Page 1

MGETM GalaxyTM 9000

50, 60 Hz

800 - 900 kVA

Installation manual

Single-unit UPS

Modular UPS

Parallel UPS with SSC

Frequency converters

Static Switch Cubicle

Page 2

34006451EN/AC - Page 2

Page 3

Contents

1. Characteristics

1.1 Characteristics common to all cubicles ............................................................................................ 4

1.2 Rectifier-inverter cubicle .................................................................................................................... 5

1.3 Static Switch Cubicle ........................................................................................................................... 5

1.4 Electrical parameters for selecting protective devices ................................................................... 6

1.5 Electrical parameters for determining cable cross-sections .......................................................... 7

2. Installation (to be carried out by qualified personnel only)

2.1 Handing .............................................................................................................................................. 10

2.2 Positioning the cubicles .................................................................................................................. 10

2.3 Floor loads (figure 5) ........................................................................................................................11

2.4 Cubicle layout on false floor or normal floor (figures 6, 7, 8) ........................................................11

2.5 Power circuit wiring diagrams ......................................................................................................... 13

2.6 Cubicle mounting and connection ................................................................................................... 17

2.7 Connection of power circuits ........................................................................................................... 19

2.8 Connection of "Media Contacts 9" standard auxiliary circuits (figure 16) ................................... 22

2.9 Connections between cubicles (modular UPSs or parallel UPSs with SSC) .............................. 23

2.10 Connections between rectifier-inverter cubicles and external maintenance bypass cubicle .26

2.11 Connection of "Media Contacts 15" additional auxiliary circuits

(figure 22) ................................................................................................................................... 27

2.12 Connection of the battery "Temperature Monitor" (optional) ...................................................... 28

2.13 Connection of the "LED" remote indications unit ....................................................................... 30

2.14 Connection of "Tele Monitor" remote control and indication unit (option) .............................. 30

2.15 Final installation steps .................................................................................................................. 30

3. Appendix (to be carried out by qualified personnel only)

3.1 Mains 2 line protection ..................................................................................................................... 31

3.2 Cubicle mounting and connection for 2000 kVA Static Switch Cubicle ....................................... 32

3.3 Details of earthing connections in the various cubicles ................................................................ 35

34006451EN/AC - Page 3

Page 4

1. Characteristics

1.1 Characteristics common to all cubicles

TM

MGE

GalaxyTM 9000 UPS: example of a rectifier-inverter cubicle

A

V

k

5

%

12

20

1

.

in

%

M

00

50

1

r

u

0%

Ho

0

1

0

0%

8

%

0

5

VA

0 k

%

0

5

00 40

60

XY

LA

GA

0

IQ

LE

el

AL

v

S

e

l

d

a

o

L

0

e

m

Ti

p

u

ck

a

B

d

le

e

t

b

c

la

e

i

t

a

v

ro

A

p

d

a

o

L

N

5

d

Q

a

e

o

t

L

n

om

e

H

m

ip

qu

e

s

m

r

a

l

A

1

Q

e

n

i

nl

O

1

F

Q

nd

e

r

T

C

l A

a

m

r

s

c

o

i

t

N

is

t

a

t

S

r

fie

ti

ec

R

S

y

r

4

e

Q

tt

a

B

05

20

5/

/0

0

3

er

t

2

r

3

e

C

4:

A

nv

2

I

:

s

5

s

1

a

p

y

B

P

B

s

Q3

s

a

yp

B

t

u

p

t

u

O

p

t u

e

S

Galaxy 6000

m

w

w

w.m

ge

u

ps

.co

H

L

P

0

0

0

VA

6

k

5

y

0%

12

2

1

x

la

a

Min.

0

00%

G

1

our 5

0%

0

H

1

0

%

w

w

80

w

.

m

g

e

u

p

s

.

c

o

m

%

0

5

A

%

0

400 kV

5

0

00

6

Y

AX

AL

G

0

IQ

E

L

vel

SAL

e

ad l

Lo

0

e

m

up Ti

k

c

a

B

d

e

l

e

t

b

a

l

ec

t

o

vai

r

p

A

d

Loa

N

5

Q

ad

o

t

L

n

Home

equipme

s

m

r

a

l

A

Q1

ne

i

l

n

O

1

QF

nd

e

r

T

s

c

i

t

Normal AC

tis

a

t

S

er

i

tif

c

Re

S

ry

4

e

Q

t

t

Ba

05

0

2

/

5

0

0/

3

r

e

t

2

r

3

e

:

4

AC

nv

2

I

15:

ypass

B

BP

s

Q3

s

ypa

B

put

t

u

O

p

u

t

e

S

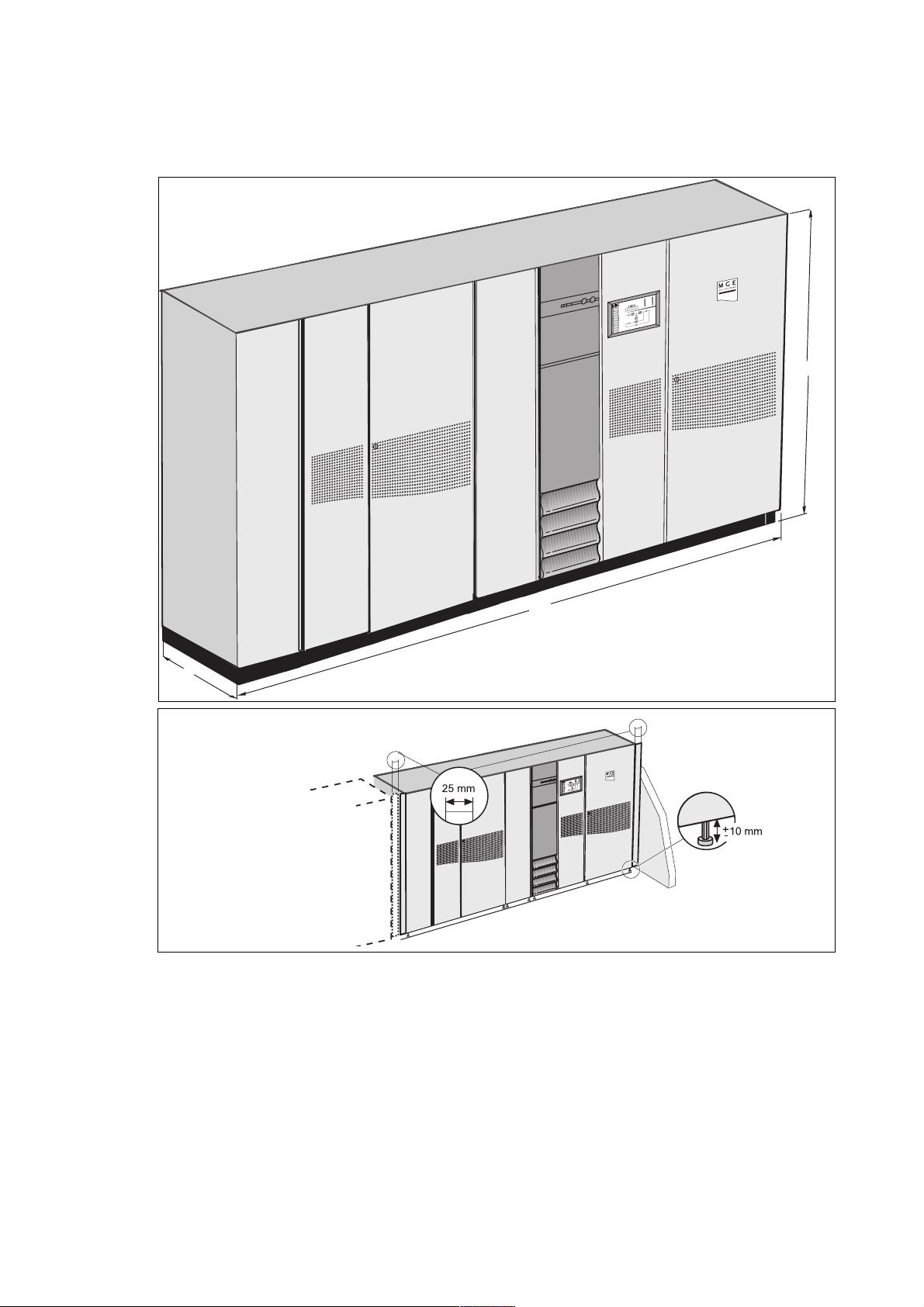

After moving them to their installation location on their pallets, MGE

pallet-mover when the front, rear and side base panels are not mounted. The forks can be inserted from all four sides into 100 mm ±10 mm

TM

GalaxyTM 9000 cubicles can be moved short distances using a forklift or

high openings;

the unadjusted cubicle height (H) is 1900/2000 mm; after lifting the cubicle, the height can be adjusted ±10 mm by screwing in or out the four

feet;

the bearing surface corresponds to the area of the four cylindrical foot pads (60 mm diameter) positioned in each corner

of the cubicle;

the cubicle depth (D) is 840 mm (800 mm without doors and panels);

operating temperature range for rectifier-inverter, frequency converter or Static Switch Cubicles: 0 °C to 35 °C at rated output (40 °C for a

maximum of 8 hours) and 30 °C maximum for overload conditions. Operation outside the specified temperature range will reduce service life;

relative humidity: 95 % maximum;

maximum operating altitude without derating: 1000 m;

connection via the bottom for rectifier-inverter cubicles, or via the top with the addtion of an optional duct that can be installed on the right side

of the cubicle. The auxiliary and Static Switch Cubicles are designed for connections via the top

or bottom.

the connection cables may be run in three ways:

in a trench running under the cubicles,

under a false floor,

on the floor under the cubicles, in the free space equal to the height of the feet; in this case the cables should be run side by side to avoid

blocking the flow of air for ventilation.

the intercubicle connection cables are not supplied (except for the wires for auxiliary interconnections);

normally the cubicles do not have to be secured to the floor; the footpads nevertheless have holes with an average depth of 12 mm designed

for the fitting of M16 anchor bolts;

the cubicle doors are secured by Ronis locks (key 405).

34006451EN/AC - Page 4

Page 5

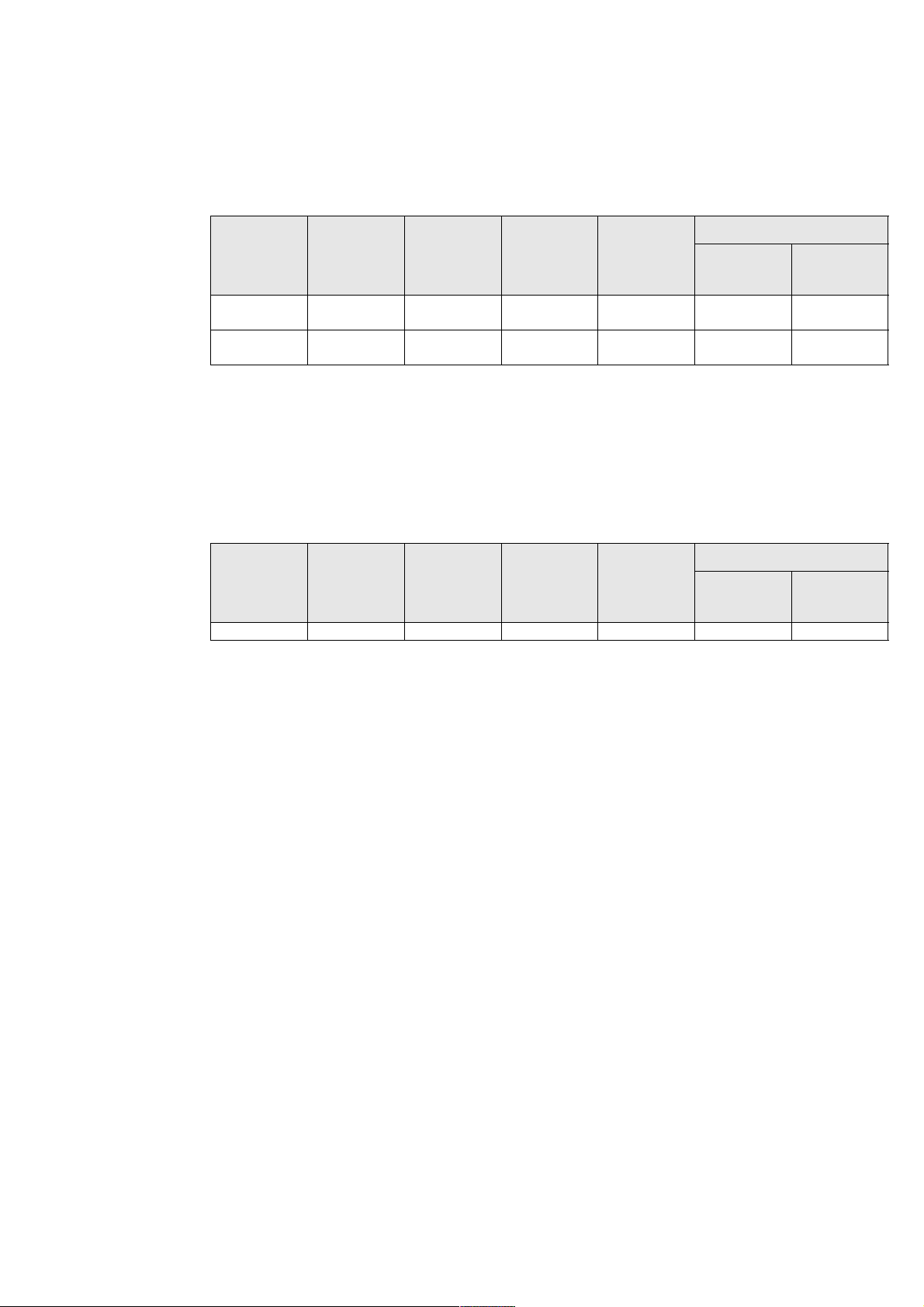

1.2 Rectifier-inverter cubicle

The parameters given in the table opposite can be used to determine the required rating of a single-unit or modular UPS, a

frequency converter, or a parallel UPS with SSC.

Characteristics of rectifier-inverter cubicles

Characteristics

rated

inverter

output

in kVA

800 3600 ±10 2000 840 4260 47 11233

900 3600 ±10 2000 840 4260 47 11233

(1) the width of the vertical side clearance bars (25 mm) on each side must be added to the indicated cubicle width, i.e. 50 mm in

all per cubicle. This applies to all cubicle installation cases. Cubicle widths have been rounded off to the nearest cm.

(2) the indicated heat losses are those produced by the unit at full rated load and with the battery float charging. They must be

taken into account when dimensioning the air conditioning system. The cubicles are cooled by forced ventilation.

The air enters via the doors and grids at the bottom and is discharged via the roof.

1.3 Static Switch Cubicle

Characteristics of Static Switch Cubicles

rated

SSC

output

in kVA

2000 2450 ±10 1900 ±10 840 1710 < 0.5 < 120

(1) 25 mm must be added on each side to the indicated cubicle width, i.e. 50 mm in all per cubicle. This applies to all cubicle

installation cases. Cubicle widths have been rounded off to the nearest cm.

