Page 1

ENGINE INSTRUCTION MANUAL

G26 Air

G26/231 Marine

G231 Heli

G38

G62

GT80 Twin

G45

®

1

1

2

3

4

5

6

7

2

3

4

5

6

7

Page 2

2

Table of Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Support Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Mounting the Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Break-In . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Starting the Engine-Aircraft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Starting the Engine-Heli & Boat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Stopping the Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Carburetor Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Engine Care and Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Servicing the Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Troubleshooting Guide for Gasoline Engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Propeller Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Engine Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Exploded Illustration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

G26/G231 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

G38 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

G45 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

G62 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

GT80 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Warranty Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Warranty Repairs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Non-Warranty Repairs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Registration Form . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Page 3

3

Introduction

Safety Instructions

Very Important

This manual describes the engine’s features and functions. For specific information on mounting, see the

instruction manual included with the model airplane, helicopter or boat in which you intend to install the engine.

This model engine will give you considerable pleasure,

satisfaction and performance if you strictly follow these

safety instructions and take heed of the warnings as to

the engine’s safe and proper use. This engine has more

than enough power to cause harm if misused or if the

safety precautions are not observed.

Always

1. Use genuine parts for replacement.

2. Check the propeller, rotor (helicopter) or screw

propeller (boat) prior to each time the engine is used.

If nicked, scratched, cracked or damaged in any way,

replace it with a new one.

3. Use the correct size and pitch of propeller for your

engine; refer to the propeller chart in this manual.

4. It is extremely important to balance the propeller

prior to installation of the engine. Failure to do so may

cause damage to the Zenoah engine and/or the airframe.

Securely tighten the propeller nut against the washer

and propeller.

5. Inspect the tightness of the propeller nut prior to

each flight.

6. Keep your face and body away from the path of the

propeller blades when starting or running your engine.

7. Use a thickly padded glove when hand starting

the engine.

8. Make all carburetor adjustments from behind

the propeller.

9. To stop the engine, the black lead wire from the

coil should be grounded to the engine body, or use the

throttle linkage to shut off the air by closing the throttle

valve completely.

DO NOT USE HANDS, FINGERS OR ANY OTHER PART

OF THE BODY TO STOP THE PROPELLER. DO NOT

THROW ANY OBJECT INTO A PROPELLER TO STOP IT!

10. Ensure that all spectators, especially children, are at

least 20 feet away when you start running the engine.

11. Make sure your fuel is kept in a safe place well away

from sparks, heat or anything that could ignite the fuel.

Recommendations

1. Use safety glasses or goggles when starting and

running your engine.

2. Do not run the engine in the vicinity of loose gravel

or sand. The propeller may throw such materials into

your eyes. The engine could also ingest these harmful

materials.

3. Avoid loose clothing when operating your model

engine, as it could become entangled in the propeller,

creating the possibility of bodily harm. All loose objects

(screwdrivers, pencils, nickel cadmium glow drivers,

etc.) should be removed from your pockets so that they

do not fall into the propeller.

Congratulations on purchasing a Zenoah®engine. Cared

for properly, these high-quality, finely crafted engines will

offer many years of reliability.

This instruction manual has been developed to ensure

optimum performance from the Zenoah engine you have

purchased. It’s important that the instructions are read

thoroughly prior to mounting and running the engine.

FAILURE TO READ AND FOLLOW THESE INSTRUCTIONS BEFORE YOU PROCEED MAY RESULT IN ENGINE

DAMAGE AND THE VOIDING OF YOUR WARRANTY!

Page 4

4

Safety Instructions (continued)

Support Equipment

Caution

1. Model engines get very hot while running. Do not

attempt to handle them until they have cooled.

2. Always run your model engines in a well-ventilated

area. Similar to automotive engines, model engines produce harmful carbon monoxide fumes.

3. Never modify the flywheel.

4. Check the flywheel. If it’s damaged, replace it with a

new one.

5. When mixing the fuel or operating the engine, do so

in a well-ventilated area

6. Remember that model engines produce a substantial

amount of power, more than enough to seriously injure

people and/or do considerable damage to property.

Always use common sense, skill and constant observation of safety precautions.

Disassembly

The Zenoah engine can be disassembled or reassembled

without any specific difficulties. Refer to the Engine

Maintenance Section for specific instructions on these

procedures. If you need service to your Zenoah engine,

please send your engine to the authorized service center

at the following address:

Horizon Hobby, Inc.

Attention: Zenoah Service

4105 Fieldstone Road

Champaign, IL 61822

Phone: (217) 355-9511

Engine Parts Identification

It’s important to be able to identify the parts of your

Zenoah engines. Attached you will find an exploded view

of Zenoah engines, as well as a chart including part

numbers and descriptions. This will assist you in easily

and rapidly identifying the respective parts of your

Zenoah engine.

