Page 1

Model 1872 Dehumidifier

Installation and Operating Manual

SAFETY INSTRUCTIONS

WARNING

1. 120 Volts may cause serious injury from electric shock. Disconnect electrical power before starting installation or servicing. Leave power

disconnected until installation/service is completed.

2. Dropping may cause personal injury or equipment damage. Handle with care and follow installation instructions.

3. Sharp edges may cause serious injury from cuts. Use care when cutting plenum openings and handling duct work.

CAUTION

1. Read all instructions before beginning installation.

2. Improper installation may cause property damage or injury. Read instructions before installation, service or maintenance.

3. Do not use in pool applications. Pool chemicals can damage the dehumidifier.

4. Do not use solvents or cleaners on or near the circuit board. Chemicals can damage circuit board components.

5. Wait 24 hours before running the unit if it was not shipped or stored in the upright position

6. Do not use dehumidification to prevent window condensation in the winter. To address window condensation, use ventilation to lower

indoor humidity in the winter.

TABLE OF CONTENTS

SAFETY INSTRUCTIONS � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 1

SPECIFICATIONS � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �2

REMOVE SHIPPING BRACKET � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 2

LOCATION CONSIDERATIONS � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 3

DRAIN INSTALLATION � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 3

Condensate Pump and Float Switch� � � � � � � � � � � � � � � � � � � � � � � � � � � � �3

SETTING THE DESIRED HUMIDITY LEVEL � � � � � � � � � � � � � � � � � � � � � � � � �4

MAINTENANCE� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 5

DUCT COLLAR INSTALLATION� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �6

Control Location� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �6

DUCTING � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 7

Ducting in Basement � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �7

Ducting to Whole Home without an Air Handler� � � � � � � � � � � � � � � � � �8

TROUBLESHOOTING � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �9

Table 1 – Diagnostic Codes � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �9

Table 2 – Troubleshooting Guide � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 10

SERVICE PARTS � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �11

LIMITED WARRANTY � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 12

READ AND SAVE THESE INSTRUCTIONS

1

Page 2

SPECIFICATIONS

CLIP OFF

REMOVE SCREWS (2)

MODEL 1872

Weight 113 lbs�

Capacity

AHAM DH-1-2008 80°F, 60% RH Conditions

Power

115 VAC, Single Phase, 60Hz

Dehumidifier Inlet Air Conditions

Filter MERV 8, washable

EXTERNAL STATIC PRESSURE ("w.c.) AIRFLOW (CFM)

Airflow

0.7"w.c. is maximum design external static pressure.

Dehumidification: 50°F – 104°F, 40°F dew point minimum

Ventilation: 40°F – 140°F, 0%RH – 99%RH (non-condensing)

