CHECKS.

1--10. Satisfactory completion of the last PERFORMANCE CHECK completes the bench maintenance

for the equipment.

Page 5

1--11. GENERAL DESCRIPTION OF AN/ARC-5 EQUIPMENT.

1--12. The model AN/ARC-5 Aircraft Radio Communication Equipment (See figure 1--1.) is a multichannel radio transmitter and receiver for use on aircraft having a 22 to 30-volt d-c power supply. The

receivers cover a frequency range of 190 kc to 9.1 mc in five independent units, each unit designed to

be mounted interchangeably into the receiver racks. Racks are available for either two, and/or threeunit installations, the receivers operating singly or simultaneously, depending upon requirements.

Provisions have been made for either local or remote control, but only remote controls are furnished

with the equipment. The receiver mounting racks will accommodate other rack types of equipment

such as the AN/ARR-2 Receiver and AN/ARC-5 VHF Transmitter-Receiver. These units will not be

covered in this procedure. The weight of the equipment, less cables and mechanical linkages, is 23.6

pounds for a two-receiver installation and 55.2 for a three-receiver installation.

1--13. The receivers are designed for the reception of CW, MCW or VOICE modulation. Manual gain

control is employed in conjunction with high level automatic gain control. The outputs of each receiver

may be paralleled on one line to a single headset, or divided for double headset reception by more

than one operator. A 600-ohm headset is to be used with this equipment. A single antenna is used for

all receivers and transmitters. The tuning dials are calibrated directly in mc and their accuracy is better

than 0.5 per cent. The transmitters cover the frequency range of 2.1 to 9.1 mc in five independent

units. They are designed to be installed in pairs. The transmitter frequency control dial is calibrated in

megacycles with an accuracy of .03 per cent or better. A crystal calibrator is used in conjunction with

an electron resonance indicator to spot-check the dial calibrations of each unit. The current drain from

the d-c power source is 8.8 amperes when transmitting with CW emission, and is reduced to 2.5

amperes on "stand-by". The carrier power output varies between eight watts with VOICE modulation to

Page 6

25 watts with CW emission.

Page 7

Figure 1-2. Receiver and Transmitter Block Diagrams

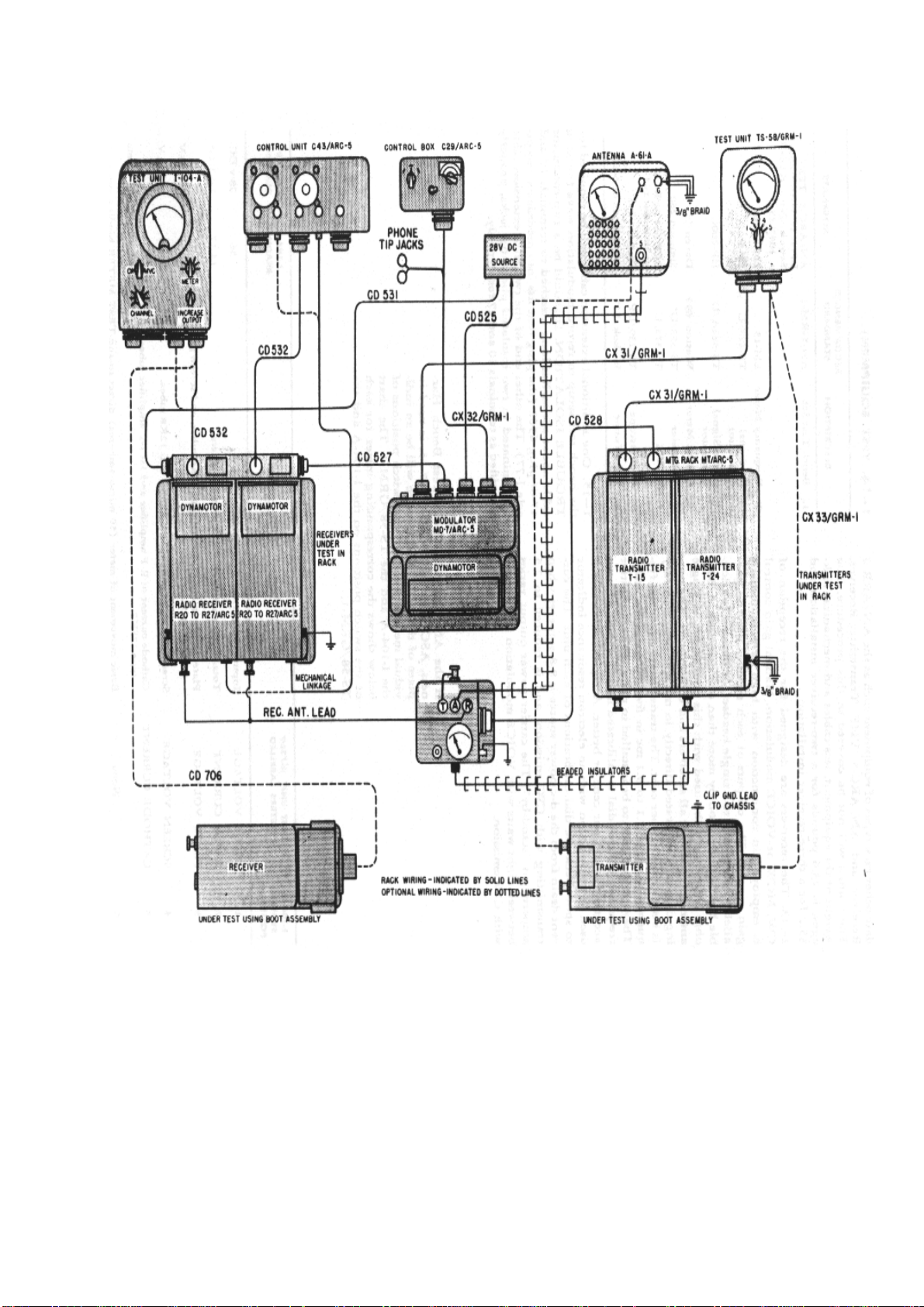

1--14. TEST EQUIPMENT.

DESCRIPTION RECOMMENDED

1. Bench Test Set AN/GRM-1 AN/ARC-5 TEST BENCH

2. Frequency Meter LM-13 LM Series

3. RF Signal

Generator

4. Audio Signal

Generator

5. Output Meter Weston 695 Daven OP-182

6. Voltmeter TS-352/U Simpson 260

7. VTVM TS-375/U RCP 662 or RCA Voltohmyst

8. Oscilloscope TS 239/UP Dumont 241

STANDARD

TS-413/U LP-5

TS-382A/U HP-200C

ALTERNATE

HARNESS Stock No. RI6-R1047-25

165

9. Tube Tester Hickok 547 Hickok 545 or 540

1--15. One additional extension cable will be required for the bench test setup to record modulation

wave forms in TROUBLE ISOLATION. It should be a two-conductor cable about six inches long

attached to terminals 10 and 17 of plug 6962 (the plug that fits into modulator receptacle (J-77). The

other end of the two wire extension cable is terminated in two insulated phone-tip jacks, properly

identified as terminals I0 and 17 respectively.

Note

If the AN/ARC-5/ARR-2A Test Bench Harness, ASO stock No. R16-R-1047-25, is

used in place of the AN/GRM-1, there will be an individual meter for each of the switch

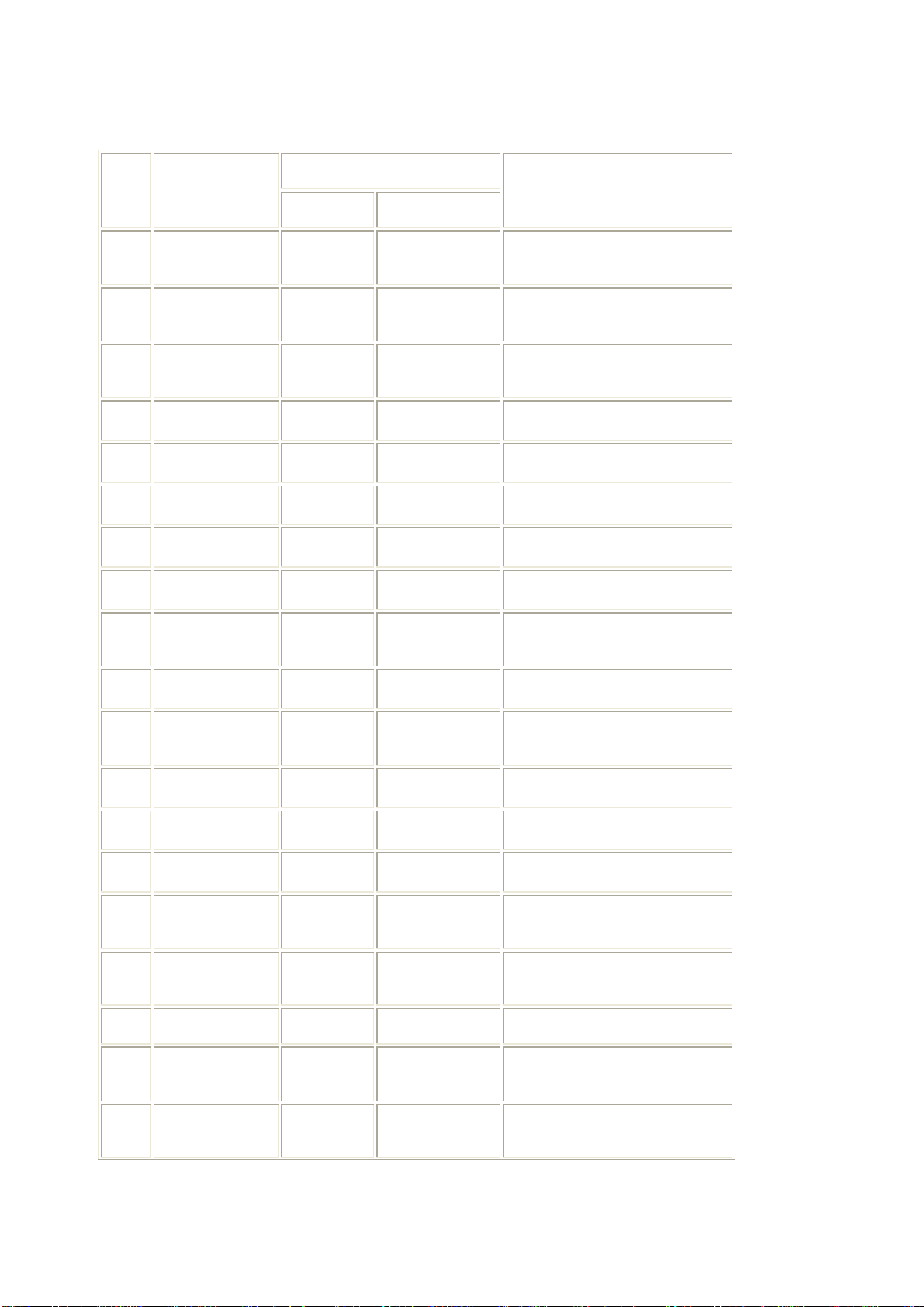

positions of the I-104-A and the TS-58/GRM-1. The chart below shows the

corresponding meter for each of the switch positions on the I-104-A and the TS58/GRM-1.

Page 8

Page 9

Figure 1-3. Test Equipment Diagram

I-104-A

SWITCH

POSITION

TEST

UNIT

#7369

CIRCUIT I-104-A

READING

#7369

READING

METERS

LABELLED

1 INPUT

VOLTAGE

2 INPUT

CURRENT

3 PLATE

VOLTAGE

Input voltage from primary

source.

Total input current from the

primary source.

Plate supply to 12SF7, 12SK7,

and 12K8 tubes, and screen grid

56 28 V DC

14-17 1.4-1.7 A

46-50 230-250 V

voltage on 12A6 tube.

4 SCREEN

VOLTAGE

5 CATHODE

CURRENT

Screen grid voltage to 12SF7,

12SK7 and 12K8 tubes.

Cathode current of R-F amplifier

and 1st I-F amplifier tubes, type

38-50 76-100 V

44-60 11-15 ma

12SK7s.

6 None Basic movement of meter (50 micro-amperes) direct to-and-

TEST METER binding posts on front panel of I-104-A. I-104A. Insert jumper wire between these two posts to protect the

meter movement.

