Appion G5TWIN User Manual

www.AppionTools.com

FOR REFRIGERANT RECOVERY

OPERATION MANUAL

⚠ DANGER

Explosion Hazard. Do NOT use with hydrocarbons. See page 4.

⚠ WARNING

TO REDUCE THE RISK OF INJURY OR PRODUCT

DAMAGE, READ OPERATION MANUAL PRIOR TO

OPERATING PRODUCT.

COPYRIGHT © 2016 - APPION INC. - ALL RIGHTS RESERVED

APPIONTM AND G5TWINTM ARE TRADEMARKS OF APPION INC.

Welcome to the G5Twin

Thank you for your purchase of the Appion G5Twin Refrigerant Recovery Machine. This machine was designed

to deliver fast, reliable recovery of Class III, IV and V refrigerants. Use of this machine for any other purpose is

done at your own risk.

Faster refrigerant recovery requires proper training, preparation, and operation. Working with refrigerants

under pressure also presents numerous safety risks and hazards.

To safely reach the full potential of this machine, read this manual and all safety material before use.

Table of Contents

Warnings and Safety Information .................................................................4 - 5

Refrigerant Storage Container Safety ...............................................................6

Getting Started ..............................................................................................7

Machine Usage

G5Twin Operational Layout .......................................................................... 8

Preparing for Operation ................................................................................ 8

Standard Recovery Procedure .......................................................................9

High-Speed Direct Liquid Recovery Procedure .............................................. 10

Standard Recovery with Inline Cooling ........................................................ 11

Push Pull Recovery Procedure ..................................................................... 12

Purging Non-Condensables from Recovery Cylinders ....................................13

Changing Between Refrigerant Types ..........................................................13

Storing the Machine Between Uses ..............................................................13

Helpful Hints

Planning Ahead .......................................................................................... 14

Tips for Maximizing Recovery Performance ............................................. 14-17

Extension Cords and Low Voltage ................................................................ 17

Care and Maintenance

Screen Cleaning & Replacement .................................................................. 18

Planned Maintenance & Bench Test ............................................................. 18

Specications and Support

Troubleshooting Guide ...............................................................................19

G5Twin Specications, Repair Part Kits & Accessories ................................... 20

Parts Diagram and Operational Diagrams ................................................ 21-22

Manufacturers Limited Warranty ................................................................. 23

3

G5TWIN OPERATION MANUAL

© 2016 APPION INC. - ALL RIGHTS RESERVED

Warnings and Safety Information

IMPORTANT - READ THIS MANUAL BEFORE OPERATION

This Operation Manual contains important information for protecting your safety and preventing equipment

problems. Unsafe operation could lead to serious injury or death to you or others. For best results and safe

operation, read this entire manual before operation. Keep this manual in a safe, accessible location during

operation.

OPERATOR TRAINING, CERTIFICATION AND RESPONSIBILITY

⚠ NOTICE

This machine compresses and pumps liquid and vapor refrigerants at high pressures, which

can create dangerous conditions. This equipment is for use by technicians that are professionally trained and

certied in the safe handling of refrigerant, and safe refrigerant recovery techniques.

⚠ NOTICE

Keep away from children at all times. Do not leave unattended.

⚠ NOTICE

Never defeat the safety features of this product. Do not operate with missing, broken, or

unauthorized parts. Remove broken or altered equipment from service immediately.

PERSONAL PROTECTIVE EQUIPMENT AND MSDS

⚠ WARNING

When working with refrigerants, always use the appropriate Personal Protective Equipment

(PPE), including eye and hand protection. Read all Material Safety Data Sheets (MSDS) for any compounds

that you are likely to encounter during operation. Failure to do so could lead to injury or death.

HAZARD: RISK OF EXPLOSION OR FIRE

⚠ DANGER

Use of this equipment may pose certain explosion and re hazards.

