Page 1

MGETM GalaxyTM 5000

20 - 120 kVA

Installation and user manual

Page 2

Introduction

Thank you for selecting an APC by Schneider Electric product to protect your electrical equipment.

The MGE

We recommend that you take the time to read this manual to take full advantage of the many features of your UPS.

TM

GalaxyTM 5000 range has been designed with the utmost care.

APC by Schneider Electric pays great attention to the environmental impact of its products.

Measures that have made MGE

◗ the eco-design approach used in product development,

◗ the elimination of harmonic disturbances reinjected into the AC source,

◗ production in an ISO 14001 certified factory,

◗ recycling of the MGE

TM

To discover the entire range of APC by Schneider Electric products and the options available for the MGE

TM

GalaxyTM 5000 a reference in environmental protection include:

GalaxyTM 5000 at the end of its service life.

TM

GalaxyTM 5000

range, we invite you to visit our web site, www.apc.com, or contact your local APC by Schneider Electric representative.

34001813EN/AE - Page 2

All products in the MGETM GalaxyTM 5000 range are protected by patents. They implement original technology not available to

competitors of APC by Schneider Electric.

To take into account evolving standards and technology, equipment may be modified without notice. Indications concerning

technical characteristics and dimensions are not binding unless confirmed by APC by Schneider Electric.

This document may be copied only with the written consent of Schneider Electric and its affiliated companies. Authorised copies

must be marked

TM

GalaxyTM 5000 Installation and user manual no. 3400181300".

"MGE

Page 3

Safety rules

Safety of persons

The UPS must be installed in a room with restricted access (qualified personnel only, according to standard 62040-1-2).

A UPS has its own internal power source (the battery). Consequently, the power outlets may be energised even if the UPS is

disconnected from the AC-power source.

Dangerous voltage levels are present within the UPS. It should be opened exclusively by qualified service personnel.

The UPS must be properly earthed.

The battery supplied with the UPS contains small amounts of toxic materials.

To avoid accidents, the instructions below must be observed.

◗ Never operate the UPS if the ambient temperature and relative humidity are higher than the levels specified in the

documentation.

◗ Never burn the battery (risk of explosion).

◗ Do not attempt to open the battery (the electrolyte is dangerous for the eyes and skin).

◗ Comply with all applicable regulations for the disposal of the battery.

◗ Caution, wait five minutes before opening the UPS to allow the capacitors to discharge.

◗ Caution, there is high leakage current, the earthing conductor must be connected first.

◗ The product must be installed on a non-inflammable surface (e.g. concrete).

◗ Caution, battery replacement must be carried out by qualified personnel.

Safety

Product safety

A protection circuit breaker must be installed upstream and be easily accessible.

◗ Never install the UPS near liquids or in an excessively damp environment.

◗ Never let a liquid or foreign body penetrate inside the UPS.

◗ Never block the ventilation grates of the UPS.

◗ Never expose the UPS to direct sunlight or a source of heat.

◗ When replacing battery cells, use the same type and number of cells.

Special precautions

◗ The UPS connection instructions contained in this manual must be followed in the indicated order.

◗ Check that the indications on the rating plate correspond to your AC-power system and to the actual electrical consumption

of all the equipment to be connected to the UPS.

◗ If the UPS must be stored prior to installation, storage must be in a dry place.

◗ The admissible storage temperature range is -25° C to +45° C.

◗ If the UPS remains de-energised for a long period, we recommend that you energise the UPS for a period of 24 hours, at

least once every month. This charges the battery, thus avoiding possible irreversible damage.

◗ The UPS is designed for normal climatic and environmental operating conditions concerning the altitude, ambient operating

temperature, relative humidity and ambient transport and storage conditions.

◗ Using the UPS within the given limits guarantees its operation, but may affect the service life of certain components,

particularly that of the battery and its autonomy. The maximum storage time of the UPS is limited due to the need to recharge

its integrated battery.

◗ Unusual operating conditions may justify special design or protection measures:

- harmful smoke, dust, abrasive dust,

- humidity, vapour, salt air, bad weather or dripping,

- explosive dust and gas mixture,

- extreme temperature variations,

- bad ventilation,

- conductive or radiant heat from other sources,

- cooling water containing acid or impurities which may cause scale, silt, electrolysis or corrosion of converter parts exposed

to water,

- strong electromagnetic fields,

- radioactive levels higher than those of the natural environment,

- fungus, insects, vermin, etc.,

- battery operating conditions.

◗ The UPS must always be installed in compliance with:

◗ the requirements of standard IEC 60364-4-42: Protection from thermal effects.

◗ standard IEC 60364-4-41: Protection from electric shock.

◗ standard IEC 60364-4-482: Electrical installations of buildings.

◗ in France, the requirements of standard NFC 15-100.

34001813EN/AE - Page 3

Page 4

Foreword

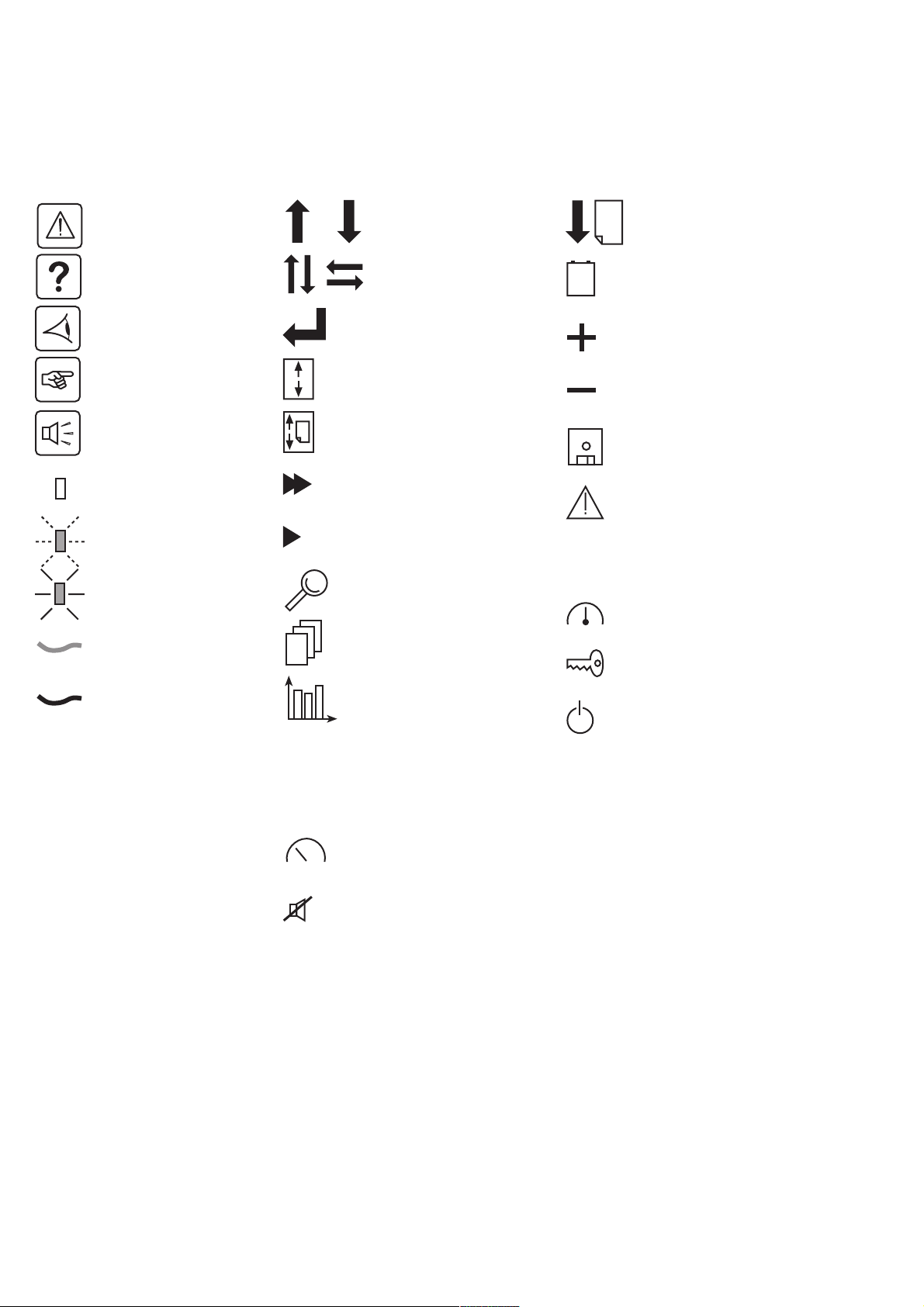

Pictograms

Document Display

Danger, these instructions are

imperative.

Information, advice, help

Visual indication

Action

Audio signal

LED OFF

LED flashing

LED ON

Earth cables

Vertical selection

Other selection

Enter / Confirm

Event scroll in log

Page scroll in log

Fast forward

Forward

Details

Circular menu

17

mai

0101

1010

0101

Move up or down one page

Event selection in log by date and

time

Increase

Decrease

Save

Alarm

Status conditions

Settings

Maintenance

Other cables

E

S

Graphical display

Control

Return to previous display

C

D

E

Delete

L

VOLT

Access to measurements

Buzzer off

34001813EN/AE - Page 4

Page 5

Contents

1. Presentation

1.1 MGE TM Galaxy TM 5000 .............................................................................................................. 8

UPS cabinet .................................................................................................................................. 8

External battery cabinet / auxiliary cabinet ...................................................................................8

1.2 Inside the UPS cabinet, access to connections ......................................................................... 9

1.3 Cabinet layout (normal or false floor) ...................................................................................... 10

1.4 User-machine interface ...............................................................................................................11

1.5 Relay communication card .........................................................................................................11

2. Installation

2.1 Location ....................................................................................................................................... 12

2.2 Layout of cabinets ...................................................................................................................... 12

2.3 Removing the cardboard protecting the batteries ................................................................... 13

In the UPS .................................................................................................................................. 13

In the external battery cabinet ..................................................................................................... 13

2.4 Required protective devices and cable sizes ........................................................................... 14

Recommended upstream protection ........................................................................................... 14

Recommended downstream protection ...................................................................................... 14

Earth-leakage current ................................................................................................................. 14

Required cable sizes ................................................................................................................... 15

Required cable sizes for parallel UPS installations with an external bypass .............................. 16

2.5 2.5 System earthing arrangements ........................................................................................... 17

TNS upstream and TNS downstream installation ....................................................................... 17

TNC upstream, TNS downstream ............................................................................................... 18

Installation with upstream IT and downstream TNS ................................................................... 18

Installation with upstream TT and downstream TT (with upstream differential protection) ......... 18

Frequency converter (without Bypass AC input) ......................................................................... 19

Parallel configuration without external bypass cabinet and with common normal and Bypass AC

inputs (maximum two units in parallel) ........................................................................................ 19

Parallel configuration without external bypass cabinet and with separate normal and Bypass AC

inputs (maximum two units in parallel) ........................................................................................ 20

Parallel UPS with external bypass cabinet and separate Normal and Bypass AC network inputs (6

UPS in parallel for 4PN) .............................................................................................................. 21

2.6 Connection of power cables in a single UPS unit ................................................................... 22

2.7 Earth-cable connection for a single unit in a TNC earthing system ...................................... 23

2.8 Connection of power cables for parallel UPS units ................................................................. 24

Equipotential bonding between parallel-connected units ............................................................ 24

Redundant parallel configuration (maximum two UPS units for Pn) ........................................... 25

2.9 Connection of the 150 kVA external bypass cabinet ............................................................... 28

2.10 Connection of the 360 kVA external bypass cabinet ............................................................. 29

2.11 Connection of the 600 kVA external bypass cabinet ............................................................. 30

2.12 Auxiliary interconnections between UPS units in parallel configurations .......................... 31

Redundant parallel configuration (maximum two UPS units) ...................................................... 31

.................................................................................................................................................... 31

Parallel configuration for increased capacity (maximum four UPS units) ................................... 32

Fitting the protection cover for the auxiliary interconnection cables ........................................... 33

2.13 Connection of general shutdown or emergency power off (EPO) terminal block .............. 33

2.14 Connection of the relay communications card ...................................................................... 34

2.15 Running the control/communications cables ........................................................................ 36

Single UPS ................................................................................................................................. 36

Parallel UPS ................................................................................................................................ 37

334001813EN/AE - Page 5

Page 6

Contents

2.16 Power connections for an external battery cabinet ...............................................................38

2.17 Assembly and connection of an empty battery cabinet ........................................................38

Mounting the battery circuit breaker kit ........................................................................................38

Mounting the shelves and the battery cells .................................................................................39

2.18 Control connections for an external battery cabinet .............................................................40

2.19 Connection of an input isolating transformer .........................................................................41

2.20 Connection of an output isolating transformer ......................................................................41

3. Operation

3.1 Shutting down a single UPS .......................................................................................................42

3.2 Restarting a single UPS ..............................................................................................................42

3.3 Shutting down a parallel configuration .....................................................................................43

3.4 Restarting a parallel configuration .............................................................................................43

3.5 Operation of mimic-panel LEDs .................................................................................................44

Single UPS start sequence on Normal AC input .........................................................................44

Single UPS start sequence on Bypass AC input .........................................................................44

3.6 Operating modes .........................................................................................................................45

Normal (double conversion) mode ..............................................................................................45

ECO mode (single UPS only) ......................................................................................................45

3.7 Load on battery power ................................................................................................................46

Transfer to battery power .............................................................................................................46

End of battery power ...................................................................................................................46

3.8 UPS personalisation ....................................................................................................................46

Access to the personalisation functions ......................................................................................46

Operating mode ...........................................................................................................................47

Frequency ....................................................................................................................................47

Automatic bypass ........................................................................................................................47

Battery .........................................................................................................................................47

3.9 Relay contacts (communications card) .....................................................................................48

3.10 Display functions .......................................................................................................................49

4. Maintenance

4.1 Identification of alarms ...............................................................................................................50

4.2 Life Cycle Monitoring (LCM) .......................................................................................................50

4.3 UPS isolation ................................................................................................................................51

Single UPS ..................................................................................................................................51

Frequency converter ....................................................................................................................51

UPS operating in ECO mode .......................................................................................................51

Parallel UPS configuration without external bypass cabinet ........................................................52

Parallel UPS configuration with external bypass cabinet .............................................................53

4.4 Return to the normal position ....................................................................................................54

Single UPS ..................................................................................................................................54

Frequency converter ....................................................................................................................54

Parallel UPS configuration without external bypass cabinet ........................................................55

Parallel UPS configuration with external bypass cabinet .............................................................56

4.5 Training centres ...........................................................................................................................57

5. Environment

6. Available options

Backfeed option ...........................................................................................................................59

334001813EN/AE - Page 6

Page 7

Contents

NMC (Network Management Card) option .................................................................................. 59

Optional communications card with additional power relay ........................................................ 59

Optional serial communications card .......................................................................................... 59

Telpac Power Services option ..................................................................................................... 59

AS4I option ................................................................................................................................. 59

Multislot option ............................................................................................................................ 59

External synchronisation module option ..................................................................................... 59

IP32 option .................................................................................................................................. 59

7. Appendices

7.1 Technical sheets ......................................................................................................................... 60

Center of gravity .......................................................................................................................... 60

Electrical characteristics ............................................................................................................. 61

Thermal characteristics ............................................................................................................... 64

General characteristics of MGE TM Galaxy TM 5000 UPSs ...................................................... 65

General characteristics of MGE TM Galaxy TM 5000 UPSs (cont.) ........................................... 66

UPS components ........................................................................................................................ 66

7.2 Options ........................................................................................................................................ 67

