Page 1

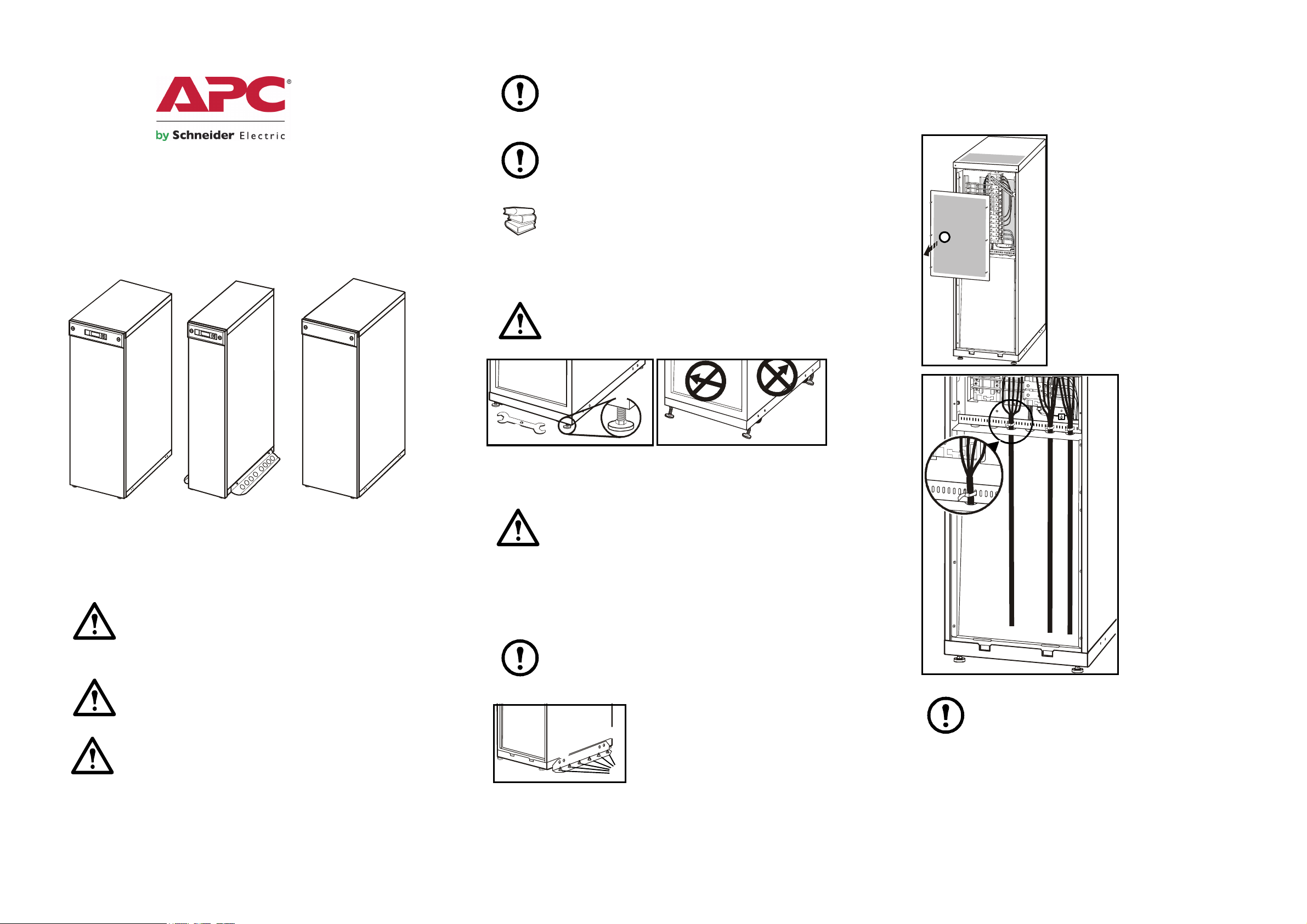

Installation

UPS

UPS

XR battery enclosure

Note: Ensure that the unit is in its final location prior to

installation.

Note: Battery and utility/mains power must not be

connected until all other wiring has been completed.

Prepare for Cables

Bottom cable entry

From the rear of the UPS, loosen the six

M4 screws from the upper cover (the cable

landing area) on the back and remove.

MGE™ Galaxy™ 3500

10-40 kVA 380/400/415 V with batteries

See Also: For parallel configurations see manual 990-

3568.

