Page 1

English

Smartups

120 VAC

Uninterruptible Power Source

Fonte de Energia Ininterrupta

Models 450, 700, 1000, 1400, 2200, 3000

Português

User’s Guide/Guia do Usuário

English/Português

Page 2

Part Number 990-7042A

Revision 2 Revised 7/97

Page 3

Contents/Índice

English ......................................................................................... 1

Português ................................................................................... 27

Please note: The troubleshooting section (section 8) offers solutions for most of the difficulties you

may encounter with this unit. Before calling customer service, please have available your unit’s serial

number (see label on the rear of the unit). A returned materials authorization (RMA) number is required for all return shipments to APC. Do not send return shipments to APC without an RMA

number. See section 9.

Por favor, observe: A seção sobre resolução de problemas (seção 8) oferece soluções para a

maioria das dificuldades que você pode encontrar com o No-Break. Antes de ligar para o serviço

de atendimento ao cliente, por favor, tenha em mãos o número de série de seu No-Break (veja o

selo na parte de trás do No-Break). É necessário um número de autorização para devolução de

materiais (RMA) em todas as devoluções para a APC. Não envie produtos para devolução à APC

sem um número de RMA. Veja a seção 9.

Serial number:/Número de série:

EnglishEspañol Português

Toll free technical support:

Assistência Técnica Gratuita:

Brasil 0800-12-7221

United States and Canada 1-800-800-4272

Ireland 1-800-702000

U. K. 0800-132990

Others/Outros:

+1 401 789 5735 (USA) or

+353 91 702020 (Ireland)

Entire contents copyright © 1997 American Power Conversion. All rights reserved; reproduction in whole or in part without

permission is prohibited. All other trademarks are the property of their respective owners.

Return shipment addresses:

Endereços para devolução de produtos:

American Power Conversion Corporation

132 Fairgrounds Road

P. O. Box 278

West Kingston, Rhode Island 02892

USA

American Power Conversion Corporation

(A. P. C.) b. v.

Ballybritt Business Park

Galway

Ireland

Page 4

Page 5

1. Introduction............................................................................ 1

2. Safety ..................................................................................... 4

3. Presentation ........................................................................... 5

4. Installation.............................................................................. 8

5. Operation .............................................................................11

6. Alarms ..................................................................................15

7. Options .................................................................................16

8. Troubleshooting.....................................................................17

9. Service ..................................................................................18

10. Replacing the battery .............................................................19

11. Storage .................................................................................22

12. Specifications.........................................................................23

13. How to Determine On-battery Run Time .................................24

14. User Configuration Items........................................................26

1. Introduction

English

1.1 Thank you!

Thank you for selecting this uninterruptible power source. It is designed for many years of reliable,

maintenance-free service.

Important!

Please read this manual. It provides safety, installation, and operating instructions that will help you

get the fullest performance and service life from your unit. This manual describes the inner workings

of the unit and how they relate to providing superior protection from utility power problems such

as blackouts, brownouts, sags, swells, EMI/RFI noise, and surges. The manual includes instructions

for obtaining factory service if necessary.

If you have a problem with the unit, please refer to this manual before calling customer service. The

troubleshooting section (section 8) can help with most situations typically encountered when using

the unit.

Please save the packaging materials!

The unit’s shipping materials are designed with great care to provide protection during shipping.

These materials are invaluable if you ever have to return the unit for service. Damage sustained during transit is not covered under the warranty.

1

Page 6

1.2 Radio Frequency Interference

450 VA - 1400 VA

Warning: Changes or modifications to this unit not expressly approved by the party responsible for

compliance could void the user’s authority to operate the equipment.

Note: This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part 15 of the FCC Rules and the Class B limits for radio noise emissions from

digital apparatus set out in the Radio Interference Regulations of the Canadian Department of Communications. These limits are designed to provide reasonable protection against harmful interference

in a residential installation. This equipment generates, uses and can radiate radio frequency energy

and, if not installed and used in accordance with the instructions, may cause harmful interference to

radio communications.

However, there is no guarantee that interference will not occur in a particular installation. If this

equipment causes interference to radio or television reception, which can be determined by

turning the equipment off and on, the user is encouraged to try to correct the interference by

one or more of the following measures:

■ reorient the receiving antenna

■ increase the separation between the equipment and the receiver

■ connect the equipment to an outlet on a circuit different from that to which the receiver is

connected

■ consult the dealer or an experienced radio/TV technician for help.

Shielded communications interface cables must be used with this product.

2200 VA and 3000 VA

Warning: Changes or modifications to this unit not expressly approved by the party responsible

for compliance could void the user's authority to operate the equipment.

Note: This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to Part 15 of the FCC Rules and the Class A limits for radio noise emissions

from digital apparatus set out in the Radio Interference Regulations of the Canadian Department

of Communications. These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance

with the instruction manual, may cause harmful interference to radio communications. Operation of this equipment in a residential area is likely to cause harmful interference in which case

the user will be required to correct the interference at his own expense.

Shielded signal cables must be used with this unit to ensure compliance with the Class A FCC

limits.

2

Page 7

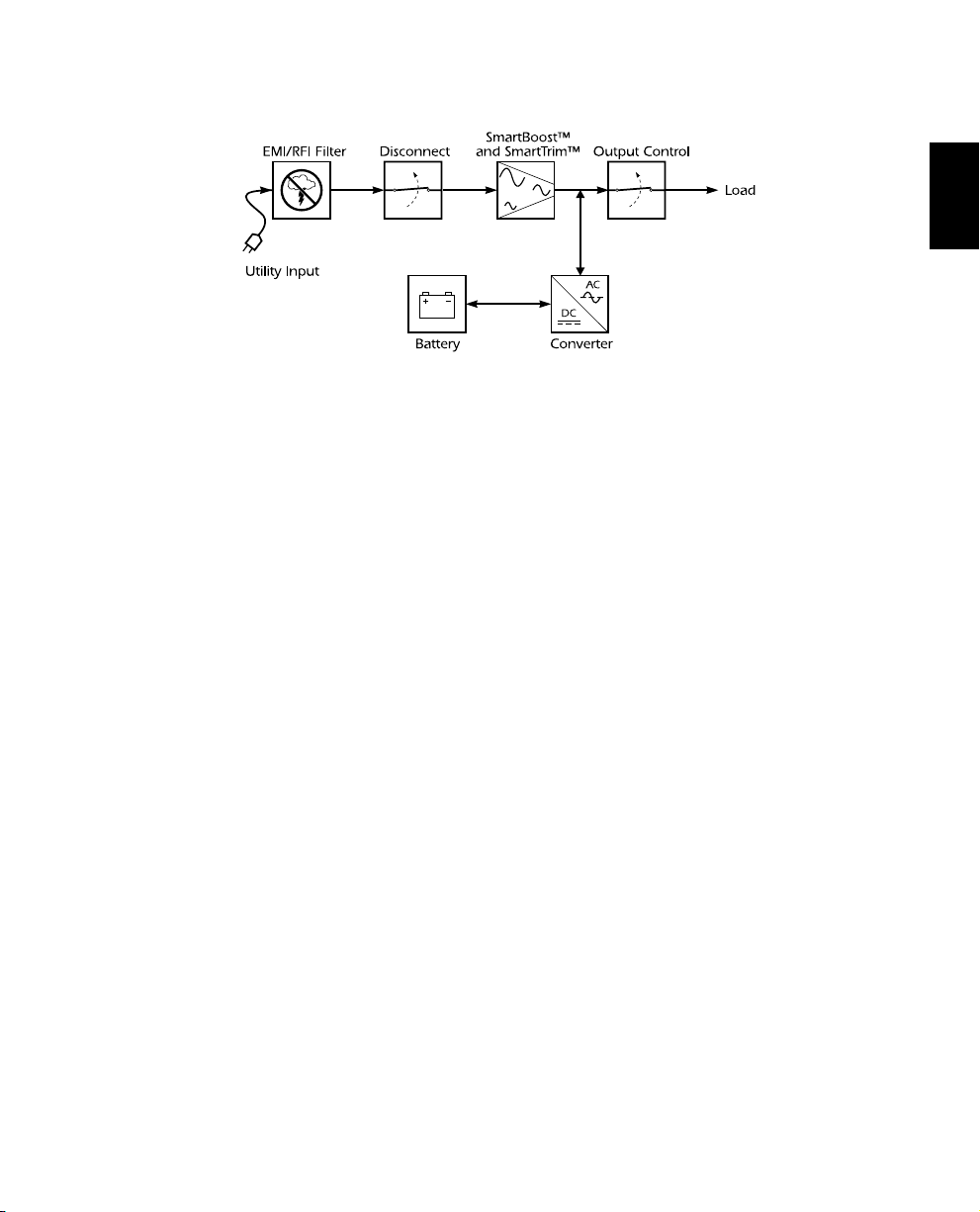

1.3 Theory of Operation

This high-performance, line-interactive, uninterruptible power source provides clean, reliable, AC

power to computer systems — protecting them from power blackouts, brownouts, swells, sags,

surges, and interference.

Normally, the unit operates “on-line,” supplying power from the utility input to the load (worksta-

tion, server, or other device). The converter circuitry is used to maintain an optimal float charge

level on the battery.

When the utility fails, the converter supplies AC power to the load and the disconnect switch opens.

The loads operate normally until shut down or until the battery is exhausted. The unit automatically

transfers the load back to utility power when the line voltage returns to normal.

The unit also provides surge protection and EMI/RFI filtering, as well as Smart-Boost™ and

SmartTrim™, which correct high and low input voltage without drawing power from the battery.

Output control uses the unit’s remote interface to turn the load on or off, without disabling other

unit functions.

English

1.4 Features

Intelligent Battery Management

The unit provides visual and audible indications of the battery’s present status including capacity,

low battery condition, and replace battery condition.

The unit exercises the battery during its self-test, and detects a weak battery before it is put into service. The unit normally performs a self-test at power up and every 14 days. Self-tests can also be

conducted manually with the on/test button at any time.

The unit features user-replaceable batteries. Batteries can be replaced without having to remove

power from the loads or send the unit in for service.

Computer Interface and Accessory Slot

Advanced monitoring, power management, and customizing functions are available through the

computer interface and accessory slot. See section 7 for more information.

3

Page 8

2. Safety

CAUTION!

■ To reduce the risk of electric shock in conditions where load equipment grounding cannot be

verified, disconnect the unit from the AC power outlet before installing a computer interface or

accessory slot signal cable. Reconnect the power cord only after all signaling connections are

made.

■ Connect the unit to a two-pole, three-wire grounding AC power outlet. The receptacle must be

connected to appropriate branch protection (fuse or circuit breaker). Connection to any other

type of receptacle may result in a shock hazard and violate local electrical codes.

■ The unit has an internal energy source (the battery). The output may be energized when the

unit is not connected to an AC power outlet.

■ To deenergize the outputs of the unit, first press the Off button for more than one second to

switch the unit off. Next disconnect the unit from the AC power outlet. To deenergize the unit

completely, disconnect the battery. See section 10.

■ This unit’s protective Earth conductor carries the leakage current from the load devices (com-

puter equipment). This unit generates approximately 1.5 mA of leakage current. To ensure a safe

limit of 3.5 mA, limit the total leakage current of the load devices to 2 mA.

■ Use of this equipment in life support applications where failure of this equipment can reason-

ably be expected to cause the failure of the life support equipment or to significantly effect its

safety or effectiveness is not recommended.

