BroadBand CTFLE Series

Metered Power Supply Enclosure

User Manual

990-5522 03/2003

Chapter 1 General Information

The CTFLE Series Metered Power Supply Enclosure provides a power source for broadband cable

operations. The enclosure is designed for mounting on the ground.

Safety

This Safety Guide contains important instructions that should be followed during installation and

maintenance of the APC equipment and batteries. It is intended for APC customers who setup,

install, relocate, or maintain APC equipment.

Changes and modifications to this unit not expressly approved by APC could void the

warranty.

Failure to observe these warnings may result in serious injury, death or damage to the

equipment.

Electrical

Warnings

Lifting

Warnings

Do not work alone under hazardous conditions.

Do not handle any metallic connector before the power has been disconnected.

Servicing this equipment may require working with protective covers removed

and utility power connected. Use extreme caution during these procedures.

High current through conductive materials could cause severe burns.

When grounding cannot be verified, disconnect the equipment from the utility

power outlet before installing or connecting to other equipment. Reconnect the

power cord only after all connections are made.

Check that the power cord(s), plug(s), and sockets are in good condition.

Replacement of fuses or other parts must be with identical types and ratings.

Substitution of nonidentical parts may cause safety and fire hazards.

These units are heavy. Use proper lifting techniques and equipment to avoid

injury.