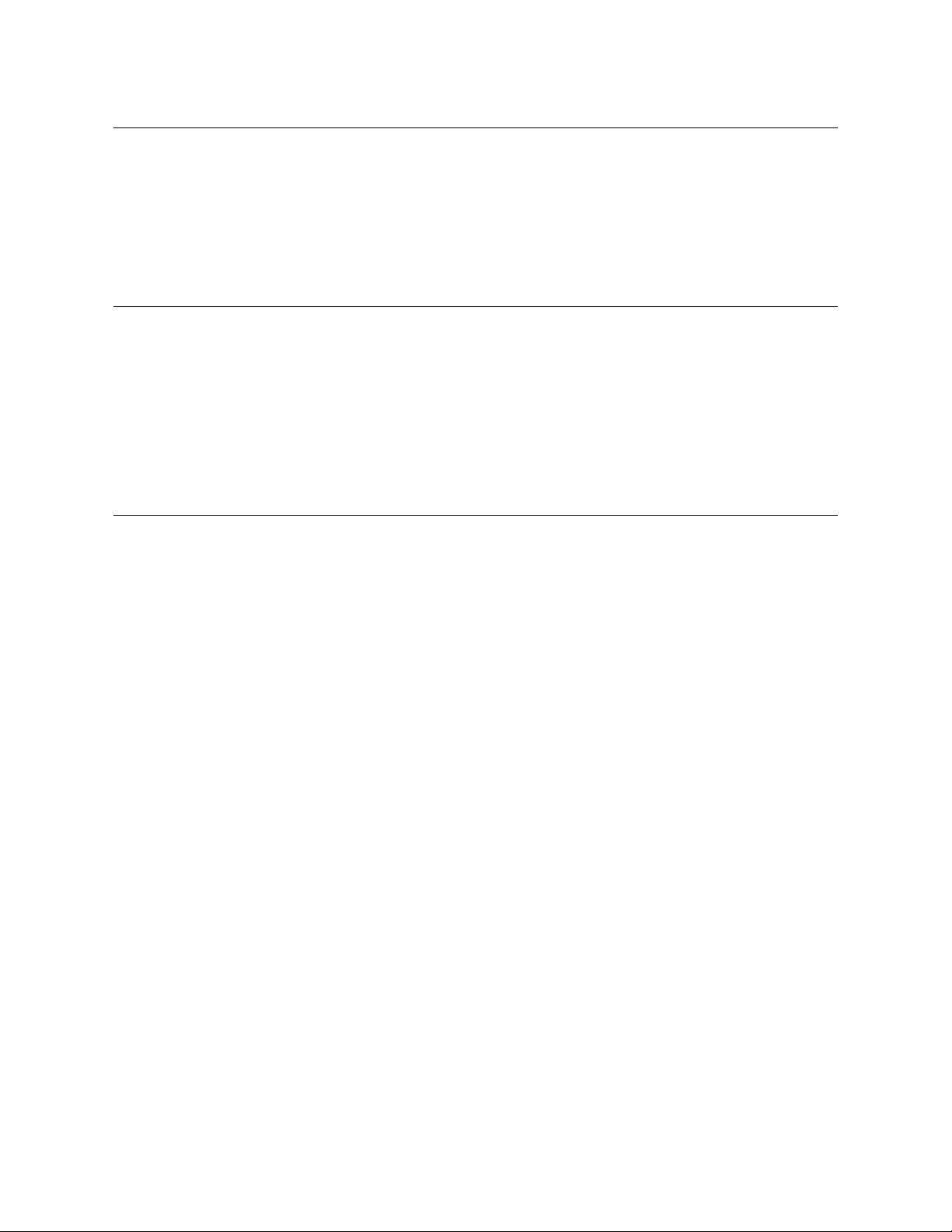

The following items, which are not included with your

Zenoah engine, are necessary in order to operate the

model engine.

Fuel—Mix gasoline and 2-stroke oil at a mixing ratio of

25-40:1.

Note: Be sure to use a gasoline-resistant fuel

tubing (do not use any silicone rubber tube).

Never use any alcohol fuel or alcohol-added

fuel as this will damage the rubber part of

the carburetor.

Propeller—Refer to the Propeller Selection Chart located

on Page 8 to determine the best initial propeller for your

particular application.

Manual or Electric Starter—For manual starts, a

chicken stick is highly recommended. Never use your

fingers to start any model engine as you could get

injured. If you must hand start a gasoline engine, be sure

to protect your hand with a heavily padded glove. There

are a variety of heavy-duty electric starters on the market

that can be used.

Zenoah Oil

ZEN20001

Zenoah Start Kit

ZEN20002

Page 5

5

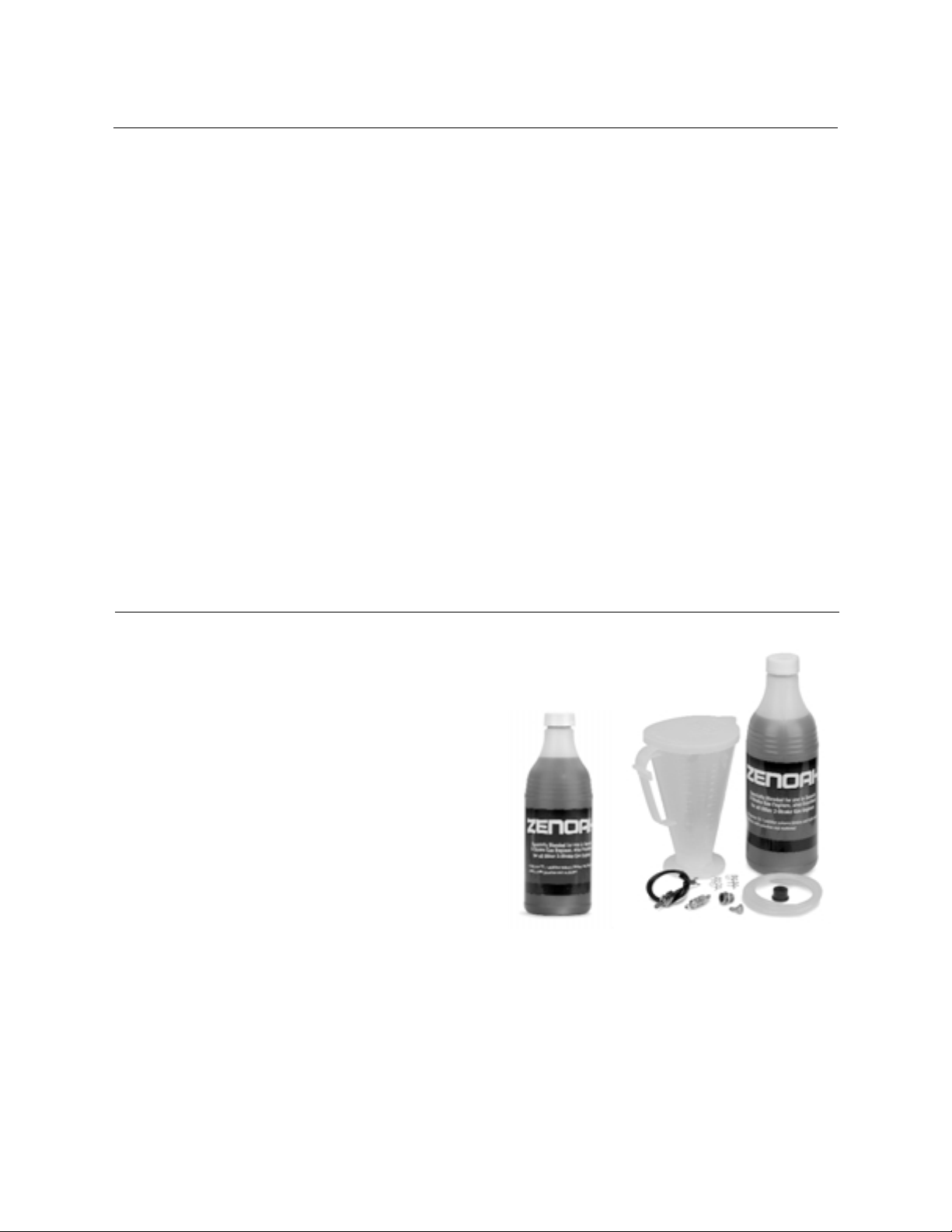

Mounting the Engine

Make sure the engine is mounted on the aircraft using

aircraft grade plywood that’s at least 6mm in thickness

for the G26 engine, and 10mm in thickness for the G38

through GT80 twin, or a mount of equivalent strength.

Make sure it’s firmly mounted with 4 bolts.

1. Be sure to set flat washers or a metal plate on the

reverse side of the mount to prevent the bolts from sinking into the mount. Periodically check the engine mount

for loose bolts.

2. Since the engine is equipped with a floatless carburetor with a diaphragm pump, the direction of the cylinder

and position of the fuel tank can be freely selected.

3. If the engine is mounted on a shock (rubber) mount

placed between the engine and the firewall for anti-vibration, check the hardness of the rubber, making sure it’s

not too soft, in order to avoid excessive vibration during

engine operating rpms. It’s suggested you note carefully

if the engine is vibrating at idle as excessive vibration

can result in erratic engine operation due to overflow at

the carburetor.