4

Page 9

3. Presentation

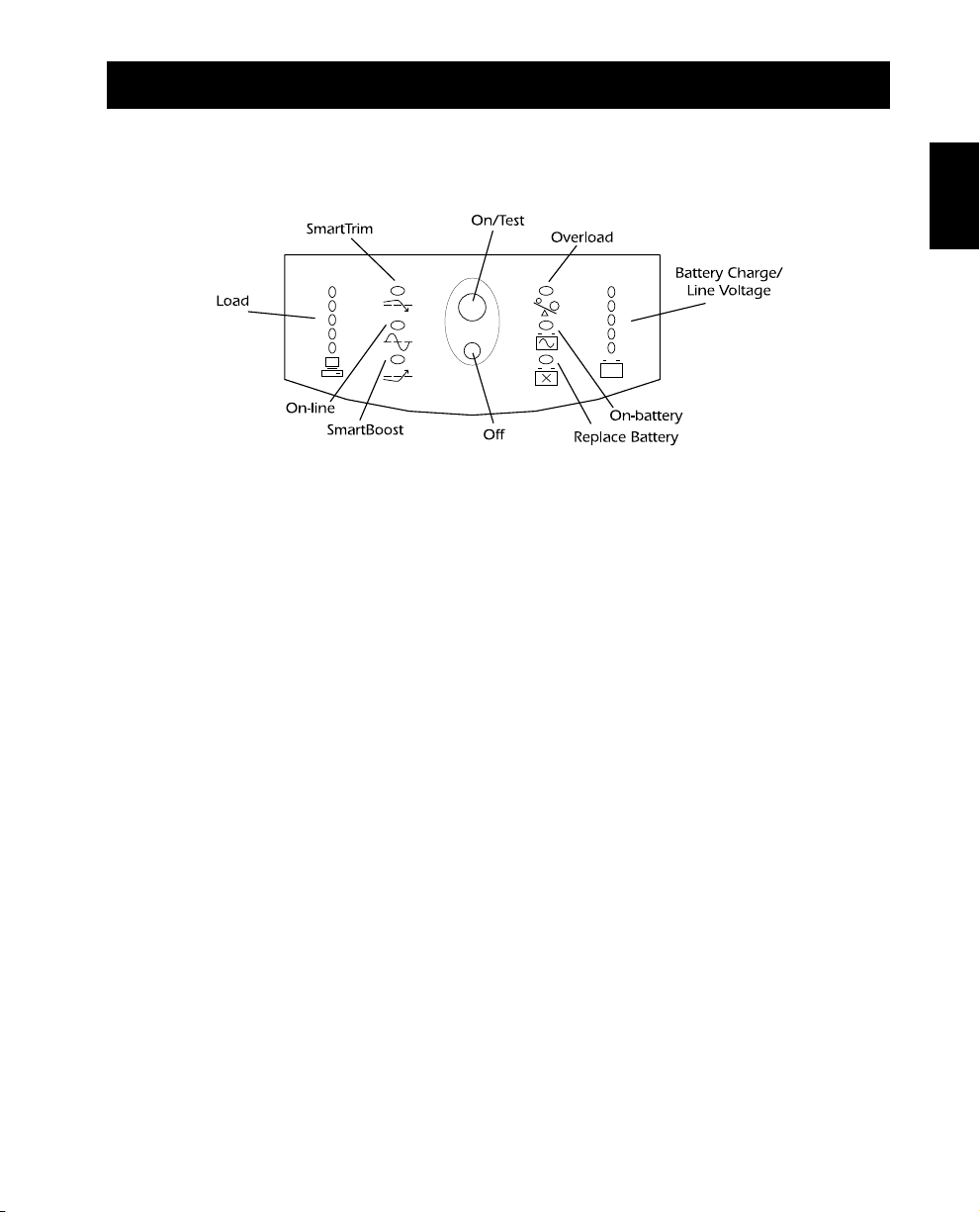

3.1 Front panel

With the unit plugged in, press the on/test button to turn on the unit and power the loads. See Sec.

5.1. On/test also activates the unit’s self-test and utility line voltage displays. See sections 5.3 and 5.6.

The overload LED lights when the loads connected to the unit exceed the unit’s capacity. See section

6.2.

The battery charge/line voltage display shows the present battery charge as a percentage of battery

capacity. See section 5.5. It also displays the voltage of the utility line. See section 5.6.

The on-battery LED comes on when the unit is supplying battery power to the loads.

The replace battery LED comes on when the unit’s battery is no longer useful and must be replaced.

See section 10.

Press the off button to turn off the unit and the load. See section 5.2.

The SmartBoost LED comes on when the unit is correcting a low utility voltage condition. The loads

receive normal power.

The on-line LED comes on when the unit is supplying utility power to the loads.

The load display shows the power being drawn by the load. See section 5.4.

The SmartTrim LED comes on when the unit is correcting a high utility voltage condition. The loads

receive normal power.

English

5

Page 10

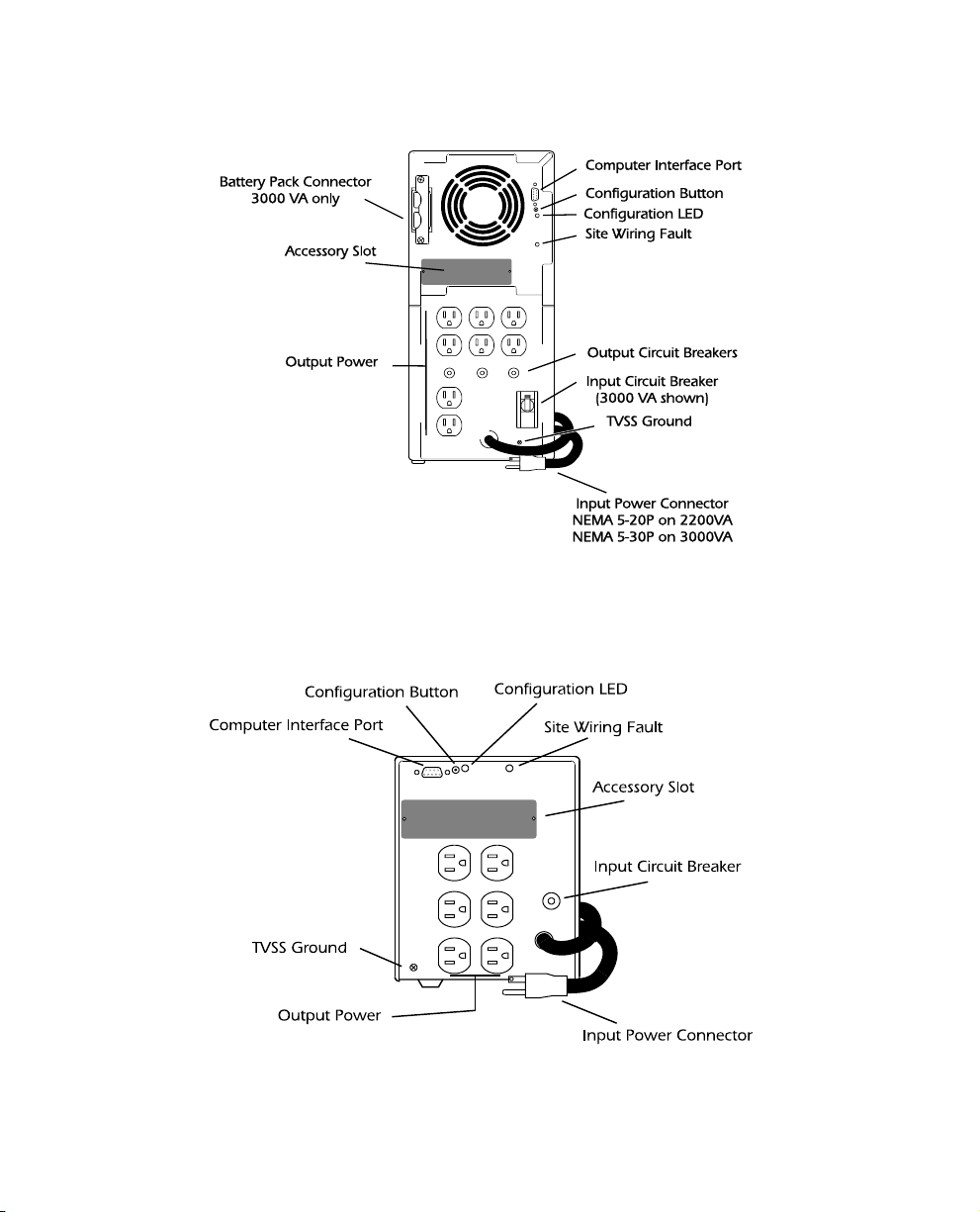

3.2 Rear Panel

2200 and 3000 VA

1000 and 1400 VA

6

Page 11

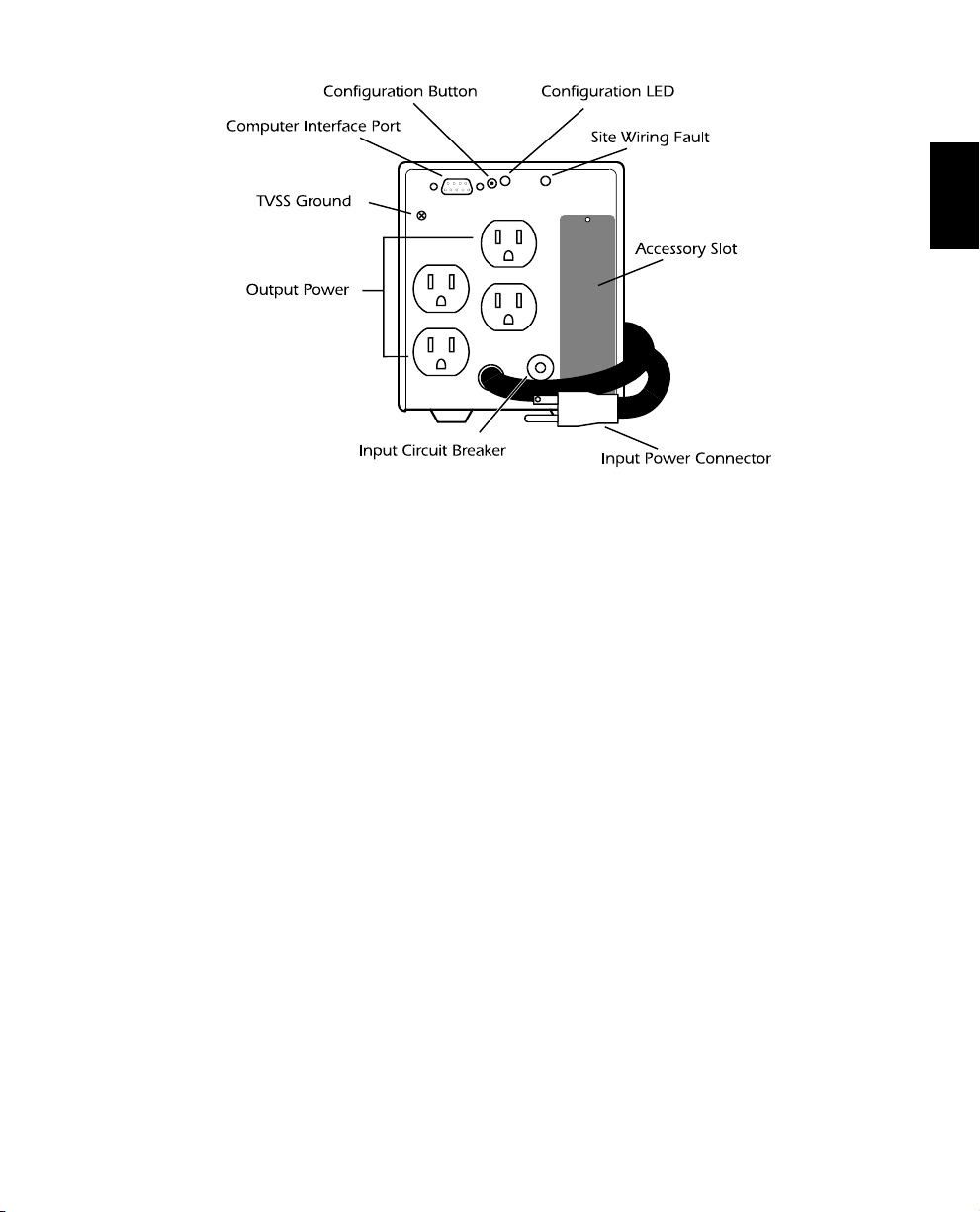

450 and 700 VA

Use the computer interface port for unit monitoring and control. See section 7.

The configuration button changes the unit’s sensitivity to utility voltage variations and the low

battery warning interval. See sections 5.9 and 5.10.

The configuration LED indicates the voltage sensitivity setting and the low battery warning

interval. See sections 5.9 and 5.10.

The site wiring fault indicator comes on when the unit is connected to an improperly wired AC

power outlet. See section 4.8.

The output circuit breakers (2200 VA and 3000 VA models only) trip when the connected loads

exceed the protected receptacle’s capacity. The center plunger of the circuit breakers extend when

tripped.

The input circuit breaker trips when loads exceed the unit’s capacity. The center plunger of the circuit

breaker extends when tripped. The paddle handle on 3000 VA model input circuit breaker shows “off”

when tripped.

