Aprilaire 1820 Installation Manual

Model 1820 Dehumidifier

Installation Instructions

SAFETY INSTRUCTIONS

WARNING

1. 120 Volts may cause serious injury from electric shock. Disconnect electrical power before starting installation or servicing.

Leave power disconnected until installation/service is completed.

2. Sharp edges may cause serious injury from cuts. Use care when cutting plenum openings and handling duct work.

3. Dropping may cause personal injury or equipment damage. Handle with care and follow installation instructions.

CAUTION

1. Read all instructions before beginning installation.

2. Improper installation may cause property damage or injury. Installation, service, and maintenance must be performed by a

qualified service technician.

3. Do not use in pool applications. Pool chemicals can damage the dehumidifier.

4. Do not use solvents or cleaners on or near the circuit board. Chemicals can damage circuit board components.

5. Wait 24 hours before running the unit if it was not shipped or stored in the upright position

TABLE OF CONTENTS

Safety Instructions........................................1

Specifications............................................2

Set Up Dehumidifier for Installation ........................2

Packaging Content .......................................2

Duct Collars ............................................2

Location Considerations...................................3

Installation...............................................3

Leveling ...............................................3

Ductwork Installation.....................................3

Drain Tubing and Condensate Pump Installation ...............4

Model 76 – Crawl Space Control and Wiring ................5

READ AND SAVE THESE INSTRUCTIONS

Air Cycling...............................................5

System Set-Up, Check & Start-Up ..........................6

Remote Control – Crawl Space.............................6

Ventilation / Air Cycling...................................7

System Check...........................................7

Crawl Space Using the Dehumidifier Control..................8

Crawl Space Remote Control Using Model 76 .................8

Start-Up ...............................................8

Troubleshooting ..........................................9

Table 1 – Diagnostic Codes................................9

Table 2 – Troubleshooting Guide...........................10

Service Parts............................................11

1

CLIP OFF

REMOVE SHIPPING BRACKET

SPECIFICATIONS

OUTLET

COLLAR

INLET

DUCT

COLLAR

Model 1820

Weight

56 lbs.

Capacity: AHAM DH-1-2008 80°F, 60% RH Conditions 70 pints per day @ 200 CFM

Power: 115 VAC, Single Phase, 60Hz 5.8 Amps operating current

Dehumidifier Inlet Air Conditions

Filter

Airflow

Dehumidification: 50°F – 104°F, 40°F dew point minimum

Ventilation: 40°F – 140°F, 0%RH – 99%RH (non-condensing)

