Page 1

APG

Thank You

Thanks for purchasing an True Echo™ GWR200 guided wave radar level transmitter from us! We

appreciate your business and your trust. Please take a moment to familiarize yourself with your

sensor and this manual before installation. If you have any questions, at any time, don’t hesitate to

call us at 888-525-7300.

NOTE: Scan the QR code to the right to see the full

user manual on your tablet or smartphone. Or visit

https://www.apgsensors.com/support to nd it on our

website.

Table of Contents

True Echo™ Guided Wave Radar

Installation Guide

For GWR200 Level Transmitter

1.Description

2. How To Read Your Label

3. Warranty

4. Dimensions

Description

1

5. Installation Guidelines

6. Sensor and System Wiring

7. True Echo™ Software

Installation and

Communication Set Up

8. True Echo™ GWR200 Default

Application Setting

9. General Care

10. Repair Information

The True Echo™ GWR200 takes the mystery and frustration out of level measurement. With

programmable 4-20 mA or RS-485 Modbus outputs, and innovative signal analysis, the True Echo™

can accurately measure solids, liquids, and slurries at depths up to 80 feet. NEMA 6 housing is

standard, and 316 SS or PFTE-coated 316 SS probes operate in process temperatures from -40° to

398° F. Robust and reliable, the True Echo™ makes dicult level measurements easy.

2

How To Read Your Label

Each label comes with a full model number, a part number, and a serial number. The model

number for the True Echo™ GWR200 will look something like this:

SAMPLE: GWR200-4-W-N6-0-1-600-NN

The model number tells you exactly what you have. You can also call us with the model, part, or the

serial number and we can help you.

You’ll also nd all hazardous certication information on the label.

R

Automation Products Group, Inc.

1025 W 1700 N Logan, UT 84321

www.apgsensors.com | phone: 888-525-7300 | email: sales@apgsensors.com

Installation Guidelines

5

Part #122950-0034

Doc #9004827 Rev A

The True Echo™ GWR200 should be installed in an area--indoors or outdoors--which meets the

following conditions:

• Ambient temperature between -40° to 158° F (-40° to 70°C)

• Ample space for maintenance and inspection

Additional care must be taken to ensure:

• The probe is securely fastened to the sensor prior to installing the sensor on the tank or

vessel.

• The sensor is mounted away from tank or vessel walls and inlets.

• The probe is free from obstructions such as inows and agitators.

• The sensor is tightened by hand to avoid cross-threading.

*Important:

For user interface guide and sensor conguration see the full user manual.

Mounting your True Echo™ GWR200 is easy if you follow a few simple steps:

• Securely connect probe to sensor head prior to mounting sensor.

• Carefully feed probe through mounting hole

• Ensure that probe hangs free from obstructions

• Begin threading sensor NPT connection by hand

• Finish with wrench as necessary

Warranty

3

This product is covered by APG’s waranty to be free from defects in material and workmanship

under normal use and service of the product for 24 months. For a full explanation of our Warranty,

please visit https://www.apgsensors.com/about-us/terms-conditions. Contact Technical Support to

recieve a Return Material Authorization before shipping your product back.

Scan the QR code below to read the full explanation of our Warranty on your tablet or smartphone.