Use the transient voltage surge suppression (TVSS) ground connector for the ground leads of

telephone or network line protectors. See section 4.9.

The input power connector is a power cord with a NEMA 5-15P connector for 450 through 1400

VA models. See the table below for input power connectors on 2200 VA and 3000 VA models.

The output power receptacles are NEMA 5-15R type. Optional output power receptacle kits are

available from the factory for the 2200 VA and 3000 VA models. See your dealer or call the

number at the front of this manual for more information.

Optional accessories can be installed in the accessory slot. See section 4.4 and section 7.

Use the battery pack connector to connect the optional external battery pack (3000 VA model

only).

English

7

Page 12

2200 VA and 3000 VA Input Power Connectors

Model

2200 VA NEMA 5-20P 1600 VA/1600 W

3000 VA NEMA 5-30P 2550 VA/2250 W NEMA L5-50 3000 VA/3000 W

Standard input

power connector

Maximum output

power with standard

connector

Available input

power connectors

NEMA 5-15 1200 VA/1200 W

NEMA L5-20 1600 VA/1600 W

NEMA L5-30 2200 VA/2200 W

Maximum output

power with available

connector

4. Installation

To obtain warranty coverage fill out and return the warranty registration card now.

4.1 Inspection

Inspect the unit upon receipt. Notify the carrier and dealer if there is damage. The packaging is recyclable; save it for reuse or dispose of it properly.

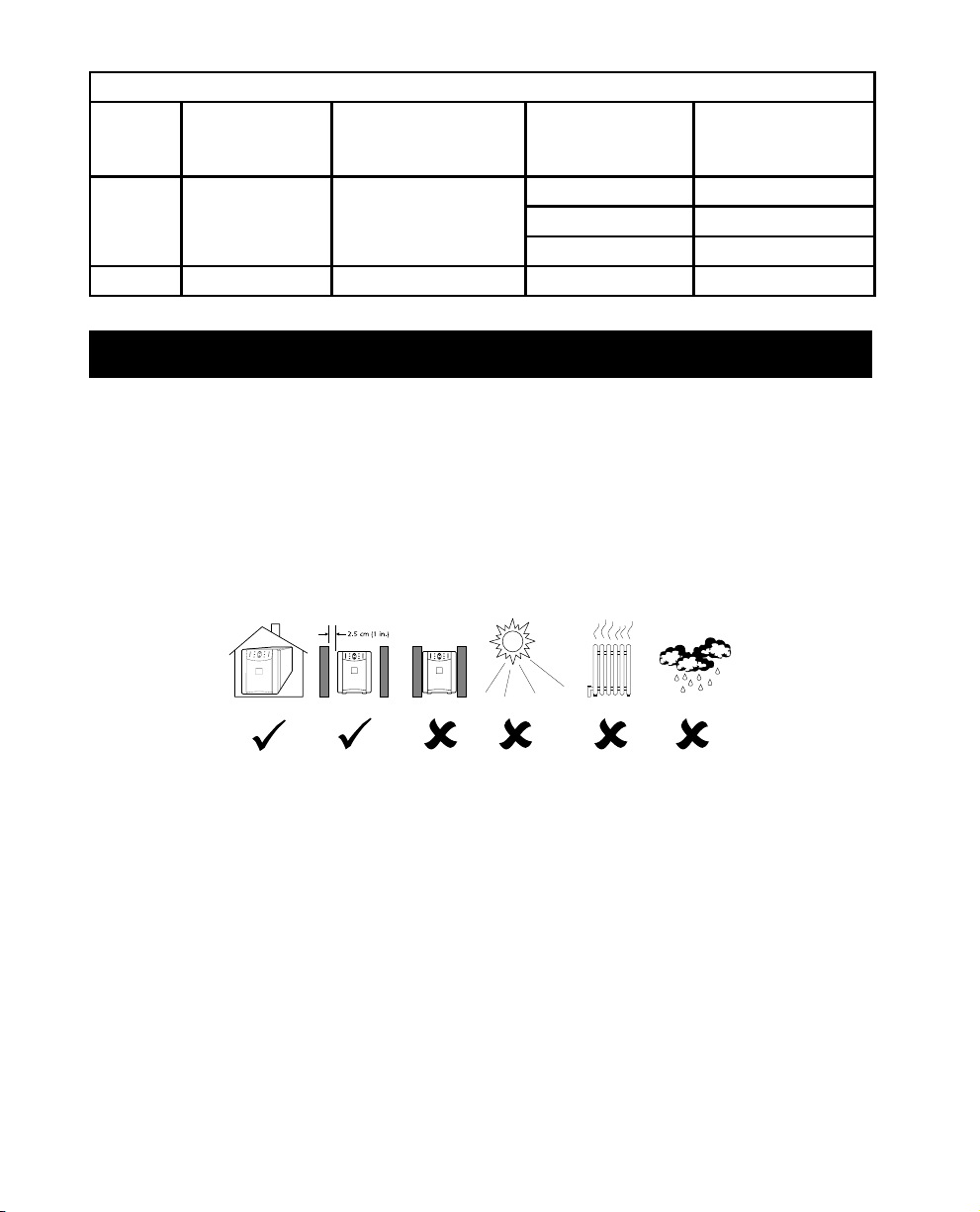

4.2 Placement

Install the unit in a protected area with adequate air flow and free of excessive dust. Do not operate the unit where the temperature and humidity is outside the specified limits. See section 12.

Allow the unit to come to room temperature before continuing.

4.3 Protection Strategies

This unit provides high performance power line protection to the loads. There are, however, other

potential entry points for damaging surges in information systems. These include serial ports (RS232, RS-422, RS-485, etc.), parallel ports, telephone lines, and network connections. These other entry points must be considered in developing a comprehensive system protection strategy. Contact

your dealer or call the number in the front of this manual for information on a complete set of related products designed to accomplish total system protection.

8

Page 13

Sensitive information systems can be further safeguarded by following these guidelines:

■ Verify that all electrical outlets are properly grounded.

■ Connect information systems to a different electrical service branch than heavy motor loads

like air conditioners, copiers, refrigerators, and heavy industrial machinery.

■ Plug all power protection and information system equipment into the same branch where

possible.

4.4 Install Accessory (Optional)

Some accessories connect to the computer interface (DB-9) port, while others install in the accessory slot. See the literature accompanying the accessory to determine proper installation. The

screws holding the slot cover are #2 Phillips head type.

To use the computer interface port, connect the accessory to the DB-9 connector and tighten

down the connector’s screws.

Connect the optional battery pack (3000 VA model only) according to the instructions with the

battery pack.

4.5 Connect to Utility

English

Plug the unit into a two-pole, three-wire, grounding receptacle only. Avoid using extension cords

and adapter plugs.

4.6 Charge the Battery

The unit charges its battery whenever it is connected to utility power. For best results, charge the

battery for 2.5 hours before use. It is acceptable to use the unit without first charging the battery,

but on-battery run time may be reduced until the battery charges.

9

Page 14

4.7 Connect the Loads

Plug the loads into the output connectors on the rear of the unit. To use the unit as a master on/

off switch, make sure that all of the loads are switched on.

Caution: Do not connect a laser printer to the unit along with other computer equipment unless

the unit is rated 1400 VA or higher. A laser printer periodically draws significantly more power

than when idle, and may overload the unit. Verify that the unit can support the loads when the

printer is in full operation (printing).

Test the system with all loads operating to make sure that the unit is not overloaded. See section

6.2.

4.8 Check the Site Wiring Fault Indicator

After plugging in the loads and the unit, check the site wiring fault indicator on the rear panel. See

section 3.2 for the location of the indicator on the back panel. It lights if the unit is plugged into an

improperly wired AC power outlet. Wiring faults detected include missing ground, hot-neutral polarity reversal, and overloaded neutral circuit.

Caution: If the unit indicates a site wiring fault, get a qualified electrician to correct the building wiring.

4.9 Connect Ground Leads to TVSS Connector (Optional)

The unit features a TVSS connector for connecting the ground lead on transient voltage surge-suppression (TVSS) devices such as telephone and network line protectors. The TVSS connector provides grounding through the unit’s power cord ground conductor.

Note: Do not use the TVSS connector if the site wiring fault indicator is lit.

To make a connection to the TVSS connector, loosen the screw and connect the surge suppression

device’s ground lead. See section 3.2 for the location of the connector. Tighten the screw to secure the

lead.

10

Page 15

5. Operation

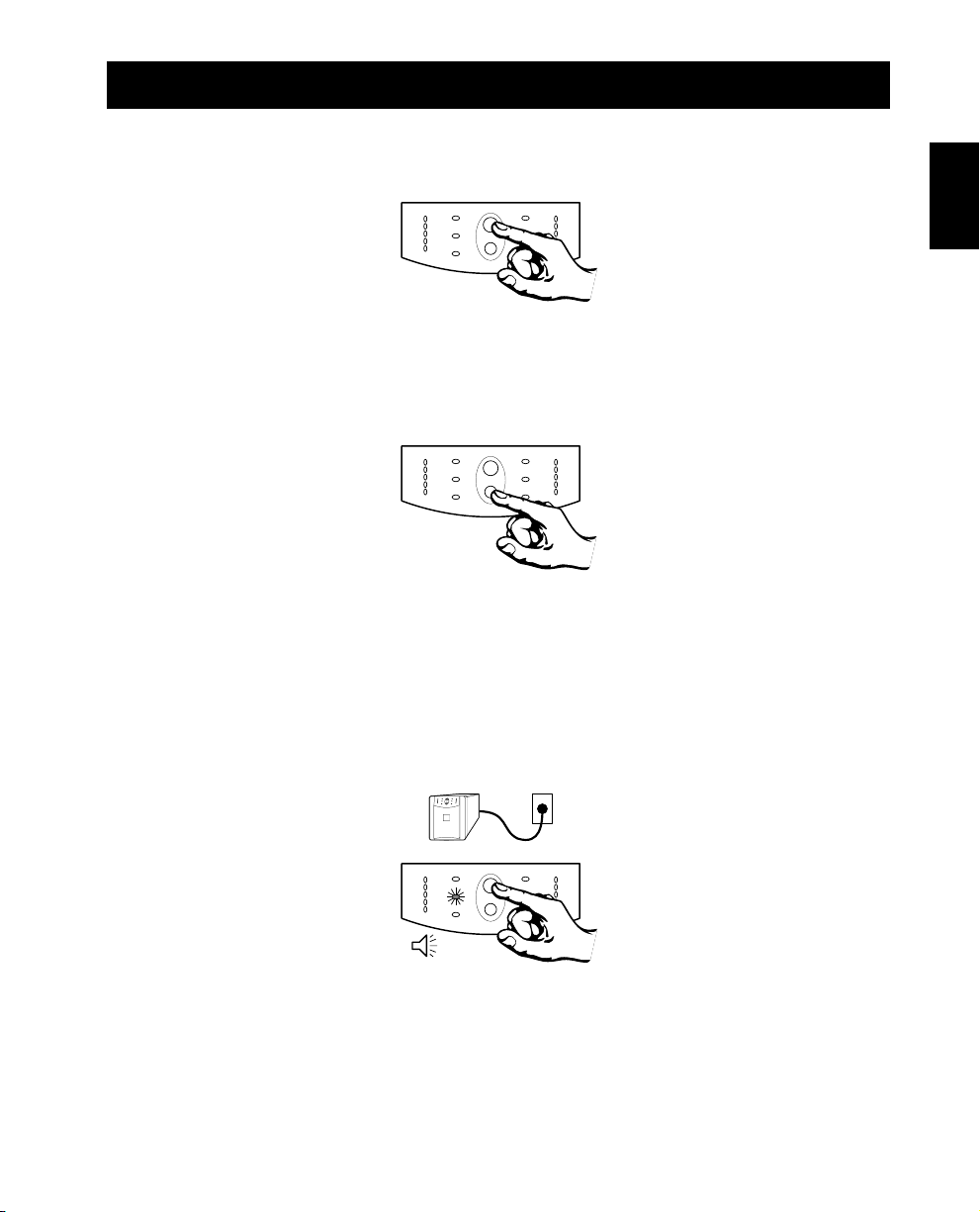

5.1 Switch On

With the unit plugged in, press the on/test (upper) button to supply power to the loads. The loads

are immediately powered while the unit beeps and performs a self-test. See section 5.3.