Level the Enclosure

Warning: The system must be installed on a level floor.

The leveling feet will stabilize the enclosure, but will not

account for a badly sloped floor.

Use a 13/14 mm wrench to adjust the four leveling feet.

Ensure that the system is level.

Caution: Do not move the enclosure after the leveling feet

have been lowered.

Route the cables from the

slanted back plate, up

through the punched

bracket, and into the cable

landing area.

Fasten the cables with

cable ties

IMPORTANT SAFETY INSTRUCTIONS

990-2258B-001

SAVE THESE INSTRUCTIONS

Warning: ALL safety instructions in the Safety Sheet

(990-2940) must be read, understood, and followed when

installing the UPS system. Failure to do so could result in

equipment damage, serious injury, or death.

Warning: After the UPS has been electrically wired, do

not start it up. Start-up is commissioned to authorized

personnel from Schneider Electric.

Caution: All electrical power and power control wiring

must be installed by a qualified electrician, and must comply

with local and national regulations for maximum power

rating.

*990-2258B-

9/2009

Floor Anchoring (if applicable)

Anchor the UPS enclosure to the floor

Note: Floor-anchoring bolts are not provided with the UPS.

Purchase the bolts locally (minimum size: M8). Follow the

specifications given by the manufacturer of the floor

anchoring system when bolting the UPS system to the floor.

Reuse the two transport brackets (one

on each side) that were used to secure the

UPS to the pallet during transport.

Drill two to six holes in the floor for

each bracket. Attach with bolts.

Note: A conduit box (part no. SUVTOPT001 or

SUVTOPT002) is available as an option.

Page 2

Connect the AC Input and AC

J108 pin connections:

1 Normally open EPO

2 Normally open EPO return

3 Normally closed EPO

4 Normally closed EPO return

5 +24 V SELV supply

6 SELV ground

J106 pin connections:

8 Ext. charging control return

7 External control of charging

6 Q3 active return

5 Q3 active

4 Battery measurement supply*

3 Battery unit quantity*

2 Max. battery temperature*

1 Battery measurement return*

* Should be used with MGE Galaxy

3500 XR Enclosures

Dual mains

Connect the Communication

Output Cables

Warning: Use compression type lugs ONLY.

Do not loosen or add cables to any factory preinstalled

cables on busbars. Use the front part of busbar for

connection only.

See Also: For different grounding configurations please

see manual 990-3606.

Single mains

Connect the AC input cables

and the neutral to the input

cable landings.

Connect the AC output

cables and the neutral to the

output cable landings.

Connect the ground cables to

the studs (earth symbol

beneath) using a screw.

Remove the

three busbars A,

B, and C by

removing two M6

screws from each

busbar.

Connect the AC

input cables and

the neutral to the

input cable

landings.

Connect the

bypass cables and

the neutral to the

bypass cable

landings.

Connect the

output cables and

the neutral to the

output cable

landings.

Cables

Warning: Make sure that the UPS is completely OFF as

the connectors are very close to the power busbars.

J106 (XR Battery Enclosure) and J108 (EPO)

Note: Use only 1-1½ mm² copper wire for the connection of

the Emergency Power Off (EPO) and other optional

equipment.

Note: The UPS must be connected to either a dry contact or

a 24 VDC EPO (Emergency Power Off) switch.

Note: The external EPO +24 VDC, 1500 mA circuit can be

supplied through other vendors.

Note: Always follow the pin connection procedures from

the top and work down: J106 (8-1), J108 (1-6).

Connect the

ground cables to

the studs (earth

symbol beneath)

using a screw.

Connect the DC Battery Cables

(if applicable)

Connect battery cables BAT+,

BAT–, and N to the battery cable

landings.

2

Page 3

EPO wiring – pin connections J108. Connect the EPO cable using

J108

1: Dry Contacts Normally Open

J108

EPO circuit

J108

EPO circuit

J108

EPO circuit

2: +24 V Normally Open

EPO is activated when an isolated SELV 24

VDC voltage is supplied on pin 1 with

reference to pin 2.

Connections: 3-5 and 4-6.

3: Dry Contacts Normally Closed

EPO is activated when a connection from

pin 3 to pin 5 is opened.

Connections: 4-6.

4: +24 V Normally Closed

EPO is activated when a SELV 24 VDC

voltage is removed from pin 3 with

reference to pin 4.