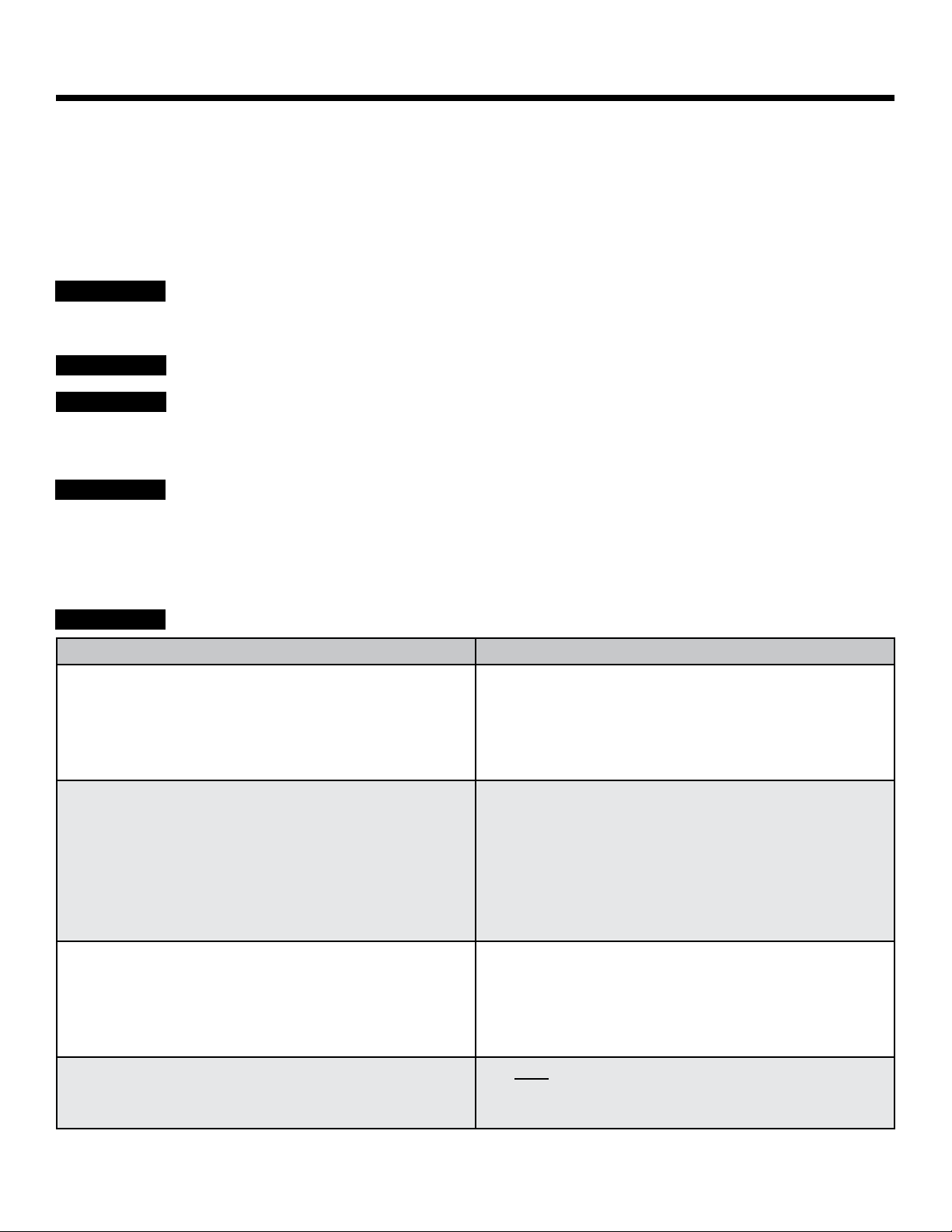

WHAT CAN HAPPEN HOW TO PREVENT IT

It is possible for electrical components within the

unit to spark. If electrical sparks come into contact

with ammable vapors, they may ignite, causing re

or explosion.

Flammable/combustible gases and air may become

unknowingly ingested through leaks in hoses,

gaskets, connections or leaking seals, leading to

compression of these gases. Air and hydrocarbons,

if pumped to a tank, create an explosive mixture

that random static electricity could ignite.

Flammable substances may ignite or explode when

compressed in certain situations.

Improper use of extensions cords may result in

overheating or re in the cord or machine.