5.2 Switch Off

To switch off the unit’s output power, press the off (lower) button. It may be convenient to use the

on and off buttons of the unit as a master on/off switch for the protected equipment.

Note: The unit is on (the internal processor is operating) whenever it is plugged in and utility voltage

is present. Even when switched off the unit maintains the battery charge and will respond to commands received through the computer interface port and the accessory slot.

English

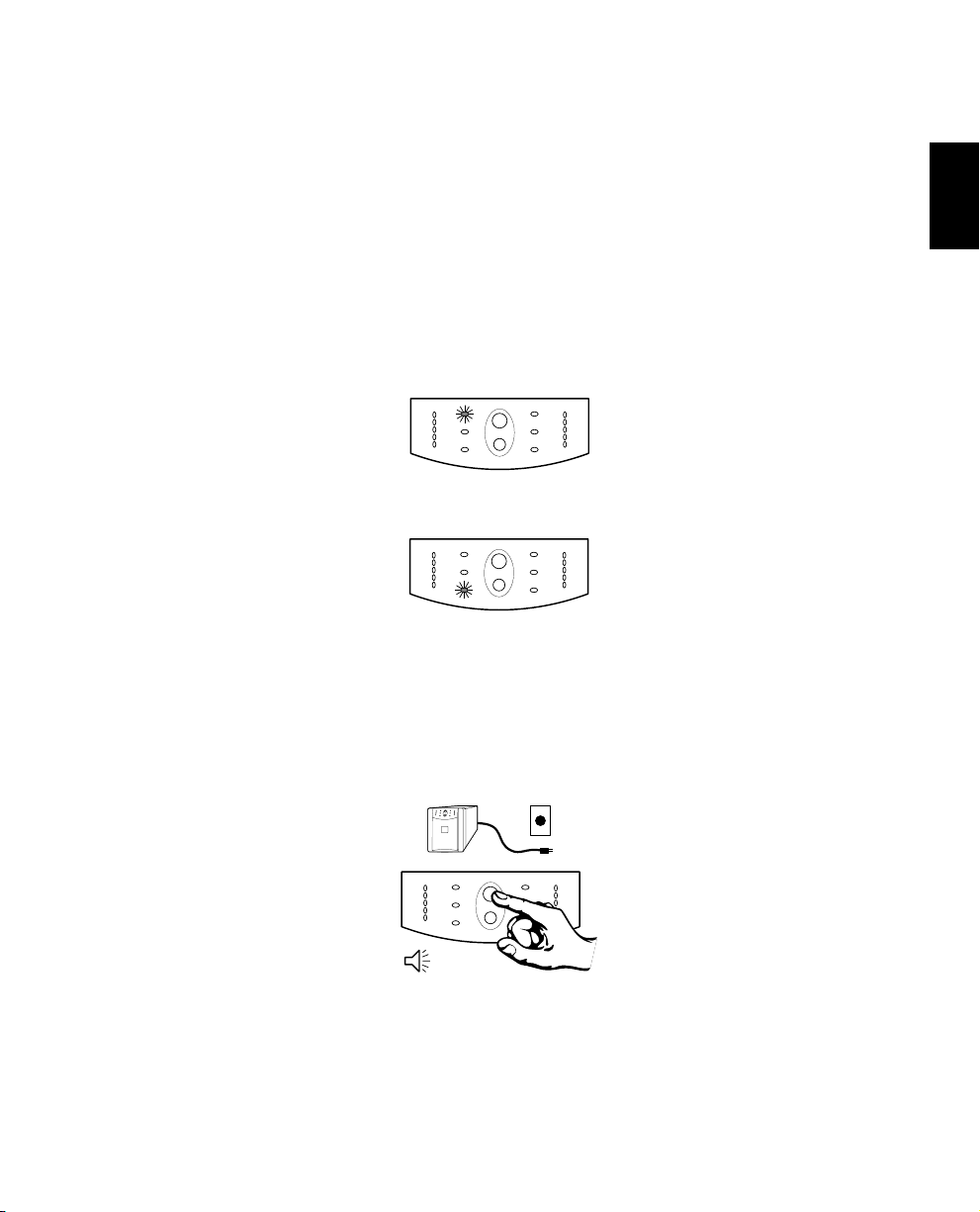

5.3 Self-test

Use the self-test to verify both the operation of the unit and the condition of the battery. With the

unit plugged in to normal utility power, activate the self-test by pressing the on/test button until the

unit beeps and the on-line LED flashes.

Note: By default the unit performs a self-test at power up and once every two weeks.

11

Page 16

During the self-test, the unit briefly operates the loads on-battery (the on-battery LED comes on).

If the unit passes the self-test, it returns to on-line operation. The on-battery LED goes off and the

on-line LED goes on steady.

If the unit fails the self-test it immediately returns to on-line operation and lights the replace battery LED. The loads are not affected. Recharge the battery overnight and perform the self-test

again. If the replace battery LED is still on, see section 10 for information on replacing the

battery.

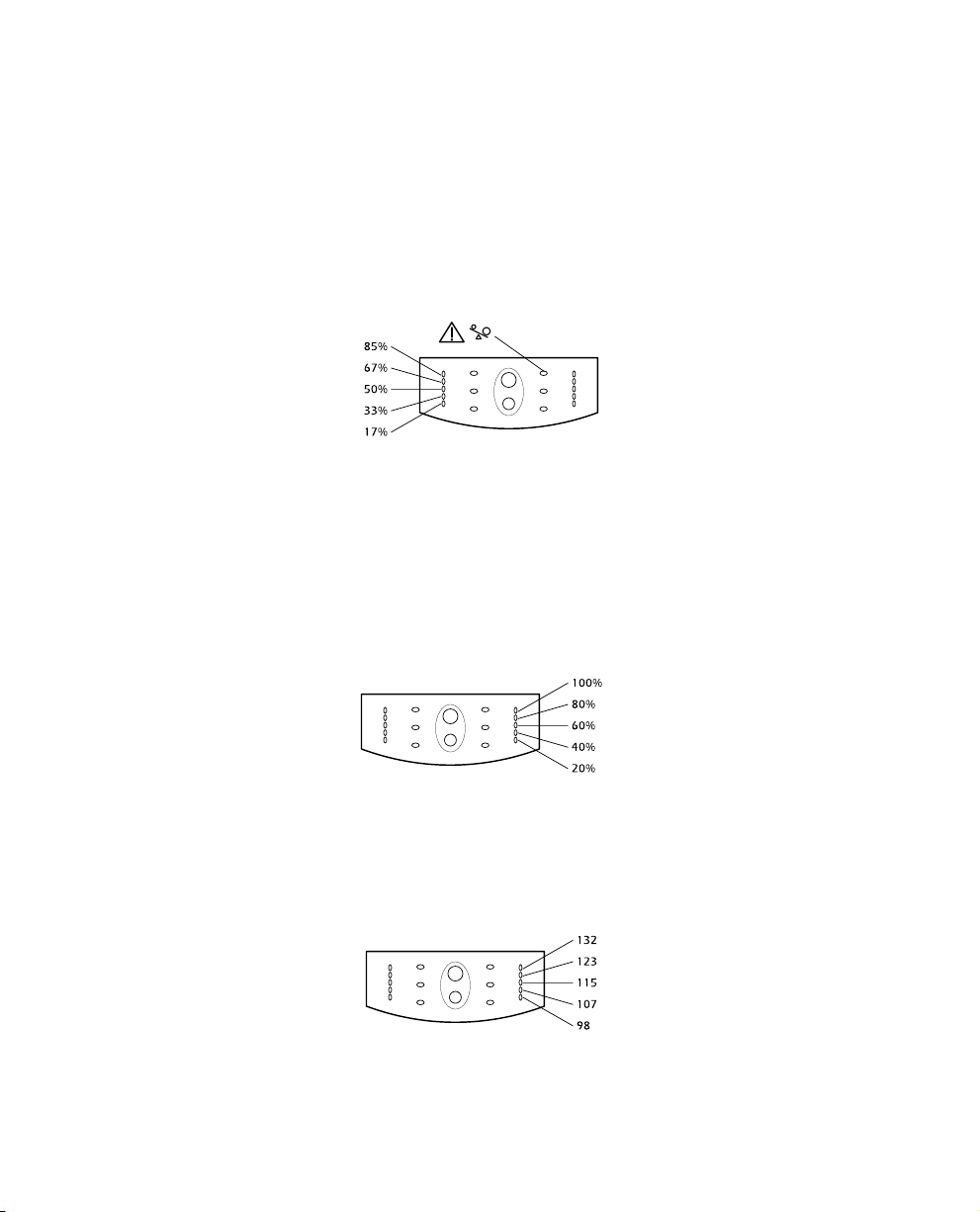

5.4 Load Bar Graph

The 5-LED display on the left of the front panel shows the power drawn from the unit by the load.

The display indicates the percentage of the unit’s rated capacity. For example, if three LEDs are lit, the

load is drawing between 50% and 67% of the unit’s capacity.

If all five LEDs light, thoroughly test your complete system to make sure that the unit will not become overloaded.

If the unit is overloaded, the overload LED lights and an alarm sounds. See section 6.2.

5.5 Battery Charge Bar Graph

The 5-LED display on the right of the front panel shows the present charge of the unit’s battery as a

percentage of the battery’s capacity. When all five LEDs light, the battery is fully charged. When the

lowest LED is flashing, the battery can supply less than two minutes of run time for the load.

5.6 Utility Voltage Bar Graph

This unit has a diagnostic feature that displays the utility voltage. With the unit plugged into the

normal utility power, press and hold the on/test button to see the utility voltage bar graph

display. After four seconds the 5-LED display on the right of the front panel shows the utility input

voltage. Refer to the list for the voltage reading.

12

Page 17

The display indicates that the voltage is between the displayed value from the list and the next

higher value. For example, with three LEDs lit, the input voltage is between 115 and 123 VAC.

If no LEDs come on and the unit is plugged into a working AC power outlet, the line voltage is extremely low.

If all five LEDs come on, the line voltage is extremely high and should be checked by an

electrician.

Note: The unit will start a self-test as part of this procedure. The self-test does not affect the

voltage display.

5.7 SmartBoost and SmartTrim

The unit automatically corrects high and low utility voltages so that the loads receive voltage within

the normal range.

The unit’s SmartTrim LED comes on to indicate that the unit is compensating for a high voltage

level.

The SmartBoost LED comes on to indicate that the unit is compensating for a low voltage

condition.

SmartTrim and SmartBoost indications are advisory. No user action is required. To check the

utility voltage use the utility voltage display. See section 5.6.

English

5.8 Cold Start

When the unit is off and there is no utility power, use the cold start feature to apply power to the

loads from the unit’s battery. Press the on/test button until the unit beeps. Release the button during

the beep and the loads are powered within 4 seconds. Cold start is not a normal operating condition.