MERV 8, washable

200 CFM

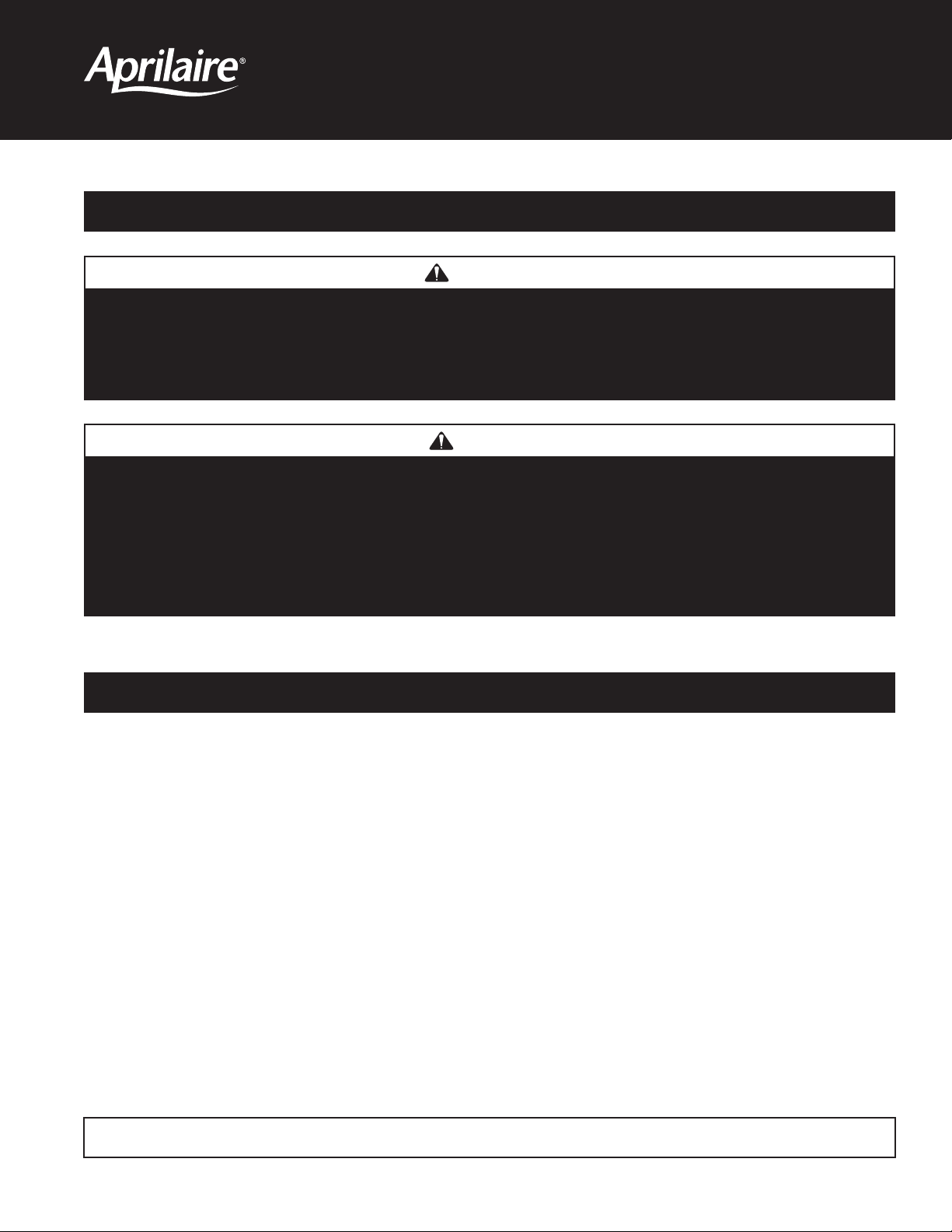

SET UP DEHUMIDIFIER FOR INSTALLATION

IMPORTANT: Cut the strap securing the compressor

shipping support bracket and remove the strap and shipping bracket.

See Figure 1.

PACKAGING CONTENT

1. Dehumidifier

2. Inlet/Outlet Collars

FIGURE 1 – Remove Shipping Bracket

3. Literature

a. Installation Instructions

b. Owner’s Manual

4. Parts Bag

a. #10 x 1/2 Screws (9)