EPO circuit

+24 V

0 V

+24 V

0 V

EPO is activated when pin 1 is connected

to pins 3 and 5.

Connections: 2-4-6,

3-5 and 1 ( )

J106

Q3 switch

Charging control

switch

J200 (XR

Batteries)

Pins 1 to 4 are for battery measurement (only applicable to

MGE Galaxy 3500 XR Battery Enclosures (see J200 drawing).

Pins 5 and 6 are for external maintenance bypass Q3

(auxiliary switch N/C type).

When Q3 is closed, signals are fed back to the UPS controller

(see Q3 drawing).

Pins 7 and 8 are for external charge control. When 7 and 8 are

closed, the UPS charges batteries with a pre-defined

percentage (0-25-50-75-100%) of the maximum charging

power. To be used in generator applications, or if special

codes require control of charging.

When Q3 is closed, signals are fed back to the UPS

controller.

BATBA

T

XR battery enclosure

J200

Model:

Serial:

BATTER

Y U

NIT

Model:

Serial:

BATTER

Y U

NIT

Model:

Serial:

BATTER

Y U

NIT

Model:

Serial:

BATTER

Y U

NIT

Model:

Serial:

BATTER

Y U

NIT

Model:

Serial:

BATTERY U

NIT

Model

:

Serial:

BATTER

Y U

NIT

Model:

Serial:

BATTERY U

NIT

one of the following four wiring configurations.

Note: When connecting the Q3 auxiliary signal, use goldplated N/C auxiliary switch.

Front panel removal.

Use a coin or similar to

turn the two black lock

devices on either side of the

display in the direction of

each other to a vertical

positon.

Push the front panel

upwards and pull it outwards

to disengage the locking

device at the top of the

enclosure.

Lift the front panel free of

the two slots at the bottom of

the enclosure.

Pin connections J106 (UPS).

Note: Reinstall the cable landing cover.

Connect APC communication options

Note: The cable routing of the power chute software and

the temperature sensor is identical.

Note: The temperature sensor is provided in a plastic bag

attached to the front of the UPS behind the front panel.

3

Page 4

Remove the two screws

Network

Management

card

from the cable-inlet at the

front and remove the cable-

inlet plate.

Guide the cable through

the hole in the bottom plate

and up through the cable-

inlet.

Guide the cable through

the side panel hole and run

the cable upwards inside the

panel.

Specifications

Warning: The UPS must be supplied from a 380/220 V,

400/230 V or 415/240 V L1, L2, L3, N, PE, 50 Hz.

AC input

10 kVA

UPS ratings 380 V 400 V 415 V

Input frequency (Hz) 40-70 40-70 40-70

Nominal input current (A)

1

13.0 12.3 11.9

AC output

10 kVA

UPS ratings 380 V 400 V 415 V

Nominal output current (A) 15.2 14.4 13.9

15 kVA 20 kVA

UPS ratings 380 V 400 V 415 V 380 V 400 V 415 V

Nominal output current (A) 22.8 21.7 20.9 30.4 28.9 27.8

Pull the cable out of the

side panel through the hole

closest to the Network

Management Card area.

Plug the cable into the

probe socket / PowerChute

inlet.

Reattach the cable-inlet

plate (

).

Max. input current (A)

Input current limit (A)

UPS ratings 380 V 400 V 415 V 380 V 400 V 415 V

Input frequency (Hz) 40-70 40-70 40-70 40-70 40-70 40-70

Nominal input current (A)

Max. input current (A)

Input current limit (A)

UPS ratings 380 V 400 V 415 V 380 V 400 V 415 V

Input frequency (Hz) 40-70 40-70 40-70 40-70 40-70 40-70

2

3

15 kVA 20 kVA

1

19.4 18.5 17.8 26.0 24.7 23.8

2

21.4 20.3 19.6 28.6 27.2 26.2

3

25.2 25.2 25.2 33.8 33.8 33.8

30 kVA 40 kVA

14.3 13.5 13.1

16.8 16.8 16.8

30 kVA 40 kVA

UPS ratings 380 V 400 V 415 V 380 V 400 V 415 V

Nominal output current (A) 45.6 43.3 41.7 60.8 57.7 55.6

Battery input

UPS ratings

Nominal voltage (V) ± 192 ± 192 ± 192 ± 192 ± 192

External battery fuse (A) 125 125 125 125 125

10 kVA 15 kVA 20 kVA 30 kVA 40 kVA

1.6-1.75 V/cell (automatic, depending on load)