IP32 installation ........................................................................................................................... 67

7.3 Glossary ....................................................................................................................................... 68

334001813EN/AE - Page 7

Page 8

1. Presentation

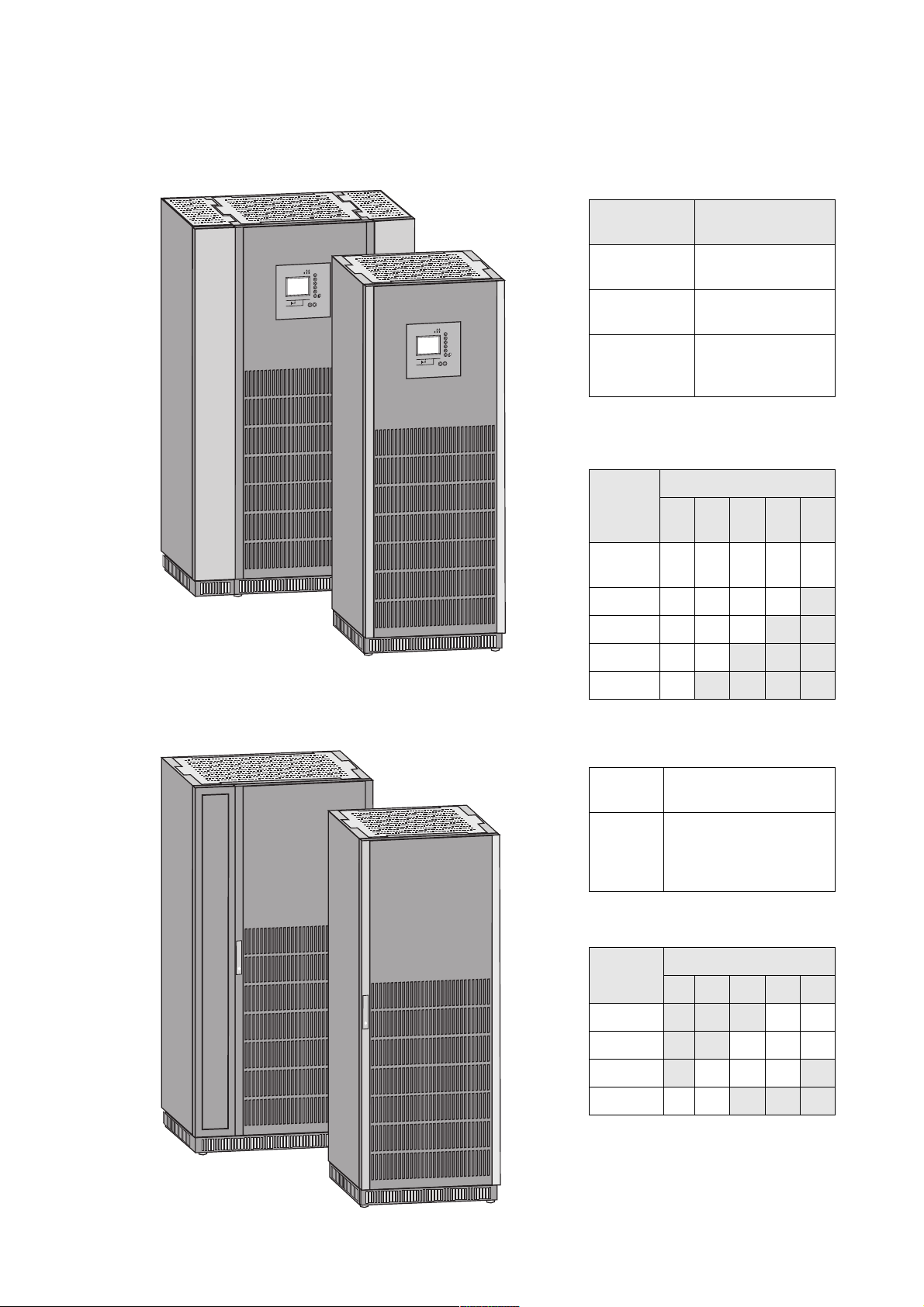

1.1 MGE

TM

UPS cabinet

Galaxy TM 5000

Dimensions

UPS power

rating (kVA)

~

?

IO

3s

~

?

IO

3s

20/30/40/60

without battery

80/100/120

without battery

20/30/40/60/80

with internal

Dimensions

(H x W x D)

1900 x 712 x 850 mm

1900 x 712 x 850 mm

1900 x 1112 x 850 mm

battery

Weight in kg (UPS without battery or with

built-in battery)

Backup

time

UPS power rating (kVA)

203040 60 80 100

120

Without

400 400 400 520 520

battery

External battery cabinet / auxiliary cabinet

5 min 808 808 958 1120

10 min 808 958 1045

15 min 958 1045

30 min 1045

Dimensions (H x W x D) and weight

Cabinet 700

mm (empty)

Cabinet

1000 mm

1900 x 712 x 850 mm

135 kg

1900 x 1012 x 850 mm

150 kg

wide

(empty)

Weight in kg (cabinet alone)

Backup

time

5 min

10 min

UPS power rating (kVA)

40 60 80 100 120

885 980

885 1142 1307

34001813EN/AE - Page 8

15 min

30 min 882 1307

885 1142 1307 1764

1764 2439 2742

Weights highlighted in grey are for double

cabinets.

Page 9

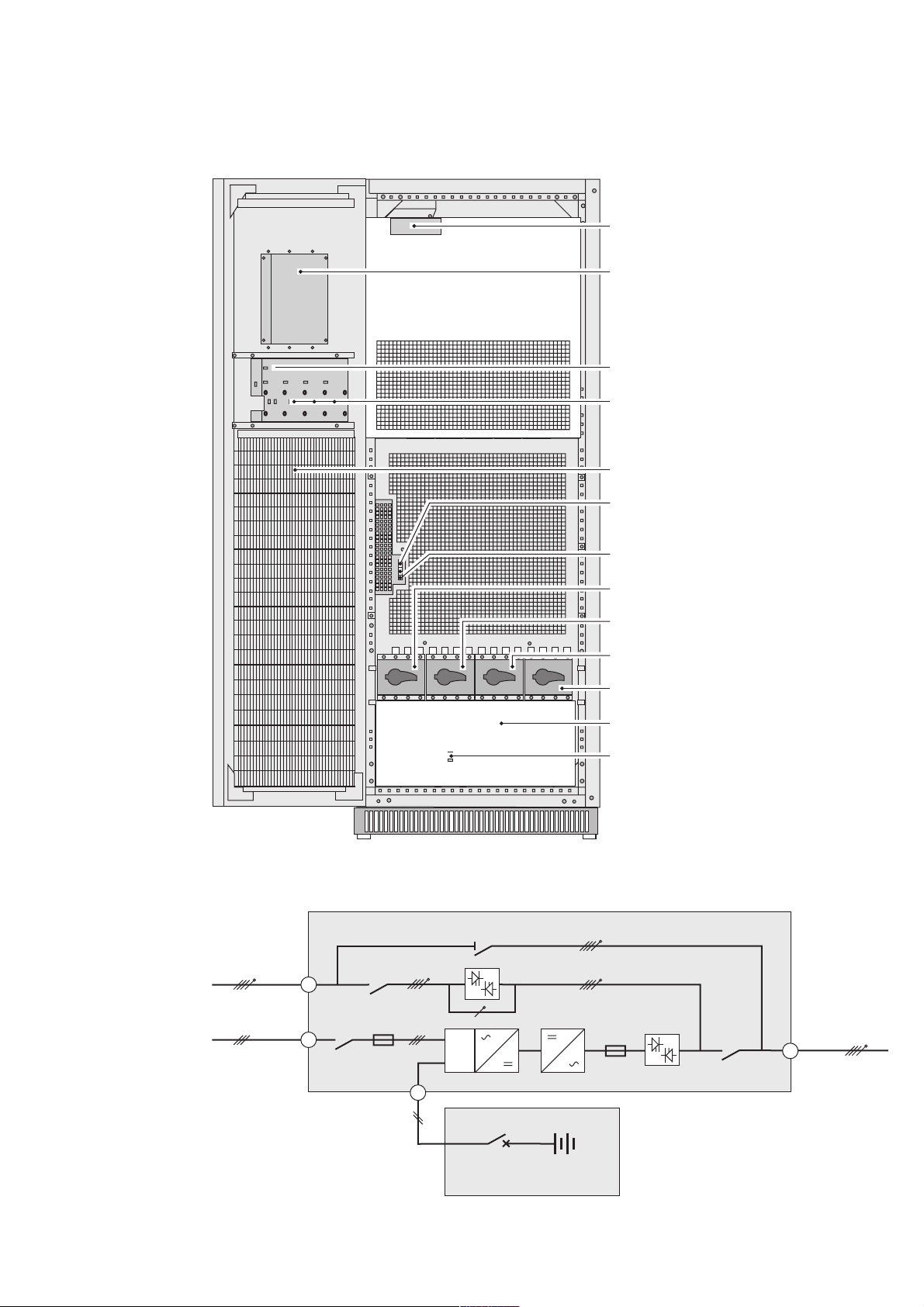

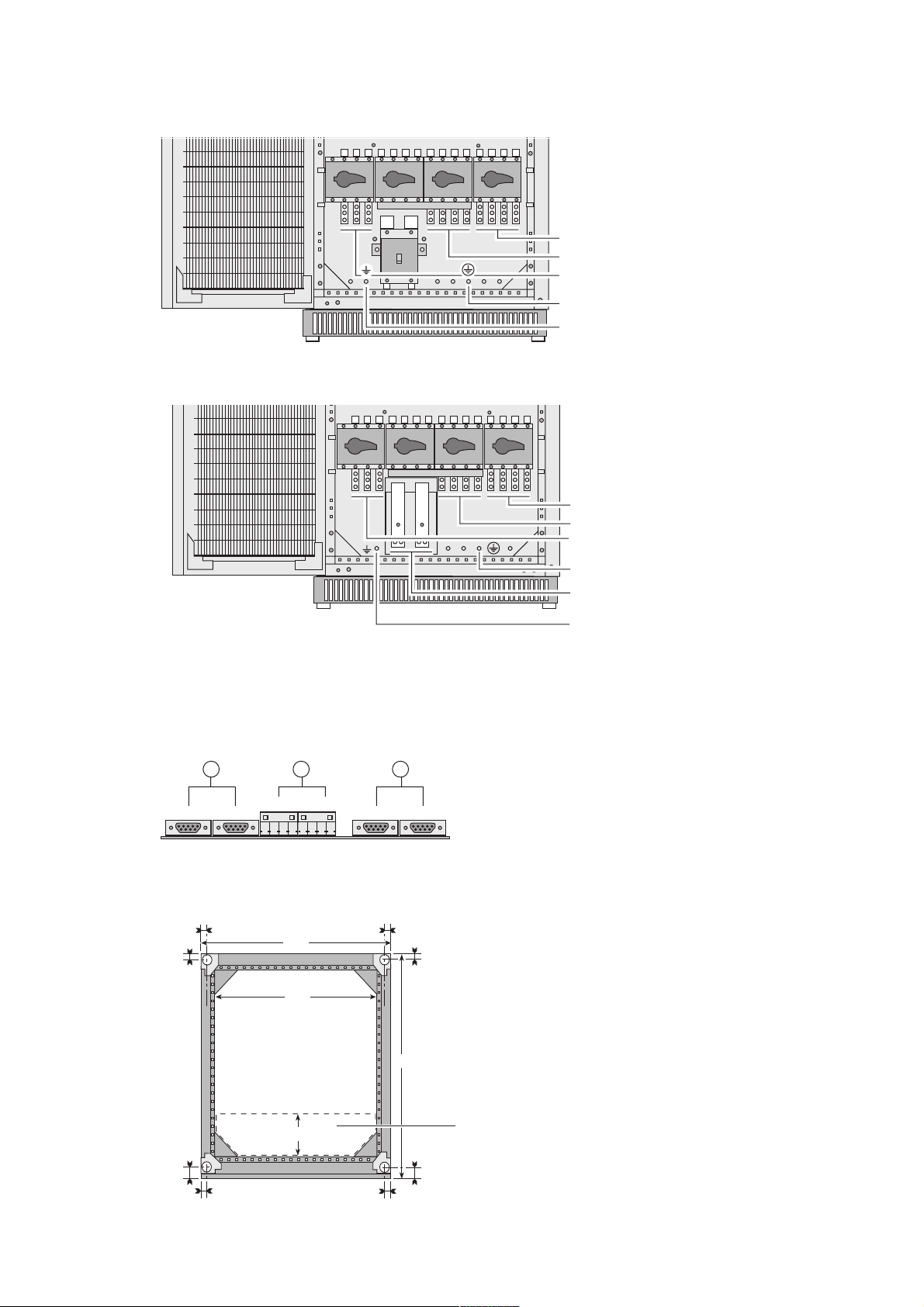

1.2 Inside the UPS cabinet, access to connections

Example of version with built-in battery

1. Presentation

(1)Connectors for auxiliary interconnections

of parallel UPS units (INTN card)

(2)User-machine interface

(3)Slot for relay communications card

(4) Free slots for optional communication

cards

(5) Open cabinet door

(6) Screw-type terminal block for connections

of contacts and coils for two external battery

circuit breakers

(7) Screw-type terminal block for connection

of emergency power off (EPO)

(8) Q1: input switch for Normal AC input

Q1 Q4S Q3BP Q5N

QF1

Simplified diagram of power connections

Q3BP

Bypass AC

Normal AC

15

16

Q1

Q4S

FU

PFC

(9) Q4S: input switch for Bypass AC input

(10) Q3BP: bypass switch

(11) Q5N: UPS output switch

(12) Protection cover for power-connection

terminal blocks

(13) QF1: battery circuit breaker (only

versions with built-in battery)

FU

Q5N

14

Load

22

QF1

Battery cabinet

34001813EN/AE - Page 9

Page 10

1. Presentation

Power-connection terminal blocks (version with built-in battery)

View with terminal-block protection cover

removed

Q1 Q4S

Q3BP

Q5N

QF1

Power-connection terminal blocks (version with external battery)

Q1 Q4S

-

+

Q3BP

Q5N

(14) Terminal block for load output

(15) Terminal block for Bypass AC input

(16) Terminal block for Normal AC input

(17) Main earthing connector

(18) Secondary earthing connector (auxiliary

cabinets)

(14) Terminal block for load output

(15) Terminal block for Bypass AC input

(16) Terminal block for Normal AC input

(17) Main earthing connector

(22) Connection of external battery

(+/- poles)

(18) Secondary earthing connector (auxiliary

cabinets)

INTN card for auxiliary interconnections of parallel UPS units

19 20 21

XMS02 XMS03

XMS04 XMS05

XMS06 XMS07

1.3 Cabinet layout (normal or false floor)

33.5

70.5

33.5

33.5

712

590

170

Front

33.5

33.5

850

70.5

33.5

(19) DB9 connectors: exchange-current

information

(20) Screw connectors: position information

on Q5N, Q4S and Q3BP switches, from the

external bypass

(21) DB9 connectors: CAN communication

information between UPSs

The four feet of the cabinet are cylindrical, 40

mm in diameter.

The measurements opposite include cabinet

siding (panels and door).