TS-58/GRM-1

SWITCH

POSITION

TEST

UNIT

#9556

METERS

LABELLED

1 INPUT

VOLTAGE

2 SCREEN

VOLTAGE

3 PLATE

VOLTAGE

4 OSC.

PLATE

CURRENT

5 AMP.

PLATE

CURRENT

CIRCUIT

Input voltage from

primary source

Screen grid voltage to

PA tubes

Plate voltage to final PA

tubes

Plate current of master

oscillator tube, type

1626

Plate current of final PA

tubes type 1625

TS-58/GRM1 READING

#9556

READING

TONE CW TONE CW

54 54 27 27

28-31 48-

60

51-56 51-

55

32-46 32-

46

140155

510550

240300

510550

16-23 16-

23

ma

27-40 60-

80

68100

150200

ma

Page 10

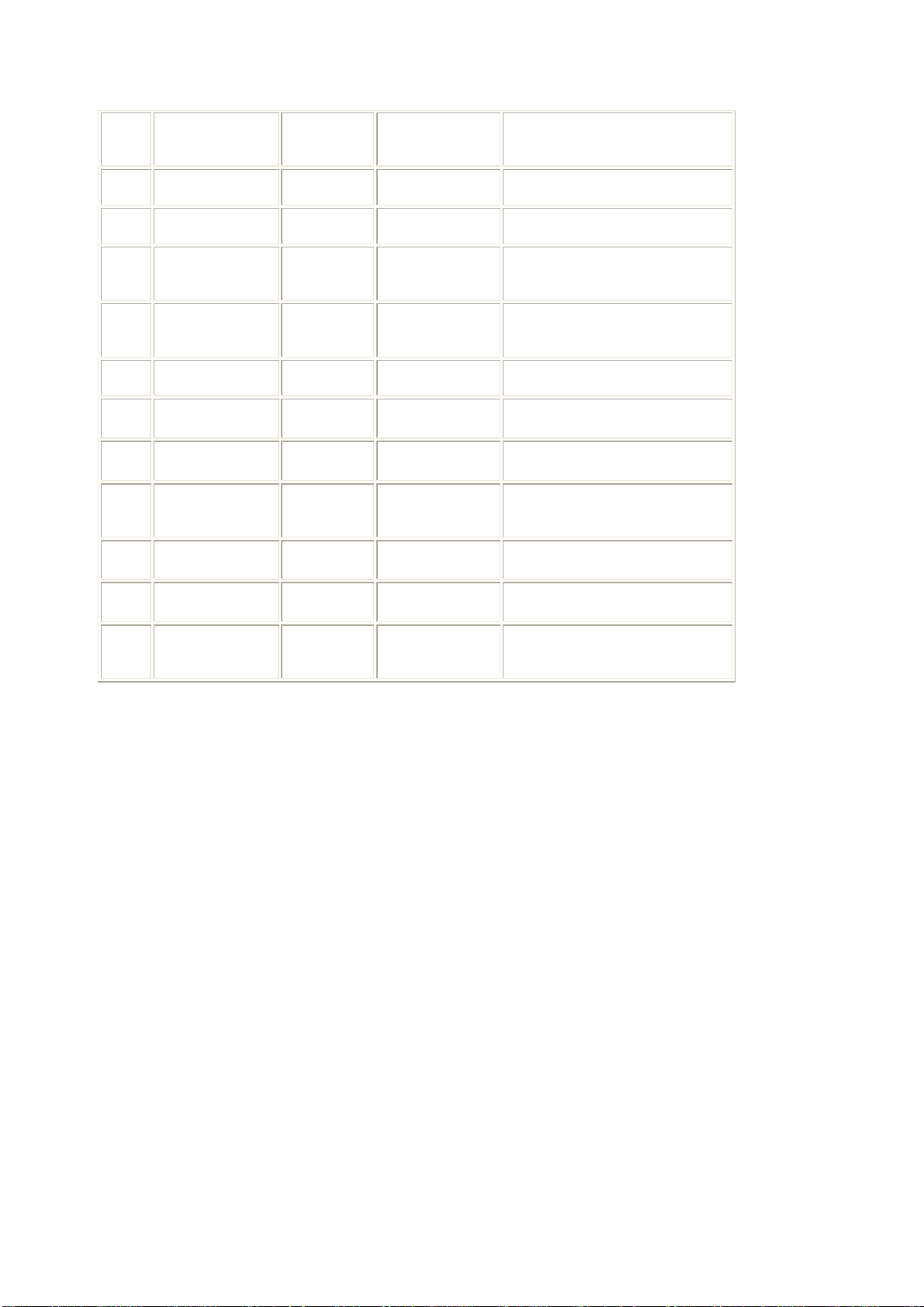

TEST SET COMPONENTS

TYPE QTY DESIGNATION

ARMY NAVY

1 Antenna A-61-A

1 ANT. Relay

Unit

1 Control Unit

1 " "

3 " " MC-237

1 Cord CD-525

2 " CD-527

1 " CD-528

BC-442-A RE-2/ARC-5 Antenna relay (LF, MF, HF

USE

C-29/ARC-5 Transmitter control (or C-

C-43/ARC-5 Receiver control

Phantom antenna (LF, MF, HF

radio transmitter)

radio transmitter)

30A/ARC-5)

Local tuning crank

DC Outlet to modulator

6-Conductor

5-Conductor

2 " CD-531

2 " CD-532

1 " CD-706

1 " CD-905

2 "

1 "

1 "

6 Diagram

1 Dynamotor DM-33-A DY-8/ARC-5 Dynamotor (transmitting)

1 Modulator

CX-31/GRM-1 12-Conductor

CX-32/GRM-1 18-Conductor

CX-33/GRM-1 Transmitter rack adapter (7-

MD-7/ARC-5 Modulator equipped with

DC Outlet to receiver rack (2Conductor)

8-conductor

Receiver Rack adapter (7Conductor)

Sidetone test

Conductor)

Instructions for test equipment

AN/GRM-1

tubes

1 Mounting Base FT-279-A MT-62/ARC-5 Mounting for MT-63/ARC-5 or

FT-277-A Receiver rack

Page 11

1 " FT-227-A MT-70/ARC-5 Mounting for MT-71/ARC-5

Radio transmitter rack

1 " FT-225-A MT-76/ARC-5 Mounting (modulator)

1 " FT-229-A MT-77/ARC-5 Mounting (antenna relay unit)

1 Mounting Plate FT-228-A MT-80/ARC-5 Mounting (transmitter control

C-29/ARC-5 or C-50A/ARC-5)

1 " FT-222-A MT-98/ARC-5 Mounting (Receiver control C-

43/ARC-5)

1 Mounting Rack FT-277-A MT-63/ARC-5 Rack for two radio receivers

1 "

1 Test Unit I-104-A

1 " TS-

1 Cord CD-307-A

1 Microphone

1 Headset HS-33

58/GRM-1

MT-71/ARC-5 Rack for two radio transmitters

RS-38A Microphone

Test unit for radio receivers

Test unit for radio transmitters

Headset extension cord

600-ohm headset (two ANB-

H-1 receivers or equivalent)