0�0 310

0�2 270

0�4 225

0�6 175

130 pints per day @ 310 CFM

8�3A operating current

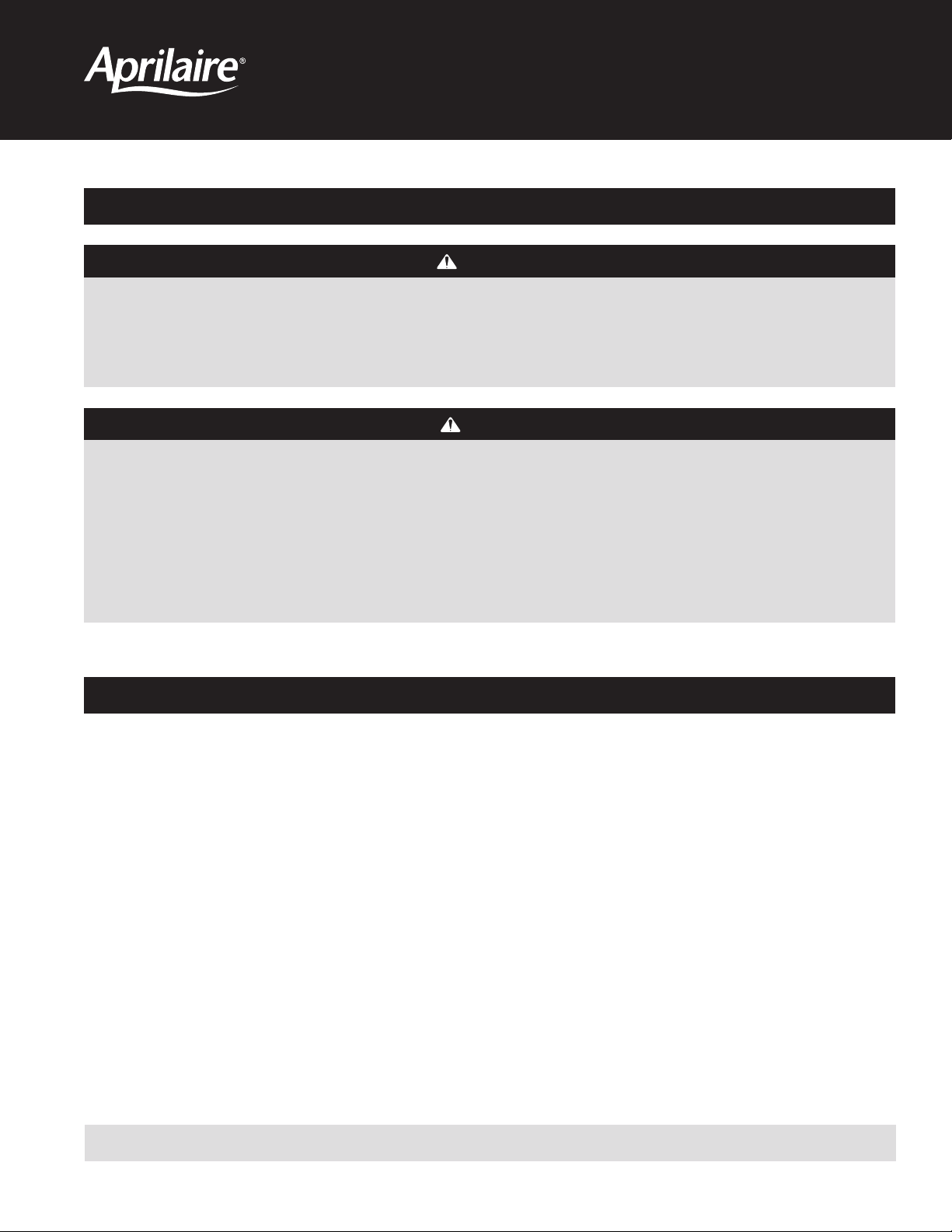

REMOVE SHIPPING BRACKET

IMPORTANT: Cut the strap securing the compressor shipping

support bracket and remove the strap, shipping bracket screws,

and bracket� See FIGURE 1�

FIGURE 1 – REMOVE SHIPPING BRACKET

DISCARD SHIPPING BRACKET

REINSTALL SCREWS (2)