13

Page 18

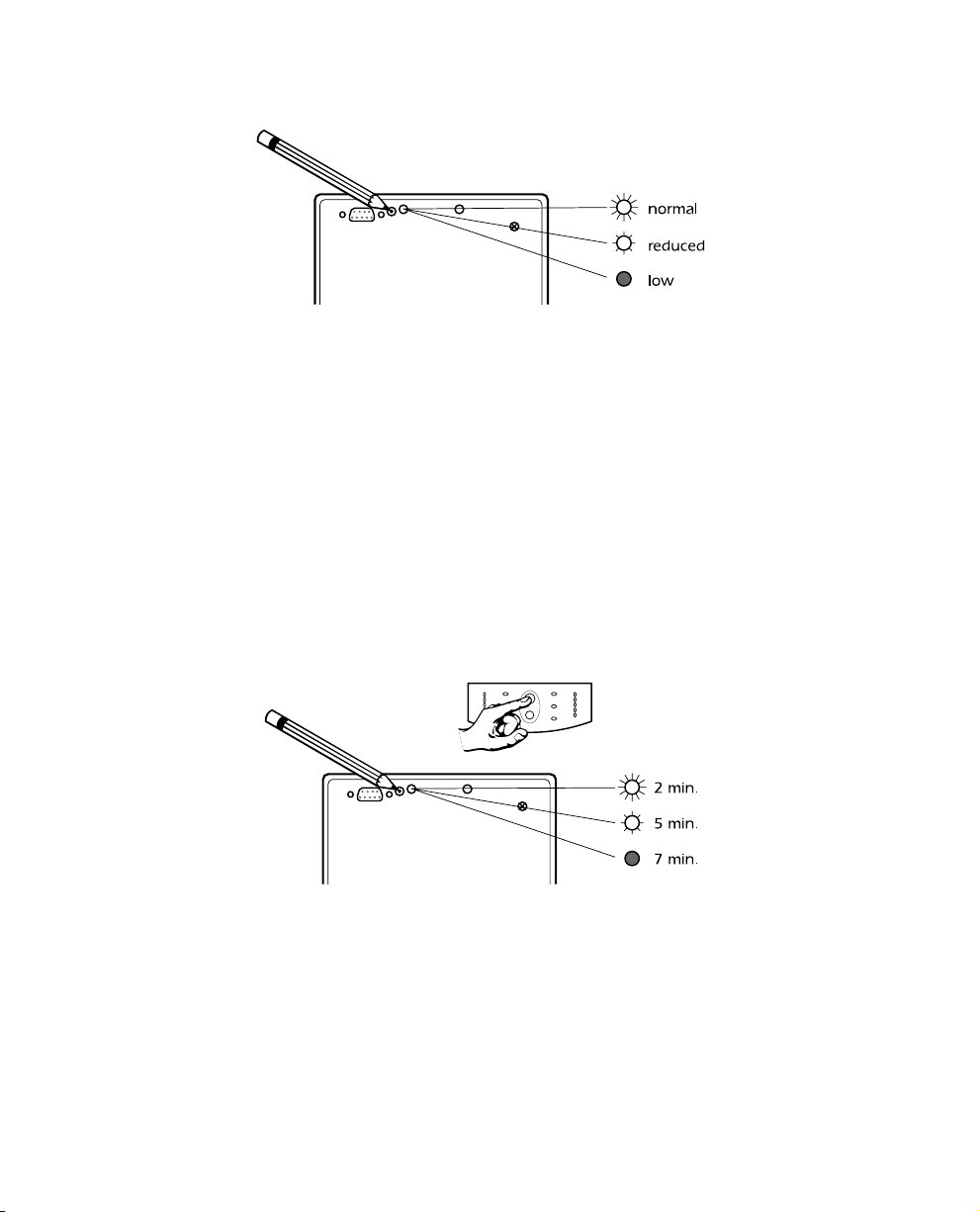

5.9 Voltage Sensitivity

The unit detects line voltage distortions such as spikes, notches, dips, and swells, as well as distortions caused by operation with inexpensive fuel powered generators. By default, the unit reacts to

distortions by transferring to on-battery operation to protect the loads. Where power quality is

poor, the unit may frequently transfer to on-battery operation. If the loads can operate normally

under such conditions, battery capacity and service life may be conserved by reducing the sensitivity

of the unit.

To reduce unit’s sensitivity, press the configuration button on the rear panel. Use a pointed object

such as a pen to press the button. Press it once to set the unit’s sensitivity to reduced. Press it again

to set the sensitivity to low. Press the button again to reset normal sensitivity.

When the unit is set to normal sensitivity, the configuration LED is brightly lit. When it is set to reduced sensitivity, the LED is dimly lit. When it is set to low sensitivity, the LED is off.

5.10 Low Battery Warning Interval

By default, the low battery warning occurs when there are approximately two minutes of on-battery run time remaining. This may not be enough time to gracefully shut down some protected

computer systems. To change the warning interval, press the rear panel configuration button while

pressing and holding the front-panel on/test button. Use a pointed object such as a pen to press

the configuration button.

Press the configuration button once to set the low battery warning interval to approximately five

minutes. Press it again to set the interval to approximately seven minutes. Press the button again

to reset the interval to two minutes.

14

Page 19

When the unit is set for a two minute warning interval the configuration LED is brightly lit. When

the unit is set for a five minute warning interval the configuration LED is dimly lit. When the unit is

set for a seven minute warning interval the configuration LED is off.

5.11 Shutdown Mode

In shutdown mode the unit stops supplying power to the load, waiting for the return of utility

power. If there is no utility power present, external devices (e. g., servers) connected to the computer interface or the accessory slot can command the unit to shut down. This is normally done to

preserve battery capacity after the graceful shutdown of protected servers. The unit will scroll the

front panel indicators sequentially in shutdown mode.

6. Alarms

6.1 On Battery

In on-battery operation, the on-battery LED comes on and the unit sounds an audible alarm consisting

of four beeps every 30 seconds. The alarm stops when the unit returns to on-line operation.

Press the on/test button during on-battery alarms to stop the beeping. This works for the current

alarm only — the next on-battery alarm will have the audible indication. Shutting off the audible

alarm in this way does not affect alarm reporting through the computer interface or accessory

slot.

English

6.2 Overload

When the unit is overloaded (when the connected loads exceed maximum listed in section 12) the

overload LED comes on and the unit emits a sustained tone. The alarm remains on until the overload is removed. Disconnect nonessential load equipment from the unit to eliminate the overload.

6.3 Replace Battery

The unit emits short beeps for one minute and the replace battery LED comes on if the battery fails

the self-test. The unit repeats the alarm every five hours. Perform the self-test procedure in section

5.3 to confirm the replace battery condition. The alarm stops when the battery passes the self-test.

6.4 Low Battery

When the unit’s battery is low the unit beeps continuously until the unit returns to on-line operation

or shuts down from battery exhaustion. The low battery warning interval is a configuration item.

See section 5.10.

15

Page 20

7. Options

7.1 Overview

This unit has several options that support advanced operation. Advanced operations include graceful shutdown of a protected computer, and several communication and command

functions.

Computer systems require time to perform an orderly shutdown, without corrupting or losing

data. In an extended power failure, a computer system protected by this unit eventually will lose

power when the battery is exhausted. Using monitoring, the unit and the computer system communicate so that the computer system is warned of impending unit shutdown and has time to shut itself down gracefully.

7.2 Software

Use available power management software for unattended operation of servers and workstations,

power quality related data logging, shutdown notification and control, auto-restart, diagnostics,

and battery conservation features. Software is available for most operating systems and is supplied with a signalling cable that connects to the unit. See your dealer or call the number at the front

of this manual for more information.

7.3 Interface Kits

For computer systems that have built-in monitoring features, a series of interface kits are available

to connect the unit to your system. Each kit includes the appropriate interface cable to convert the

unit’s status signals into signals your system recognizes (use only factory supplied or authorized

monitoring cables). See your dealer or call the number at the front of this manual for more information.

7.4 Accessory Slot

The capabilities of the accessories that plug into the unit’s accessory slot include; SNMP monitoring

and control, multiple server support for one unit, out-of-band management, special signalling,

power control, and environment monitoring. See your dealer or call the number at the front of this

manual for more information.

7.5 Wall Mount Bracket

A special wall mount bracket for units up to 1400 VA is available. See your dealer or call the number

at the front of this manual for more information.

16

Page 21

8. Troubleshooting

Problem Possible Cause Solution

On/test button not

pushed.

Unit will not turn on .

Unit will not turn on or

off.

Unit operates on-battery

even though normal line

voltage is thought to

exist.

Unit beeps occasionally. Normal operation. None. The unit is protecting the load.

Unit does not provide

expected back up time.

Unit’s input circuit breaker

tripped.

Very low or no utility

voltage.

Computer interface or

accessory problem.

Unit’s input circuit breaker

tripped.

Very high, low, or

distorted line voltage.

The unit’s battery is weak

due to recent ou tage or is

near the end of its service

life.

Press the on/test button to power the unit

and the load

Reduce the load on the unit by unplugging

equipment and reset the circuit breaker by

pressing the plunger back in.

Check the AC power supply to the unit

with a table lamp. If very dim, have the

utility voltage checked.

Disconnect the computer interface or

accessory. If the unit now works normally,

check the interface cable, the attached

computer, and the accessory.

Reduce the load on the unit by unplugging

equipment and reset the circuit breaker.

Test the input voltage with the utility

voltage display. See section 5.6. Inexpensive

fuel powered generators can distort the

voltage. If acceptable to the load, reduce

the unit’s sensitivity. See section 5.9.

Charge the battery. The unit"s batteries

require recharging after an extended

outage. Batteries wear faster when put into

service often and when operated at

elevated temperatures. If the battery is near

the end of its service life, consider

replacing the battery even if the replace

battery indicator is not yet lit.

English

Front panel indictors

flash sequentially.

All indicators are lit and

the unit emits a constant

tone.

The unit is overloaded.

The unit has been shut

down by remote control.

Internal unit fault.

Check the unit’s load display. See section

5.4. Unplug less needed equipment, such as

printers.

None. The unit will restart automatically

when utility power returns.

Do not attempt to use the unit.. Turn the

unit off and have it serviced immediately.

17

Page 22

Problem Possible Cause Solution

Low battery light is

on and the on-line

light is off.

The replace battery

light is lit.

The unit is shut down and the

battery is discharged from an

extended power outage.

Weak batteries.

Replacement batteries not

connected properly.

None. The unit will return to normal

operation when the power is restored and

the battery has a sufficient charge.

Allow the batteries to recharge for at least

four hours. If the problem persists after

recharging, replace the batteries. See

section 10.

Confirm the battery connections. See

section 10.

9. Service

If the unit requires service:

1. Use the troubleshooting section (section 8) to eliminate obvious causes.

2. Verify that no circuit breakers are tripped. A tripped circuit breaker is the most common unit

problem! See section 6.2.

3. Go to section 5.3 and perform a self-test to check the battery.

4. See the front of this manual for the correct telephone number. Call customer service for a return

material authorization number (RMA#). If customer service is not available in your area, call

the dealer that sold the unit.

■ Note the model number of the unit, the serial number, and the date purchased. A techni-

cian will ask you to describe the problem and help solve it over the phone, if possible, or

will give you an RMA#.

■ If the unit is under warranty, repairs are free. If not, there will be a charge for repair.

5. Pack the unit in its original packaging. If the original packing is not available, ask customer service about obtaining a new set.

■ It is important to pack the unit properly to avoid damage in transit. Never use styrofoam

beads for packaging. Damage sustained in transit is not covered under warranty.

■ Include a letter with your name, RMA#, address, copy of the sales receipt, description of the

trouble, your daytime phone number, and a check (if necessary).

6. Mark the RMA# on the outside of the package. The factory cannot accept any package without

this marking.

7. Return the unit by insured, prepaid carrier to the address at the front of this manual.

18

Page 23

10. Replacing the Battery

This unit has a replaceable battery. Please read section 10.1 before performing the procedure in sections 10.3 or 10.4.

10.1 Warning

■ This Uninterruptible Power Source contains potentially hazardous voltages. Do not attempt to

disassemble the unit beyond the battery replacement procedures below. Except for the battery,

the unit contains no user serviceable parts. Repairs are performed only by factory trained service personnel.

■ The batteries in this unit are recyclable. Dispose of the batteries properly. The batteries contain

lead and pose a hazard to the environment and human health if not disposed of properly. Refer

to local codes for proper disposal requirements or return the battery to a factory authorized

service center. See the instructions with the new battery for more information.

CAUTION—Do not dispose of batteries in a fire. The batteries may explode.

CAUTION—Do not open or mutilate batteries. They contain an electrolyte which is toxic and

harmful to the skin and eyes.

English

CAUTION—To avoid personal injury due to energy hazard, remove wrist watches and jewelry

such as rings when replacing the batteries. Use tools with insulated handles.

CAUTION—Replace batteries with the same number and type of batteries as originally installed

in the unit.

10.2 Replacement Batteries

See your dealer or call the number at the front of this manual for information on replacement battery kits and battery recycling.

19

Page 24

10.3 Battery Replacement Procedure (450 through 1400 VA

models)

Note: Please read the cautions in section 10.1.

Battery replacement is a safe procedure, isolated from electrical hazards. You may leave the unit and

loads on for the following procedure.

1. Grasp the top of the front cover and tilt it out and down.

2. Unhook the bottom of the cover from the chassis and lift it upward to expose the battery door.

Be careful not to strain the ribbon cable. Do not touch the exposed printed circuit board.

3. Fold the front cover on top of the unit as shown.

4. Use a flat-blade screwdriver or a coin to remove the two battery door screws and open the

door.

5. Grasp the tab and gently pull the battery out of the unit.

6. Disconnect the battery leads.

■ For the 450 through 1000 VA models, loosen the connectors by gently wiggling them while

pulling straight back from the battery connector.

■ For the 1400 VA model, pull the two gray couplers apart to disconnect the battery.