Page 12

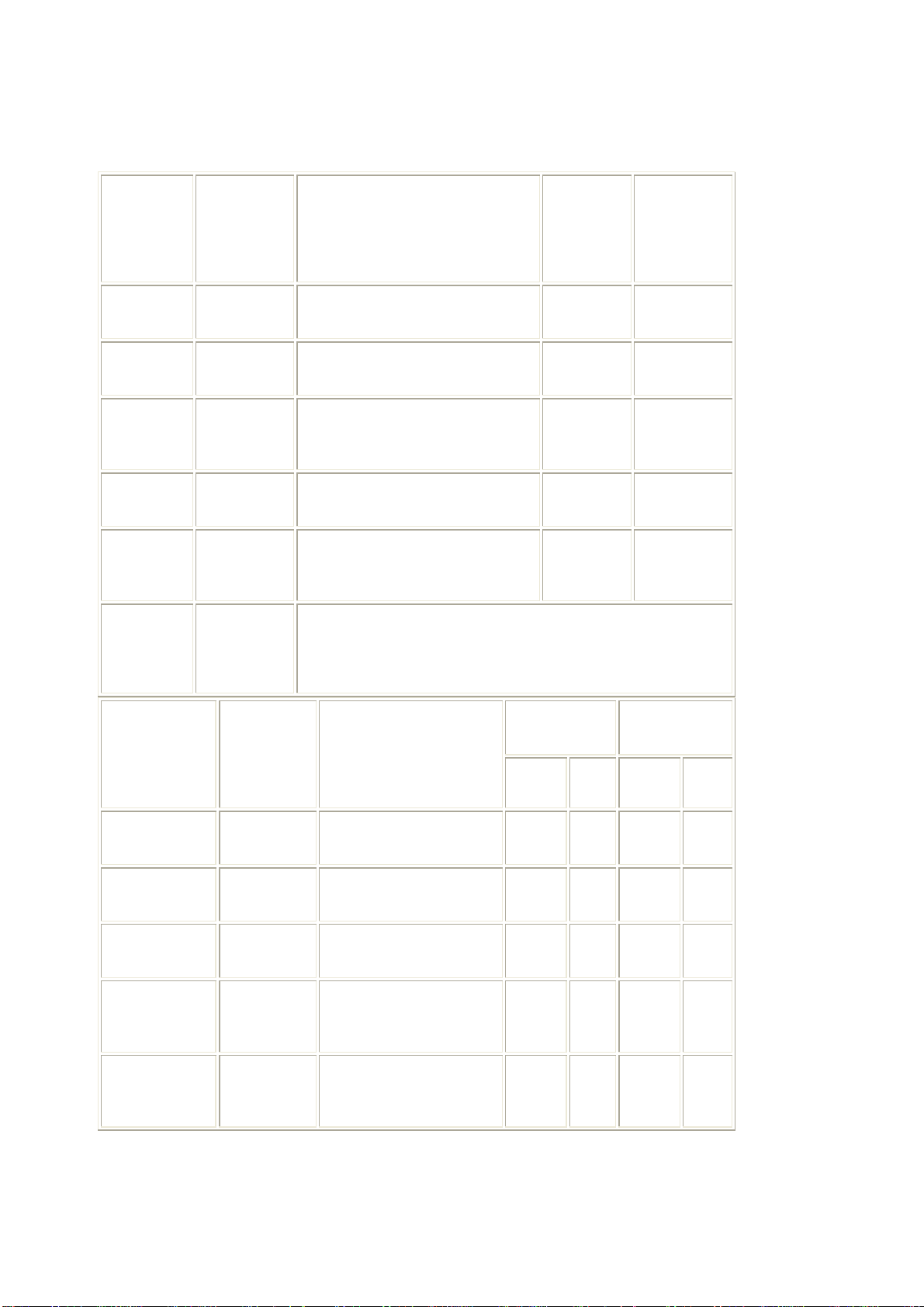

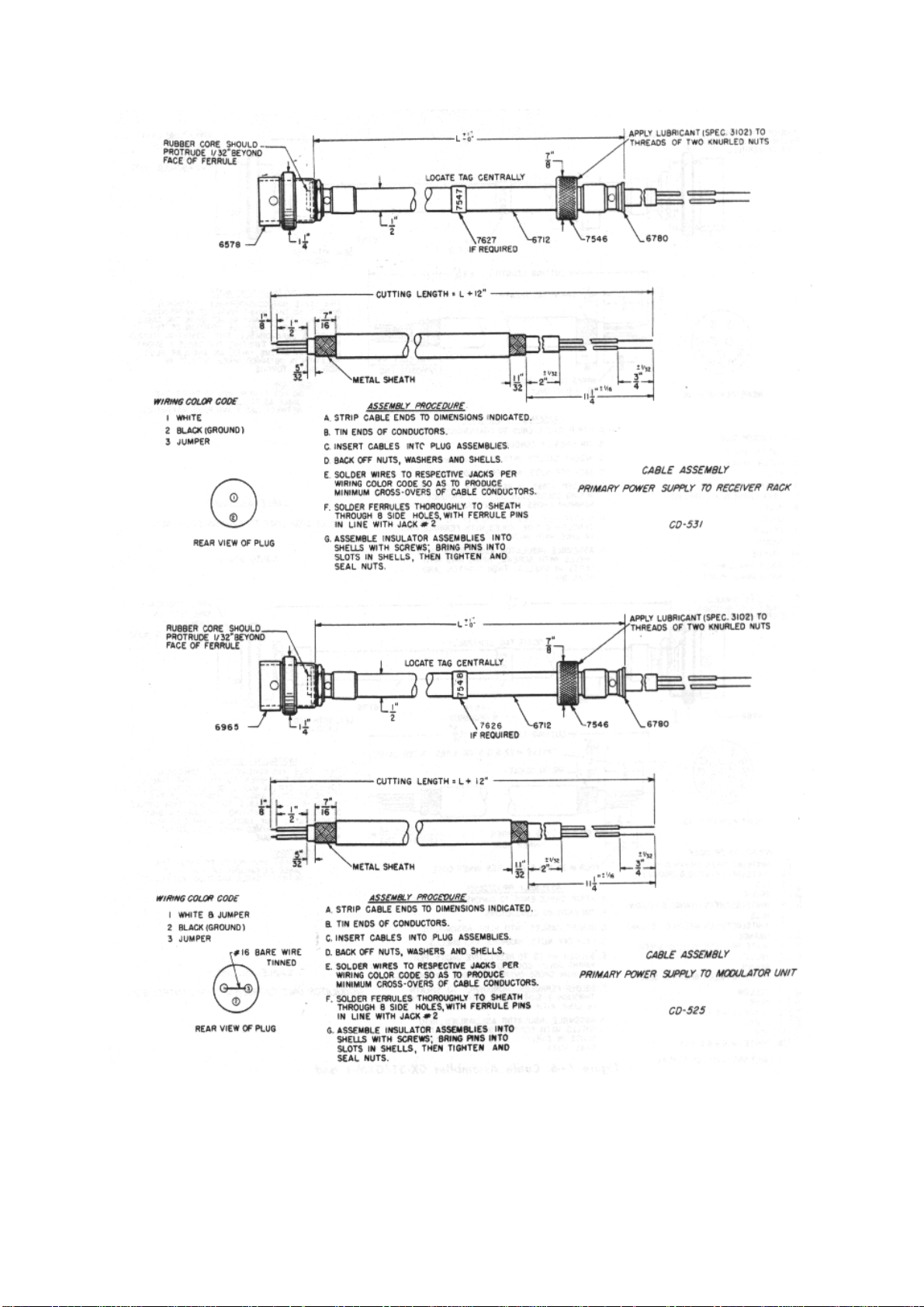

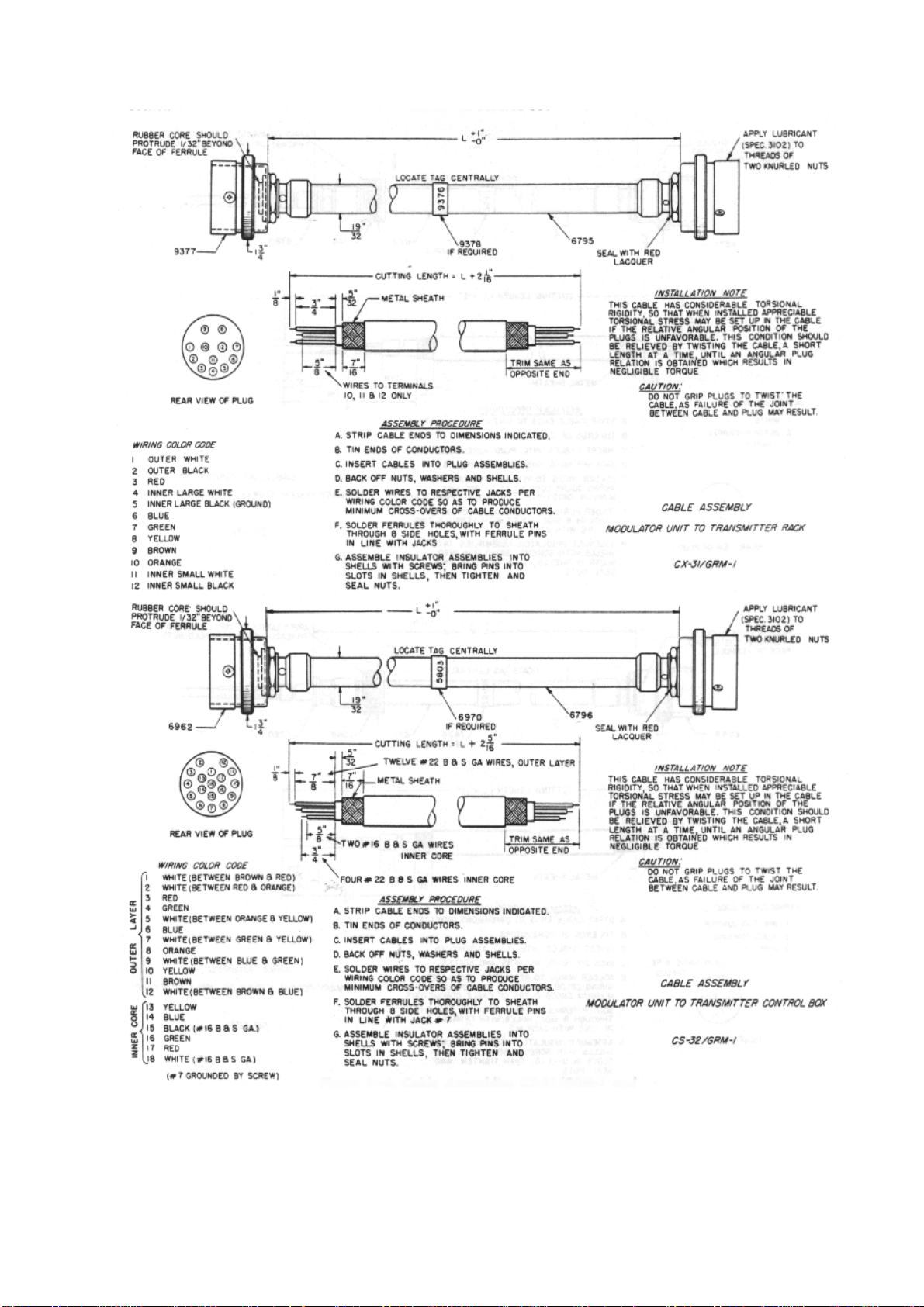

Figure 1-4. Cable Assemblies CD 532 and CD 528

Page 13

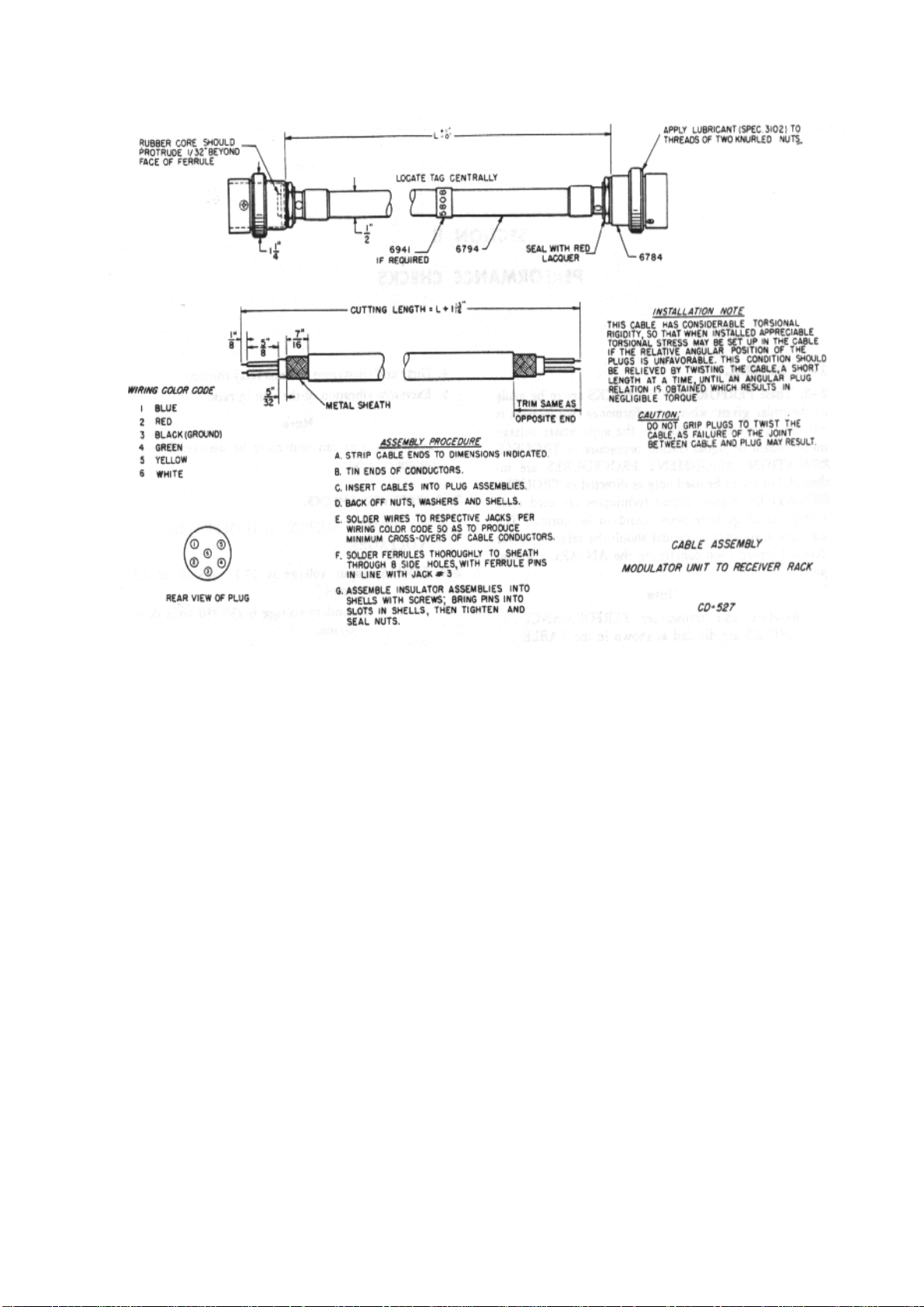

Figure 1-5. Cable Assemblies CD 531 and CD 525

Page 14

Figure 1-64. Cable Assemblies CX-31/GRM-1 and CS-32/GRM-1

Page 15

Figure 1-74. Cable Assembly CD 527

Page 16

NOTES

1. If Antenna relay unit RE-2/ARC-5, being tested, does not have a series capacitor, connect the

transmitter to "TRANS". Connect "ANT" of the antenna relay unit to terminal "A", instead of to terminal

"5", of antenna A-61-A.

2. Test Unit I-104-A normally is used with adapter cord CD-706 as shown. It may be used by attaching

cord CD-532 to either position of the receiver rack and when so employed, the meter will not indicate

when the meter switch is in position four or five. Volume control on AVC directly affects sidetone level.

3. The drawing shows the mechanical linkage (Part No. 6151) so that the mechanical tuning features

of the control units C-26 and C-43/ARC-5 and radio receivers R-20 to R-27/ARC-5 may be tested. No

linkage is furnished with the test equipment. Control unit MC-257 (local tuning crank) is furnished for

testing these receivers.

4. Test unit I-104-A may be made to function as a control unit and provide the channel selection when

testing VHF radio receiver R-28/ARC-5, by connecting cord CD-527 between jack J-103 on the radio

receiver and jack J-600 on the test unit.

5. Dynamotors *DY-2/ARR-2 and *DY-2A/ARR-2 are furnished with the particular radio receivers as

shown. Both dynamotors are interchangeable with dynamotors DM-32-A or CBY-21531.

6. Transmitters and receivers may be tested either by direct connection to the test equipment, using

cords CX-33/GRM-1 and CD-706, or by mounting in a one or two unit rack and using cords CX31/GRM-1 and CD-532.

Page 17

SECTION II PERFORMANCE CHECKS

2--1. GENERAL.

2--2. These PERFORMANCE CHECKS are to be made in the order given; when a performance

requirement is not met, a reference is made to the appropriate voltage measurement or signal tracing

procedure in TROUBLE ISOLATION. ALIGNMENT PROCEDURES are included, but are to be used

only as directed in TROUBLE ISOLATION. Signal tracing techniques are used after voltage readings

have been found to be normal. The standard maintenance manual should be referred to for detailed

information concerning the AN/ARC-5 Equipment.

Note

Receiver and transmitter PERFORMANCE CHECKS are divided as shown in the

TABLE OF CONTENTS.

2--3. VISUAL CHECKS. Connect the unit to be checked on the Test Set AN/GRM-1 rack and inspect

the unit for the following:

l. Faulty plugs, threads and pins.

2. Improper fusing.

3. Note evidence of excessive dynamotor ripple at the headset while tuning through the frequency

band.

4. Dirty and chattering antenna relay contacts.

5. Excessive vibration of the unit in rack.

Note

Open filaments can sometimes be detected by noting cold tubes.

2--4. RECEIVER CHECKS.

2--5. D-C POWER SUPPLY AND OPERATING VOLTAGES.

2--6. LIMITS: Input voltage is 27.5 volts dc at 1.7 amps.

Secondary voltage is 230-250 volts dc at 60 ma.

2--7. PRELIMINARY INSTRUCTIONS: Use Test Set AN/GRM-1, as shown in figure 1-3.

Use "Optional Wiring" for greater ease in maintenance testing. Do not key the transmitter. Apply d-c

power and turn the CONTROL SWITCH of Test Set I-104-A to MCW position, allowing the equipment

time to warm up. Do not remove the cover plates until trouble isolation or alignment is indicated by

performance failure. Advance INCREASE OUTPUT control to full clockwise position.

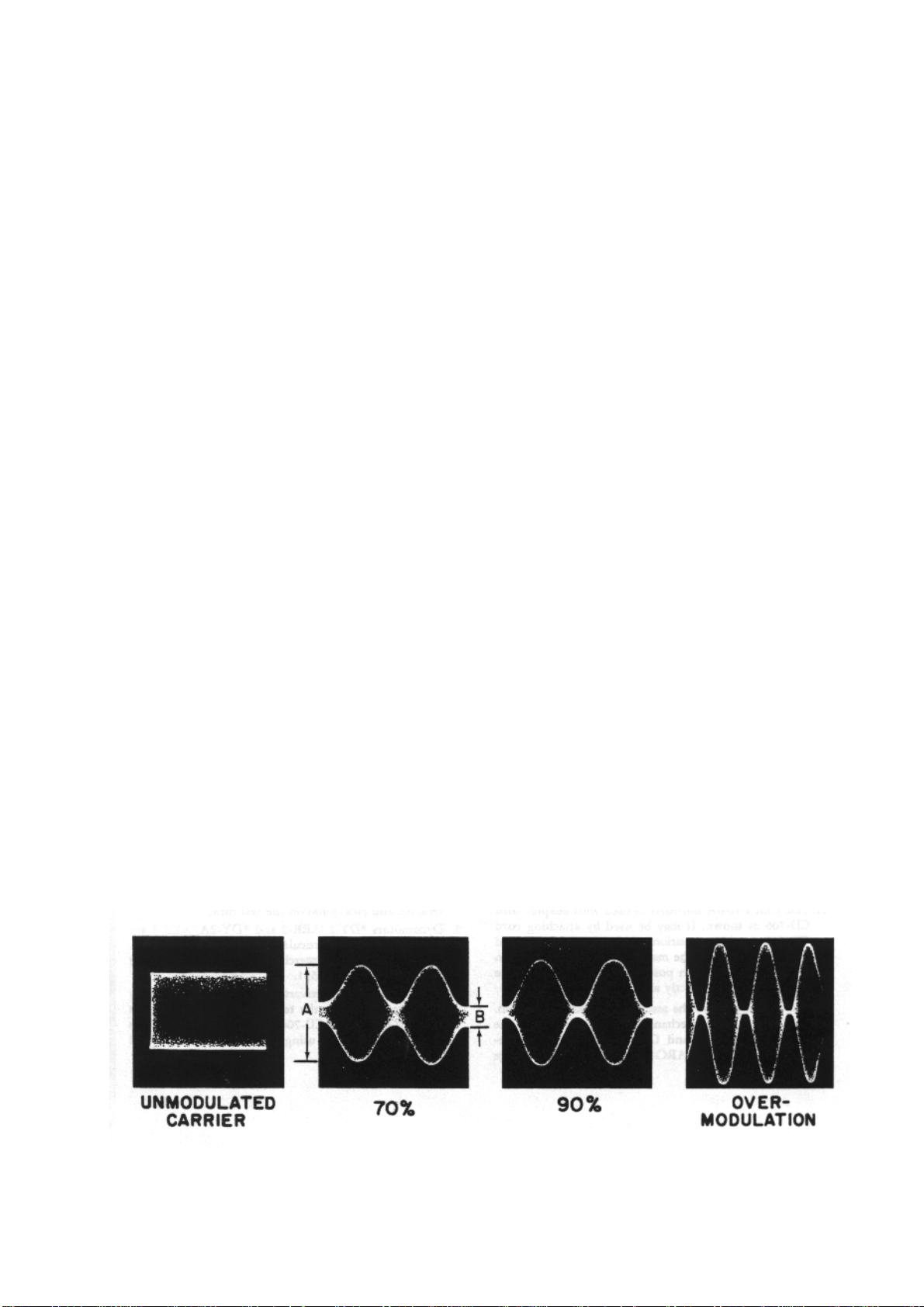

Figure 2-1. Modulation Envelopes

Page 18

2--8. TEST PROCEDURE.

