Page 1

User Manual For

DC Series

MX06 40A Shelf

User Manual 990-9178A

DC MX06 40A Shelf Page 1 of 44 18

th

FEB 02

Page 2

DC MX06 40A Shelf

The MX06 40A Shelf is a 19” compatible

modular power plant capable of supplying

up to 42A at –48V DC (54V). The unit

contains a controller that can configure up

to 4 x 10.5A rectifiers. Power distribution,

Integral LVD contact and alarm signals

are all included. Optional mounting

brackets are offered to allow the system

to be fitted in a 23” rack. Easy subassembly access and replacement allows

for convenient and efficient maintenance.

Applications

n Cellular and PCS

n Distributed Networks

n PABX

n Customer premises

n Industrial

n Microwave

n Broadband Wireless

n Fibre

Features

nnnn Integral LVD Contact

nnnn Hot Plugable Fan Cooled Units

nnnn Form C relay signals and visual

alarms

nnnn Single or 3-phase versions available

with a wide Input voltage range

nnnn Battery temperature compensation

of charging voltage

nnnn Overvoltage and reverse voltage

protection

nnnn LED Meter available

nnnn 2400W Output Power

User Manual 990-9178A

DC MX06 40A Shelf Page 2 of 44 18

th

FEB 02

Page 3

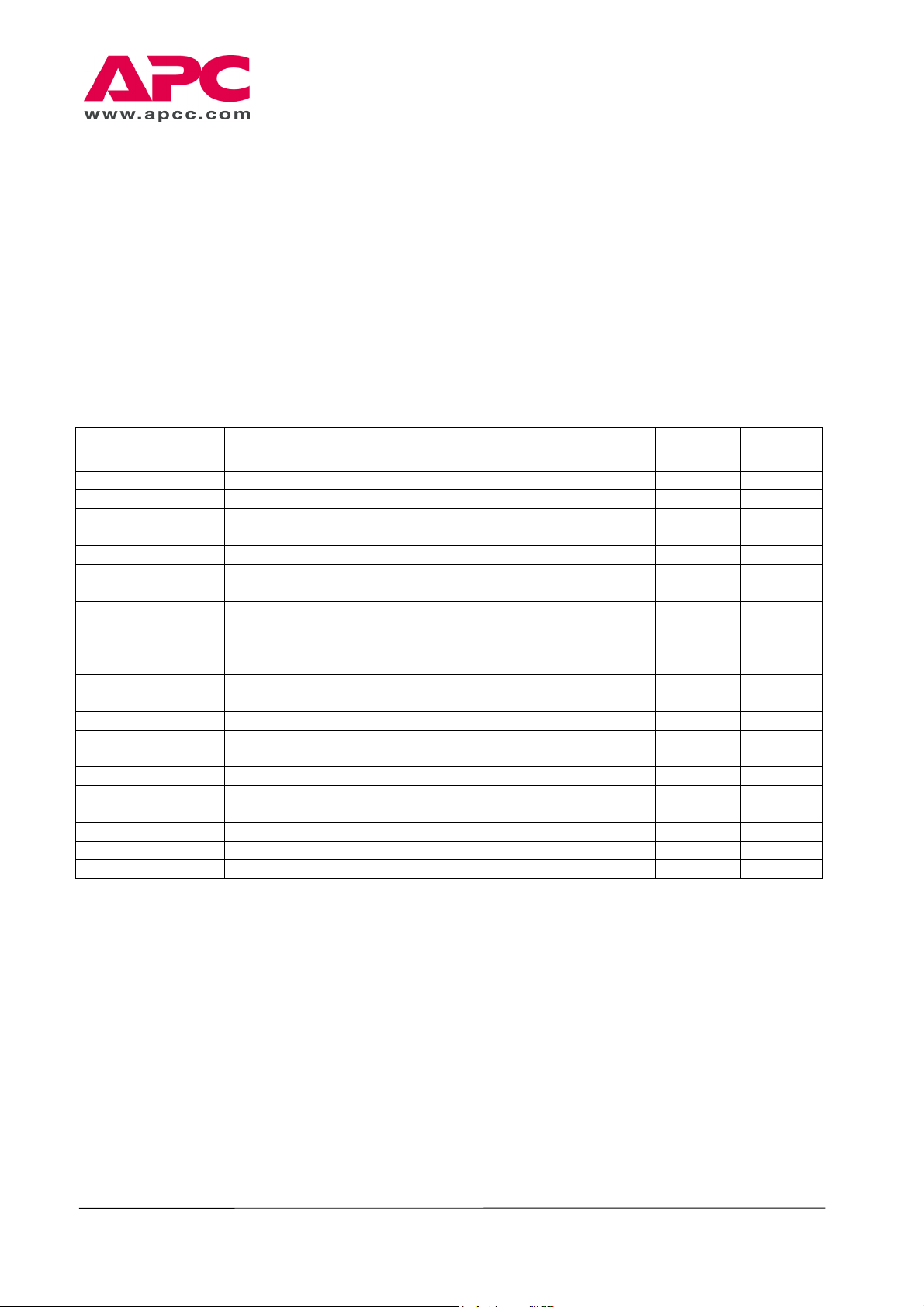

Contents

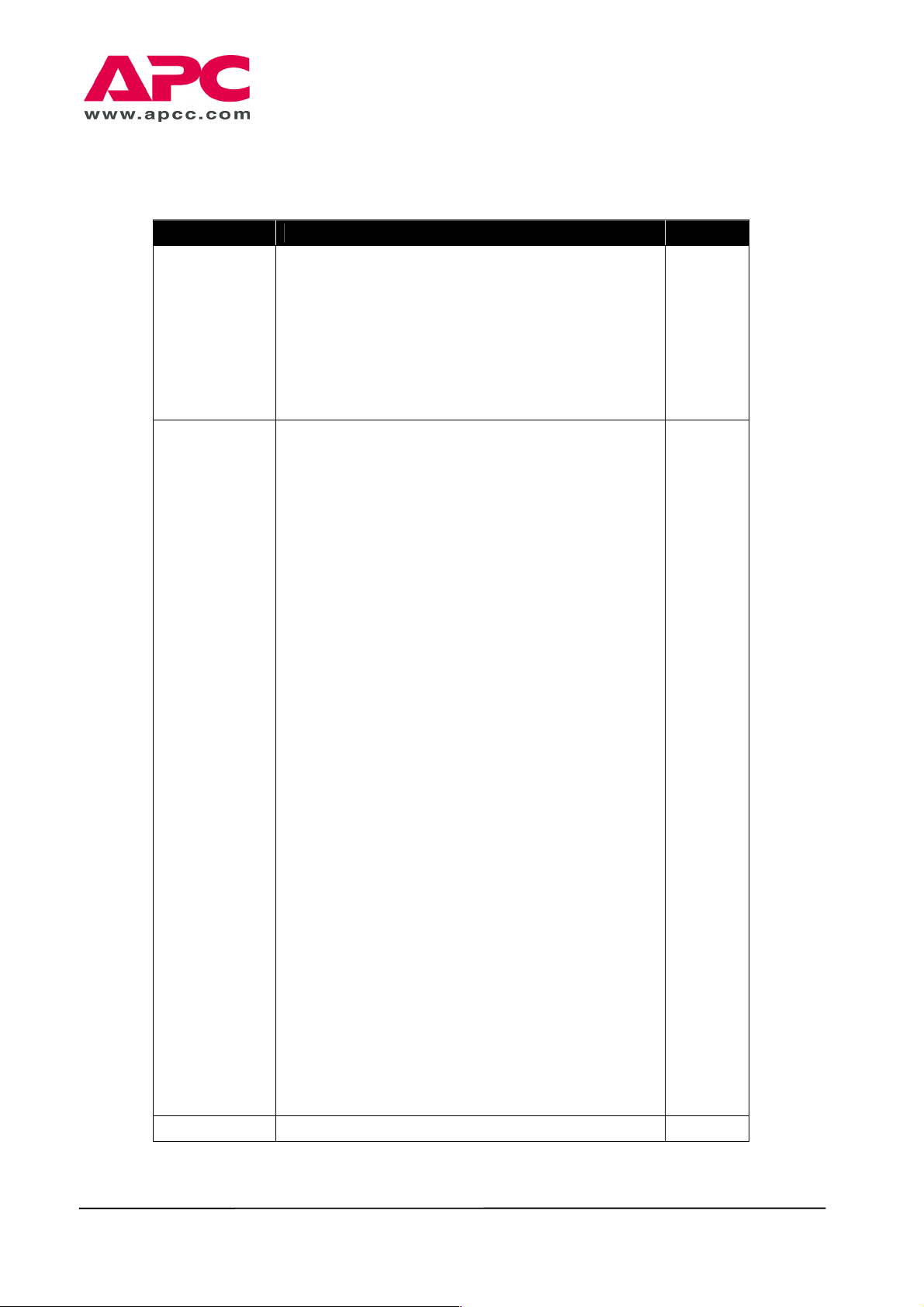

SECTION DESCRIPTION PAGE

1 General Information 5

1.1 Introduction 5

1.2 Safety Precautions 5,6

1.3 Types Of Hazard 6

1.4 Inspection Of Goods 7

1.5 APC Worldwide customer support 8

1.6 Warranty Information 9

2 Product Overview + Technical Description 10

2.1 Specification 10

2.2 Display + LED’s 11

2.3 Controller 12

2.4 Alarms 13

2.5 Customer Inputs 16

2.6 Mechanical 19

2.7 Schematic 21

3 System Configuration 23

2.1.1 Rectifier

2.1.2 System AC Input

2.1.3 System Output

2.1.4 Environmental

2.1.5 Approvals

2.3.1 Controller Layout

2.4.1 Available Alarms

2.4.2 Rear Access Alarms

2.4.3 Front Access Alarms

2.4.4 Major and Minor Alarms

2.5.1 Current Limit Programming

2.5.2 Output Voltage Programming

2.5.3 Battery Test Function

2.5.4 Enable Function

2.5.5 Temperature Compensation

2.6.1 Dimensions

2.6.2 Weight

2.6.3 Mounting Options

2.7.1 Positive Earth Configuration

2.7.2 Negative Earth Configuration

10

10

11

11

11

12

13

14

14

15

16

16

17

17

18

19

19

20

21

22

User Manual 990-9178A

DC MX06 40A Shelf Page 3 of 44 18

th

FEB 02

Page 4

4 Installation Procedure 24

4.1 AC Primary Supply 24

4.1.1 Single Phase

4.1.3 Single Phase AB Feed

4.1.4 3 Phase Star Supply

4.1.5 3 Phase Delta Supply

4.2 DC Distribution 32

4.2.1 10 GMT Fuses Rear Access

4.2.2 10 GMT Fuses Front Access

4.2.3 4 Circuit Breakers Rear Access

4.2.4 4 Circuit Breakers Front Access

4.2.5 4 Cartridge Fuses Rear Access

4.2.6 4 Cartridge Fuses Front Access

4.3 Cable Routing 37

4.3.1 Input Cables

4.3.2 Output Cables

4.4 External Battery Installation 39

4.4.1 Battery Back-up Function

4.4.2 LVD Function

4.4.3 Installation Procedure

4.4.4 Battery Connection Diagram

4.5 System Output Earthing 40

5 Commissioning the System 41

5.1 General 41

5.2 Powering up the

6 Manual Handling Procedure 42

6.1 General 42

6.2 Preparation 42

6.3 Method 42

7 Fault Finding / Symptoms 43

7.1 Warnings 43

7.2 Fault Symptoms 43

8 Service, Accessories & Spares 44

8.1 Rectifier Replacement 44

8.2 Alarm Module Replacement 44

24,25

26,27

28,29

30,31

32

33

34

35

36

36

37

38

39

39

39

40

MX06 40A Shelf 41

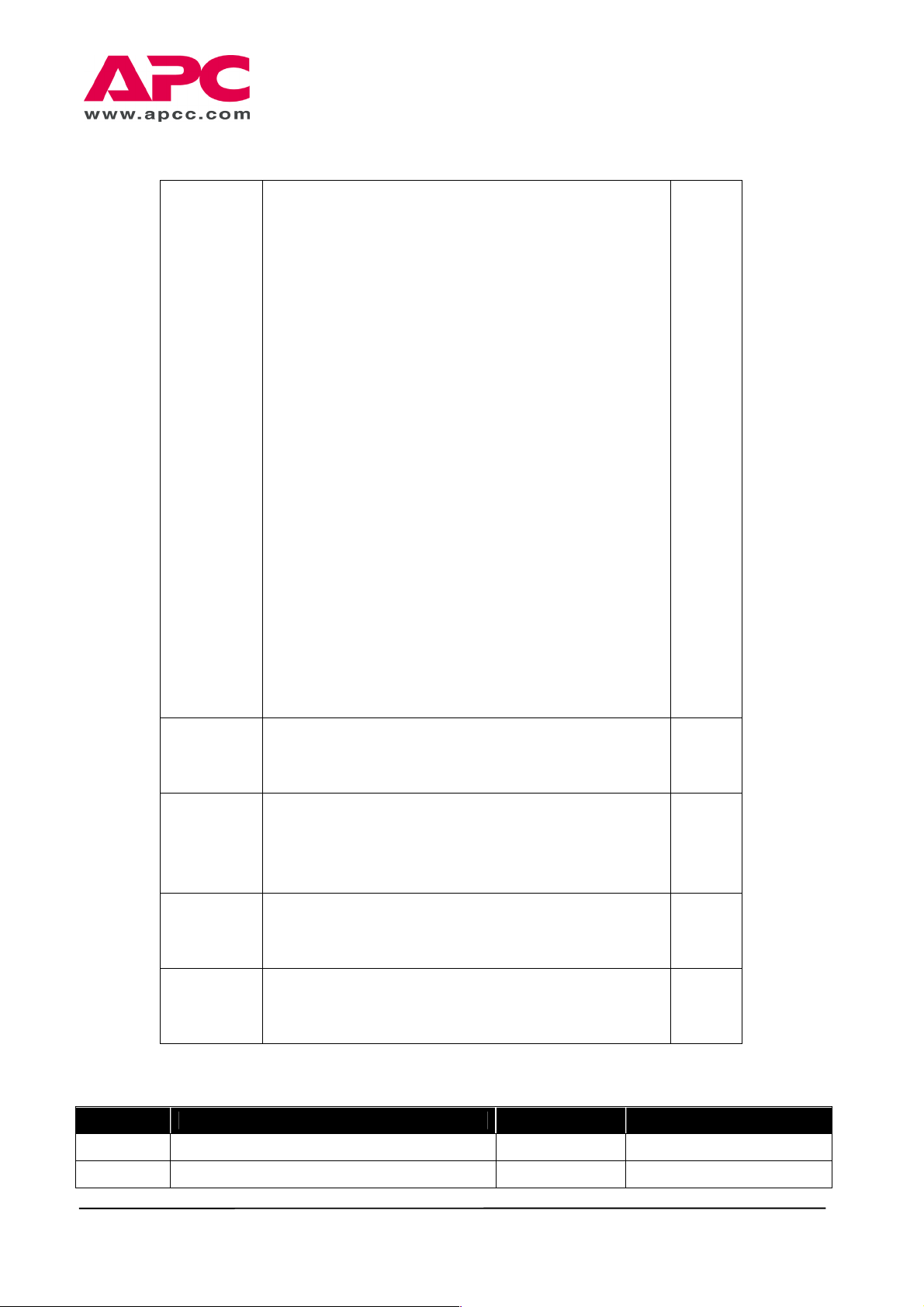

Issue Record

Issue Record

Issue RecordIssue Record

ISSUE DESCRIPTION DATE APPROVED

Rev 01 New document 4th JAN 2002 YES

Rev 02 Update 18th FEB 2002 YES

User Manual 990-9178A

DC MX06 40A Shelf Page 4 of 44 18

th

FEB 02

Page 5

1 General Information

1.1 Introduction

DC Power Plants from APC have unique features that make them easy to install, maintain, and upgrade.

The rectifier units are modular and truly “hot-pluggable” into the shelf assembly without any separate ac

wiring.

All system settings are controlled from the system control unit that provides monitoring and control

