Page 1

Thermostatic Expansion Valve (TXV) is a precision device

Model 1750

Model 1770

1

used to modulate the flow of refrigerant entering the

evaporator coil at the same rate as the refrigerant being

boiled off in the evaporator coil. The TXV also provides the

necessary pressure drop within the system to separate the

high and low pressure sides of the system. This separation

allows the low pressure refrigerant to absorb heat.

The cabinet of the Model 1750/1770 is fully insulated with a

2

1" insulation that is designed to reduce unit operating

sound levels, prevent condensation from forming on the

exterior of the unit, and prevent the possibility of heat gain

when the unit is located in higher temperature locations,

such as mechanical rooms or above ceilings.

The evaporator coil features a unique lanced fin and

3

double row tube design, giving the Model 1750/1770 better

surface contact with the moisture-laden air. The R-22

refrigerant within the coil provides the maximum

temperature differential required for the air to reach

dewpoint sooner, removing more moisture. These features

provide the unit with a 60% SHR rating at 80˚F and 60% RH.

The Model 1750/1770 can be controlled two ways; by using

4

the control that is integrated into the cabinet of the unit, or

by using a separate Model 70 control mounted in the

occupied space. When the integral control is utilized, it is

designed as a “set it and forget it control”, the only

interaction required is through a “more” or “less” dry

adjustment knob located on the inlet side of the unit. When

the Model 70 control is utilized, it becomes the sensor,

determines unit operation, and display the space RH%.

Inlet and Discharge connections are designed for 8"

5

insulated, flexible duct or can be ducted with standard 8"

round or spiral duct.

The unit is equipped with a safety disconnect switch that

6

will completely shut the power off during any service or

maintenance.

The internal blower is a direct drive forward curved blower

7

designed to deliver the air flow required for air “sampling”

and distribution. The unit is designed to deliver the proper

amount of air quietly and efficiently.