1

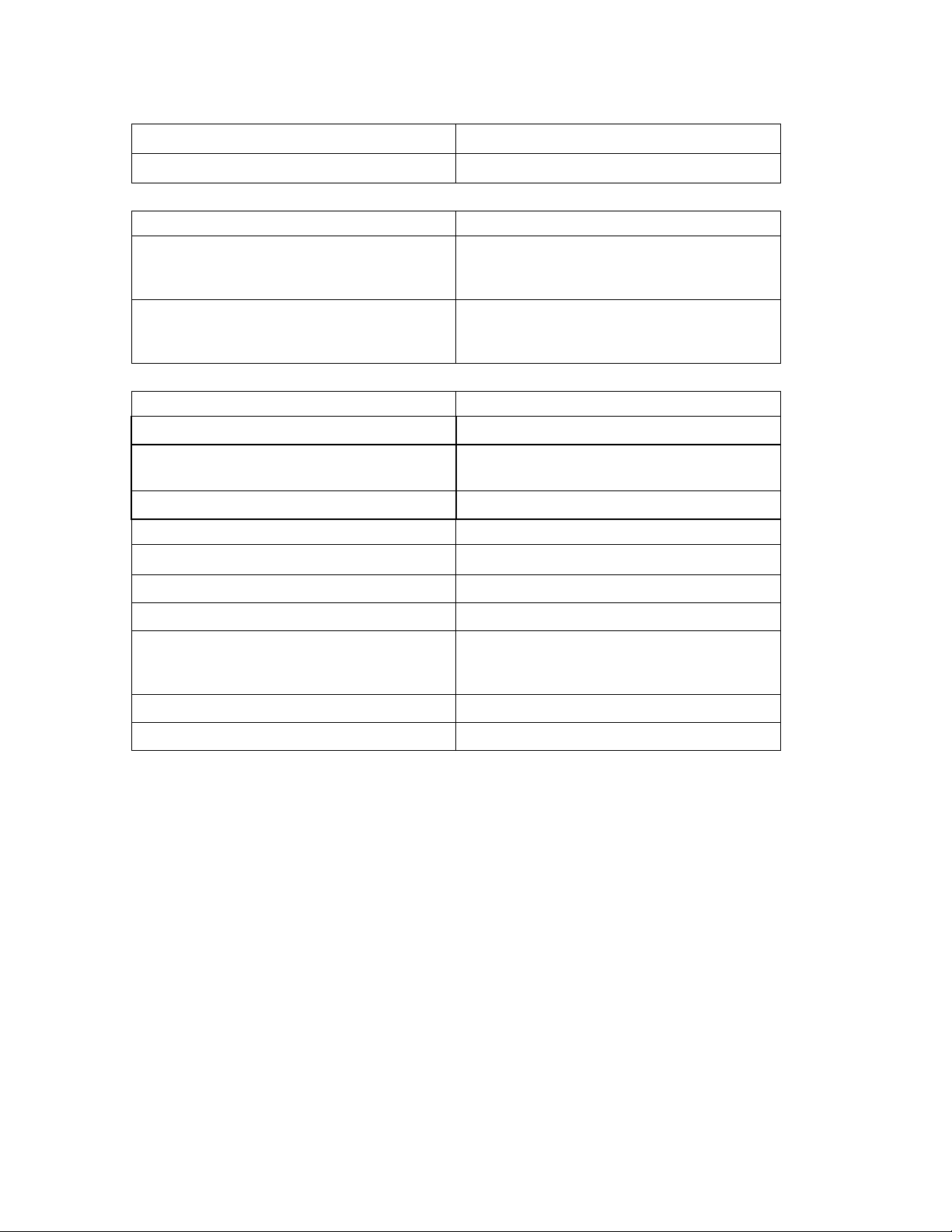

Specifications

Environmental Specifications

Operating Temperature

Humidity

Physical Specifications

Characteristic Specification

Height X Width X Depth

CTFLEH150

CTFLEH500

Weight

CTFLEH150

CTFLEH500

Electrical Specifications

Input Characteristic Input Specification

Input Voltage 120 Vac

Input Current

Input Frequency 60 Hz ± 1 Hz

Output Characteristic Output Specification

Output Voltage Fixed 60 Vac

Output Current 60 Vac @ 15 A

-40º F to 140º F (-40º C to 60º C)

5% to 95% noncondensing within enclosure

36” x 9.5” x 11” (91cm x 24 cm x 28 cm)

50” x 9.5” x 11” (127 cm x 24 cm x 28 cm)

20 lbs (9 kg)

27 lbs (12 kg)

15 A Max

Output Frequency 60 Hz

Output Regulation

Normal

Standby

Output Protection

Transfer Time

2

± 3%

± 5%

20 A Circuit Breaker (optional)

<20 milliseconds

Cable

Chapter 2 Installation and Maintenance

Only trained service personnel should install and maintain the power supply.

Prior to installation, utility line voltage must be routed to the enclosure. Local, state, federal and/or

National Electric Code (NEC) regulations regarding location, permits and electrical wiring must be

adhered to.

Do not operate the power supply where the temperature and humidity are outside the specified limits.

See Specifications in this manual.

Unpacking

Inspect the unit upon receipt. Notify the carrier if there is damage.

The packaging is recyclable; save it for reuse or dispose of it properly.

Check the package contents. The package contains the enclosure and product documentation.

Models Supported

Model Number Description

CTFLEH150 ENCL, CTFLE Series, 36”, Metered

CTFLEH500 ENCL, CTFLE Series, 50”, Metered

CTFLE Enclosure Installation

Ensure the utility circuit breaker is OFF.

1. Set the CTFLE near the installation site.

2. Remove the screws that secure the front panels and

the top section on the enclosure.

3. Unlock the bottom panel. When unlocked this panel

will drop off the CTFLE easily.

4. Lift the top section off the CTFLE.

5. Remove the CTFLE floor plate and use as a template

to mark the locations for the mounting stakes.

6. Remove enough topsoil so that when installed, the

enclosure will sit one inch below grade.

Note: Position the stakes so that the utility and coax

cables will enter through the bottom of the enclosure.

4. Bolt the floor plate onto the stakes.

5. Set the enclosure on the floor plate and replace the

bolts securing the CTFLE to the floor plate.

6. Install conduit over the utility and coax cables inside

the CTFLE.

3

y

Meter Installation

1. Use the meter cabinet as a template and

mark the mounting holes in the CTFLE.

Note: Mark the holes so that the meter

indicator is visible through the window in the

top panel.

2. Drill the holes.

3. Mount the meter in the CTFLE.

CTFLM 6009/6015 Installation

1. Insert the CTFLM into the enclosure so that

the guide pins on the CTFLM and the

CTFLE engage.