functions for each component of the system as well as alarm outputs for system diagnosis and

maintenance.

The APC international network of sales and service offices and qualified representatives provides sales

assistance for proposals, purchases, and after-sales support.

1.2 Safety Precautions

The unit must be installed into an enclosure which conforms to the requirements of EN60950 : 2000,

CAN/CSA 22.2 # 60950, UL60950 3

but is not limited to providing external disconnection devices.

The end use equipment must be installed in accordance with the local building code and practices, by

proper licensed installation personnel, taking into consideration all cautions and requirements detailed in

this manual.

For proper guidance on the selection of any external disconnects and cabling requirements see the CEC

and NEC codes or the local electrical code of the country of installation.

Before using the power system, carry out the following:

rd

Edition and be connected to comply with the standard. This includes

1.2.1 READ AND FOLLOW THE SAFETY PROCEDURES.

1.2.2 REFER TO THE FOLLOWING DOCUMENTS. ALL PROCEDURES MUST BE

CARRIED OUT IN ACCORDANCE WITH THE INSTRUCTIONS THEREIN.

• EN60950 : 2000, CAN/CSA 22.2 # 60950, UL60950.

• MANUFACTURER’S INSTRUCTIONS

• MATERIAL SAFETY DATA SHEET (MSDS) FOR THE BATTERY

(If batteries are supplied with the system)

• HEALTH AND SAFETY AT W ORK ACT, 1974 (UK)

• OCCUPATIONAL SAFETY & HEALTH STANDARDS (OHSA) (USA)

• ELECTRICITY AT WORK ACT, 1989 (UK)

• NFPA 70 NATIONAL ELECTRICAL CODE (USA)

User Manual 990-9178A

DC MX06 40A Shelf Page 5 of 44 18

th

FEB 02

Page 6

•

• CONTROL OF SUBSTANCES HAZARDOUS TO HEALTH (COSHH) REGS

• MANUAL HANDLING REGULATIONS, 1993 (See Section 6)

CEC Code C22.1-98 ( Canada )

1.2.3 BECOME FAMILIAR WITH THE HAZARDS ASSOCIATED WITH THE POWER

SYSTEM AS DETAILED IN PARA 2.

1.2.4 CAUTION - BEFORE INSTALLING RECTIFIERS (POWER SUPPLIES) INTO AN

UNPOPULATED SYSTEM SEE INSTALLATION INSTRUCTIONS IN SECTION 4.

1.3 Types of Hazards

The following hazards are present in the power system:

• ELECTRICAL VOLTAGE

• ELECTRICAL ENERGY

• HEAVY MASS

POTENTIALLY LETHAL VOLTAGES AND SOURCES OF HIGH ENERGY ARE PRESENT WITHIN THE

POWER SYSTEM. EXTREME CAUTION MUST BE OBSERVED AT ALL TIMES. ACCESS TO THE

INTERIOR OF THE SYSTEM FOR INSTALLATION, COMMISSIONING, MAINTENANCE AND REMOVAL

AND REPLACEMENT PURPOSES IS LIMITED TO FULLY TRAINED SERVICE PERSONNEL ONLY.

THIS SHOULD BE DONE WITH ALL POWER SOURCES DISCONNECTED EXCEPT WHEN

ABSOLUTELY NECESSARY.

User Manual 990-9178A

DC MX06 40A Shelf Page 6 of 44 18

th

FEB 02

Page 7

1.4 Inspection upon Receipt of Goods

1.4.1 General

APC has taken precautions in packing the power equipment for shipment to ensure its safe arrival;

however, the entire shipment including any boxes or crates should be inspected upon receipt for evidence

of damage that may have occurred during transit.

1.4.2 Visible External Damage

It is the responsibility of the person receiving the shipment to inventory and inspect all materials against the

bill of lading or waybill provided IMMEDIATELY upon taking delivery while the carrier representative is still

on site. Please be sure that all items are accounted for, including the correct number of pallets and the

quantity of accessory and/or component boxes. Also, note any visible external damage that may have

occurred during transit.

If damage has occurred or the quantity of items is not correct, then:

1) Make a descriptive notation on the delivery receipt before signing.

2) File a damage or shortage report with the carrier that delivered the shipment.

1.4.3 Concealed Damage

It is the customer’s responsibility to unpack the power system and equipment received from APC and

check for concealed damage. Within 15 days of receipt, check the materials received against the detailed

packing list to verify that the quantity and condition are complete and satisfactory.