Cable-

running

zone

34001813EN/AE - Page 10

Page 11

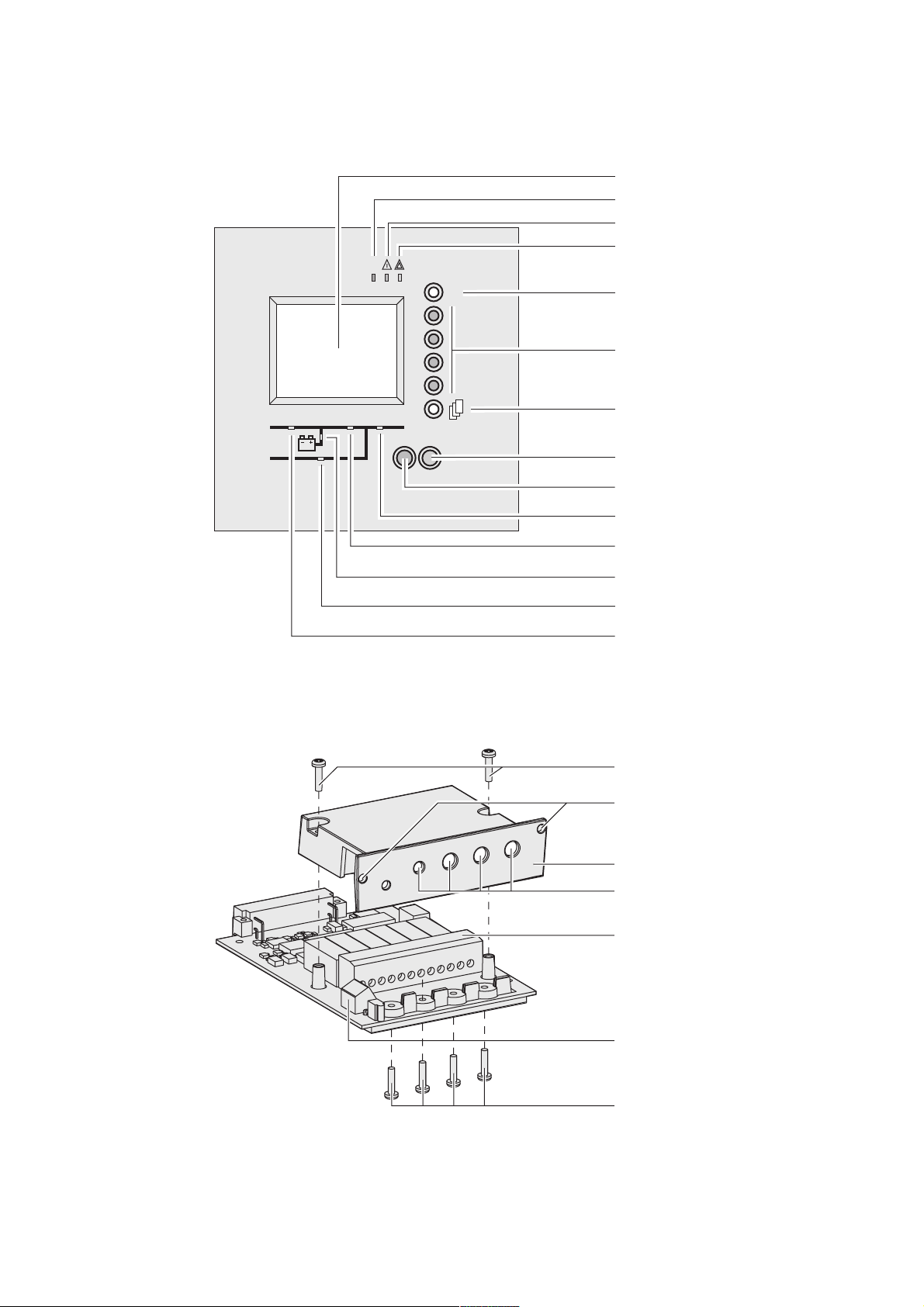

1.4 User-machine interface

1. Presentation

(30) Graphical display

(31) Load protected LED

(32) Minor fault LED

(33) Major fault LED

~

?

(34) Help key

(35) Function keys

(36) Menu key

1.5 Relay communication card

IO

3s

(38) OFF button

(37) ON button

(42) Load supplied LED

(40) UPS ON LED

(41) Operation on battery power LED

(43) Bypass in operation LED

(39) PFC ON LED

(50) Card cover screws

(51) Card screw holes

(52) Card cover

(53) Cable entry holes

(54) Output terminal block

6

5

4

3

2

1

B

A

(55) Input terminal block

(56) Cable clamping screws

34001813EN/AE - Page 11

Page 12

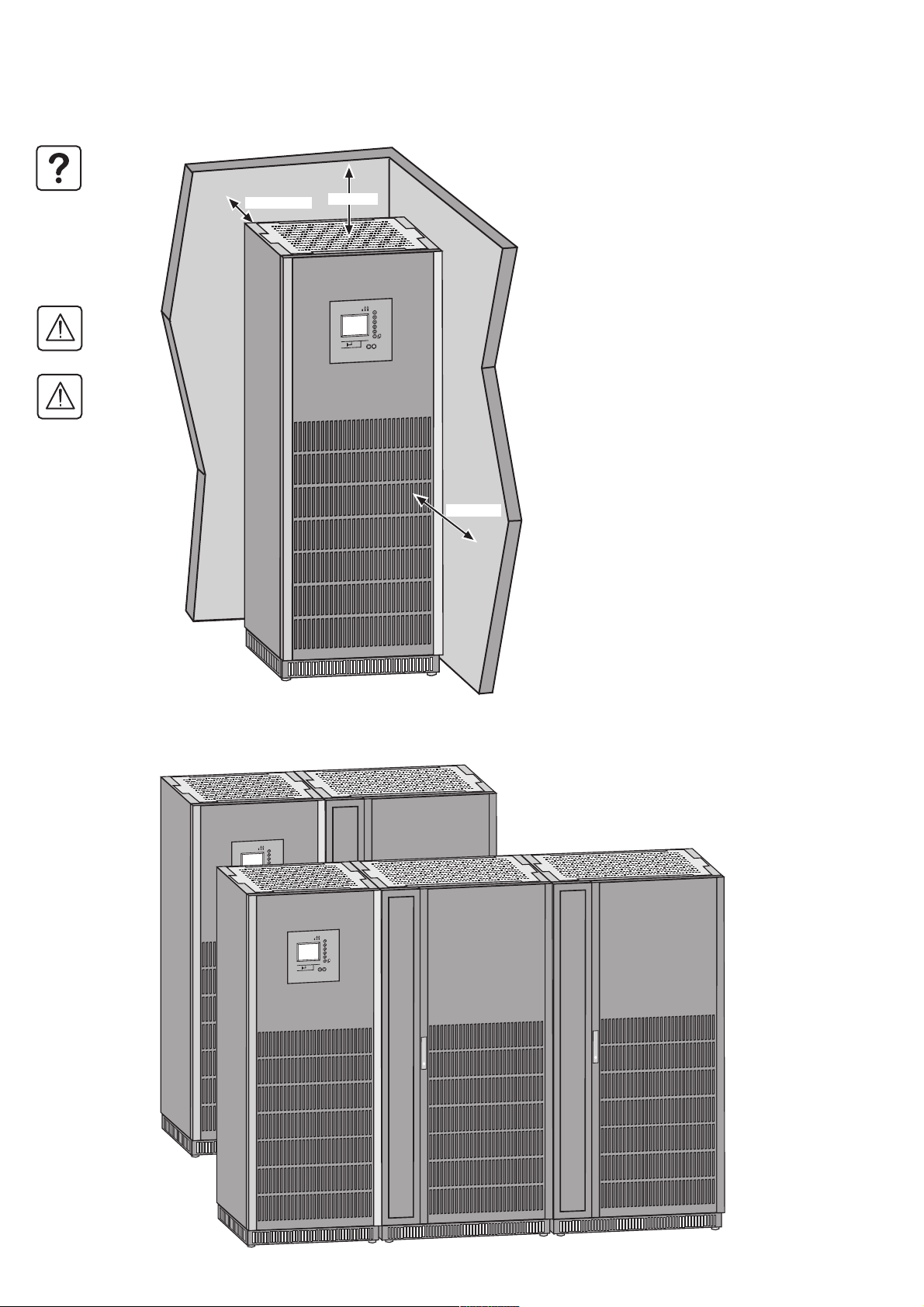

2. Installation

2.1 Location

To ensure correct ventilation, leave nothing

0 - 600 mm*

>500 mm

on top of the UPS.

Leave one meter of free space in front of the

UPS for door opening.

The cabinet rests on four cylindrical feet,

40 mm in diameter, positioned in the four

corners of the cabinet to spread the weight.

If 500 mm of free space is not maintained

~

?

above the UPS, abnormal temperature rise

IO

3s

may occur.

The UPS must be installed in a room with

restricted access (qualified personnel

only).

(*) The UPS can operate correctly back to the

wall, but it is preferable to leave some space

for easier maintenance.

>1000 mm

2.2 Layout of cabinets

UPS cabinet

~

?

IO

3s

UPS cabinet

Battery cabinet

Battery cabinet 1

~

?

O

I

3s

Battery cabinet 2

34001813EN/AE - Page 12

Page 13

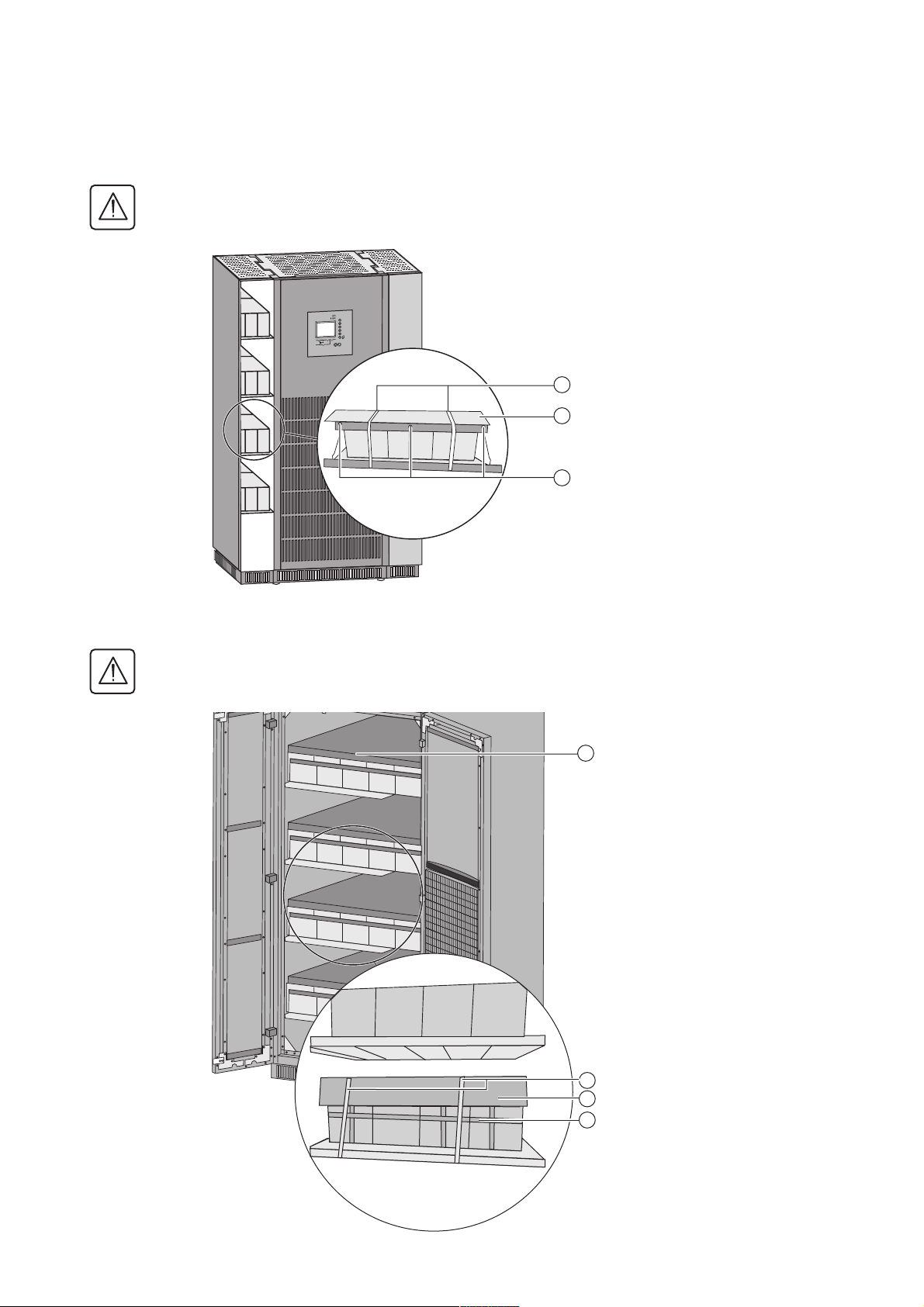

2.3 Removing the cardboard protecting the batteries

In the UPS

The cardboard protecting the batteries must always be removed once the equipment is installed in its final location.

~

?

IO

s

3

1

2

3

2. Installation

1 - Remove the ties holding the cardboard (1).

2 - Remove the cardboard (2).

3 - Remove the struts (3).

In the external battery cabinet

The cardboard protecting the batteries must always be removed once the equipment is installed in its final location.

1 - Remove the battery support upright (1).

1

2 - Remove the ties holding the cardboard (2)

(1000 mm external battery cabinet).

3 - Remove the cardboard protecting the

batteries (3).

4 - Remove the ties holding the batteries (4).