7. Connect the battery leads to the new battery. Note: Small sparks at the battery connectors are

normal during battery connection.

■ For the 450 through 1000 VA models, connect the red wire to the positive (+) terminal and

the black wire to the negative (–) terminal.

■ For the 1400 VA model, connect the gray battery coupler to the unit’s coupler.

Now slide the battery into the unit, close the battery door, replace the battery compartment

screws, and replace the front cover.

8. Dispose of the old battery properly at an appropriate recycling facility or return it to the supplier in the packing material for the new battery. See the new battery instructions for more information.

20

Page 25

10.4 Battery Replacement Procedure (2200 and 3000 VA models)

English

Note: Please read the cautions in section 10.1.

Battery replacement is a safe procedure, isolated from electrical hazards. You may leave the unit and

loads on for the following procedure.

1. Grasp the top edge of the bottom front cover and tilt it out.

2. Unhook the bottom section of the front cover from the chassis and set it aside.

3. Use a flat-blade screwdriver or a coin to remove the two battery door screws and open the

door.

4. Grasp the battery tray handle and pull the batteries part way out of the unit.

5. Press down on the side tabs of the first battery’s connector clips to release the connector.

6. Disconnect the battery leads by pulling the gray couplers apart.

21

Page 26

7. Pull the battery tray completely out of the unit. Press down on the side tabs of the second

battery’s connector clips to release the connector. Disconnect the battery leads by pulling the

gray couplers apart.

8. Reversing steps 6 and 7, replace the rearmost battery in the tray. Connect the battery, push

the connector into the connector clip and slide the tray part way into the unit. Now replace the

other battery into the tray and connect it. Push the connector into the connector clip and slide

the tray completely into the unit. Note: Small sparks at the battery connectors are normal dur-

ing battery connection.

9. Now close the battery door, replace the screws, and replace the lower front cover.

10. Dispose of the old battery properly at an appropriate recycling facility.

11. Storage

11.1 Storage conditions

Store the unit covered and upright in a cool, dry location, with its battery fully charged. Before storing, charge the unit for at least 2 hours. Remove any accessories in the accessory slot and disconnect

any cables connected to the computer interface port to avoid unnecessarily draining the battery.

11.2 Extended storage

During extended storage in environments where the ambient temperature is –15 to +30 °C

(+5 to +86 °F), charge the unit’s battery every 6 months.

During extended storage in environments where the ambient temperature is +30 to +45 °C

(+86 to +113 °F), charge the unit’s battery every 3 months.

22

Page 27

12. Specifications

450 VA 700 VA 1000 VA 1400 VA 2200 VA 3000 VA

Acceptable input voltage 0 - 160 VAC

Maximum input voltage range* 92-146 VAC

Output voltage* 103-132 VAC

Nominal input frequency 50 or 60 Hz, autosensing

Input Protection Resettable circuit breaker

Frequency limits (on-line operation) 50 or 60 Hz, ±5%

Transfer time 2 ms typical, 4 ms maximum

Maximum load

On-battery output voltage 115 VAC

On-battery frequency

On-battery waveshape Low-distortion sine wave

Protection

Surge energy rating

(one time, 10/1000 µs waveform)

Surge current capability

(one time, 8/20 µs waveform)

Surge response time

Surge voltage let-through

(percentage of applied ANSI C62.41 Cat. A

±6 kV test waveform)

Noise Filter

Batter y type Spill proof, maintenance free, sealed lead-acid

Typical batter y life

Typical recharge time 2 to 5 hours from total discharge

450 VA

280 W

Overcurrent and short-circuit protected, latching shutdown on

700 VA

450 W

50 or 60 Hz, ±0.1 Hz; unless synchronized to utility during

320 J 480 J

0.70% 0.30%

Normal and common mode EMI/RFI suppression,

3 to 6 years, depending on number of discharge cycles and

1000 VA

670 W

6500 A maximum

0 ns (instantaneous) normal mode;

<5 ns common mode

100 kHz to 10 MHz

ambient temperature

1400 VA

950 W

brownout.

overload

2200 VA

1600 W

English

3000 VA

2250 W

*Adjustable via optional software.

23

Page 28

450 VA 700 VA 1000 VA 1400 VA 2200 VA 3000 VA

Operating temperature 0 to +40 °C (+32 to +104 °F)

Storage temperature -15 to +45 °C (+5 to +113 °F)

Operating and storage relative humidity 0 to 95%, non-condensing

Operating elevation 0 to +3,000 m (0 to +10,000 ft)

Storage elevation 0 to +15,000 m (0 to +50,000 ft)

Electromagnetic immunity IEC 801-2 level IV, 801-3 level III, 801-4 level IV

Audible noise in dBA at 1 m (3 ft) <45 <55

Size (H x W x D)

Weight - net (shipping)

Safety approvals Listed to UL 1778, cert ified to CSA 107.1

EMC verification

15.8 x 13.7 x 35.8 cm

(6.2 x 5.4 x 14.1 in.)

10.5

(11.9)

kg

23.2

(26.2)

lb.

13.1

(14.5)

kg

29

(32)

lb.

Class B certified

21.6 x 17 x 43.9 cm

(8.5 x 6.7 x 17.3 in.)

18.8

(20.8)

kg

41.5

(46)

lb.

FCC/D OC

24.1

(26.1)

kg

53

(57.5)

lb.

43.2 x 19.6 x 54.6 cm

(17.0 x 7.7 x 21.5 in.)

51

(60)

kg

112.3

(132.3)

lb.

FCC/DOC

Class A certified

54.4

(63.4)

kg

120

(140)

lb.

13. How to Determine On-battery Run Time

Knowing the on-battery run time of the unit is an important part of use, especially in situations

where the protected device uses an operating system that requires some time to gracefully shut

down.

1. To calculate the on-battery run time first determine the total load protected by the unit in

Volt-Amps. Obtain load figures from either the labelling on the protected equipment or the

accompanying literature. For loads specified in watts, multiply the specified figure by 1.4. For

loads specified in Amps, multiply the specified figure by 120.

2. Add the individual loads to determine the total load.

3. Compare the total load of your system to the run time table below.

24

Page 29

Typical On-Battery Run Time Versus Load, in Minutes

Model 450 700 1000 1400 2200 3000

50 VA 100 140 150 251 366 297 640

75 VA 77 113 125 199 309 258 557

100 VA 54 85 100 163 268 228 491

150 VA 33 55 75 118 209 183 394

200 VA 22 38 58 90 170 152 328

250 VA 15 26 44 71 142 128 281

300 VA 11 20 36 57 121 110 245

350 VA 8 17 28 47 104 96 216

400 VA5 1424399184193

450 VA4 1120338075174

500 VA - 9 18 29 71 67 157

550 VA - 8 15 25 64 60 143

600 VA - 6 13 21 57 54 131

700 VA - 5 11 18 46 44 112

800 VA - - 9 15 38 36 96

900 VA - - 7 12 32 31 84

1000 VA - - 6 11 27 26 73

1200 VA - - - 8 21 20 58

1400 VA - - - 7 17 16 46

1600 VA----141337

2000 VA----101026

2200 VA----8822

2500 VA-----718

3000 VA-----513

3000 w/

ext. batt.

English

25

Page 30

14. User Configuration Items

Note: Setting these items requires optional software or hardware.

Function

Automatic Self-Test

Unit ID UPS_IDEN

Date of Last Battery

Replacement

Minimum Capacity

Before Return from

Shutdow n

Sensitivity Normal Reduced, Low

Duration of Low

Battery Warning

Alarm Delay After

Line Fail

Shutdown Delay 20 seconds

Synchronized Turn-on

Delay

Factory

Default

Every 14

days (336

hours)

Manufacture

Date

0 percent 15, 50, or 90 percent

2 minutes 5, 7, or 10 minutes

5 second

delay

0 seconds 60, 180, 300 seconds

User Selectable

Choices

Every 7 days (168

hours), On Startup

Only, No Self-Test

Up to eight characters

to define the unit.

Date of Battery

Replacement

30 second delay, At

Low Battery

Condition, No Alarm

180, 300, or 600

seconds

Description

Sets the interval at which the unit will

execute a self-test.

Use this field to uniquely identify the

unit for network management

purposes.

Reset this date on battery replacement.

The unit will charge its batteries to the

specified percentage before return

from a shutdown.

Set lower than normal sensitivity to

avoid lowered battery capacity and

service life in situations where the load

can tolerate minor power disturbances.

Sets the time before shutdown at

which the unit issues a low battery

warning. Set higher than the default

only if the OS needs the time for

graceful shutdown.

To avoid alarms for minor power

glitches, set the alarm delay.

Sets the interval between when the

unit receives a shutdown command

and when shutdown occurs.

To avoid branch circuit overload, the

unit will wait the specified time after

the return of utility power before

turn-on.

High Transfer Point 132 Vac 135, 138, 129 Vac

Low Transfer Point 103 Vac 100, 97, 106 Vac

26

Page 31

1. Introdução ........................................................................... 27

2. Segurança............................................................................ 30

3. Apresentação ....................................................................... 31

4. Instalação............................................................................. 34

5. Operação............................................................................. 37

6. Alarmes ................................................................................ 42

7. Opções ................................................................................ 43

8. Resolução de Problemas ....................................................... 44

9. Assistência Técnica ............................................................... 45

10. Substituição da Bateria ......................................................... 46

11. Armazenamento .................................................................. 49

12. Especificações ...................................................................... 50

13. Como Determinar o Tempo de Funcionamento da Bateria .... 51

14. Itens Configuráveis pelo Usuário........................................... 53

1. Introdução

1.1 Obrigado!

Obrigado por selecionar esta fonte de energia ininterrupta (No-Break). Ela foi projetada para

muitos anos de serviço confiável e livre de manutenção.

Importante!

Leia este manual. Ele fornece instruções de segurança, instalação e operação que irão ajudá-lo a

obter o melhor desempenho e tempo de vida útil do seu No-Break. Este manual descreve o

funcionamento interno do No-Break e o modo como ele atua para proporcionar uma proteção

superior contra problemas de energia externa como blackouts, quedas de voltagem, subtensões,

oscilações, ruídos EMI/FRI e surtos. O manual inclui instruções sobre a obtenção de assistência

técnica, se necessário.

Se você tiver algum problema com o No-Break, consulte este manual antes de ligar para o

serviço de assistência técnica ao cliente. A seção sobre resolução de problemas (seção 8) pode

ajudá-lo na maioria das situações normalmente encontradas quando você usa o No-Break.

Português

Guarde a embalagem!

O material da embalagem do No-Break foi projetado cuidadosamente para proporcionar

proteção durante o transporte. Esse material é inestimável se você tiver que devolver o No-Break

para assistência. Os danos ocorridos durante o transporte não estão cobertos pela garantia.

27

Page 32

1.2 Interferência de Radiofreqüência

450 VA - 1400 VA

Aviso: As modificações feitas a esta unidade que não tiverem sido expressamente aprovadas pela

parte responsável pela permissão podem anular a autorização do usuário para utilização do

equipamento.

Nota: Este equipamento foi testado e verificado de forma a cumprir os limites de dispositivo

digital de Classe B, de acordo com a Parte 15 dos Regulamentos da FCC e os limites da Classe B

quanto a emissões de ruídos de rádio de aparelhos digitais estabelecidos pelas Radio Interference

Regulations do Canadian Department of Communications (Departamento Canadense de

Comunicações). Esses limites foram criados para proporcionar uma proteção razoável contra

interferências nocivas em instalações residenciais. Este equipamento gera, usa e pode difundir

energia de radiofreqüência e, se não for instalado e usado de acordo com as instruções, pode

causar interferências prejudiciais às radiocomunicações.

Entretanto, não há nenhuma garantia de que não ocorrerão interferências em uma determinada

instalação. Se este equipamento causar interferências na recepção de rádio ou televisão, o que

pode ser verificado ligando-se e desligando-se o aparelho, o usuário deve tentar corrigir a

interferência adotando uma ou mais das seguintes medidas:

■ reposicionar a antena receptora

■ aumentar a distância entre o equipamento e o receptor

■ conectar o equipamento a uma tomada em um circuito diferente daquele no qual o receptor

está conectado

■ consultar o fornecedor ou um técnico experiente de rádio/TV para obter ajuda.

Este produto deve ser usado com cabos de interface de comunicações blindados.