Again, note any damage to the internal packing material and/or material shortages. If damage or shortage

is noted, then:

3) Request an inspection by the carrier

4) File a concealed damage claim; and/or

5) File a material shortage claim with your APC representative.

DELAY IN NOTIFYING THE CARRIER MAY RESULT IN LOSS OF RIGHT TO REIMBURSEMENT FOR

DAMAGES OR LOSS.

If you are unsure about the appearance of a part while conducting the materials inventory and inspection,

refer to the manual or contact the Customer Service Department of APC.

Should you have any questions concerning potential damages or should you experience a lack of

cooperation from your carrier, please contact your APC representative, or call APC

.

1.4.4 Return of Damaged Goods

Should equipment be damaged and require return to APC for repair, the APC service representative will

provide instructions along with a valid returned material authorization (RMA) number to facilitate return of

the damaged goods to the APC repair center.

It is important that the steps outlined in Section 1.4.2 and also Section 4 and 5 are followed carefully. Your

APC representative will assist you, if required, in obtaining proper disposition of an initial delivery return

issue; however, a valid RMA number must be obtained before returning any equipment to APC.

User Manual 990-9178A

DC MX06 40A Shelf Page 7 of 44 18

th

FEB 02

Page 8

1.5 APC Worldwide Customer Support

Customer support for this or any other American Power Conversion (APC) product is available at no

charge in any of the following ways:

l Visit the APC web site to find answers to frequently asked questions (FAQs), to access documents

in the APC Knowledge Base, and to submit customer support requests.

http://www.apc.com (Corporate Headquarters)

Connect by links to APC web pages for specific countries and regions, each of which provides

customer support information.

http://www.apc.com/support/

Submit customer support requests.

l Contact an APC Customer Support centre by telephone or email.

Regional Centres:

APC Headquarters (US and Canada)

Latin America

Europe, Middle East, Africa

l Local, country-specific centers: go to http://www.apc.com/support/contact for contact information.

(1) (800) 800 4272 (toll free)

apctech@apcc.com

(1) (401) 789 5735 (United States)

apctchla@apcc.com

(353) 91 702020 (Ireland)

apceurtech@apc.com

Contact the APC representative or other distributor from whom you purchased your APC product

for information on how to obtain local customer support.

User Manual 990-9178A

DC MX06 40A Shelf Page 8 of 44 18

th

FEB 02

Page 9

1.6 Warranty Information

1.6.1 Limited Warranty

American Power Conversion (APC) warrants the DC MX06 40A Shelf to be free from defects in materials

and workmanship for a period of two years from the date of purchase. It’s obligation under this warranty is

limited to repairing or replacing, at it’s own sole option, any such defective products. This warranty does

not apply to equipment that has been damaged by accident, negligence, or misapplication or has been

altered or modified in any way. This warranty applies only to the original purchaser.

1.6.2 Warranty Limitations

Except as provided herein, American Power Conversion makes no warranties, express or implied,

including warranties of merchantability and fitness for a particular purpose.

Some jurisdictions do not permit limitation or exclusion of implied warranties; therefore, the aforesaid

limitation(s) or exclusion(s) may not apply to the purchaser.

Except as provided above, in no event will APC be liable for direct, indirect, special, incidental, or

consequential damages arising out of the use of this product, even if advised of the possibility of such

damage.

Specifically, APC is not liable for any costs, such as lost profits or revenue, loss of equipment, loss of use of

equipment, loss of software, loss of data, costs of substitutes, claims by third parties, or otherwise. This

warranty gives you specific legal rights and you may also have other rights, which vary from state to state.

User Manual 990-9178A

DC MX06 40A Shelf Page 9 of 44 18

th

FEB 02

Page 10

2 Product Overview and Technical Description

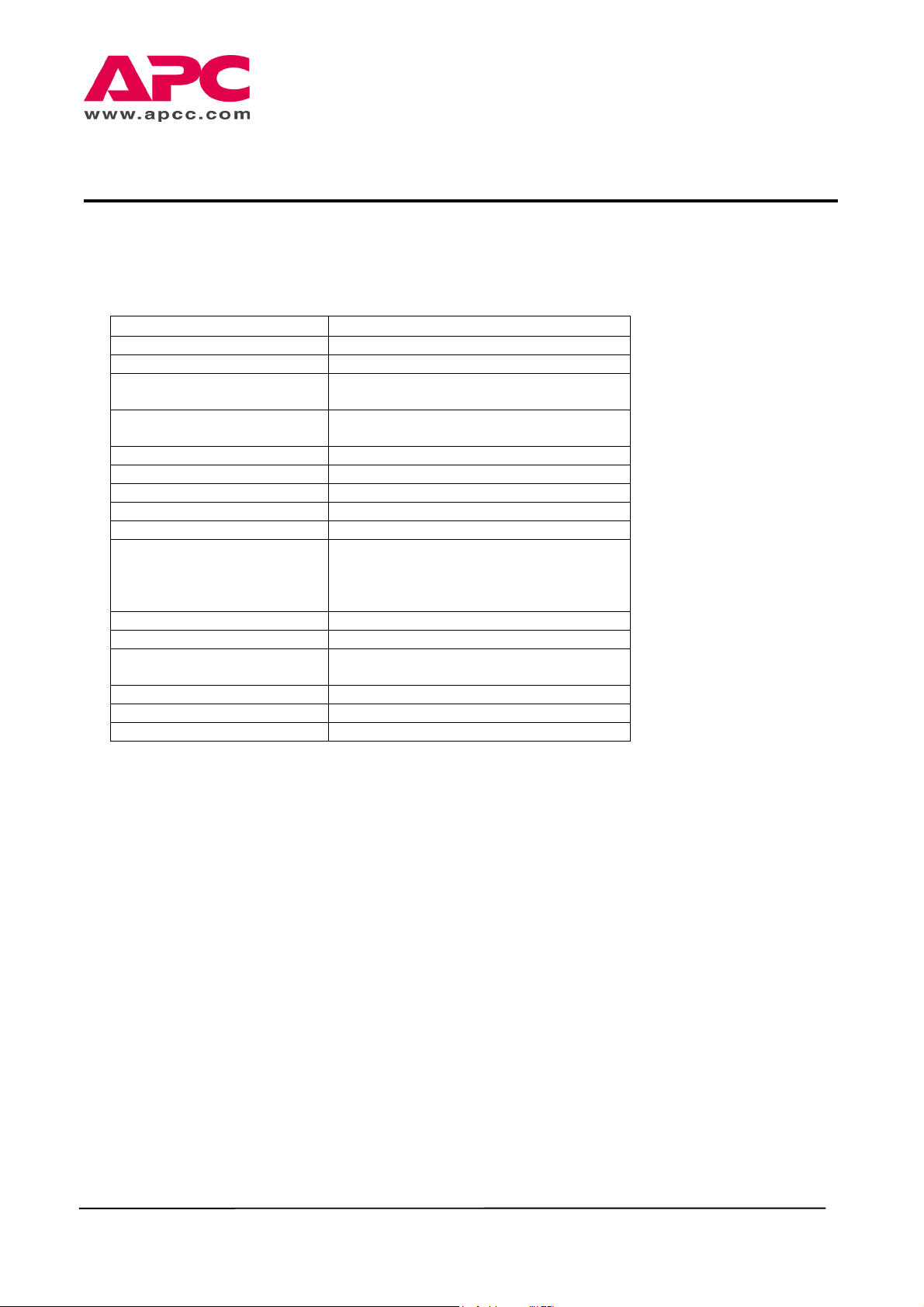

2.1 Specification

2.1.1 Rectifier

Parameter (per rectifier) 1TWF0500H54**

Approved Input Rating 115V or 230Vac

I/p Operating Range 103.5V to 264V

RMS Input Current

“ “ “

Approved Input Frequency

range

Turn-on Surge < 10A

Turn-on Time < 2 Seconds

Internal Fuse 7 amp 250V time lag

Power Factor 99 % typical, 90 % min

Output Voltage (Nominal) 54.5V dc

O/p Current (Rated) 10.5A @ 230V, 0-50°C

Current Limit 105 % of rated

Over Volts Protection 59.5V dc ± 0.5V

Power O/p (Rated) 500W @ 115V

Efficiency 83 % typical

Cooling Fan Cooled, front to rear

Ambient Temp -40 to 50°C (de-rate above 50°C)

Note :- See TWF0500 Rectifier datasheet for further or more detailed information

2.1.2 System AC Input

Input Voltage (Single phase)

(3 Phase Star)

(3 Phase Delta)

RMS Current (max) single phase

RMS Current (max) 3 phase star

RMS Current (max) 3 phase delta

Frequency

Efficiency

Harmonic Distortion

90 - 264Vac (Live to Neutral)

26A @ 115V ±10%, 14.5A @ 230V ±10% (total)

45 – 65 Hz

83% Typical

Complies with EN61000-3-2

6.5A max @115V

3.6A max @230V

45 – 65Hz

9A @ 230V, 50-65°C

9A @ 115V, 0-50°C

8A @ 115V, 50-65°C

600W @ 230V

208Vac, 380Vac, 400Vac or 415Vac (phase to phase)

208Vac only (phase to phase)

13A @ 208Vac, 7.2A @ 415Vac (per phase)

9.5A @ 208Vac (per phase)

User Manual 990-9178A

DC MX06 40A Shelf Page 10 of 44 18

th

FEB 02

Page 11

V

t

t

t

y

r

G

G

r

Y

2.1.3 System Output

Output Voltage Nominal

oltage Adjustment Range

Current Rating

Temperature Coefficien

Current Limi

Reverse Quiescent Curren

Regulation

Over voltage

2.1.4 Environmental

Temperature Range

Humidity

2.1.5 Safety Approvals

54.5Vdc

44 V – 57 V (Below 42V LVD contact opens)

42 A @ 230Vac, 36 A @ 115Vac, 28A @ 100Vac

-76mV/°C ±10% (over range 0°C - 50°C)

100% - 110% of Rated Current

Less than 100mA, Typically 50mA

250mV max for any line or load condition

59.5V ± 0.5V (reset by interruption of AC Input)

-25°C to 50°C operating range

85% non condensing

Approved to the following

CE marked to the European Low Voltage

Directive 73/23/EEC amended by 93/68/EEC

complies with BS EN60950:2000

Certified to CAN/CSA 22.2#950-00 (NRTL/C

UL1950 3rd Edition)

2.2 Display + LED’s

3½ Digit LED Displa

“Volts”

“Amps”

4 LED Rectifie

Single LED Rectifie

Alarm Card LED’s

Switchable between “Volts” and “Amps”

System Output Voltage

Total Output Load Current

Load Current = Rectifier Current – Batt Charge Current

Input Healthy

Output Healthy

Current Limit Red

Overvoltage Red

Rectifier Fail Red

Input Fail Red

Distribution Trip Red

Major Fault Red

Minor Fault

reen

reen

ellow

NB/ LED’s are lit when description is true.