(2) the indicated heat losses are those produced by the unit at full rated load when operating on Mains 2. They are not to be taken

into account when dimensioning the air conditioning system. The cubicles are cooled by forced ventilation.

cubicle

width W

in mm (1)

cubicle

width W

in mm (1)

cubicle

height H

in mm

cubicle

height H

in mm

cubicle

depth D

in mm

cubicle

depth D

in mm

maximum

weight

in kg

maximum

weight

in kg

heat losses (2)

in kW in cal./s

heat losses (2)

in kW in cal./s

34006451EN/AC - Page 5

Page 6

Characteristics

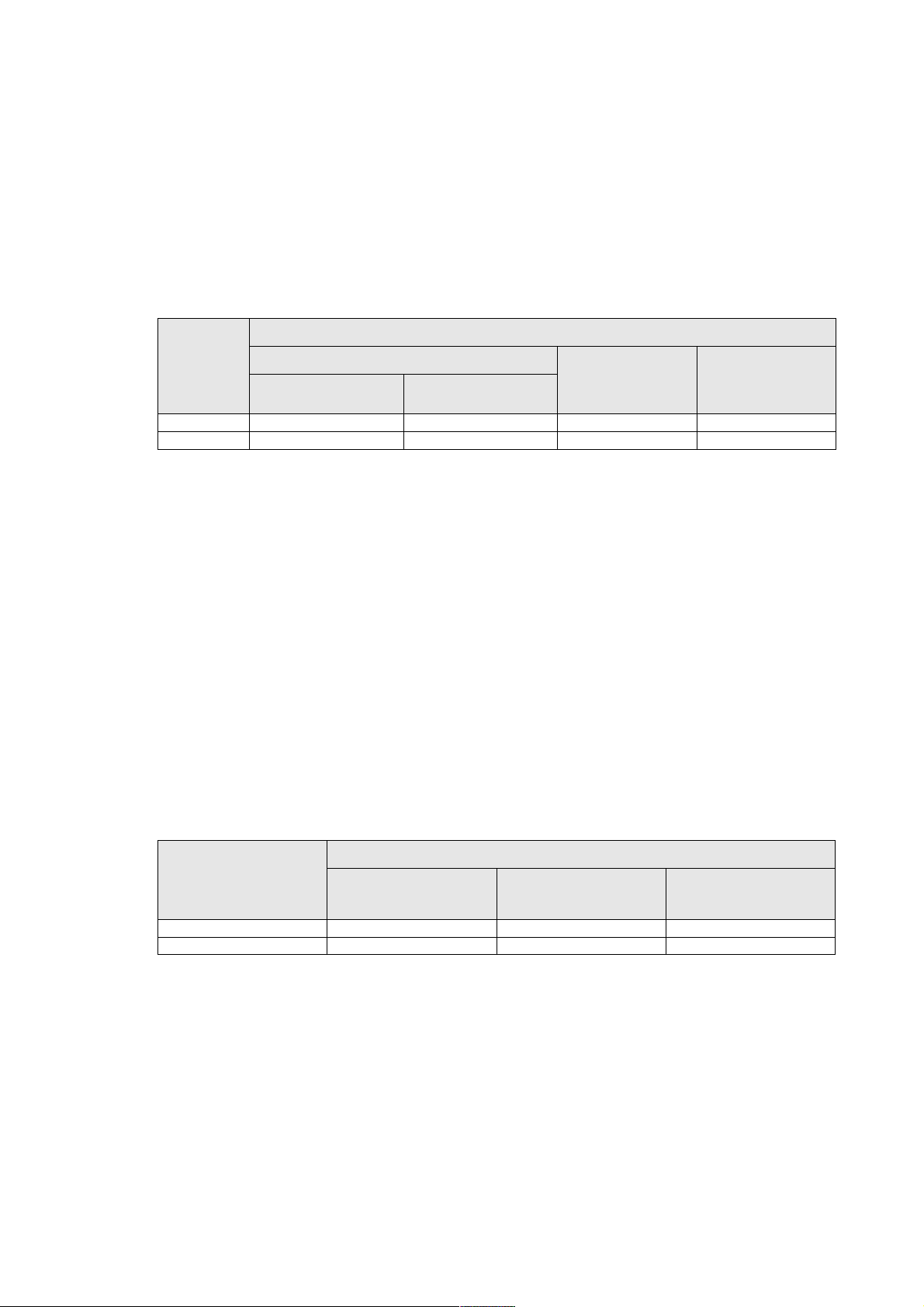

1.4 Electrical parameters for selecting protective devices

The parameters given in the table below can be used to determine the required rating of the source side protective circuit

breaker on Mains 1 of a single-unit or modular UPS, a frequency converter, or a parallel UPS with SSC.

Important:

It is essential to choose the type of circuit breaker according to its breaking capacity and the prospective short-circuit current

at its place of installation.

Note:

For Mains 1 power supply voltages of 380, 400 and 415 V, the Mains 1 current is the same because it is a function

of the DC voltage.

Electrical parameters for Mains 1

rated

inverter

output

in kVA

800 1555 1329 1819 2183

900 1555 1329 1819 2183

(1) the rated Mains 1 currents (In) have been determined for a rated phase-to-phase voltage of 380 V to 415 V, a battery with a

15 minute backup time (206 cells at 2 V per cell, i.e. 412 V) and at the beginning of its recharge cycle, and full rated load with a

power factor of 0.9.

(2) the rated Mains 1 currents (In) have been determined for a minimum float charging voltage of 423 V and full rated load with

a power factor of 0.9.

(3) the Mains 1 currents given for an overload of 25 % or 50 % are maximum values. They have been determined for a battery

drawing the minimum float charging voltage and a load power factor of 0.9. When choosing the circuit breaker rating, use the

"rated current" column and check that the circuit breaker tripping curves are compatible with the values in the overload columns.

The parameters given in the table below can be used to determine the required rating of the source side protective circuit

breaker on the Mains 2 line for a single-unit or modular UPS.

Important:

– It is essential to choose the type of circuit breaker according to its breaking capacity and the prospective short-circuit current

at its place of installation.

This choice must also be made so as to protect the static switch semiconductors and ensure discrimination with respect to

the UPS output fuses (refer to "appendix" chapter).

– For an installation with a Static Switch Cubicle, the Mains 2 currents indicated in the table must be multipled by the number

of parallel-connected rectifier-inverter cubicles required to supply the load power (i.e. without taking redundant rectifierinverter units into account).

Remark:

If the installation includes a transformer on the Mains 2 input, allow for the inrush current caused by magnetization of the

transformer windings.

Mains 1 current

rated current In for unit: for 25 %

with battery at start

of charge cycle (1)

without battery (2)

overload (3)

for 50 %

overload (3)

Electrical parameters for Mains 2 (415 V)

rated

inverter

output

in kVA

800 1155 1444 1733

900 1299 1624 1949

(1) the Mains 2 currents have been determined for a rated phase-to-phase voltage of 415V, a load power factor of 0.9 and for full

rated load as well as overloads of 25 % or 50 %. When choosing the circuit breaker rating, use the "rated curent" column and check

that the circuit breaker tripping curves are compatible with the data in the overload columns.

For a Mains 2 voltage of 380 V, multiply the currents indicated in this table by 1.09.

For a Mains 2 voltage of 400 V, use the table in another language version of this manual.

Mains 2 current (1)

rated current In for 25 %

overload

for 50 %

overload

34006451EN/AC - Page 6

Page 7

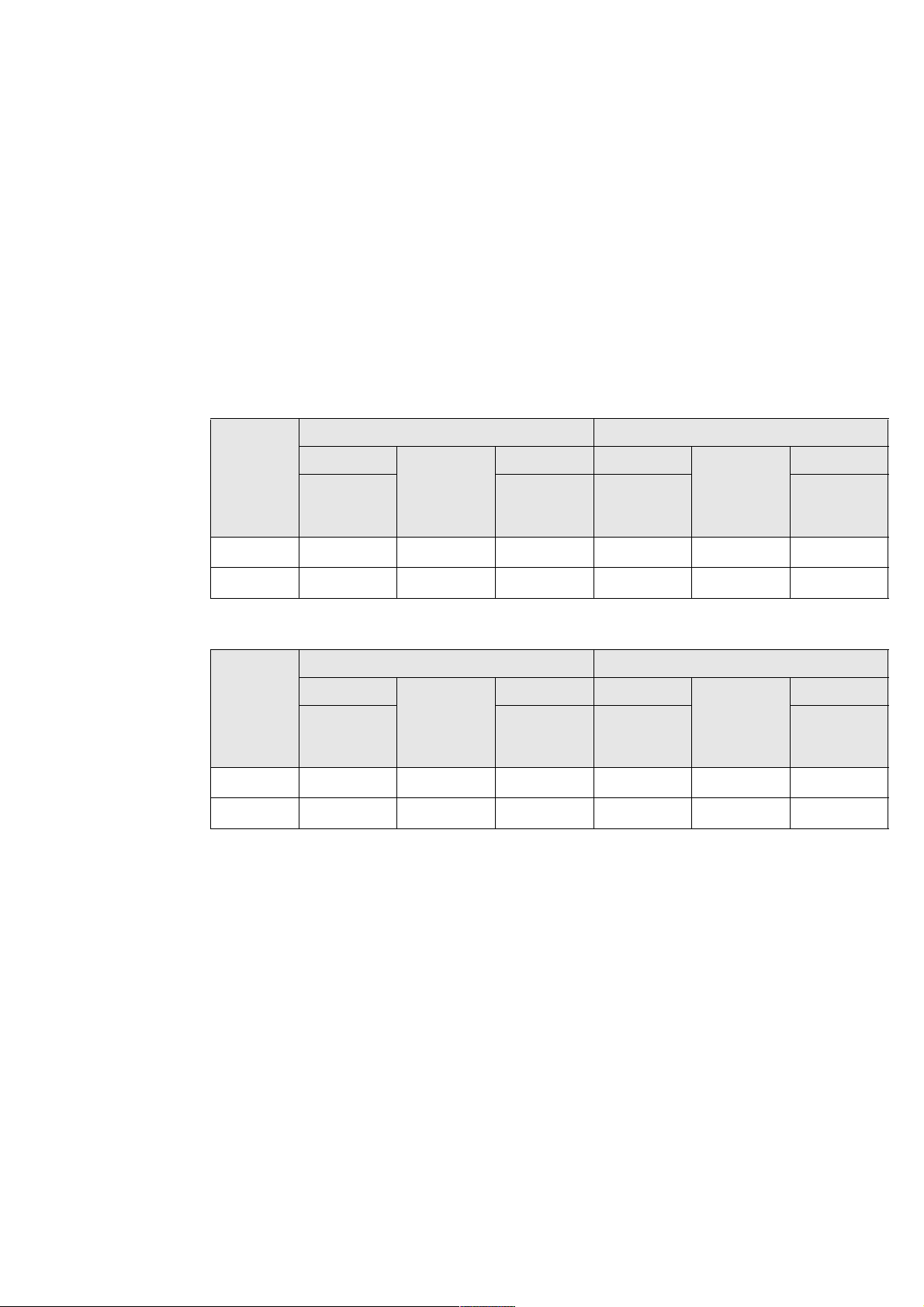

1.5 Electrical parameters for determining cable cross-sections

– this table has been drawn up for rated phase-to-phase Mains and load voltages of 415 V. For voltages of 380 V, multiply

the currents for Mains 2 and load by 1.09; for voltages of 400 V, use the table in another language version of this manual;

– the current values and cable cross-sections for Mains 1 are given for full rated load with a power factor of 0.9 and a battery

consuming its minimum float charging voltage;

– the battery current values and cable cross-sections have been determined for a battery at the end of a charge cycle;

– the current values and cable sections for Mains 2 and load are given for full rated load with a power factor of 0.9.

For frequency converters, the parameters concerning Mains 2 are not applicable.

The load parameters common to all the converters are given in the table below.

For a parallel UPS, the parameters for Mains 2 and load are also provided in the table below.

For a modular UPS, the parameters for Mains 2 and load are also provided in the table below.

Parameters for single-unit UPS cables

Copper conductors

rated

inverter

output

in kVA

800 1455 1155 2274 4 x 240 4 x 185 3 x 240

line currents absorbed in Amps cross-sectional area of cables in mm2 (2)

Mains 1 415 V

with or

without

battery (1)

Mains 2

and load

battery Mains 1 415 V

with or

without

battery (1)

Characteristics

battery

Mains 2

and load

900 1455 1299 2274 4 x 240 4 x 240 3 x 240

Aluminium conductors

rated

inverter

output

in kVA

800 1455 1155 2274 4 x 400 4 x 300 3 x 400

900 1455 1299 2274 4 x 400 4 x 400 3 x 400

(1) the rated Mains 1 currents (In) have been determined for a minimum float charging voltage of 423 V and full rated load with a

power factor of 0.9.

(2) the cable cross-sections are calculated according to permissible temperature rise and allow for line voltage drops over a

maximum length of 100 m (AC circuits) or 25 m (DC circuits if cables not provided). For greater lengths, the cross-sections should

be chosen to limit voltage drops to 3 % (AC)

or 1 % (DC).

line currents absorbed in Amps cross-sectional area of cables in mm2 (2)

Mains 1 415 V

with or

without

battery (1)

Mains 2

and load

battery Mains 1 415 V

with or

without

battery (1)

Mains 2

and load

battery

34006451EN/AC - Page 7

Page 8

Characteristics

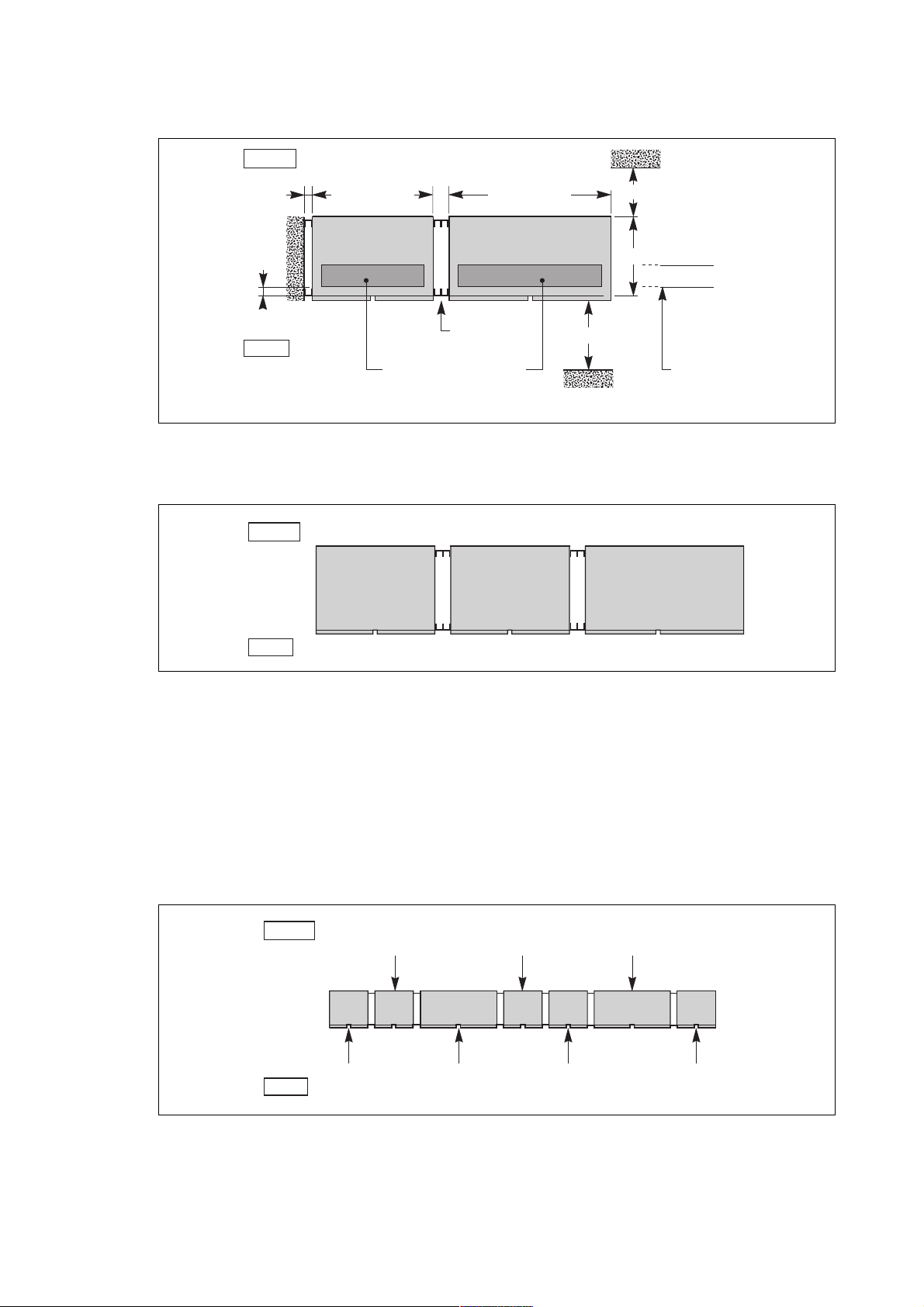

The table below serves as an example for an installation comprising up to four frequency converters or four parallel UPSs

with a centralised SSC.