2

3

4

34001813EN/AE - Page 13

Page 14

2. Installation

2.4 Required protective devices and cable sizes

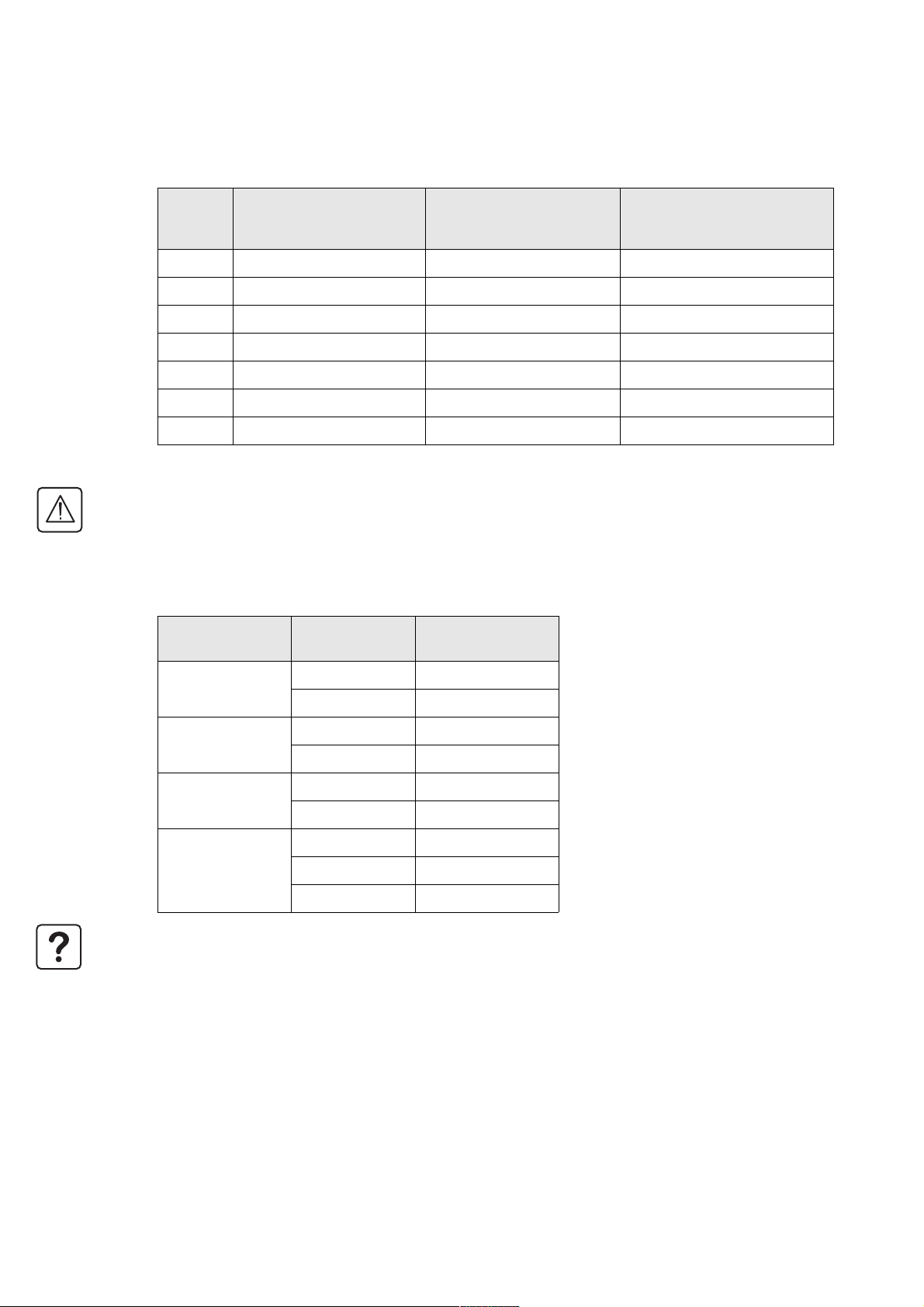

Recommended upstream protection

UPS

power

rating

20 kVA C60L - 50 A NS100N 4P-TM100A NS100N 4P-TM100A

30 kVA C60L - 63 A NS100N 4P-TM100A NS100N 4P-TM100A

40 kVA NS100N 3P-TM80A NS100N 4P-TM100A NS100N 4P-TM100A

60 kVA NS125E 3P-TM125A NS125E 4P-TM125A NS125E 4P-TM125A

80 kVA NS160N 3P-TM160A NS160N 4P-TM160A NS160N 4P-TM160A

100 kVA NS250N 3P-TM200A NS250N 4P-TM250A NS250N 4P-TM250A

120 kVA NS250N 3P-TM250A NS250N 4P-TM250A NS250N 4P-TM250A

The circuit breakers recommended above respect the requirements for discrimination with the UPS fuses

Upstream circuit-breaker on

separate Normal AC input

Upstream circuit-breaker on

separate Bypass AC input

Upstream circuit-breakers on

common bypass and Normal AC

input

Stick a label with the following text on each upstream circuit breaker:

"Isolate Uninterrptible Power Supply (UPS) before working on this circuit".

Recommended downstream protection

UPS power rating Downstream

circuit breaker

20-30-40 kVA C60N C 16A

C60N B 25A

60 kVA C60N C 20A

C60N B 32A

80 kVA C60N C 25A

C60N B 50A

100-120 kVA C60N C 32A

C120N B 63A

NS100 TMG 50A

Note. See the simplified diagrams in the appendix for common or separate AC inputs, indicating the positions of the protection

devices, the characteristics of the internal UPS fuses and UPS line currents under overload conditions.

Trip unit Curve N for the downstream circuit breaker

may be replaced by curve H or L, depending

on the installation.

The indicated protection ensures

discrimination for each output circuit

downstream of the UPS, whether supplied by

via the normal or the Bypass AC source. If

these recommendations are not followed, a

short-circuit on an output circuit can result in

a break in power longer than 20 milliseconds

on all the other output circuits.

Earth-leakage current

UPS earth-leakage current is 1 A.

34001813EN/AE - Page 14

Page 15

Required cable sizes

Cable sizes are determined for copper conductors (for aluminium conductors, increase the size by 30%). Size

calculations also take into account a voltage of 400 V and grouping of four cables.

2. Installation

UPS power

rating

20 kVA 10 mm

30 kVA 16 mm

40 kVA 16 mm

60 kVA 25 mm

80 kVA 50 mm

100 kVA 50 mm

120 kVA 70 mm

Minimum sizes for

separate Normal AC

input copper cables

(<100 m)

2

2

2

2

2

2

2

Minimum sizes for

separate Bypass

AC input copper

cables (<100 m)

16 mm

16 mm

16 mm

25 mm

50 mm

70 mm

70 mm

Connections are made to pre-drilled terminals.

Hole diameter: 6.5 mm (8.5 mm for 120 kVA).

Earthing cables connect to the earthing plate.

Hole diameter: 6.5 mm (8.5 mm for 120 kVA).

Minimum sizes

for common

bypass and

Normal AC input

Minimum sizes

for copper loadcircuit cables

(<100 m)

Battery/terminal

connection

(<15 m)

copper cables

(<100 m)

2

2

2

2

2

2

2

16 mm

16 mm

16 mm

25 mm

50 mm

70 mm

70 mm

2

2

2

2

2

2

2

16 mm

16 mm

16 mm

25 mm

50 mm

70 mm

70 mm

2

2

2

2

2

2

2

2

16 mm

2

25 mm

2

35 mm

2

70 mm

2

95 mm

2 x 50 mm

2 x 70 mm

2

2

34001813EN/AE - Page 15

Page 16

2. Installation

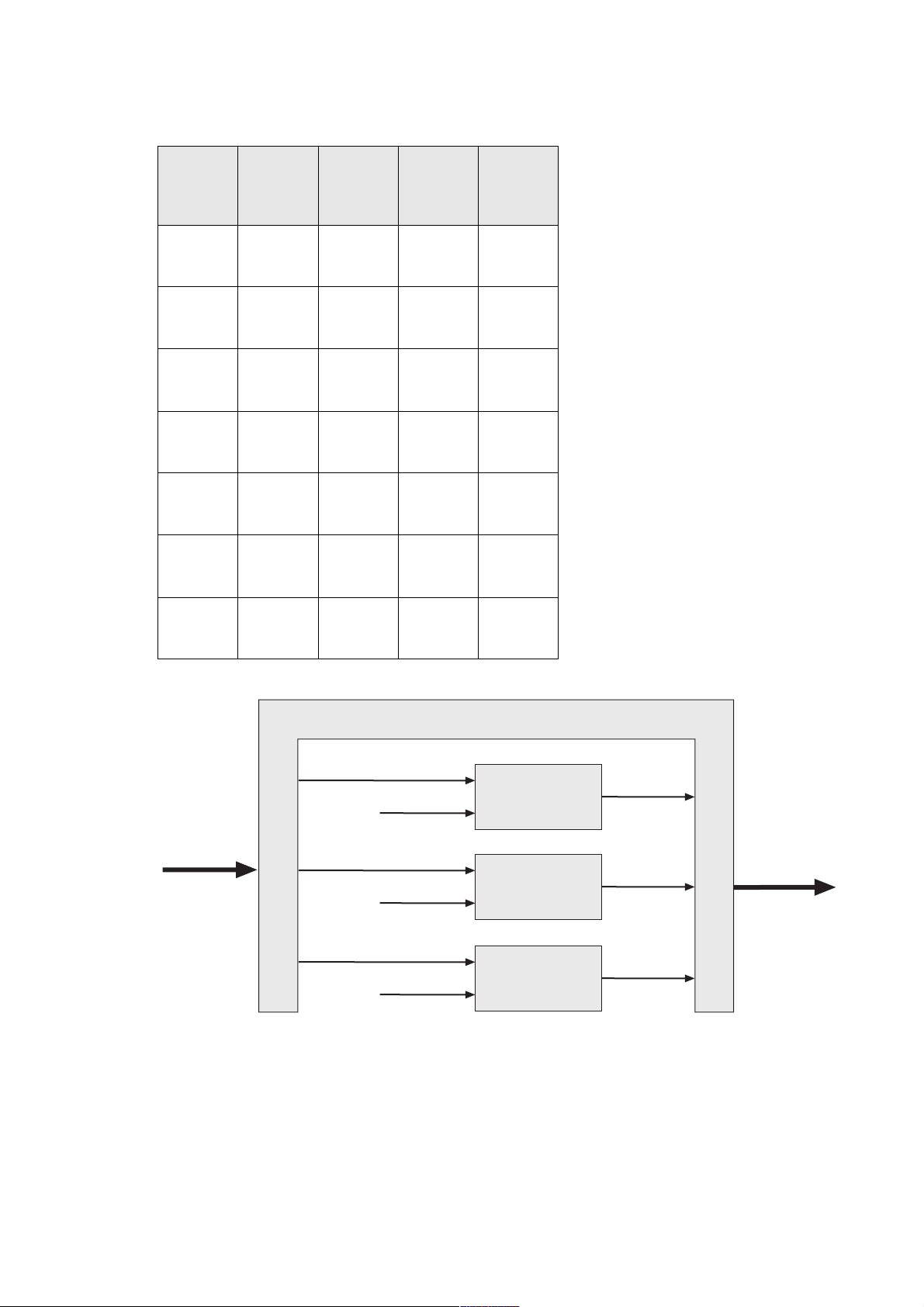

Required cable sizes for parallel UPS installations with an external bypass

Rated

power of

each UPS

unit

20 kVA 2

30 kVA 2

40 kVA 2

60 kVA 2

80 kVA 2

Number of

parallel

UPS units

3

4

3

4

3

4

3

4

3

4

Total rated

power of

the UPS

40 kVA

60 kVA

80 kVA

60 kVA

90 kVA

120 kVA

80 kVA

120 kVA

160 kVA

120 kVA

180 kVA

240 kVA

160 kVA

240 kVA

320 kVA

Bypass AC

input or

load line

current

58 A

87 A

116 A

80 A

129 A

172 A

116 A

174 A

232 A

174 A

261 A

348 A

232 A

348 A

464 A

Cable

(1)

size

in mm

16

35

50

25

50

70

35

70

120

70

150

185

120

185

2 x 120

The table opposite is an example for an

2

installation with up to four UPS units.

◗ For installations with redundant units, take

into account only the number of units required

to supply the loads (e.g. in a three-unit

installation where one unit is redundant, only

two units count in determining the input and

load currents).

◗ This table is valid for 400 V input and load

phase-to-phase voltages, at rated load with a

power factor of 0.8. For voltages of 380 or

415 V, multiply the current values by 1.05 or

0.96 respectively and, if necessary, modify

the cable sizes accordingly.

◗ The cable sizes in this table concern the bold

sections in the diagram below.

(1) Cable sizes are determined for U1000

R02V type copper conductors (for aluminium

conductors, increase the size by 30%). Size

calculations also take into account a voltage

of 400 V and grouping of four cables.

100 kVA 2

120 kVA 2

Bypass AC

200 kVA

3

4

300 kVA

400 kVA

240 kVA

3

4

360 kVA

480 kVA

288 A

432 A

576 A

348 A

522 A

696 A

150

2 x 95

2 x 150

185

2 x 150

2 x 185

External bypass

Bypass AC

Normal AC

Bypass AC

Normal AC

Bypass AC

Normal AC

GALAXY 5000

1

GALAXY 5000

2

GALAXY 5000

3

Load

34001813EN/AE - Page 16

Page 17

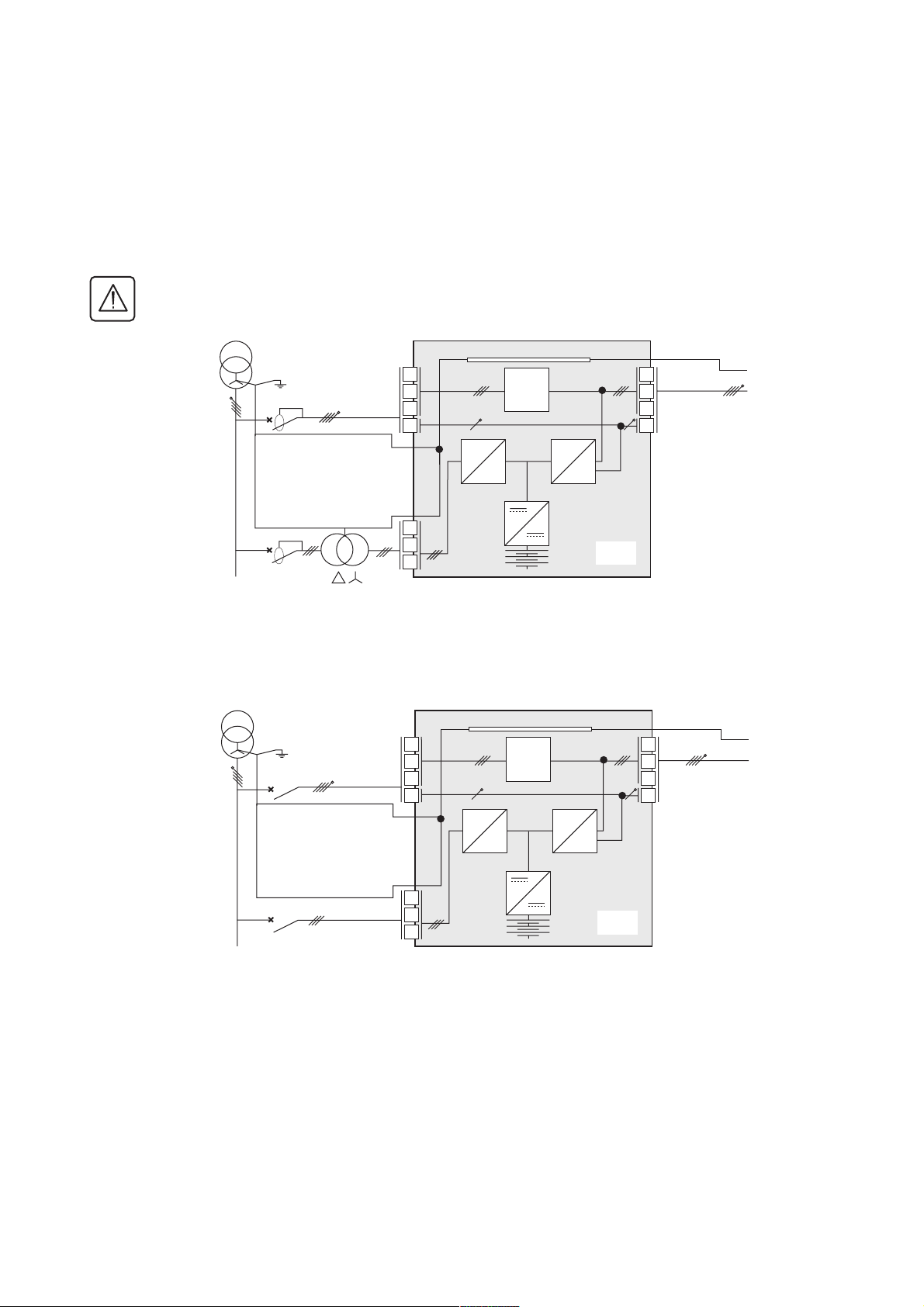

2.5 2.5 System earthing arrangements

This chapter lists the main system earthing arrangements and their wiring requirements. For system earthing arrangements

which are not listed in this document, please refer to the “SEA guide” reference 34002636XT..

TNS upstream and TNS downstream installation

For separate Normal AC and Bypass AC lines from a single source.