b. Threaded Barbed Fitting for Drain

Connections

c. Torx Bit

5. 10 foot, 3/4” Drain Tube

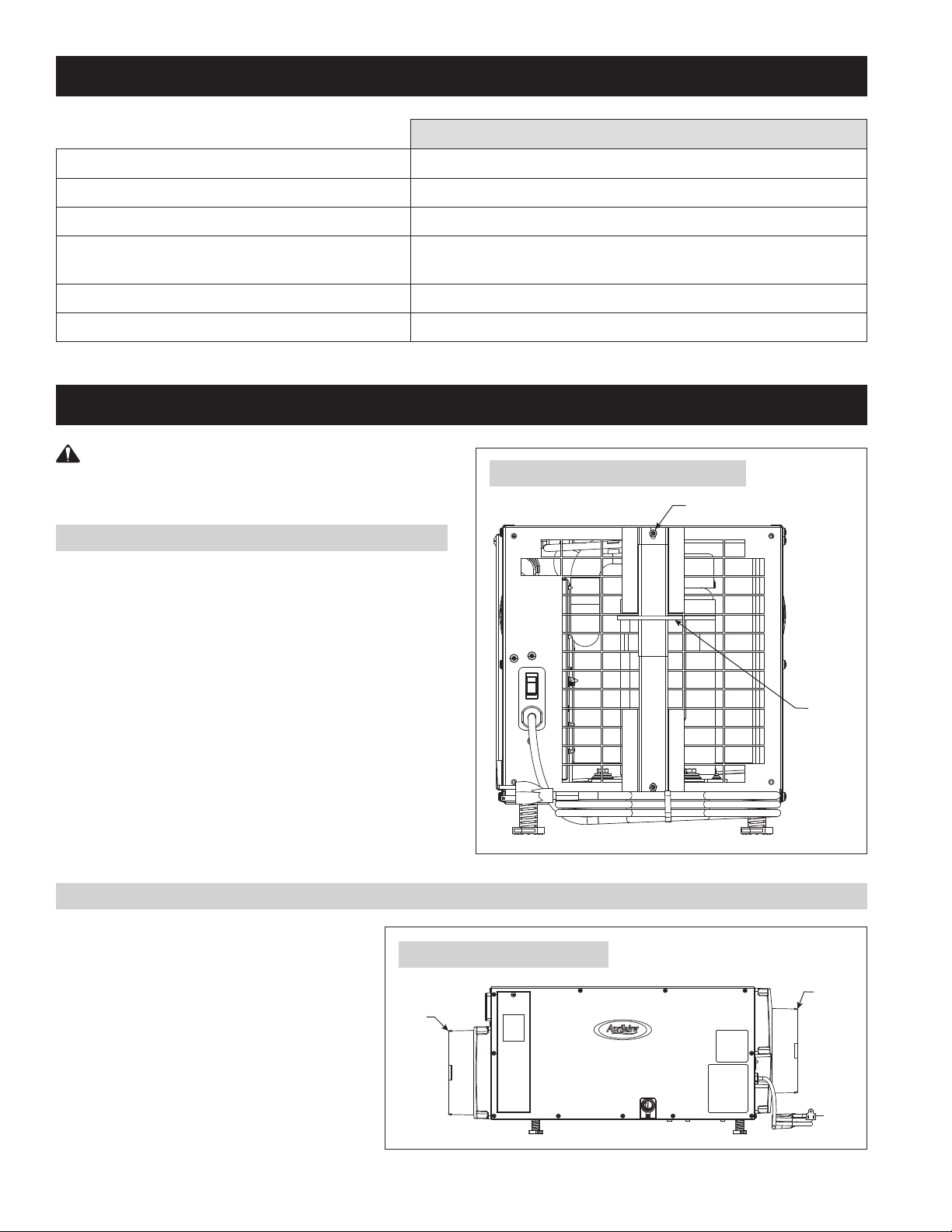

DUCT COLLARS

Use the screws in the parts bag to attach the duct

collars to the inlet and outlet of the dehumidifier.

See Figure 2.