– for installations with redundant units, take into account only the units required to supply the load power

(e.g. for an installation made up of 3 parallel-connected rectifier-inverter cubicles, one being redundant, only 2 rectifierinverter cubicles are used to determine Mains 2 and load currents and cable cross-sections);

– this table has been drawn up for rated phase-to-phase Mains 2 and load voltages of 415 V and full rated load with a power

factor of 0.9. For voltages of 380 or 400 V, multiply the indicated currents by 1.09 and 1.04 respectively, then modify the cable

cross-sections accordingly if necessary.

The cable cross-sections in this table are for the parts illustrated in bold on the following block diagrams (installation examples,

figures 1 and 2).

Parameters for Mains 2 and load cables for an installation comprising frequency converters or parallel

UPSs with a centralised SSC.

rated

inverter

output

number of

parallel-connected

inverters

total UPS

rated output

in kVA

Mains 2 or load

line current

in Amps

cable

cross-section (1)

in mm²

in kVA

800 2 1600 2310

3 2400 3465

4 3200 4620

900 2 1800 2598

3 2700 3897

4 3600 5196

(1) cable cross-sections are given for copper conductors of the U1000 R02V type (increase by 30 % for aluminium conductors).

They are calculated according to permissible temperature rise and allow for line voltage drops over a maximum length of 100 m.

For greater lengths, the cross-sections should be chosen to limit voltage drops to 3 %.

Please consult us*

Please consult us*

Please consult us*

Please consult us*

Please consult us*

Please consult us*

* NF C 15-100 authorizes a maximum of 4 cables per phase.

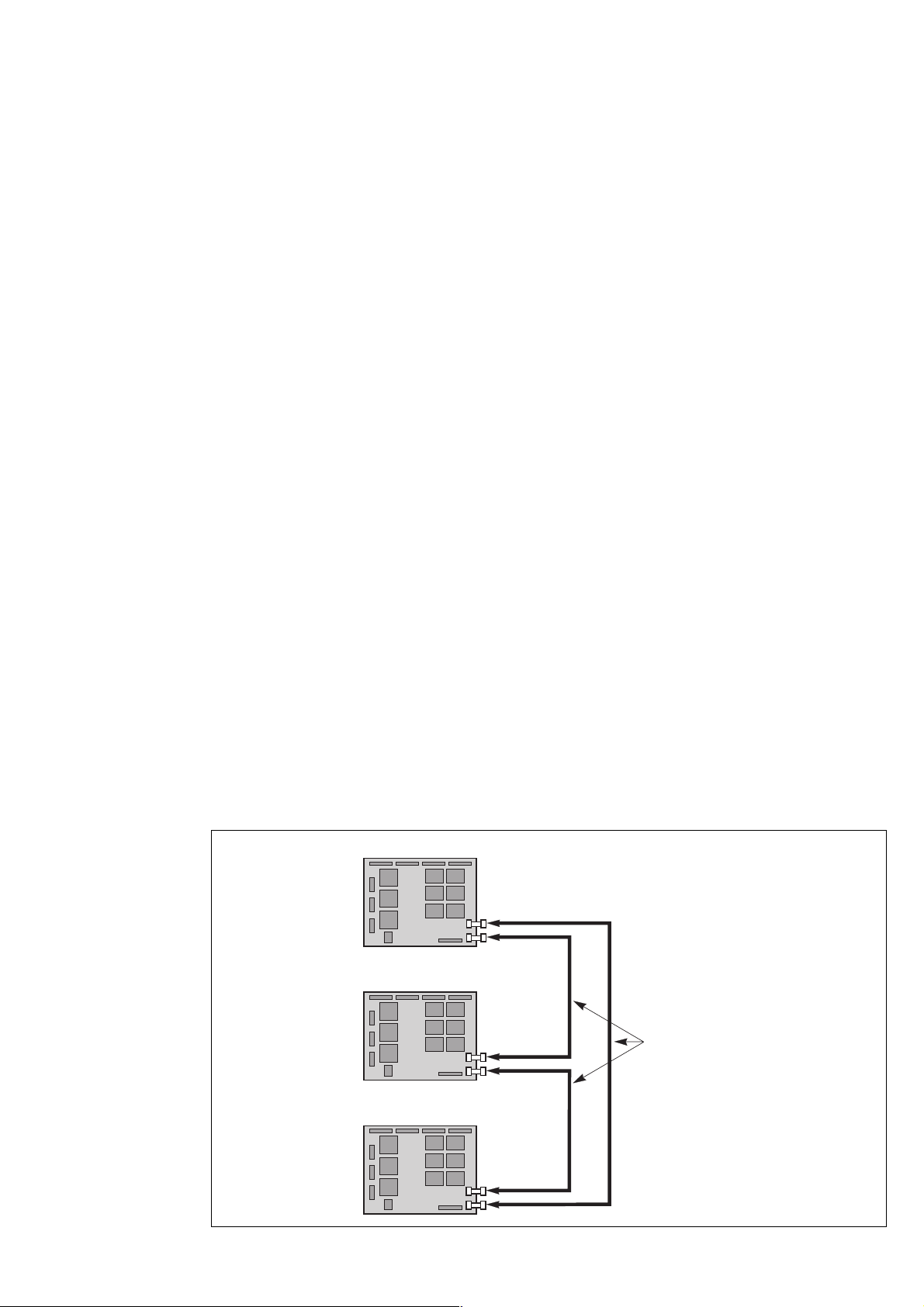

Installation with parallel frequency converters I

mains 1

mains 1

mains 1

inverter 1

inverter 2

inverter 3

load

Fig. 1

Installation with parallel UPSs with a centralised SSC

mains 2

mains 1

mains 1

mains 1

Fig. 2

inverter 1

inverter 2

inverter 3

static

switch

cubicle

load

34006451EN/AC - Page 8

Page 9

Characteristics

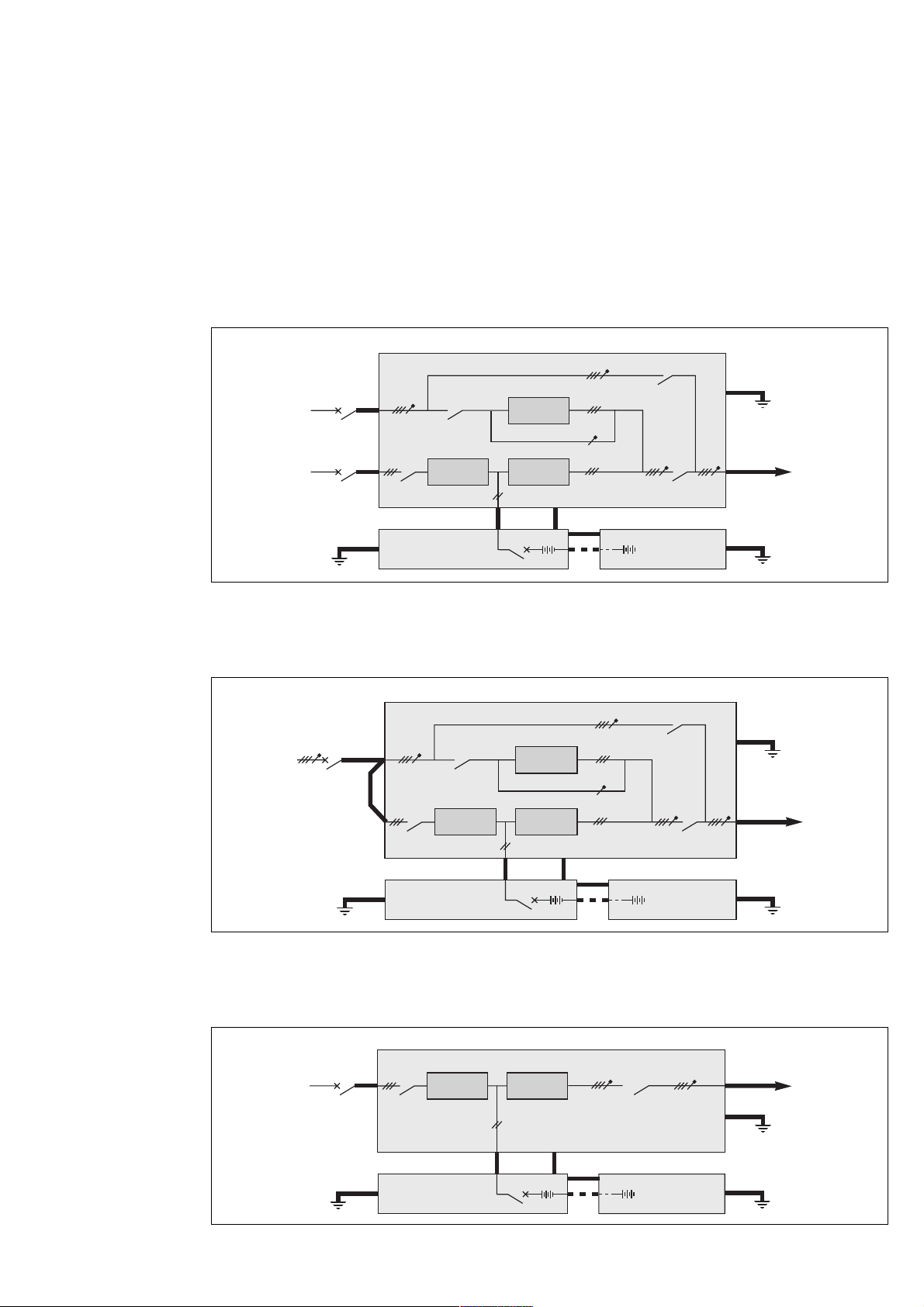

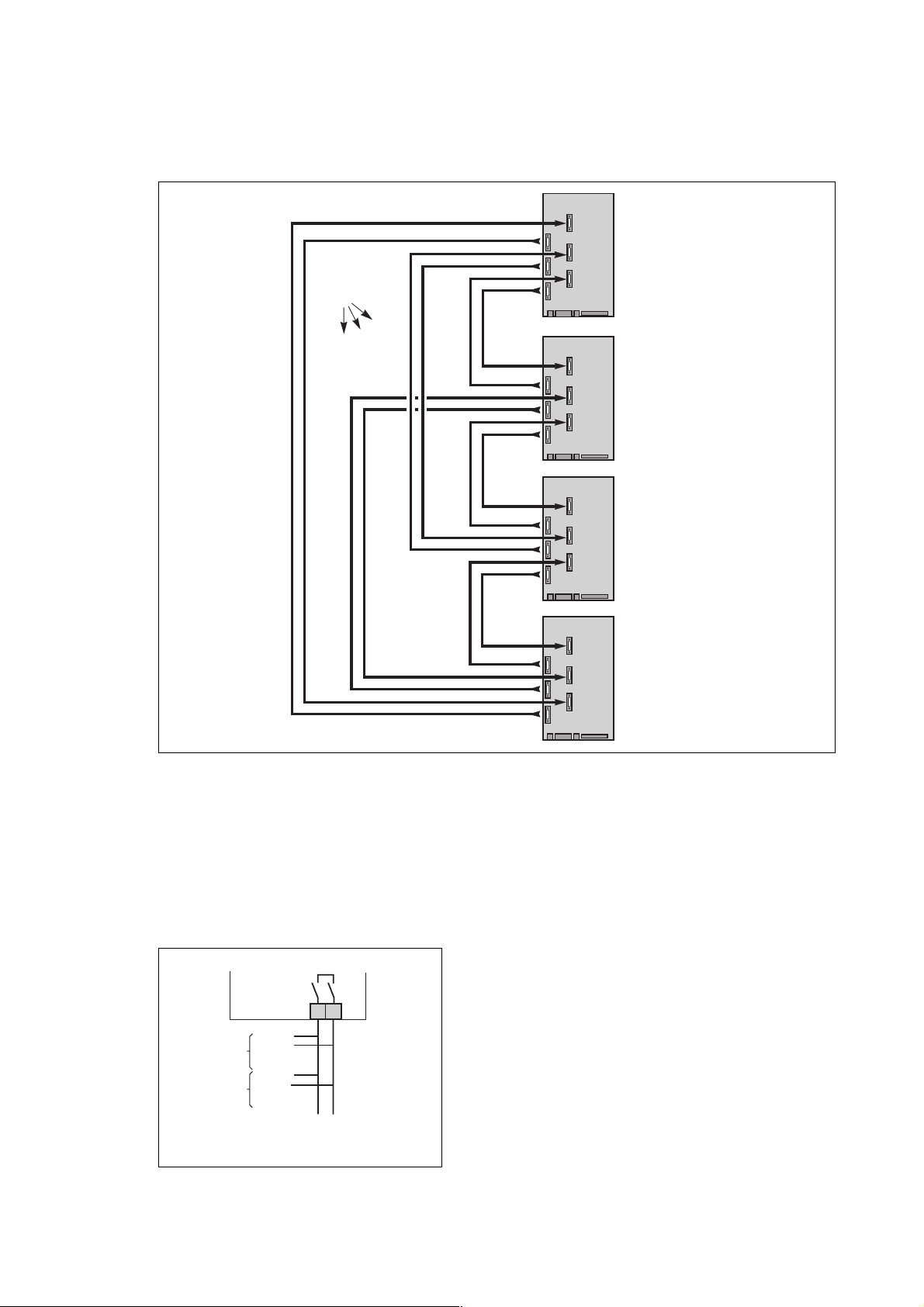

The table below serves as an example for an installation with up to four modular UPSs with an external maintenance bypass.