With differential circuit breaker:

The Normal and Bypass AC lines must be galvanically isolated

Upstream differential protection rating must be at least 3A

2. Installation

L1

L2

L3

Bypass AC

PE

Normal AC

MLVS

N

L1

L2

L3

Without differential circuit breaker:

L1

L2

L3

Bypass AC

PE

N

PFC

PFC

PE

SS

PE

SS

INV

INV

UPS

PE

L1

L2

L3

N

L1

L2

L3

N

Load

PE

Load

MLVS

Normal AC

L1

L2

L3

UPS

34001813EN/AE - Page 17

Page 18

2. Installation

TNC upstream, TNS downstream

For separate Normal AC and Bypass AC lines from a single source

1.the UPS internal PEN bar must be connected to the Q4S neutral upstream of Q4S

2.The UPS internal PEN bar must be connected to the Q5N neutral downstream of Q5N

3.The UPS internal PE bar must be transformed into a PEN bar (cables supplied for TNC options)

L1

L2

L3

Bypass AC

PEN

PEN

Normal AC

MLVS

N

PFC

L1

L2

L3

Installation with upstream IT and downstream TNS

For separate Normal AC and Bypass AC lines from a single source

L1

R1

Bypass AC

L2

L3

N

PEN

SS

SS

PE

INV

UPS

L1

L2

L3

N

L1

L2

L3

N

PE

Load

PE

Load

INV

CPI2

UPS

MLVS

R2

Normal AC

CPI

PFC

L1

L2

L3

Installation with upstream TT and downstream TT (with upstream differential protection)

For separate Normal AC and Bypass AC lines from the same source

The upstream differential protection rating must be at least 3A

PE

UPS

L1

L2

L3

N

Load

Bypass AC

Normal AC

L1

L2

L3

N

L1

L2

L3

PFC

SS

INV

34001813EN/AE - Page 18

MLVS

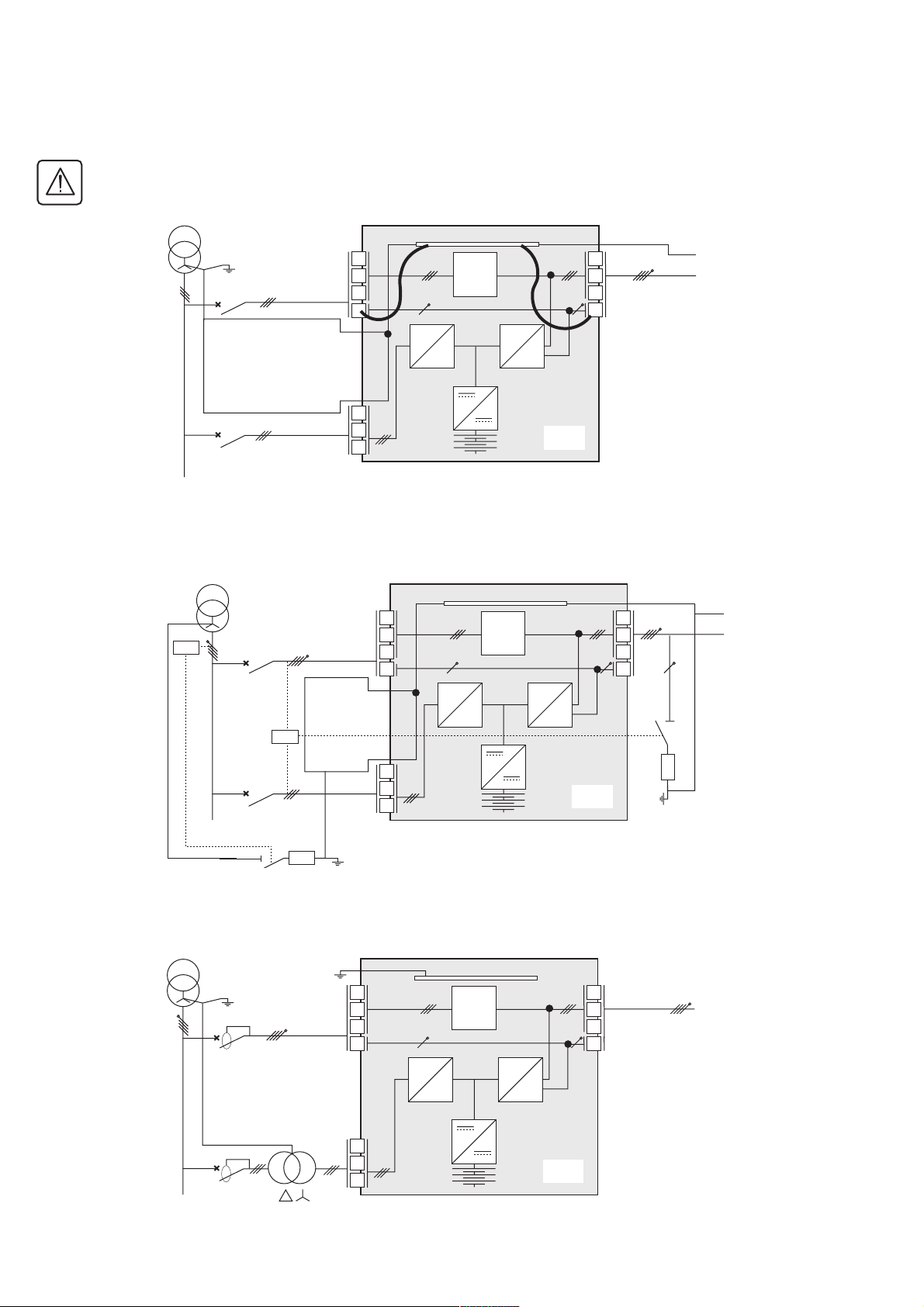

Page 19

Frequency converter (without Bypass AC input)

The UPS installation may be equipped with earth-leakage protection upstream on the condition that the protection

apply to:

- the normal and Bypass AC inputs

- all the parallel-connected UPSs.

Upstream and downstream: TT, TN or IT system with neutral distributed

2. Installation

Main lowvoltage

switchboard

(MLVS)

b

Normal AC

15

16

14

Load

Upstream and downstream: Neutral not distributed

Main lowvoltage

switchboard

(MLVS)

b

Normal AC

15

16

14

Load

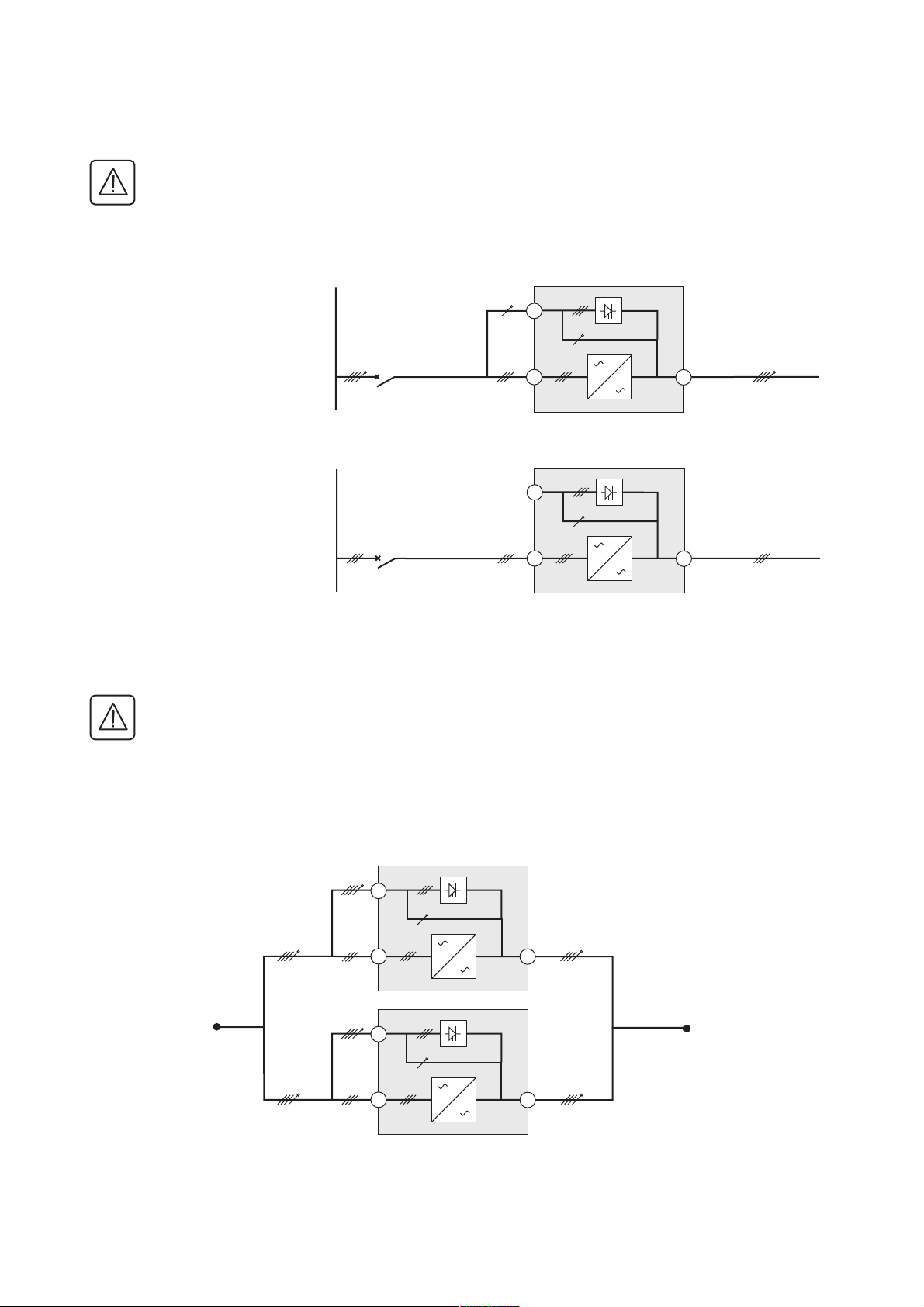

Parallel configuration without external bypass cabinet and with common normal and Bypass AC inputs (maximum two units in parallel)

The UPS installation may be equipped with earth-leakage protection upstream on the condition that the protection

apply to:

- the normal and Bypass AC inputs

- all the parallel-connected UPSs.

The requirements for the different system earthing arrangements (SEA) are similar to those for single UPS

configurations. In the diagrams on page 17, simply replace the single UPS units between points A and B by the

following parallel configuration.

Bypass AC

Normal AC

A

Bypass AC

Normal AC

15

16

14

B

15

16

14

34001813EN/AE - Page 19

Page 20

2. Installation

Parallel configuration without external bypass cabinet and with separate normal and Bypass AC inputs (maximum two units in parallel)

The UPS installation may be equipped with earth-leakage protection upstream on the condition that the protection

apply to:

- the normal and Bypass AC inputs

- all the parallel-connected UPSs.

The requirements for the different system earthing arrangements (SEA) are similar to those for single UPS

configurations. In the diagrams on page 18, simply replace the single UPS units between points A, B and C by the

following parallel configuration.

A

Bypass AC

15

B

Normal AC

Bypass AC

Normal AC

16

14

C

15

16

14

34001813EN/AE - Page 20

Page 21

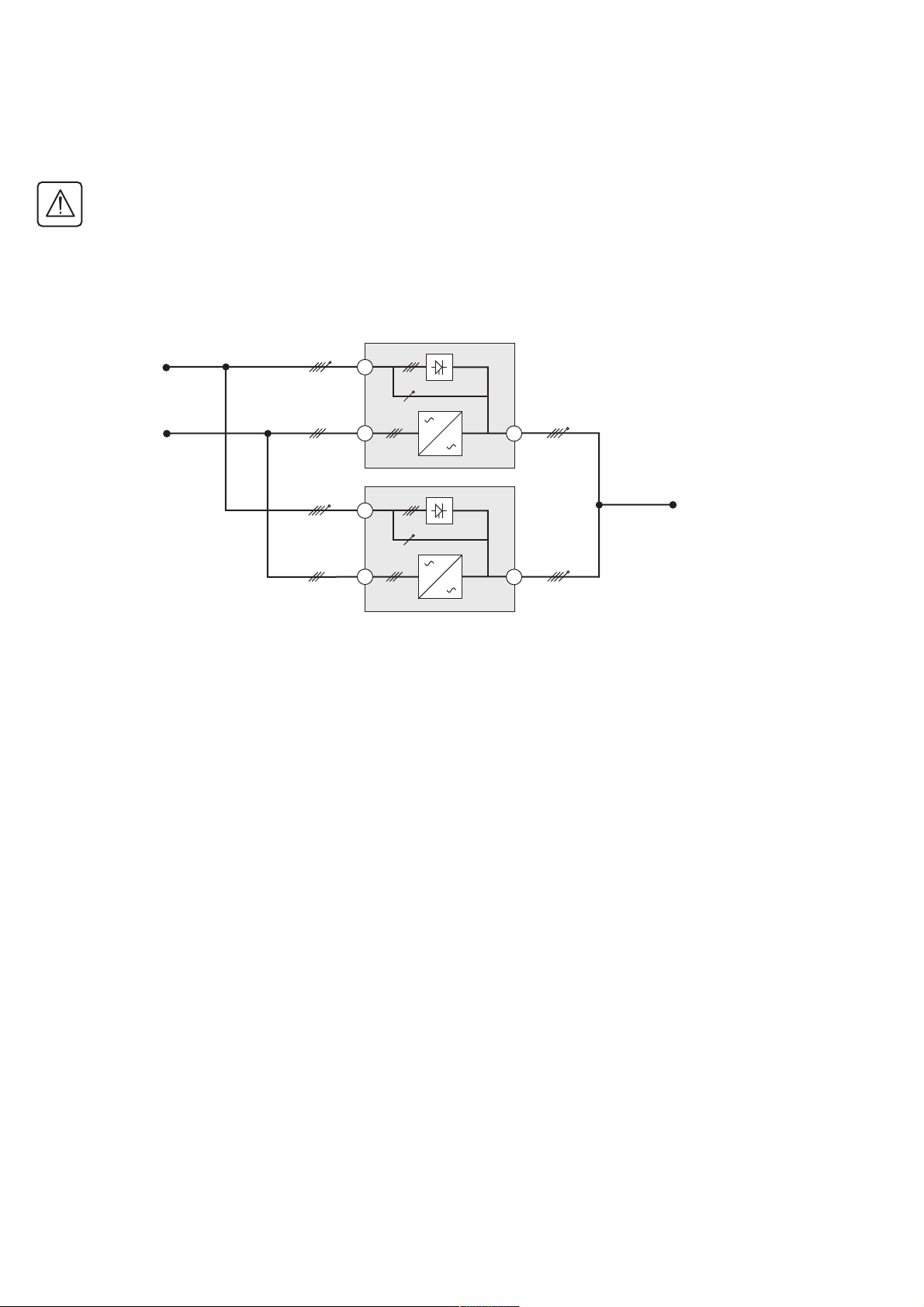

2. Installation

A

Parallel UPS with external bypass cabinet and separate Normal and Bypass AC network inputs (6 UPS in parallel for 4PN)

The UPS installation may be equipped with earth-leakage protection upstream on the condition that the protection

apply to:

- the normal and Bypass AC inputs

- all the parallel-connected UPSs.

The standard diagrams presented below may be adapted to your needs by qualified personnel.

The requirements for the different system earthing arrangements (SEA) are similar to those for single UPS

configurations. In the diagrams on page 18, simply replace the single UPS units between points A, B and C by the

following parallel configuration.

Q3BP

Q4S

B

B

B

Bypass AC

Normal AC

Bypass AC

Normal AC

Bypass AC

Normal AC

Bypass AC

15

Q5N

16

15

16

15

16

15

14

14

14

C

Normal AC

16

Connection for the Bypass AC input and the output cables to the external bypass cabinet must use cables having the same

length and size to ensure correct balancing of the Bypass AC input currents.