4. It is suggested you coat the bolts for the muffler with

threadlock when mounting the muffler to the engine.

Break-In

No specific break-in is required. The engine is gradually

broken-in as it is used, and the output power increases

gradually as the engine breaks in.

Starting the Engine—Aircraft

Before attempting to start the engine, be sure to read

through all the steps for starting the engine as outlined

below:

Zenoah engines are equipped with the ultra compact

C.D.I. type flywheel magneto ignition system and should

be started according to the following procedure:

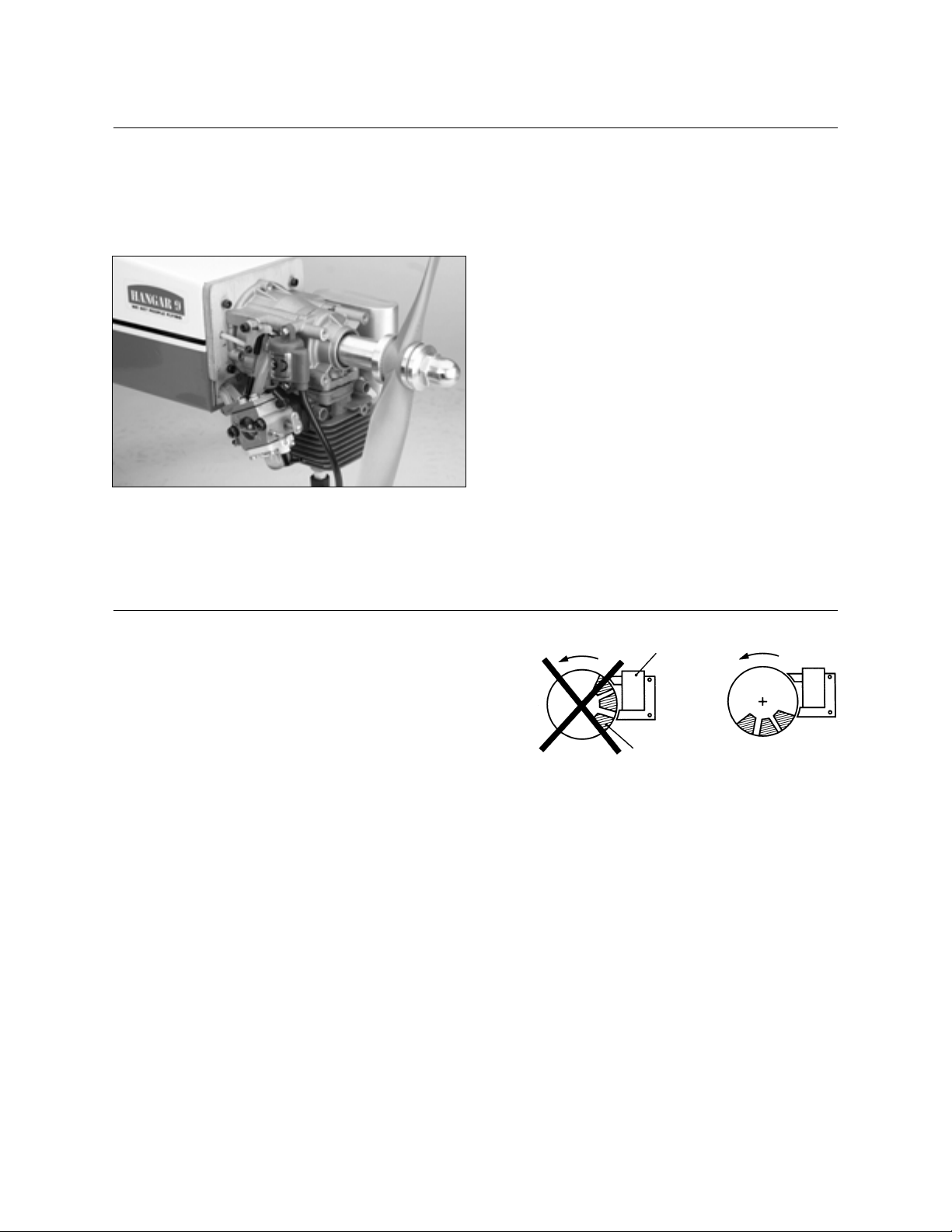

Note: The magneto system is timed in such a

way that when the compression stroke starts

(refer to Figure 1-A) sparks are never produced

on the spark plug, no matter how fast the propeller is flipped. The correct starting procedure

is to quickly flip the propeller when the edge of

the magnet on the rotor is approaching the coil

(Figure 1-B). This means that the propeller

should be quickly flipped at about 90 degrees

in crank angle before the compression stroke is

about to start.

1. Make sure the spark (glow) plug(s) are installed and

tightened. Check the condition of the plug cap for cracks

or breaks.

2. Be sure the propeller is properly secured.

3. Make sure the fuel tank line(s) are properly connected.

The main line should be connected to the carburetor

spray bar.

4. Be certain the mufflers are installed properly.

5. Fill the fuel tank.

6. Choke the engine and turn the propeller through a

few times until the fuel appears at the carburetor.

7. Set the throttle valve at the idle position or at the

position slightly open from idle.

Fig 1-A

Coil

Magnet

Fig 1-B

Operation

Page 6

6

Operation (continued)

8. Quickly flip the propeller in a counterclockwise

direction according to the procedure described in

the note above.

9. The engine should start after a few flips of the

propeller.

10. Be sure to open the choke when the initial firing

of the engine is heard.

11. When the choke is opened, be sure to close the

throttle valve to a position near the idle position before

the next flipping of the propeller is attempted.

CAUTION: If the engine is started when the throttle is wide open, a great thrusting force will be

generated, which can be very dangerous.

12. If you do not use a chicken stick to start the engine,

be sure to wear a thick glove when flipping the propeller

and use all fingers, except the thumb, for the flipping

operation.

13. Do not over-rev the engine. These engines are

designed to develop maximum output with the standard

muffler and the recommended propeller size. Please

refer to the propeller chart on page 10 to confirm the

proper propeller for the applicable Zenoah engine.

Starting the Engine— Helicopter and

Boat

1. Fill the tank with fuel.

2. Push the priming bulb located on the carburetor until

fuel appears in the priming bulb (for helicopter).

3. Choke the engine and open the throttle valve approximately 1/3–1/2 of the full open position.

4. Quickly pull the starter cord until the initial firing of

the engine is heard.

5. When the initial firing is heard, open the choke, set

the throttle valve at the idle position or at the position

slightly open from the idle position and quickly pull the

starter cord a few more times until the engine starts.

6. For helicopter operation, you should adjust the rotorpitch to obtain a 9,000 to 10,000 rpm of the engine at

full throttle operation.