– for installations with redundant units, take into account only the units required to supply the load power

(e.g. for an installation made up of 3 parallel-connected rectifier-inverter cubicles, one being redundant, only 2 units are used

to determine the currents on the maintenance bypass line and the load, and the cross-sectional areas of cables);

– this table has been drawn up for rated phase-to-phase Mains 2 and load voltages of 415 V and full rated load with a power

factor of 0.9. For voltages of 380 or 400 V, multiply the indicated currents by 1.09 and 1.04 respectively, then modify the cable

cross-sections accordingly if necessary.

The cable cross-sections in this table are for the parts illustrated in bold on the following block diagrams (installation example,

figure 3);

– important. In an installation with an external maintenance bypass, the power cables between each UPS and the

upstream protection devices must be the same length. The same holds for the power cables between each UPS cubicle

and the external maintenance bypass.

rated

inverter

output

number of

parallel-connected

inverters

total UPS

rated output

in kVA

mains 2 or load

line current

in Amps

cable

cross-section (1)

in mm²

in kVA

800 2 1600 2310

Please consult us*

3 2400 3465 Please consult us*

4 3200 4620 Please consult us*

900 2 1800 2598 Please consult us*

3 2700 3897 Please consult us*

4 3600 5196 Please consult us*

(1) cable cross-sections are given for copper conductors of the U1000 R02V type (increase by 30 % for aluminium conductors).

They are calculated according to permissible temperature rise and allow for line voltage drops over a maximum length of 100 m.

For greater lengths, the cross-sections should be chosen to limit voltage drops to 3 %.

* NF C 15-100 authorizes a maximum of 4 cables per phase.

Installation comprising modular UPSs with an external maintenance bypass

maintenance Bypass cubicle

mains 1

mains 2

mains 1

mains 2

mains 1

mains 2

inverter 1

inverter 2

inverter 3

load

Fig. 3

34006451EN/AC - Page 9

Page 10

2. Installation (to be carried out by qualified personnel only)

2.1 Handing

Unpacked cubicles may be moved using a forklift from the front or from the back. Distances must not exceed a few meters.

2.2 Positioning the cubicle

– prior to moving the cubicles to their final position, remove the packing material and withdraw the base panels from the space

on the side created by the spacing uprights. The panels will be installed at the end of the installation procedure;

– spacing uprights on the sides of the cubicles create a 50 mm clearance when cubicles are positioned next to each other,

enabling users to open the doors (see figure 4). If a cubicle is installed next to a wall, leave additional space so that the cubicle

is 50 mm from the wall;

– when the spacing uprights are not required (cubicles are not positioned next to a wall or another cubicle), they may be

removed:

– loosen the four screws securing the upright,

– lift the upright and pull it free,

– replace the long gold-coloured screws with the black screws supplied in a bag attached to the cable terminals in the cubicle;

– adjust the height of the feet until the first cubicle is perfectly vertical; adjust the feet of the subsequent cubicles so that the

all the doors are perfectly aligned.

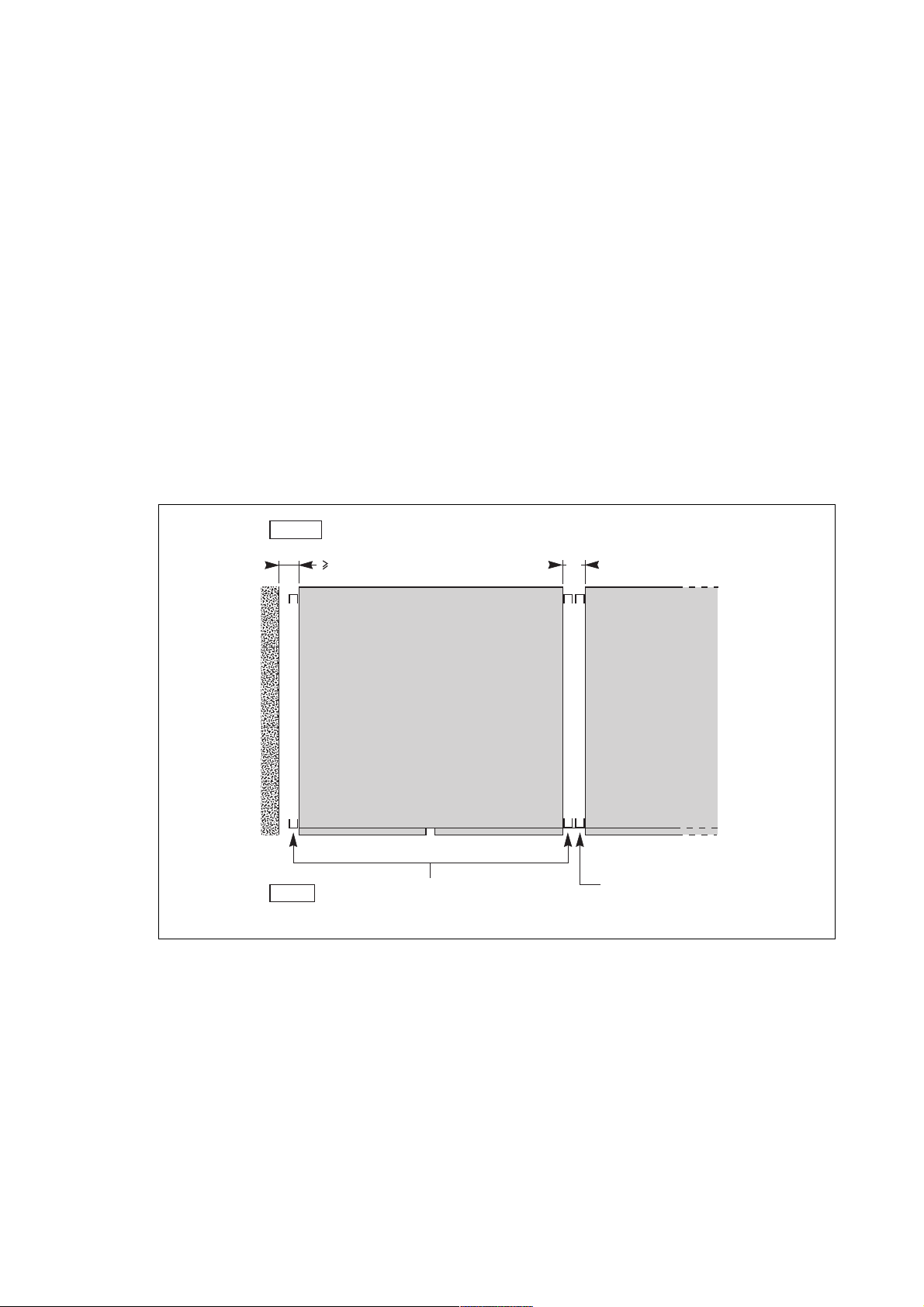

Side clearances provided by the spacing uprights

rear

s

50

50

Fig. 4

front

cubicle 1

spacing uprights

of cubicle 1

cubicle 2

spacing uprights

of cubicle 2

34006451EN/AC - Page 10

Page 11

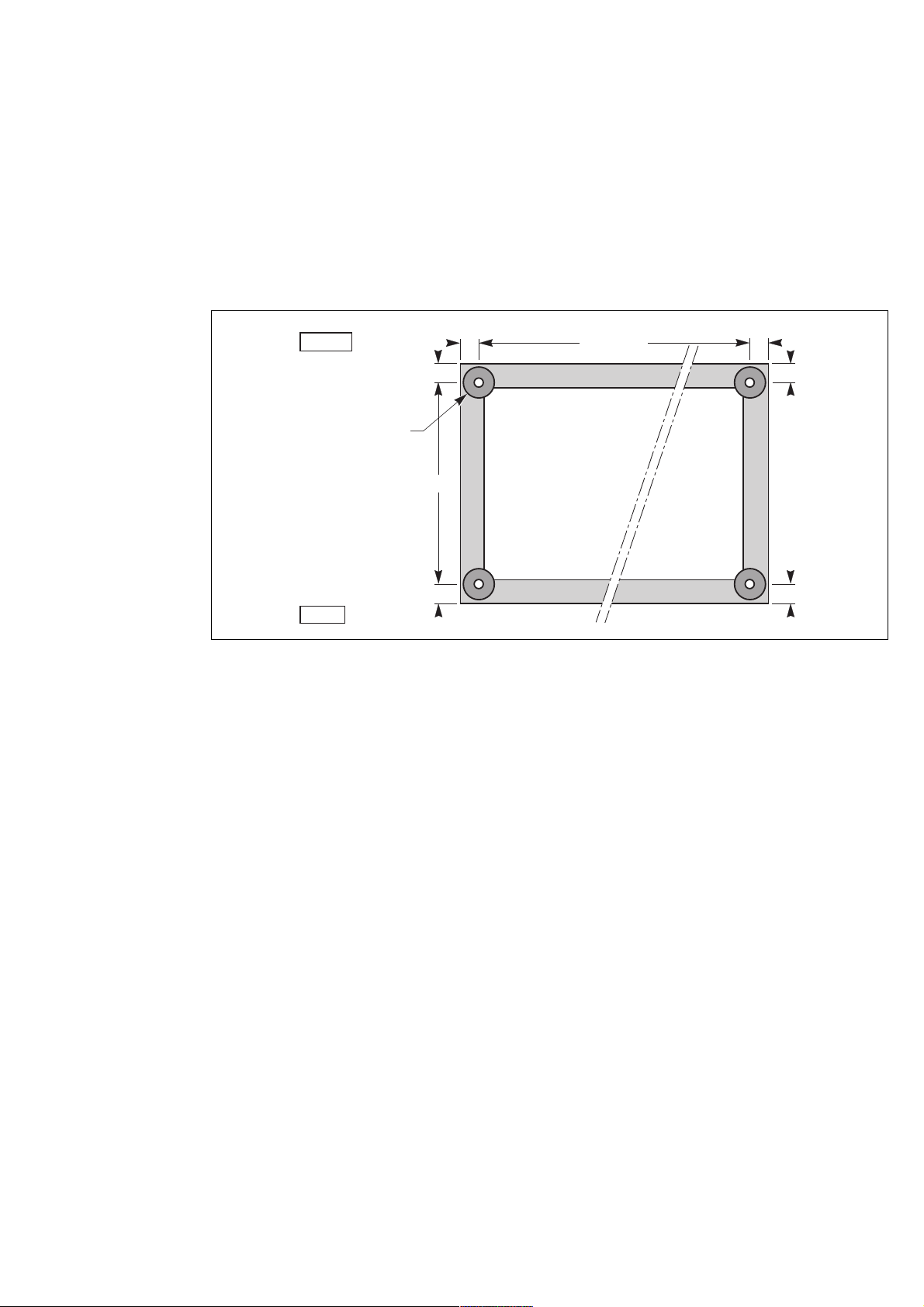

2.3 Floor loads (figure 5)

– the floor supports the weight of each cubicle via the four 60 mm diameter pads at the bottom of the feet screwed into the

corners of the frame;

– the exact locations of the footpads are indicated in the figure;

– normally the cubicles do not have to be secured to the floor; the footpads nevertheless have holes with an average depth

of 12 mm designed for the fitting of M16 anchor bolts;

– to determine the stresses applied by the cubicle feet on the floor, divide the cubicle weight (see the first 3 tables of this

manual) by the total area of the 4 footpads (110 cm

Cubicle footpads

Installation

2

).

rear

four 60 mm dia.

footpads with

12 mm average

depth holes for

M16 anchor bolts

33 33

33

736

cubicle width

less 66 mm

front

Fig. 5

2.4 Cubicle layout on false floor or normal floor (figures 6, 7, 8)

– the cubicles can be installed directly up against the rear wall;

– an overall clearance of 400 mm must be left above the entire surface of the cubicles for ventilation;

– a side clearance of 25 mm is provided by the vertical bars on the sides of the cubicles to allow door opening. For cubicles

mounted side by side, the two adjacent bars ensure an inter-cubicle clearance of 50 mm;

– a minimum clearance of 1000 mm is required in front of the cubicles to allow complete opening of the doors and easy

access for maintenance work (replacement of subassemblies);

– for extended battery backup times or high output systems, the UPS may have several battery cubicles (see the table at the

end of the previous chapter). If this is the case, install the battery cubicles on the left side of the rectifier-inverter cubicle with

the cubicle containing the battery circuit breaker QF1 closest to the rectifier-inverter cubicle (figure 7);

– when an auxiliary cubicle is included in the UPS, it should be installed to the left of the battery cubicle(s);

connection via the bottom

The connection cables may be run in three ways:

– in a cable trench running underneath the front of the cubicles (see trench dimensions and layout in figure 6),

– under a false floor. A cutout must in this case be made in the floor for cable entry (see figure 6 for dimensions),

33

3333

34006451EN/AC - Page 11

Page 12

Installation

Layout for a single-unit UPS with one battery cubicle

rear

>25

80

cubicle width W

(see table)

battery cubicle

50

cubicle width W

(see table)

rectifier-inverter cubicle

spacing uprights

front

cutouts necessary for

cable entry from underneath

a false floor:

200 mm x (W 160 mm)

Fig. 6

Layout for a single-unit UPS with several battery cubicles

rear

battery cubicle 1

battery cubicle 2

containing battery

circuit breaker QF1

can equal 0

800

> 1000

rectifier-inverter cubicle

location

of trench

under cubicles

(if applicable)

front

Fig. 7

– on the floor under the cubicles, in the free space equal to the height of the feet. In this case the cables should be run side

by side to avoid blocking the flow of air for ventilation. The cables exit from the rear or sides of the cubicles;

connection via the top

– the Static Switch, filter and auxiliary cubicles are designed for connection via the bottom or top,

– for the rectifier-inverter cubicles, a special 400 mm wide connection duct must be added to the right of the cubicle to allow

connection via the top.