PLASTIC

STRAP

90-2302

FIGURE 2 – Install Duct Collars

DUCT

2

90-2308

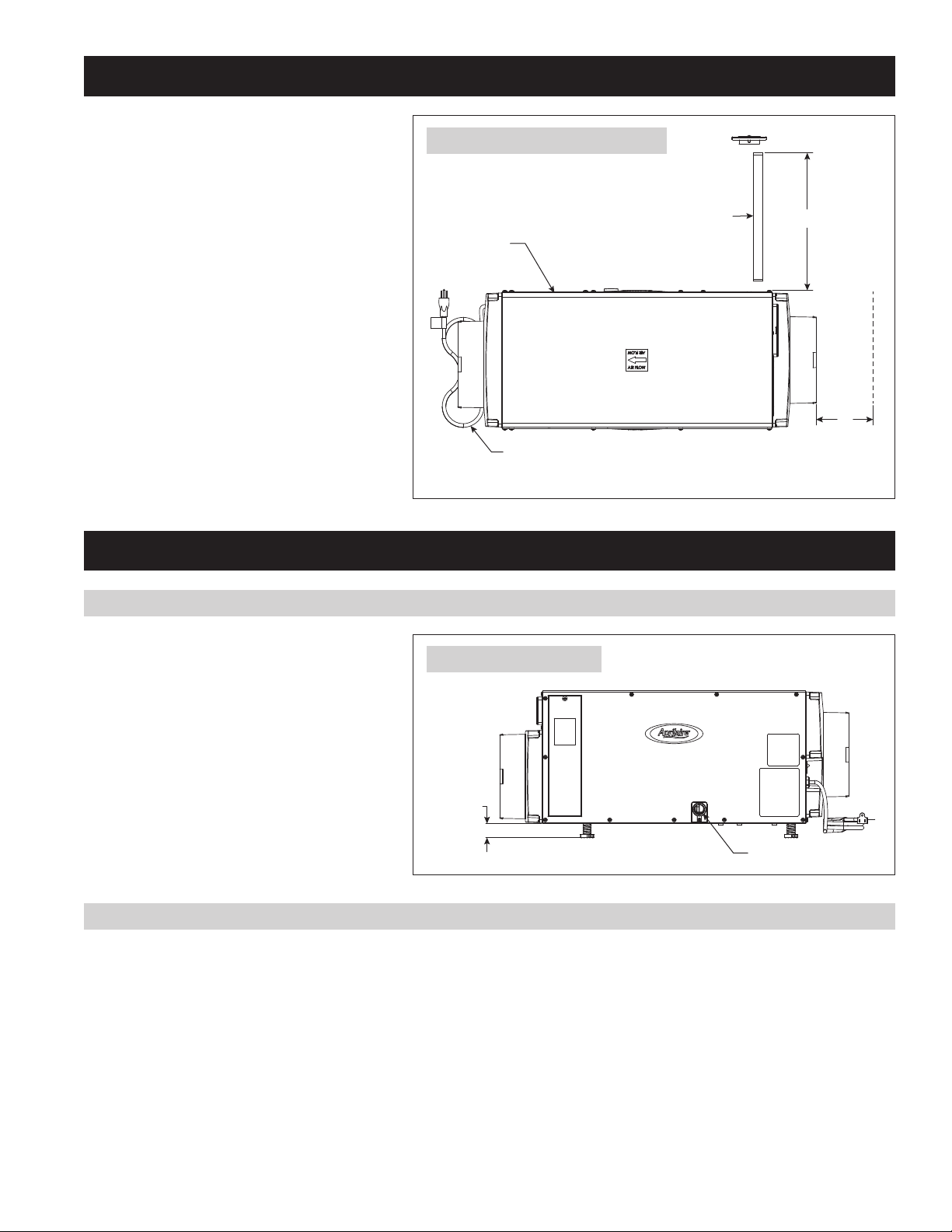

LOCATION CONSIDERATIONS

FOR PROPER

AIR FLOW

2.00" MAX

3/4" FNPT DRAIN

• Allow sufficient clearance for filter removal and

to prevent airflow obstruction

• Electrical service access will require the removal

of the side panel shown. Allow sufficient space

for service on this side of the unit.

FIGURE 3 – Filter Access Clearance

ELECTRICAL

SERVICE ACCESS

THIS SIDE

8 FT. POWER CORD

90-2304

TOP VIEW

FILTER

MINIMUM

13"

CLEARANCE

FOR FILTER

MINIMUM

CLEARANCE

6"

INSTALLATION

LEVELING

The feet can be adjusted to level the unit, and

if required, to accommodate drain fittings and a

secondary condensate pan. Leveling is required

to ensure proper drainage from the dehumidifier.

See Figure 4.

DUCTWORK INSTALLATION

Adding 5-10 feet of insulated ductwork to the inlet and outlet of the dehumidifier will ensure dehumidified air is circulated throughout the crawl

space and will reduce the noise level of the dehumidifier. Point the inlet and outlet ducts in opposite directions to minimize recirculation of

dehumidified air.

FIGURE 4 – Level the Unit

0.38" MIN

90-2305

• Maximum recommended total duct length is 100 feet.

• To avoid pulling in dirt and other particles, do not lay intake duct on the floor of the crawl space.

NOTE: This dehumidifier is designed for crawl space and stand-alone applications only. Do not duct to HVAC system.