User Manual 990-9178A

DC MX06 40A Shelf Page 11 of 44 18

th

FEB 02

Page 12

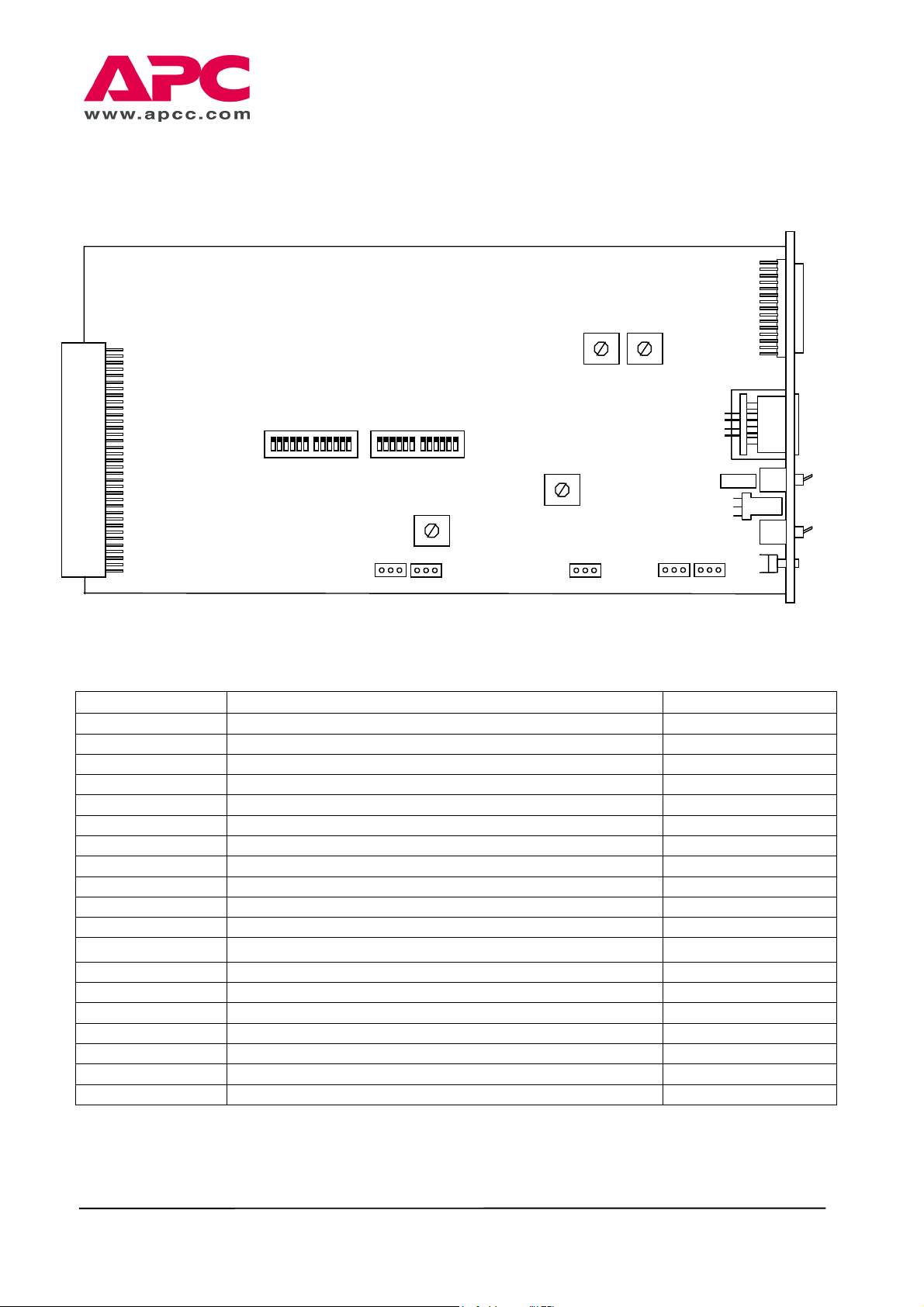

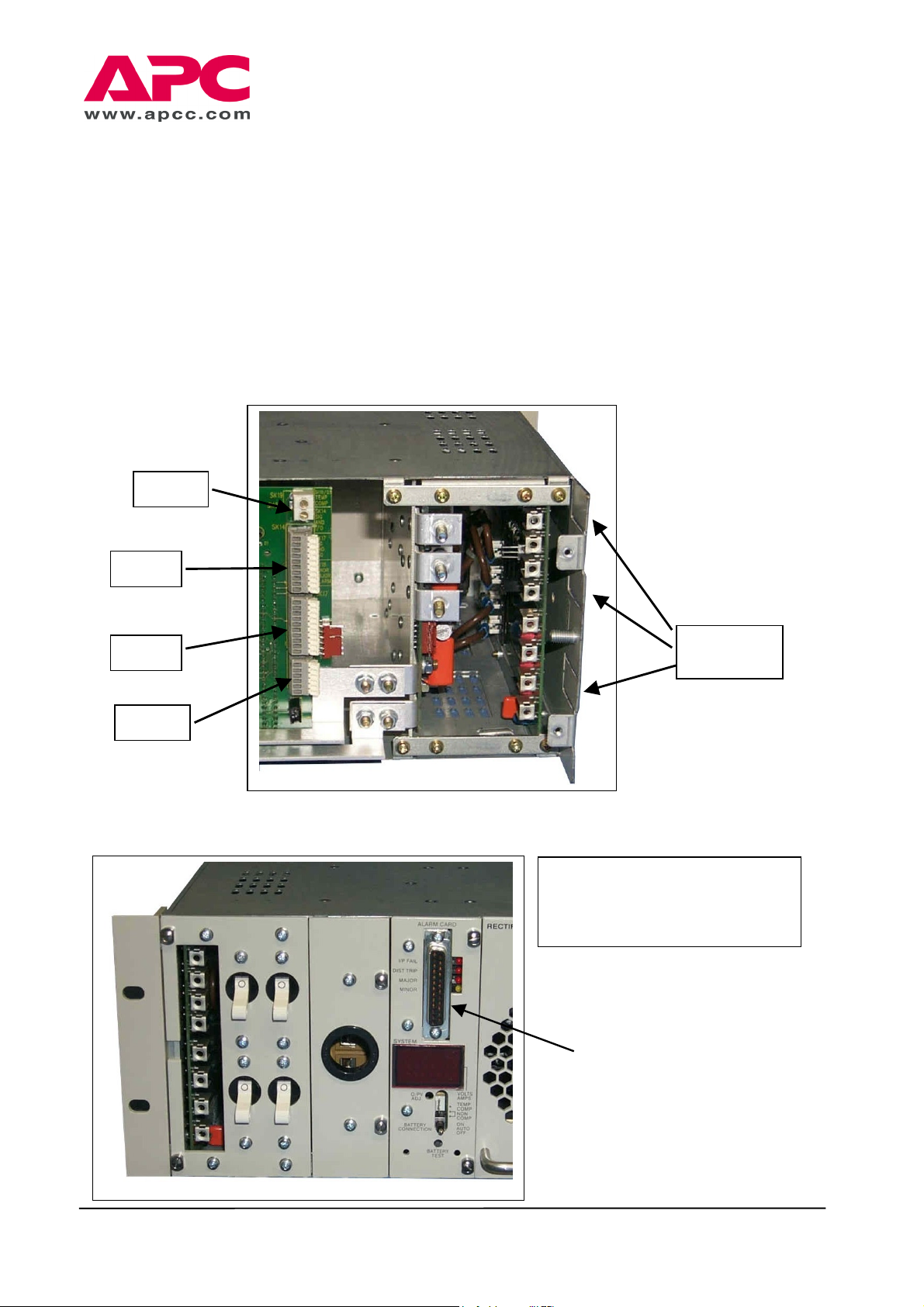

2.3 Controller

2.3.1 Alarm Card Layout

SK11

32

P5P4P3

SW2SW5

12

112 1

P2

SK10

1

1

11

SK7SK2SK3

1

SK1

Part Reference Function Adjustment

P1

Output Volts Adjust Via Front Panel

P2

LVD Disconnect Volts Adjust Factory Pre-set

P3

Meter Current Calibration Factory Pre-set

P4

Meter Reading Zero Adjust Factory Pre-set

P5

Meter Volts Calibration Factory Pre-set

SK1

SK2

SK3

SK4

SK5

SK7

SK10

SK11

SW1

SW2

SW3

SW5

SW6

LED Meter

Link Pins 1+2 (27V), 2+3 (54V) (Temp Compensation) Factory Pre-set

Link Pins 1+2 (27V), 2+3 (54V) (LVD Coil) Factory Pre-set

Link Pins 1+2 (27V), 2+3 (54V) (LVD Circuit) Factory Pre-set

Optional front panel access to signals N/A

Link Pins 1+2 (27V), 2+3 (54V) (Voltage Programming) Factory Pre-set

Link Pins 1+2 (27V), 2+3 (54V) (Meter Current) Factory Pre-set

Link Pins 1+2 (Temp Comp), 2+3 (Non Comp) Factory Pre-set

Main 64 Pin Connector N/A

Battery connection (LVD) “ON”, “AUTO” or “OFF” Via Front Panel

Selects any of 11 alarms to give a “MAJOR” alarm Remove Controller

Battery Test function (press and hold for test) Via Front Panel

Selects any of 11 alarms to give a “MINOR” alarm Remove Controller

Selects “Volts” or “Amps” reading for LED meter Via Front Panel

Optional 3½ digit LED Display N/A

1

SK4

P1

1

SK5

LED

Meter

SW6

SW1

User Manual 990-9178A

DC MX06 40A Shelf Page 12 of 44 18

th

FEB 02

Page 13

2.4 Alarms

2.4.1 Available Alarms

To monitor the system status a selection of alarm outputs are available. Dependant upon the rectifiers

fitted either 4 front panel LED’s or a single LED give visual notification of a system fault. There is also a

range of open collector transistor alarm outputs, which can be accessed at the rear of the shelf or on a

front panel connector (selected models). Finally there are 2 sets of relay contacts that can be configured to

represent 1 or more alarms selected by the user.