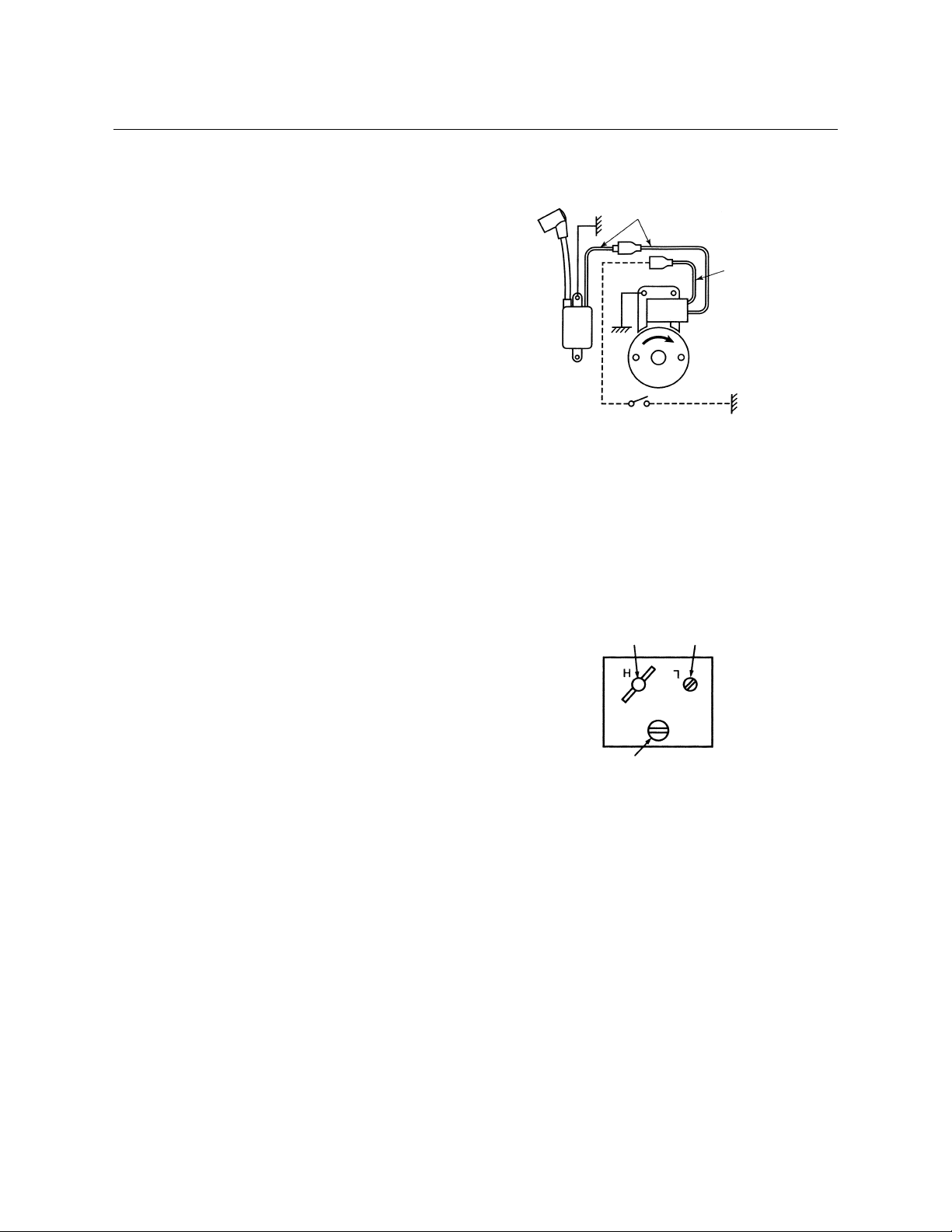

Stopping the Engine

The ability to shut down the engine in an emergency is

extremely important. For stopping the engine, the black

lead wire from the coil should be grounded to the engine

body, or the throttle valve should be closed completely.

Installation of a “stop” or “kill” switch is recommended.

Refer to the example shown in the following diagram.

Carburetor Adjustment

The carburetor is provided with three adjustment screws,

which are factory set to the best (approximate) positions. They may need minor adjustment, depending upon

the temperature, humidity, atmospheric pressure (altitude), etc., of the area where the engine is being used.

1. Start the engine without making any adjustments.

2. Make adjustments only when the engine shows signs

of inefficient operation.

3. Standard settings of each needle is as follows:

a. Low-Speed Needle: 11/8plus/minus 1/4

b. High-Speed Needle: 13/8plus/minus 1/4

Idle Screw: Turning this screw clockwise increases the

idling RPM. Turning it counterclockwise decreases the

idling RPM.

Low-Speed Needle: This is the fuel adjust screw (not

the air screw). Turning this needle clockwise makes the

gas mixture leaner, and turning it counterclockwise

makes it richer.

Red Lead

Black Lead

Kill Switch

Engine

Body

Ground

High-Speed Needle

Low-Speed Needle

Idle Screw

Page 7

7

Operation (continued)

High-Speed Needle: Turning this needle clockwise

makes the gas mixture leaner, and turning it counterclockwise makes it richer. Set this needle at a position

which is 1/4 open from the maximum rpm position while

the aircraft is on the ground.

Note: Do not tighten the high and low speed

needles too tightly.

When the engine has just started and is not warm

enough, there may be insufficient acceleration

and the engine may die. Be sure to allow the

engine to warm up at idle for a few minutes

before conducting normal operation.

Recommendations

To extend the life of your Zenoah®engine, the following

is recommended:

1. Use a Zenoah quality 2-stroke oil mixed at 32 to 1.

2. Use the recommended spark plugs.

3. Use the proper propeller size and balance the propeller prior to use.

4. Always adjust the engine to a slightly rich setting.

5. For long-term storage, make sure there is no fuel left

in the tank or the engine. Remove the spark plug(s) and

apply several drops of high-quality oil (e.g., Marvel Air

Tool Oil) to the top of the engine and into the spark plug

hole. Rotate the crankshaft several times. Store the

engine in the box it came in or on the airplane with the

nose down in order to keep oil in the bearings.

Servicing the Engine

Required Tools

• Regular screwdriver

• Phillips screwdriver

• Hexagonal wrench (4mm/5/32")

• Open wrench (19mm/3/4")

• Plastic hammer

• Thickness gauge

• Tapered round rod

• Liquid gasket (Permatex or equivalent)

• Thread lock (Blue Threadlock Z-42 or equivalent)

• Lithium grease

• Engine oil

• Washing gasoline

• Brush

• Scraper

• Cloth

The engine can be disassembled or reassembled without

any specific difficulties, but note the following:

For disassembling, the special tools shown in the parts

list are required (stopper, puller assembly), in addition

to general tools. Be sure to use a new gasket when the

crankcase and cylinder have been disassembled.

Note: Because the crankshaft is of the assembly type,

do not disassemble, hit or twist its end.

Disassembly

1. Dismount the engine from the model.

2. Remove the carburetor and insulator carefully without

damaging the gasket.

3. Remove the muffler.

4. Remove the spark plug and ignition module.

5. Remove the propeller hub.

6. Remove the rotor (flywheel). If it cannot be detached,

use a plastic hammer and hit the part lightly.

a. Screw the stopper in place of the spark plug, then

turn the rotor counterclockwise until the piston

touches the stopper. Take care as it can cause damage to the piston or connecting rod if the stopper is

not screwed in to the bottom.

b. Loosen and remove the rotor securing nut.