14

34001813EN/AE - Page 21

Page 22

2. Installation

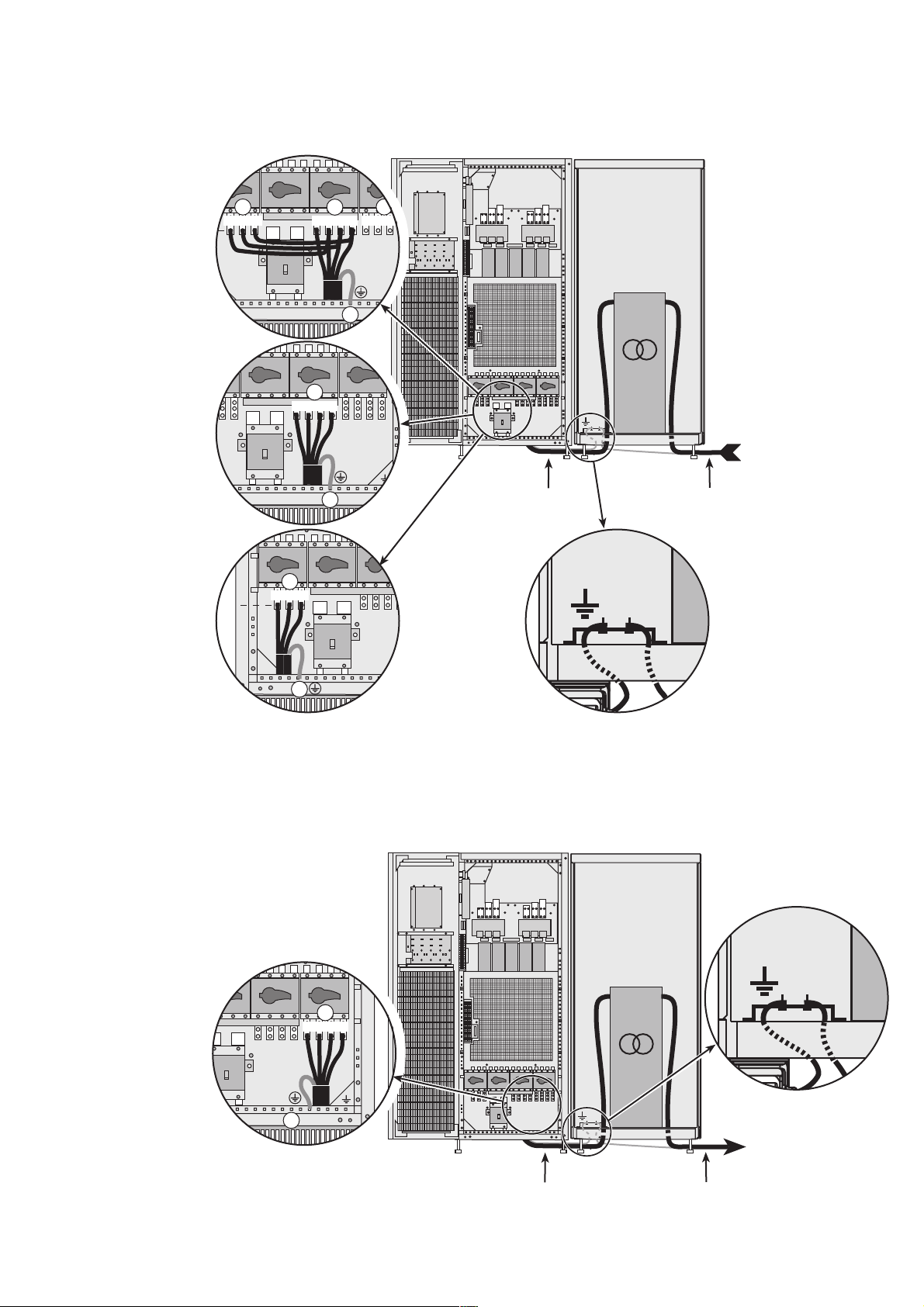

2.6 Connection of power cables in a single UPS unit

Interconnecting the cabinet earths

All the cabinet earths must be interconnected: external Bypass cabinet, external battery cabinet, etc.

UPS units with common normal and Bypass AC inputs

To access the connection terminal blocks, see section 1.2.

1 - The earthing conductors must be connected to the UPS earthing-plate

connectors (17) and (18).

2 - Connect the four conductors of the Normal AC source to terminal block

(15).

3 - Connect the three phases of the Normal AC input (16) with the three

phases of the Bypass AC input (15).

4 - Connect the four conductors supplying the load to terminal block (14).

5 - Tie the cables down to the frame.

6 - Put the cover back in place (see section 1.2).

370 mm

16

N L1 L2 L3L1 L2 L3

15

17 18

14

N L1 L2 L3

UPS units with separate normal and Bypass AC inputs

To access the connection terminal blocks, see section 1.2.

1 - The earthing conductors must be connected to the UPS earthing-plate

connectors (17) and (18).

16

370 mm

N L1 L2 L3L1 L2 L3

15

17 18

14

N L1 L2 L3

2 - Connect the three phases of the Normal AC source to terminal block

(16).

3 - Connect the four conductors of the Bypass AC source to terminal block

(15).

4 - Connect the four conductors supplying the load to terminal block (14).

5 - Tie the cables down to the frame.

6 - Put the cover back in place (see section 1.2).

Frequency converter

To access the connection terminal blocks, see section 1.2.

1 - The earthing conductors must be connected to the UPS earthing plate.

2 - Connect the neutral conductor of the Normal AC source to the neutral

16

17

370 mm

15

N L1 L2 L3L1 L2 L3

14

N L1 L2 L3

18

terminal on terminal block (15).

3 - Connect the three phases of the Normal AC source to terminal block

(16).

4 - Connect the four conductors supplying the load to terminal block (14).

5 - Connect the neutral on terminal block (15) with the neutral of the

supplied loads on terminal block (14).

6 - Tie the cables down to the frame.

7 - Put the cover back in place (see section 1.2).

34001813EN/AE - Page 22

Do not connect anything to the three phases on the Bypass AC

source terminal block (15).

Page 23

2. Installation

2.7 Earth-cable connection for a single unit in a TNC earthing system

16

370 mm

15

N L1 L2 L3

17 18

14

N L1 L2 L3

1.Connect the power network cable PEN to the UPS earthing terminal

2.Connect the usage cable PEN to the UPS earthing terminal

3.Connect the Q4S (15) neutral terminal to the UPS earth using the cable

supplied

4.Connect the Q5N (14) neutral terminal to the UPS earth using the cable

supplied

34001813EN/AE - Page 23

Page 24

2. Installation

2.8 Connection of power cables for parallel UPS units

Equipotential bonding between parallel-connected units

Connect the exposed conductive parts (ECP) of the parallel-connected UPS units using an additional earthing cable (not

supplied) with the following characteristics:

- size equivalent to that of the supply cables,

- as short as possible.

Connection of earth cable and tying of cables

Connections must be made according to the diagram below:

Main earth

UPS 1 UPS 3

N L1 L2 L3N L1 L2 L3L1 L2 L3 N L1 L2 L3N L1 L2 L3L1 L2 L3N L1 L2 L3N L1 L2 L3L1 L2 L3

Additional equipotential

bonding between units.

UPS 2

Main earth

34001813EN/AE - Page 24

Page 25

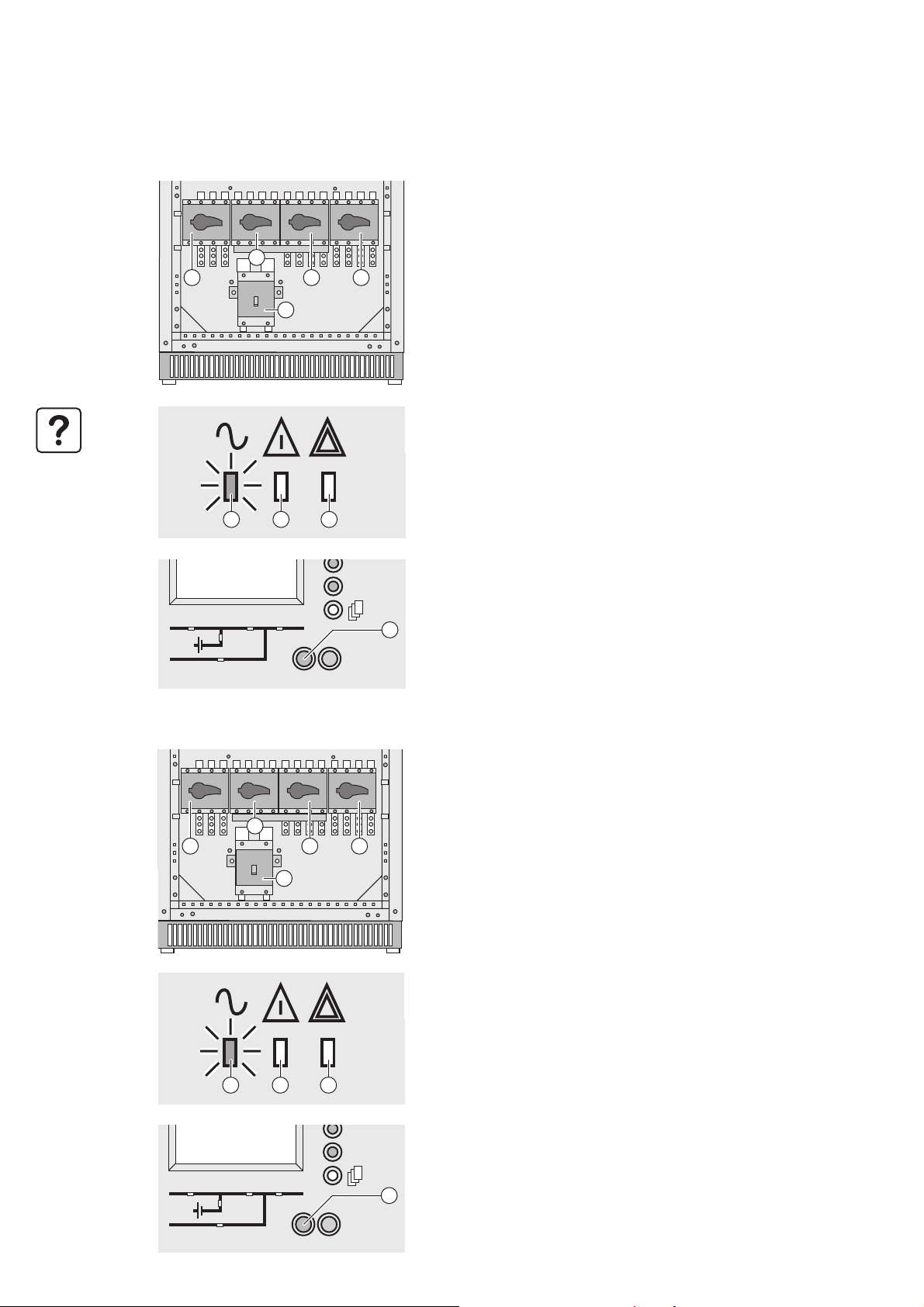

Redundant parallel configuration (maximum two UPS units for Pn)

This configuration does not have an external bypass.

UPS units with common normal and Bypass AC inputs

To access the connection terminal blocks, see section 1.2.

UPS 2

15

17

To normal / bypass

AC source

14

N L1 L2 L3N L1 L2 L3L1 L2 L3

18

400 mm

370 mm

16

UPS 1

To loadTo loadTo loadTo load

15

17

14

N L1 L2 L3N L1 L2 L3L1 L2 L3

N L1 L2 L3N L1 L2 L3L1 L2 L3

16

370 mm

18

2. Installation

To access the connection terminal blocks,

see section 1.2.

1 - The earthing conductors must be

connected to the earthing plate of each UPS.

2 - Connect the four conductors of the Bypass

AC source to terminal block (15) in each UPS

unit.

3 - Connect the three phases of the Normal

AC input (16) with the three phases of the

Bypass AC input (15) in each UPS unit.

4 - Connect the four conductors of the

supplied loads to terminal block (14) in UPS1.

5 - Connect terminal block (14) in UPS2 to

terminal block (14) in UPS1 using the four

load conductors.

6 - Tie the cables down to the cabinet frames.

7 - Put the covers back in place (see section

1.2).

UPS units with separate normal and Bypass AC inputs

To access the connection terminal blocks,

see section 1.2.

1 - The earthing conductors must be

connected to the earthing plate of each UPS.

2 - Connect the three phases of the Normal

AC source to terminal block (16) in each UPS

unit.

3 - Connect the four conductors of the Bypass

AC source to terminal block (15) in each UPS

unit.

4 - Connect the four conductors of the

supplied loads to terminal block (14) in UPS1.

5 - Connect terminal block (14) in UPS2 to

terminal block (14) in UPS1 using the four

load conductors.

6 - Tie the cables down to the cabinet frames.

7 - Put the covers back in place (see section

1.2).

16

370 mm

To load

UPS 1

15

17

14

N L1 L2 L3N L1 L2 L3L1 L2 L3

N L1 L2 L3N L1 L2 L3L1 L2 L3

18

To normal

AC source

16

UPS 2

370 mm

15

17

To by p a ss

AC source

14

N L1 L2 L3N L1 L2 L3L1 L2 L3

18

Caution. If the two UPSs are placed side by side, connect as indicated above. In the other configurations, always make sure

that the cables between the UPSs and Bypass AC source have the same cross-section and the same length. The same is

true for the cables between the UPSs and the load.

34001813EN/AE - Page 25

Page 26

2. Installation

Frequency converter

UPS 1

16

17

To normal

AC source

15

14

18

To load

370 mm

16

L1 L2 L3

17

UPS 2

To access the connection terminal blocks,

see section 1.2.

1 - The earthing conductors of each UPS

must be connected to the UPS earthing plate.

14

15

N L1 L2 L3

N

18

2 - Connect the neutral conductor of the

Normal AC source to the neutral terminal on

terminal block (15) of UPS1.

3 - Connect the three phases of the Normal

AC source to terminal block (16).

4 - Connect terminal block (16) in UPS1 to

terminal block (16) in UPS2 using the three

conductors of the Normal AC source.

5 - Connect the neutral cable on terminal

block (15) in UPS1 to terminal block (15) in

UPS2.

6 - Connect the four conductors supplying the

load to terminal block (14).

7 - Connect terminal block (14) in UPS1 to

terminal block (14) in UPS2 using the four

load conductors.

8 - Connect the neutral on terminal block (15)

with the neutral of the supplied loads on

terminal block (14).

9 - Tie the cables down to the frame.

10 - Put the cover back in place (see section

1.2).

Do not connect anything to the three

phases on the Bypass AC source terminal

block (15).

34001813EN/AE - Page 26

Page 27

UPS units with separate normal and Bypass AC inputs

/

/

/

2. Installation

UPS 1

UPS 2

To access the connection terminal blocks,

see section 1.2.

1 - The earthing conductors must be

16

15

14

N L1 L2 L3N L1 L2 L3L1 L2 L3

16

15

14

N L1 L2 L3N L1 L2 L3L1 L2 L3

connected to the earthing plate of each UPS.

2 - Connect the three phases of the Normal

AC source to terminal block (16) in each UPS

370 mm

17

18

370 mm

17

18

unit.

3 - Connect the four conductors of the Bypass

AC source to terminal (61) in the bypass

cabinet.

4 - Connect terminal blocks (15) in each UPS

63

Bypass

Q4S

Q3BP

Q5N

N

L1

L2

L3

N

L1

L2

L3

60

N

L1

L2

L3

61

N

L1

L2

L3

62

To

Normal

AC

source

The cables marked A must be identical,

AB AB

To

Normal

AC

source

unit to terminal (60) in the bypass cabinet,

using cables with identical lengths and sizes.