Layout for an installation with two parallel UPSs and a centralised SSC

rear

front

auxiliaries

cubicle 2

(if applicable)

battery

cubicle(s) 2

rect./inv.

cubicle 2

auxiliaries

cubicle1

(if applicable)

battery

cubicle(s) 1

rect./inv.

cubicle 1

static switch

cubicle

34006451EN/AC - Page 12

Fig. 8

Page 13

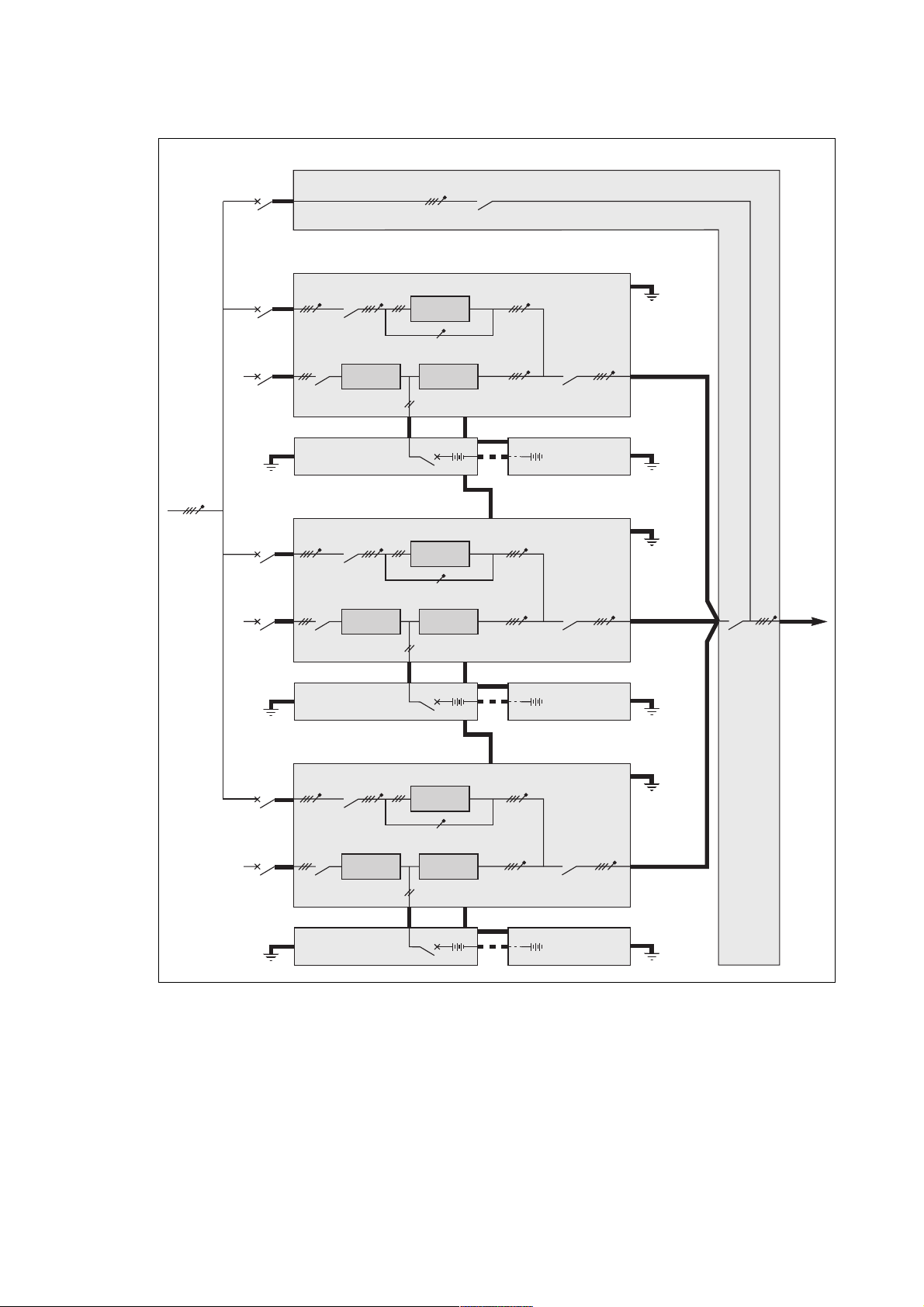

2.5 Power circuit wiring diagrams

The single-wire diagrams for typical UPS installations are given in figures 9 to 15. The heavy lines represent the cables that

must be connected

(see the table in the previous chapter for the required cross-sectional areas of the cables).

Note:

– for frequency converters, the input and output frequencies may be different (50 or 60 Hz);

– for frequency converters without batteries, ignore the battery cubicles and the + and - cables shown in the diagram.

Special case:

The UPSs can be optionally supplied with the neutral conductor not interrupted by switches Q4S, Q3BP and Q5N.

Diagram for a single-unit or single modular UPS with common Mains 1 and 2

rectifier-inverter cubicle

Installation

Q3BP

mains 2

mains 1

earth

Q1 Q5N

battery cubicle

beside the

rectifier-inverter cubicle

Q4S

rectifier

charger

QF1

static

switch

inverter

+

frames interconnections for earthing

other battery

-

+

-

cubicles (if

applicable)

Fig. 9

Diagram for a single-unit or single modular UPS with common Mains 1 and 2

rectifier-inverter cubicle

Q3BP

mains

mains 2

input

mains 1

input

Q1 Q5N

Q4S

rectifier

charger

static

switch

inverter

earth

load

earth

earth

load

earth

battery cubicle

beside the

rectifier-inverter cubicle

QF1

Fig. 10

Diagram for a frequency converter with batteries

rectifier-inverter cubicle

mains 1

earth

Fig. 11

Q1 Q5N

rectifier

charger

battery cubicle

beside the

rectifier-inverter cubicle

inverter

QF1

frames interconnections for earthing

other battery

+

-

frames interconnections for earthing

+

-

+

+

-

cubicles (if

applicable)

other battery

-

cubicles (if

applicable)

earth

load

earth

earth

34006451EN/AC - Page 13

Page 14

Installation

Diagram for a frequency converter without batteries

rectifier-inverter cubicle

mains 1

Q1 Q5N

rectifier

charger

inverter

Fig. 12

Example of a 2 parallel UPS rectifier-inverters with SSC

Static Switch Cubicle

Q3BP

mains 2

rectifier-inverter cubicle 1

mains 1

Q4S

Q1 Q5N

rectifier

charger

static

switch

inverter 1

frames interconnection for earthing

Q5N

load

earth

load

inverter 1

output

earth

earth

frames interconnections for earthing

earth

mains 1

earth

battery cubicle

beside rectifierinverter cubicle 1

rectifier-inverter cubicle 2

Q1 Q5N

rectifier

charger

battery cubicle

beside rectifierinverter cubicle 2

QF1

inverter 2

QF1

+

-

frames interconnections for earthing

frames interconnections for earting

+

-

+

+

other battery

-

cubicles (if

applicable)

other battery

-

cubicles (if

applicable)

inverter 2

output

earth

earth

earth

Fig. 13

Note:

Both the rectifier-inverter cubicles and the Static Switch Cubicle can be supplied from a common Mains, in which case there

is only one upstream circuit breaker (same as the case of a single-unit UPS with a common Mains 1 and 2).

34006451EN/AC - Page 14

Page 15

Example of 2 multi-bypass modular UPS cubicles for redundancy

modular UPS cubicle 1

Q3BP

Installation

earth

mains 2

mains 1

earth

mains 2

mains 1

Q4S

Q1 Q5N

rectifier

charger

battery cubicle

beside rectifierinverter cubicle 1

modular UPS cubicle 2

Q4S

Q1 Q5N

rectifier

charger

static

switch

inverter 1

QF1

static

switch

inverter 2

frames interconnection for earthing

+

-

Q3BP

+

frames interconnection for earthing

other battery

-

cubicles (if

applicable)

inverter 1

output

earth

earth

inverter 2

output

load

Fig. 14

earth

battery cubicle

beside rectifierinverter cubicle 2

QF1

frames interconnection for earthing

other battery

+

-

+

-

cubicles (if

applicable)

earth

34006451EN/AC - Page 15

Page 16

Installation

Example of an installation comprising three modular UPSs with an external maintenance bypass

External

maintenance

bypass line

mains 2

mains 1

earth

mains 2

mains 1

External maintenance bypass cubicle

Q3BP

modular UPS cubicle 1

Q4S

Q1 Q5N

rectifier

charger

battery cubicle

beside rectifierinverter cubicle 1

modular UPS cubicle 2

Q4S

Q1 Q5N

rectifier

charger

static

switch

inverter 1

QF1

static

switch

inverter 2

frames interconnection for earthing

+

-

frames interconnection for earthing

+

other battery

-

cubicles (if

applicable)

earth

earth

earth

Q5N

load

frames interconnection for earthing

earth

mains 2

mains 1

earth

battery cubicle

beside rectifierinverter cubicle 2

modular UPS cubicle 3

Q4S

Q1 Q5N

rectifier

charger

battery cubicle

beside rectifierinverter cubicle 3

QF1

static

switch

inverter 3

QF1

+

-

frames interconnection for earthing

frames interconnection for earthing

+

-

+

+

other battery

-

cubicles (if

applicable)

other battery

-

cubicles (if

applicable)

earth

earth

earth

Fig. 15

Important. The power cables between each UPS and the upstream protection devices must be the same length. The

same holds for the power cables between each UPS cubicle and the external maintenance bypass.

34006451EN/AC - Page 16

Page 17

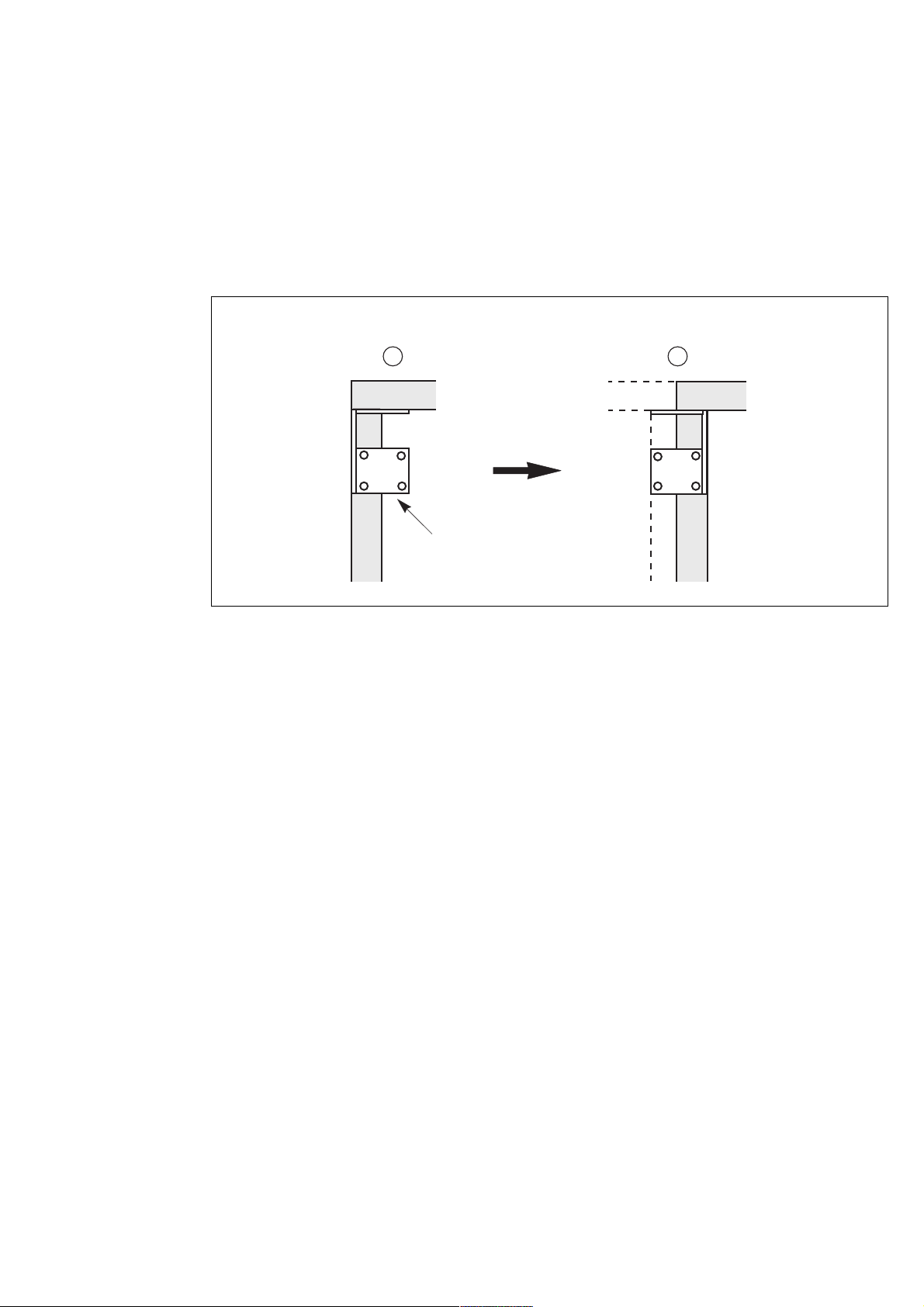

2.6 Cubicle mounting and connection

Mounting of the left and right cubicles

Gusset plates have been fitted to the top corners on all four sides of the cubicles to provide reinforcement for transportation.

– prior to joining the two cubicles, remove the rear gusset from the right side of the left cubicle;

– move the cubicles to their operating location;

– adjust the front foot pads so that the cubicles are vertical and their doors aligned;

– remove the top panel on the left side of the right cubicle for access to the side gussets (see figure opposite);

– remove the rear double gusset on the right cubicle, turn it around and bolt the two cubicles together.

right cubicle

A B

Installation

double gusset

to be

turned around

34006451EN/AC - Page 17

Page 18

Installation

Internal connections between cubicles

– removal of inverter leg no.6 is recommended prior to bolting fish-plates L+ and L-;

– first remove the two fuses and the two cables connected to the leg;

– then pull the leg out;

– bolt fish-plates L+ and L-;

– refit inverter leg no 6;

– intended only for transportation, the front gussets do not need to be refitted;

– bolt cables L1, L2, L3 and N (4 x 2) coming from the left cubicle to the bars in the right cubicle (see figure opposite);

– connect the earth strap to the front uprights of both cubicles;

– connect the connectors marked XF286 to XF2810 on the five ribbon cables coming from the right cubicle to connectors

XM286 to XM2810 respectively on the interface board located on the right side of the left cubicle;

– connect the connectors marked XFGD01 to XFGD05 (XFGD01 to XFGD05 and XMGD06 for parallel UPSs) on the control

wires coming from the left cubicle to connectors XMGD01 to XMGD05 (XMGD01 to XMGD05 and XFGD06 for

parallel UPSs).