STEP HEAD

TEST

SET

1 I-I04-A 1 Input voltage 27.5 v 56

2 I-I04-A 2 Input current 1.4-1.7 a 14-17

3 I-I04-A 3 Plate supply 230-250 v 46-50

4 I-I04-A 4 Screen

5 I-I04-A 5 Cathode

METER

SW

CIRCUIT

MEASURED

supply

current RF

and 1st IF

tubes

NORMAL

VALUES

76-100 v 38-50

11-15 ma 44-60

NORMAL

METER

INDIC.

2--9. BAND NOISE.

2--10. LIMITS: (Less than 15 milliwatts.)

2--11. TEST PROCEDURE.

ABNORMAL

METER INDIC.

Refer to

TROUBLE

ISOLATION

PROCEDURE,

Section IV,

Paragraph 4-1.

STEP TEST SET I-1O4-A NORMAL OUTPUT

INDICATION AND

CONNECTIONS

1 CONTROL SWITCH to CW or

MCW. INCREASE OUTPUT control

to maximum. Connect dummy

antenna (100 mmfd capacitor) from

Antenna post to ground. Use short

leads.

2 Peak receiver ALIGN INPUT

trimmer for maximum output at the

high frequency end of dial.

3 Turn the receiver frequency dial

from high to the low end and note

the maximum noise in the output

meter.

Output Meter, OP182, and

headphones

connected to

headset jack of 1104-A. Switch set to

600 ohms.

Reads less than 1.5

mw of noise.

Never exceed 1.5

mw.

POSSIBLE

CAUSES OF

ABNORMAL

IND.

Check dynamotor

brushes and

bearings.

Replace

dynamotor, if

necessary.

Same.

Page 19

2--12. SENSITIVITY.

2--13. LIMITS. Less than 10 uv R-F input to obtain 10 mw audio output with INCREASE OUTPUT

control set at maximum.

2--14. TEST PROCEDURE.

STEP RECEIVER

SETTINGS

1 FREQUENCY

at high end;

MCW

operation:

INCREASE

OUTPUT

control at

maximum.

2 Same as

Peak ALIGN

INPUT

trimmer.

Step 1.

SIG. GEN

CONNECTIONS

Through .006

mfd capacitor,

to receiver

Antenna post.

Set frequency to

agree with

receiver.

Use modulated

RF 30 per cent

at 400 or 1000

cycles.

Vary attenuator

to obtain 10 mw

receiver output.

OUTPUT INDIC.

&

CONNECTIONS

Output meter,

OP-182, and

headphones

connected to

headphone jack.

Set switch to

600 ohms.

Maximum

output.

Same as Step

1.

NORMAL

INDICATION

A peak on

output

meter.

10 uv input,

or less, to

obtain 10

mw audio

output.

POSSIBLE

CAUSES OF

ABNORMAL

IND.

Refer to

TROUBLE

ISOLATION,

Section IV,

paragraphs 4-4 to 4--11, and

ALIGNMENT

PROCEDURE,

Section 3--1.

3 Same as

Step 1.

except switch

to CW. Rock

receiver dial

carefully for

maximum

output.

4 Repeat Steps 1 through 3 with receiver dial set at low end.

Turn

MODULATION

switch to OFF.

Vary attenuator

to obtain 10 mw

receiver output.

Same as Step

1.

3.5 uv input

to obtain 10

mw output.

Check CW

oscillator and

ALIGNMENT

PROCEDURE,

Section III,

paragraph 3--

1.

Page 20

2--15. SELECTIVITY.

2--16. PRELIMINARY ADJUSTMENTS: Set the Model 695 output meter to the 1.5 volt range. Connect

a 300-ohm one-half or one watt composition resistor in parallel with the output meter; connect output

meter to receiver phone jack. Set the receiver INCREASE OUTPUT control to full counterclockwise

position. Tune the receiver and the signal generator to the proper frequency, as given in Table below.

Adjust the signal generator attenuators for 50 microvolts output, 30 per cent modulated at 400 cycles.

Advance the INCREASE OUTPUT control clockwise until the Model 695 output meter reads 1.0 volts.

The receiver dial and the ALIGN INPUT trimmer should be adjusted for maximum output meter

reading. Readjust the INCREASE OUTPUT control as necessary to give output meter reading of 1.0

volts. Receiver should be set for MCW operation.

STEP OUTPUT METER

SETTINGS

1 Switch output meter to 15

volt range.

2 Switch output meter to 6

volt range.

3 Switch output meter to 1.5

volt range.

4

5 Repeat Steps 1 through 4. Repeat Steps 1 through 4, detuning the

6 Compare values obtained in Steps 4 and 5; they should be very nearly equal in

value. Amount of frequency deviation recorded in Steps 4 and should not

exceed values given in Table below by more than 10 per cent.

SIGNAL GENERATOR SETTINGS

Adjust the output attenuators for 500 microvolts

output. (Switch MULTIPLIER to 100 position.)

Slowly detune FREQUENCY dial higher in

frequency until output meter reads less than 6.O

volts.

Slowly detune FREQUENCY dial higher in

frequency until output meter reads slightly less

than 1.5 volts.

Slowly and carefully detune FREQUENCY dial

higher in frequency until output meter reads 1.0

volts.

Record the amount of frequency deviation from

original setting at resonance, as given in

PRELIMINARY ADJUSTMENTS.

FREQUENCY dial lower in frequency.

7 Repeat Steps I through 5 on the R-23 (.19-.55 mcs.) receiver, with 50,000

microvolts input, instead of 500. Specifications given in Step 6 also apply.

RECEIVER FREQUENCY FREQUENCY DEVIATION EITHER SIDE OF

RESONANCE

R-23 .19-.55 mcs. .19 mcs. 3.0 kcs. 6.0 kcs.***

R-24 .52-1.5 mcs. .52 mcs. 5.0 kcs.

R-25 1.5-3.0 mcs. 1.5 mcs. 7.0 kcs.

R-26 3.0-6.0 mcs. 3.0 mcs. 15.0 kcs.

R-27 6.0-9.0 mcs. 6.0 mcs. 28.0 kcs.

Page 21

*** at 50,000 microvolts input

2--17. AVC CHARACTERISTICS.

2--18. LIMITS:

10X Normal sensitivity -- 50 to 150 mw.

100X Normal sensitivity -- 100 to 200 mw.

1000X Normal sensitivity -- 200 mw.

10000X Normal sensitivity -- 200 to 400 mw.

Note

Normal sensitivity is that setting of the signal generator output necessary to produce

10 mw receiver output.

2--19. PRELIMINARY INSTRUCTIONS. Obtain normal sensitivity before starting this check. This

check may be omitted on R-23 and R-24 navigation receivers.

2--20. TEST PROCEDURE.

STEP SIGNAL

GENERATOR

CONNECTIONS

1 Same as Steps 1

and 2 of

SENSITIVITY check.

2 Increase attenuator

setting 1000X the

setting at normal

sensitivity.

3 Increase attenuator

setting 10000X the

setting at normal

sensitivity.

OUTPUT INDIC.

&

CONNECTIONS

NORMAL

INDIC.

Record reading of

output meter.

Same as Step 1. 200 to 400

200 mw

indicates that

the audio level

is sufficient for

normal

operation.

mw

POSSIBLE

CAUSES OF

ABNORMAL

INDICATION

1. Audio

amplification is

insufficient.

Refer to

TROUBLE

ISOLATION,

Section IV,

paragraph 4--4.

2. Faulty AVC

indicated by a

decreasing

output with

increased signal

input.

Refer to

TROUBLE

ISOLATION,

Section IV,

paragraph 4--7.

4 Set attenuator to

100X the setting at

normal sensitivity.

5 Set attenuator to

10X the setting at

normal sensitivity.

Same as Step 1. 100 to 200

mw

Same as Step 1. 50 to 150 mw

Page 22

2--21. TRANSMITTER CHECKS.

2--22. POWER SUPPLY.

2--23. LIMITS: Input voltage 27.5 v dc.

Secondary voltage 545 v dc.

2--24. PRELIMINARY INSTRUCTIONS: Use Test Set, AN/GRM-1, as shown in figure 1--3. Apply d-c

power and allow time for the equipment to warm up. Depress the test key when recording all tests.

2--25. TEST PROCEDURE.

STEP C-29/ARC-5

CONTROL

BOX

1 Select

transmitter 1 or

2

corresponding

to the rack

position of unit.

Switch to CW

and key

transmitter.

2 Same. Switch TS-

3 Same. Switch TS-

OPERATION TS-

Dynamotor

runs. Note

any

evidence of

overload in

the form of

excessive

noise or

heat.

58 to

Position 1;

read heater

voltage.

58 to

Position 3;

read B+.

58/GRM-1

READS

54

divisions.

51-55

divisions.

VOLTMETER

VALUES

27.5 v

510-550 v

POSSIBLE

CAUSES

OF

ABNORMAL

IND.

Refer to

TROUBLE

ISOLATION,

Section IV,

paragraph

4--12.

4 Switch to

VOICE or

TONE. Key

transmitter.

Same. 51-55

divisions.

510-550 v

Page 23

2--26. TRANSMITTER TRACKING AND LOADING.

2--27. LIMIT: Phantom Antenna Plate Current:

No load (zero

coupling)

Loaded-MCW-VOICE 20-40 50-100 ma

Loaded-CW 60-80 150-200 ma

Frequency Calibration:

Within 0.03% of dial reading at any frequency, except at crystal frequency, where tolerance b 0.05%.

****

R-F Power Output:CW emission--2.25 amps minimum (25 watts)

VOICE emission--l.61 amps minimum (13 watts) unmod.

TONE emission--1.85 amps minimum (17 watts)

**** Above -- listed values of current measured on the ARC No. 7777 Phantom Antenna R-F current

meter.

TS-58/GRM-1, pos. 5

Current

10 25 ma

Page 24

2--28. TEST PROCEDURE.

STEP TRANSMITTER

CONTROLS

1 Select and

switch on

transmitter 1 or

2 depending on

position in rack.

Switch to CW.

Unlock all

transmitter

controls. Set

COUPLING

and ANT.

INDUCTANCE

at zero.

2 Set

FREQUENCY

dial, 100 kc

from high end.

3 Set COUPLING

at 3, and key

the transmitter.

OPERATION NORMAL

INDICATION

Set TS-58/GRMI switch to

position 5. Set

transmitter dial

to the lowest

frequency.

Observe TS-58

GRM-1 meter

while tuning

transmitter dial

throughout its

range.

TS-58/GRM-1

meter reading

should not exceed

10 through out the

range of the

tranmitter

FREQUENCY dial.

Vary ANT

INDUCTANCE

from 0 upward,

until antenna

current is

indicated. Adjust

COUPLING and

ANT

INDUCTANCE

carefully for

maximum

antenna current.

Antenna meter

reads 2.0 to 3.0

amps. TS58/GRM-1,

position 5, reads

60.80 (150-200

ma).

ABNORMAL

INDICATION

Refer to

TRANSMITTER

ALIGNMENT,

Section III,

paragraph 3t6.

Refer to TROUBLE

ISOLATION,

Section IV,

paragraph 4---16.

Refer to TROUBLE

ISOLATION,

Section IV,

paragraphs 4--15

and 4--16.

4 Switch to

VOICE. Key

transmitter,

5 Same. Key

transmitter,

6 Repeat Steps 3, 4, and 5 with transmitter dial set at 100 kc from low end of band.

7 Repeat Steps 3, 4, and 5 with transmitter dial set to the crystal frequency.

8 Repeat Steps 3, 4, and 5 with transmitter dial set to the operating trequency.

Reduce

COUPLING to

zero; then

advance

clockwise until

antenna meter

reads 1.6 amps.

Loosely couple

LM frequency

meter to

transmitter and

adjust it for zerobeat with

transmitter

frequency.

Antenna meter

reads 1.6 amps.

TS-58/GRM-1,

position 5, reads

20-40 (50-100

ma).

Frequency as

indicated by the

LM should be

within .03 per cent

of the frequency

indicated on

transmitter dial.

Refer to TROUBLE

ISOLATION,

Section IV,

paragraphs 4--16

and 4--17.

Refer to

TRANSMITTER

ALIGNMENT,

Section III,

paragraph 3----6.

Page 25

9 Lock all controls except coupling control.

2--29. MODULATION CHECK.

2--30. PRELIMINARY INSTRUCTIONS:

Modulation capabilities of the transmitter are determined by use of the oscilloscope, displaying a

modulation envelope type of pattern. In addition to the normal oscilloscope control settings, the

following should be observed:

Oscilloscope Settings--Vertical input to plates direct. Sync control to EXTERNAL.