PLASTIC

STRAP

90-2013

2

Page 3

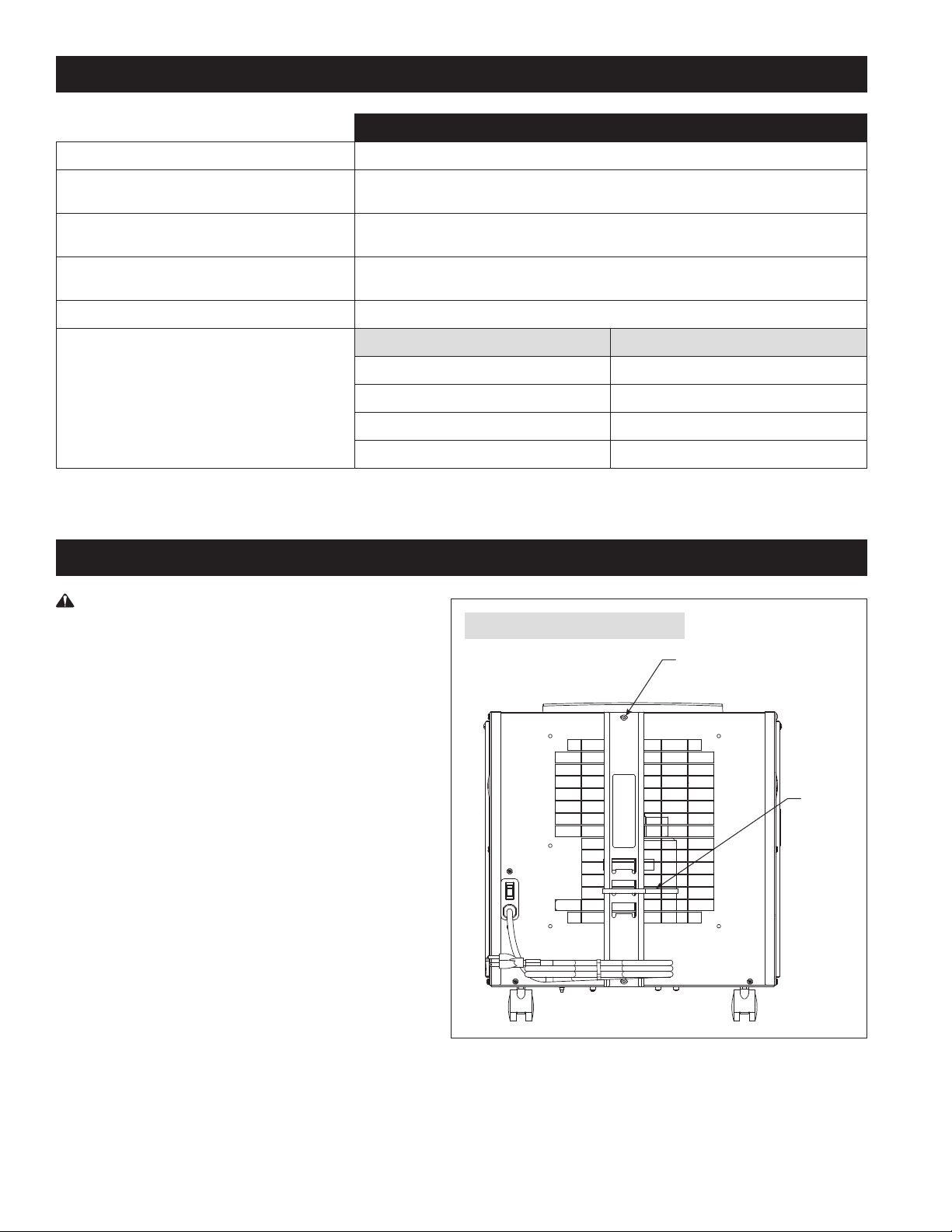

LOCATION CONSIDERATIONS

FOR PROPER

ELECTRICAL SERVICE ACCESS THIS SIDE

• Allow sufficient clearance for filter removal and

to prevent airflow obstruction

• Electrical service access will require the removal

of the side panel shown� Allow sufficient space

for service on this side of the unit�

FIGURE 2 – FILTER ACCESS CLEARANCE

6" MINIMUM

CLEARANCE

AIR FLOW

6 FT. POWER CORD

TOP VIEW

FILTER

MINIMUM

20"

CLEARANCE

FOR FILTER

(EITHER SIDE)

90-2020

DRAIN INSTALLATION

The drain outlet on the dehumidifier can be hard piped using a 3/4" PVC Slip x 3/4" MNPT fitting and 3/4" nominal drain tubing or the provided 3/4"

MNPT x 3/4" hose barb fitting and 3/4" clear PVC tubing can be used to drain the dehumidifier� Always maintain a constant downward slope from the

dehumidifier to the drain and do not allow soft tubing to curl up which may result in air lock� Note: PTFE thread seal tape is recommended for the

threaded connection and hand tighten only� If hard pipe is used, PVC primer and cement is recommended for the slip fit connection�

A level surface is required to ensure proper drainage from the dehumidifier�

Always install the dehumidifier in a condensate pan when locating in or above a finished space� Adhere to local codes regarding draining of the

