Page 1

g

g

y

y

g

y

y

y

g

g

g

gy

y

y

g

g

g

p

g

prop

Thank You!

Thank you for selecting the American Power Conversion SmartSlot Series

Measure-UPS II. It has been desi

nance-free service. Please read this manual! It provides installation and

operatin

Save this manual! It includes important instructions for the safe installation of

tor

instructions that will help you get the most from your accessory.

our accessory. Further, it includes instructions for obtaining fac-

service.

ned for many years of reliable, mainte-

Radio frequency interference

WARNING:

approved b

authorit

NOTE:

limits for a Class A di

These limits are desi

ful interference when the equipment is operated in a commercial environment. This equipment

ener

manual, ma

tion of this equipment in a residential area is likel

ference in which case the user will be required to correct the interference

at his own expense.

This di

emissions from di

tions of the Canadian Department of Communications.

Le présent appareil numérique n’émet pas de bruits radioélectriques

dépassant les limites applicables aux appareils numériques de la Class A

prescrites dans le Rè

ministère des Communications du Canada.

Chan

es or modifications to this unit not expressly

the party responsible for compliance could void the users

to operate the equipment.

This equipment has been tested and found to compl

ital device pursuant to Part 15 of the FCC Rules.

ned to provide reasonable protection against harm-

enerates, uses, and can radiate radio frequency

and, if not installed and used in accordance with the instruction

cause harmful interference to radio communications. Opera-

to cause harmful inter-

ital apparatus does not exceed the Class A limits for radio noise

ital apparatus set out in the Radio Interference Regula-

lement sur le brouillage radioélectrique édicté par le

with the

Entire contents copyright © 1995 American Power Conversion. All rights

reserved. Re

hibited. PowerChute is a re

Call-UPS, and the stylized APC logo are trademarks of APC. All other trademarks are

roduction in whole or in part without written permission is pro-

istered trademark of APC. SmartSlot, PowerNet,

erty of their respective owners.

Page 2

Contents

g

y

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

2 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

3 Operation Check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

4 Sensor Zone Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

5 Sensor Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

6 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

7 Troubleshootin

8 Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

9 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

10 Declaration of Conformit

11 Index. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Page 3

1. Introduction

g

g

y

y

The SmartSlot Measure-UPS II performs temperature and humidity

sensin

Measure-UPS II supports up to four zones of contact monitorin

of which supports both normall

Measure-UPS II reports temperatures from 0 to 60 °C (32 to 140 °F)

and relative humidit

Measure-UPS II model AP9612T includes:

Measure-UPS II model AP9612TH includes:

, as well as contact monitoring.

, each

open and normally closed contacts.

from 10 to 90%.

• Measure-UPS II SmartSlot UPS accessory

• Temperature probe (model AP9512T)

• Screw terminal connector for contact monitoring

• Hook and loop probe fasteners.

• The Measure-UPS II SmartSlot UPS accessory

• Combined temperature and humidity probe (model

AP9512TH)

• Screw terminal connector for contact monitoring

• Hook and loop probe fasteners.