Use only in well ventilated areas. In enclosed areas,

mechanical ventilation should provide at least four

air changes per hour.

Do not use in the vicinity of spilled or open

containers of gasoline, propane, butane, acetylene,

or other ammable gases.

Do not use near open sewer lines which may be

emitting sewer gases.

Do not use this machine to pump hydrocarbons,

including blends containing butane, isobutane, or

propane. Hydrocarbons are ammable substances

and may ignite or explode when compressed in

certain situations.

Use only 12AWG or 10AWG extension cords:

- Up to 25 Feet: 12/3 UL/CSA cord

- Up to 100 Feet: 10/3 UL/CSA cord

G5TWIN OPERATION MANUAL

© 2016 APPION INC. - ALL RIGHTS RESERVED

4

Warnings and Safety Information (continued)

HAZARD: RISK TO BREATHING (ASPHYXIATION)

⚠ DANGER

Air and refrigerants pumped by this machine may pose certain breathing hazards.

WHAT CAN HAPPEN HOW TO PREVENT IT

Refrigerant vapors may be harmful or toxic when

inhaled.

Compressed air from this machine may contain

carbon monoxide or toxic refrigerant vapors.

Use only in well ventilated areas. In enclosed areas,

mechanical ventilation should provide at least four

air changes per hour.