Below is a list of the available alarms along with their function and pin number.

Note/ Alarms marked with a * are not available if system is fitted with single LED rectifiers.

Alarm / User

Outputs

Bus Voltage Low System volts dropped to LVD set level +10%, LVD imminent SK14-2 SK4-25

* Fan Fail One or more of the Rectifier fans have stopped SK14-3 SK4-24

2+ Rectifiers Fail 2 or more rectifiers giving output less than 31Vdc SK14-4 SK4-5

Rectifier Fail 1 Rectifier giving output less than 31Vdc SK14-5 SK4-6

Distribution Trip 1 or more fuse blown or breaker tripped SK14-6 SK4-2

AC Fail 1 or more of the AC input feeds failed SK14-7 SK4-1

* Over Current 1 or more rectifiers in current limit state SK14-8 SK4-23

* Over Voltage 1 or more rectifiers tripped due to excessive o/p voltage

(interrupt AC input or remove rectifier and refit to reset)

* Over Temperature 1 or more rectifiers tripped due to excessive internal

temperatures (resets itself when cooled down)

Signal Common Use to reference all alarms to SK17-1 SK4-17

Current Share Use for paralleling purposes only SK17-3 SK4-16

Current Analogue Analogue voltage representing load current (1V = 5A ± 5%) SK17-4 SK4-19

5V Auxiliary Low current capability 5V supply for use with current limit

programming.

Major Failure ‘Minor’ relay contact (closed for alarm) SK18-1 SK4-11

“ “ ‘Minor’ relay contact (Common) SK18-2 SK4-10

“ “ ‘Minor’ relay contact (open for alarm) SK18-3 SK4-12

Minor Failure ‘Major’ relay contact (closed for alarm) SK18-4 SK4-8

“ “ ‘Major’ relay contact (Common) SK18-5 SK4-7

“ “ ‘Major’ relay contact (open for alarm) SK18-6 SK4-9

Description Rear

Access

SK14-9 SK4-22

SK14-10 SK4-21

SK17-5 SK4-15

Warning!

max voltage rating of 60Vdc and a current sink capability of 20mA

All alarm outputs other than the relay contacts are open collector transistors. Each output has a

Front

Access

User Manual 990-9178A

DC MX06 40A Shelf Page 13 of 44 18

th

FEB 02

Page 14

2.4.2 Rear Access Alarms

To access the alarm outputs first ensure batteries are disconnected from the system by setting battery

connection switch to “OFF” via controller front panel (see section 2.3) and by turning the external battery

breaker off. The input mains supply must then be turned off by operating the local isolator or disconnection

device. Remove the rear cover to leave the view as shown below. Labelled are the 3 signal output

connectors SK14, SK17 and SK18 and also the temperature compensation connector SK19, where a

thermistor is wired.

To use a particular alarm signal simply strip the ends of your alarm cables and enter into connectors by

pushing down on respective lever, push in alarm cable and release lever to clamp cable. Cables should be

routed through one of the knockout panels in the side of the shelf.

2.4.3 Front Access Alarms

SK19

SK14

SK17

SK18

1

2

3

4

1

2

3

4

DISTRIBUTI ON

Knockout

panels

The front access alarms are

available from a 25 way ‘D’

connector socket (SK4) mounted

in the controller front panel.

Alarms socket SK4

User Manual 990-9178A

DC MX06 40A Shelf Page 14 of 44 18

th

FEB 02

Page 15

2.4.4 Major and Minor Alarms

In an MX06 40A Shelf, 9 of the available alarms can be set to show as a “Minor” or “Major” alarm. As

standard the alarm outputs are open collector transistor outputs available from the connectors as detailed

in the 2 previous sections. If an alarm is selected as a Minor or Major alarm it also lights the corresponding

“Major” or “Minor” front panel LED and the “Major” or “Minor” relay contacts also change over. More than

one alarm can be selected at once and each alarm can be selected as both Major and Minor if required.

The relay contacts are rated as follows:

AC Rating - 0.5A @ 125Vac

DC Rating - 1A @ 24Vdc

Max VDC - 0.6A @ 110Vdc

Alarm Description Major alarm

selection

Over Temperature 1 or more rectifiers tripped due to excessive

internal temperatures

(Resets itself when cooled down)

Over Volts 1 or more rectifiers tripped due to excessive

o/p voltage (interrupt AC input or remove

rectifier and refit to reset)

Over Current 1 or more rectifiers in current limit state SW2-3 SW5-3

Fan Fail One or more of the Rectifier fans have

stopped

Bus Voltage Low System volts below 48V LVD imminent SW2-5 SW5-5

A.C Fail 1 or more of the AC input feeds failed SW2-6 SW5-6

Fuse Fail 1 or more fuse blown or breaker tripped SW2-7 SW5-7

2 or more Rectifier Fail 2 or more rectifiers giving output < 31Vdc SW2-10 SW5-10

Rectifier Fail 1 Rectifier giving output less than 31V dc SW2-11 SW5-11

SW2-1 SW 5-1

SW2-2 SW 5-2

SW2-4 SW 5-4

See sections 2.3 for info on SW2 and SW5 location and relay contact pin-outs.

Minor alarm

selection

User Manual 990-9178A

DC MX06 40A Shelf Page 15 of 44 18

th

FEB 02

Page 16

2.5 Customer Inputs

2.5.1 Current Limit Programming

Input Description Controller

Type

Current Limit

Program

5V aux

Connect a DC voltage to this pin (referenced to

signal common or –Ve output) to reduce the system

output current limit point.

Current limit is programmed down 1A per 1.5V

program voltage. Max program voltage 7.5V.

5V aux can be used to program down current limit

level by linking to program pin.

Rear Access

Front Access

Rear Access

Front Access

The system output current limit can also be set to either the standard “High” (100%) level or “Low” (70%)

level by using SK13.

For “High” current limit level link pins 1 and 2 (default setting)

For “Low” current limit level link pins 2 and 3

Selecting “Low” current limit level will program down each rectifiers current limit level to roughly 70% of the

default level. (See section 2.1.1 for default levels). This is the same as connecting the 5V aux pin to the

current limit program pin as detailed above.

Note/ using both programming methods

together will not double the effect

Connector

SK17-2

SK4-20

SK17-5

SK4-15

SK13

2.5.2 Output Voltage Programming

Input Description Controller

type

Voltage

Programming

Connect a DC voltage to this pin (referenced to

signal common or –Ve output) to adjust the system

output voltage.

This pin floats at 2.5V nominal with respect to

negative output (O/P @ 54.5V)

Applying a DC voltage adjusts the output by –1V/V.

(For 1V swing on program pin the output voltage

changes by –1V)

The programming voltage range is 0V – 14V, giving a

max adjustment range of 57V to 43V.

Note: See section 2.4 for SK4, SK17 location photo

Rear Access

Front Access

Connector

SK17-7

SK4-18

User Manual 990-9178A

DC MX06 40A Shelf Page 16 of 44 18

th

FEB 02

Page 17

2.5.3 Battery Test Function

Input Description Location

Battery Test

Front panel momentary push button. Push and hold drops

output volts to 45Vdc. This is below battery float voltage and

is used to check the batteries can supply the system load.

2.5.4 Enable Function

Input Description Location

Enable

Back-plane circuit board mounted 3-way Molex header. Link

pins 1 and 2 with supplied link for “local” enable of rectifier

outputs. Link pins 2 and 3 for “remote” enable.

If “remote” enable SK17-1 and SK17-6 must be linked to

enable rectifier outputs.

System is set to “Local Enable” as standard

SK17

SK22

Note: Prior to accessing and making connections ensure batteries are disconnected from the system by

setting battery connection switch to “OFF” via controller / alarm card front panel (see section 2.3) and by

turning the external battery breaker off.

The AC input supply must then be turned off by operating the local isolator or disconnection device.

Push button mounted on

controller front panel.

SK22 (mounted on back-

plane board).

User Manual 990-9178A

DC MX06 40A Shelf Page 17 of 44 18

th

FEB 02

Page 18

2.5.5 Temperature Compensation

Input Description Socket Pin

Temp Compensation

This function allows a temperature probe to be used to

automatically adjust the output voltage of the system. This

ensures the charging voltage stays within the battery

manufacturers recommended limits. To connect thermistor,

simply enter striped wires into SK19 and screw to clamp

(polarity not important). Check controller configuration link

as explained below.

Note: See page 14 for SK19 location photo

MX06 40A Calculated Temperature Compensation (54V)

59.00

Voltage (V)

58.00

57.00

56.00

55.00

54.00

Output Voltage max

Output Voltage nom

Output Voltage min

Minimum Battery Voltage

Maximum Battery Voltage

53.00

52.00

-10.00 0.00 10.00 20.00 30.00 40.00 50.00 60.00 70.00

Temperature (°C)

ALARM CARD

System Controller

SK19 1 - 2

Link fitted on top

2 pins for Temp

Comp

Link fitted on

bottom 2 pins for

no compensation

(fixed o/p Volts)

User Manual 990-9178A

DC MX06 40A Shelf Page 18 of 44 18

th

FEB 02

Page 19

2.6 Mechanical

2.6.1 Dimensions

Dimension A B C D E F

Length 482.6mm

(19in)

132.5mm

(5.22in, 3U)

283.6mm

(11.17in)

82.5mm

(3.25in)

138.5mm

(5.45in)

438.2mm

(17.25in)

2.6.2 Weight

Item Measured Shelf + Dist + Controller Single Rectifier Full System

Weight (Kg) 7.65 1.75 14.70

Weight (lbs) 16.85 3.85 32.35

User Manual 990-9178A

DC MX06 40A Shelf Page 19 of 44 18

th

FEB 02

Page 20

2.6.3 Mounting Options

The MX06 40A Shelf has 3 positions for mounting ears. If mounting ears were ordered with the system

they will be fitted in the front position as standard. The 2 alternative mounting positions are shown below.