right cubicle

fuses and cables

to be disconnected

inverter

leg no. 6

interface board

XM286 to XM2810

XMGD01 to XMGD04

XFGD06

earth strap to be

connected to the front

uprights of both cubicles

XMGD05

L

fish-plates

to be

bolted

L+

cables to be

connected

N L1 L2 L3

left cubicle

34006451EN/AC - Page 18

Page 19

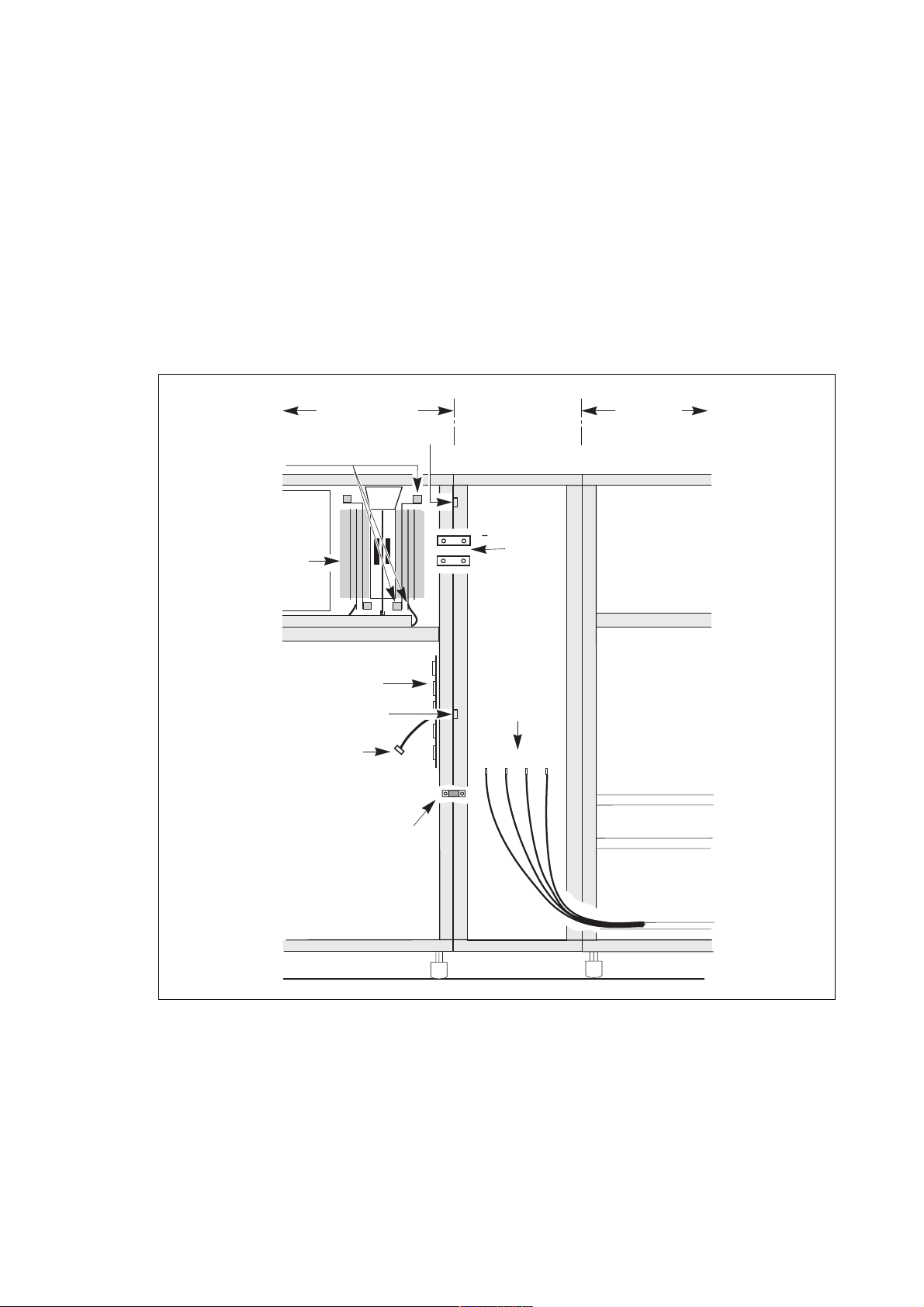

2.7 Connection of power circuits

Before making connections, check that switches Q1, Q4S, Q3BP and Q5N are in the "open" position (toggle opposite the "O"

mark).

General:

– in the case of parallel-connected rectifier-inverter cubicles with SSC, switches Q4S and Q3BP are not included and

mains 2 is connected to the Static Switch Cubicle. The other connections are the same;

– for modular UPSs with an external maintenance bypass, switch Q3BP must be locked open;

– the power cables for the connections between cubicles are not supplied;

– open the doors and remove the lower terminal shields (secured by screws to the cubicle chassis) of the rectifier-inverter

and Static Switch Cubicles;

– connect the cables shown in heavy lines in the wiring diagrams shown previously to the terminals specified in the figures

below;

– each cubicle must be earthed;

– the routing of the power cables is shown in the figures;

– the auxiliary wiring is routed in troughs located nearby (not shown in the drawings);

– outside the cubicles, separate the auxiliary wiring from the power cables;

– all the cubicles must be interconnected for earthing, forming a mesh which is itself connected to the building structure and

earthing electrode;

– the connection drawings hereafter show the cubicles with doors open and terminal shields removed.

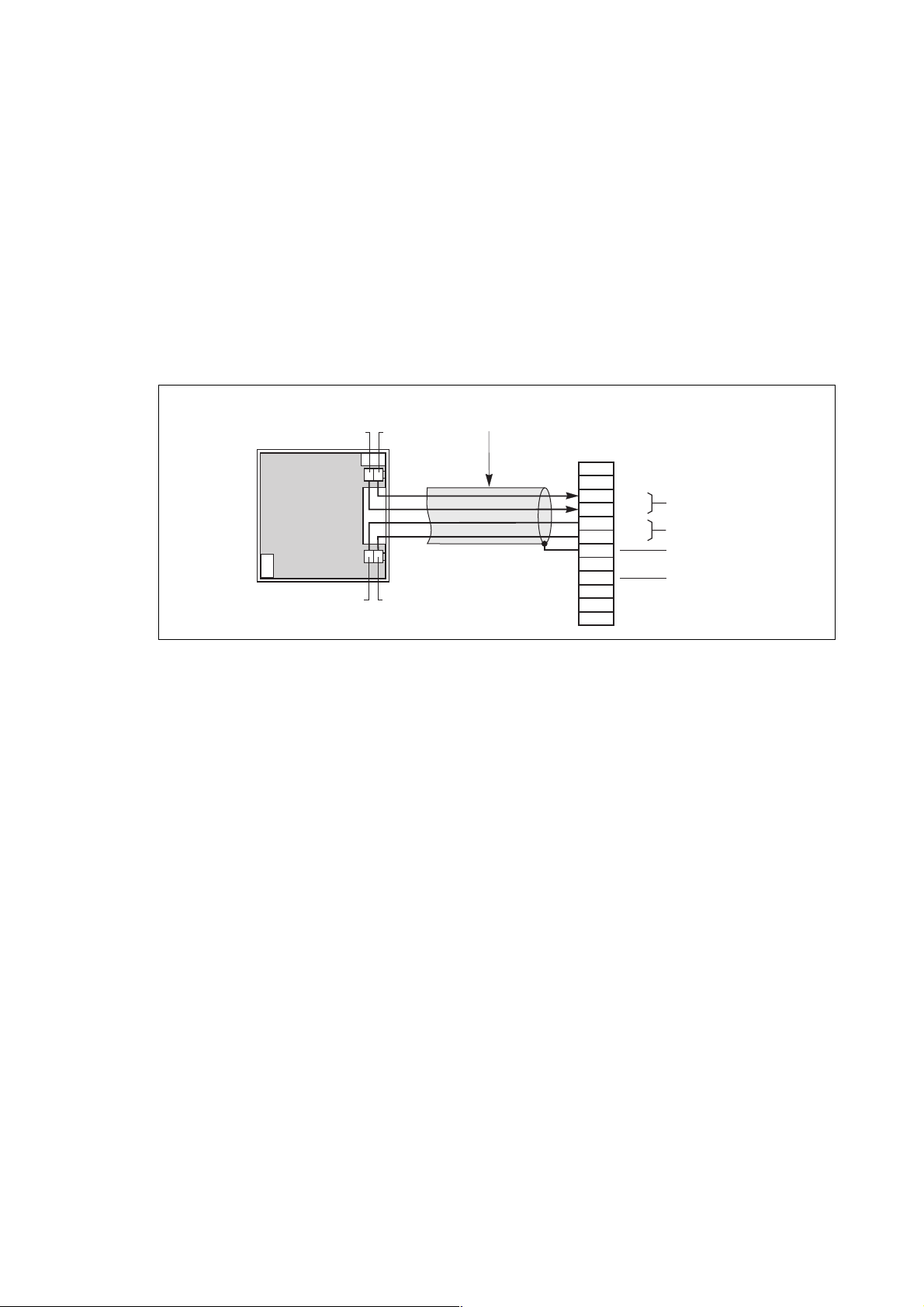

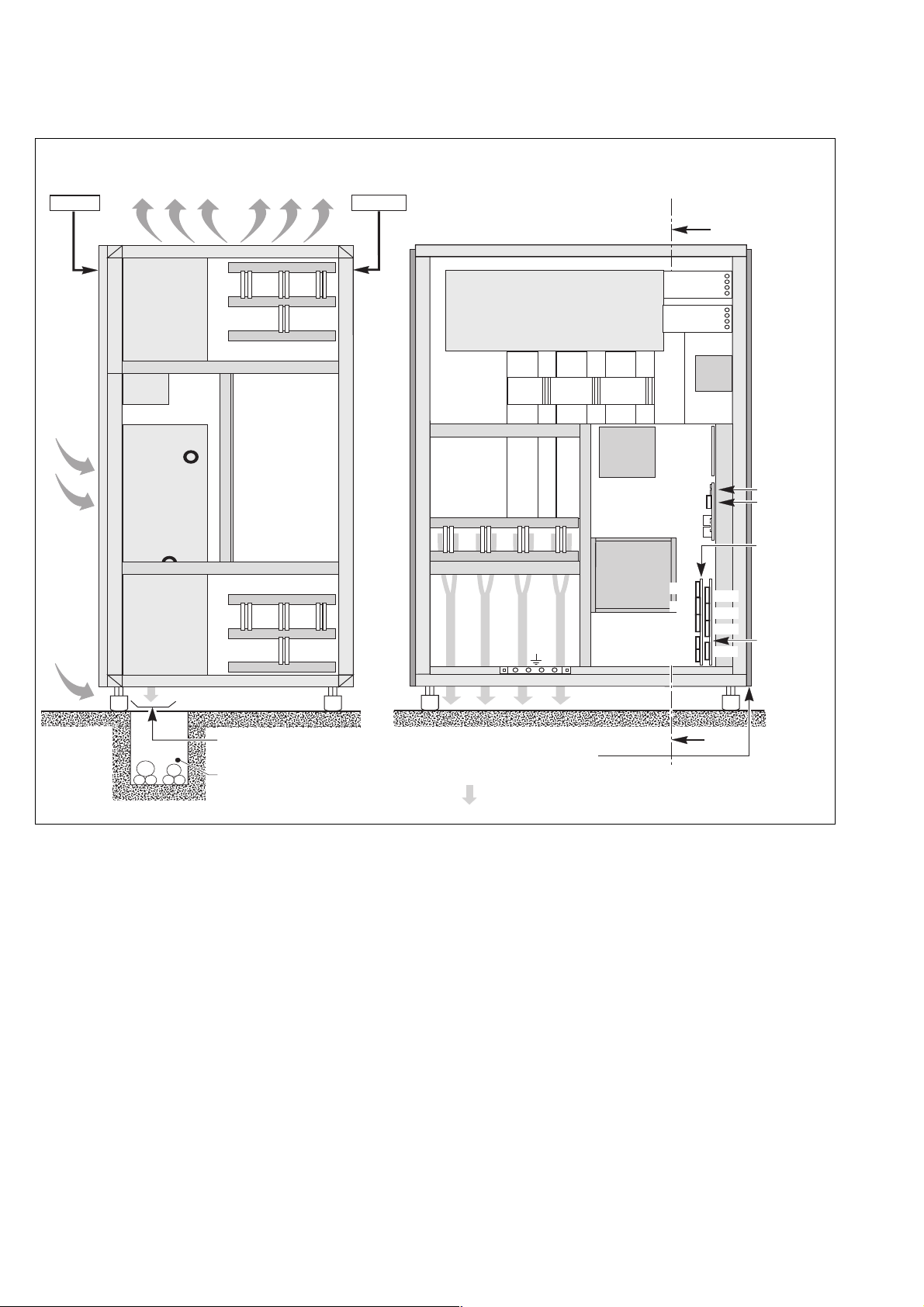

Left cubicle of single-unit or parallel UPS with SSC

installation

cross-section AA

air

admission

battery

mains 1

air

admission

air extraction

transformer

rearfront

front view

rectifier

charger

inverter

stack

off

on

L1

mains 1

A

inverter

stack

FHCZ

board

Q1

L2

L3

inverter

stack

L+

battery

L

cable tie bar

connection

from below

trough (if applicable)

spacing

uprights

cable

tie bar

power cable routing

via the bottom

Cables connected by lugs to 100 x 8 mm copper terminals and 13 mm diameter holes.

Height of connections relative to floor:

– mains 1: 450 mm;

– battery: 480 mm.

A

34006451EN/AC - Page 19

Page 20

Installation

Right cubicle of single-unit UPS

cross-section AA front view

air extraction

rearfront

A

air

admission

mains 2,

load

air

admission

card

cage

transformer

cable tie bar

card

cage

remote relay

board

off

on

XR1

XR2

XR3

XR4

inverter

stack

XR8

XR9

XR5

XR6

XR7

additional remote

relay board (optional)

Q4S

off

on

L1 L2 L3N

mains 2

inverter

stack

Q3BP

inverter

stack

off

Q5N

on

L1 L2 L3N

load

connection

from below

trough (if applicable)

earth

bar

cable

tie bar

power cable routing via the bottom

Cables connected by lugs to 100 x 8 mm copper terminals and 13 mm diameter holes.

Height of connections relative to floor:

– mains 2 and load: 430 mm;

– remote relay board: 1030 mm.

A

spacing

uprights

34006451EN/AC - Page 20

Page 21

Right cubicle of a parallel UPS with SSC

Installation

cross-section AA front view

air extraction

front

air

admission

card

cage

transformer

rear

XM133

ACPZ

board

XM136

XM137

card

cage

APOZ

board

XR1

XR2

XR3

XR4

inverter

stack

XR8

XR9

XR5

XR6

XR7

inverter

stack

remote relay board

remote relay board

A

inverter

stack

off

Q5N

on

load

air

admission

cable tie bar

connection

from below

trough (if applicable)

earth

bar

power cable routing via the bottom

Cables connected by lugs to 100 x 10 mm copper terminals and 14 mm diameter holes.