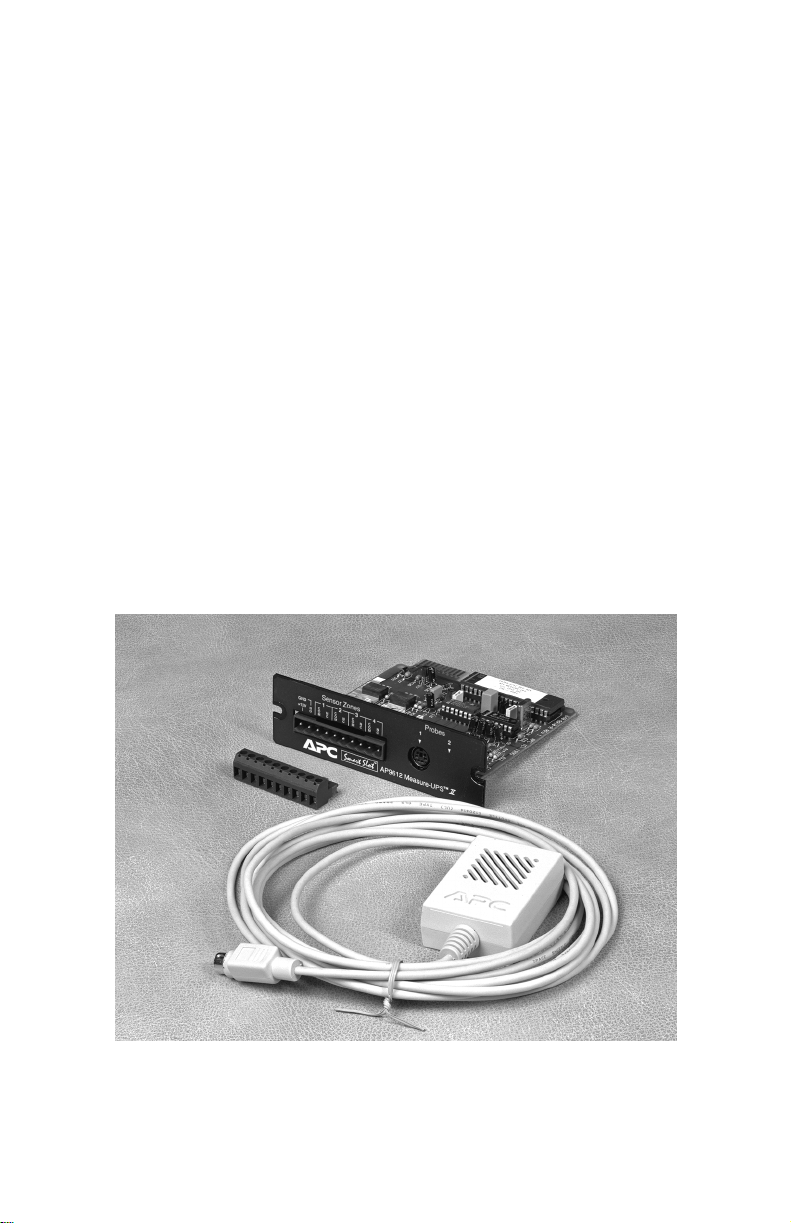

Figure 1, SmartSlot Measure-UPS II

Page 4

Safety Notice

y

y

gly

y

g

y

y

j

g

g

g

The SmartSlot Measure-UPS II UPS accessory is intended solely for

use in supplementar

mend this product for life or propert

in

sell Measure-UPS II for use in such applications. APC disclaims

all liabilit

described herein.

arising out of improper use of Measure-UPS II as

surveillance of equipment. APC does not recom-

protection. APC will not know-

Hardware and Software Compatibility

SmartSlot Measure-UPS II requires an APC device with a SmartSlot

as a host. This can be a UPS equipped with a SmartSlot, or a SmartSlot Expansion Chassis in combination with a UPS that supports the

Expansion Chassis.

Measure-UPS II also requires some means of reportin

can be an

Note

UPS II information when it is installed in con

PowerNet SNMP adapter or PowerNet SNMP a

SNMP Mana

within popular network mana

number on the back cover of this manual for more information.

one or a combination of the following:

• Call-UPS II™ Remote UPS Management Device

®

•PowerChute

software

• PowerNet SNMP adapter

• PowerNet SNMP agent.

: An

SNMP management system can read and use Measure-

er provides a high level graphical user interface for use

Plus UPS power management and diagnostic

unction with an APC

ement systems. Contact APC at the

its data. This

ent. PowerNet

Page 5

2. Installation

Use the following procedure to install SmartSlot Measure-UPS II:

1. Install and configure any software or hardware that will be used

with Measure-UPS II for data reporting (see software and hardware compatibility above).

2. Using figure 2 as a guide, install Measure-UPS II in the host

SmartSlot. Use a #2 Phillips head screwdriver to remove the host

device SmartSlot cover plate. Install Measure-UPS II. Replace the

cover plate screws. Note: Measure-UPS II is sensitive to static

electricity. Handle Measure-UPS II by the end plate only. Do not

touch the exposed printed circuit board. While it is not possible to

install Measure-UPS II upside down, it is possible to damage it in

the attempt. Note that the edges of the printed circuit board align

with the locating slots in the sides of the SmartSlot. The SmartSlot may be oriented horizontally or vertically in the host device.

The host device may be on or off during installation.

3. Connect the supplied probe to probe connector 1 on MeasureUPS II.

4. Place the probe where desired using the supplied hook and loop

fasteners, if needed. Note: The Measure-UPS II probe is designed

for use in a controlled environment. Place it in an area that is

within the environment limits set in the specifications (see section

9.) The location must be free from direct sunlight, excessive

moisture, and dust.

Note

: probe connector 2 is not used in Measure-UPS II.

Figure 2, SmartSlot installation

Page 6

Do not:

g

• Cover any of the ventilation holes on the probe

• Immerse the probe or place it where dew can be expected to

form

• Use the probe in an environment with chlorine gas or insecticides.

5. The contact monitoring connection is a two piece design. Connect

contact closure-type sensors to the removable screw terminal

block using the information in section 4 as a guide. The connector

accepts wire sizes from 14 AWG (1.6 mm2) to 26 AWG (.4

mm2). Strip the wire insulation 0.25" (6 mm). Connect the screw

terminal block to the Sensor Zones connector of Measure-UPS II.