5 - Connect the four load conductors to

terminal (62) in the bypass cabinet.

6 - Connect terminal blocks (14) in each UPS

unit to terminal (63) in the bypass cabinet,

using cables with identical lengths and sizes.

7 - Tie the cables down to the frames of the

UPS cabinets and the bypass cabinet.

8 - Put the covers back in place (see section

1.2).

i.e. same size and length.

Similarly, the cables marked B must be

identical, i.e. same size and length.

To load

To bypass AC source

16

370 mm

To normal AC

To normal AC

To normal AC

To Normal AC

bypass AC

bypass AC

bypass AC

source

UPS 3

15

17

14

N L1 L2 L3N L1 L2 L3L1 L2 L3

18

B

To Normal AC

16

UPS 4

370 mm

15

17

14

N L1 L2 L3N L1 L2 L3L1 L2 L3

18

B

source

A

A

To avoid errors, it is advised to remove the handle on switch Q3BP (10) in each UPS.

34001813EN/AE - Page 27

Page 28

2. Installation

2.9 Connection of the 150 kVA external bypass cabinet

A

C

15,5

120

303

UPS 1

XMS04 /

XMS05

UPS 2

XMS04 /

XMS05

Q4S

Q3BP

123456

UPS 3

UPS 4

Q5N

317

317

15

B

N

L1

L2

L3

Q4S

D

N

L1

L2

L3

G

N

L1

L2

L3

E

Q3BP

H

N

L1

L2

L3

Q5N

F

N

L1

L2

L3

750

800

857,5

950

1000

1057,5

Key

A: top view of cabinet

B: front view of cabinet

C: 317 x 120 mm opening for cable running

D: connection of Bypass AC source to the UPSs

E: connection of auxiliary wires for position of Q4S, Q3BP and Q5N switches

F: connection of UPS load outputs

G: connection of Bypass AC source

H: connection of the load

34001813EN/AE - Page 28

Page 29

2.10 Connection of the 360 kVA external bypass cabinet

A

B AA

2. Installation

C

D

E

1900

F

N

L1

L2

L3

Q4S

N

L1

L2

Q3BP

N

L1

L2

Q5N

N

L1

L2

L3

K

E

G

L3

H

L3

D

G

H

F

A

Q4S

Q5N

E

J

UPS 1

XMS04 /

XMS05

Q3BP

123456

I

L

UPS 2

XMS04 /

XMS05

UPS 3

UPS 4

Key

AA: section AA of cabinet

B: front view of cabinet

C: front

D: connection of Bypass AC source to the UPSs

E: connection of auxiliary wires for position of Q4S, Q3BP and Q5N switches

F: connection of UPS load outputs

G: connection of Bypass AC source

H: connection of the load

I : ventilation grate for air exit from cabinet

J: cable running through top, 460 x 197 mm opening and gland plate

K: protection fuses for RC voltage surge suppressor on the Bypass AC line (must be replaced when LED is ON)

L: top view of cabinet

34001813EN/AE - Page 29

Page 30

2. Installation

2.11 Connection of the 600 kVA external bypass cabinet

A

B

AA

C

D

Q4S

D

E

Q3BP

Q5N

G

E

H

F

G

H

F

A

Q4S

Q5N

E

J

I

UPS 1

L

UPS 2

XMS04 /

XMS05

XMS04 /

XMS05

Q3BP

123456

34001813EN/AE - Page 30

UPS 3

UPS 4

Key

AA: section AA of cabinet

B: front view of cabinet

C: front

D: connection of Bypass AC source to the UPSs

E: connection of auxiliary wires for position of Q4S, Q3BP and Q5N switches

F: connection of UPS load outputs

G: connection of Bypass AC source

H: connection of the load

I : ventilation grate for air exit from cabinet

J: cable running through top, 460 x 197 mm opening and gland plate

L: top view of cabinet

Page 31

2. Installation

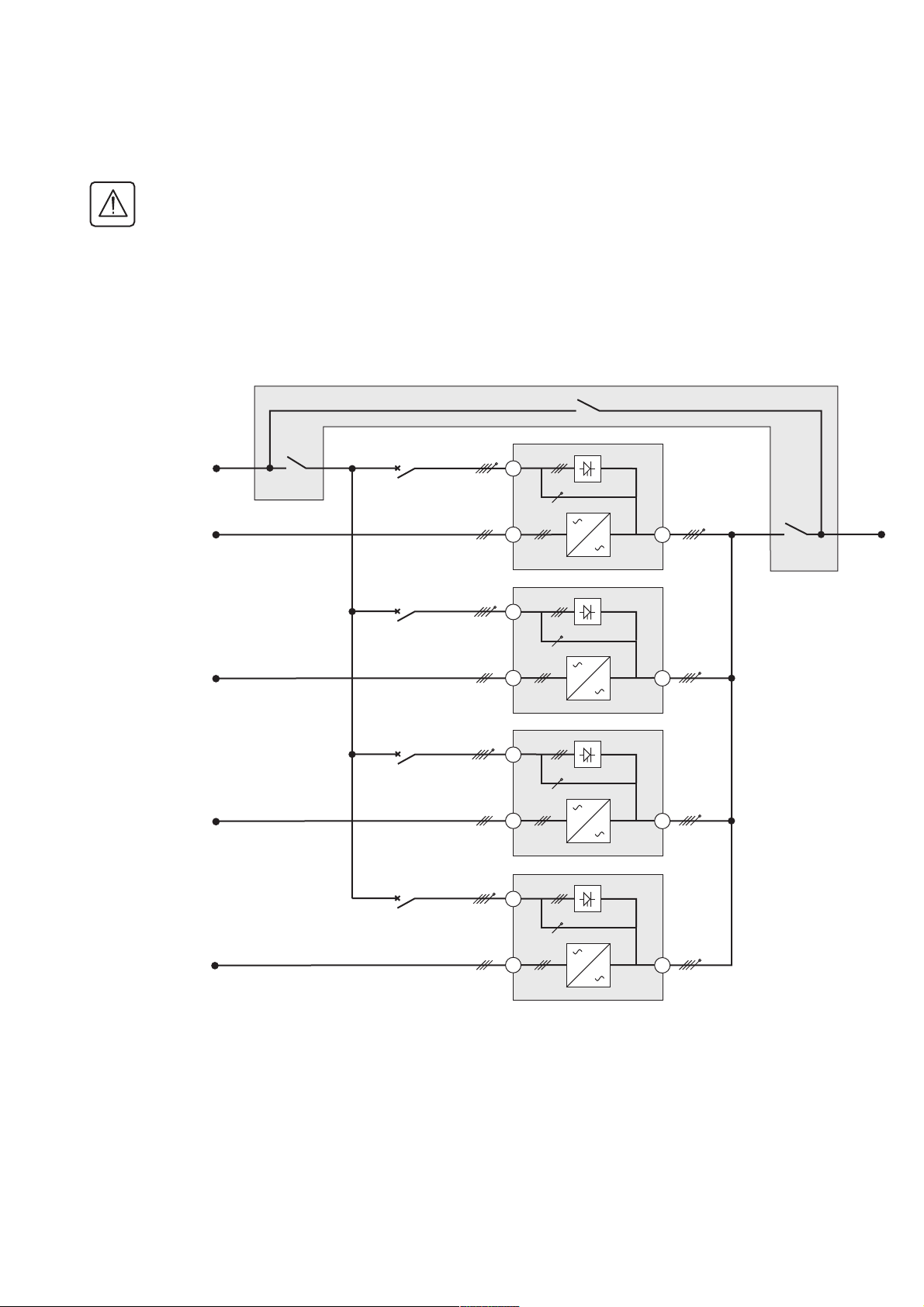

2.12 Auxiliary interconnections between UPS units in parallel configurations

Redundant parallel configuration (maximum two UPS units)

Note. The supplied cables (10 m) limit the

For security reasons, the connections of the auxiliary interconnections of the parallel UPSs must be carried out

whilst all the UPSs are de-energised.

10 10 12 12 10 10 12 12

XMS02 XMS03

UPS 1

XMS04 XMS05

CAN //

XMS06 XMS07

Blue

plug

XMS02 XMS03

UPS 2

XMS04 XMS05

CAN //

XMS06 XMS07

Red plug

Exchange-current interconnections

Link connectors XMS02 and XMS03 on the

two UPS units.

CAN // interconnections:

Fit a blue plug on connector XMS06 on

UPS1.

Link connector XMS07 on UPS1 to connector

XMS06 on UPS2.

Fit a red plug on connector XMS07 on U PS2.

distance between the two UPS units to

approximately six meters.

34001813EN/AE - Page 31

Page 32

2. Installation

Parallel configuration for increased capacity (maximum four UPS units)

UPS 1

XMS02 XMS03

XMS04 XMS05

XMS06 XMS07

Blue

plug

11

External bypass cabinet

2 3 4 5 61

Q3BP

Q4S

Q5N

CAN //

XMS02 XMS03

Jumpers connected to

aux. terminal block of

external bypass cabinet

(if necessary)

XMS04 XMS05

UPS 2

CAN //

XMS06 XMS07

11

Interconnections with the external bypass

cabinet

◗ Interconnect terminals 1, 3 and 5 on the

auxiliary terminal block in the cabinet.

◗ Create a loop between the cabinet and the

UPS units for terminals 1, 2, 4 and 6 on the

auxiliary terminal block in the cabinet. The

order for the XMS04 and XMS05 connectors

in each UPS unit, from right to left, is

common, Q3BP, Q4S and Q5N.

Details of terminal blocks (11)

XMS 04 / XMS 05

11

UPS 4

XMS02 XMS03

XMS04 XMS05

CAN //

XMS06 XMS07

Red

plug

UPS 3

XMS02 XMS03

XMS04 XMS05

10 10 12 12 10 10 12 12

11

CAN //

XMS06 XMS07

Q4S

Q5N

Q3BP

Common

Note. The interconnection cables for the

external bypass cabinet are not supplied

(size 2.5 mm

2

maximum).

Exchange-current interconnections (10):

Use the XMS02 and XMS03 connectors to

create a loop between the UPS units (all the

XMS02 XMS03

UPS 1

XMS04 XMS05

CAN //

XMS06 XMS07

Blue

plug

XMS02 XMS03

UPS 2

XMS04 XMS05

CAN //

XMS06 XMS07

XMS02 and XMS03 connectors must be

used).

CAN // interconnections (12):

Daisy-chain the UPS units using the XMS06

and XMS07 connectors. Fit a blue plug on the

first UPS unit and a red plug on the last unit

(all the XMS06 and XMS07 connectors must

be used).

Note. The supplied cables are ten meters

long.

XMS02 XMS03

XMS04 XMS05

UPS 4

CAN //

XMS06 XMS07

Red plug

XMS02 XMS03

UPS 3

XMS04 XMS05

CAN //

XMS06 XMS07

To ensure sufficient isolation of

exchange-current, CAN and external

bypass cabinet cables, they must be run

separately from the power cables

34001813EN/AE - Page 32

Page 33

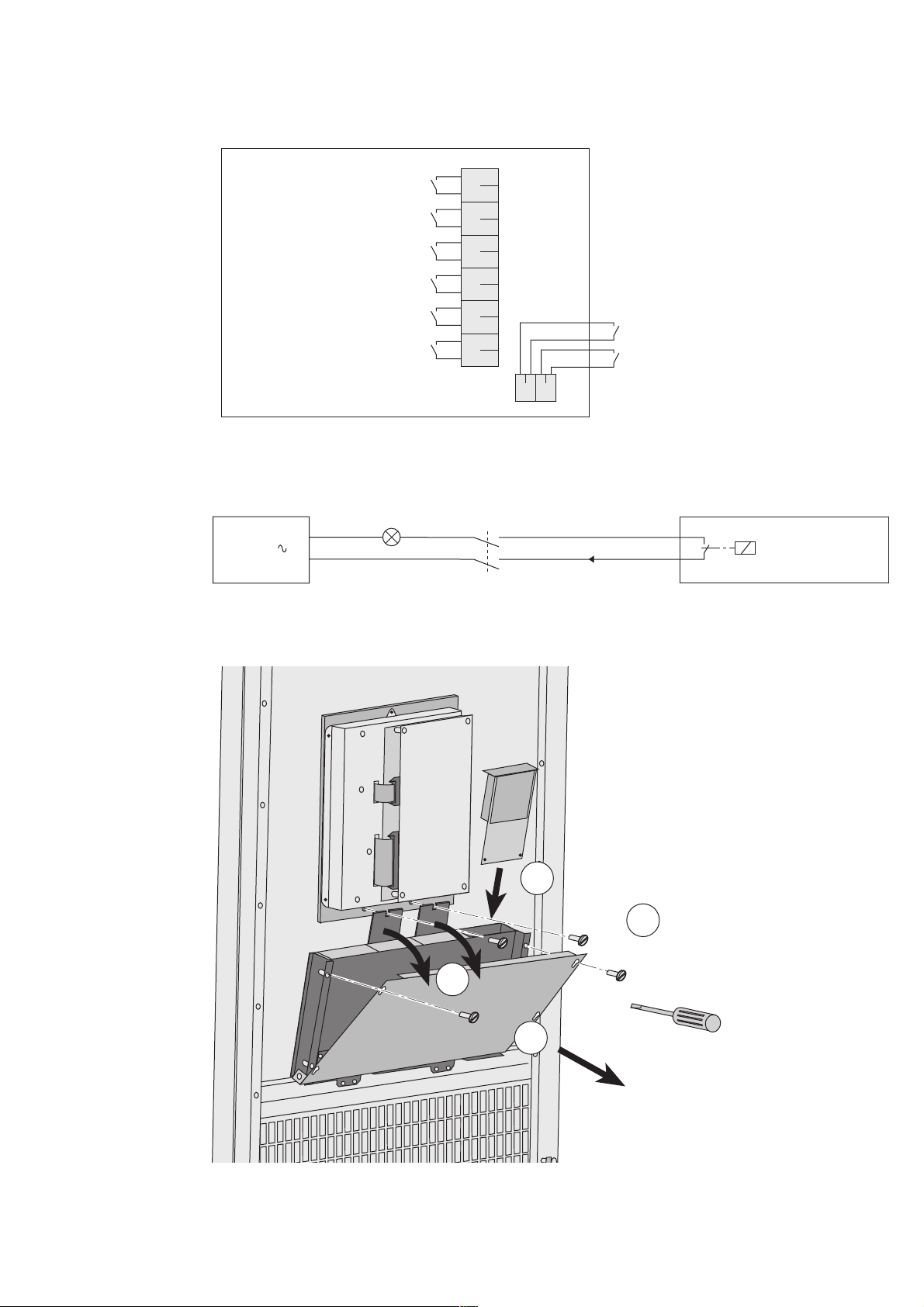

Fitting the protection cover for the auxiliary interconnection cables

The protection cover supplied with the parallel connected UPS units protects the user against direct contact with voltages

other than SELVs and ensures the auxiliary interconnection cables are maintained in position.

2. Installation

Note. Tie down the cables as indicated in the diagram in section 2.10.

2.13 Connection of general shutdown or emergency power off (EPO) terminal block

XMB 08 XMB 07 XMS 06

7

Caution.

In the UPS, pressing the general shutdown button causes UPS shutdown and opening of the battery circuit breaker

(with opening of the bypass static switch depending on personalisation settings) .

The Emergency Power Off (EPO) notion is applicable to installations where pressing the button also causes the

upstream Normal AC source and Bypass AC source circuit-breakers to open.