Engine Care and Maintenance

Page 8

8

c. Remove the rotor by using the puller. Do not hit

the crankshaft with the plastic hammer, as this can

increase the runout of the shaft.

7. Remove the mounting plate.

8. Remove the four bolts from the crankcase.

9. Tap around the case fitting side gently with the plastic

hammer and slowly separate the crankcase from the

cylinder block.

10. Pull out the crankshaft with the piston, bearings, and

other parts attached.

11. Remove the Woodruff key from the crankshaft.

12. Remove the oil seal, snap ring and bearings.

13. Remove the circlip and pull out the piston pin.

14. Remove the thrust washers and needle bearing from

the smaller end of the con rod (G38).

15. Remove the piston ring.

16. Wash each part. Check for abrasion and damage, and

replace any part that is defective.

Assembly (G38)

1. Apply engine oil (SAE #30) to the inside of the

cylinder and to the needle bearings on the larger end

of the connecting rod.

2. Fit the piston ring to the piston.

3. Mount the needle bearing and thrust washer (with

its oil slot facing inside) to the smaller end of the connecting rod and apply engine oil (SAE #30).

4. With the arrow on the top of the piston facing the

straight side (opposite side to the propeller) of the

crankshaft, fit the piston to the top of the connecting

rod and insert the piston pin with its blank end to the

exhaust port side.

5. Fit the circlip.

6. Fit the bearings, snap ring and oil seal to the crankshaft. (Apply lithium grease to the lip area of the oil seal

and fit it, paying attention to its direction.)

7. Wipe the contact surfaces of the cylinder block

and crankcase, and apply liquid gasket (Permatex

or equivalent).

8. Put the piston in the cylinder, with the piston’s arrow

facing in the exhaust port direction. Set the crankshaft

to the cylinder block. Then, fit the oil seal to the cylinder

block. The snap ring joint should be set vertically to

the cylinder.

9. Fit the crankcase to the cylinder block and tighten

the bolts.

10. Check that the crankshaft can be smoothly turned

by hand.

11. Put back the Woodruff key.

12. Replace the rotor (flywheel), fitting it to the Woodruff

key. Tighten the hub nut after having applied threadlock

(Blue Threadlock Z-42 or equivalent) to the threads.

13. Apply threadlock (Blue Threadlock Z-42) to the muf-

fler bolts and mount the muffler.

14. Apply threadlock (Blue Threadlock Z-42) to the igni-

tion module set screws and fix the coil temporarily.

15. Set the rotor (flywheel) so that the magnet is located

on the opposite side of the module (G-38). Place a thickness gauge between the core of the module and rotor

(flywheel) and adjust the clearance to 0.25 ^ 0.35 mm

(0.01 ^ 0.014 in). Then tighten the set screws after

having applied threadlock (Blue Threadlock Z-42)

to them.

16. Using a new gasket, fix the insulator with screws

to which threadlock (Blue Threadlock Z-42) has been

applied.

17. Using a new gasket, mount the carburetor with

screws, paying attention to its mounting direction.

18. Tighten the mounting plate, using screws with

threadlock (Blue Threadlock Z-42) applied.

19. Install the spark plug.

Note: Disassembly and assembly steps were

written using a G38 engine as an example, but

they apply to all engines.

Engine Care and Maintenance (continued)

Troubleshooting Guide for Gasoline Engines

Generally speaking, there are very few things that will

keep today’s modern engines from starting. Use good

quality “fresh” fuel and make sure that good plugs are

installed. Should the engine fail to start after these items

are verified, refer to the charts on the following page.

Page 9

9

Troubleshooting Guide for Gasoline Engines

a) The engine does not start.

The crankshaft

does not rotate

Seizure, intrusion of a foreign substance

The fuel has not been fed to

the carburetor

The fuel has been fed to the

carburetor

The Stop switch has

been turned off

Wiring is disconnected

Disassemble and repair

Disassemble and clean

Clean

Loosened

spark plug

Abrasion or damage of

the cylinder, piston, or

piston ring

Tighten further

Replace

Readjust

Replace

Wet plug

Remove the spark

plug and dry it

The carburetor has

not been properly

adjusted

The fuel is not

suitable

Turn on

Repair

The spark plug does not spark

The spark plug does spark

Clogging inside the

carburetor

Clogging of the fuel

piping

No compression

(normally 7 kg/cm

2

99.5 psi or more)

The crankshaft

rotates

The spark plug is defective

The ignition module is defective

Replace

Replace

The air gap is too large Adjust

The spark plug gap is too large Adjust

Compression adequate

b) The engine stops by itself

It suddenly stops

The crankshaft does not rotate

or is abnormally heavy

The crankshaft

rotates

Out of fuel

Not out of fuel

The carburetor has not beeen properly adjusted

See a)

See a)

Put back

Repair

Use a standard plug

Turn on

Use clean fuel

Replace

The fuel is not fed to the carburetor

Water is mixed in the fuel

Replace

Replace

Refuel

Readjust

It slows down and stops

The plug cap has come off

Wiring disconnection

Spark plug bridge

The Stop switch has

been turned off

Air suction from a carburetor joint or oil seal

Abrasion of the piston ring

Repair

Replace

The fuel is not suitable

Clean

Clogging of the muffler or exhaust port due to carbon

The spark plug heat range is not proper

See c)

Repair

Overheating

Repair

The Stop switch is defective

Switch wiring is disconnected

c) Lower power output

d) The engine does not stop

Overheating

Page 10

10

Propeller Chart

Troubleshooting Guide for Gasoline Engines

(continued)

In the event that none of the above procedures results

in the engine running properly, contact our service

department for suggestions at:

Horizon Hobby, Inc.

4105 Fieldstone Road

Champaign, IL 61822

Phone: 217-355-9511 (M–F 8:00–5:00 CST)

This chart enables you to select the best propeller for

initial set-up of your Zenoah®engine.

Remember, it’s imperative to balance each propeller

prior to installation onto your Zenoah engine. Failure to

do so may cause unwanted vibration in your aircraft.

Note: All recommendations are based on engines using

APC brand props.