Height of connections relative to floor:

– load: 410 mm;

– remote relay board: 1030 mm.

cable

tie bar

L1 L2 L3N

load

A

spacing

uprights

34006451EN/AC - Page 21

Page 22

Installation

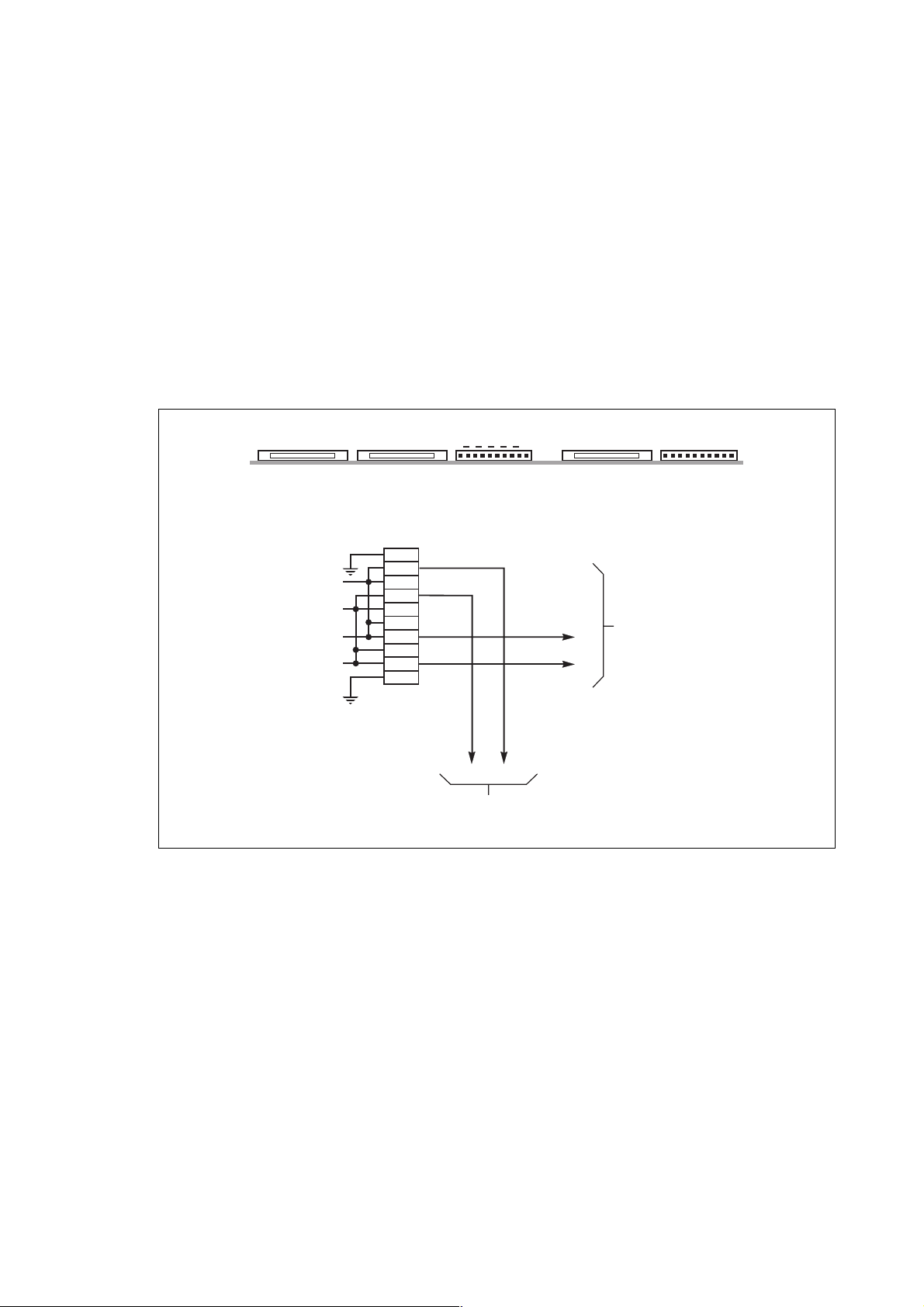

2.8 Connection of "Media Contacts 9" standard auxiliary circuits (figure 16)

The standard auxiliary circuits of the rectifier-inverter and Static Switch Cubicles are connected to the remote relay board by

4 connectors (see the location of this board in the figures of the previous section).

– recommended cable cross-section: 1 mm

– the male connectors that fit the female connectors on the board (XR1 to XR4) are supplied;

– the contacts are volt-free and are shown in the diagram under the following conditions: UPS on, contact at rest;

– contact breaking capacity: 250 V, 5 A.

Connection of auxiliary circuits on the remote relay board

2

(use a shielded cable to connect the battery cell);

remote

relay board

connector XR1

connector XR2

connector XR3

+12V

24 V DC

-

12V

connector XR4

temperature

signal

power

supply

earth

earth

-12V

+12V

1

1

2

3

4

5

6

7

8

9

10

11

12

1

2

3

4

5

6

7

8

9

10

11

12

1

2

3

4

5

6

7

8

9

10

11

12

1

2

3

4

5

6

7

8

9

10

11

12

12

XR1 XR2 XR3

output signals:

low battery shutdown warning (1)

low battery shutdown warning (1)

load on battery (1)

load on battery (1)

output signals:

load on inverter (2)

load on inverter (2)

general alarm (2)

general alarm (2)

input or output signals:

maintenance position (2)

maintenance position (2)

battery circuit breaker

QF1 opening command (1)

input or output signals:

and/or harmonics filter temperature fault

connection with the optional electronic

board for measuring battery temperature (1)

emergency shutdown button contact

(jumper if not used) (1)

1

battery room ventilation fault (1)

12

1

shielded cable

(2 twisted

telephone pairs)

12

1

(1) for:

single-unit UPS cubicle,

modular UPS cubicle,

parallel UPS cubicle with SSC.

(2) for:

single-unit UPS cubicle,

modular UPS cubicle,

parallel UPS cubicle with SSC,

Static Switch cubicle.

battery cubicle (1)

XR1 terminal block

3

4

1

2

harmonics filter cubicle

XR1 terminal block

1

2

12

XR4

battery circuit

breaker QF1

opening command

battery circuit

breaker QF1

closing command

temperature

monitoring of

the harmonics

filter inductor

Fig. 16

34006451EN/AC - Page 22

Page 23

Installation

Connection to battery circuit breaker QF1

Connect the cable from connector XR3 (pins 7 to 12) of the rectifier-inverter cubicle remote relay board to connector XR1 of

the battery cubicle containing battery circuit breaker QF1.

Emergency shutdown

The UPS emergency shutdown function is generally wired to a "mushroom-head" type emergency off button.

Important:

In the case of a complex installation with a number of units, there should only be one emergency shutdown pushbutton and

this pushbutton must interrupt all the active conductors of all the units.

For the same reason, it is essential for the pushbutton to open the upstream mains 1, mains 2, and external maintenance

bypass line protective circuit breakers.

Each type of unit (UPS and Static Switch Cubicle) must have an independent, volt-free contact connected to the emergency

shutdown pushbutton. This pushbutton must therefore have as many contacts as there are units in the installation, as well as

the contact or contacts required to open the upstream mains 1 and 2 protective circuit breakers. The emergency shutdown

pushbutton turns off the rectifier-chargers and inverters and opens the battery circuit breakers. The emergency shutdown

signal will be cleared when the emergency shutdown pushbutton contact has been reset.

The emergency shutdown pushbutton should not be connected to the Static Switch Cubicle since the pushbutton opens the

circuit breaker protecting the upstream circuit (mains 2) and the Static Switch Cubicle is therefore no longer powered (inverters off and mains 2 down).

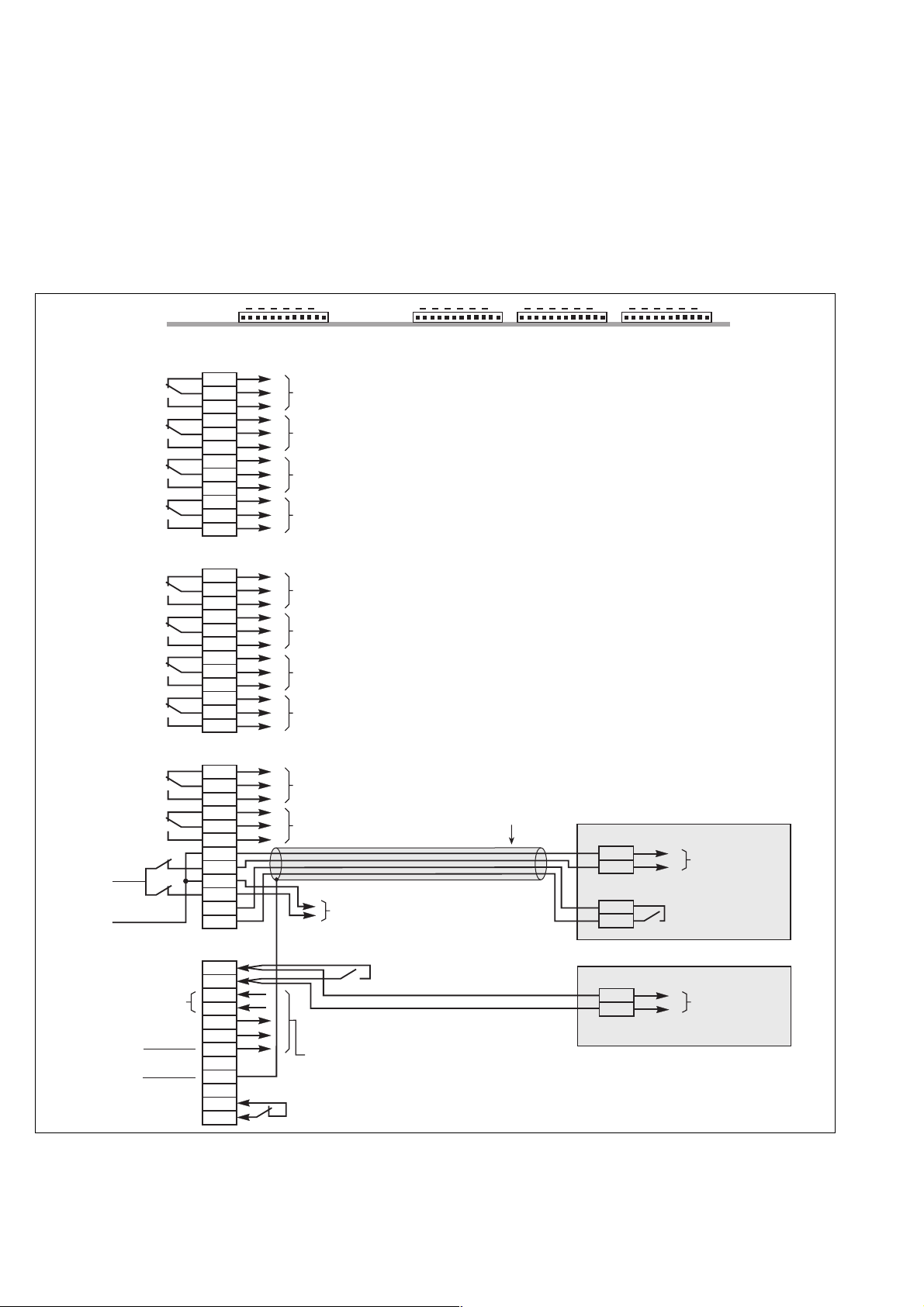

2.9 Connections between cubicles (modular UPSs or parallel UPSs with SSC)

On modular UPSs, interconnections are made on the APOZ (figure 17) and MISI (figures 19 to 21) boards in the UPS cubicles

(see the layout of the boards in the figures in the previous section).

For parallel UPSs with a centralised SSC, interconnections are made on the APOZ boards in the UPS cubicles (figure 17)

and the ACPZ boards (see the layout of the boards in the figures in the previous section) in the SSC (figure 18).

Connections between APOZ boards

– these connections are made using the ribbon cables supplied;

– the purpose of the connection is to make a loop: connector XM137 of the APOZ board of one UPS being connected to

connector XM136 of the APOZ board of the next UPS and so on until the first board is returned to.

Important:

Outside the cubicles, group the APOZ inter-board and ACPZ or MISI inter-board connections with the inter-cubicle auxiliary

connections, and separate this assembly from the power cables.

Connections between rectifier-inverter cubicles

APOZ board

rectifier-inverter 1

XM137

XM136

APOZ board

rectifier-inverter 2

XM137

XM136

ribbon cables supplied

Fig. 17

APOZ board

rectifier-inverter 3

XM137

XM136

34006451EN/AC - Page 23

Page 24

Installation

Connections between ACPZ boards (frequency converters or parallel UPSs

with SSC)

– these connections are made through the special cables supplied;

– these connections only concern installations with a Static Switch Cubicle and should be made in addition to the connections

between rectifier-inverter cubicles described previously;

– the ribbon cable from connector XM133 of the ACPZ board of one rectifier-inverter cubicle is connected to one of the

connectors XM127 to XM132 of the ACPZ board of the Static Switch Cubicle.

Important:

Outside the cubicles, group the APOZ inter-board and ACPZ inter-board connections with the inter-cubicle auxiliary

connections, and separate this assembly from the power cables.

Connections between each rectifier-inverter cubicle and the Static Switch Cubicle (example

of 3 parallel UPS rectifier-inverters with SSC)

ACPZ board

rectifier-inverter 3

ribbon cable

supplied

XM133

Fig. 18

ACPZ board

rectifier-inverter 2

ACPZ board

rectifier-inverter 1

XM133

XM133

ribbon cable

supplied

ribbon cable

supplied

ACPZ board

of the static

switch cubicle

XM

127XM128XM129XM130

XM

131XM132

34006451EN/AC - Page 24

Page 25

Installation

Connections between MISI boards (modular UPSs)

See figures 19 to 21.

– these connections are made using the special cables (A) supplied;

– connectors XM5, XM6 and XM7 on the MISI board are used to transmit signals;

– connectors XM10, XM11 and XM12 on the MISI board are used to receive signals;

– connector XM5 is associated with connector XM10 for communication with a second UPS unit; similarly, XM6 is associated

with connector XM11 for communication with a third UPS unit and XM7 is associated with connector XM12 for communication

with a forth UPS unit;

– situation with two modular UPS units: see figure 19;

– situation with three modular UPS units: see figure 20;

– situation with four modular UPS units: see figure 21.

Fig. 19

MISI

board

UPS 1

XM12

XM7

XM6

XM5

A

XM7

XM6

XM5

XM11

XM10

XM12

XM11

XM10

MISI

board

UPS 2

A

XM7

XM6

XM5

XM7

XM6

XM5

XM7

XM6

XM5

XM12

XM11

XM10

XM12

XM11

XM10

XM12

XM11

XM10

MISI

board

UPS 1

MISI

board

UPS 2

MISI

board

UPS 3

Fig. 20

34006451EN/AC - Page 25

Page 26

Installation

Important

Outside the cubicles, group the cables between the MISI boards and those between the APOZ boards with the other auxiliary

links between cubicles and separate all these cables from the power cables.