In parallel configurations, there must be a single general shutdown button with a separate contact for each UPS unit.

1 - Remove the wire from terminal block (7).

2 - Connect the general shutdown NC contact to terminals 1 and 2 (SELV).

3 - Tie the cable down as illustrated in section 2.10.

34001813EN/AE - Page 33

Page 34

2. Installation

2.14 Connection of the relay communications card

Isolate and lock-out all power sources for this card before making connections.

Never connect SELV (safety extra low voltage) and non-SELV circuits to the different outputs of the same card.

1 - Remove the cover (52) secured by the screws (50).

2 - Run the communications cables through the cable entry holes (53).

3 - Connect the conductors to the input (55) and output (54)terminal blocks.

6

5

4

3

2

1

B

A

55

52

4 - Put the cover back in place and secure it with the screws (50).

5 - Tighten the screws (56) to block the cables.

6 - Indicate the locations of the power sources on the labels.

7 - Insert the card in its slot.

8 - Secure the card with two screws (51).

54

53

51

34001813EN/AE - Page 34

51 56

50

51

Page 35

Characteristics of the contacts on the relay communications card.

Characteristics of the output contacts:

Permissible voltage: 250V AC, 30V DC.

Low battery warning

Load on battery power

Load on automatic bypass

Load on UPS

Battery fault

6

5

4

3

Permissible current: 2 A.

Cable : 4 x 0.93 mm

Characteristics of the input contacts:

Switched voltage: 5 V DC

Consumption: 10 mA.

Cable: 4 x 0.34 mm

2. Installation

2

, Ø 6.6 ± 0.3 mm.

2

, Ø 5 ± 0.5 mm.

General alarm

2

1

UPS OFF

UPS ON

BA

Communications card connection example

If a SELV (safety extra low voltage) source is used, it must always be possible to isolate the communications card from the

upstream source to ensure the safety of personnel working on the installation.

communication

AC

source

Disconnecting device that can be locked

Adding communication cards

carte de

communication

card

4

2

3

1

34001813EN/AE - Page 35

Page 36

2. Installation

2.15 Running the control/communications cables

Single UPS

The following assembly recommendations must be followed to ensure correct positioning and support of the various strands

of the control and communication cables on the front face of the UPS.

Separate the control and communication

cables from the power cables.

Run the cables together in front of the

protection panels and tie them to the panels

as indicated in the figure opposite.

Slot for relay communications card

Free slot for optional communication cards

3

Cable description Insulation level Location on illustration

4

Tie

Screw-type terminal block for connection of

EPO and battery circuit-breakers.

6

7

Ties

To ensure sufficient isolation of exchange-current, CAN and external bypass cabinet cables, they must be run

34001813EN/AE - Page 36

Relay communication card SELV or LV 3

Optional communication card SELV 4

General-shutdown cable SELV 6

External battery circuit-breaker cables SELV 7

separately from the power cables. Reinforce the insulation of these control and communication cables if any risk of

contact with the power cables subsists.

Page 37

Parallel UPS

2. Installation

1

Parallel-connection cables for connection to

the external bypass cabinet (not supplied

max. 2.5 mm

cables are supplied.

3

4

Relay communication card

Optional communications cards

Ties

2

). The CAN and I exchange

6

7

General-shutdown cable (not supplied, max.

2

2.5 mm

) and external battery circuit breaker

cable must be tied down separately

Ties

Cable description Insulation level Location on illustration

External bypass cabinet cable ELV 1

CAN cables SELV 1

Exchange-current cables SELV 1

Relay communication card SELV or LV 3

Optional communication card SELV 4

General-shutdown cable SELV 6

External battery circuit-breaker cables SELV 7

To ensure sufficient isolation of exchange-current, CAN and external bypass cabinet cables, they must be run

separately from the power cables. Reinforce the insulation of these control and communication cables if any risk of

contact with the power cables subsists.

34001813EN/AE - Page 37

Page 38

2. Installation

2.16 Power connections for an external battery cabinet

The earth on an external battery cabinet must be connected to the UPS

1

Q1 Q4S Q3BP Q5N

-

+

2.17 Assembly and connection of an empty battery cabinet

Mounting the battery circuit breaker kit

Secure:

1 - The base plate (60) supporting the circuit

breaker.

2 - Connector XR1.

x2

60

x4

Please contact our Sales department when

4

3 - The temperature sensor (3).

4 - The front plate (4), after connecting the

batteries to the circuit breaker.

Only one circuit breaker is necessary even if

there are several battery cabinets.

The coil control wires and the position

contact wires of circuit-breaker QF1 must

be connected to the UPS (see page 24).

selecting the battery circuit breaker.

34001813EN/AE - Page 38

XR1

3

Page 39

Mounting the shelves and the battery cells

Caution. Assembly of the battery cabinet

2. Installation

must be carried out by certified personnel

1

(standard EN 50091-1-2).

1

1

2

3

3

Caution. The minimum clearance between

the top of battery cells and the next shelf

is 150 millimeters.

1 - Secure the angle supports (6 screws per

support).

For each shelf:

2 - position the shelf,

3 - secure the shelf with two screws in each

angle,

4 - install the battery cells, secure and

interconnect them.

5 - Interconnect all the shelves and then

connect the overall battery assembly to the

battery circuit breaker.

34001813EN/AE - Page 39

Page 40

2. Installation

2.18 Control connections for an external battery cabinet

1 - Connect wires 1-2-3-4 on connector XR1 (QF1 position and coil) in the external battery cabinet to connector XMB07 (6)

(SELV) and wires 7-8-9-10 (temperature sensor) to connector XMD3 (22) (SELV).

22

XMD3

XMD3

+

12V

+

BC

BC

12V

Pass through

three times

5

XMB 08 XMB 07 XMB 06

Circuit breaker 2

Circuit breaker 1

6

Common

Open-close contact

QF1 command

-12V

+12V

BC+

BC-

QF1

XR1

8

7

6

5

4

3

2

1

34001813EN/AE - Page 40

Note. The wires for the screw-type terminal block are not supplied (max. size 2.5 mm

2

and total length less than 100 m).

Page 41

2.19 Connection of an input isolating transformer

16

L1 L2 L3

17

N L1 L2 L

14

16

15

N L1 L2 L3L1 L2 L3

17

15

N L1 L2 L3

17

N L1 L2 L3

14

17

A

B

Q1 Q4S Q3BP Q5N

QF1

Cable not supplied Cable not supplied

2. Installation

Option

AC input

C

A - Connection of an input transformer for common normal and Bypass AC source.

B - Connection of a Bypass AC input transformer for separate normal and Bypass AC sources.

C - Connection of a Normal AC input transformer for separate normal and Bypass AC sources.

2.20 Connection of an output isolating transformer

Option

Q1 Q4S Q3BP Q5N

QF1

Cable not supplied

To load

Cable not supplied

34001813EN/AE - Page 41

Page 42

3. Operation

All operations concerning system start-up and compliance with standards and regulations, including those related to the

battery cabinet, must be carried out by trained and certified personnel before using the UPS.

3.1 Shutting down a single UPS

The UPS remains energised unless it is shut down.

1 - Press a button to exit sleep mode.

2 - Confirm by pressing the function key (38) for 3 seconds.

Q1 Q4S Q3BP Q5N

8

QF1

13

3.2 Restarting a single UPS

Check that switches Q4S (9) and Q5N (11) are closed. If this is the case, continue with this procedure, otherwise refer

to paragraph 4.4 "Return to the Normal position, Single UPS".

Q1 Q4S Q3BP Q5N

9

8

QF1

13

IO

3s

11

38

The load is no longer protected by the UPS. It is supplied via the

bypass.

3 - Set the battery circuit-breaker QF1 (13) (or set the battery circuitbreakers of the auxiliary cabinets if any) to OFF.

4 - Set the input circuit-breaker Q1 (8) to OFF.

The charger no longer operates to keep the batteries fully charged.

5 - Open the upstream circuit-breakers of the Normal AC source and

Bypass AC source to completely power off the UPS.

1 - Set the Normal AC source input switch Q1 (8) to the ON position.

2 - Wait until the end of the start sequence.

3 - Set the battery circuit breaker QF1 (13) (or the battery circuit breakers

in the auxiliary cabinets) to the ON position.

The UPS unit starts automatically.

LED (31) is ON.

The load is protected by the UPS.

34001813EN/AE - Page 42

31 32 33

~

37

?

IO

3s

If LED (31) remains OFF, press the ON button (37)

If LED (31) still remains OFF and either of LEDs (32) or (33) is ON, a fault

has occurred (see section 4.1).

Page 43

3.3 Shutting down a parallel configuration

1 - Press a button on each unit to exit sleep mode.

2 - Press the OFF button (38) on each unit for 3 seconds.

3. Operation

IO

Q1 Q4S Q3BP Q5N

8

QF1

13

38

3s

3.4 Restarting a parallel configuration

Check that switches Q4S (9) and Q5N (11) are closed. If this is the case, continue with this procedure, otherwise refer

to paragraph 4.4 "Return to the Normal position, Parallel UPS...".

Q1 Q4S Q3BP Q5N

9

8

QF1

13

11

The load is no longer protected by the UPSs. It is supplied via the

bypass.

3 - Set the battery circuit breaker QF1 (13) in each UPS unit to the OFF

position (or trip the battery circuit breakers in the auxiliary cabinets if

applicable).

4 - Set the input switch Q1 (8) in each UPS unit to the OFF position.

The charger no longer operates to keep the batteries fully charged.

5 - Open the upstream circuit-breakers of Normal AC source and Bypass

AC source to completely power off the installation.

1 - Check that the Bypass AC source input switch Q4S in the external

bypass cabinet is closed.

2 - Check that the output switch Q5N in the external bypass cabinet is

closed.

3 - Check that the bypass switch Q3BP in the external bypass cabinet is

open.

Then carry out steps 4 to 6 below on all the UPS units.

4 - Set the Normal AC source input switch Q1 (8) to the ON position.

5 - Wait until the end of the start sequence.

6 - Set the battery circuit breaker QF1 (13) (or the battery circuit breakers

in the auxiliary cabinets) to the ON position.

31 32 33

~

37

IO

3s

The UPS units start automatically. On each unit, LEDs (32) and (33) go

OFF and LED (31) goes ON.

?

35

The load is protected by the UPSs.

If LED (31) remains OFF, press the ON button (37) on each UPS unit (the

UPS is in manual start mode) and confirm if necessary by pressing the

function key (35) marked

If LED (31) still remains OFF and either of LEDs (32) or (33) is ON, a fault

has occurred (see section 4.1).

©.

34001813EN/AE - Page 43

Page 44

3. Operation

3.5 Operation of mimic-panel LEDs

39 40 42

41

43

Single UPS start sequence on Normal AC input

Steps Action LED (39) LED (40) LED (41) LED (42) LED (43)

1 Q1 open Off Off Off Off Off

2 Close Q1 green Off red Off red

3 Close QF1 green Off Off Off red

4 Close Q4S green Off Off Off green

5 Close Q5N green Off Off green green

6 Open Q3BP green Off Off green green

7 Press ON button (37) green green Off green Off

Single UPS start sequence on Bypass AC input

Steps Action LED (39) LED (40) LED (41) LED (42) LED (43)

IO

3s

1Q4S open Off Off Off Off Off

2 Close Q4S red Off red Off green

3 Close Q5N red Off red green green

4 Open Q3BP red Off red green green

5 Close Q1 green Off red green green

6 Close QF1 green Off Off green green

7 Press ON button (37) green green Off green Off

34001813EN/AE - Page 44

Page 45

3.6 Operating modes

Normal (double conversion) mode

This is the standard operating mode, set by default in the factory. Two possible cases:

31 32 33

31 32 33

3. Operation

1 - Normal AC source available:

LED (31) is ON.

The load is protected by the UPS.

2 - Normal AC source not available:

LED (32) is ON.

The buzzer sounds intermittently.

The load is supplied by the UPS from battery power.

The display indicates any anomalies related to the AC source or the UPS as well as remedial action if applicable.

Press the function key (35) indicated by the display to turn the buzzer OFF.

ECO mode (single UPS only)

The main advantage of this mode is that it reduces the consumption of electrical power.

ECO mode may be selected exclusively via the control panel on the UPS.

31 32 33

Three possible cases:

1 - Bypass AC source available:

LED (31) is ON.

The load is supplied in ECO mode.

2 - Bypass AC source not available:

LED (31) is ON.

The buzzer sounds intermittently.

The load is automatically supplied in normal mode via the Normal AC

input.

3 - Both normal and Bypass AC sources not available or out of

tolerance:

LED (32) is ON.

The buzzer sounds intermittently.

The load is supplied by the UPS from battery power.

31 32 33

The display indicates the UPS operating status conditions and the required action.

34001813EN/AE - Page 45

Page 46

3. Operation

3.7 Load on battery power

The load continues to be protected by the UPS when the Normal AC source is not available. Power is supplied by the battery.

Transfer to battery power

31 32 33

End of battery power

31 32 33

LED (32) is ON.

The buzzer sounds intermittently.

The load is supplied by the battery.

LED (33) is ON.

The buzzer sounds intermittently.

The load is transferred on the Bypass AC input if it is present.

3.8 UPS personalisation

Access to the personalisation functions

Personalisation must be carried out with switches Q1 (8) and Q5N (11) open (OFF) and switches Q4S (9) and Q3BP

(10) closed (ON).

~

?

IO

3s

The password is factory set.

To change the password, see the Settings menu.

ØØØ

35

36

1 - Press the menu key (36) .

2 - Select "Settings", then "Personalisation" using the function keys (35)

Ï or Ð.

3 - Confirm by pressing the function key (35)

4 - Enter the password by successively selecting each icon using the

corresponding function key.

5 - Confirm by pressing the function key (35)

6 - To save the personalisation settings, confirm by pressing the function

key (35)

©.

©.

©.

34001813EN/AE - Page 46

Page 47

Operating mode

Function Factory setting Options

UPS operating mode NORMAL ECO

UPS automatic start Disabled Enabled

Authorised number of starts 4 1 to 255

3. Operation

Delay before reset of number of

executed automatic starts

Frequency

UPS output frequency 50 Hz 60 Hz

Tolerance for Bypass AC source 8 % 0.5 - 1 - 2 - 4 %

Synchronisation speed with Bypass

AC source

Automatic bypass

Transfer to Bypass AC source Enabled Disabled - disabled when limiting

Transfer to bypass with Bypass AC

source out of tolerances

Battery

Low battery warning threshold if

battery monitor inactive

Low battery warning threshold if

battery monitor active

Interval between two battery tests 30 days 1 to 180 days

4 seconds 1 to 60 seconds

2 Hz / s 1 Hz / s

Enabled Disabled

40% remaining backup time 20 - 60 - 80 % remaining backup time

4 minutes of battery backup time 1 to X minutes of battery backup time

34001813EN/AE - Page 47

Page 48

3. Operation

3.9 Relay contacts (communications card)

Inputs Factory setting Options (available on all contacts)

1.A

UPS ON

- Room temperature fault

- Transfer to bypass disabled

- Transfer to bypass disabled if Bypass AC source out of tolerance

- Desynchronise UPS from Bypass AC source

1.B

UPS OFF

Outputs Factory setting Options (available on all contacts)

1.1

1.2

General alarm

Battery fault

(1)

- Overload

- PFC fault

- Inverter fault

- Charger fault

- Automatic-bypass fault

- Bypass AC source out of tolerance

1.3

Load on NORMAL source

- Battery-temperature fault

- Fan fault

- Emergency power off activated

1.4

Load on automatic bypass

- Battery circuit breaker(s) open (at least one)