Oscilloscope Connections-Sync voltage is obtained from one of the phone jacks in receiver rack or

junction box. The vertical input terminal of the oscilloscope is loosely coupled to the transmitter R-F

output, by attaching a wire, having good R-F insulation, to the vertical input terminal. The other end of

this wire is brought close to the phantom antenna lead from the transmitter. The degree of coupling

between these two leads will determine the vertical height of the modulation pattern.

STEP TRANSMITTER

CONTROLS

1 Set emission to

TONE. Key

transmitter.

Adjust

COUPLING

control for

maximum

Antenna

current.

2 Set emission to

VOICE. Key

transmitter.

MODULATION FORMULA: (A-B)/(A+B) * 100 = % modulation

OPERATION NORMAL

INDICATION

Adjust sweep

frequency

controls of

scope until two

or more audio

cycles are

displayed.

Adjust Sync

control for

steady pattern.

Speak in mike at

normal voice

level.

Sinewave

envelope pattern

with no

appreciable

distortion; see

figure 2--1.

Modulation

percentage should

be 60 per cent or

better as

calculated by use

of formula below.

Observe that the

modulation peaks

rise to a higher

value than that

obtained for

normal indication

in Step 1.

ABNORMAL

INDICATION

Refer to TROUBLE

ISOLATION,

Section IV,

paragraph 4--17.

Refer to TROUBLE

ISOLATION,

Section IV,

paragraph 4--17.

Page 26

SUMMARY TEST DATA CHECK OFF SHEET

AN/ARC-5

Antenna Relay__________Mike Jack___________Phone Jack___________Dynamotor Ripple

___________

Calibration (.08%)__________Vibration____________Align Input__________Dyn. Overhaul

Date_________

Max. Band Noise .19-.55mc .52-1.5mc 1.5-3.0mc 3.0-6.0mc 6.0-9.1mc

(15 mw) ________ ________ ________ ________ _________SENSITIVITY HIGH END LOW END

AVC CHARACTERISTICS

(7uv) CW MCW INPUT OUTPUT

RATIO LIMITS

.19-.55mc _________________ _________________ NOR. SENS. ________ uv. (mw)

.52-1.5mc _________________ _________________ 5X ________ 50-1001.5-3.0mc

_________________ _________________ 10X ________ 50-150

3.0-6.0mc _________________ _________________ 100X ________ 100-200

6.0-9.1mc _________________ _________________ 1000X ________ 100-300

10000X ________ 200-400 AUDIO OUTPUT CW ________ MCW ________ 200 200

SELECTIVITY

RECEIVER .19-.55mc .52-1.5mc 1.5-3.0mc 3.0-6.0mc 6.0-9.1mc LIMITS

2X ________ ________ ________ ________ _________ 2X -- 2.1-10 kc

10X ________ ________ ________ ________ _________ 10X -- 5-10 kc

10000X ________ ________ _________ ________ _________ 10000X -- 18 kc

TRANSMITTER POWER TRANSMITTER TRANSMITTER TRANSMITTER

OUTPUT FREQUENCY MODULATION TUNE-UP

CW __________

26 to 40 CW _________ VOICE _________ VOICE _________

.05% Approx. 70% Max. ant.

current

TONE __________

13 to 26

VOICE __________ CHANNEL SEL. POWER SUPPLY

13 to 26 1 ______ 2 ______ IN _______ OUT ______

27.5Vdc 545Vdc

Page 27

SECTION III ALIGNMENT PROCEDURE

3--1. RECEIVER ALIGNMENT.

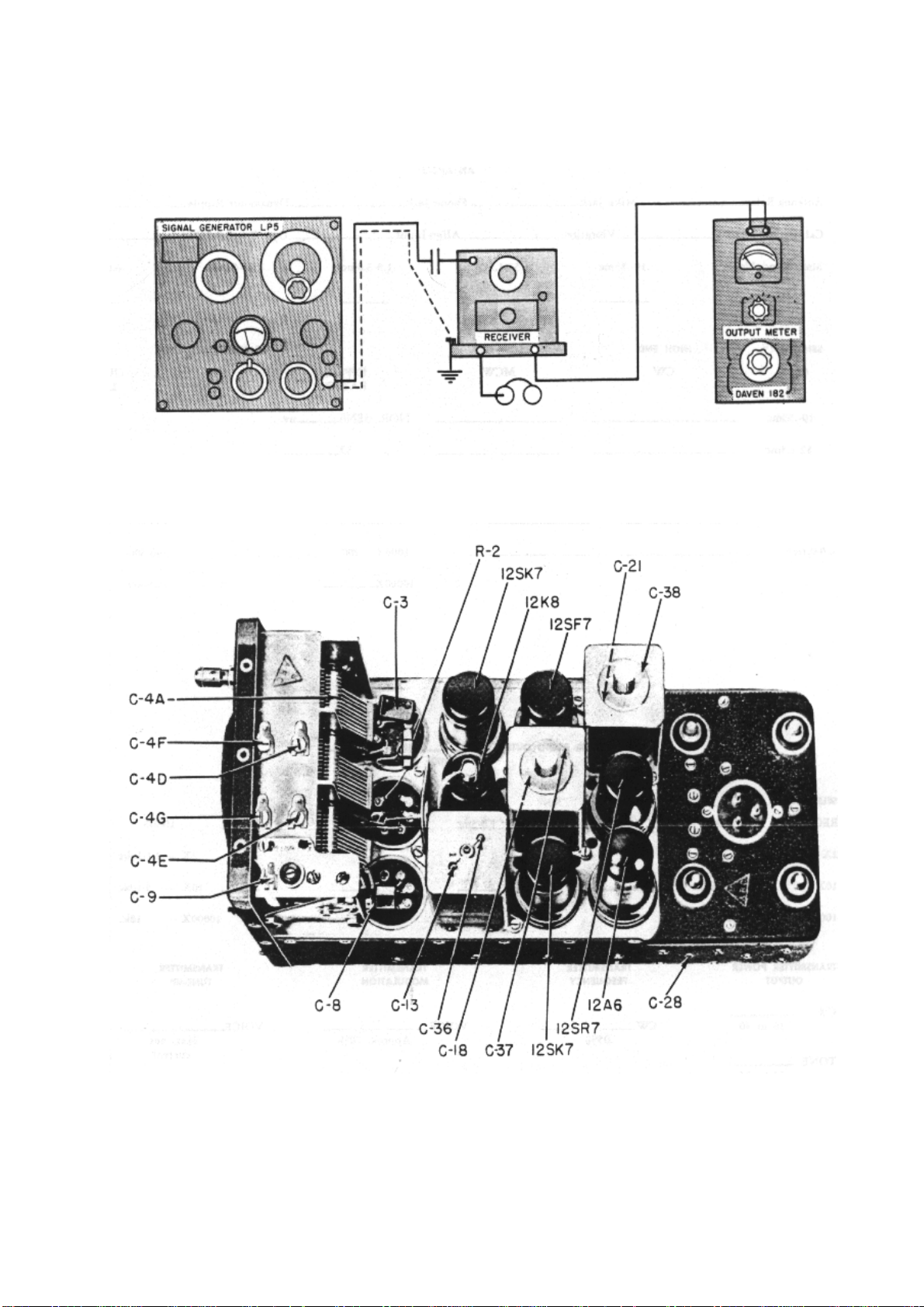

Figure 3-1. Receiver Alignment Connections

Figure 3-2. Location of Trimmers, Typical Receiver

Page 28

3--2. PRELIMINARY INSTRUCTIONS.Output Meter--Daven, Model OP-182, connected into headset jack on

receiver rack; IMPEDANCE SELECTOR set at 300 ohms.

Signal Generator--LP-5 or Hickok 19X connected between the point indicated on alignment chart and ground.

Controls-Set gain control at maximum, emission to MCW, signal generator switch ON, and dial as indicated in

chart.

Output Level--During alignment, the signal generator output must be attenuated to maintain the receiver output

at 10 mw as indicated by output meter.3--3. RECEIVER ALIGNMENT NOTES.3--4. The receivers R-23, R-24

and R-23A normally operate with over-coupled I.F stages. For alignment, each I-F stage must be loosely coupled

by pulling out the bakelite rod to the snap-out position. After the entire alignment is completed, the I-F stage

must be returned to the same over-coupled condition. For the R-23 and R-24, over-couple the first I-F stage; for

the R-23A and R-148, over-couple all I-F stages.

3--5. RECEIVER ALIGNMENT PROCEDURE. (See figures 3--1 and 3--2.) Before beginning alignment, check

the positions of C4F and C4G and adjust them if necessary

to the position shown in the table which follows. The positions shown are as seen from the FRONT of the

receiver.

RECEIVER C4F C4G

R-23

R-24

R-25

R-26

R-27

Front of Receiver

SIGNAL GENERATOR RECEIVER STEP

CONNECTIONS

TO RECEIVER

1 Through .006

mfd capacitor to

mixer grid use

MOD RF.

FREQUENCY

SETTINGS

85 kc

239 kc

705 kc

1415 kc

2830 kc

TYPE DIAL

SETTING

R-23

R-24

R-25

R-26

R-27

ANY

DIAL

SETTING

SPECIAL

INSTRUCTIONS

See Receiver

Alignment Note,

paragraph 3--3.

Adjust all I-F

trimmers as

indicated at

right, for

maximum output

meter reading.

TRIMMERS

C-21

C-38

C-37

C-18

C-36

C-13

2 Same Use

PURE RF.

Same

Switch receiver

to CW and

adjust BFO

trimmer for zerobeat.

C-28

Page 29

3 Same Use MOD

RF.

.52 mc

1.4 mc

2.9 mc

R-23

R-24

R-25

R-26

R-27

.52 mc

1.4 mc

2.9 mc

Switch to MCW.

Adjust oscillator

trimmer for

maximum output

meter reading.

C-4E

5.8 mc

8.9 mc

4 Through .006

mfd capacitor to

ANT post.

5 Same Same

6 Same

Same

.21 mc

.57 mc

1.55 mc

3.1 mc

R-23

R-24

R-25

R-26

R-27

5.8 mc

8.9 mc

Same Adjust R-F

trimmer and

ALIGN INPUT

trimmer for

maximum

output.

Same Adjust oscillator

trimmer for

maximum

output.

.21 mc

.57 mc

1.55 mc

3.1 mc

Adjust oscillator

padder, while

carefully rocking

the receiver dial,

for maximum

output.

C-4D

C-2

C-4E

C-9

6.1 mc

7 Repeat Steps 5 and 6 two or more times until there is no further increase in output when

Step 5 is performed. Then, proceed with Step 8.

8 Same Use

PURE RF.

9 Return I-F transformers to overcoupled condition: See Receiver Alignment Note,

paragraph 3--3.

Same as

Step 5

6.1 mc

Same as

Step 5

Switch to CW.

Adjust oscillator

trimmer for zerobeat.