ENGINE PROPELLER

G26A 16x8 @ 8,700

G231 Heli Adjust pitch of rotor to obtain

9,000–10,000 rpm of the

engine at full throttle

G26 Marine

G231 Marine Diameter=65–75mm

Pitch ratio 1.9–1.4mm*

G38 Gas 18x10 @ 7,300

G45 Gas 20x10 @ 7,200

G62 Gas 22x10 @ 7,200

GT80 Gas 22x12 @ 7,200

24x10 @ 7,200

Page 11

11

Engine Specifications

Items

G26A

G26M

G231 HELI

G231 MARINE

G38

G45

G62

GT80

139mm

139mm

142mm

142mm

170mm

152mm

162.5mm

191.5mm

105mm

105mm

105mm

105mm

130mm

130mm

140mm

257mm

181mm

181mm

181mm

181mm

215mm

185mm

185mm

190mm

2,000–10,000

2,000–10,000

3,000–11,000

3,500–15,000

2,000–9,000

2,000–10,000

2,000–10,000

1800–10,000

BIS07123

—

—

—

BIS07138

BIS07145

BIS07163

BIS07445/6

Length Width Height

Operating

RPM

Optional

Mufflers

OUTSIDE DIMENSIONS (MM)

G26A/M

G231M/H

G38

G45

G62

GT80

* w/spring starter

1.55

1.4

2.3

2.74

3.8

4.8

1.41

1.3

1.5

1.69

1.9

1.59x2

1.1

1.1

1.3

1.22

1.4

1.22x2

54

54

67

74

73

126

M8x1.25/6x1

M8x1.25

M10x1.25

8x1

10x1

—

2.4

2.2

2.2

3.3

4.75

6

WT645/WT644

WT644/WT643

WT338/WTA-6A

HDA-48D

HDA-48D

WJ-64

Displacement

(cu in)

Bore

(in)

Stroke

(in)

Weight

(oz)

K

(ISO)

HP

(H/M)

Carb

(Walboro)

SPECIFICATIONS

Page 12

1-1

1-2

2-1

2-2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23-1

23-2

24-1

24-2

25-1

25-2

26

27

28

29

30

31

32

33

34

35

36

37

38-1

38-2

39

40

41

42

43

44

45

46

47

48

49

50

12

Exploded Illustration

Index

No.

Part No.

Description

ZEN2601

ZEN2301RC

ZEN2601M

ZEN23102M

ZEN23103M

ZEN2304M

ZEN23105M

ZEN23106M

ZEN23107M

ZEN23108

ZEN2309

ZEN23110

ZEN23111

ZEN23112

ZEN23114

ZEN6213

ZEN23116

ZEN2317

ZEN2318

ZEN2319

ZEN2320

ZEN2321M

ZEN2322

ZEN2623

ZEN2320RC

ZEN2624

ZEN2321RC

ZEN2625

ZEN2325

ZEN2326

ZEN2327

ZEN2328

ZEN23129

ZEN2330

ZEN2331

ZEN2332

ZEN2333M

ZEN2634

ZEN2431

ZEN6227

ZEN2337

ZEN6236

ZEN2339M

ZEN2354

ZEN6241

ZEN2341

ZEN2638

ZEN6239

ZEN6237

ZEN26451

ZEN2648

ZEN2647

ZEN2649

ZEN23150H

ZEN2650

CYLINDER

CYLINDER

CYLINDER

CYLINDER

JACKET

JOINT

O

-

RING3X

40

O-RING

1.5X15.5

BOLT M3X

8

GASKET

, C

YLINDER

BOLT M5X

20

GASKET

, I

NSULATOR

INSULATOR

GASKET

,

CARBURETOR

CRANKCASE, COMP

.

CRANKCASE

, (R)

CRANKCASE

, (F)

PIN

GASKET

SEAL

12X22X7

BEARING

SNAPRING

BEARING

SEAL12X28X

7

BOLT M5X

30

PISTON

PISTON

RING

RING

PISTON RING

PISTON RING

SNAP RING

BEARING

WASHER

CRANKSHAFT

,

COMP

.

MOUNT, PLATE

SCREW M5X

16

NUT M

8

PULLEY

RECIL ASSY

SCREW M

4X14

KEY

SHIM

COIL

, (

GREY

)

COIL

, (

RED

)

ROTOR

SCREW M

4X22

SCREW M4X

14

PLUG CAP

SPRING

COIL

SPARK PLUG RZ

7

C

SCREW M5X

55

SPACER5X10X

1.6

AIR-FUNNEL

CLEANER ASSEMBLY

TUBE

Q’ty per unit

1

–

–

–

–

–

–

–

–

1

6

1

1

1

1

1

1

3

1

1

2

1

1

–

4

1

–

1

–

1

–

2

1

2

1

1

3

1

–

–

–

1

1

1

–

1

2

2

1

1

1

1

2

2

1

–

1

–

–

1

–

1

2

1

1

2

1

6

1

1

1

1

1

1

3

1

1

2

1

–

1

4

1

–

1

–

1

–

2

1

2

1

1

3

–

1

1

4

1

1

–

1

1

2

2

1

1

1

–

2

2

1

–

1

–

–

–

1

1

2

1

1

2

1

6

1

1

1

1

1

1

3

1

1

2

1

–

1

4

–

1

–

1

–

1

2

1

2

1

1

3

–

1

1

4

1

1

–

1

1

2

2

1

1

1

–

2

2

1

–

1

G260

PU

G231

PUH

G260

PUM

G2301

PUM

Index

No.

Part No.

Description

51-1

51-2

51-3

52

53

54

55

56

57-1

57-2

58-1

58-2

59-1

59-2

60

61

62

ZEN2651

ZEN23151

ZEN23152

ZEN2359

ZEN2360

ZEN2361

ZEN2362

ZEN23156

ZEN2357

ZEN2357H

ZEN2358

ZEN2358H/RC

ZEN2655

ZEN2355

ZEN2366

ZEN2367

ZEN23124RC

CARBURETOR ASSY WT

-645

CARBURETOR ASSY WT

-644

CARBURETOR ASSY WT

-643

HUB

STUD

WASHER

NUT M

8

GASKET, MUFFLER

BOLT M5X

50

BOLT M5X

60

SCREW M4X

8

SCREW M4X

16

MUFFLER

MUFFLER

SPACER

SPACER

SOCKET

Q’ty per unit

1

–

–

1

1

1

1

1

2

–

1

–

1

–

–

–

1

–

1

–

–

–

–

–

–

–

–

–

–

–

–

–

–

1

–

–

1

–

–

–

–

2

–

2

–

1

–

1

1

1

1

–

1

–

–

–

–

–

–

–

–

–

–

–

–

–

–

1

G260

PU

G231

PUH

G260

PUM

G2301

PUM

–

1

–

–

–

–

–

–

–

1

6

1

1

2

1

1

1

3

1

1

2

1

1

–

4

–

1

–

1

–

1

2

1

2

1

1

3

–

1

1

4

1

1

–

1

1

2

2

1

1

1

1

2

–

–

1

–

G26/G231

Page 13

13

Exploded Illustration

Index

No.

Part No.

Description

1

2

3

4

5

6

11

12

13

14

15

16

17

18

19

20

ZEN3801

ZEN3802

ZEN3803

ZEN3804

ZEN3805

ZEN3806

ZEN3811

ZEN3812

ZEN3813

ZEN3814

ZEN3815

ZEN3816

ZEN3817

ZEN3818

ZEN3819

ZEN3820

CYLINDER

INSULATOR

CARB GASKET

INSULATOR SCREW

INSULATOR GASKET

MUFFLER ASS

’Y

MUFFLER GASKET

MUFFLER BOLT

CRANKCASE

CASE BOLT

CASE WASHER

CASE PLUG

PLUG GASKET

PISTON

PISTON RING

PISTON PIN

Q’ty/

unit

1

1

1

2

1

1

1

2

1

4

4

1

1

1

1

1

Index

No.