2200 VA e 3000 VA

Aviso: As modificações feitas a essa unidade que não tiverem sido expressamente aprovadas pela

parte responsável pela permissão podem anular a autorização do usuário para utilização do

equipamento.

Nota: Este equipamento foi testado e verificado de forma a cumprir os limites de dispositivo

digital da Classe A, de acordo com a Parte 15 dos Regulamentos da FCC e os limites da Classe A

quanto a emissões de ruídos de rádio de aparelhos digitais estabelecidos pelas Radio Interference

Regulations do Canadian Department of Communications (Departamento Canadense de

Comunicações). Esses limites foram criados para proporcionar uma proteção razoável contra

interferências nocivas quando o equipamento funciona em um ambiente comercial. Este

equipamento gera, usa e pode difundir energia de radiofreqüência e, se não for instalado e usado

de acordo com o manual de instruções, pode causar interferências prejudiciais às

radiocomunicações. A operação do equipamento em uma área residencial provavelmente

causará interferências prejudiciais e, neste caso, o usuário será solicitado a corrigir as

interferências por sua própria conta.

Esta unidade deve ser usada com cabos de sinal blindados para garantir o cumprimento dos

limites da Classe A da FCC.

28

Page 33

1.3 Método de Operação

Esta fonte de energia ininterrupta (No-Break) de alto desempenho, interativa com a linha, fornece

energia de CA estável e confiável para sistemas de computadores — protegendo-os de blackouts

de energia, quedas de voltagem, oscilações, subtensões, surtos e interferências.

Normalmente, o No-Break opera “on-line”, fornecendo energia da entrada externa para a carga

(estação de trabalho, servidor ou outro dispositivo). O conjunto de circuitos do conversor é

usado para manter um nível ideal de carga flutuante na bateria.

Quando a energia externa falha, o conversor fornece energia de CA para a carga e a chave de

desconexão se abre. A carga funciona normalmente até o desligamento ou até que a bateria

acabe. O No-Break automaticamente transfere a carga para a energia externa quando a voltagem

da linha volta ao normal.

O No-Break também fornece proteção contra surtos e filtragem EMI/FRI, bem como o Smart-

Boost™ e o SmartTrim™, que corrigem oscilações da voltagem de entrada sem consumir energia

da bateria.

O controle de saída usa a interface remota do No-Break para ligar ou desligar a carga, sem

desativar outras funções.

1.4 Recursos

Gerenciamento Inteligente de Baterias

O No-Break fornece indicações visuais e audíveis do status atual da bateria, inclusive sua

capacidade, condições de bateria fraca e condição de troca de bateria.

O No-Break verifica a bateria durante seu autoteste e detecta uma bateria fraca antes que ela seja

colocada para funcionar. Normalmente, o No-Break executa um autoteste na hora em que é

ligado e a cada 14 dias. Os autotestes também podem ser realizados manualmente com o botão

Ligar/teste a qualquer momento.

O No-Break apresenta baterias que podem ser substituídas pelo usuário. As baterias podem ser

trocadas sem que o usuário tenha que interromper a energia das cargas ou mandar o No-Break

para a assistência técnica.

Português

29

Page 34

Interface do Computador e Slot de Acessórios

Monitoração avançada, gerenciamento de energia e funções personalizadas estão disponíveis

através da interface do computador e do slot de acessórios. Consulte a seção 7 para obter mais

informações.

2. Segurança

CUIDADO!

■ Para reduzir o risco de choques elétricos em condições nas quais o aterramento do

equipamento de carga não possa ser verificado, desconecte o No-Break da tomada de energia

de CA antes de instalar um cabo de sinais da interface do computador ou slot de acessórios.

Só conecte novamente o cabo de força depois que todas as conexões de sinalização tiverem

sido feitas.

■ Conecte o No-Break a uma tomada aterrada trifilar e bipolar de energia de CA. A tomada

deve ser conectada à um ramal apropriadamente protejido (fusível ou disjuntor de circuito).

A conexão a qualquer outro tipo de tomada pode resultar no risco de choques e violação de

códigos elétricos locais.

■ O No-Break tem uma fonte de energia interna (a bateria). A saída pode ser ativada quando a

unidade não estiver conectada a uma tomada de energia de CA.

■ Para desativar as saídas do No-Break, primeiro pressione o botão de Desligar por mais de

um segundo para desligar o No-Break. A seguir, desconecte-o da tomada de energia de CA.

Para desativar completamente o No-Break, desconecte a bateria. Veja a seção 10.

■ O condutor protetor à Terra desse No-Break transporta a corrente de dispersão dos

dispositivos de carga (equipamento do computador). Este No-Break gera aproximadamente

1,5 mA de corrente de dispersão. Para garantir um limite seguro de 3,5 mA, restrinja a

corrente de dispersão total dos dispositivos de carga a 2 mA.

■ Não recomendamos o uso deste equipamento em aplicações de manutenção das funções

vitais, nas quais um possível mau funcionamento possa causar falha de um aparelho de

suporte à vida ou afetar significativamente a segurança ou eficiência deste.

30

Page 35

3. Apresentação

3.1 Painel frontal

Com o No-Break conectado, pressione o botão Ligar/teste para ligá-lo e ativar as cargas. Veja a

seção 5.1. O botão Ligar/teste também ativa o autoteste do No-Break e os mostradores de

voltagem de linha externa. Veja as seções 5.3 e 5.6.

O LED de sobrecarga acende quando as cargas conectadas ao No-Break ultrapassam a

capacidade do aparelho. Veja a seção 6.2.

O mostrador de Carga da Bateria/Voltagem da Linha exibe a carga atual da bateria como uma

percentagem da capacidade da bateria. Veja a seção 5.5. Ele também mostra a voltagem da linha

externa. Veja a seção 5.6.

O LED de bateria ligada acende quando o No-Break está fornecendo energia da bateria para as

cargas.

O LED de substituição de bateria acende quando a bateria do No-Break não é mais útil e deve

ser trocada. Veja a seção 10.

Pressione o botão de Desligar para desligar o No-Break e a carga. Veja a seção 5.2.

O LED de SmartBoost acende quando o No-Break está corrigindo uma condição de voltagem

externa baixa. As cargas recebem energia normal.

O LED de on-line acende quando o No-Break está fornecendo energia externa para as cargas.

O mostrador de carga mostra a energia sendo extraída pela carga. Veja a seção 5.4.

O LED do SmartTrim acende quando o No-Break está corrigindo uma condição de voltagem

externa alta. As cargas recebem energia normal.

Português

31

Page 36

3.2 Painel Traseiro

Conector de Pacote

de Baterias

3000 VA apenas

Slot de Acessórios

Energia de Saída

Botão de Configuração

Porta de Interface

do Computador

Porta de Interface

do Computador

Botão de Configuração

LED de Configuração

Falha da Fiação Local

Disjuntor do Circuito

de Saída

Disjuntor do Circuito

de Entrada

(mostra 3000 VA)

Aterramento TVSS

Conector de Energia de Entrada

NEMA 5-20P em 220VA

NEMA 5-30P em 3000VA

2200 e 3000 VA

LED de Configuração

Falha da Fiação Local

32

Slot de Acessórios

Disjuntor do

Circuito de Entrada

Aterramento

TVSS

Energia de Saída

Conector de Energia de Entrada

1000 e 1400 VA

Page 37

Botão de Configuração

Porta de Interface

do Computador

Aterramento

TVSS

Conector de

Energia de

Saída

LED de Configuração

Falha da Fiação Local

Slot de Acessórios

Português

Disjuntor do Circuito

de Entrada

Conector de Energia

de Entrada

450 e 700 VA

Use a porta de interface do computador para monitoração e controle do No-Break. Veja a seção 7.

O botão de Configuração muda a sensibilidade do No-Break a variações da voltagem externa e o

intervalo do aviso de bateria fraca. Veja as seções 5.9 e 5.10.

O LED de Configuração indica configuração de sensibilidade à voltagem e o intervalo do aviso de

bateria fraca. Veja as seções 5.9 e 5.10.

O indicador de falha da fiação local acende quando o No-Break está conectado a uma tomada de

energia de CA instalada de forma inadequada. Veja a seção 4.8.

Os disjuntores de circuito de saída (apenas nos modelos de 2200 VA e 3000 VA) desarmam

quando as cargas conectadas ultrapassam a capacidade da tomada protegida. O centro dos

disjuntores de circuito se estende quando desarmado.

O disjuntor de circuito de entrada desarma quando as cargas ultrapassam a capacidade do No-

Break. O centro do disjuntor de circuito se estende quando desarmado. A chave de lâmina no

disjuntor de circuito de entrada do modelo de 3000 VA mostra “desligado” quando desarmada.

Use o conector de aterramento de supressão de surtos de voltagem transitórios (TVSS - transient

voltage surge suppression) para fins de aterramento dos protetores da linha de rede ou de

telefone. Veja a seção 4.9.

O conector de energia de entrada é um cabo de força com um conector NEMA 5-15P para

modelos de 450 até 1400 VA. Veja a tabela a seguir para conectores de energia de entrada nos

modelos de 2200 VA e 3000 VA.

As tomadas de energia de saída são do tipo NEMA 5-15R. Existem kits de tomadas de energia de

saída opcionais de fábrica para os modelos de 2200 VA e 3000 VA. Consulte seu fornecedor ou

ligue para o número que está no início deste manual para obter mais informações.

Acessórios opcionais podem ser instalados no slot de acessórios. Veja as seções 4.4 e 7.

Use o conector do pacote de baterias para conectar o pacote de baterias externo opcional (apenas

no modelo de 3000 VA).

33

Page 38

Conectores de Energia de Entrada para 3000 VA e 2200 VA

Conector de

Modelo

2200 VA NEMA 5-20P 1600 VA/1600 W

3000 VA NEMA 5-30P 2550 VA/2250 W NEMA L5-50 3000 VA/3000 W

energia de

entrada padrão

Energia de saída

máxima com conector

padrão

Conectores de

energia de entrada

disponíveis

NEMA 5-15 1200 VA/1200 W

NEMA L5-20 1600 VA/1600 W

NEMA L5-30 2200 VA/2200 W

Energia de saída

máxima com

conector dispon ível

4. Instalação

Para obter a cobertura da garantia preencha e envie agora o cartão de registro de garantia.

4.1 Inspeção

Verifique o No-Break ao recebê-lo. Notifique a transportadora e o fornecedor se houver algum

dano. A embalagem é reciclável; guarde-a para reutilizá-la ou descarte-a de forma adequada.

4.2 Localização

2,5 cm

Instale o No-Break em uma área protegida com ventilação adequada e livre de poeira excessiva.

Não use o No-Break em locais onde a temperatura e a umidade estiverem fora dos limites

especificados. Veja a seção 12.

Deixe que o No-Break se adapte à temperatura ambiente antes de continuar.

4.3 Estratégias de Proteção

Este No-Break fornece proteção de linha de energia de alto desempenho para as cargas. Há,

entretanto, outros pontos de entrada potenciais para surtos nocivos em sistemas de informação.

Isso inclui portas seriais (RS-232, RS-422, RS-485, etc.), portas paralelas, linhas telefônicas e

conexões de rede. Esses outros pontos de entrada devem ser levados em consideração quando

você desenvolver uma estratégia de proteção de sistemas abrangente. Entre em contato com seu

fornecedor ou ligue para o número que está no início deste manual para obter informações

sobre um conjunto completo de produtos relacionados, projetados para que você obtenha total

proteção ao sistema.

34

Page 39

Sistemas de informação sensíveis podem ser mais protegidos se você seguir estas diretrizes:

■ Verifique se todas as tomadas estão aterradas de forma apropriada.

■ Conecte os sistemas de informação a ramais elétricos onde não haja cargas de motores

pesados como condicionadores de ar, copiadoras, geladeiras e equipamento industrial

pesado.

■ Conecte todo o equipamento de proteção de energia e os sistemas de informação no mesmo

ramal quando for possível.

4.4 Instalação de Acessórios (Opcional)

Alguns acessórios do No-Break são conectados à porta de interface do computador (DB-9),

enquanto outros são instalados no slot de acessórios. Consulte a documentação que acompanha

o acessório para determinar o tipo de instalação adequado. Os parafusos que prendem a tampa

do slot são do tipo Phillips nº 2.

Para usar a porta de interface do computador, conecte o acessório ao conector DB-9 e aperte os

parafusos do conector.