The end user can simply unscrew the ears and re-fit in the desired position.

Ensure all screws are re-tightened sufficiently.

Mounting Ears

Optional Mounting

Positions

User Manual 990-9178A

DC MX06 40A Shelf Page 20 of 44 18

th

FEB 02

Page 21

2.7 Schematic

2.7.1 Positive Earth Configured

User Manual 990-9178A

DC MX06 40A Shelf Page 21 of 44 18

th

FEB 02

Page 22

2.7.2 Negative Earth Configured

User Manual 990-9178A

DC MX06 40A Shelf Page 22 of 44 18

th

FEB 02

Page 23

3 System Configuration

The MX06 40A shelf is designed to meet a wide range of customer requirements/applications. A number of

versions and options are available including various distribution types, alternative input supply

configurations, 19 and 23 inch mounting versions, temperature probes etc.

Contact APC for details.

Alternatively the following pre configured systems are available:

DCM00K02W481

Rear access 40A system with 4 x 10A circuit breaker output distribution, includes alarm card with LED

display option, 19” mounting brackets, single phase – single feed input, 3 rectifier blanking panels and a

non temperature compensated output voltage of 54.5Vdc. Probe for temperature compensation supplied.

DCM00K02W482

Front access 40A system with 4 x 10A circuit breaker output distribution, includes front access alarm card

with LED display option, 19” mounting brackets, single phase – single feed input, 3 rectifier blanking panels

and a non temperature compensated output voltage of 54.5Vdc. Probe for temperature compensation

supplied.

DCM00K02W483

Rear access 40A system with 10 way GMT fuse output distribution, includes a selection of GMT output

fuses, alarm card with LED display option, 19” mounting brackets, single phase – single feed input, 3

rectifier blanking panels and a non temperature compensated output voltage of 54.5Vdc. Probe for

temperature compensation supplied.

DCM00K02W484

Front access 40A system with 10 way GMT fuse output distribution, includes a selection of GMT output

fuses, front access alarm card with LED display option, 19” mounting brackets, single phase – single feed

input, 3 rectifier blanking panels and a non temperature compensated output voltage of 54.5Vdc. Probe for

temperature compensation supplied.

User Manual 990-9178A

DC MX06 40A Shelf Page 23 of 44 18

th

FEB 02

Page 24

AC3AC4A

A

4 Installation Procedure

4.1 AC Primary Supply

4.1.1 Single Phase

The MX06 40A Shelf can be used on a Single Phase AC supply. The system can be connected

to a 230V or 115V supply.

Maximum input current is 26A at 115Vac and 15A at 230Vac. Choose AC Input cabling rated

accordingly and colour coded as required for country/state concerned.

4.1.1.1 Rear Access Connection

To connect the input supply to the MX06 40A Shelf proceed as follows:

• The AC input current to the system should also be limited by an appropriate device in the

event of a short circuit as defined in EN60950 to protect the internal wiring of the end use

equipment.

• Ensure that the AC supply intended for connection is isolated, locked off and under single

operator control. Remove the rear cover to leave the view as shown below.

• There are 3 pairs of AC Input connectors: AC1 (Live), AC2 (Neutral)

AC3 (Live), AC4 (Neutral)

AC5 (Live), AC6 (Neutral)

• Connection can be made to any of the 3 pairs but for optimised EMC performance use AC5

(Live), AC6 (Neutral) and the nearest safety earth stud. Access to this should be through the

top left knockout tab. If an alternative knockout is to be used ensure additional insulation is

used where cabling passes over secondary parts. NB/ Earth connection should be made first.

• Connect the cables terminated with M4 ring crimps using the M4 x 8 screws supplied in the

accessory kit.

Top Left

AC5

Safety

Earth

AC6

• Cables should be routed as close to the top of the shelf using the supplied routing clips (see

section 4.3 for further routing details).

• Refer to section 5 entitled “Commissioning the system” before applying AC power.

Safety

Earth

C2

C1

User Manual 990-9178A

DC MX06 40A Shelf Page 24 of 44 18

th

FEB 02

Page 25

4.1.1.2 Front Access Connection

To connect the input supply to the MX06 40A Shelf proceed as follows:

• The same protection devices and cable parameters are required for front access connection

as explained for “single-phase rear access” previously.

• Ensure that the AC supply intended for connection is isolated, locked off and under single

operator control.

• Strip the ends of the AC Input cables to be connected to the Input terminal block.

• By unscrewing the 2 front panel screws the AC Input connection drawer can be opened as

shown below. The AC Input cable is fed through the gland and screwed into the terminal

block visible.

• Connect as follows: Safety earth to position marked with earth symbol (connect first)

Live to AC1

Neutral to AC2

• The alarm card adjacent to the AC Input drawer may need to be removed for easier access

• A strain relief bush can be fitted instead of the standard cable gland shown. Contact factory

Terminal Block

Cable Gland

to the terminal block screws.

for details.

User Manual 990-9178A

DC MX06 40A Shelf Page 25 of 44 18

th

FEB 02

Page 26

4.1.2 Single Phase, AB Feed

The MX06 40A Shelf can be used on a Single Phase AB Feed system. This means that 2

separate supply’s can be used, each powering 2 of the 4 rectifiers fitted. The system can be

connected to a 230V or 115V supply.

The maximum input current per feed is 7.5A at 230V and 13A at 115V. Choose AC Input cabling

rated accordingly and colour coded as required for country/state concerned.

4.1.2.1 Rear Access Connection

• The AC input current to the system should also be limited by an appropriate device in the

event of a short circuit as defined in EN60950 to protect the internal wiring of the end use

equipment. The device(s) should be rated according to the input current as stated above.

• Ensure that the AC supply intended for connection is isolated, locked off and under single

operator control. Remove the rear cover to leave the view as shown below

• The main circuit board should have been configured for single phase AB feed use, by

removing LK3 and LK4. This is normally factory configured.

• First the two safety earth connections should be connected to the studs labelled below.

• Feed A should be wired to: AC1 (Live) and AC2 (Neutral)

• Feed B should be wired to: AC5 (Live), AC6 (Neutral)

• Connect the cables terminated with M4 ring crimps using the M4 x 8 screws supplied in the

accessory kit.

Top Left

AC5

Feed B

Earth

AC6

LK4

LK3

Feed A

AC3 AC4 AC2

LK2

Earth

AC1

LK1

• Cables should exit through the top left knockout tab. If an alternative knockout is to be used

ensure additional insulation is used where cabling passes over secondary parts. Cables

should be routed as close to the top of the shelf using the supplied routing clips (see section

4.3 for further routing details).

• Refer to section 5 entitled “Commissioning the system” before applying AC power.

User Manual 990-9178A

DC MX06 40A Shelf Page 26 of 44 18

th

FEB 02

Page 27

4.1.2.2 Front Access Connection

To connect the input supply to the MX06 40A Shelf proceed as follows:

• Ensure that the AC supply intended for connection is isolated, locked off and under single

operator control.

• The main circuit board should have been configured for an AB Feed by removing LK3 and

LK4. This is normally factory configured.

• Strip the ends of the AC Input cables to be connected to the input terminal block.

• By unscrewing the 2 front panel screws the AC Input connection drawer can be opened as

shown below. The AC Input cable is fed through the gland and screwed into the terminal

block visible.

• Connect as follows: Safety earth to position marked with earth symbol (connect first)

Feed A Live to AC1

Feed A Neutral to AC2

Feed B Live to AC3

Feed B Neutral to AC4

• The alarm card adjacent to the AC Input drawer may need to be removed for easier access

• A strain relief bush can be fitted instead of the standard cable gland shown. Contact factory

Terminal Block

Cable Gland

to the terminal block screws.

for details.

User Manual 990-9178A

DC MX06 40A Shelf Page 27 of 44 18

th

FEB 02

Page 28

4.1.3 3 Phase Star Supply

The MX06 40A Shelf can be used on any of the following supplies: 415V, 400V, 380V or 208V

phase to phase.

The maximum input current is 13A per phase on a 208Vac phase to phase supply and 7.2A per

phase on a 380Vac, 400Vac or 415Vac supply. Choose AC Input cabling rated accordingly and

colour coded as required for country/state concerned.

4.1.3.1 Rear access connection

To connect the input supply to the MX06 40A Shelf proceed as follows:

• The AC input current to the system should also be limited by an appropriate device in the

event of a short circuit as defined in EN60950 to protect the internal wiring of the end use

equipment. The device(s) should be rated accordingly.

• Ensure that the AC supply intended for connection is isolated, locked off and under single

operator control. Remove the rear cover to leave the view as shown below

• The main circuit board should have been configured for 3-phase star use by removal of LK2

and LK3. This is normally factory configured.

• First the safety earth connection should be connected to one of the studs labelled below

• Connect inputs: Phase 1 to AC1, Phase 2 to AC3, Phase 3 to AC5, Neutral to AC2, 4 or 6

(neutral is required as system is a star configuration)

• Connect the cables terminated with M4 ring crimps using the M4 x 8 screws supplied in the

accessory kit.

Top Left

Phase 3

AC5

• Cables should exit through the top left knockout tab. If an alternative knockout is to be used

ensure additional insulation is used where cabling passes over secondary parts. Cables

should be routed as close to the top of the shelf using the supplied routing clips (see section

4.3 for further routing details.

• Refer to section 5 entitled “Commissioning the system” before applying AC power.

Safety

Earth

AC6

LK3

Phase 2

AC3

AC4 AC2

LK2

Safety

Phase 1

User Manual 990-9178A

DC MX06 40A Shelf Page 28 of 44 18

th

FEB 02

Page 29

4.1.3.2 Front access connection

To connect the input supply to the MX06 40A Shelf proceed as follows:

• The AC input current to the system should also be limited by an appropriate device in the

event of a short circuit as defined in EN60950 to protect the internal wiring of the end use

equipment. The device(s) should be rated accordingly.

• Ensure that the AC supply intended for connection is isolated, locked off and under single

operator control.

• The main circuit board should have been configured for 3-phase star use by removal of LK2

and LK3. This is normally factory configured.

• Strip the ends of the AC Input cables to be connected to the Input terminal block.

• By unscrewing the 2 front panel screws the AC Input connection drawer can be opened as

shown below. The AC Input cable is fed through the gland and screwed into the terminal

block visible.