MISI

board

XM12

XM7

XM6

A

XM5

XM7

XM6

XM5

XM7

XM6

XM5

XM11

XM10

XM12

XM11

XM10

XM12

XM11

XM10

UPS 1

MISI

board

UPS 2

MISI

board

UPS 3

MISI

board

UPS 4

XM7

XM6

XM5

XM12

XM11

XM10

Fig. 21

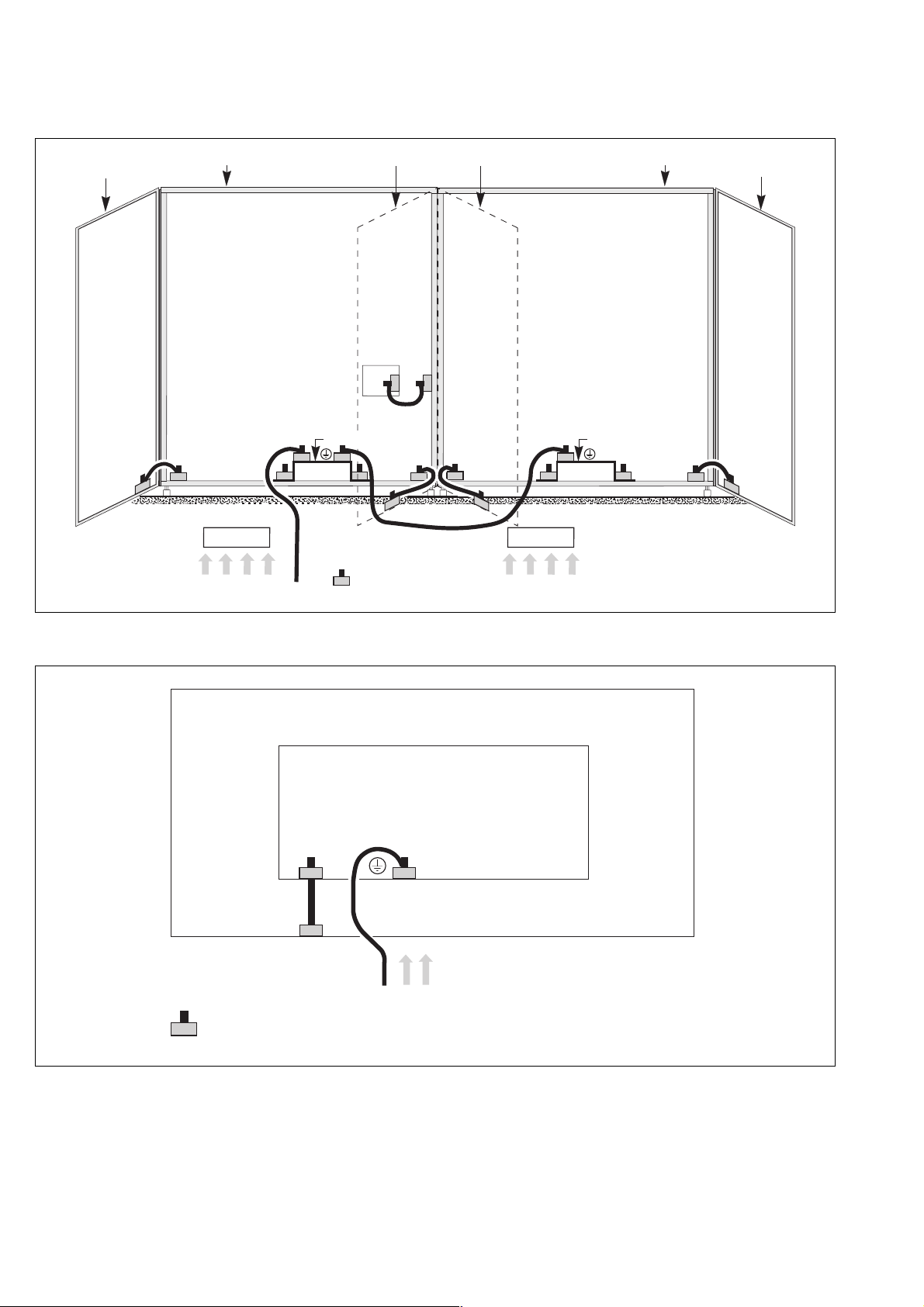

2.10 Connections between rectifier-inverter cubicles and external maintenance

bypass cubicle

– make connections with 1 mm

– connect terminals 1 and 2 on connector XM8 on the MISI board in the UPS to terminals 1 and 2 in the external

maintenance bypass.

maintenance

bypass

cubicle

Q3BP +

MISI 1

MISI 2

Q3BP -

Q3BP +

Q3BP -

2

wires (recommended size, not supplied);

Q3BP12Q5N

1

XM8

2

1

XM8

2

34006451EN/AC - Page 26

MISI 3

MISI 4

Page 27

2.11 Connection of "Media Contacts 15" additional auxiliary circuits

(figure 22)

The additional auxiliary circuits of the rectifier-inverter and Static Switch Cubicles are connected to additional remote relay

board by means of the 4 connectors (see location of this board in the figures of the "connection of power circuits" section).

– recommended cable cross-section: 1 mm

– the male connectors that fit the female connectors on the board (XR5 to XR9) are supplied;

– the contacts are volt-free and are shown in the diagram under the following conditions: UPS on, contact at rest;

– contact breaking capacity: 250 V, 5 A.

Note:

In a parallel-connected UPS installation the "load" and "mains 2" signals are provided by the Static Switch Cubicle.

ACPZ board of the Static Switch Cubicle

2

;

Installation

additional remote

relay board

connector XR5

(option)

connector XR6

(option)

connector XR7

(option)

connector XR8

(option)

connector XR9

(option)

12

XR7

UPS cubicle,

UPS cubicle,

UPS cubicle,

UPS cubicle,

XR8

10

1

overload (2)

overload (2)

inverter function fault (1)

inverter function fault (1)

rectifier-charger operating (1)

rectifier-charger operating (1)

rectifier-charger function fault (1)

rectifier-charger function fault (1)

transfer to Mains 2 inhibited (3)

transfer to Mains 2 inhibited (3)

transfer function fault (2)

transfer function fault (2)

transfer to Mains 2 inhibited (4) (5)

transfer to Mains 2 with interruption inhibited (4) (5)

desynchronization with Mains 2 (3)

battery charge current limiting (1)

gradual rectifier-charger shutdown (1)

current limiting on generator power (1)

remote inverter on (1)

remote inverter off (1)

auxiliary signal (2)

1

1

2

3

4

5

6

7

8

9

10

11

12

1

2

3

4

5

6

7

8

9

10

11

12

1

2

3

4

5

6

7

8

9

10

11

12

1

2

3

4

5

6

7

8

9

10

1

2

3

4

5

6

7

8

XR9

10

1

XR5

12

1

output signals:

XR6

input signals:

12

1

(1) for:

single-unit

modular UPS cubicle,

parallel UPS cubicle with SSC.

(2) for:

single-unit

modular UPS cubicle,

parallel UPS cubicle with SSC,

Static Switch cubicle.

(3) for:

single-unit

modular UPS cubicle,

Static Switch cubicle.

(4) in modular UPSs, these functions are

available via the "auxiliary information" contact

(connector XR9, terminals 7-8).

(5) for:

single-unit

static Switch cubicle.

Fig. 22

34006451EN/AC - Page 27

Page 28

Installation

2.12 Connection of the battery "Temperature Monitor" (optional)

Connections

This unit must be connected to connector XR4 of the remote relay board of the rectifier-inverter cubicles (see the location of

the remote relay board in the figures of the "power circuit connection" section).

– use a shielded cable made up of 2 twisted telephone pairs with a conductor cross-section of at least

–0.1 mm

– do not forget to connect the cable shield to ground pin 7 of connector XR4;

– in the case of a parallel UPS configuration, the connections between cubicles may be made by means of a shielded cable

made up of 1 or 2 twisted telephone pairs. In this case, the total length of all the connecting cables should not exceed 100 m;

– a "Temperature Monitor" can only be connected to several rectifier-inverter cubicles when the batteries of these cubicles

are located in the same room at the same ambient temperature.

Connection of the battery "Temperature Monitor" (for a single-unit UPS)

2

and up to 100 m in length;

Fig. 23

battery "Temperature

Monitor"

BC+ BC

XR2

XR1

12 +12

(unit shown open)

shielded cable

(2 twisted

telephone pairs)

remote relay board

connector XR4:

1

2

3

BC

BC +

4

5

12V

6

+

12V

7

8

9

10

11

12

temperature

signal

power supply

earth

earth

34006451EN/AC - Page 28

Page 29

Installation

Connection of the battery "Temperature Monitor" (for a parallel UPS with batteries in the same room)

battery "Temperature

Monitor"

BC+ BC

XR2

XR1

12 +12

(unit shown open)

shielded cable

(2 twisted

telephone pairs)

shielded cable

(1 or 2 twisted

telephone pairs)

remote relay board

connector XR4 on

rectifier-inverter cubicle 1:

1

2

3

BC

BC +

4

5

+

6

7

8

NC

9

10

11

12

remote relay board

connector XR4 on next

rectifier-inverter cubicle:

3

4

5

6

7

8

NC

remote relay board

connector XR4 on nth

rectifier-inverter cubicle:

1

2

3

BC

4

BC +

5

6

7

8

9

10

11

12

12V

12V

BC

BC +

temperature

signal

power supply

earth

earth

temperature

signal

earth

temperature

signal

earth

earth

Fig. 24

"Temperature Monitor" installation in a battery room

The "Temperature Monitor" should be secured against a wall or any vertical support:

– choose a location near the batteries and away from draughts which adversely affect the accuracy of temperature

measurements;

– position the unit correctly ("on" light in the top left hand corner and cable fed through from the right-hand side);

– use the holes provided in the base plate to screw the unit to the vertical support (see figure 25);

– unless the connecting cable runs on the surface, break the knock-out in the unit base plate provided for cable entry;

– secure the cable by suitable means so that it does not pull on the unit.

"Temperature Monitor" base

oblong holes

for fastening screws

board

oblong holes

for fastening screws

dimensions of the "Temperature Monitor": 75 x 75 x 21 mm

knock-out for

lateral cable

entry

Fig. 25

34006451EN/AC - Page 29

Page 30

Installation

2.13 Connection of the "LED" remote indications unit

This unit is connected to connectors XR1 and XR2 of the remote relay boards of the rectifier-inverter and Static Switch

Cubicles (see the location of these boards in the figures of the "connection of power circuits" section).

For the installation of the unit and details of connections at the unit end, see the instructions delivered with the unit

nr 5102990400.

– recommended cable cross-section: 1 mm

2

.

2.14 Connection of "Tele Monitor" remote control and indication unit

This unit is connected by means of a signal loop connecting the XR10 connectors of the RAUZ 1 boards of the rectifier-inverter

and Static Switch Cubicles to the unit connectors. These RAUZ 1 boards are located near the remote relay boards.

– recommended cable cross-section: shielded 0.4 mm

– consult manual 6739388XU for further information.

Connection of "Tele Monitor" remote control and indication unit

RAUZ 1 board

XM098

connector XR10

reception

reception

+

transmission

transmission

+

XM097 XM096

1

2

3

4

5

6

7

8

9

10

2

cables;

1

XR11

10

XR10

to connector XR081

on the COMZ board

2

in the "Tele Monitor" unit

4

(option)

Fig. 26

2.15 Final installation steps

After making the connections:

– install the front and rear base plates of the cubicles, clipping them to the feet of the cubicles (unless the connecting cables

are fed through these openings);

– refit the terminal shields of the terminal blocks, switches and circuit breakers.

97

to connector XR10

of another rectifier-inverter

or static switch cubicle

34006451EN/AC - Page 30

Page 31

3.1 Mains 2 line protection

The rating of the mains 2 line upstream protection circuit-breaker must be chosen:

– to protect the static switch thyristors with respect to maximum permissible currents. Refer to the table opposite for a 400 V

mains 2 voltage;

– to ensure discrimination with respect to the UPS output fuses (refer to fuse time-current curves below) and to the

downstream protective devices.

rated inverter output (kVA) maximum permissible current

800 19 In for 20 ms

900 19 In for 20 ms

3. Appendix (to be carried out by qualified personnel only)

t(s)

4

10

3

10

2

10

1

10

1

-1

10

-2

10

-3

10

-4

10

3

10

4

10

5

10

I(A)

Time-current curve 1600 A fuse

34006451EN/AC - Page 31

Page 32

Appendix

3.2 Cubicle mounting and connection for 2000 kVA Static Switch Cubicle

Cubicle mounting

– move the cubicles to their operating location;

– adjust the front foot pads so that the cubicles are vertical and their doors aligned.

Internal connections between cubicles

– install and bolt the supplied fish-plates on the bars for the phases and neutral (L1, L2, L3, N) between the two cubicles

(four bars in top and four bars in bottom);

– connect the earth strap to the front uprights of both cubicles;

– connect the connectors marked XM1 and XM2 from the left cubicle to the connectors marked XF1 and XF2

in the right cubicle.

left cubicle right cubicle

K2S

L3

L1

N

L2

XF1-XF2

XM1-XM2

L1 L2 L3N

card cage

off

off

off

Q4S

on

Q3BP

Q5N

on

on

L2

L3

L1

N

34006451EN/AC - Page 32

earth strap to be connected

to the front uprights of both

cubicles

spacing

uprights

Page 33

Right cubicle of a 2000 kVA Static Switch

cross-section AA front view

air extraction

front

air

admission

rear

Appendix

A

on

off

Q4S

L2

L3

on

off

Q3BP

L1

N

air

admission

mains 2

on

off

Q5N

connection

from below

trough (if applicable)

spacing uprights

power cable routing via the bottom

Cables connected by lugs to 5 x (5 x 100) mm copper terminals and 16 mm diameter holes.

Height of connections relative to floor:

– mains 2 : 1400 mm;

– load: 800 mm.

load

L2

L3

A

L1

N

34006451EN/AC - Page 33

Page 34

Appendix

Left cubicle of a 2000 kVA Static Switch

cross-section AA front view

air extraction

front

air

admission

rear

A

K2S switch

ACPZ board

XM127 to 132

air

admission

card cage

connection

from below

trough (if applicable)

L1 L2 L3N

inverter outputs

spacing

uprights

power cable routing via the bottom

Cables connected by lugs to 5 x (5 x 100) mm copper terminals and 16 mm diameter holes.

Height of connections relative to floor:

– inverter outputs : 700 mm

– remote relay board: 500 mm.

XR7

XR6

XR5

XR9

XR8

remote

relay

board

XR4

XR3

XR2

remote

XR1

relay

board

A

34006451EN/AC - Page 34

Page 35

3.3 Details of earthing connections in the various cubicles

Rectifier-inverter cubicle

Appendix

door

three-phase

inductor

frame

left cubicle right cubicle

battery

inductor

inverter

transformer

inverter

input

mains 1

door

transformer

AIRZ AIRZ

door

inverter

input

connection with

a bolt, nut and

contact washer

mains 2

inverter

transformer

earth bar

frame

transformer

door

door

120 to 1200 kVA Static Switch Cubicles

frame

earth bar

transformer

AIRZ

AIRZ

only for 120

to 800kVA

static-switch

cubicles

door

connection with a bolt,

nut and contact washer

mains 2

input

inverters

34006451EN/AC - Page 35

Page 36

Appendix

2000 kVA Static Switch Cubicles

door

input

inverters

door

SYNI

earth bar earth bar

input

connection with

a bolt, nut and

contact washer

mains 2

framedoorframe

door

"Tele-Monitor" unit

connection with a bolt,

nut and contact washer

Tele Monitor unit

COMZ

mains

34006451EN/AC - Page 36

Page 37

34006451EN/AC - Page 37

Page 38

34006451EN/AC - Page 38

Page 39

34006451EN/AC - Page 39

Page 40

34006451EN/AC

Loading...

Loading...