2. Push the CTFLM until a light “snap” is felt

as the contacts lock into place.

3. Pull lightly on the CTFLM. If properly

seated the CTFLM will not easily disengage.

Note: Connecting power to the CTFLM will

be done in a later step.

Circuit Breaker Installation

1. Use the circuit breaker box as a template and

mark the mounting holes in the CTFLE.

2. Drill the holes.

3. Mount the meter in the CTFLE.

Circuit Breaker

Box

Cable Coax Cable

Utilit

Meter

CTFLM

4

Wiring

Install an approved 20 A high-magnetic utility circuit breaker.

1. Refer to the diagram below for wiring details.

• Connect the black and white wires from the incoming utility line.

• Route the power feed coax to the bottom of the enclosure and attach to the coax cable

adapter using a pin connector.

• Attach the stinger lug to the pin connector center pin.

• Attach suitable solid copper ground wire to the enclosure ground lug and ground in

accordance with local codes.

• Check for voltages between each connector pin and ground using a multimeter.

Presence of voltage indicates an improper ground. If voltage is present ensure the

ground contact is secure.

• Reinstall the panels on the CTFLE.

Connect the CTFLM

Refer to the User Manual 990-5501 packaged with the CTFLM for connecting and operating

instructions.

5

Chapter 3 Troubleshooting and Maintenance

Troubleshooting Power Supply Failure

Problem Possible Cause Solution

Power Supply

Failure

No input voltage detected at connector J1, pins

1 and 2.

Replace the wiring harness

Input voltage present at connector J1, pins 1

and 2.

No input voltage at the black and white wires

Disconnect power from the

supply

Replace the Euro block

input lines.

Input voltage present at the black and white

Replace the wiring harness.

wires input lines.

Reconnect power to the CTFLM.

Power Supply

No voltage at the Coax stinger. Replace the CTFLM module

Failure

Maintenance

Routine Maintenance Schedule

Operation Interval

Visual Inspection

External Surfaces

Connectors

Operator Controls

Wiring/Cable Assemblies

Cleaning

External Surfaces

External Controls/Receptacles

Internal Receptacles/Circuit Boards

Semiannually

Annually

Annually

Annually

Annually

Annually

Annually

Performance Verification

Refer to Initial Startup in the manual

Semiannually

6

Routine Maintenance Procedures

• Visual Inspection

• Check external surfaces, connectors, indicators and wiring/cable assemblies for signs of

dirt, wear, and damage.

• Cleaning

• Brush dust from controls and receptacles using a small paintbrush.

• Wipe surfaces with clean, dry cheesecloth.

• Clean exterior surface with clean cheesecloth moistened with isopropyl alcohol or a

general purpose detergent.

NOTE: Do not allow cleaning solution into the interior of the enclosure or into any connectors.

• Clean electrical contacts with approved spray-type contact cleaner.

Clean internal receptacles and circuit boards with hand controlled, dry-air jet (not more than 15

lb/in²), clean cheesecloth moistened with isopropyl alcohol. Wipe dry with clean, dry cheesecloth.

Replacement Procedures

• Wiring Harness Replacement

• Switch the utility circuit breaker OFF.

• Open the door(s) of the enclosure.

• Switch the CTFLM OFF.

• Remove the CTFLM.

• Disconnect the stinger lug from the pin connector, center pin.

• Disconnect the stinger lug from the pin connector center pin.

• Disconnect the utility wires and the ground wires.

• Remove the two quick disconnect connectors from the top of the indicator lamp socket.

• Remove the module connector plate by removing the Phillips head screws located on

the front and back of the enclosure.

• Slide the module connector plate and harness to the left and out of the harness plate.

• Slide the replacement connector plate and harness onto the harness plate and replace the

screws.

• Reattach the ground wires.

• Replace the quick disconnects on the indicator lamp socket.

• Reconnect the utility wires and the stinger lug.

• Close the front door of the enclosure.

7

• Reinstall the CTFLM. Ensure the module is seated properly.

• Switch the CTFLM and the utility circuit breakers ON.

• Complete Performance Verification. Refer to Initial Startup in this manual.