3

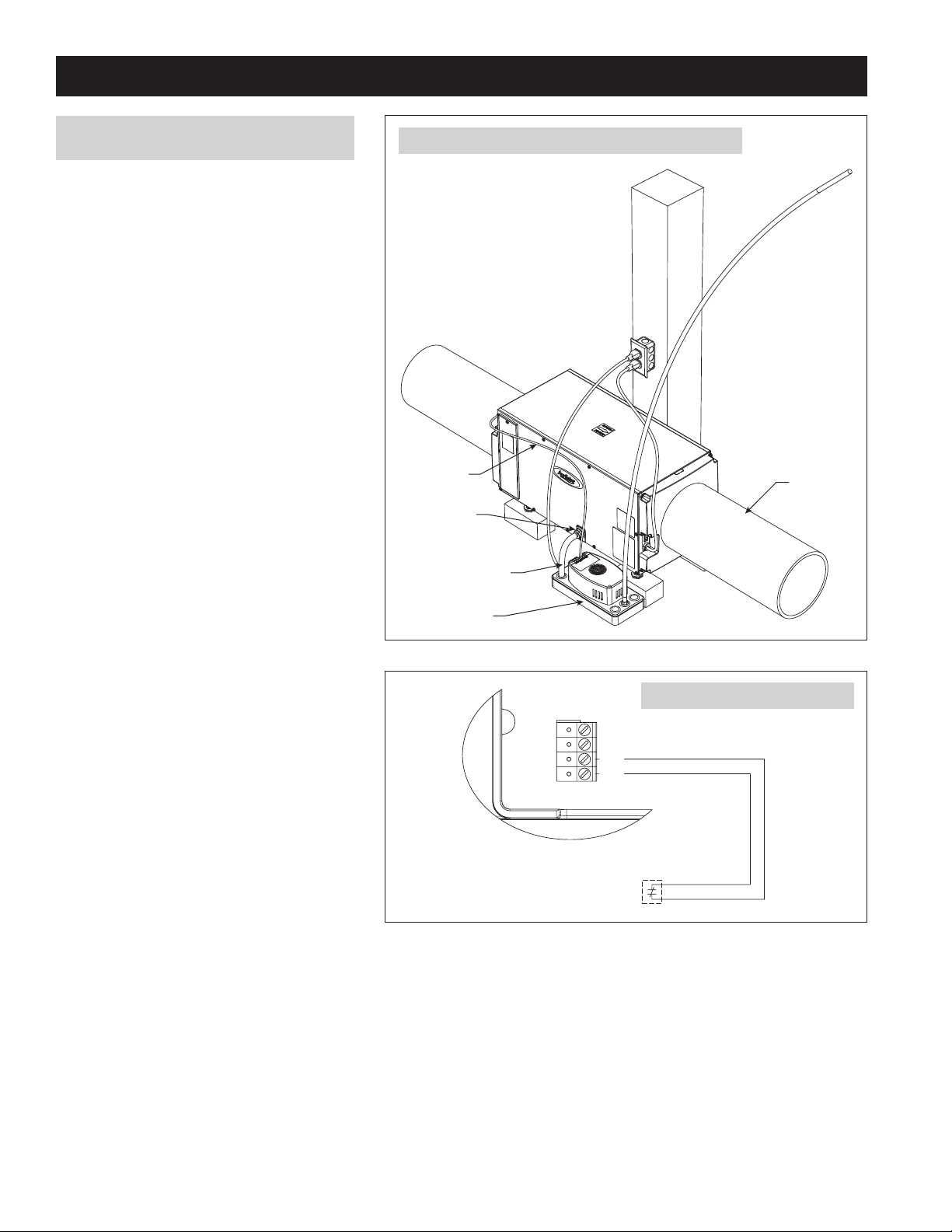

INSTALLATION (CONTINUED)

3/4" CLEAR PVC TUBING

(INCLUDED)

CONDENSATE PUMP

FLOAT SWITCH

WIRE

3/4" MNPT x 3/4"

BARB FITTING

(INCLUDED)

DRAIN TUBING AND CONDENSATE PUMP

INSTALLATION

The drain outlet on the dehumidifier can be plumbed

directly to a condensate pump (see Figure 5) using

the provided 3/4” MNPT x 3/4” hose barb fitting

and 3/4” clear PVC tubing. Always maintain a

constant downward slope from the dehumidifier to

the condensate pump. NOTE: PTFE thread seal tape

is recommended for the threaded connection. Hand

tighten only. The 4856 condensate pump is capable

of lifting water up to 22 feet. The dehumidifier can

be elevated (while remaining level) to increase

downward slope for proper draining. Wire the float

switch terminals to the normally closed contacts on

the condensate pump (see Figure 6).

FIGURE 5 – Drain and Condensate Pump Installation

8" DIAMETER

INSULATED

FLEX DUCT

FIGURE 6 – Float Switch Wiring

DH DH

FLOAT

Switch

LOW VOLTAGE NORMALLY CLOSED

CONTACTS ON CONDENSATE PUMP

90-2306

90-1857

4

Loading...

Loading...