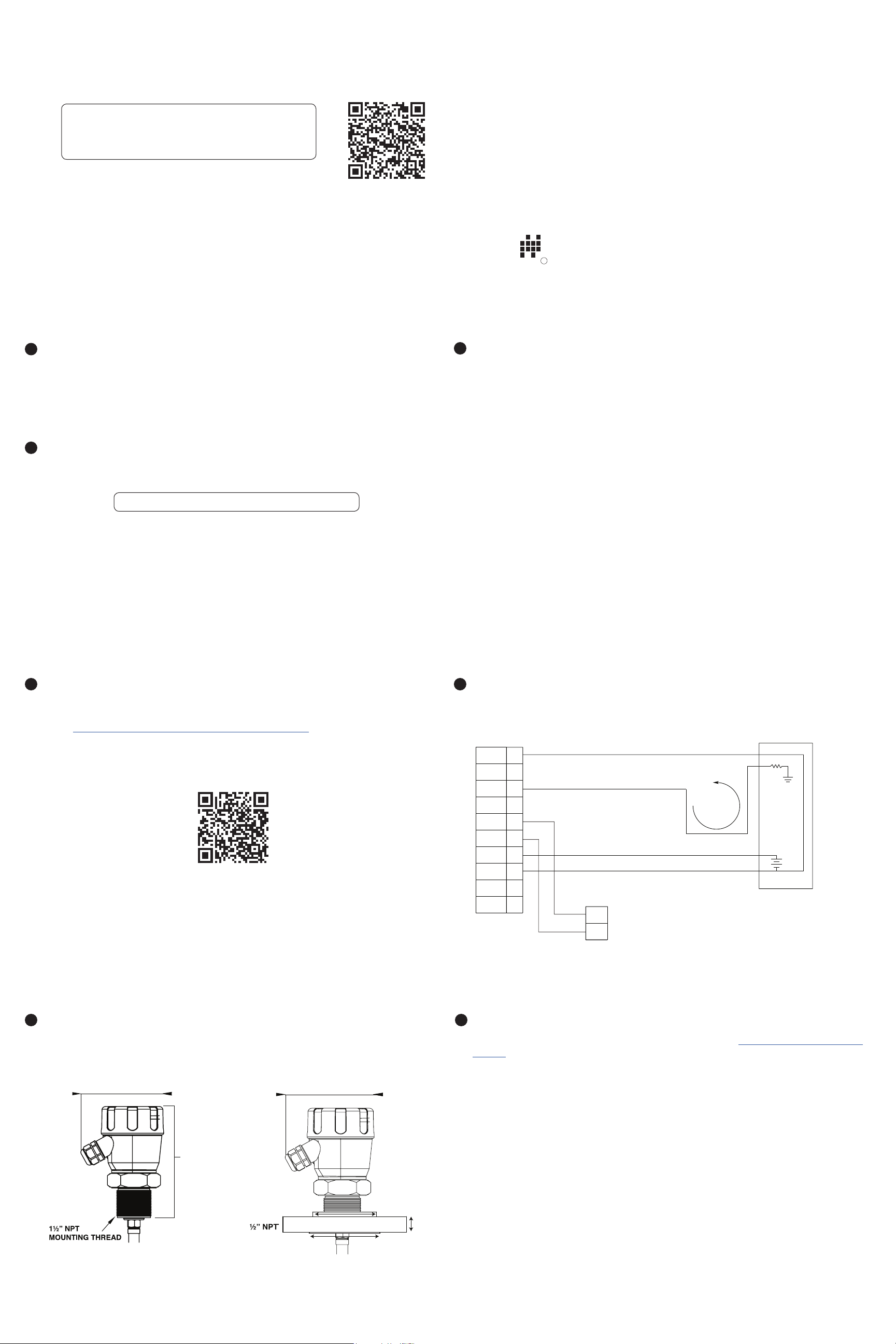

Sensor and System Wiring Diagram

6

Isolated 4-20 mA Circuit

True Echo

Terminals

4-20mA-

4-20mA+

IS+

4

Comm A

Comm B

DC In +

DC In -

9

10

Isolated 4-20mA Output

TX A-

TX B+

Modbus

Network Node

TX A-

TX B+

Note: Modbus Network connection

is seperate from supply voltage and

4-20 mA output.

4-20 mA

CURRENT

LOOP

Supply Voltage

Process

Controller

DC Gnd

R

L

+

DC Gnd

Dimensions

4

Standard

4.3” (110mm) 4.3” (110mm)

6” (154mm)

Flange Option

2-9/16” (65mm)

2-7/8” (73mm)

7/8”

(22mm)

True Echo™ Software Installation and Communication Set Up

7

• Download True Echo™ Software and windows driver ziple from https://www.apgsensors.com/

support.

• Open the zip le.

• Choose “Install” from the options at the top of the zip le window.

• The software will create True Echo.exe which will run from a folder in your Start Menu titled

“APG”.

• Connect the True Echo™ Communication Tool to the Modbus Network Terminals shown in

Section 6. Connect A on the True Echo™ Communication Tool to Comm A (TX A-) and B to

Comm B (TX B+).

• Connect the USB side of the True Echo™ Communication Tool to a USB port on your PC.

• Double click the True Echo

™

icon on your desktop or in your Start Menu.

Page 2

True Echo™ GWR200 Default Application Setting

8

General Care

9

The default Application setting for the True Echo™ GWR200 is Level, which will work in a wide variety

of settings. The True Echo™ GWR200 has additional Application settings that can be congured to

meet your needs. The analog 4-20 mA output will automatically scale to the length of the probe.

All of the True Echo™ GWR200’s adjustable settings are accessible through the True Echo™

Software, which is available at https://www.apgsensors.com/support.

Your level sensor is very low maintenance and will need little care as long as it was installed

correctly. However, in general, you should periodically inspect your True Echo™ GWR200 sensor

to ensure the sensor probe is free of any buildup that might impede the function of the sensor. If

sediment or other foreign matter builds up on the probe, detection errors can occur.

If you need to remove the sensor, be sure to store it in a dry place at a temperature between -40°

and 158° F.

Repair Information

10

If your True Echo™ GWR200 needs repair, contact us via email, phone, or online chat on our

website. We will issue you an RMA number with instructions.

• Phone: 888-525-7300

• Email: sales@apgsensors.com

• Online chat at www.apgsensors.com

Loading...

Loading...