condensate pan�

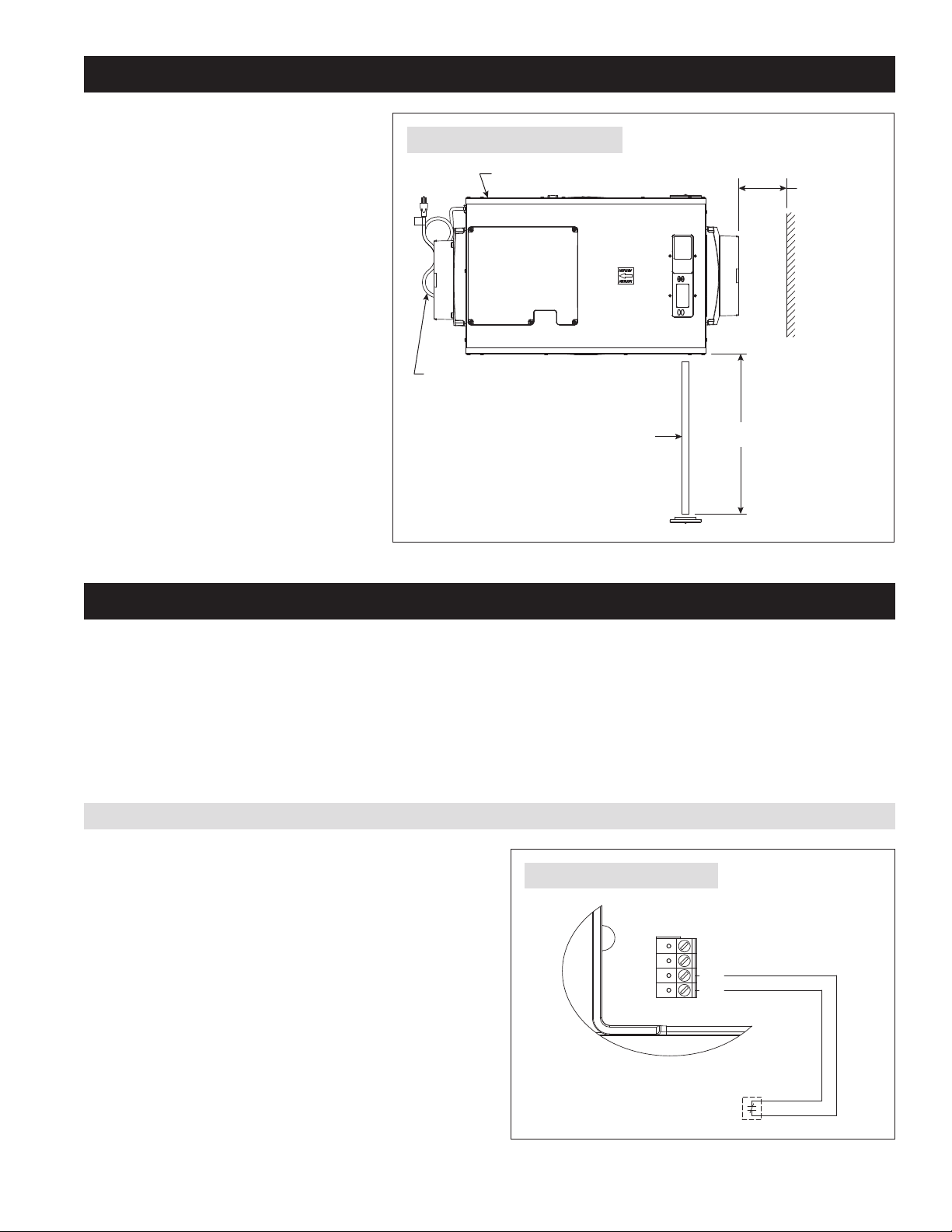

CONDENSATE PUMP AND FLOAT SWITCH

If a condensate pump is needed, install it in the condensate pan if

installed�

Install a condensate overflow safety switch (i�e� float switch) in the

condensate pan, remove the factory installed jumper wire between

the Float Switch terminals on the control and wire the float switch to

the dehumidifier as shown in FIGURE 3� Overflow safety switches on

condensate pumps can be wired to the Float Switch terminals in a

similar fashion�

FIGURE 3 – FLOAT SWITCH WIRING

DH DH

FLOAT

Switch

NORMALLY CLOSED

FLOAT SWITCH

90-1857

3

Page 4

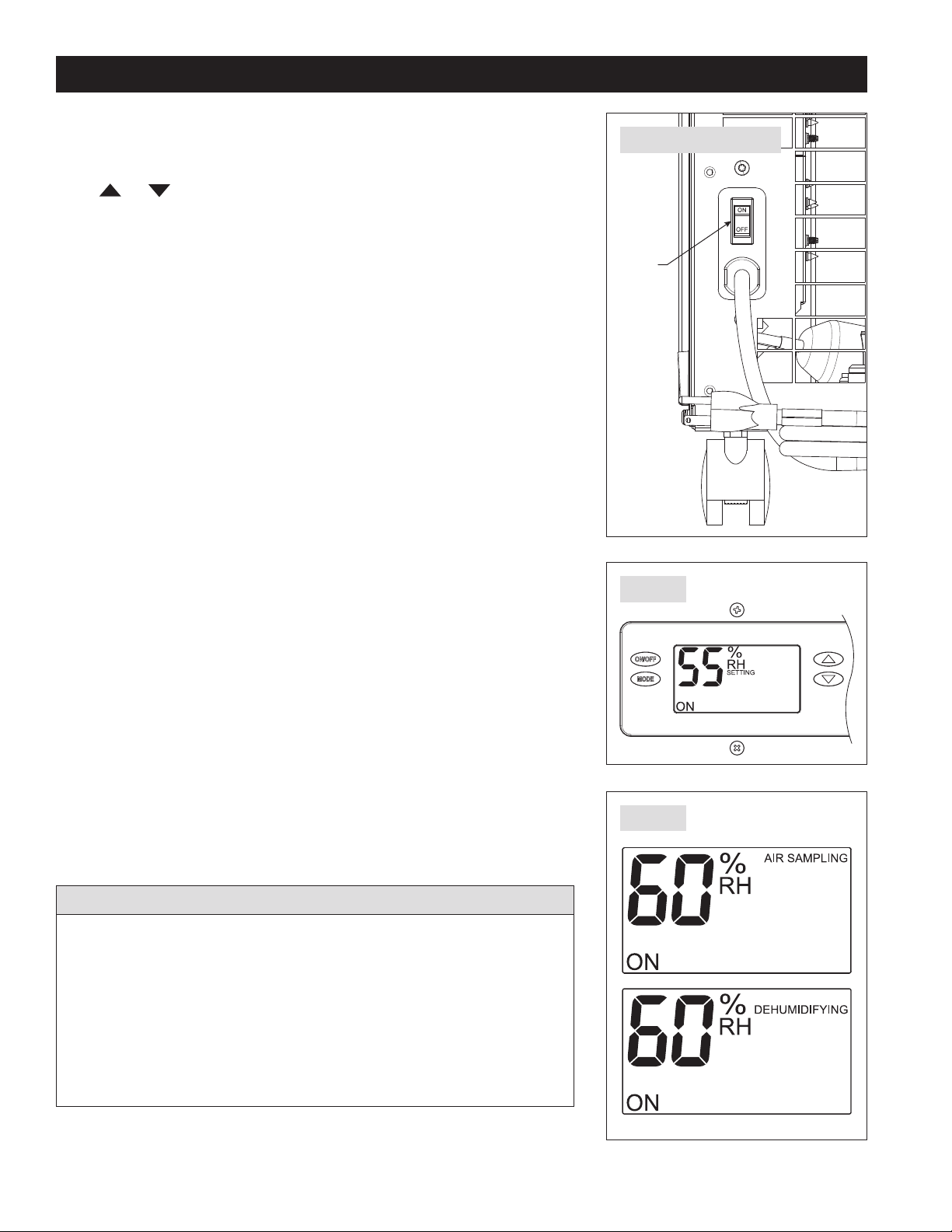

SETTING THE DESIRED HUMIDITY LEVEL

ON/OFF

SWITCH

1. Plug in dehumidifier and turn on/off switch ON� See FIGURE 4�

2. Press the ON/OFF button to turn the dehumidifier control ON� The display will show the

current setting, and the dehumidifier blower will turn on to start sampling the air�

3. The and buttons allow the humidity level to be set from 40% to 80% relative

humidity� Use the ON/OFF button to turn the dehumidifier ON or OFF�

Set the control at 55%RH when first installed� Allow the dehumidifier to run until it reaches

the setting before deciding if you want to change the setting� See FIGURE 5�

• If you prefer the air to be more dry, decrease the humidity setting�

• If you prefer the air to be less dry, increase the humidity setting�

4. After three (3) minutes of sampling, the measured humidity will be compared to the setting:

a. If the humidity is above the setting, the dehumidifier compressor turns on and “AIR

SAMPLING” will be replaced by “DEHUMIDIFYING”� The compressor remains on until the

measured humidity falls 3% RH below the setting� See FIGURE 6�

b. If the measured humidity is below the setting, the blowers turn off and the display

returns to showing the RH setting�

5. The dehumidifier will sample again every 60 minutes, or at any time if the humidity setting

is lowered�

Your comfort is the best measure of how to adjust your setting� When first installed, your

dehumidifier has to remove all the moisture that is initially in your home� The home acts like

a sponge so the moisture in the materials of your home is at the same level as the air� After

drying the air, the materials of the home will release moisture back into the air until they are

again at the same level� As a result, it is not uncommon for the dehumidifier to operate for an

extended period when first installed�

FIGURE 4 – ON/OFF SWITCH

90-1908

FIGURE 5

Your dehumidifier is equipped with two features that protect against unwanted energy

consumption� Defrost is a normal operating mode that helps to prevent significant ice formation

on the refrigeration system coil� The dehumidifier display will show “DEFROSTING” when