Air from this machine should never be used to

supply air for human consumption

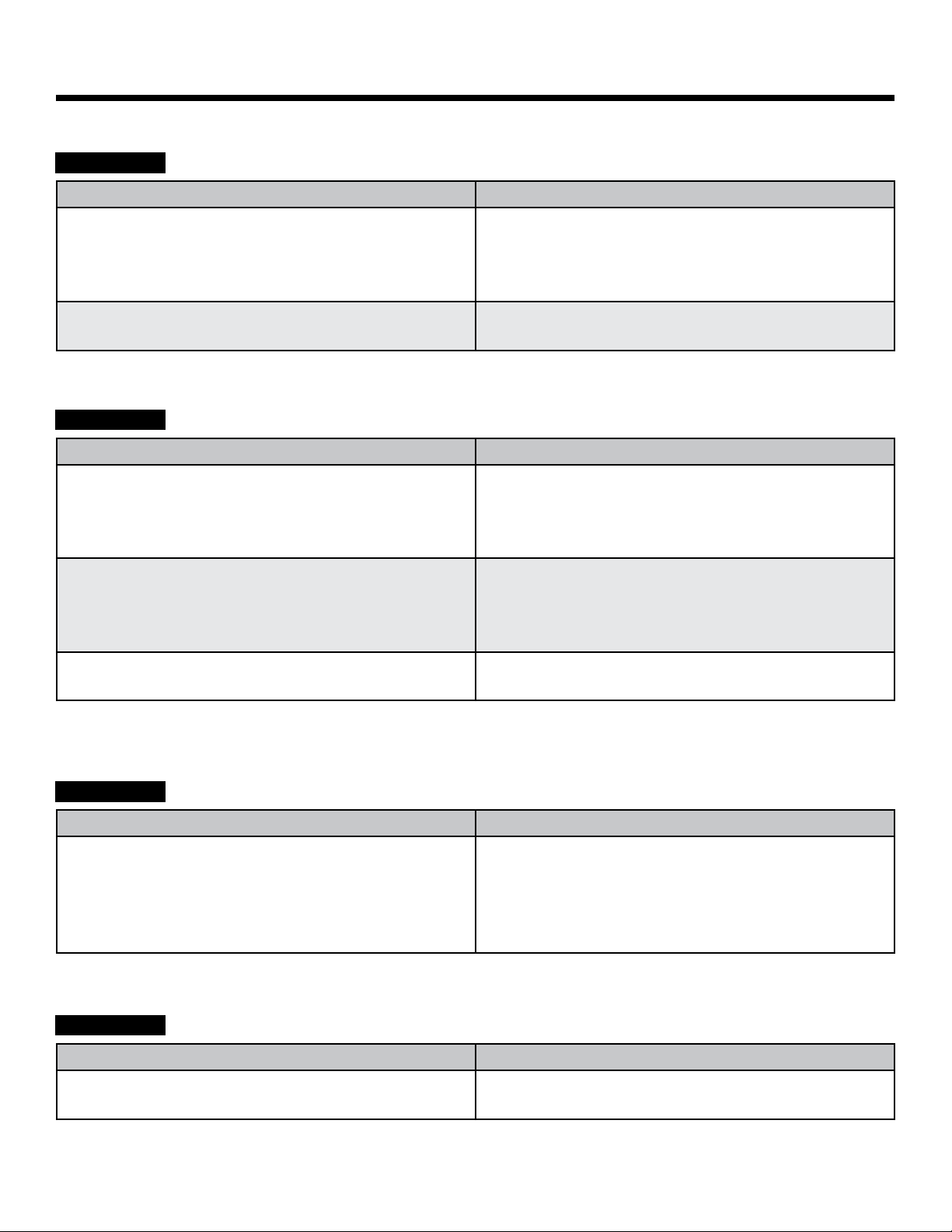

HAZARD: RISK FROM MOVING COMPONENTS

⚠ WARNING

This machine is equipped with a fan and motor rotating at high speeds.

WHAT CAN HAPPEN HOW TO PREVENT IT

Debris or other objects may enter the machine

housing through the air vents, causing machine

damage.

Physical damage may occur to body parts, tools,

or other objects if inserted into the air vents of the

machine while it is running.

Damage may occur to the machine and surrounding

objects if the machine is dropped while running.

Be sure the area around the machine is free and

clear of debris before operating the machine.

Always unplug the machine and ensure that the fan

and motor are not rotating before opening the case

or inserting any object into the machine.

Use caution while moving this equipment,

especially during operation.

HAZARD: RISK FROM UNATTENDED OPERATION

⚠ CAUTION

Factors aecting operation may change during the recovery process.

WHAT CAN HAPPEN HOW TO PREVENT IT

As refrigerant recovery is a dynamic process, and

oen performed in open spaces, factors aecting

the operation of the unit may change.

Always remain in attendance with the machine

while it is operating.

Remain observant to changes in environment,

refrigerant pressure and refrigerant temperature.

HAZARD: RISK FROM NOISE

⚠ CAUTION

Moving components, high airow, and pumping refrigerant can all cause noise.

WHAT CAN HAPPEN HOW TO PREVENT IT

Under some conditions and duration of use, noise

from the unit may contribute to hearing loss.

Always wear certied safety equipment, including

ANSI or equivalent hearing protection.

