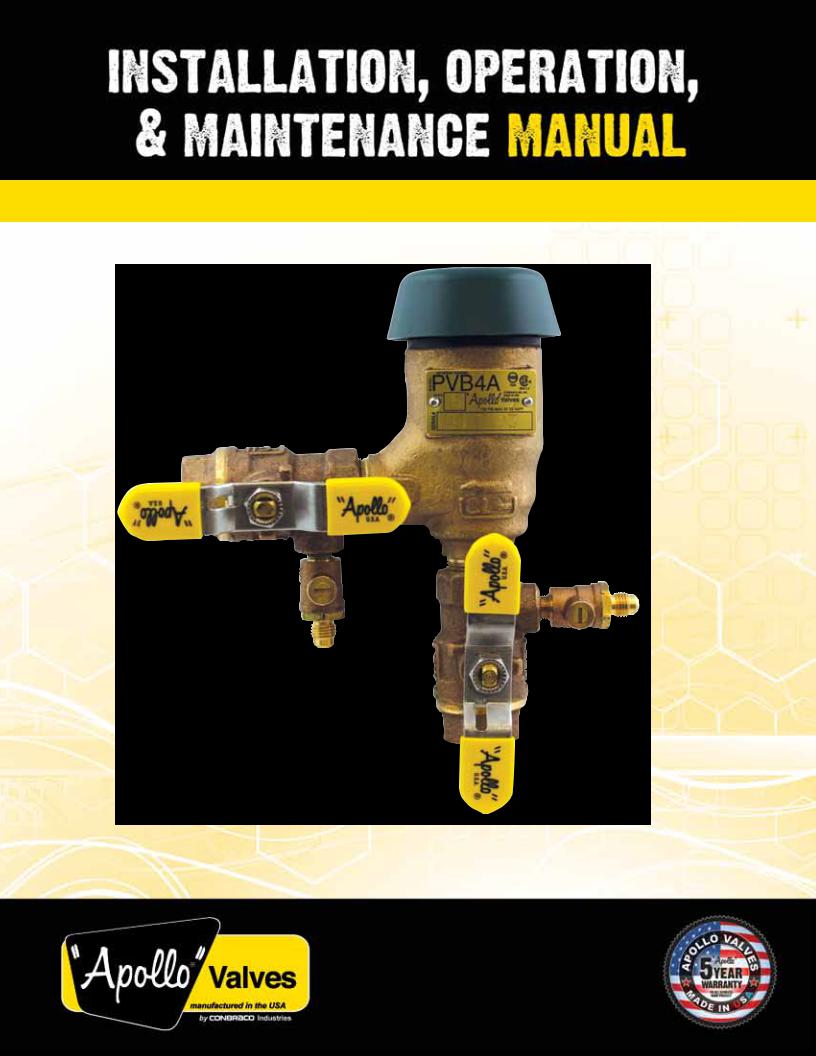

Apollo Conbraco PVB4A Installation Manual

BFMM PVB4A 1-2012

1/2” - 2”

Pressure Vacuum Breaker (PVB) Back!ow Preventer Model PVB4A

|

INSTALLATION, OPERATION, & MAINTENANCE MANUAL |

|

|

TABLE OF CONTENTS |

|

Pressure Type Vacuum Breaker 1/2” – 2” |

|

|

Section |

Page |

|

I |

Description and Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . .3 |

II |

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . .3 |

III |

Trouble Shooting Guide. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . .4 |

IV |

Maintenance Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . .5 |

V |

Testing Procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. .6-7 |

Parts List

Parts List (1/2”- 2”) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-10

Repair Kits

Repair Kits (1/2”- 2” ) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2 |

www.apollovalves.com |

Customer Service (704) 841-6000 |

BFMM PVB4A

PRESSURE TYPE VACUUM BREAKER 1/2” ! 2”

I. DESCRIPTION AND OPERATION

The Apollo PVB4A Series Pressure Type Vacuum Breaker consists of a replaceable check valve cartridge and a unique atmospheric vent bonnet/!oat assembly located between two resilient seated shut-o" valves. The modular design allows for unprecedented ease of inspection and maintenance.

During normal !ow conditions, the check valve remains open and the !oat seals on the bonnet assembly. A minimum supply pressure of 10 psig is normally required to fully shut the !oat. As the line pressure falls to 1 psig, a spring-loaded atmospheric vent valve opens, breaking the vacuum and thereby preventing back-siphonage. In the event of exposure to short-term freezing temperatures, a spring-loaded relief valve in the !oat protects the PVB body and internal components from damage. As the temperature increases above freezing, the relief valve automatically reseats. During normal operating conditions, the relief valve will not discharge.

NOTE: The freeze resistant feature is for a short term dip in temperature. The PVB should be winterized for extended periods below freezing.

II. INSTALLATION

Pressure vacuum breaker assembly’s critical level (CL is marked in raised lettering on the body of the PVB) should be installed at least 12 inches above the highest piping or outlet downstream of the device and with the supply line connected to the bottom of the device. Install the device in an accessible location to facilitate periodic #eld-testing and any required maintenance. Contact local water authorities for installation/service requirements.

Flush upstream piping thoroughly to remove foreign matter prior to installation. Use pipe dope sparingly on external threads only. When initially pressurizing the device, some spillage of water from the air inlet may occur.

To winterize the valve:

1.Secure the water source at a location that will not freeze.

2.Open #1 and #2 test cocks to drain the PVB.

3.Place the inlet and outlet isolation ball valves in the halfway open/shut position.

4.If possible, blow the lines clear with pressurized air.

Customer Service (704) 841-6000 |

www.apollovalves.com |

3 |

INSTALLATION, OPERATION, & MAINTENANCE MANUAL

Figure 1 |

Figure 2 |

$FLOWING CONDITION% |

$NO FLOW CONDITION% |

III. TROUBLE SHOOTING

SYMPTOM |

CAUSE |

CORRECTIVE ACTION |

|||

1. |

Air inlet fails to open or opens |

a. |

Float not moving freely. |

a. |

Inspect for fouling debris or |

|

below 1 psig. |

|

|

|

deposits. |

|

|

b. |

Float disc sticking to seat. |

b. |

Clean !oat seat area on bonnet |

|

|

|

|

|

and replace !oat disc/turn disc |

|

|

|

|

|

over. |

|

|

|

|

|

|

2. |

Air inlet fails to close. |

a. |

Float not moving freely. |

a. |

Inspect for fouling debris or |

|

|

|

|

|

deposits. |

|

|

b. |

Float disc fouled with debris. |

b. |

Clean !oat seat area on bonnet |

|

|

|

|

|

and remove debris. |

|

|

|

|

|

|

3. |

Check valve fails to hold 1 psig. |

a. |

Check valve fouled with debris. |

a. |

Remove, clean, or replace check |

|

|

|

|

|

valve. |

|

|

b. |

Check valve seat damage. |

b. |

Replace seat |

|

|

|

|

|

|

4. |

Water continues to !ow from test |

a. |

#1 shut-o" valve not completely |

a. |

Close #1 shut-o" valve. |

|

cock #2 during test #2. |

|

closed |

|

|

|

|

|

|

|

|

4 |

www.apollovalves.com |

Customer Service (704) 841-6000 |

Loading...

Loading...