SPECIFICATION SHEET

DEHUMIDIFIER

MODEL 1750/1770

2

5

7

6

MODEL 1750 PERFORMANCE

AT INLET AIR CONDITIONS AND 275 CFM

MODEL 1770 PERFORMANCE

AT INLET AIR CONDITIONS AND 500 CFM

3

4

5

1

PRODUCT SPECIFICATIONS

Page 2

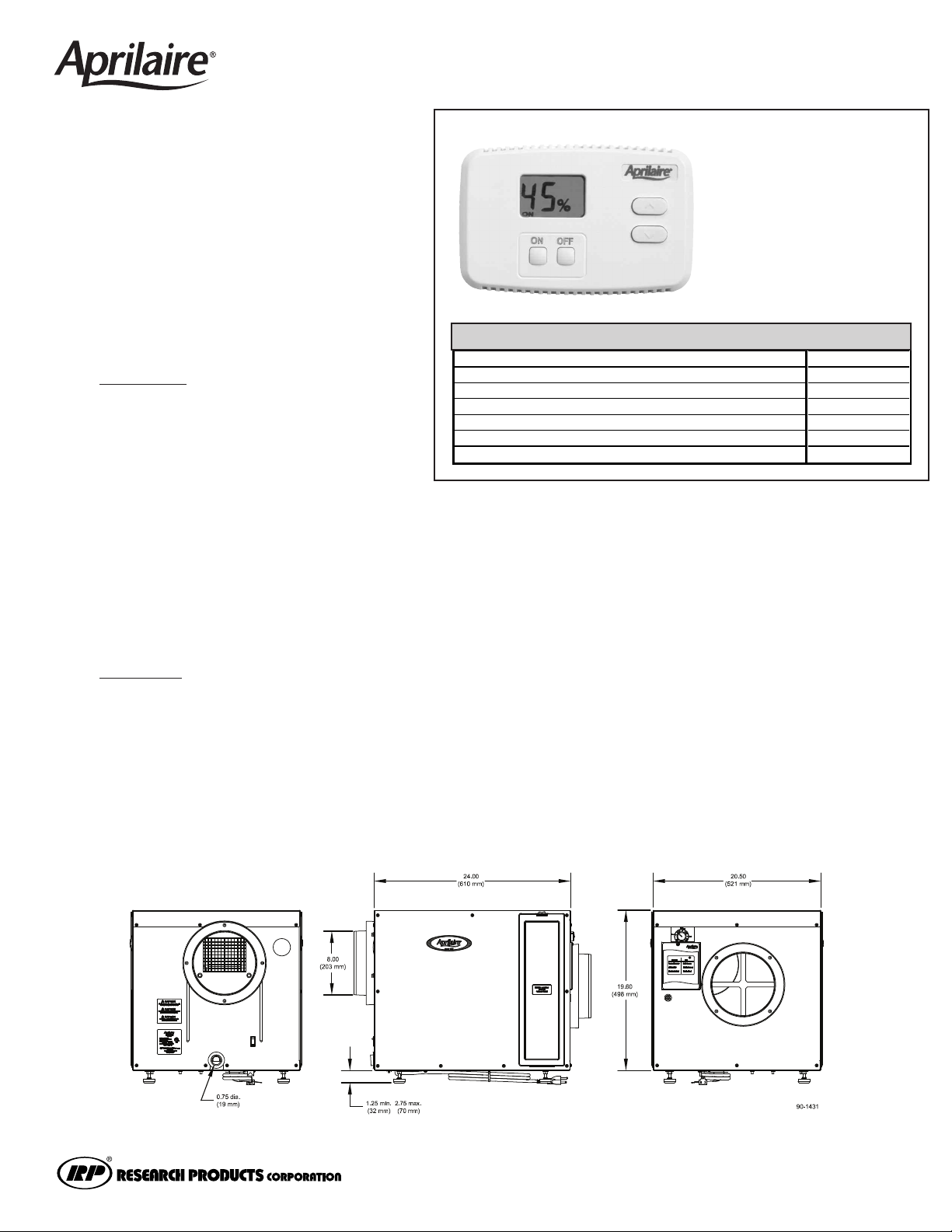

MODEL 1750/1770 DEHUMIDIFIER

Low Dewpoint Control Level ("MORE DRY" or 7 bars on display) 40°F

High Dewpoint Control Level ("LESS DRY" or 1 bar on display) 65°F

Temperature Sensor Range 40°F to 100°F

Relative Humidity Sensor Range 30% to 100%

Temperature Storage Range -30°F to 120°F

Relative Humidity Storage Conditions 0% to 100%

Supply Voltage (DC from Model 1700/1720 Control Board) 12 VDC

PRINCIPLE OF OPERATION

The Aprilaire Model 1750/1770 is designed to dehumidify the air

coming into the unit by passing the incoming air over a cooling

coil to drop the air temperature and dewpoint of the air.

oisture is removed from the air and drained out of the unit to a

M

common floor or waste drain. The air is then reheated in the

condenser coil and exits the unit.

It dehumidifies until a preset dewpoint setpoint is reached, then

shuts off until periodic sampling determines a need for operation.

The Model 1750 can be installed in two types of configurations:

“Whole-Building” or “Localized/Spot”.

Typical “Whole-Building” Operation:

In the “Whole-Building

used to dehumidify the entire building. In this application, the

Model 1750/1770 must be wired to the HVAC equipment blower.

In this configuration, the unit can be installed two ways:

1. Pulling air from the occupied space, through the dehumidifier

and discharging it into the supply duct/plenum of the HVAC

system.

2. In a bypass method, pulling air from the return, through the dehumidifier and discharging it into the supply duct/plenum of the HVAC system.

In order to check the dewpoint of the incoming air, the 1750/1770 must “sample” the air. To do this, the 1750/1770 will turn on with the first HVAC

equipment blower call in each selectable cycle (time) period. In the event that the blower is on continuously or during occupied times, the

dehumidifier will sample at the first available opportunity within the cycle period. If no HVAC equipment blower call occurs during the cycle period,

the 1750/1770 will activate it’s internal blower 3 minutes prior to the end of the cycle to enable it to sample the air. If the incoming air is above the

desired set point, the dehumidifier compressor will turn on. If the HVAC equipment blower call ends prior to the dehumidification set point becoming

satisfied, the 1750/1770 will continue to run and operate until the set point is met. The unit can be set to “sample” the air every 30 minutes, 1 hour, 2

hours, or 3 hours.

Typical “Localized/Spot” Operation:

In the “Localized/Spot

In this configuration, the unit can be installed two ways:

1. Pulling air from the occupied space, through the dehumidifier, and discharging it directly back into the occupied space. This is typically done

using wall grilles or ceiling diffusers.

2. Pulling air from the occupied space, through the dehumidifier, and discharging it into the supply duct serving the same occupied space that the air

was pulled from. This allows the warmer, dehumidified air to mix with cooler supply air from the HVAC System when the HVAC system air

conditioning is on.

If the Model 1750/1770 is wired to the HVAC equipment blower, the operation is the same as the typical “Whole-Building” operation.

If the Model 1750/1770 is operated independently of the HVAC equipment blower, the unit will use its internal blower to both sample the air and

provide the air flow necessary to distribute the air into the space.

” configuration, the Model 1750/1770 is

” configuration, the Model 1750/1770 is used to dehumidify a specific room or location within the building.

PRODUCT SPECIFICATIONS

ODEL 70

M

OCCUPIED SPACE CONTROL

• On/Off buttons

• Displays set point indication bars

and measured RH in the area

• Senses dewpoint in the

occupied space

• Adjustable to achieve “more” or

“less” dry conditions

Form No. 4251 05.09

RESEARCH PRODUCTS RESERVES THE RIGHT TO CHANGE SPECIFICATIONS WITHOUT NOTICE.

PO Box 1467 • Madison, WI 53701-1467 • Phone 800/334-6011 • Fax 608/257-4357 • www.aprilairecontractor.com

©2009 Research Products Corporation

Printed in USA

Loading...

Loading...