• Connect as follows: Safety earth to position marked with earth symbol (connect first)

Phase 1 to AC1

Phase 2 to AC3

Phase 3 to AC4

Neutral to AC2 (neutral is required as system is a star configuration)

• The alarm card adjacent to the AC Input drawer may need to be removed for easier access

to the terminal block screws.

• Refer to section 5 entitled “Commissioning the system” before applying AC power.

Terminal Block

Cable Gland

User Manual 990-9178A

DC MX06 40A Shelf Page 29 of 44 18

th

FEB 02

Page 30

A

art

4.1.4 3 Phase Delta Supply

Warning!

In a delta connection system each rectifier input is connected directly across two phases. Due to

the maximum voltage rating of the rectifiers being 264Vac this is the maximum phase-to-phase

voltage that can be applied.

The maximum input current on a 208Vac supply is 9.5A per phase. Choose AC Input cabling

rated accordingly. The cabling should be colour coded as required for the country/state

concerned.

The MX06 40A Shelf can only be used on a 208Vac phase to phase supply.

4.1.4.1 Rear Access Connection

To connect the input supply to the MX06 40A Shelf proceed as follows:

• The AC input current to the system should also be limited by an appropriate device in the

event of a short circuit as defined in EN60950 to protect the internal wiring of the end use

equipment. The device(s) should be rated accordingly.

• Ensure that the AC supply intended for connection is isolated, locked off and under single

operator control. Remove the rear cover to leave the view as shown below.

• The main circuit board should have been factory configured for 3-phase delta prior to sale.

LK2 and LK4 should be fitted but LK1 and LK3 should be removed. Also an external link

should connect AC2 to AC5. This is normally factory configured.

• Connect as follows: Safety earth to either earth stud (connect first)

Phase 1 to AC1, Phase 2 to AC5, Phase 3 to AC4

• Connect the cables terminated with M4 ring crimps using the M4 x 8 screws supplied in the

accessory kit.

Phase 2

AC5

Safety

Earth

AC6

AC3

Phase 3

C4

Safety

h

E

AC2

LK4

LK3

LK2

LK1

• Cables should exit through the top left knockout tab. If an alternative knockout is to be used

ensure additional insulation is used where cabling passes over secondary parts. Cables

should be routed as close to the top of the shelf using the supplied routing clips (see section

4.3 for further routing details.

• Refer to section 5 entitled “Commissioning the system” before applying AC power.

Phase 1

User Manual 990-9178A

DC MX06 40A Shelf Page 30 of 44 18

th

FEB 02

Page 31

4.1.4.2 Front access connection

To connect the input supply to the MX06 40A Shelf proceed as follows:

• The AC input current to the system should also be limited by an appropriate device in the

event of a short circuit as defined in EN60950 to protect the internal wiring of the end use

equipment. The device(s) should be rated accordingly.

• Ensure that the AC supply intended for connection is isolated, locked off and under single

operator control.

• The main circuit board should have been factory configured for 3-phase delta prior to sale.

LK2 and LK4 should have been fitted but LK1 and LK3 should be removed. Also an external

link should connect AC2 to AC5. This is normally factory configured.

• Strip the ends of the AC Input cables to be connected to the Input terminal block.

• By unscrewing the 2 front panel screws the AC Input connection draw can be opened as

shown below. The AC Input cable is fed through the gland and screwed into the terminal

block visible.

• Connect as follows: Safety earth to position marked with earth symbol (connect first)

Phase 1 to AC1

Phase 2 to AC2

Phase 3 to AC4

• The alarm card adjacent to the AC Input drawer may need to be removed for easier access

to the terminal block screws

• Refer to section 5 entitled “Commissioning the system” before applying AC power.

Terminal Block

Cable Gland

User Manual 990-9178A

DC MX06 40A Shelf Page 31 of 44 18

th

FEB 02

Page 32

r

4.2 DC Distribution

The MX06 40A Shelf has a DC distribution module fitted. This module contains the chosen distribution

components of either circuit breakers or fuses. It also contains an LVD contact (controlled by the controller)

and a current shunt measuring load current. The modules can be configured for either positive or negative

earthed output. The output can also be left floating to facilitate external grounding. A tripped output will give

an alarm displayed as a front panel LED.

There are three standard distribution component types:

1/ 10 GMT Fuses

2/ 4 Cartridge Fuses

3/ 4 Circuit Breakers

As explained earlier all three types are offered with either front or rear cable access giving six modules

types.

4.2.1 10 GMT Fuses Rear Access

No. of Outputs :

Output Rating :

DISTRIBUTION

FUSES

1

2

3

4

5

• Cables should be rated to at least the same

current rating as the corresponding output fuse

and be colour coded as to meet all the local

installation regulations.

6

7

8

9

10

• To attach the cables remove the rear cover fo

access to output connectors.

• Simply strip the ends of the cables and screw into

output terminal block.

Fuses :

Trip Alarm :

Output 1

Top Connector :

Common (0V Return) / Earth (if link fitted)

10 max

10A max per output

(42A total)

GMT-** (Bussmann)

YES

Output 10

Distributed Output 1

Bottom Connector :

- 54Vdc (when positive earthed)

Distributed Output 10

User Manual 990-9178A

DC MX06 40A Shelf Page 32 of 44 18

th

FEB 02

Page 33

g

t

4.2.2 10 GMT Fuses Front Access

To connect the cables to the system proceed as follows:

• Cables should be rated to at least the same current rating as the corresponding output fuse

and be colour coded as to meet all the local installation regulations

• Remove the distribution front panel to give easier access to terminal block if required. To

attach the cables simply strip the ends and screw into output terminal block

• Ensure stray wires do not contact the front panel metalwork.

Top Connector :

Common (0V Rtn) / Earth (if

earth link fitted)

Bottom Connector :

- 54Vdc, +Ve earth

GMT Fuse ratings

No. of Outputs :

Output Rating :

Trip Alarm :

Output 1

Output 10

Output 1

Output 10

Fuses :

10

10A max per output

(42A total)

GMT-** (Bussmann)

YES

FUSES

INPUT DISTRIBUTION CONTRO LLER

1

2

3

4

5

6

7

8

9

10

GMT Fuse 1

GMT Fuse 10

Ambient Temperature

20oC 50oC 65oC

10A 7A 6A 5A

This table shows that the continuous curren

rating of a GMT fuse is less than the specified

current rating. It also shows that it is affected

by ambient temperature.

Lower value fuses follow the same pattern.

12A 8A 7A 6A

Continuous

15A 10A 9A 8A

Current Ratin

User Manual 990-9178A

DC MX06 40A Shelf Page 33 of 44 18

th

FEB 02

Page 34

4.2.3 4 Circuit Breakers Rear Access

DISTRIBUTION

1

2

CONTROLLER

No. of Outputs :

Output Rating :

Circuit Breakers :

Trip Alarm :

4

4 O/P’s up to 20A max

2 O/P’s up to 40A max

1 O/P up to 50A max

Series DC Current trip,

Medium time delay.

YES

43

• Remove the rear cover to give access to the output terminals (shown below).

• To connect to the output terminals use M4 ring crimps with cables rated to at least the same

current rating as the corresponding output breaker and colour coded as to meet all the local

installation regulations.

Cables should be routed through

knockout panels in rear cover or in

the side of the shelf itself.

Output 1

Top 4 Terminals :

0V / Earth, when output earthed

Output 4

Distributed Output 1

Bottom 4 Terminals :

+ 54Vdc when negative earth

- 54Vdc when positive earth

Distributed Output 4

User Manual 990-9178A

DC MX06 40A Shelf Page 34 of 44 18

th

FEB 02

Page 35

R

R

4.2.4 4 Circuit Breakers Front Access

To connect the cables to the system proceed as follows:

• To connect to the output terminals use M4 ring crimps with cables rated to at least the same

current rating as the corresponding output breaker and colour coded as to meet all the local

installation regulations.

Top Connector = 0V / Earth

(when output earthed)

Distributed Output 1

Bottom Connector :

- 54Vdc, +Ve earth

Distributed Output 4

No. of Outputs :

Output Rating :

Circuit Breakers :

Trip Alarm :

Output 1

Output 4

4

4 O/P’s up to 20A max

2 O/P’s up to 40A max

1 O/P up to 50A max

Series DC Current trip

Medium time delay

YES

DISTRIBUTION

DISTRIBDISTRIB

1

2

3

4

1

2

3

4

UTION

UTIONUTION

12

34

INPUT

INPUT DISTRIB

INPUTINPUT

CONTROLLER

CONTROLLE

CONTROLLERCONTROLLE

User Manual 990-9178A

DC MX06 40A Shelf Page 35 of 44 18

th

FEB 02

Page 36

4.2.5 4 Cartridge Fuses Rear Access

No. of Outputs :

Output Rating :

Fuses :

Trip Alarm :

4

4 O/P’s up to 20A max

2 O/P’s up to 25A max

1 O/P up to 25A max

Bussmann NITD range

YES

To connect the cables to the system follow the same procedure as for the “4 Circuit Breaker Rear Access”

distribution module (section 4.2.3).

4.2.6 4 Cartridge Fuses Front Access

The ratings are the same as for the rear access version above.

To connect the cables to the system follow the same procedure as for the 4 Circuit Breaker Front Access

distribution module. (see section 4.2.3)

1

2

3

4

1

2

3

4

1 2

FUSES

3 4

INPUT DISTRIBUTION

Note/ to gain access to the fuses remove the distribution front panel (front and rear access versions)

CONTROLLER

User Manual 990-9178A

DC MX06 40A Shelf Page 36 of 44 18

th

FEB 02

Page 37

f

r

4.3 Routing Of Cables

4.3.1 Input cables

One or more of the top 3 knockouts (top left hand side knockout and 2 actually in the rear cover) must be

used for entry of the input AC cable. This is essential if the input cabling used is not double insulated and

recommended as this optimises the EMC performance by ensuring the AC Input cables are as far away

from the output wiring as possible. Cables should be routed as near the top of the system as possible

using the cable clips provided, with big loops of cable inside the shelf being avoided.

Top 3 Knockouts

300mm of cable protecto

grommet strip supplied.