• Replace the top door of the enclosure.

• Indicator Lamp Replacement

Gently pry the lens off the indicator lamp using the tip of a screwdriver.

NOTE: Place a hand over the lens as it is loosened to ensure that the lens is not lost during the

procedure.

• Remove the spent lamp and replace it with a new one.

• Snap the lens back into place.

Euro Block Replacement

Switch the utility circuit breaker OFF.

Remove the doors to the enclosure.

Remove the CTFLM.

Disconnect (and tag), the wiring harness and utility wires from the Euro block.

Remove the screws that secure the Euro block in the enclosure, and lift out the Euro block.

Insert the new Euro block and secure it in the enclosure.

Reconnect the wiring harness to the Euro block.

Reinstall the CTFLM.

Replace the doors on the enclosure.

Switch the utility circuit breaker ON.

Complete Performance Verification. Refer to Initial Startup in this manual.

8

Chapter 4 Service, Contact and Warranty Information

Service

APC makes every effort to ensure parts and equipment arrive in working condition. Occasionally, it

may be necessary to return parts or equipment that are not in working condition.

If the unit requires service do not return it to the dealer. Instead, follow these steps:

1. Contact APC Customer Service through the APC web site, www.apc.com/support

Note the product model number, the serial number, and the date purchased. If you call APC

.

Customer Service, a technician will ask you to describe the problem and try to solve it over

the phone. If this is not possible the technician will issue a Returned Material Authorization

Number (RMA#).

If the product is under warranty, repairs are free. If not, there is a repair charge.

Procedures for servicing or returning products may vary internationally. Refer to the APC

web site. Select the appropriate country from the country selection field. Select Support

from the tab at the top of the web page.

2. Pack the product in its original packaging.

Pack the unit properly to avoid damage in transit. Never use Styrofoam beads for packaging.

Damage sustained in transit is not covered under warranty.

3. Mark the RMA# on the outside of the package.

4. Return the unit by insured, prepaid carrier to the address given to you by Customer Service.

How to Contact APC

In the USA … Outside the USA …

Refer to the APC web site,

www.apc.com/support.

Refer to the APC web site, www.apc.com. Select the appropriate

country from the country selection field. Select Support from the

tab at the top of the web page.

9

Limited Warranty

American Power Conversion (APC) warrants its products to be free from defects in materials and workmanship for a period of

two years from the date of purchase. Its obligation under this warranty is limited to repairing or replacing, at its own sole

option, any such defective products. To obtain service under warranty you must obtain a Returned Material Authorization

(RMA) number from customer support. Products must be returned with transportation charges prepaid and must be

accompanied by a brief description of the problem encountered and proof of date and place of purchase. This warranty does

not apply to equipment that has been damaged by accident, negligence, or misapplication or has been altered or modified in

any way. This warranty applies only to the original purchaser who must have properly registered the product within 10 days of

purchase.

EXCEPT AS PROVIDED HEREIN, AMERICAN POWER CONVERSION MAKES NO WARRANTIES, EXPRESSED OR

IMPLIED, INCLUDING WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

Some states do not permit limitation or exclusion of implied warranties; therefore, the aforesaid limitation(s) or exclusion(s)

may not apply to the purchaser.

EXCEPT AS PROVIDED ABOVE, IN NO EVENT WILL APC BE LIABLE FOR DIRECT, INDIRECT, SPECIAL,

INCIDENTAL, OR CONSEQUENTIAL DAMAGES ARISING OUT OF THE USE OF THIS PRODUCT, EVEN IF

ADVISED OF THE POSSIBILITY OF SUCH DAMAGE. Specifically, APC is not liable for any costs, such as lost profits or

revenue, loss of equipment, loss of use of equipment, loss of software, loss of data, costs of substitutes, claims by third parties,

or otherwise.

Regulatory Approval

Entire contents copyright © 2003 by American Power Conversion Corporation. All rights reserved. Reproduction in whole or

in part without permission is prohibited.

APC is a registered trademark of American Power Conversion Corporation. All other trademarks are the property of their

respective owners.

10

Loading...

Loading...