C-4E

Page 30

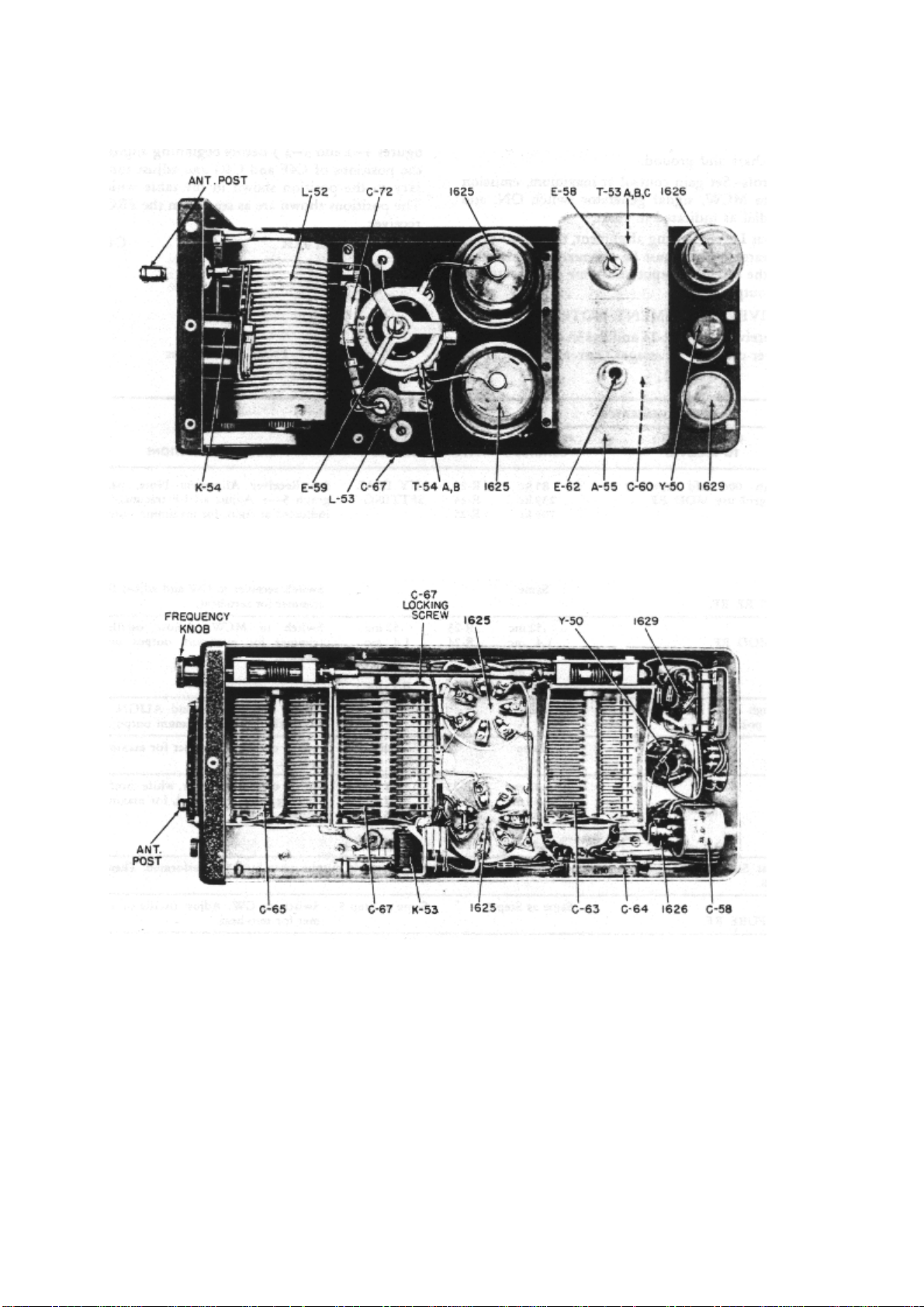

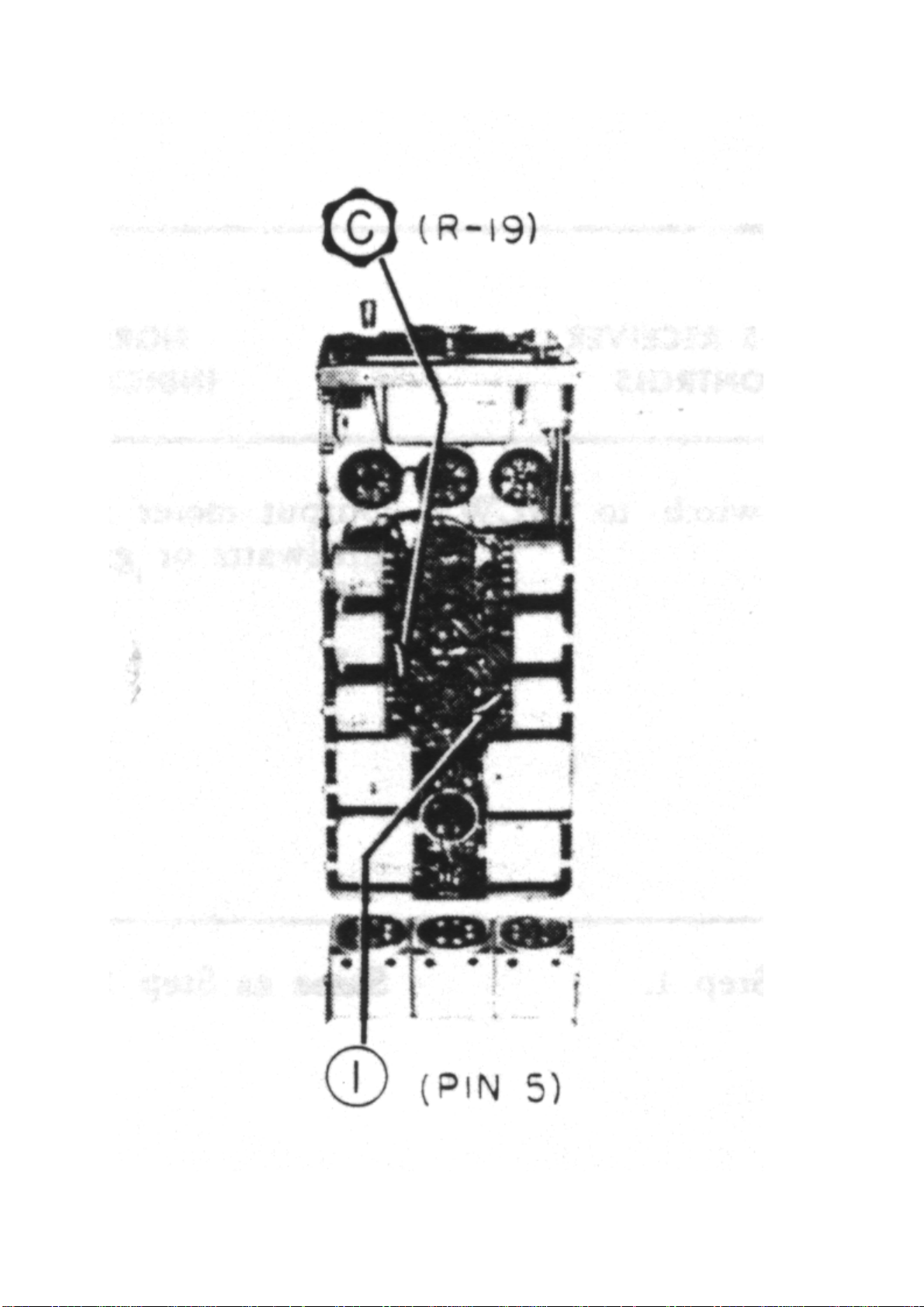

Figure 3-3. Transmitter Alignment Connections)

Figure 3-4. Transmitter Adjustment Points (Top)

Figure 3-5. Transmitter Adjustment Points (Bottom)

Page 31

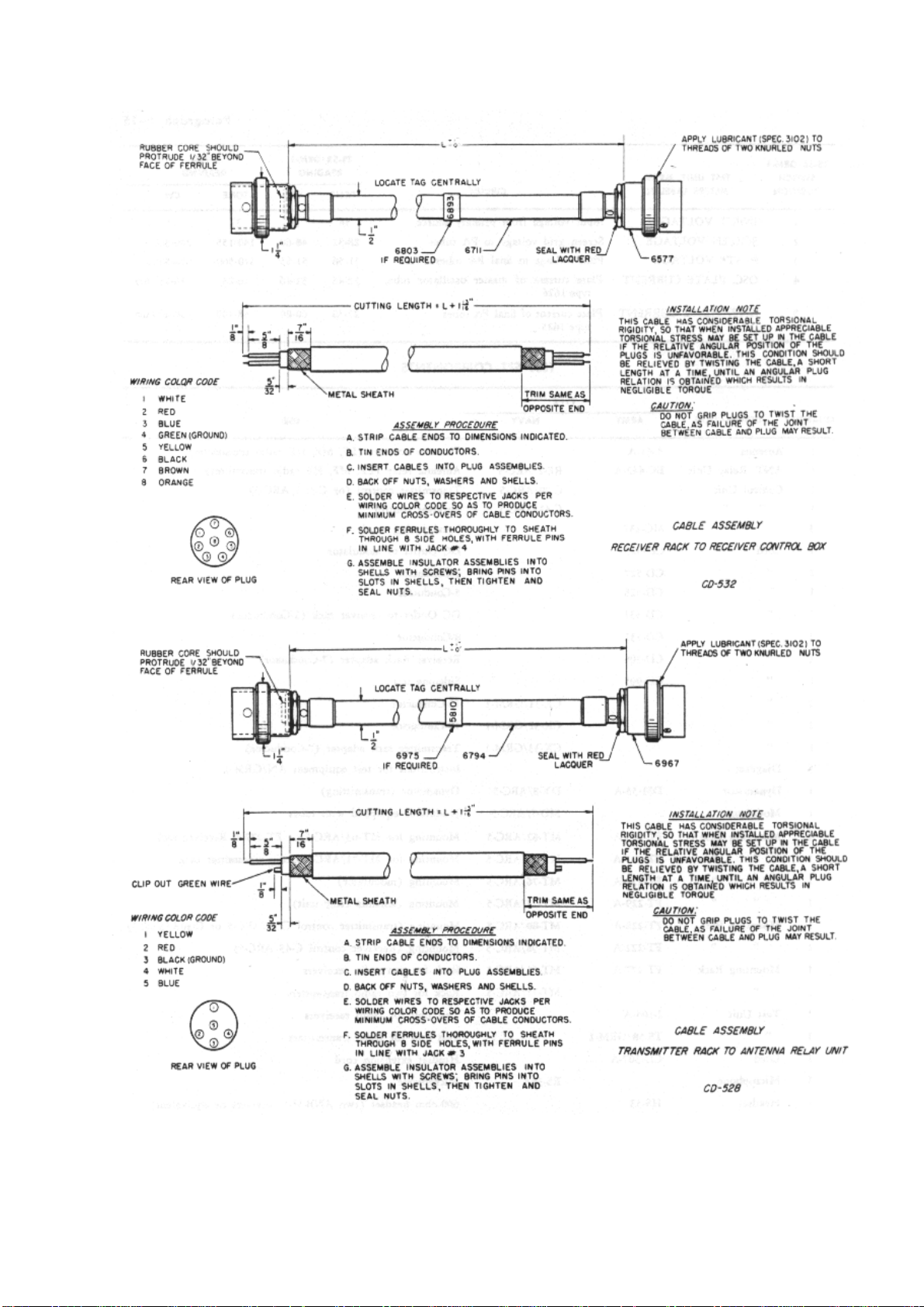

3--6. TRANSMITTER ALIGNMENT.

3--7. PRELIMINARY INSTRUCTIONS.

Bench Setup- Connect transmitter, with outer shield removed, to AN/GRM-1, as shown in figure 1--3.

Frequency Meter -- LM-13 -- Couple as indicated in Transmitter Alignment Chart, (See figure 3--3.).

3-8. TRANSMITTER ALIGNMENT NOTES.

3--9. Zero-beat should occur at mid-position of E-62. If it is impossible to obtain a zero-beat with E-62,

C-60 may be unlocked from its normal locked position and adjusted to give a zero-beat with E-62 at

mid-position.

3-10. To correct frequency error at the low end, transmitter FREQUENCY by over-shooting the correct

setting an amount one-half that of the error. Adjust E-58 for zero-beat. Reset FREQUENCY to correct

setting and retrim C-60 for zero-beat. The reason for the latter operation is to achieve accuracy at the

high and low frequency points with a minimum number of steps.

3-11. To correct the tracking error, E-59 should be adjusted at the low frequency and by over-shooting

by one-half the number of turns necessary to obtain minimum plate current.TRANSMITTER

ALIGNMENT CHART (See figures 3--4 and 3--5.)

STEP CONNECTIONS

ON TS-58/GRM1

1 Connect

Phantom

Antenna to

transmitter

antenna post.

2

3 Frequency meter

loosely coupled

to dummy load

and set to same

frequency.

DIAL SETTING TRANSMITTER

OPERATION

T-18 2.9 mc

T-19 3.9 mc

T-20 5.2 mc

T-21 6.9 mc

T-22 9.0 mc

Same as Step 2. Adjust master

Turn transmitter ON.

Key transmitter.

Check

FREQUENCY

against crystal

frequency by tuning

for greatest shadow

on resonance

indicator.

Turn FREQUENCY

dial to setting

indicated; Emission

switch to VOICE.

Key transmitter.

Load transmitter by

adjusting for

maximum antenna

current.

oscillator trimmer for

zero-beat in

frequency meter

headphones. (See

Transmitter

Alignment Notes,

paragraph 3--9.)

ADJUST

FREQUENCY

knob

ANT IND.

ANT COUP.

E-62

4 Same as Step 3.

T-18 2.2 mc

Turn FREQUENCY

dial to setting

indicated. Vary

E-58

Page 32

T-19 3.1 mc

T-20 4.1 mc

T-21 5.4 mc

T-22 7.1 mc

5 Repeat Steps 3 and 4 until the final setting of E-62 with to cover in place is at a mid-

position and dial setting at the high and low is accurate. Dial setting should be within

0.03 per cent of actual frequency as indicated by LM frequency meter.

FREQUENCY dial

for zero-beat and

note error. To

correct, adjust

master oscillator

inductance. (See

Transmitter

Alignment Notes,

paragraph 3--10.)

6 Remove Phantom Antenna

to align R-F amplifier.

Remove frequency meter

and coupling. TS-58/GRM-I

switch to position 5.

7

Same as Step

2.

Same as Step

4.

Adjust for

minimum R-F

amplifier plate

current, which

should be

below 10

divisions (25

ma) on TS58/GRM-1

meter.

Turn

FREQUENCY

dial to setting

indicated to

check

tracking; note

if the minimum

R-F plate

current is

within 10 ma

of the

minimum

obtained in

Step 6. To

correct, adjust

iron core. (See

Transmitter

Alignment

Notes,

paragraph 3-1 l.)

C-67 (normally

locked)

8 Repeat Steps 6 and 7 until R-F amplifier is operating at minimum plate current at the

high frequency end and until tracking error is corrected.

9 Reconnect Phantom

Antenna to transmitter

antenna post.

Adjust

transmitter for

maximum

antenna

current output.

Lock all dial

controls at

completion of

this check.

ANT IND.

ANT COUP.

Page 33

SECTION IV TROUBLE ISOLATION

Figure 4-1. Typical Communications Receiver, Bottom View

Figure 4-2. Typical Receiver, Top View Inside, and Bottom View Dynamotor

Page 34

4--1. RADIO RECEIVER.

4--2. DYNAMOTOR UNIT.4--3. PRELIMINARY INSTRUCTIONS: All tests on the receiver will be

performed using the AN/GRM-1 Test Setup, as shown in figure 1--3.

STEP TEST

POINT

1. A Control switch to

2. B Control switch to

TEST

EQUIPMENT

CONTROLS

MCW or CW

position. Meter

switch to position

3.

MCW or CW

position. Meter

switch to position 1

and 2.

NORMAL INDICATION POSSIBLE

CAUSES OF

ABNORMAL

INDICATION

Dynamotor scans; I104-A meter indicates

from 46 to 50 (230 to

250 volts dc):

Position 1; meter reads

56 (28 volts dc).

Position 2; meter reads

14 to 17 (1.4-1.7 amps).

Shorted or open

dynamotor windings;

defective plugs or

jacks; open choke L14, L-15.

Blown fuses;

defective plugs or

jacks; open wiring,

shorted or open

dynamotor windings.