Part No.

Description

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

ZEN3821

ZEN3822

ZEN3823

ZEN3824

ZEN3825

ZEN3826

ZEN3827

ZEN3828

ZEN3829

ZEN3830

ZEN3831

ZEN3832

ZEN3833

ZEN3834

ZEN3835

ZEN3836

PIN RETAINER

CONROD SPACER

CONROD BEARING

CRANKSHAFT

CRANKSHAFT BEARING

FRONT OIL SEAL

SNAP RING

REAR OIL SEAL

KEY

ROTOR NUT

LOCK WASHER

ROTOR WASHER

PROP HUB

(NEW)

HUB BOLT

PROP WASHER (NEW)

PROP BOLT (NEW)

Q’ty/

unit

2

2

1

1

2

1

1

1

1

1

1

1

1

2

1

2

Index

No.

Part No.

Description

37

38

39

40

41

42

43

44-1

44-2

45

46

47

ZEN3837

ZEN3838

ZEN3839

ZEN6238

ZEN6239

ZEN6242

ZEN3843

ZEN3844

ZEN3850

ZEN3845

ZEN3846

ZEN3847

ZEN3870

ZEN3871

MODULE

ROTOR (NEW)

SPACER (MODULE)

PLUG CAP (BLACK)

CAP SPRING

SPARK PLUG, C859

MODULE BOLT

CARB ASS’Y(HT

-338) W/

CHOKE

CARB ASS’Y (WTA-6) W/O CHOKE

CARB SCREW

MOUNT

MOUNTING BOLT

GASKET SET

SCREW

/NUT SET

Q’ty/

unit

1

1

3

1

1

1

3

1

1

2

1

4

1

1

}

for

G380PU

(Standard Accessory for

G380PU)

G38

Page 14

14

Exploded Illustration

Index

No.

Part No.

Description

1

2

3

4

5

6

7

8

9

10

11

13

14

15

16

17

18

19

20

ZEN4501

ZEN4502

ZEN4503

ZEN4504

ZEN6204

ZEN4506

ZEN4504

ZEN6207

ZEN6208

ZEN6209

ZEN6210

ZEN4513

ZEN6213

ZEN6214

ZEN6215

ZEN6216

ZEN6217

ZEN6276

ZEN4520

CYLINDER

INSULATOR

INSULATOR GASKET

BOLT

CARBURETOR GASKET

CYLINDER GASKET

BOLT

MUFFLER

MUFFLER GASKET

MUFFLER BOLT

MUFFLER NUT

CRANKCASE COMP

.

CASE PIN

SNAP RING

BEARING

REAR OIL SEAL

FRONT OIL SEAL

ELBOW FUEL NIPPLE

CASE GASKET

Q’ty/

unit

1

1

1

2

1

1

4

1

1

2

2

1

3

1

2

1

1

1

1

Index

No.

Part No.

Description

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

ZEN4504

ZEN4522

ZEN4523

ZEN4524

ZEN4525

ZEN6223

ZEN6224

ZEN4528

ZEN4529

ZEN6228

ZEN6227

ZEN6229

ZEN6230

ZEN6232

ZEN6233

ZEN6234

ZEN6257

ZEN6235

ZEN6236

BOLT

PIPE

PISTON

PISTON RING

PISTON PIN

PIN RETAINER

CONROD BEARING

WASHER

CRANKSHAFT COMP

.

SHIM

KEY

FLYWHEEL NUT

PROP HUB

HUB BOLT

WASHER

PROP BOLT

MAGNETO ASS

’Y

ROTOR

SOURCE COIL

Q’ty/

unit

4

1

1

2

1

2

1

2

1

0-2

1

1

1

2

1

1

1

1

1

Index

No.

Part No.

Description

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

ZEN6237

ZEN6238

ZEN6239

ZEN4543

ZEN6241

ZEN6242

ZEN6243

ZEN4547

ZEN6245

ZEN6246

ZEN6247

ZEN6248

ZEN6249

ZEN6250

ZEN6251

ZEN6252

ZEN6253

ZEN4557

IGNITION COIL

PLUG CAP (BLACK)

CAP SPRING

SOURCE COIL SCREW

COIL SCREW

SPARK PLUG

CARBURETOR ASS

’Y

BOLT

WASHER

WASHER

BOLT

MOUNT

BOLT

WASHER

PULLER ASS

’Y

STOPPER (OPTIONAL)

GUIDE (OPTIONAL)

WRENCH (OPTIONAL)

Q’ty/

unit

1

1

1

2

2

1

1

2

2

2

1

1

4

4

1

1

1

1

}

*

for G450PU

G45

Page 15

15

Exploded Illustration

Index

No.

Part No.

Description

1

2

3

4

5

6

7

8

9

10

11,12

13

14

15

16

17

18

19

20

ZEN6201

ZEN6202

ZEN6203

ZEN6204

ZEN6205

ZEN2309

ZEN6207

ZEN6208

ZEN6209

ZEN6210

ZEN6211

ZEN6213

ZEN6214

ZEN6215

ZEN6216

ZEN6217

ZEN6218

ZEN6219

ZEN6220

CYLINDER

INSULATOR GASKET

INSULATOR

CARBURETOR GASKET

CYLINDER BASE GASKET

CYLINDER BOLT

MUFFLER

MUFFLER GASKET

MUFFLER BOLT

MUFFLER NUT

CRANKCASE COMP

.

CASE PIN

SNAP RING

BEARING

REAR OIL SEAL

FRONT OIL SEAL

CRANKCASE GASKET

CASE ASS

’Y BOLT

PISTON

Q’ty/

unit

1

1

1

1

1

4

1

1

2

2

1

3

1

2

1

1

1

4

1

Index

No.

Part No.

Description

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

ZEN6221

ZEN6222

ZEN6223

ZEN6224

ZEN6225

ZEN6226

ZEN6227

ZEN6228

ZEN6229

ZEN6230

ZEN44553

ZEN6232

ZEN6233

ZEN6234

ZEN6235

ZEN6236

ZEN6237

ZEN6238

ZEN6239

PISTON RING

PISTON PIN

PIN RETAINER

NEEDLE BEARING

CONROD SPACER

CRANKSHAFT COMP

.

KEY

SHIM

FLYWHEEL NUT

PROPELLER COMP. FOR G

620PU-1

HUB

PIN FOR G620PU-1

HUB BOLT

PROP WASHER

PROP BOLT

ROTOR

SOURCE COIL

IGNITION COIL

PLUG CAP

(BLACK)

PLUG CAP SPRING

Q’ty/

unit

4

1

1

2

1

2

1

2

1

0-2

1

1

2

1

1

1

1

1

1

Index

No.

Part No.