See fi

ure 3 below for a completed installation.

Figure 3, completed installation

Page 7

3. Operation Check

1. Confirm the basic operation of Measure-UPS II. Use the data

reporting system (see hardware and software compatibility in section 1) to confirm that Measure-UPS II is working. W ith the probe

(temperature or temperature and humidity) connected to probe

connector 1, Measure-UPS II should transmit temperature or temperature and humidity values to the reporting system. Note:

Reported humidity values will be less than 2% RH when using the

temperature only probe. If the probe is not properly connected

both temperature and humidity readings will be very low.

2. Confirm contact sensing by activating each sensor in turn according to the sensor manufacturers recommendation. Use the data

reporting system to verify that each sensor operates as planned.

Page 8

4. Sensor Zone Connections

y

y

g

y

p

p

y op

y

y

y

y

Sensor Zones Connector Pinout

Pin Function

1

2

3 zone 1 common

4 zone 1 normall

5 zone 2 common

6 zone 2 normall

7 zone 3 common

8 zone 3 normall

9 zone 4 common

10 zone 4 normall

ower supply, +12 Vdc nominal, 60 mA max.

ower supply ground

and normall

en connection for all zones

closed

closed

closed

closed

Connection Information

Measure-UPS II supports normally open and normally closed loop

s

stems, and allows mixing of normally open and normally closed

sensors on an

usin

multiple sensors in one zone and for system hookup.

Note:

Do not cross connect sensors used with Measure-UPS II with

those of an

zone. See the figures below for more information on

other system.

Page 9

In order to avoid receiving alarm indications on unused zones, install a

j

g

y

umper wire between the COM and NC connectors for each unused

zone.

To use more than one sensor on a zone, follow the dia

Connect normall

in series.

open sensors in parallel and normally open sensors

ram below.

Page 10

See below for a typical hookup. Note that in this example system zone

y

y

y

1 is a normall

detector supplied b

Zone 3 is a combination normall

Zone 4 is not used.

closed motion zone with power for the passive infrared

Measure-UPS II. Zone 2 is a normally open zone.

open and normally closed zone.

Page 11

5. Sensor Selection

g

g

y

y

g

y

y

y

y

y

Measure-UPS II may be used with any dry contact closure type sensors. The Measure-UPS II sensor inputs are desi

cuits that have no volta

Measure-UPS II sensor inputs to an

t

pe will void the warranty and may result in damage to Measure-UPS

II.

In

eneral, any normally open (NO) or normally closed (NC) dry con-

tact sensor ma

• Magnetic contact switches

• Window foil

• Tamper switches

• Heat detectors

• Water sensors

• Pressure sensors

Additionall

detectors that need power. These t

• Passive infrared (body heat) detectors

•Smoke sensors

• Photo relay detectors

and 2 of the Sensor Zones connector for sensors that require power.

For more information in what sensors ma

Measure-UPS II, please call the APC PowerFax Interactive Fax S

tem at the number on the back cover of this manual. Request document number 1310. Or call technical support. See the back cover for

more information.

be used with Measure-UPS II. Such sensors include:

, Measure-UPS II provides a source of power for those

Measure-UPS II provides 12 Vdc at up to 60 mA at pins 1

e potential of their own. Connection of

circuit other than a dry closure

pes include:

ned to monitor cir-

or may not be used with

s-

Page 12

6. Maintenance

g

g sy

y

y

y ty

Measure-UPS II requires periodic maintenance. Confirm contact sensin

using the sensor manufacturers recommended intervals and methods. Use the data reportin

as planned.

Clean the temperature (or temperature and humidit

there is a visible buildup of dust. Gentl

Do not blow an

pe of compressed gas into the probe.

stem to verify that each sensor operates

) probe whenever

brush or vacuum off the dust.

Page 13

7. Troubleshooting

Problem Possible Cause Solution

Constant Alarm on

one or more unused

zones.

Constant low tem-

perature and humid-

ity readings.

No communication

with UPS or acces-

sories.

Unused zones not

jumpered.

12 Vdc supply (pin

1) shorted to ground

or overloaded.

Measure-UPS II has

failed.

Connect a wire

between the COM

and NC terminals of

all unused zones (see

section 4).

Correct short

circuit—examine all

sensors that use the

12 Vdc power

supply.

If removing Mea-

sure-UPS II from the

host cures the com-

munication problem

for other accessories,

call technical support at the number

on the back cover of

this manual.

Incorrect sensor

readings.

Always reports very

low temperature

and/or humidity.

Improper sensor

wiring.

Probe not connected

properly.

Correct sensor

wiring—see

section 4.

Connect probe

properly—see

section 2.

Page 14

8. Service

If the SmartSlot Measure-UPS II requires service:

1. Check Measure-UPS II using the troubleshooting chart in section

7 before calling for service.