operating in this mode� This mode can occur when there is not enough air moving through the

dehumidifier or if the temperature and/or humidity of the incoming air is too low� The second

protection feature is the E8 code� E8 on the dehumidifier display indicates that the air entering

the dehumidifier is below 50°F or above 104°F, or the dew point of the incoming air is below

40°F� There would be a significant reduction in dehumidifier efficiency if the dehumidifier

operated outside of these conditions� Low dew point conditions can be seen in some basements

or crawl spaces and usually occur in the Winter and Spring months� The dehumidifier continues

to monitor the incoming air and when the conditions are within the operating range, E8 will be

removed from the display and dehumidification will begin as needed�

ENERGY SAVINGS TIPS

Energy Savings Tip #1: Adjust the humidity setting to be as high as is comfortable to

reduce dehumidifier run time� If it feels clammy or “smells musty”, lower the humidity

setting� To save energy, turn the dehumidifier to OFF when you open your windows, just as

you would with air conditioning�

Energy Savings Tip #2: If vacating your home for an extended period in the summer, set

the RH at 55% and set your thermostat as high as you are comfortable setting it to in the

cooling mode� Consult with appropriate professionals regarding the highest temperature

that is safe for your pets or possessions� This will keep the humidity at a controlled level

while minimizing the amount of cooling energy used�

90-1853

FIGURE 6

90-1853

4

Page 5

MAINTENANCE

90-1854

CLEAN OR REPLACE THE AIR FILTER

After initial installation the air filter should be checked and cleaned every 6 months� The

CLEAN FILTER service reminder will display on the on-board control screen every 6 months�

To clear the service message, press the

Filter Cleaning Procedure

1� Turn the ON/OFF switch OFF�

2� Remove the filter access door from either side of the dehumidifier�

3� Slide the filter out of the dehumidifier�

4� Flush the filter with warm water and a mild detergent solution�

5� Shake off the excess water from the filter�

6� Replace the filter, making sure the filter is secured in both the top and bottom filter rails�

7� Replace the filter access door�

8� Turn the ON/OFF switch ON�

9� Press the and buttons simultaneously for 3 seconds to clear the service message�

CHECK THE DRAIN

and buttons simultaneously for 3 seconds�

The drain should be checked annually to ensure there are no blockages or air lock in the drain system� If the unit is not draining properly, have it

checked by a qualified service professional�

CAUTION

Do not use spray solvents or cleaners on or near the inlet side of the dehumidifier.