4--4. AUDIO-FREQUENCY CIRCUIT.

(See chart below.)

4--5. PRELIMINARY INSTRUCTIONS: Set Audio Signal Generator to 1000 cycles, zero output.

Connect TS-375/U or TS-352/U a-c test leads across Audio Signal Generator output terminals.

Connect the other pair of test leads from Audio Signal Generator output terminals to indicated test

points and chassis.

STEP

1 C Set voltmeter on 3 (or 2.5) volt

2 D Same as Step 1. Same as

TEST

POINT

TEST EQUIPMENT

CONTROLS

a-c range. Advance the output

level control on Audio Signal

Generator for 2.25 volt reading

on voltmeter.

ARC-5

RECEIVER

CONTROLS

Control

switch to

MCW

position.

Step 1.

NORMAL

INDICATION

Output

meter

reading of

200

miIliwatts or

greater.

Same as

Step 1.

POSSIBLE

CAUSES OF

ABNORMAL

INDICATION

If normal,

proceed to

paragraph 4-

-6. If not,

proceed with

Step 2,

paragraph 4-

-5.

Faulty power

amplifier

tube and/or

circuit

components,

Repair and

return to

Step 1,

paragraph 4-

-5 before

going to

paragraph 4-

Page 35

-6.

Figure 4-3. Dynamotor Test Points

Page 36

Page 37

Figure 4-4. Audio Frequency Test Points

4--6. INTERMEDIATE-FREQUENCY CIRCUIT.

(Follow chart below.)4--7. PRELIMINARY INSTRUCTIONS: Insert a 0.006 ufd capacitor in series with

the "hot" lead from the Signal Generator to the receiver. Use a signal modulated 30 per cent at 400 or

1000 cycles. Connect Signal Generator to indicated TEST POINT.

STEP

1 D Tune the Signal Generator to

TEST

POINT

TEST EQUIPMENT

CONTROLS

the following appropriate

frequency. (Rock the Signal

Generator FREQUENCY dial

for maximum output meter

reading.)

UNIT FREQUENCY

.19-.55 mc 85 kc 310 uv

.52-1.5 mc 239 kc 360 uv

ARC-5

RECEIVER

CONTROLS

Set the

CONTROL

switch on

the I-104-A

Test Unit to

MCW

position.

NORMAL

INDICATION

Output of 10

milliwatts or

greater

across the

300-ohm

load, for

Signal

Generator

input as

follows:

POSSIBLE

CAUSES OF

ABNORMAL

INDICATION

If normal,

proceed to

Step

1,paragraph

4--8. If not,

proceed to

Step 2,

paragraph 4-

-7.

2 1 Same as in Step 1. Same as in

1.5-3.0 mc 705 kc 910 uv

3.0-6.0 mc 1415 kc 330 uv

6.0-9.1 mc 2830 kc

Step 1.

430 uv

Same output

as in Step 1.

Signal

Generator

input as

follows:

8100 uv

7500 uv

10,000 uv

2400 uv

2500 uv

If normal,

trouble it in

converter

stage. If not

normal

proceed to

Step 3,

paragraph 4-

-7.

Page 38

3 2 Same as in Step 1. Same as in

Step 1.

Note

When a stage is found defective, test the tube in a tube checker and replace with

good tube if necessary. Conduct routine resistance and voltage measurements to

locate the defective or faulty component or components within a stage. When trouble

has been located and corrected, return to Step 1, paragraph 4--7 to determine that I-F

stages are operating satisfactorily.

Same output

as in Step 1.

Signal

Generator

input as

follows:

210,000 uv

220,000 uv

130,000 uv

99,000 uv

85,000 uv

If normal,

trouble is in

1st I-F

stage. If not

normal,

trouble is

probably in

2nd I-F

stage.

Page 39

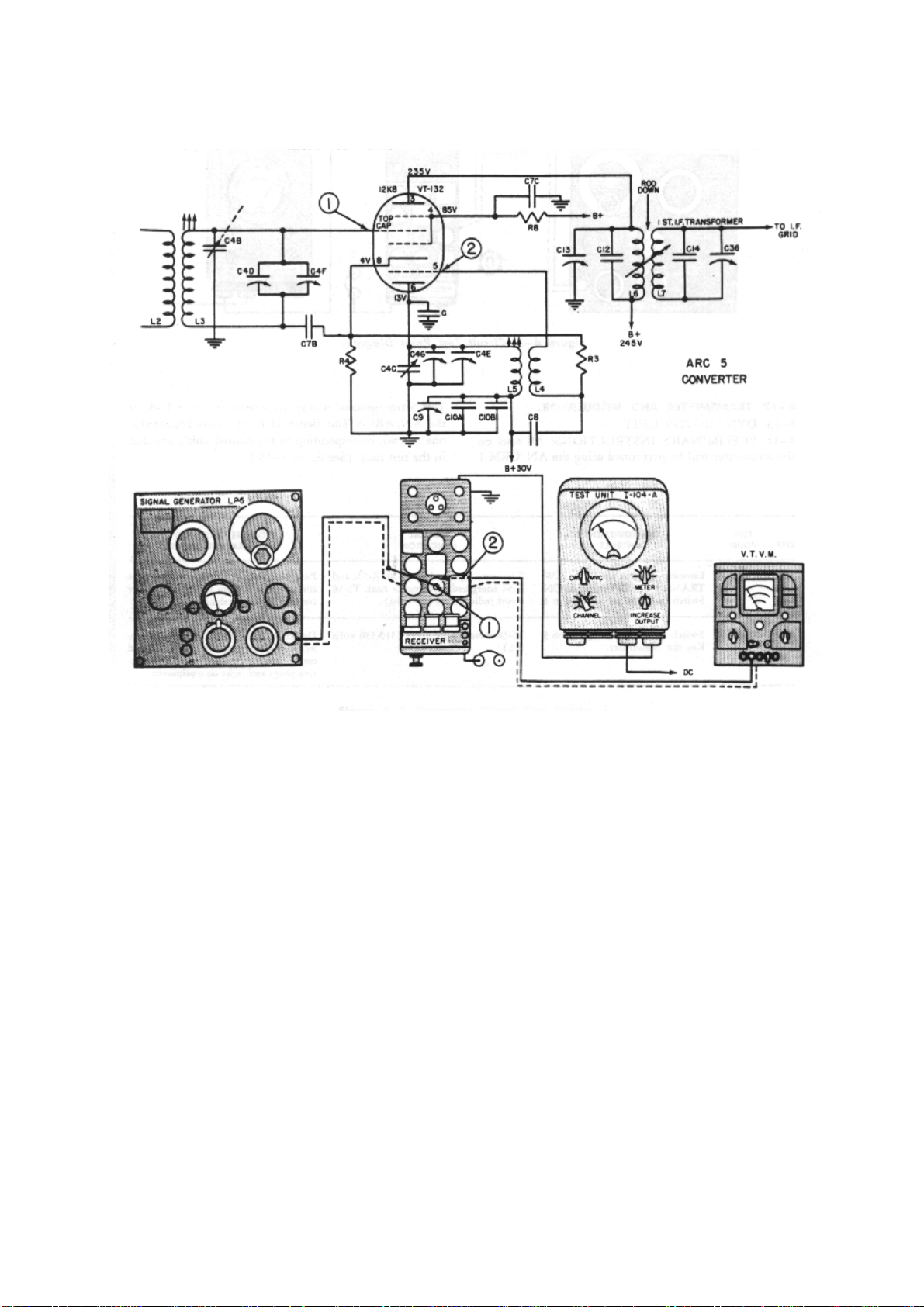

4--8. CONVERTER CIRCUIT.(Follow chart below).

4--9. PRELIMINARY INSTRUCTIONS: Use a signal 50 per cent modulated at 400 or 1000 cycles.

Connect R-F Signal Generator between the TEST POINT and chassis. When using the VTVM, the d-c

probe having several megohms of series isolating resistance inserted at its tip should be used. (See

figures 4--7 and 4--8.)

STEP

1 1 Tune the Signal Generator to

TEST

POINT

TEST EQUIPMENT

CONTROLS

the following appropriate

frequency. (Rock the Signal

Generator FREQUENCY dial

for maximum output.)

UNIT FREQUENCY FREQUENCY NORMAL

ARC-5

RECEIVER

CONTROLS

Set the

CONTROL

switch on the

I-104-A Test

Unit to MCW

position.

NORMAL

INDICATION

Output of 10

milliwatts or

greater

across the

300-ohm

load, for

Signal

Generator

input as

follows:

SENS.

POSSIBLE

CAUSES OF

ABNORMAL

INDICATION

Defective

12K8 tube;

defective

circuit

components;

improper

alignment.

(Proceed to

step 2 to

check the

oscillator

circuit.) If

normal,

proceed to

step 1,

paragraph 4--10.

2 2 Set VTVM to 12-volt d-c

.19-.55 mc .55 mc .55 mc 370 uv

.52-1.5 mc 1.5 mc 1.5 mc 430 uv

1.5-3.0 mc 3.0 mc 3.0 mc 990 uv

3.0-6.0 mc 6.0 mc 6.0 mc 390 uv

6.0-9.1 mc 9.1 mc 9.1 mc 480 uv

range, negative polarity.

Connect d-c probe to TEST

POINT.

Vary the

frequency

from the high

end to the low

end of the

dial.

VTVM

indicates a 6 to -9 volts.

This voltage

varies over

the

frequency

range.

Weak or

defective

oscillator

section of

12K8

converter

tube.

Defective

components.

Improper

alignment.

Page 40

4--10. RADIO-FREQUENCY CIRCUIT.

( Follow chart below).

STEP

1 1 Same as Step 1, paragraph

TEST

POINT

TEST EQUIPMENT

CONTROLS

4--8.

UNIT FREQUENCY FREQUENCY NORMAL

.19-.55

mc

.52-1.5

mc

1.5-3.0

mc

3.0-6.0

mc

.55 mc .55 mc 50 uv

1.5 mc 1.5 mc 80 uv

3.0 mc 3.0 mc 150 uv

6.0 mc 6.0 mc 130 uv

ARC-5

RECEIVER

CONTROLS

Control to

MCW

NORMAL

INDICATION

Loud clear

tone.

SENS.

POSSIBLE

CAUSES OF

ABNORMAL

INDICATION

R-F tube or

circuit. If

normal

proceed to

Step 1,

paragraph 4-

-11.

6.0-9.1

mc

9.1 mc 9.1 mc 100 uv

4--11. ANTENNA CIRCUIT.

(Follow chart below).

STEP TEST

POINT

1. E Same as Step 1, paragraph

TEST EQUIPMENT

CONTROLS

4--8

UNIT FREQUENCY FREQUENCY NORMAL

.19-.55 mc .55 mc .55 mc 5 uv

.52-1.5 mc 1.5 mc 1.5 mc 7 uv

1.5-3.0 mc 3.0 mc 3.0 mc 7 uv

ARC-5

RECEIVER

CONTROLS

Control to

MCW

NORMAL

INDICATION

Loud clear

tone in

headset.

SENS.

POSSIBLE

CAUSES OF

ABNORMAL

INDICATION

Antenna

circuit. If

normal, this

completes

the receiver

check.

3.0-6.0 mc 6.0 mc 6.0 mc 6 uv

6.0-9.1 mc 9.1 mc 9.1 mc 6 uv

Page 41

Figure 4-5. Circuit Test Point Diagram

Page 42

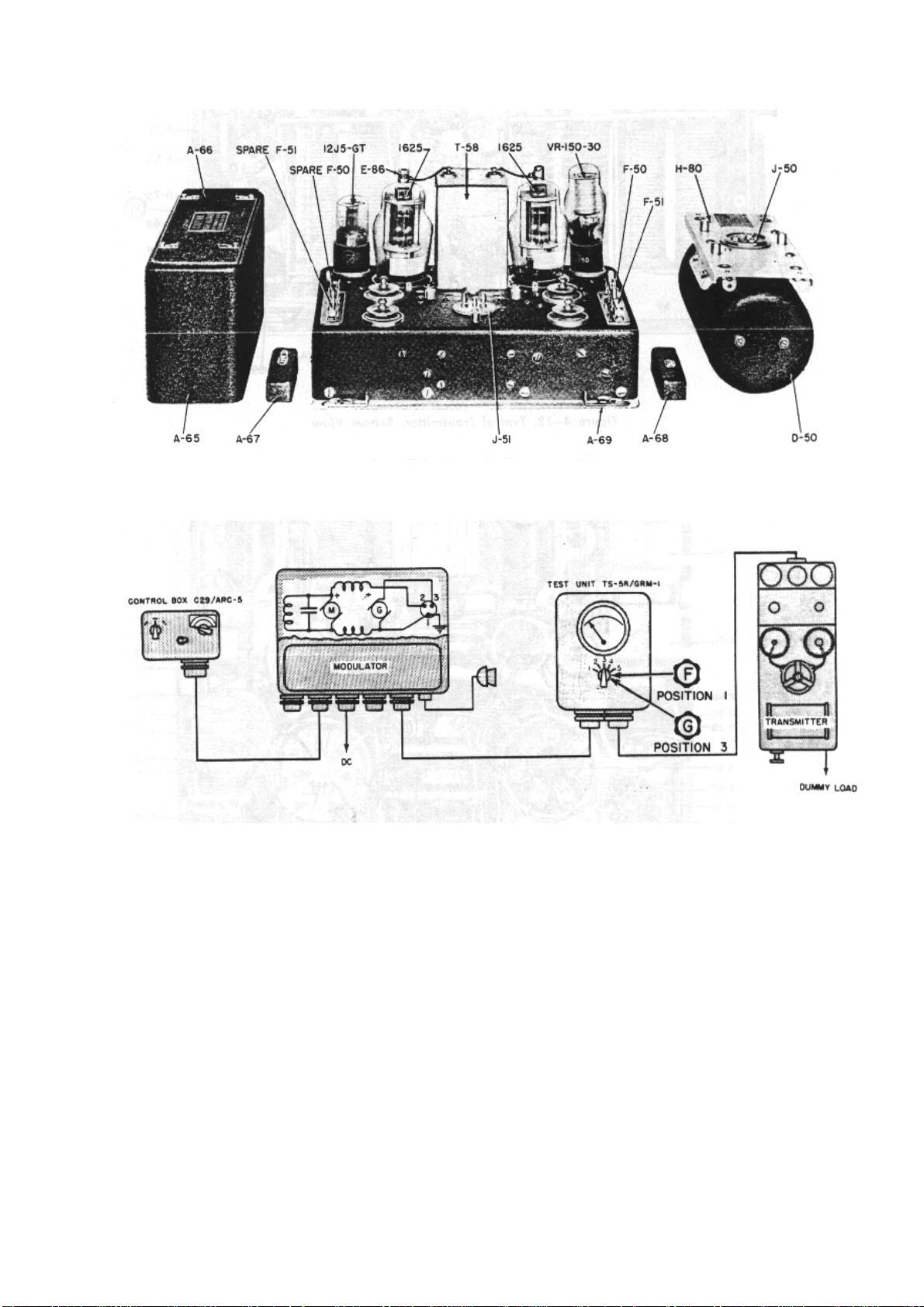

4--12. TRANSMITTER AND MODULATOR.