5

G5TWIN OPERATION MANUAL

© 2016 APPION INC. - ALL RIGHTS RESERVED

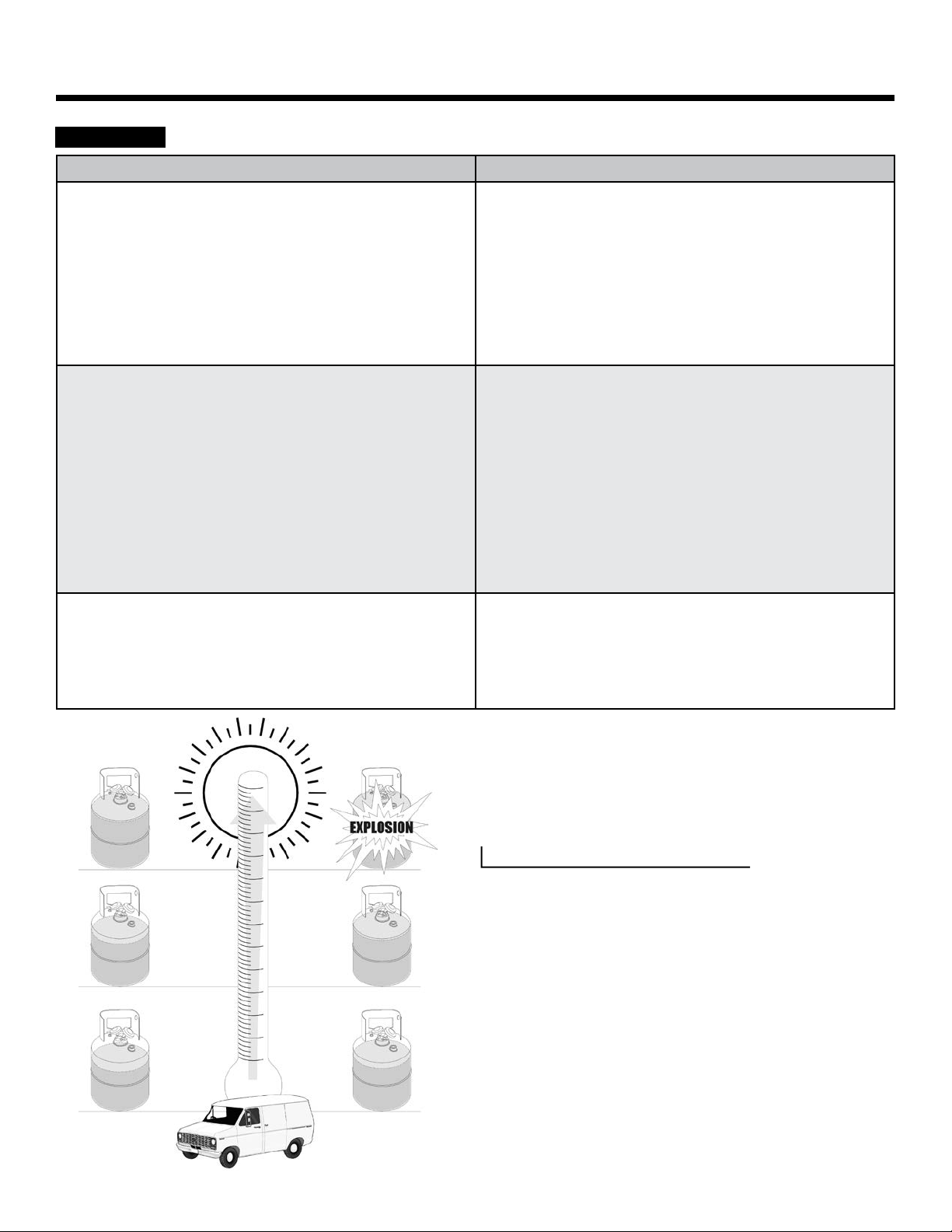

Refrigerant Storage Container Safety

⚠ WARNING

WHAT CAN HAPPEN HOW TO PREVENT IT

Use only DOT CFR 49 or UL-approved storage containers for recovered refrigerant.

Refrigerant storage containers may vent or explode

when the working pressure of the container is

exceeded.

“80% Shut O Switches,” also known as Tank

Overll Sensors and Overll Protection devices, may

fail to prevent overlling of the storage cylinder,

leading to venting or explosion.

These sensors only cut power to the recovery

machine, and do not stop the ow of refrigerant,

which may continue due to a siphon, or due to

temperature-induced migration.

Refrigerant expands when heated (Diagram 1),

storage containers may vent or explode when lled

over 80% capacity.

and

Refrigerant storage containers are designed with

dierent working pressures. Verify that the rating

of the storage cylinder is appropriate for the

refrigerant being recovered.

For R-410a, 4BA400 and 4BW400 are appropriate ratings for refrigerant storage containers.

Do not rely on these switches to prevent overlling.

Only a refrigerant scale can provide an active and

accurate measurement of the amount of refrigerant

in the storage container.

Do not rely on these switches to stop the ow of

refrigerant into the container. Only the valves on the

recovery machine and on the cylinder can stop the

ow of refrigerant into the container.

A refrigerant scale must be used to monitor the

amount of refrigerant in the storage container.

Be sure to close the valves on the storage container

when it has reached 80% capacity.

Filled to

80% Capacity

Filled to

90% Capacity

Diagram 1

Overlled storage containers may

explode due to liquid refrigerant

expanding when heated.

Transportation of refrigerant storage

cylinders more than 80% full is a DOT

violation.

6

G5TWIN OPERATION MANUAL

© 2016 APPION INC. - ALL RIGHTS RESERVED

Getting Started

⚠ CAUTION

Always use a grounded outlet that meets minimum voltage supply requirements for industrial

equipment. Do not use with portable power generators.