Nominal input current (A)

Max. input current (A)

Input current limit (A)

2

3

1

38.6 36.7 35.3 51.7 49.1 47.3

42.5 40.3 38.9 56.8 54.0 52.1

50.1 50.1 50.1 66.9 66.9 66.9

4

Page 5

Bypass input

∞∞∞∞∞

Recommended current protection

Minimum breaker settings

10 kVA

UPS ratings 380 V 400 V 415 V

Input frequency (Hz)

Nominal input current (A)

4

1

50±10 or

60±10

50±10 or

60±10

50±10 or

60±10

15.2 14.4 13.9

15 kVA 20 kVA

UPS

ratings

Input

frequency

(Hz)

Nominal

380 V 400 V 415 V 380 V 400 V 415 V

50±10 or

60±10

4

50±10 or

60±10

50±10 or

60±10

50±10 or

60±10

50±10 or

60±10

22.8 21.7 20.9 30.4 28.9 27.8

input

current

1

(A)

30 kVA 40 kVA

UPS

ratings

Input

frequency

(Hz)

Nominal

380 V 400 V 415 V 380 V 400 V 415 V

50±10 or

60±10

4

50±10 or

60±10

50±10 or

60±10

50±10 or

60±10

50±10 or

60±10

45.6 43.3 41.7 60.8 57.7 55.6

input

current

1

(A)

Notes

1

Input current based on rated load and batteries fully charged.

2

Input current based on full battery recharge, nominal voltage and rated load.

3

Current limitation through electronic current limiting is based on full battery

recharge and low input voltage.

4

Synchronization adjustable: ± 10Hz, ± 3Hz or ± 0.1Hz.

50±10 or

60±10

50±10 or

60±10

Note: AC input/output over-current protection and AC

input/output disconnect must be provided by the customer

1

Q1

Q3 Q2

Utility input Bypass input Output

10 kVA

15 kVA

20 kVA

30 kVA

40 kVA

1

Required upstream current protection, mains input: gL type fuse.

16 16 16

25 25 25

35 35 35

50 50 50

63 63 63

.

Recommended cable sizes

Note: The recommended cable sizes are based on an

environment with an ambient temperature of 30°C.

Battery input

2

[mm

] 75ºC

Wire

10 kVA

15 kVA

20 kVA

30 kVA

40 kVA

Mains input

2

[mm

]

AC output

[mm2]

2.5 2.5 50 2.5

66506

10 10 50 10

16 16 50 16

25 25 50 25

Note: Use Molex lug type or equivalent, and crimp to

manufacturer’s specifications.

Warning: At 100% switch mode load, the neutral must

be rated for 200% phase current.

Bypass input

2

[mm

]

125%

overload

normal/

battery

operation Continuously

800%

overload

bypass

operation

150%

overload

normal/

battery

operation

10 kVA

Mains input –

1

–– 16.4 A

Bypass input 121.5 A – – 16.7 A

Output 121.5 A 22.8 A 19 A 16.7 A

Duration 500 ms 60 s 10 min.

15 kVA

Mains input –

1

–– 24.6 A

Bypass input 182 A – – 25.1 A

Output 182 A 34.2 A 25.4 A 25.1 A

Duration 500 ms 60 s 10 min.

20 kVA

Mains input –

1

–– 32.5 A

Bypass input 244 A – – 33.4 A

Output 244 A 45.6 A 38 A 33.4 A

Duration 500 ms 60 s 10 min.

30 kVA

Mains input –

1

–– 49.1 A

Bypass input 364 A – – 50.1 A

Output 364 A 68.4 A 57 A 50.1 A

Duration 500 ms 60 s 10 min.

40 kVA

Mains input –

1

–– 65.6 A

Bypass input 487 A – – 66.9 A

Output 487 A 91.2 A 76 A 66.9 A

Duration 500 ms 60 s 10 min.

1

At single feed use the higher value of mains and bypass.

Recommended lug size and torque value

Note: Power terminal lug diameter: 6 mm. Torque value: 7

Nm.

5

Page 6

Contact Information

Diagram with Maintenance

Bypass Panel

Diagram without

Maintenance Bypass Panel

For local, country-specific centers: go to www.apc.com/support/

contact.

Appendix

Wiring diagrams

6

Loading...

Loading...