2. Note the model number of the Measure-UPS II, the serial number,

and the date purchased. See the back cover of this manual for the

correct telephone number and call customer service. A technician

will ask you to describe the problem and help solve it over the

phone, if possible, or will give you an RMA#. If customer service

is not available in your area, call the dealer that sold the SmartSlot

Measure-UPS II. If Measure-UPS II is under warranty , repairs are

free. If not, there will be a charge for repair.

3. It is important to pack the SmartSlot Measure-UPS II properly to

avoid damage in transit. Damage sustained in transit is not covered under warranty.

4. Include a letter with your name, RMA#, address, copy of the sales

receipt, description of the trouble, your daytime phone number,

and a check (if necessary).

5. Mark the RMA# on the outside of the package. The factory cannot accept any package without this marking.

6. Return Measure-UPS II and its probe by insured, prepaid carrier

to the address given by the technician.

Page 15

9. Specifications

g

g

y

y

y

g

g

g

g

g

g

g

g

Electrical

SmartSlot specification compatible

Operatin

Operatin

Temperature accurac

Humidit

Sensor Zone input response time: 100 milliseconds

Power output: 12 Vdc nominal, 60 mA max.

Physical

Size (H x W x D): 4 x 4 x 1.5 inches

Wei

Shippin

voltage: 16 - 27 Vdc

current draw: 30 mAdc (exclusive of an

attached sensors)

: ±2° C (±3.6° F), from 0 to 40° C

(32 to 104° F)

accuracy: ±8% RH, 10 to 90% RH, at 25° C

(77° F);

±8% RH, 30 to 80% RH, from 15

to 30° C (from 59 to 95° F)

round referenced

(10.2 x 10.2 x 3.8 cm)

ht: 0.3 lb. (140 g)

weight: 0.7 lb. (320 g)

Environmental

Operating elevation: 0 to 3,000 m

Stora

e elevation: 0 to 15,000 m

Operatin

Stora

Probe operatin

temperature: 0 to 40 °C (32 to 104° F)

e temperature: 0 to 45 °C (32 to 113° F)

temperature: 0 to 60° C (32 to 140° F)

Approvals

EMC verification: FCC Class A, DOC class A,

EN55022 Class A

Electroma

netic immunity: EN50082-1 verified

Page 16

10. Declaration of Conformity

y

g

g

y

g

g

Application of Council Directives: 89/336/EEC

Standards to Which Conformit

Manufacturers Name: American Power Conversion

Importer’s Name and Address:

T

pe of Equipment: Measure-UPS II

Model Number: AP9612T, AP9612TH

Serial Numbers: A95050000001–A961299999999

Year of Manufacture: 1995, 1996

is Declared: EN55022, EN50082-1

132 Fair

West Kin

rounds Road

ston, RI 02892 USA

I, the undersi

conforms to the above directive(s).

Place: No. Billerica, MA USA Joseph Pomata,

Date: 6/1/95

ned, hereby declare that the equipment specified above

re

ulatory compliance engineer

Page 17

Limited Warranty

American Power Conversion (APC) warrants its products to be free from defects in

materials and workmanship for a period of two years from the date of purchase. Its obligation under this warranty is limited to repairing or replacing, at its own sole option, any

such defective products. To obtain service under warranty you must obtain a Returned

Material Authorization (RMA) number from APC or an APC service center. Products

must be returned to APC or an APC service center with transportation charges prepaid

and must be accompanied by a brief description of the problem encountered and proof

of date and place of purchase. This warranty does not apply to equipment which has

been damaged by accident, negligence, or misapplication or has been altered or modified in any way. This warranty applies only to the original purchaser who must have

properly registered the product within 10 days of purchase.

EXCEPT AS PROVIDED HEREIN, AMERICAN POWER CONVERSION MAKES

NO WARRANTIES, EXPRESS OR IMPLIED, INCLUDING WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. Some

states do not permit limitation or exclusion of implied warranties; therefore, the aforesaid limitation(s) or exclusion(s) may not apply to the purchaser.

EXCEPT AS PROVIDED ABOVE, IN NO EVENT WILL APC BE LIABLE FOR

DIRECT, INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES ARISING OUT OF THE USE OF THIS PRODUCT, EVEN IF ADVISED OF

THE POSSIBILITY OF SUCH DAMAGE. Specifically, APC is not liable for any

costs, such as lost profits or revenue, loss of equipment, loss of use of equipment, loss of

software, loss of data, costs of substitutes, claims by third parties, or otherwise.

Life support policy

Use of this equipment in life support applications where failure of this equipment can

reasonably be expected to cause the failure of the life support equipment or to significantly affect its safety or effectiveness is not recommended.

Loading...

Loading...