4--13. DYNAMOTOR UNIT.

4--14. PRELIMINARY INSTRUCTIONS: All tests on the transmitter will be performed using the

AN/GRM-1 Test Setup optional wiring, illustrated in Figure 1--3, or the AN/ARC-5 Test Bench

Harness. Select transmitter one or two, corresponding to the desired unit's position in the test rack.

(See figure 4--15.)

STEP TEST

POINT

1. F Emission selector

2. G Switch on TS-58

TEST

EQUIPMENT

CONTROLS

switch to CW.

TRANS. POWER

switch to ON.

Switch on TS-58

set to position 1.

set to position 3.

Key the

transmitter.

NORMAL INDICATION POSSIBLE

CAUSES OF

ABNORMAL

INDICATION

Filaments light; relays

K-5O, K-53, and K-54

energized; dynamotor

runs. TS-58 meter

indicates 54 (27 volts).

TS-58 meter reads 5155 (510-550 volts d-c.)

Fuses F-50 and F-5I

blown; defective

coils on relays; dirty

or corroded

contacts; defective

dynamotor.

Defective relay K-52;

defective dynamotor

windings; shorted C55; shorted

components in 550volt circuit; defective

plugs and jacks on

equipment.

Page 43

Page 44

Figure 4-6. Circuit Test Points

Figure 4-7. Converter Circuit Test Points

Page 45

Page 46

Figure 4-8. Converter Circuit Test Points

Figure 4-9. Antenna Circuit Test Diagram

Figure 4-10. Antenna Circuit Test Points

Figure 4-11. Typical Transmitter, Top View, Shield Removed

Page 47

4--15. OSCILLATOR.

(Follow chart below.)

STEP

1.

2.

TEST

POINT

TEST

EQUIPMENT

CONTROLS

Emission selector

switch to CW. Set

VTVM on 120-volt

d-c scale, --polarity

and connect to

TEST

POINT H, the

ungrounded

terminal of PA grid

resistor, R-74 and

chassis. TRANS.

POWER switch to

ON. depress the

Microphone

button. See figure

4--17.

Set switch on TS58 to position 4.

Depress the

Microphone

button.

NORMAL

INDICATION

VTVM should indicate 40 to -70 volts d-c grid

bias, if oscillator is

supplying proper

excitation to PA grid

circuit.

TS-58 meter should

read 32-46 (16 to 23

ma. oscillator plate

current.)

POSSIBLE

CAUSES OF

ABNORMAL

INDICATION

Defective oscillator

tube or circuit

components

defective relay K-53;

defective PA tubes;

open R-74; low

voltage on oscillator.

Same as above;

oscillator not

oscillating; open R68, shorted C-58A.

3.

Tune transmitter

FREQUENCY

dial to calibrator

crystal frequency.

Depress the

Microphone

button.

Maximum shadow angle

on the "Magic

Eye" tube screen as the

FREQUENCY

dial is rotated to the

crystal frequency.

Same as above;

defective "Magic

Eye" tube; defective

crystal; no or low

voltages.

Page 48

Figure 4-12. Typical Transmitter, Bottom View

Figure 4-13. Modulator, Type MD-7/ARC-5, Bottom View

Page 49

Figure 4-14. Typical MD-7/ARC-5 Modulator

Figure 4-15. Transmitter and Modulator Test Points

Page 50

Figure 4-16. Diagram

Page 51

Page 52

4--16. FINAL AMPLIFIER.

(Follow chart below.)

Figure 4-17. Oscillator Check Points

STEP TEST

POINT

1.

TEST

EQUIPMENT

CONTROLS

Emission switch to

CW. Power switch

to ON. Set

COUPLING

control to zero. Set

the TS-58 switch

to position 5.

Press the

Microphone

button. (See figure

4--19.)

NORMAL INDICATION POSSIBLE

CAUSES OF

ABNORMAL

INDICATION

TS-58 meter indicates

l0 (25 ma final PA plate

current.)

HIGH CURRENT:

Poor tracking, refer

to ALIGNMENT

section, paragraph

3--5; defective tubes

or other circuit

components in PA;

shorted capacitor

C-72.

NO CURRENT:

Defective relay K53; defective PA

tubes; no plate or

screen voltage on

PA tubes.

2.

3.

Same as Step 1,

except set TS-58

switch to position

2.

Same as Step I,

advance

COUPLING

control to 3. Adjust

ANT

TS-58 meter indicates

34-38 (170-190 volts PA

screen voltage.)

ANT current of over 2.0

amperes. TS-58

reading of 60 to 80 (150

HIGH VOLTAGE:

Defective PA tubes;

defective R-89.

LOW VOLTAGE:

Insufficient

excitation; refer to

TROUBLE

ISOLATION,

OSCILLATOR

section, paragraph

4--14; shorted

screen by-pass

capacitors C-64, C75, C-71; open

screen resistors R90, R-94, R-81 and

R-89; open

secondary windings

on modulation

transformer T-58.

Same as above: if

normal indications

are obtained in

Page 53

INDUCTANCE

control for

maximum PA plate

current and

maximum ANT

current.

to 200 ma final

PA plate current.)

Steps 1 and 2, but

not Step 3, relay K54 (K-55 also, if

used) may be

defective. Sliding

roller contact on

ANT TUNING coil

may be dirty,

corroded, and not

making good

electrical contact.

Page 54

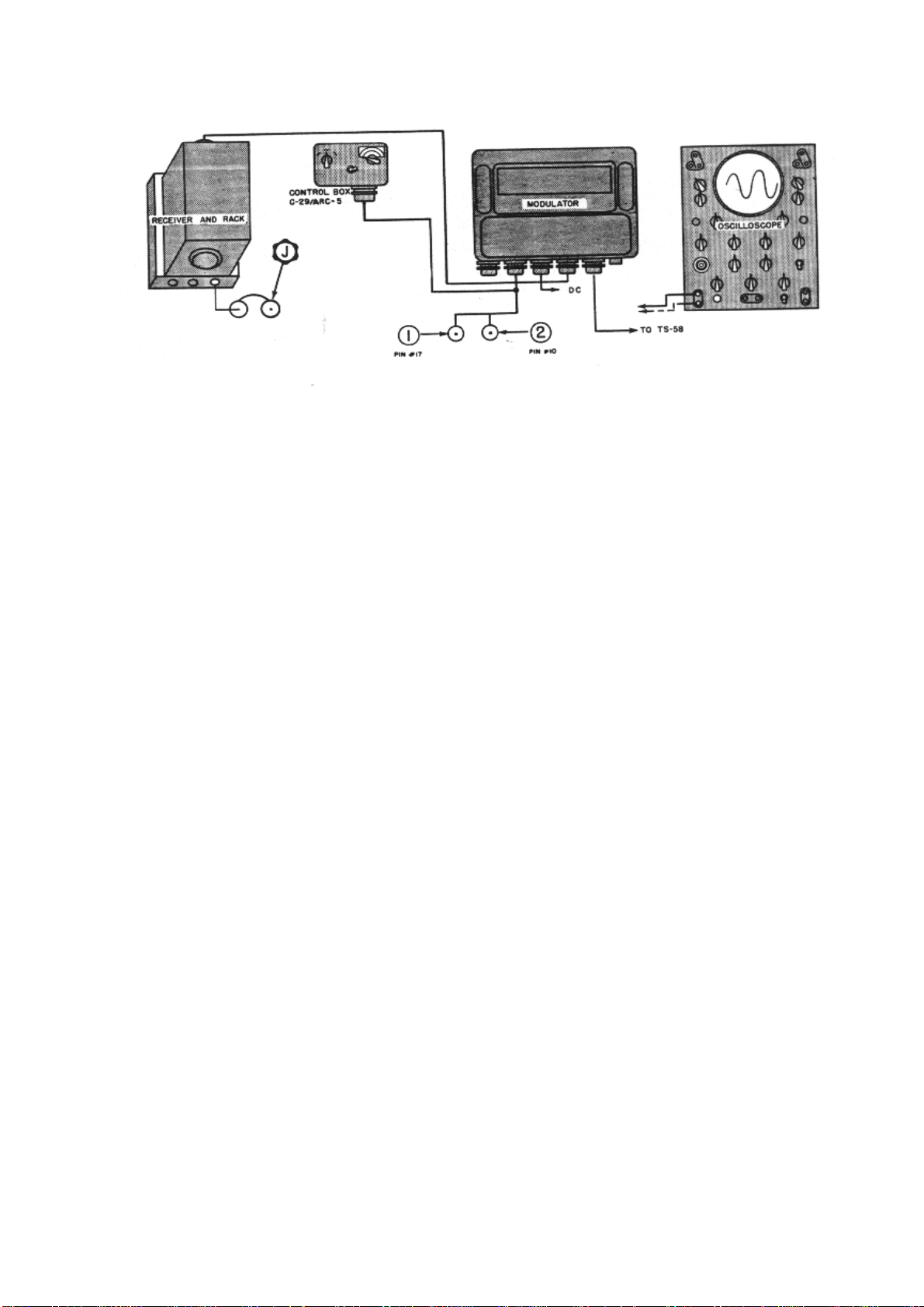

4--17. MODULATOR.

(Follow chart below.)

4--18. PRELIMINARY INSTRUCTIONS: Set up equipment as illustrated in Figure

4--19, with the transmitter and associated equipment connected as in PERFORMANCE section. By

means of shielded cable, connect from vertical input terminals of scope to indicated TEST POINT.

Connect output meter across vertical input terminals of the scope. If Weston model 695 output meter

is used, set it to "0" decibel range. (If Daven model OP-182 is used set the power multiplier switch to

"1" position and set the impedance multiplier switch Phantom Antenna for maximum antenna current,

on CW emission, as described in the PERFORMANCE section, TRANSMITTER TRACKING AND

LOADING, paragraph 2-30, Steps 1, 2, and 3. Plug a pair of headphones into the headphone jack on

the receiver control box, or receiver rack. A loud audio tone or whistle should be heard during each

Step given below.

STEP TEST

POINT

1.

TEST

EQUIPMENT

CONTROLS

Emission switch to

VOICE. Ro-

tare COUPLING

control to zero,

key transmitter,

and advance

COUPLING

control clockwise

until Phantom

Antenna meter

reads 1.6

amperes. Set

emission

switch to TONE

and key

transmitter.

NORMAL INDICATION POSSIBLE CAUSES

OF ABNORMAL

INDICATION

Antenna current should

increase from

1.6 to 1.9 amperes,

when going from

VOICE to TONE

emission. Audio sine

wave pattern scope

output meter

should read +2

decibels. (1.5 mw on

OP-182.)

If no or low output

meter reading, tone

oscillator is defective.

If normal output

meter reading, but no

increase in an-

tenna current,

modulator tubes and

cir-

cuit components are

defective.

2.

Set emission

switch to VOICE.

Plug microphone

into MIC. jack,

J-73, on front of

modulator. Set

output meter on +

12 db range

(power multiplier

switch to 100

Antenna current should

increase from 1.6 to

1.9 amperes when

mike is Whistled into.

Output meter should

indicate + 14 db (+ 2

db, with 0 db now

being + 12 db) on loud

sustained whistle. (OP182 should read I000

mw). Approximate

audio sine wave

pattern on 'scope.

Defective modulator

tubes and circuit

components.

defective C-29/ARC5 control box.

Defective receptacles

on

modulator. Defective

microphone circuit.

Improper or no

voltages on

modulator tubes.

Defective modulation

transformer T-58.

Page 55

on OP-182). Press

microphone

button and whistle

loud, sustained

tone of constant

pitch into micro

phone.

Measure all voltages

and make continuity

measurements.

3.

Set emission

switch to TONE.

Key

transmitter.

Antenna current should

rise to 1.9 amperes.

Output meter should

read + 14 db (+ 2 db,

with 0 db being + 12

db).

(OP-182 meter should

read 700 milliwatts.)

Same as above.

Replace modulator

tubes with known

good ones. Check

for shorted

capacitors and open

resistors. Check

continuity from

modulator to

transmitter.

Figure 4-18. Final Amplifier Check Diagram

Page 56

Figure 4-19. Modulator Check Diagram

Loading...

Loading...