Description

40

41

42

43

44

45

46

47

48

49

50

51

52

53

ZEN6240

ZEN6241

ZEN6242

ZEN6243

ZEN6244

ZEN6245

ZEN6246

ZEN6247

ZEN6248

ZEN6249

ZEN6250

ZEN6251

ZEN6252

ZEN6253

ZEN6200

ZEN6255

ZEN6256

ZEN6257

IGNITION COIL SCREW

SOURCE COIL SCREW

SPARK PLUG, C859

CARBURETOR ASS’Y

CARB MOUNT SCREW

CARB WASHER

WASHER

TAPPROPBOLT

MOUNT

BOLT

WASHER

PULLER ASS

’Y

STOPPER (OPTIONAL)

PISTON PIN GUIDE (OPTIONAL)

SPRING STARTER

HIGH

-SPEED NEEDLE

LOW-SPEED NEEDLE

MAGNETO ASS’Y

Q’ty/

unit

2

2

1

1

2

2

2

1

1

4

4

1

1

1

1

1

1

1

}

*

for G62PU

*

(Accessory for G620PU-1)

G62

Page 16

16

Exploded Illustration

Index

No.

Part No. Description

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

ZEN44501

ZEN44502

ZEN44503

ZEN44504

ZEN44505

ZEN44506

ZEN4547

ZEN44508

ZEN44509

ZEN44510

ZEN6213

ZEN6215

ZEN6214

ZEN44514

ZEN6217

ZEN6276

ZEN44517

ZEN44518

ZEN44509

ZEN44520

ZEN44521

CYLINDER

MANIFOLD

MANIFOLD GASKET

MANIFOLD BOLT

CARBURETOR ASS

’Y

CARBURETOR GASKET

CARB BOLT

CYLINDER GASKET

BOLT

CRANKCASE ASS

’Y

PIN

BEARING

SNAP RING

BEARING

FRONT OIL SEAL

FUEL NIPPLE ELBOW

PIPE

CRANKCASE GASKET

BOLT

PISTON

PISTON RING

Q’ty/

unit

2

1

2

4

1

1

2

2

8

1

4

2

2

1

1

1

1

1

4

2

4

Index

No. Part No.

Description

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

ZEN44522

ZEN44523

ZEN44524

ZEN44525

ZEN44526

ZEN6228

ZEN6227

ZEN6229

ZEN6235

ZEN6236

ZEN6238

ZEN44533

ZEN6238

ZEN6239

ZEN6242

ZEN44537

ZEN44538

ZEN44539

ZEN44540

ZEN6209

ZEN44542

PISTON PIN

PIN RETAINER

BEARING

THRUST WASHER

CRANKSHAFT COMP

SHIM

KEY

NUT

ROTOR

SOURCE COIL

IGNITION COIL

CORD

PLUG CAP

(BLACK)

CAP SPRING

SPARK PLUG, C859

SCREW

SCREW

MUFFLER

MUFFLER GASLET

MUFFLER BOLT

NUT

Q’ty/

unit

2

4

2

4

1

0-2

1

1

1

1

2

1

2

2

2

4

2

2

2

4

Index

No. Part No.

Description

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

ZEN44543

ZEN44544

ZEN44545

ZEN44546

ZEN44547

ZEN44548

ZEN44549

ZEN44550

ZEN44551

ZEN44552

ZEN44553

ZEN6232

ZEN6233

ZEN6234

ZEN6247

ZEN44555

ZEN6251

ZEN44554

ZEN44556

ZEN44557

MOUNT

BOLT

BOSS

CLUTCH COMP

SPRING

COLLAR

WASHER

BOLT

PAD

HUB

. PROPELLER COMP

PIN

HUB BOLT

HUB WASHER

PROP BOLT

TAP PROP BOLT

SOCKET

PULLER ASS

’Y (OPTIONAL)

STOPPER (OPTIONAL)

HIGH-SPEED NEEDLE

LOW-SPEED NEEDLE

Q’ty/

unit

1

3

1

1

1

1

1

1

1

1

2

2

1

1

1

1

1

1

1

1

Index

No. Part No.

Description

01

02

20

21

ZEN8001

ZEN8002

ZEN8020

ZEN8021

CYLINDER

INTAKE MANIFOLD(BLACK

)

PISTON

PISTON RING

Q’ty/

unit

2

1

2

2

G80A

GT80

Page 17

17

Warranty Information

Zenoah®engines are guaranteed against workmanship

and manufacturing defects for a period of 3 years from

the original date of purchase. This warranty is limited to

the original purchaser and is not transferable.

Warranty repairs will not cover:

• Normal engine wear

• Damage due to insufficient maintenance

• Damage related to over-revving of the engine due

to small prop size or unreasonable use

• Rusted bearings

• Crash damage

• Damage due to use of improper fuel and/or spark plug

• Damage due to lean runs, such as rusted bearings,

seized connecting rod or piston, etc.

• Damage caused by foreign objects

• Damage caused by unreasonable mounting or running

conditions (dust, insufficient cooling, improper mounting, improper propeller size of lack of balancing, etc.)

• Damage due to improper disassembly

• Modifications of any kind

If your engine needs repair, ship it in its original box,

freight prepaid to:

Horizon Service Center

Attn: Zenoah Service

4105 Fieldstone Road

Champaign, IL 61822

Phone: (217) 355-9511

Note: Do not use the engine’s original box as the

shipping box. Rather, package this box inside a

sturdy shipping box.

1. Include complete name and address information

inside the carton, as well as clearly writing it on the

outer label/return address area.

2. Include a note containing a brief summary of the

difficulty and include the following information:

• Propeller size and brand used

• Type of spark plug used

• Type of engine mount

• Approximately how much running time the engine had

before difficulty

3. Date your correspondence and be sure your name and

address appear on this enclosure.

4. Include a phone number where you can be reached

during the business day.

Warranty Repairs

To receive warranty service you must include your original dated sales receipt to verify your proof-of-purchase

date. Providing that warranty conditions have been met,

your engine will be repaired without charge.

Non-Warranty Repairs

Should your repair cost exceed 50% of the retail

purchase cost, you will be provided with an estimate

advising you of your options. Any return freight for

non-warranty repairs will be billed to the consumer.

We accept both Visa and MasterCard for payment.

Please include your card number and expiration date.

The Consumer Warranty Registration below must be

completely filled out and mailed to:

Horizon Service Center

Attn: Zenoah Warranty

4105 Fieldstone Road

Champaign, IL 61822

Page 18

18

Warranty Information (continued)

Engine Type: ________________________________________________________________________________

Date of Purchase: ______________________________________________________________________________

Owner’s Name: ______________________________________________________________________________

Street Address: ______________________________________________________________________________

City/State/Zip: ________________________________________________________________________________

Daytime Phone Number: ________________________________________________________________________

Purchased From: ______________________________________________________________________________

Dealer’s Name: ________________________________________________________________________________

Street Address: ______________________________________________________________________________

City/State/Zip: ________________________________________________________________________________

Please cut on dotted line.

Registration Form

Fill in and mail this form along with your dated sales

receipt (send a copy, keep the original for your files)

within 10 days of purchase to:

Horizon Service Center

Attn: Zenoah Warranty Dept.

4105 Fieldstone Road

Champaign, IL 61822

Page 19

19

Page 20

© Copyright 2002, Horizon Hobby, Inc.

www.horizonhobby.com

5140

Loading...

Loading...