Conecte o pacote de baterias opcional (apenas para o modelo de 3000 VA) de acordo com as

instruções do pacote de baterias.

4.5 Conexão à Energia Externa

Português

Ligue o No-Break a apenas uma tomada terra trifilar e bipolar. Evite usar cabos de extensão e

plugues adaptadores.

4.6 Carregue a Bateria

O No-Break carrega sua bateria sempre que está conectado à energia externa. Para obter

melhores resultados, carregue a bateria por duas horas e meia antes de usá-la. É aceitável usar o

No-Break sem carregar a bateria primeiro, mas o tempo de funcionamento no modo de bateria

pode ser reduzido até que ela seja carregada.

35

Page 40

4.7 Conecte as Cargas

Conecte as cargas nos conectores de saída na parte de trás do No-Break. Para usar o No-Break

como uma chave mestra ligar/desligar, certifique-se de que todas as cargas estão ativadas.

Cuidado: Não conecte uma impressora a laser ao No-Break junto com outro equipamento de

computador, a menos que o No-Break seja de 1400 VA ou superior. Periodicamente, uma

impressora a laser exige uma quantidade muito mais significativa de energia do que quando está

ociosa, e pode sobrecarregar o No-Break. Verifique se o No-Break pode suportar as cargas

quando a impressora estiver em funcionamento (imprimindo).

Teste o sistema com todas as cargas operando para assegurar que o No-Break não está

sobrecarregado. Veja a seção 6.2.

4.8 Verifique o Indicador de Falha da Fiação Local

Depois de conectar todas as cargas e o No-Break, verifique o indicador de falha da fiação local no

painel traseiro. Veja a seção 3.2 para obter a localização do indicador no painel traseiro. Esse

indicador se acende se o No-Break estiver conectado a uma tomada de energia de CA instalada

de forma inadequada. Os problemas de fiação detectados incluem falta de aterramento, inversão

de polaridade fase-neutro e sobrecarga do circuito neutro.

Cuidado: Se o No-Break indicar uma falha da fiação local, chame um eletricista qualificado para

corrigir a fiação do local.

4.9 Conecte a Fiação de Aterramento ao Conector TVSS

(Opcional)

O No-Break apresenta um conector TVSS para conectar a fiação de aterramento a dispositivos de

supressão de surtos de voltagem transientes (TVSS - Transient Voltage Surge Suppression), como

protetores de linha de rede e de telefone. O conector TVSS proporciona aterramento através do

condutor de aterramento do cabo de força do No-Break.

Nota: Não use o conector TVSS se o indicador de falha da fiação local estiver aceso.

Para estabelecer uma conexão ao conector TVSS, solte o parafuso e conecte a fiação de

aterramento do dispositivo de supressão de surto. Veja a seção 3.2 para obter a localização do

conector. Aperte o parafuso para prender a fiação.

36

Page 41

5. Operação

5.1 Ligar

Com o No-Break conectado, pressione o botão Ligar/teste (superior) para fornecer energia às

cargas. As cargas são imediatamente ativadas enquanto o No-Break emite um “bip” e executa um

autoteste. Veja a seção 5.3.

5.2 Desligar

Para desligar a energia de saída do No-Break, pressione o botão de Desligar (inferior). Pode ser

conveniente usar os botões de Ligar e de Desligar do No-Break como uma chave mestra ligar/

desligar para o equipamento protegido.

Nota: O No-Break estará ligado (o processador interno estará funcionando) sempre que estiver

conectado à tomada e a voltagem externa estiver presente. Mesmo que esteja desligado, o NoBreak manterá a carga da bateria e responderá aos comandos recebidos através da porta de interface do computador e do slot de acessórios.

Português

5.3 Autoteste

Use o autoteste para verificar o funcionamento do No-Break e as condições da bateria. Com o NoBreak conectado à energia externa normal, ative o autoteste pressionando o botão Ligar/teste até

que o No-Break emita um “bip” e o LED de on-line comece a piscar.

37

Page 42

Nota: Por default, o No-Break executa um Autoteste no momento em que é ligado e uma vez a

cada duas semanas.

Durante o autoteste, o No-Break rapidamente verifica as cargas na bateria (o LED de bateria

ligada acende). Se o No-Break não encontrar nada errado durante o autoteste, ele retorna ao

modo de operação on-line. O LED de bateria ligada se apaga e o LED de on-line se acende de

forma constante.

Se o No-Break falhar no autoteste, ele retorna imediatamente ao modo de operação on-line e

acende o LED de substituição da bateria. As cargas não são afetadas. Recarregue a bateria durante

a noite e execute o autoteste novamente. Se o LED de substituição da bateria ainda estiver aceso,

consulte a seção 10 para obter informações sobre como substituir a bateria.

5.4 Indicadores de Carga

O mostrador com cinco LEDs à esquerda do painel frontal mostra a energia consumida através

do No-Break pela carga. O mostrador indica a percentagem da capacidade estimada do NoBreak. Por exemplo, se três LEDs estiverem acesos, a carga está consumindo entre 50% e 67% da

capacidade do No-Break.

Se todos os cinco LEDs estiverem acesos, teste todo o seu sistema cuidadosamente para se

certificar de que o No-Break não ficará sobrecarregado.

Se o No-Break estiver sobrecarregado, o LED de sobrecarga se acenderá e um alarme será

emitido. Veja a seção 6.2.

38

Page 43

5.5 Indicadores de Carga da Bateria

O mostrador com cinco LEDs à direita do painel frontal mostra a carga atual da bateria do NoBreak como uma percentagem da capacidade da bateria. Quando todos os cinco LEDs estiverem

acesos, a bateria estará completamente carregada. Quando o LED mais abaixo estiver piscando, a

bateria poderá fornecer menos de dois minutos de tempo de funcionamento para a carga.

5.6 Indicadores de Voltagem Externa

Este No-Break apresenta um recurso de diagnóstico que mostra a voltagem externa. Com o NoBreak conectado à energia externa normal, pressione e mantenha pressionado o botão Ligar/teste

para ver os indicadores de voltagem externa. Depois de 4 segundos o mostrador com cinco LEDs

à direita do painel frontal mostra a voltagem de entrada externa. Consulte a lista para saber a

leitura da voltagem.

O mostrador indica que a voltagem está entre o valor exibido na lista e o valor mais alto a seguir.

Por exemplo, com três LEDs acesos, a voltagem de entrada está entre 115 e 123 VAC.

Se nenhum dos LEDs acender e o No-Break estiver conectado a uma tomada de energia de CA

operacional, é porque a voltagem da linha externa está extremamente baixa.

Se todos os cinco LEDs estiverem acesos, é porque a voltagem de linha externa está

extremamente alta, e deverá ser verificada por um eletricista.

Nota: O No-Break iniciará um autoteste como parte desse procedimento. O autoteste não afeta o

mostrador de voltagem.

5.7 SmartBoost e SmartTrim

O No-Break corrige automaticamente voltagens externas altas ou baixas para que as cargas

recebam uma voltagem que esteja dento da variação normal.

Português

39

Page 44

O LED do SmartTrim do No-Break se acende para indicar que o No-Break está compensando

uma voltagem externa alta.

O LED do SmartBoost se acende para indicar que o No-Break está compensando uma condição

de voltagem externa baixa.

As indicações do SmartTrim e do SmartBoost são uma advertência. Não é necessária nenhuma

ação por parte do usuário. Para verificar a voltagem externa use o mostrador de voltagem

externa. Veja a seção 5.6.

5.8 Inicialização Fria

Quando o No-Break estiver desligado e não houver nenhuma energia externa, use o recurso de

inicialização fria para fornecer energia às cargas com a bateria do No-Break. Pressione o botão

Ligar/teste até que o No-Break emita um “bip”. Solte o botão durante o bip e as cargas estarão

energizadas em 4 segundos. A inicialização fria não é uma condição de funcionamento normal.

5.9 Sensibilidade da Voltagem

normal

reduzida

baixa

O No-Break detecta distorções na voltagem externa como picos, interrupções, quedas e

oscilações, assim como distorções causadas por operação com geradores de energia baratos

movidos a combustível. Por default, o No-Break reage às distorções passando para o modo de

operação com bateria para proteger as cargas. Quando a qualidade da energia é fraca, o No-Break

pode passar com freqüência para a operação com bateria. Se as cargas puderem funcionar

normalmente com bateria em tais condições, a capacidade da bateria e sua vida útil poderão ser

conservadas reduzindo-se a sensibilidade do No-Break.

40

Page 45

Para reduzir a sensibilidade do No-Break, pressione o botão de Configuração no painel traseiro.

Use um objeto pontiagudo como uma caneta para pressionar o botão. Pressione-o uma vez para

configurar a sensibilidade do No-Break como reduzida. Pressione-o novamente para configurar a

sensibilidade como baixa. Pressione o botão outra vez para voltar à sensibilidade normal.

Quando o No-Break estiver configurado para sensibilidade normal, o LED de configuração

apresentará uma luz intensa. Quando ele estiver configurado para sensibilidade reduzida, o LED

apresentará uma luz fraca. Quando ele estiver configurado para sensibilidade baixa, o LED ficará

apagado.

5.10 Intervalo do Aviso de Bateria Fraca

Por default, o aviso de bateria fraca ocorre quando restam aproximadamente dois minutos do

tempo de funcionamento da bateria. Este pode não ser um tempo suficiente para que você

desligue adequadamente alguns sistemas de computadores protegidos. Para mudar o intervalo de

aviso, pressione o botão de Configuração do painel traseiro junto com o botão Ligar/teste do

painel frontal. Use um objeto pontiagudo como uma caneta para pressionar o botão de

configuração.

Pressione o botão de configuração uma vez para definir o intervalo do aviso de bateria fraca para

aproximadamente cinco minutos. Pressione-o novamente para definir o intervalo em

aproximadamente sete minutos. Pressione outra vez para restaurar o intervalo para dois

minutos.

Quando você configurar o No-Break para um intervalo de aviso de dois minutos, o LED de

configuração apresentará uma luz brilhante. Quando você configurar o No-Break para um

intervalo de aviso de cinco minutos, o LED de configuração apresentará uma luz fraca. Quando

você configurar o No-Break para um intervalo de aviso de sete minutos, o LED de configuração

ficará apagado.

Português

5.11 Modo de Desligamento

No modo de desligamento o No-Break interrompe o fornecimento de energia para a carga,

esperando pelo retorno da energia externa. Se não houver nenhuma energia externa, os

dispositivos externos (por exemplo, servidores) conectados à interface do computador ou ao slot

de acessórios podem solicitar o desligamento do No-Break. Isso normalmente é feito para

preservar a capacidade da bateria depois do desligamento dos servidores protegidos. O No-Break

percorrerá os indicadores do painel frontal seqüencialmente no modo de desligamento.

41

Page 46

6. Alarmes

6.1 Com Bateria

No modo de operação com bateria, o LED de bateria ligada se acende e o No-Break emite um

alarme audível que consiste em quatro bips a cada 30 segundos. O alarme pára quando o NoBreak retorna ao modo de operação on-line.

Pressione o botão Ligar/teste durante os alarmes da bateria para interromper os sinais sonoros.

Isso funciona apenas para o alarme atual — o próximo alarme da bateria terá a indicação

audível. Desligar o alarme audível dessa forma não afeta o funcionamento do alarme através da

interface do computador ou do slot de acessórios.

6.2 Sobrecarga

Quando o No-Break está sobrecarregado (quando as cargas conectadas ultrapassam o máximo

listado na seção 12), o LED de sobrecarga se acende e o No-Break emite um som constante. O

alarme continua soando até que a sobrecarga seja removida. Para eliminar a sobrecarga,

desconecte do No-Break o equipamento de carga que não for essencial.

6.3 Substituição da Bateria

O No-Break emite “bips” curtos por um minuto e o LED de substituição de bateria se acende se

a bateria não passar no autoteste. O No-Break repete o alarme a cada cinco horas. Realize o

procedimento de autoteste da seção 5.3 para confirmar a condição de substituição da bateria. O

alarme irá parar quando a bateria passar no autoteste.

6.4 Bateria Fraca

Quando a bateria do No-Break estiver fraca, ele emitirá um bip continuamente até retornar ao

modo de operação on-line ou ser desligado devido ao término da bateria. O intervalo de aviso da

bateria fraca é um item de configuração. Veja a seção 5.10.

42

Page 47

7. Opções

7.1 Visão Geral