Simply cut into required

lengths and fit around edge

of knockout holes (as

shown below)

Cable protector

grommet

AC Input Cable

Note/ This picture does not

show a 40A Shelf and is to be

used only as an example o

how to use the grommet strip

User Manual 990-9178A

DC MX06 40A Shelf Page 37 of 44 18

th

FEB 02

Page 38

Supplied cable

clips for routing

of input cables

4.3.2 Output Cables

The output cables may be of quite large diameter and therefore it may be necessary to use more than one

knockout hole. The right hand side knockouts should be used to keep the output cables physically as far

from the input cables as possible to optimise EMC performance.

User Manual 990-9178A

DC MX06 40A Shelf Page 38 of 44 18

th

FEB 02

Page 39

4.4 External Battery Installation

4.4.1 Battery Back-up function

Battery backup may be achieved by connecting 48V strings of batteries onto the external battery terminals

of the distribution module at the rear of the system. This battery string will be connected to the system bus

voltage via an internal LVD contact. If for any reason the rectifier outputs are not present, either by

component failure or by the loss of AC power then the battery string can supply the load for a limited time.

4.4.2 LVD Function

An internal LVD contact is fitted for battery string protection. Its function is to connect or disconnect the

battery string from the system bus. The LVD can be set to “ON”, “AUTO”, or “OFF”. In the On position the

batteries are connected to the system bus. In “Off” the connection is broken. In “Auto” the batteries are

connected to the system bus under normal system running conditions. If the system bus voltage falls the

battery string will supply the load. If the battery voltage then falls below 42Vdc the LVD contact opens and

disconnects the batteries to protect them. When system bus voltage is re-established the battery string will

be trickle charged until the battery voltage is >50Vdc and then the batteries will be reconnected to the

system.

4.4.3 Installation procedure

!!! CAUTION !!!

Only connect external battery strings of 48V to the MX06 40A Shelf.

External batteries MUST have circuit breakers fitted at source.

Observe the polarity of the external battery connector.

See section 4.3.4 for connection photo.

Note : It is possible to connect external battery strings of different capacities but the backup duration will be

affected.

• Ensure the battery breaker/s for the external batteries are in the ‘OFF’ position before

connecting external batteries.

• Set the front panel “battery connection” switch to “OFF”.

• Choose cables rated at 50A and colour coded to meet local installation regulations.

• Cables should be crimped with M5 ring crimps for connection to system battery terminals.

• Connect battery string to system ensuring correct polarity of connection.

• Conduct a final check before turning on the external battery breaker.

User Manual 990-9178A

DC MX06 40A Shelf Page 39 of 44 18

th

FEB 02

Page 40

4.4.4 Battery Connection Diagram

Earth connection for grounding output

Battery Positive

Earth Stud

Battery Negative

4.5 System Output Earthing

The MX06 40A Shelf has its output earthed as default. The output is earthed by the earth cable joining the

earth stud to the output earthing bus-bar (as shown in the above picture). The earth link can be removed to

leave the output floating but the user must then earth the output at some other point in the system.

The default configurations are as follows:

54 V systems are set to earthed positive output

27 V systems are set to earthed negative output

User Manual 990-9178A

DC MX06 40A Shelf Page 40 of 44 18

th

FEB 02

Page 41

5 Commissioning the System

5.1 General

All site preparation and equipment installation in the previous chapters must be completed before

commissioning.

• Ensure that the AC power source isolator is switched OFF.

• Switch all MX06 40A Shelf and any external battery circuit breakers to the OFF position.

5.2 Powering up the MX06 40A Shelf

• Set the required alarms to show a “Major” or “Minor” alarm. To do this remove the alarm card

from the shelf and operate switches SW2 and SW5 (see section 2.3.4)

• Switch on the external ac power supply to the MX06 40A Shelf.

• Check the Rectifier module LED’s:

• Check that each rectifier module has 2 green LED’s lit (if fitted), representing Input Healthy

and Output Healthy. There should be no red LED’s lit.

• Check the alarm card LED’s:

• The alarm card has 4 LED’s (3 red and 1 yellow) the only LED that may be lit is the red “Dist

Trip” which will be lit if the system has output circuit breakers that are turned off. The other

LED’s should be off unless “Major” or “Minor” have been allocated to “Dist Trip”.

• Set alarm card meter to read “Volts” and check that the output volts are set to the desired

level. If the voltage is slightly higher or lower than required simply adjust using the alarm card

front panel potentiometer (see section 2.3.1). If the output voltage is outside the specified

range this may indicate a fault.

• Switch on the Distribution Breakers (1, 2, 3 and 4 as required) if fitted.

• Ensure the correct polarity of any connected battery strings (see section 4.4.4) then switch on

any external battery breakers as required.

• Switch the “Battery Connection” switch to the desired setting “ON”, “AUTO” or “OFF” (see

section 4.4.2)

User Manual 990-9178A

DC MX06 40A Shelf Page 41 of 44 18

th

FEB 02

Page 42

6 Manual Handling Procedure

6.1 General

6.1.1 Items within the sub-system present a hazard due to mass. A fully configured system fitted with 4

rectifiers weighs almost 15Kg.

6.1.2 The Manual Handling of Loads Regulations, 1993 require that all persons working on the

equipment are familiar with the Regulations, that they take care to minimise risk of injury to themselves and

others, that they are properly trained, and that the correct equipment is used. Safety shoes are to be worn.

6.1.3 If in doubt about methods, ability to handle the loads, training or equipment, do not proceed

without first seeking advice from a competent person.

6.2 Preparation

6.2.1 Before commencing work check the following:

The floor is level, clean, firm and dry.

The working area is clear of obstacles that could obstruct movement or cause tripping.

There is adequate room for the operator(s), equipment and load.

The lighting is sufficient for the load, equipment, loading surfaces, potential hazards and working

environment to be seen clearly.

Sound levels are not too high to cause distraction.

6.3 Method

6.3.1 The following is not intended to replace other documents and training courses, only to serve as a

guide and checklist. For full guidance refer to the Regulations and supporting documents.

6.3.2 Before lifting, stand as close as possible to the load.

6.3.3 Keep the back straight and as vertical as possible.

6.3.4 Use the leg muscles in preference to the arms.

6.3.5 Minimise twisting, stretching and stooping.

User Manual 990-9178A

DC MX06 40A Shelf Page 42 of 44 18

th

FEB 02

Page 43

7 Fault Finding / Symptoms

The sub-system is designed for maximum reliability and therefore faults during normal operation are

unlikely. If faulty operation does occur the source of the failure can usually be readily determined by

inspection of the LED meter and the LED’s.

7.1 Warnings

POTENTIALLY LETHAL VOLTAGES AND SOURCES OF HIGH ENERGY ARE PRESENT WITHIN THE

POWER SYSTEM. EXTREME CAUTION MUST BE OBSERVED AT ALL TIMES. ACCESS TO THE

INTERIOR OF THE SYSTEM FOR INSTALLATION, COMMISSIONING, MAINTENANCE AND

REMOVAL AND REPLACEMENT PURPOSES IS LIMITED TO FULLY TRAINED SERVICE

PERSONNEL ONLY.

RINGS, WATCHES AND JEWELLERY SHOULD BE REMOVED AND ONLY SINGLE ENDED

INSULATED TOOLS SHOULD BE USED WHEN WORKING OR MAKING MEASUREMENTS INSIDE

THE SYSTEM. A SOLDERING IRON MUST NOT BE USED UNLESS THE INPUT, OUTPUT AND

BATTERY (IF CONNECTED) HAVE FIRST BEEN ISOLATED.

7.2 Fault Symptoms

Typical fault symptoms and their possible causes are shown in table below. If the fault cannot be

diagnosed contact the manufacturer.

SYMPTOM POSSIBLE CAUSE(S)

Output voltage is zero at load

All Rectifiers Input Healthy LED’s are lit (4 LED

rectifiers) or Rectifier Fail LED not lit (single

LED Rectifier) but system bus voltage is zero

(LED display extinguished).

One or more rectifiers “output healthy” LED is

extinguished temporarily (4 LED rectifiers). Or

one or more “Rectifier Fail” LED lit temporarily

(single LED Rectifier).

One or more rectifiers output healthy LED

extinguished (4 LED rectifiers). Or one or more

“Rectifier Fail” LED lit (single LED Rectifier).

Battery String not connected to system.

Battery string doesn’t disconnect when voltage

drops below LVD level.

1. Failure of AC supply.

2. Distribution device(s) tripped (check dist trip LED).

3. Failure of external disconnect device.

1. Rectifiers have tripped due to over-voltage.

2. System output not enabled, could be set to remote

enable instead of local enable. (see section 2.5.4)

1. Rectifiers tripping due to over temperature condition,

(Local ambient may be above rated level). (see section

2.1.1)

1. System in overload condition (check current limit

LED’s).

2. System tripped due to over-voltage condition (check

rectifier over-voltage LED’s).

1. Battery connection switch set to “off”.

2. Battery connection switch set to “auto” and battery

string voltage below LVD level (see section 4.4.2)

3. System output voltage is below low voltage reconnect

level.

1. Battery disconnect switch set to “on” instead of “auto”

(see section 4.4.2)

User Manual 990-9178A

DC MX06 40A Shelf Page 43 of 44 18

th

FEB 02

Page 44

8 Service, Accessories & Spares

8.1 Rectifier replacement

If a faulty rectifier is to be replaced simply unscrew the two front panel fixings on the rectifier front panel

and withdraw the rectifier from the shelf. A replacement rectifier can then be inserted directly into the shelf

and will start-up automatically.

Note – The rectifiers are “hot plugable” and therefore can be replaced without turning the system off.

8.2 Controller replacement

If the alarm card is to be replaced simply unscrew the two front panel fixings and withdraw the module from

the shelf. A replacement module can then be inserted directly into the shelf and will start-up automatically.

Note - with the module removed the system will revert to default rectifier conditions of 54.5V. Some alarms

and all control functions will be unavailable including battery monitoring.

Entire contents copyright © 2001 American Power Conversion. All rights reserved. Reproduction in whole or in part

without permission is prohibited. APC and the APC logo are registered trademarks of American Power Conversion

Corporation. All other trademarks, product names, and corporate names are the property of their respective owners

and are used for informational purposes only.

User Manual 990-9178A

DC MX06 40A Shelf Page 44 of 44 18

th

FEB 02

Loading...

Loading...