If desired, apply cleaner to a cloth and use to clean the cabinet.

5

Page 6

DUCT COLLAR INSTALLATION

OUTLET COVER

COLLAR W/BACK

INLET

DUCT

COLLAR

INLET

DUCT

COLLAR

TOP DISCHARGE

PANEL COVER

CONTROL

FILTER ACCESS DOOR

HORZONTAL DISCHARGE:

• Use the screws in the parts bag to attach the duct collars to the

inlet and outlet of the dehumidifier� The outlet collar has a backflow

damper�

• The outlet duct collar may be attached to the top or end of the unit�

Move the outlet cover to the location not being used� See FIGURE7�

• Make sure there are no bends in the ductwork coming off the outlet

for a minimum of 4"� This will ensure that the ductwork will not

interfere with the backflow damper function�

FIGURE 7 – FULLY DUCTED INSTALLATIONS

OUTLET DUCT

DRAFT DAMPER

VERTICAL DISCHARGE:

Use the screws provided in the parts bag to attach the duct collars:

• When the dehumidifier requires a ducted vertical discharge, remove

the top access panel and remount on the outlet of the unit� Install

the outlet duct collar with backflow damper on top of the unit� See

FIGURE7�

CONTROL LOCATION

The on-board control can be located on the top of the

dehumidifier or can be relocated to the front of the

FIGURE 8 – CONTROL LOCATION

dehumidifier if the control can not be seen/accessed in

the top orientation�

TO MOVE THE CONTROL:

1. Remove the front control panel cover�

CONTROL

2. Remove the filter access door and filter�

CONTROL

END DISCHARGE

MOVE OUTLET

COVER AND

INSTALL OUTLET

DUCT COLLAR TO

TOP DISCHARGE

LOCATION

90-2393

PANEL COVER

CONTROL

3. Detach the on-board control by removing the four

(4) screws around the control� Note: Use one hand

to support the bottom of the on-board control

when removing�

4. Keep the control in the unit and relocate to the front

access hole�

5. Secure the control with the same four screws used

to attach the control to the top of the unit�

6. Secure the control panel cover to the top of the unit�

6

90-2017

Page 7

DUCTING

SUPPLIED TO THE

DEHUMIDIFIER

10" DUCT

DUCTING IN BASEMENT

The dehumidifier can be ducted to pull air from and return dehumidified air to the HVAC return duct� This installation will ensure warm, dehumidified

air is thoroughly mixed with the HVAC system air before being discharged into the living space� Alternatively, the dehumidifier can be ducted to

discharge to the supply duct, but the external static pressure of the HVAC system must not exceed 0�7"w�c�

REQUIRED COMPONENT:

• 10" Ductwork

FIGURE 9 – PREFERRED BASEMENT INSTALLATION FIGURE 10 – ALTERNATE BASEMENT INSTALLATION

AIR IS DISCHARGED

TO SUPPLY DUCT

HVAC/ FURNACE

AIR IS PULLED

FROM AND

RETURN DUCT

10" DUCT

6 ft

MIN

0.7"w.c.

MAX

HVAC/FURNACE

AIR IS

PULLED FROM

RETURN DUCT

90-2022 90-2023

DUCTING NOTES:

• Use insulated duct when the discharge is ducted to the supply side of the HVAC system�

• Use a minimum of 12" of flex duct at the dehumidifier inlet and outlet to prevent vibration noise transmission�

• When ducting return to return (preferred), the dehumidifier must be wired to turn on the HVAC fan when operating�

• When ducting return to supply, allow adequate space before the first branch duct to ensure the warm dehumidified air is thoroughly mixed with

the HVAC system air�

7

Page 8

DUCTING TO WHOLE HOME WITHOUT AN AIR HANDLER

DEHUMIDIFIER

DEHUMIDIFIED AIR IS SUPPLIED TO DUCTED SPACE

AIR IS PULLED FROM

GRILLE WITH 10" DUCT COLLAR (2 PLACES)

In this installation the dehumidifier is not ducted to the HVAC system�

REQUIRED COMPONENTS:

• 10" Ductwork

• Grilles with 10" Duct Collars

FIGURE 11 – STAND ALONE DUCTED

DUCTED SPACE

90-2026

DEHUMIDIFIED SPACE

10' MIN

8

Page 9

TROUBLESHOOTING

90-1854

Technical Support is available Monday through Friday, 7:00 a�m� to 5:00 p�m� CST, at (800) 334-6011� Use the guides on the following pages to identify

and correct system faults� Contact Technical Support before replacing the unit or any components and for additional troubleshooting�

DIAGNOSTIC CODES

When an error occurs, the Diagnostic Code along with SERVICE REQUIRED

will be displayed on the control screen�

TABLE 1 – DIAGNOSTIC CODES

Diagnostic

Code Failure Mode Action Reset

E1

E2

E3

E4 Insufficient Capacity

Internal Humidity or

Temperature Sensor

Open or Shorted

High Refrigeration

Pressure

Model 76

Remote Control

Communication Loss

1. Check the connection between the sensor board and control board�

2. If connection okay, replace sensor board, Part No� 5460�

1. Verify that the fan works, and that there is nothing restricting air flow�

2. If the fault persists, call Technical Support�

1. Check connections between Model 76 and dehumidifier control board� Terminals should be fully

inserted and secured in the control board and Model 76 control terminals�

2. If connections are correct and secure, turn off the dehumidifier and remove the Model 76� Use a short

section of 4-wire cable to reconnect the Model 76 to the control board� Turn the dehumidifier back on

and increase the dryness level setting on the Model 76� If the dehumidifier turns on, the problem is

with the wiring between the dehumidifier and control�

3. If the dehumidifier does not turn on, call Technical Support�

1. Check the frost sensor connection at the power board� Terminal should be fully seated on the power

board pins�

2. Remove the side access panel and verify that the sensor is secured to the suction line�

3. If the sensor is connected and secured to the refrigeration line proceed to the next step�

4. Reset the fault by cycling power to the dehumidifier�

5. Turn the humidity setting down (below room/home humidity level) to make a dehumidification call�

6. Allow the fan and compressor to run for approximately 10-15 minutes and then enter diagnostic test

mode by simultaneously pressing the

the temperature measured by the internal sensor while also displaying AIR SAMPLING and ON, the

humidity measured by the internal sensor while also displaying %RH and ON, and the frost sensor

temperature while also displaying ON� Scroll through these values and by using the

buttons�

7. Record values and call Technical Support�

and MODE buttons for 3 seconds� The LCD will display

and

Cycle Power

Cycle Power

Self-Correcting

Cycle Power

E5

E6

High Temperature

Thermistor Failure

Low Temperature

Thermistor Failure

1. Check the high temperature sensor connection at the power board� Terminal should be fully seated

on the power board pins�

2. Remove the side access panel and verify the sensor is not damaged and connected to the

refrigeration line coming from the compressor�

3. If the sensor is connected and secured to the refrigeration line, it may need to be replaced with Part

No� 5456 — contact Technical Support to confirm�

1. Check the low temperature sensor connection at the power board�

2. Remove the side access panel and verify the sensor is not damaged and connected to the suction

line�

3. If the sensor is connected and secured to the refrigeration line, it may need to be replaced with Part

No� 5455 — contact Technical Support to confirm�

Cycle Power

Cycle Power

9

Page 10

TABLE 1 – DIAGNOSTIC CODES

Diagnostic

Code Failure Mode Action Reset

1. Empty the condensate pan�

2. Check the float switch connection at the control board�

E7 Float Switch Open

3. If not using a float switch, verify jumper is between float switch terminals on dehumidifier control

Self-Correcting

board�

4. If the problem persists, replace the float switch�

Inlet Air

E8

50°F – 104°F range,

or dew point below

Temperature Out of

1. If temperature is out of range, no action, normal operation�

2. If air temperature is between 50°F – 104°F with a dewpoint above 40°F, contact Technical Support�

Self-Correcting

40°F

TABLE 2 – TROUBLESHOOTING GUIDE

Symptom Possible Reason Troubleshooting Procedure

• Check that the dehumidifier is plugged in�

Dehumidifier does not

turn on/run�

No power to unit�

• Check that the power switch is turned ON�

• Check that the control is turned ON�

• Check that the circuit breaker has not tripped�

Dehumidifier blower is

running but with little or

no airflow�

Dehumidifier blower is

running but compressor

is not�

Dehumidifier is not

draining properly�

Dehumidifier is

producing hot air�

The HVAC fan turns on

unexpectedly�

Pressure drop across dehumidifier

is higher than 0�7"w�c�

Float switch open�

Coil frosting�

Inlet air temperature is outside of

the 50°F – 104°F range or the dew

point is below 40°F and there is a

demand for dehumidification�

Drain line blocked or unit not level�

Normal function�

Dehumidifier is sampling�

• Check dehumidifier air filter and wash or replace�

• Check for blocked duct work and clear�

• Verify that the outlet collar with backflow damper is installed on the outlet side of the

dehumidifier�

• Check if backflow damper is blocked or stuck and remove obstruction

• If float switch installed, check connections at control board and empty condensate pan�

• If no float switch installed check that the jumper is installed at the float switch terminals on

the control board�

• Lack of or reduced airflow� Check dehumidifier air filter and wash or replace�

• Check that there is nothing blocking the inlet or outlet of the dehumidifier�

• Inlet air conditions below 60°F� Increase the humidity setting�

• Verify all ductwork is properly sealed�

• No action� The compressor will not run if inlet conditions are out of range�

• Verify that the unit is level�

• Check the drain line blockages and for a continuous downward slope�

• Air is reheated across the condenser coil, resulting in a temperature rise between inlet and

outlet�

• The dehumidifier will turn on the HVAC fan during air sampling or as needed to meet the

ventilation time�

10

Page 11

SERVICE PARTS

4

5

9

17

3

10

19

1

7

11

13

14

2

16

15

6

No. Part Description Part No.

1 Filter, 14" x 19" x 1" EZK 5569

2 Internal Control Board, Deh 5444

3 User Interface Assembly, Deh 5445

4 Wiring Access Door, AA Deh 5446

5 Hole Cover, UI Ctrl, Deh 5447

6 Door, Filter Access, AA Deh 5571

7 Outlet Duct Panel, Deh 5449

8 Backflow Damper, 10", Deh 5450

9 Inlet Duct Panel, AA Deh 5451

8

12

90-2031

18

No. Part Description Part No.

11 Fan, 130pt Deh, with 10MFD Capacitor 5572

12 Wire Harness, Power, Deh 5454

13 Sensor, Low Temperature, Deh 5455

14 Sensor, High Temperature, Deh 5456

15 Capacitor, 50MFD, 370VAC 5594

16 Capacitor, 10MFD, 250VAC 5573

17 RH Sensor, Deh 5460

18 Drain Tube + Fitting 5665

19 Compressor Overload Switch 5574

10 Cover, Outlet, AA Deh 5452

11

Page 12

LIMITED WARRANTY

Your Research Products Corporation Aprilaire® Dehumidifier is expressly warranted for five (5) years from date of installation to be free from defects in materials or workmanship�

Research Products Corporation’s exclusive obligation under this warranty shall be to supply, without charge, a replacement for any component which is found to be defective within such

five (5) year period and which is returned not later than thirty (30) days after said five (5) year period by you to either your original supplier or to Research Products Corporation, Madison,

Wisconsin 53701, together with the model number and installation date of the dehumidifier�

THIS WARRANTY SHALL NOT OBLIGATE RESEARCH PRODUCTS CORPORATION FOR ANY LABOR COSTS AND SHALL NOT APPLY TO DEFECTS IN WORKMANSHIP OR MATERIALS

FURNISHED BY YOUR INSTALLER AS CONTRASTED TO DEFECTS IN THE DEHUMIDIFIER ITSELF�

IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE SHALL BE LIMITED IN DURATION TO THE AFORESAID FIVE YEAR PERIOD� RESEARCH PRODUCTS

CORPORATION’S LIABILITY FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES, OTHER THAN DAMAGES FOR PERSONAL INJURIES, RESULTING FROM ANY BREACH OF THE AFORESAID

IMPLIED WARRANTIES OR THE ABOVE LIMITED WARRANTY IS EXPRESSLY EXCLUDED� THIS LIMITED WARRANTY IS VOID IF DEFECT(S) RESULT FROM FAILURE TO HAVE THIS UNIT

INSTALLED BY A QUALIFIED HEATING AND AIR CONDITIONING CONTRACTOR� IF THE LIMITED WARRANTY IS VOID DUE TO FAILURE TO USE A QUALIFIED CONTRACTOR, ALL DISCLAIMERS

OF IMPLIED WARRANTIES SHALL BE EFFECTIVE UPON INSTALLATION�

Some states do not allow limitations on how long an implied warranty lasts or the exclusion or limitation of incidental or consequential damages so the above exclusion or limitations may

not apply to you�

This warranty gives you specific legal rights and you may also have other rights which vary from state to state�

WARRANTY REGISTRATION

Visit us online at www.aprilaire.com to register your Aprilaire product� If you do not have online access, please mail a postcard with your name, address, phone number, email address, product

purchased, model number, date of purchase, and dealer name and address to: Research Products Corporation, P�O� Box 1467, Madison, WI 53701�

Your warranty registration information will not be sold or shared outside of this company.

AprilairePartners.com

P.O. Box 1467

Madison, WI 53701-1467

800.334.6011 F: 608.257.4357

Printed in USA

©2019 Aprilaire – Division of Research Products Corporation

10014202 B2208523A 6.19

12

Loading...

Loading...