⚠ CAUTION

Always open valves slowly for safety, and to check for leaks.

⚠ CAUTION

The G5Twin is equipped with a 550psi (38.6 kg/cm2) pressure shut o switch to protect the

machine from damage. This does not prevent overlling of the storage container. (See Page 6)

ACCESSORY EQUIPMENT

Additional equipment may be used to connect the G5Twin to the system you are recovering refrigerant from.

Verify operational details and safety information from the manufacturers of other equipment before use.

• . A leaking hose may cause venting of refrigerant, and may introduce atmospheric air or other

⚠ CAUTION

contaminants into the recovered refrigerant. Examine the gaskets on each hose to ensure they are intact,

checking for any damage or wear that may lead to leaks.

• Use the shortest length of 3/8”-diameter hoses possible on every connection. IMPORTANT: Do not use

“quick disconnect” or “auto-shuto” hoses for refrigerant recovery, as this can bring the recovery to a halt.

• Use Valve Core Removal Tools with a ball valve (such as Appion MegaFlow VCT) to remove all “Schrader”-

type access valve cores from the System access ttings. This prevents restrictions that would otherwise

limit the performance of the G5Twin and/or cause overheating of the recovery cylinder. See Page 15 for

more information.

• The recovery cylinder should have extra capacity beyond the amount you intend to recover. For maximum

recovery speeds, use a recovery cylinder that is already evacuated (500 microns or better). Note: new

recovery cylinders may not be suiciently evacuated - always verify before use.

• Check your refrigerant scale with a known weight to ensure that is operating correctly. A malfunctioning

scale may not alert you to the amount of refrigerant in the storage container.

• Examine your external manifold gauges for proper valve operation and calibration of the gauges. Contact

the manifold gauge manufacturer for instructions in this process.

• Use a new inline lter dryer as shown when pumping dirty refrigerant. Replace the lter dryer aer each

use. If the lter has exceeded its capacity, this may aect the performance of the machine.

• Use a sight glass to verify liquid ow. This can also be useful for troubleshooting purposes. Make sure that

the sight glass is in good condition and does not leak.

CHECKING YOUR RECOVERY EQUIPMENT

Before connecting or operating the G5Twin, verify that the G5Twin will be able to operate properly:

• Check that the debris screen at the inlet tting is clean before starting every job. This screen prevents

damage to the machine that may get past the inline lter. When pumping dirty/used refrigerant, this screen

may quickly clog and slow the process when used without an inline lter.

• Verify the power source provides adequate voltage at the machine while it is running (within 10% of the

rated power). When using an extension cord, follow the sizing guidelines on Page 4.

Review the information for Care and Maintenance on Page 17 regularly to ensure optimal performance.

7

G5TWIN OPERATION MANUAL

© 2016 APPION INC. - ALL RIGHTS RESERVED

Machine Usage

G5TWIN OPERATIONAL LAYOUT

Diagram 2

Diagram 3

Horizontal Knobs: Valves Closed Vertical Knobs: Valves Open

PREPARING FOR OPERATION

Every recovery procedure starts with the same ve basics:

• Remove any access valve cores from the AC/R System access ttings with a Valve Core Removal Tool;

• Remove any core depressors from the hose ttings. Do not use “quick disconnect” or “auto-shuto” hose

connections for refrigerant recovery, as this can bring the recovery to a halt. Use only ball valves for low-loss.

• Use the shortest length of 3/8”-diameter hoses possible on every connection. Even with 1/4” ttings, the

larger hose diameter can deliver better performance during recovery.

• Purge the hoses of non-condensables as you connect the hoses, as needed, using best practices to minimize

any refrigerant release (aka “de minimis”). Excess non-condensables can cause tank overheating, and may

contaminate recovered refrigerant.

• Connect the G5Twin to a grounded power source for the proper voltage of the machine (115v/230v). If using

an extension cord, follow the cord sizing guidelines on Page 4.

✪ For additional refrigerant recovery tips, see pages 14-17.

G5TWIN OPERATION MANUAL

© 2016 APPION INC. - ALL RIGHTS RESERVED

8

Loading...

Loading...